Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Achieve electrical insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

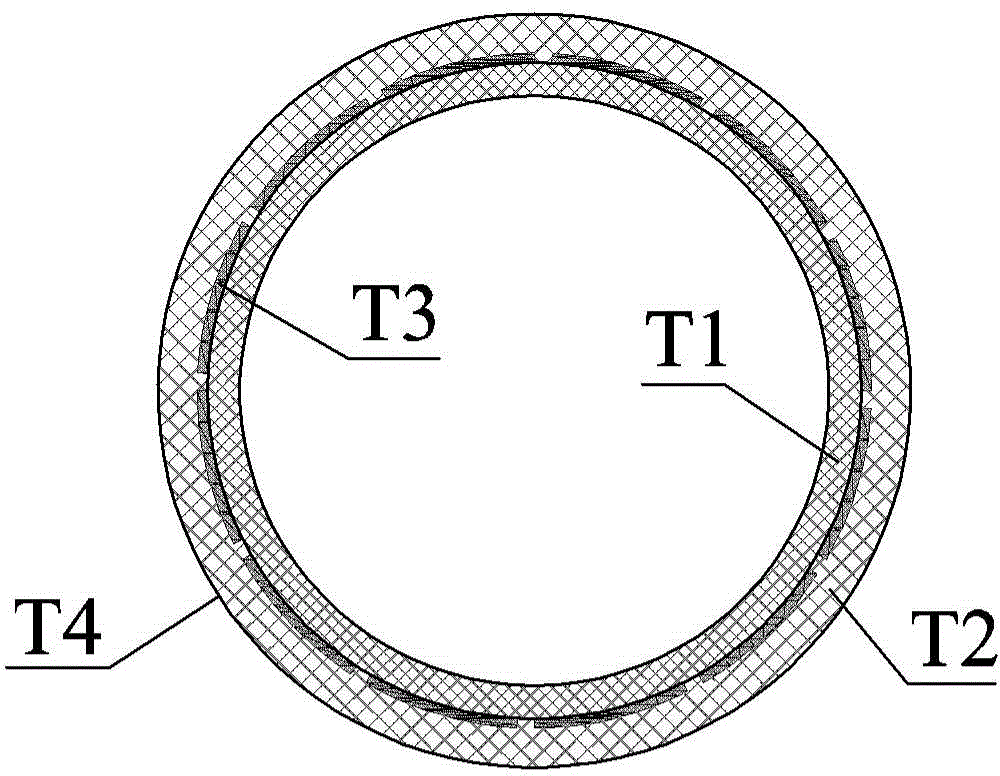

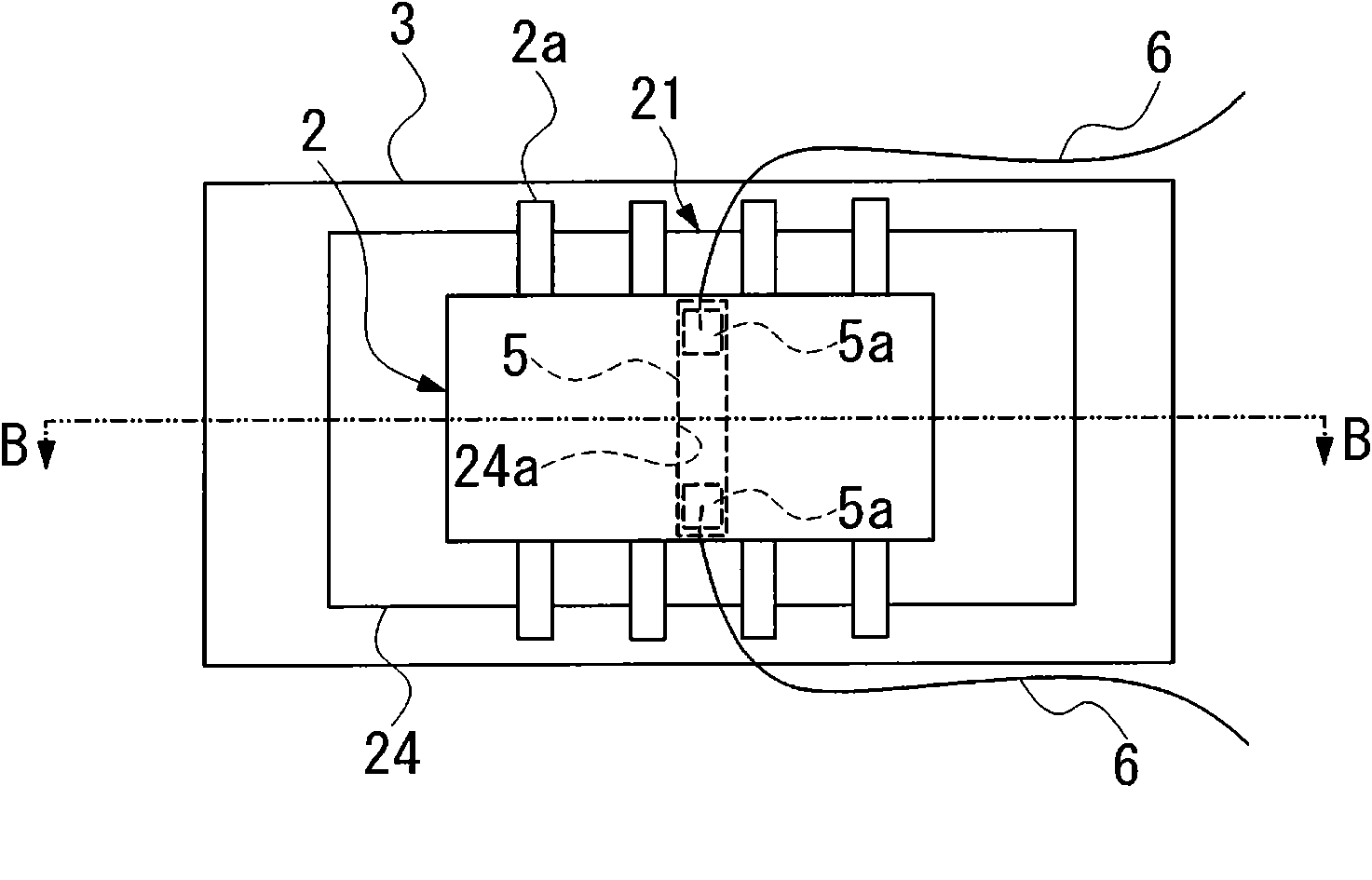

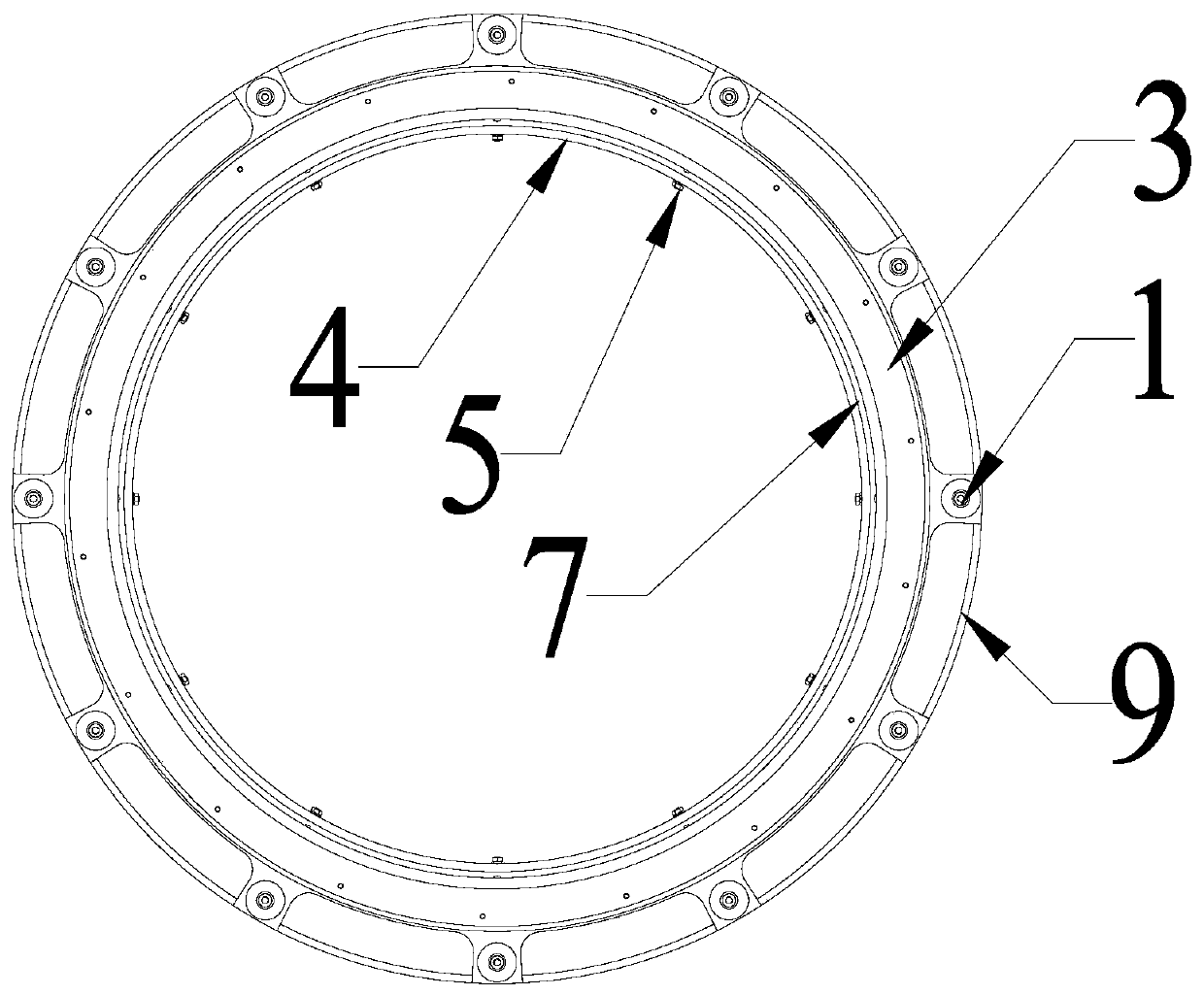

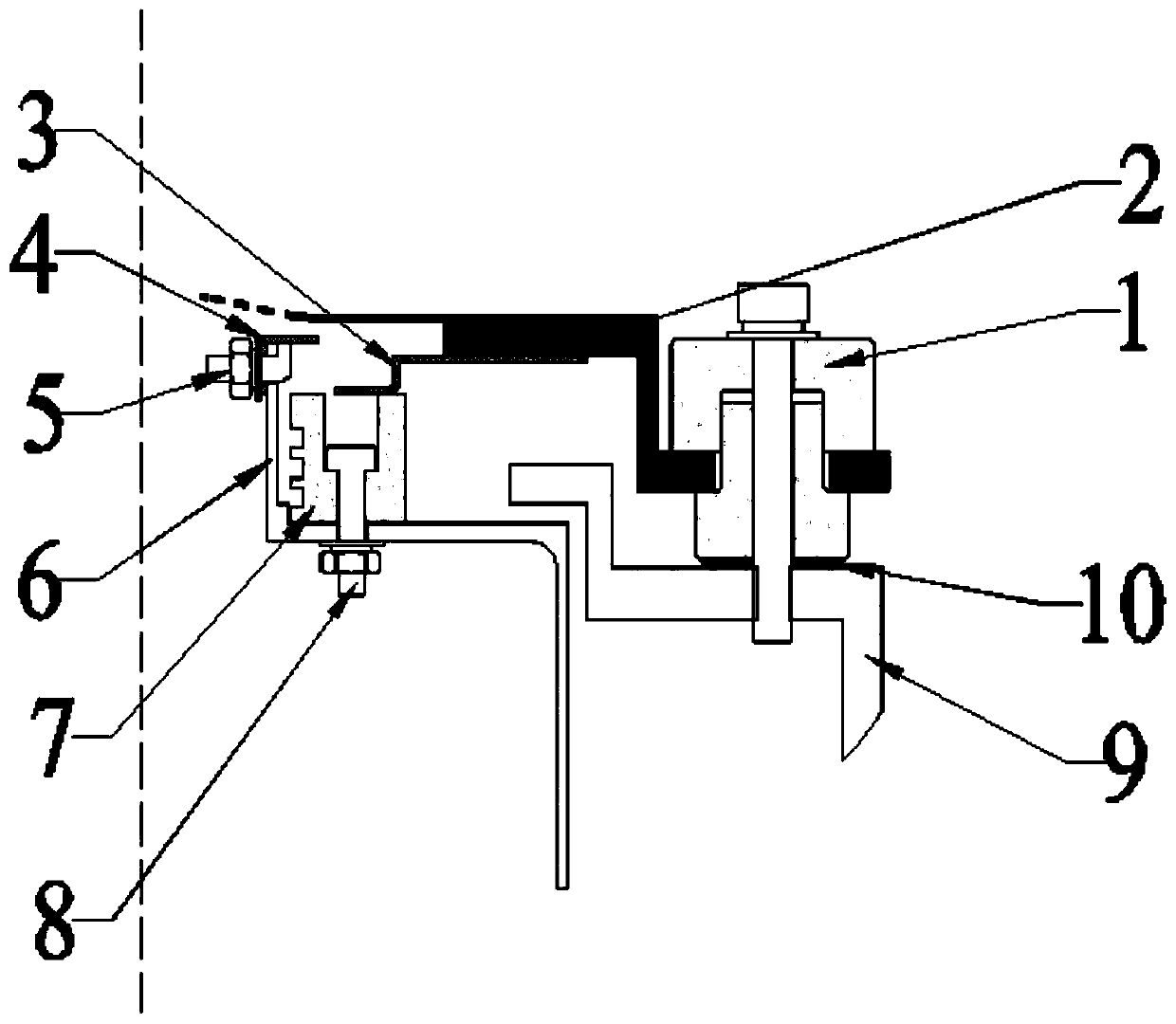

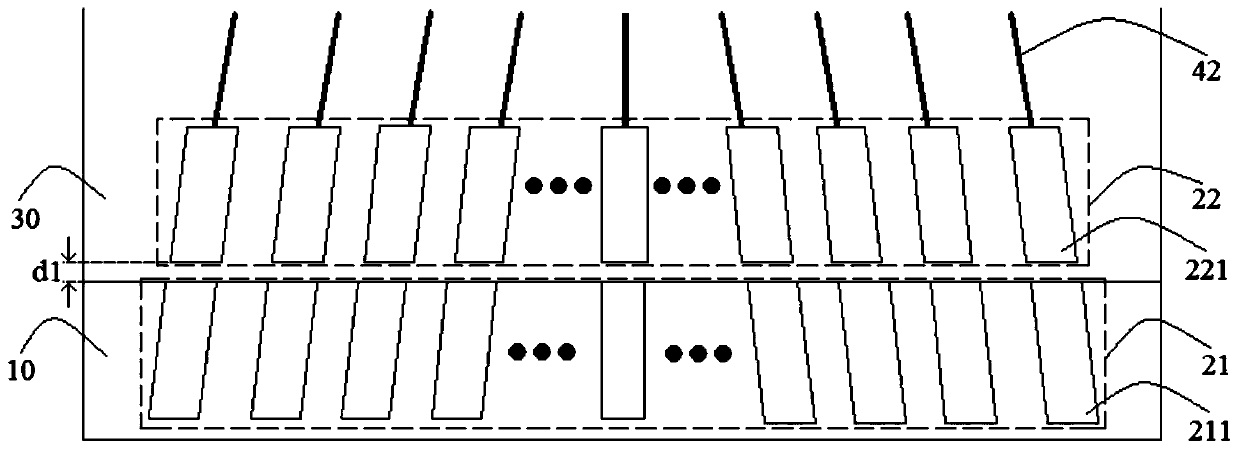

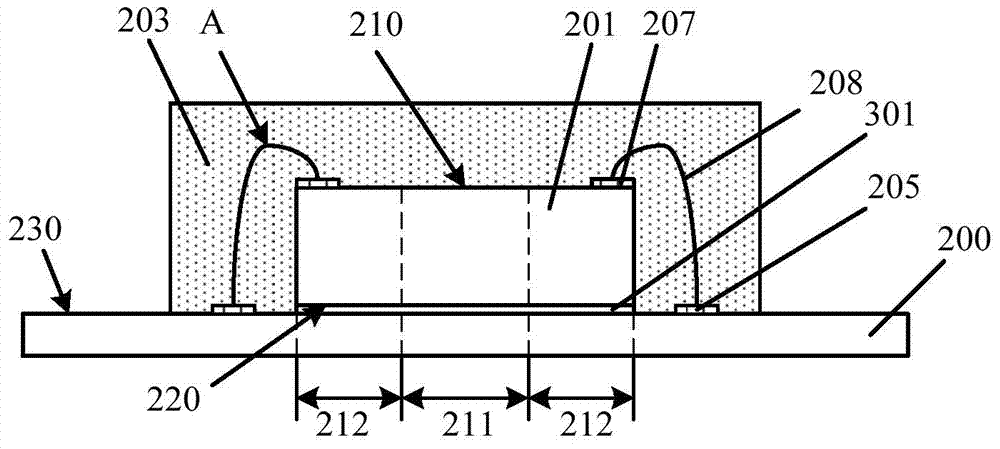

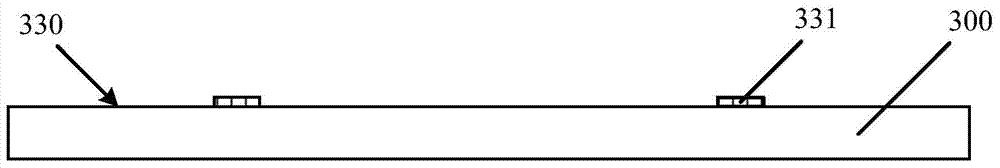

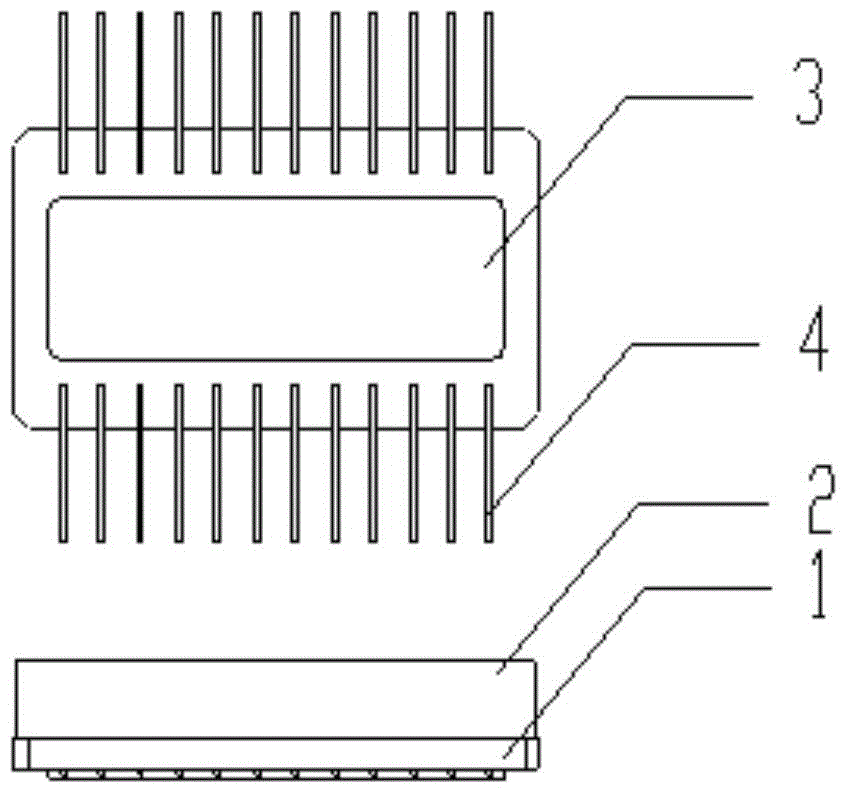

Capacitance tomography sensor

ActiveCN104655692AFlexible installationAvoid direct contactMaterial capacitanceTomographyBiomedical engineering

A capacitance tomography sensor is provided in the invention, wherein a sensor framework is added to the capacitance tomography sensor. A measurement electrode is arranged on an inner wall of the sensor framework to prevent direct contact between the measurement electrode and a to-be-test fluid. A shield electrode group is disposed on an outer side surface of the sensor framework to achieve electrical insulation from the measurement electrodes. By means of the structure, installation of the measurement electrode and the shield electrode group is more flexible.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

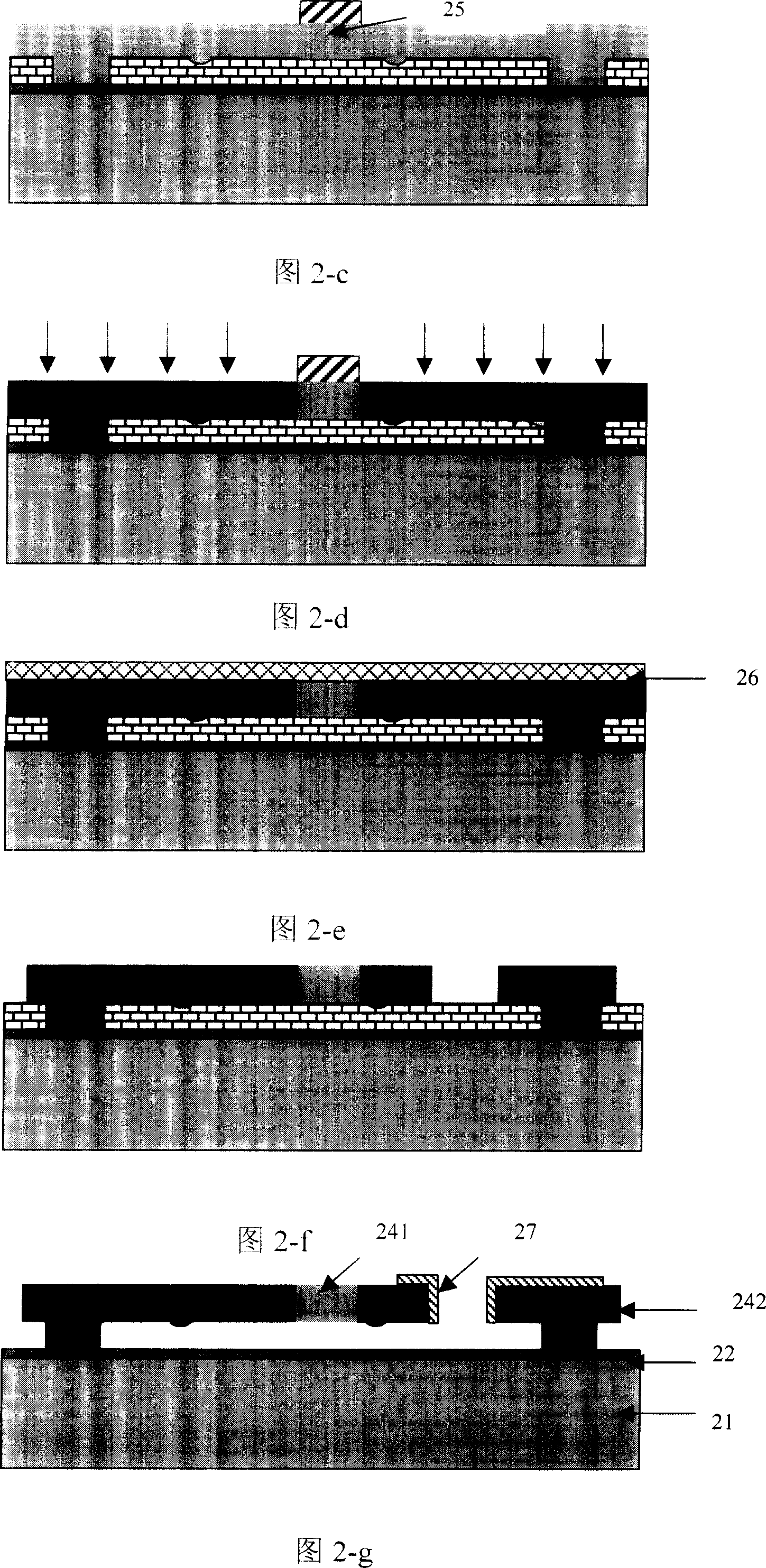

Silicon micro-resonance mode pressure sensor core and manufacturing method

InactiveCN103557967AGood long-term stabilityQuick responseForce measurement by measuring frquency variationsFluid pressure measurement using ohmic-resistance variationPhysicsResonance

The invention discloses a silicon micro-resonance mode pressure sensor core and a manufacturing method, and belongs to the field of sensors, wherein the complex technologies such as silicon-silicon direct bonding and silicon slice thinning are not used, and large residual stress is prevented from being led in during the manufacturing process of harmonic oscillators. The silicon micro-resonance mode pressure sensor core comprises a lower layer substrate and an upper layer substrate, and the lower layer substrate and the upper layer substrate are bonded into a whole. The lower layer substrate is provided with a resonance beam, a pressure sensitive membrane, a lower layer exciting electrode, a voltage dependent resistor and a lower layer lead bonding pad. The lower layer exciting electrode and the voltage dependent resistor are arranged on the upper surface of the resonance beam. The pressure sensitive membrane is arranged at the bottom of a resonant cavity. An oscillating trough and an upper layer exciting electrode are arranged on the upper layer substrate, wherein the oscillating trough is formed in the lower surface of the upper layer substrate, and the upper layer exciting electrode covers the surface of the bottom of the oscillating trough. The oscillating trough formed in the lower surface of the upper layer substrate and the resonant cavity where the resonance beam is located form a closed space. The lower layer exciting electrode corresponds to the upper layer exciting electrode in position. An SOI silicon slice is selected and used as the lower layer substrate; a glass sheet is selected and used as the upper layer substrate.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

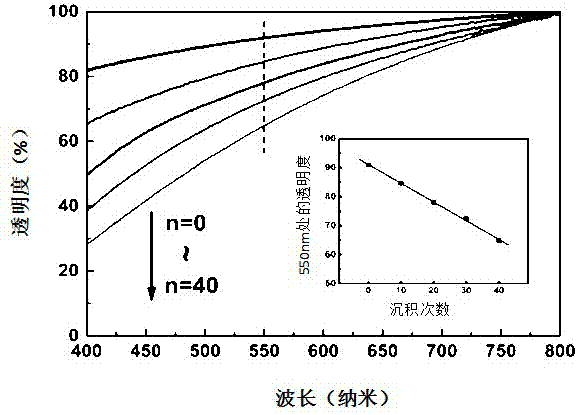

Transparent and insulating graphene composite heat-conducting film and preparation method thereof

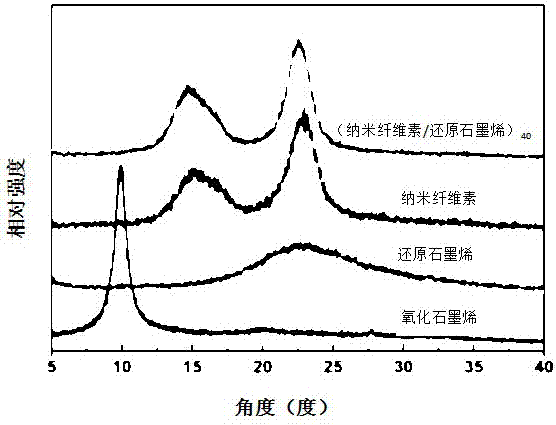

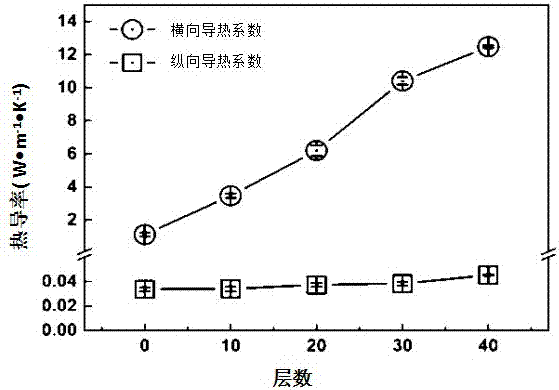

InactiveCN106893128ASmall coefficient of thermal expansionEnvironmentally friendly and degradableHeat-exchange elementsCoatingsComposite filmHeat conducting

The invention relates to a method for preparing a transparent and insulating graphene composite heat-conducting film. According to the method, the heat-conducting film is prepared through the compositing of nanocellulose, graphene and boron nitride. Through filtration drying of nanocellulose dispersion liquid, a nanocellulose film is obtained, the nanocellulose film is immersed in graphene oxide solution, the obtained film is immersed in the nanocellulose dispersion liquid, and a nanocellulose - graphene oxide composite film is obtained by repeating the two-step operations many times, the composite film is placed in a solution to be restored, and a nanocellulose-graphene film is obtained. Mixed solution of the nanocellulose and boron nitride is prepared through an ultrasonic mixing method. The obtained film is immersed in the mixed solution of the cellulose and boron nitride, and a nanocellulose - graphene - boron nitride heat-conducting film is obtained. The film has superhigh anisotropy and is suitable for horizontal heat dissipation of a modern electronic device. The film is good in transparency. Since an outer layer is a mixed film of boron nitride and cellulose, an electric insulation effect can be achieved, and requirements of special electronic devices are met.

Owner:SHANGHAI UNIV

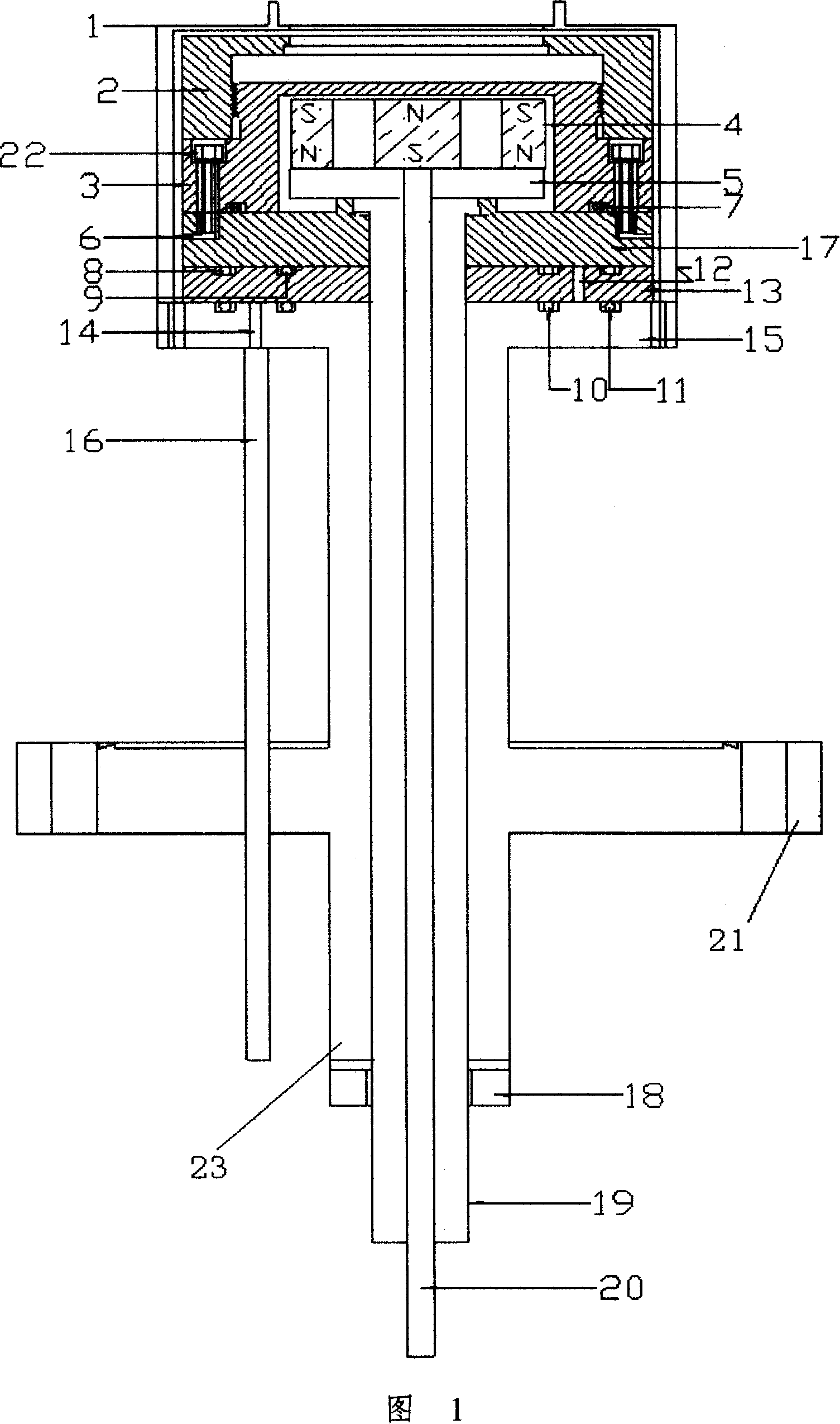

Sealing device used for 10(-8)Pa ultra-high vacuum round plane magnetron sputtering target

InactiveCN101148752AEasy maintenanceEasy to replaceEngine sealsVacuum evaporation coatingUltra-high vacuumMetal

The present invention discloses one kind of sealing device for 6x10<-8> Pa aultra high vacuum circular planar magnetically controlled sputtering target. The sealing device includes one water cooling cavity with soft iron and magnetic steel, one water cooling cavity sealing flange with metal O-ring, one water inlet pipe and one water outlet pipe welded to the water cooling cavity sealing flange, one target supporting seat with one electrode insulating layer and two groups of O-rings, one installing flange welded to the target supporting seat and other parts. The present invention can ensure vacuum degree as high as 6x10<-8> Pa.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Temperature sensor

InactiveCN101988854ASuppresses the influence of thermal resistanceAccurate temperatureThermometer detailsElectricityEngineering

Owner:MITSUBISHI MATERIALS CORP

Implementing method for interconnected structure of RF MEMS switch

Owner:PEKING UNIV

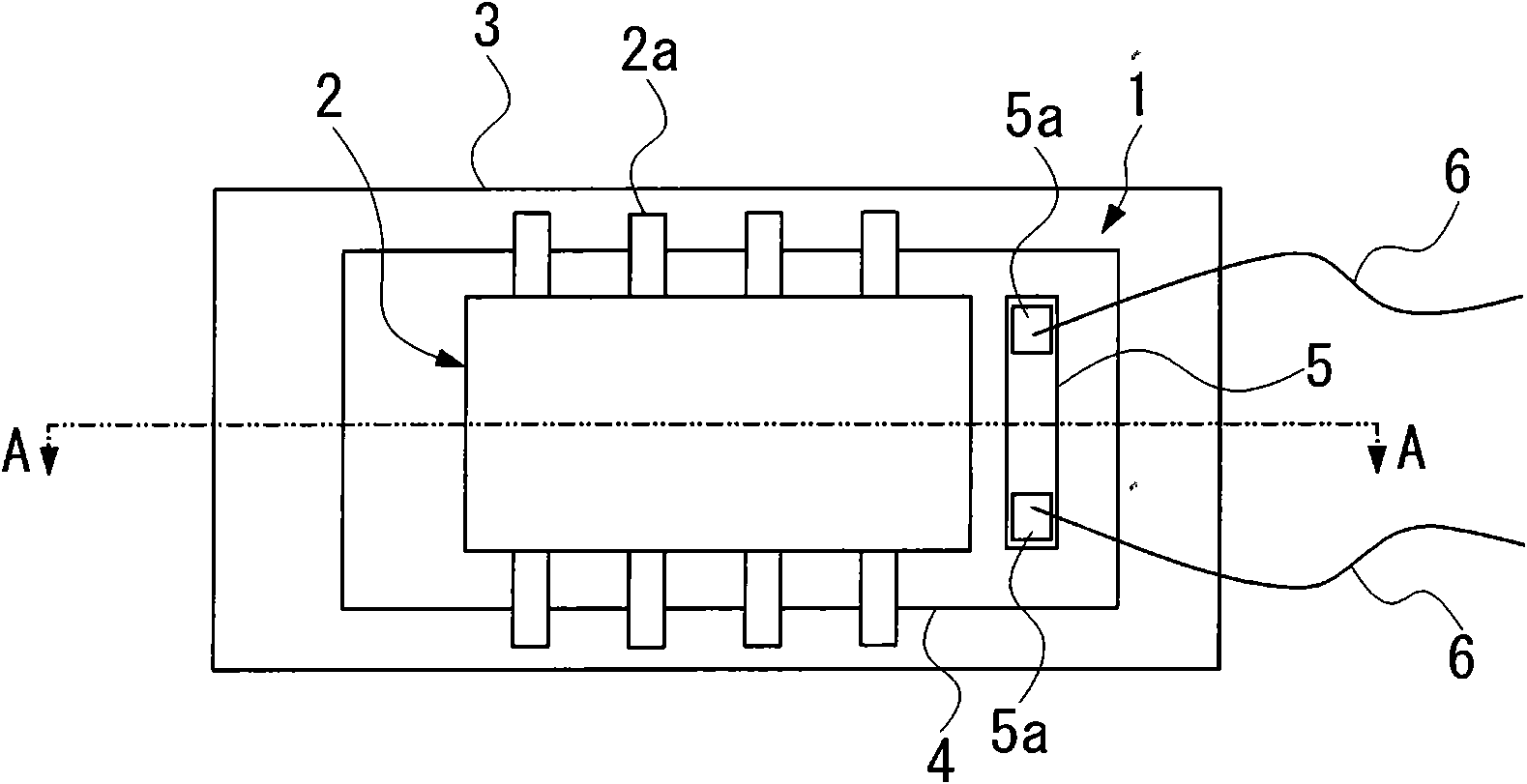

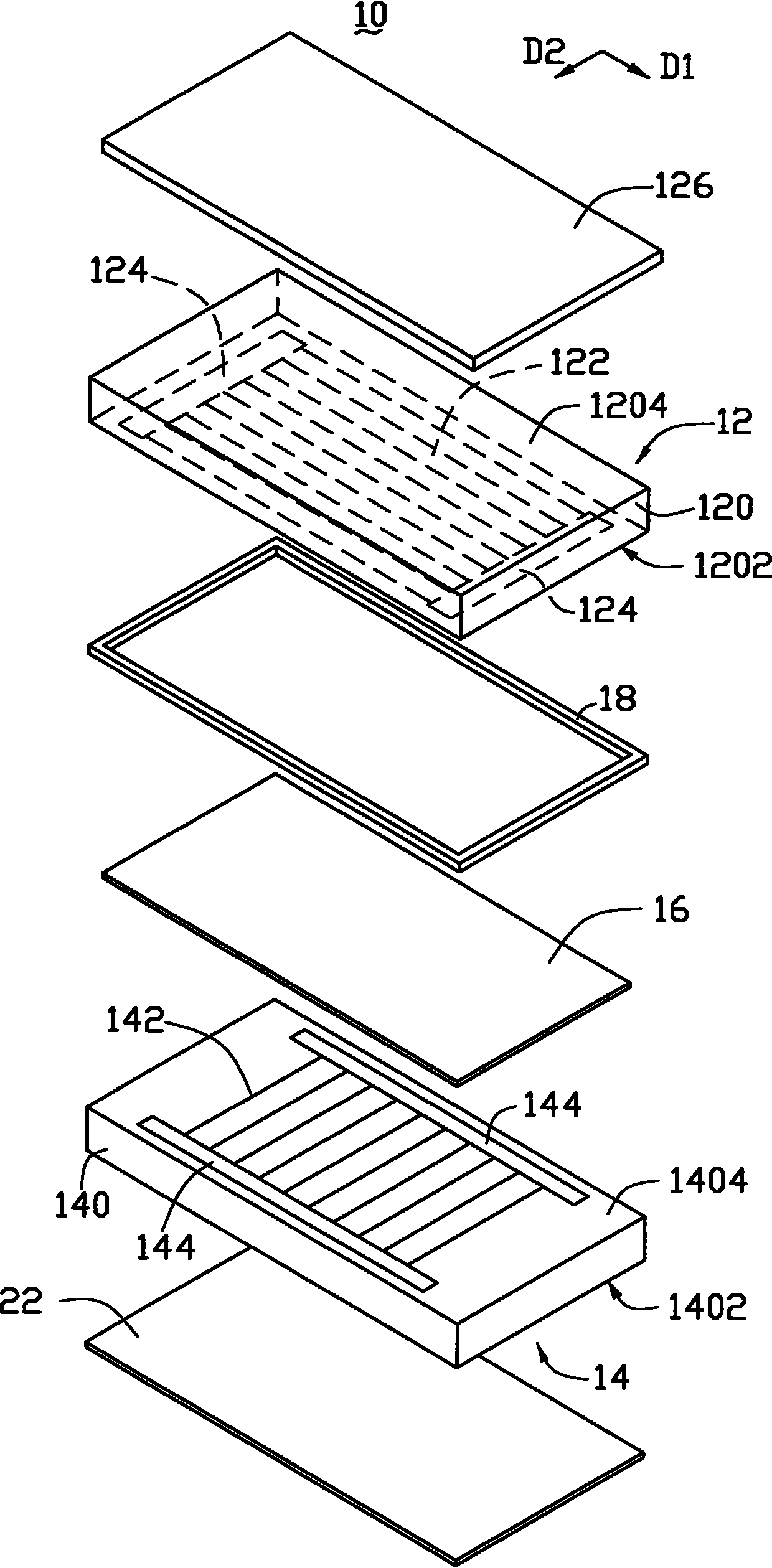

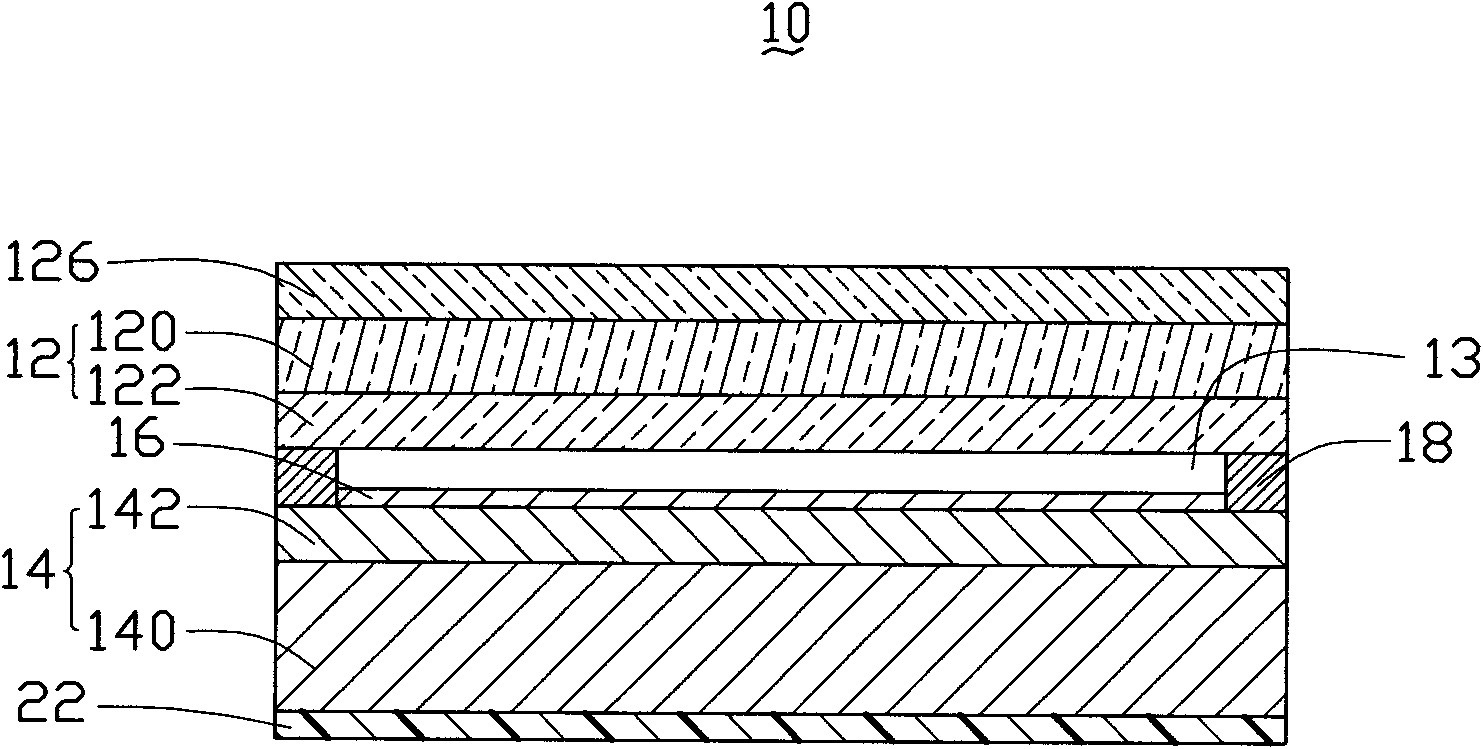

Touch screen and display device

ActiveCN102063214AUniform resistance distributionUniform light transmission effectInput/output processes for data processingCarbon nanotubeDisplay device

The invention relates to a touch screen and a display device employing the touch screen. The touch screen comprises a first electrode plate and a second electrode plate, wherein the first electrode plate comprises a first substrate, a first conductive layer and two first electrodes; the first conductive layer is arranged on the surface of the first substrate; the two first electrodes are electrically connected with the first conductive layer; the second electrode plate and the first electrode plate are arranged at intervals; the second electrode plate comprises a second substrate, a second conductive layer and two second electrodes; the second conductive layer is arranged on the surface of the second substrate and is opposite to the first conductive layer; and the two second electrodes are electrically connected with the second conductive layer. The touch screen also comprises a transparent insulating layer arranged between the first conductive layer and the second conductive layer; and at least one of the first conductive layer and the second conductive layer comprises a carbon nanotube structure.

Owner:BEIJING FUNATE INNOVATION TECH

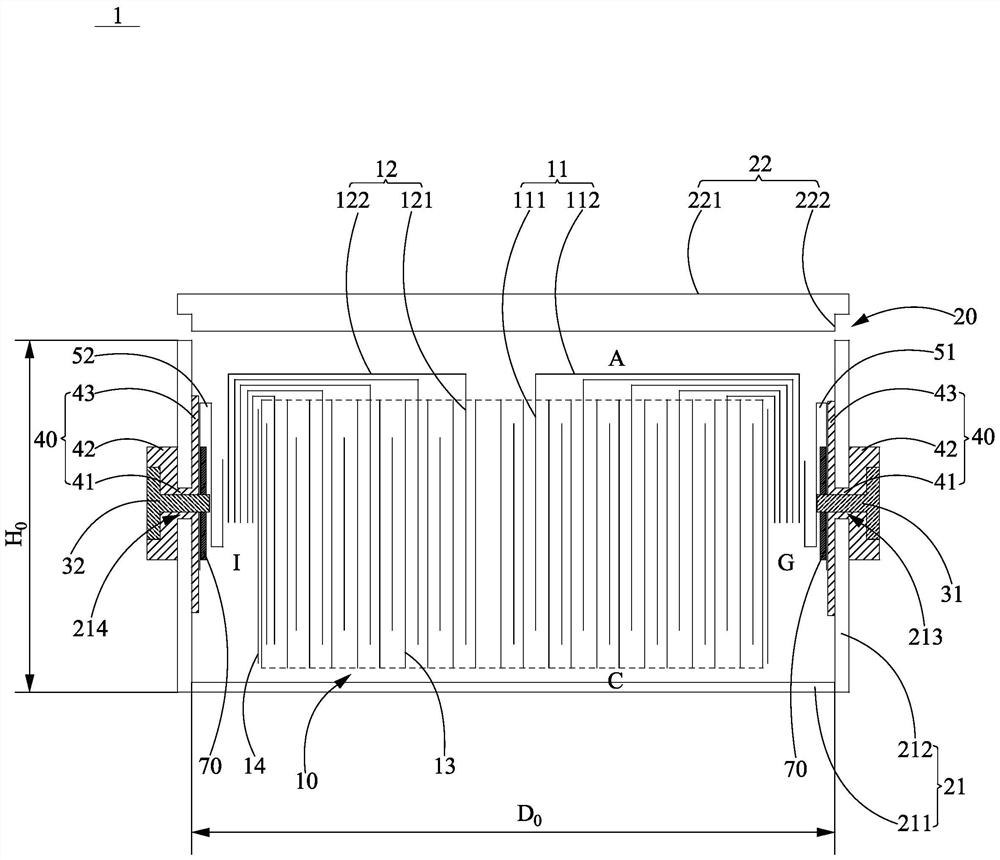

Plasma sealing structure for discharge chamber of annular magnetic steel ring cutting field ion thruster

ActiveCN111005849AGuaranteed long-term insulation capabilityEnsure electrical insulationMachines/enginesUsing plasmaStructural engineeringMechanical engineering

The invention provides a plasma sealing structure for a discharge chamber of an annular magnetic steel ring cutting field ion thruster. The plasma sealing structure comprises a ceramic ring, a shielding cover and a Z-shaped sealing ring; peripheral equipment comprises a grid assembly, an anode, an insulation supporting assembly and a supporting ring of the ion thruster, and the anode is of a stepped cylinder structure and comprises a large-diameter cylinder and a small-diameter cylinder; the shielding cover is installed on the outer wall of the upper end of the small-diameter cylinder of the anode, the ceramic ring is located below the shielding cover and fixed to the end face between the large-diameter cylinder and the small-diameter cylinder of the anode, and the shielding cover shieldspart of the end face of the ceramic ring and the inner wall face of the ceramic ring to realize shielding and realize electric insulation between the anode and the grid assembly; and the horizontal end face of one side of the Z-shaped sealing ring is fixed to the bottom face of the grid assembly, and the horizontal end face of the other side is compressed at the top end of the ceramic ring to complete plasma sealing of the discharge chamber. The problems of electric insulation between the grid assembly and the anode of the ion thruster in a long-term plasma environment and plasma sealing of the discharge chamber are solved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

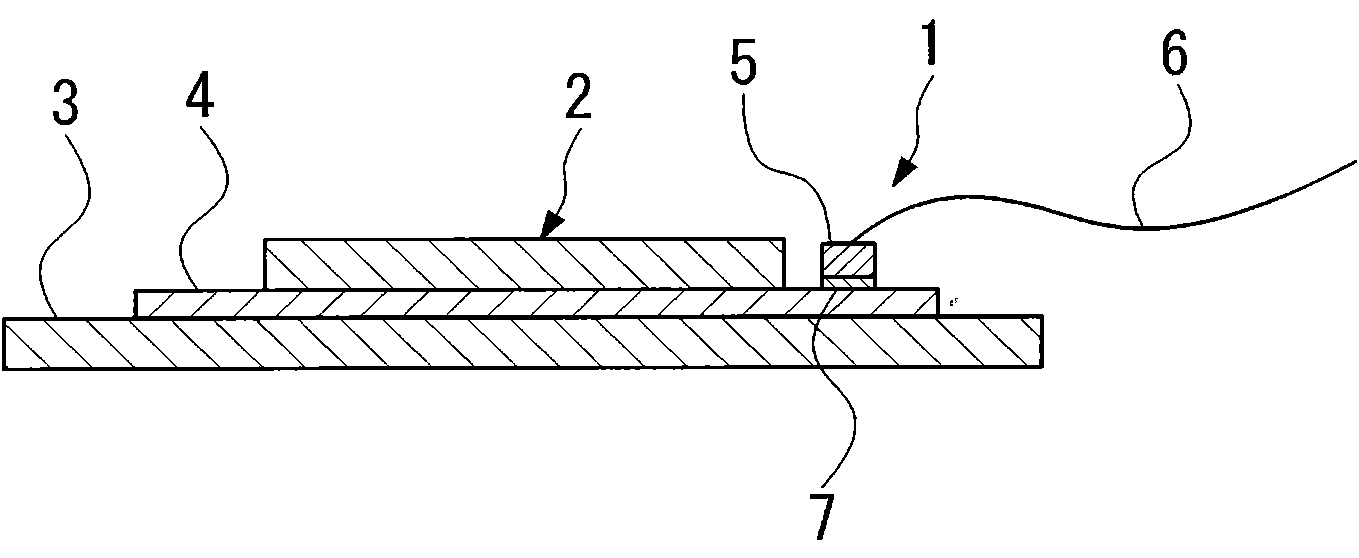

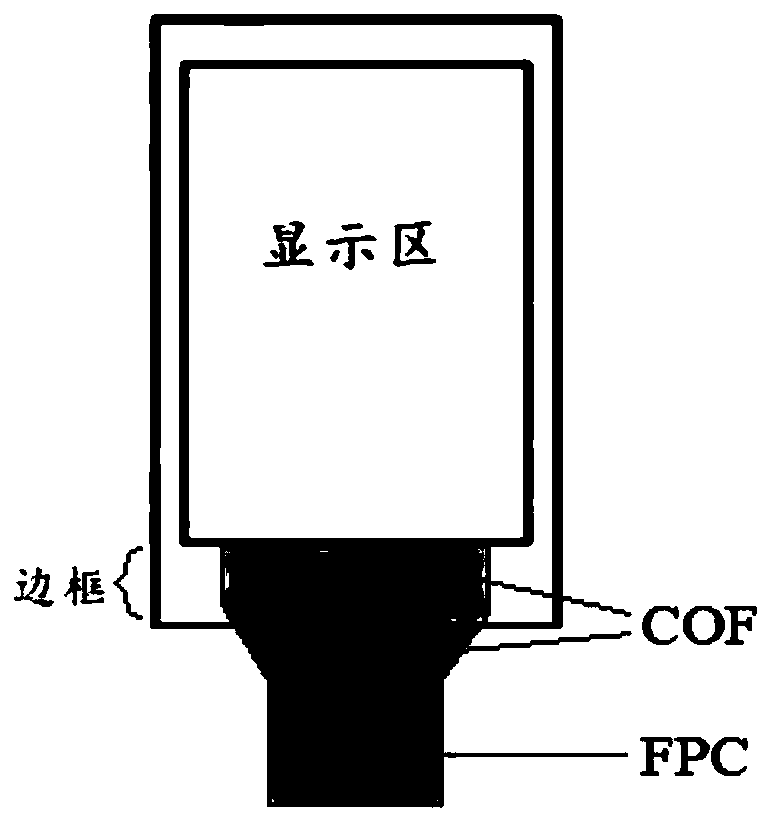

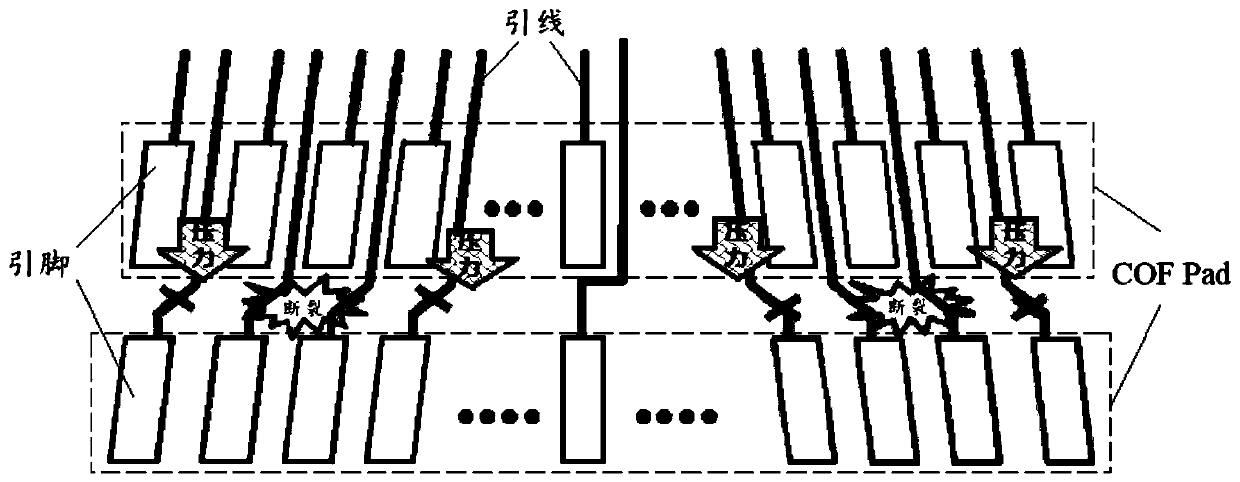

Display device and manufacturing method thereof

PendingCN111430421AGuaranteed stabilityImprove bonding yieldStatic indicating devicesSolid-state devicesThin membraneChip on film

The invention provides a display device and a manufacturing method thereof. The display device comprises an underlying substrate, and a first binding pattern layer, a first insulating layer and a second binding pattern layer which are stacked, wherein the first insulating layer is used for enabling the first binding pattern layer and the second binding pattern layer to be electrically insulated, and at least one same-side edge of the first binding pattern layer, the first insulating layer and the second binding pattern layer which are arranged in a stacked mode forms a stepped structure; the first binding pattern layer comprises a first pin, and the first pin is electrically connected with a first lead; the second binding pattern layer comprises a second pin, and the second pin is electrically connected with a second lead; the first pin and the second pin are respectively used for being bound with corresponding chip on films; the first lead and the first binding pattern layer are in the same layer, and / or the second lead and the second binding pattern layer are in the same layer. According to the display device and the manufacturing method thereof, the binding yield can be promptedto a certain extent.

Owner:BOE TECH GRP CO LTD +1

Electrical capacitance tomography sensor

ActiveCN104655692BFlexible installationAvoid direct contactMaterial capacitanceEngineeringTomography

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Multi-tab battery

PendingCN113113738AImprove the safety of useLower internal resistanceSmall-sized cells cases/jacketsStructural engineeringMechanical engineering

The invention discloses a multi-tab battery. The multi-tab battery comprises a battery cell assembly, a shell assembly, a pole assembly and insulating parts. The battery cell assembly comprises a positive plate and a negative plate; the positive plate comprises a positive substrate and a plurality of positive tabs; the negative plate comprises a negative substrate and a plurality of negative tabs; the positive tabs and the negative tabs extend outwards from the same end of the battery cell assembly along the radial direction to two opposite sides of the battery cell assembly and then are bent towards the other end along the axial direction; the shell assembly comprises a shell, the shell comprises a bottom wall and a side wall extending upwards from the periphery of the bottom wall, and a positive electrode hole and a negative electrode hole which are oppositely distributed are formed in the side wall; the pole assembly comprises a positive pole penetrating through the positive hole and connected with the positive tabs and a negative pole penetrating through the negative hole and connected with the negative tabs; and the insulating parts are arranged between the shell and the battery cell assembly and between the shell and the pole assembly. According to the multi-tab battery disclosed by the invention, the utilization rate of the shell space, the high-rate charge-discharge performance of the multi-tab battery and the use safety can be effectively improved.

Owner:FUJIAN NANPING YANPING DISTRICT NANFU NEW ENERGY TECH CO LTD

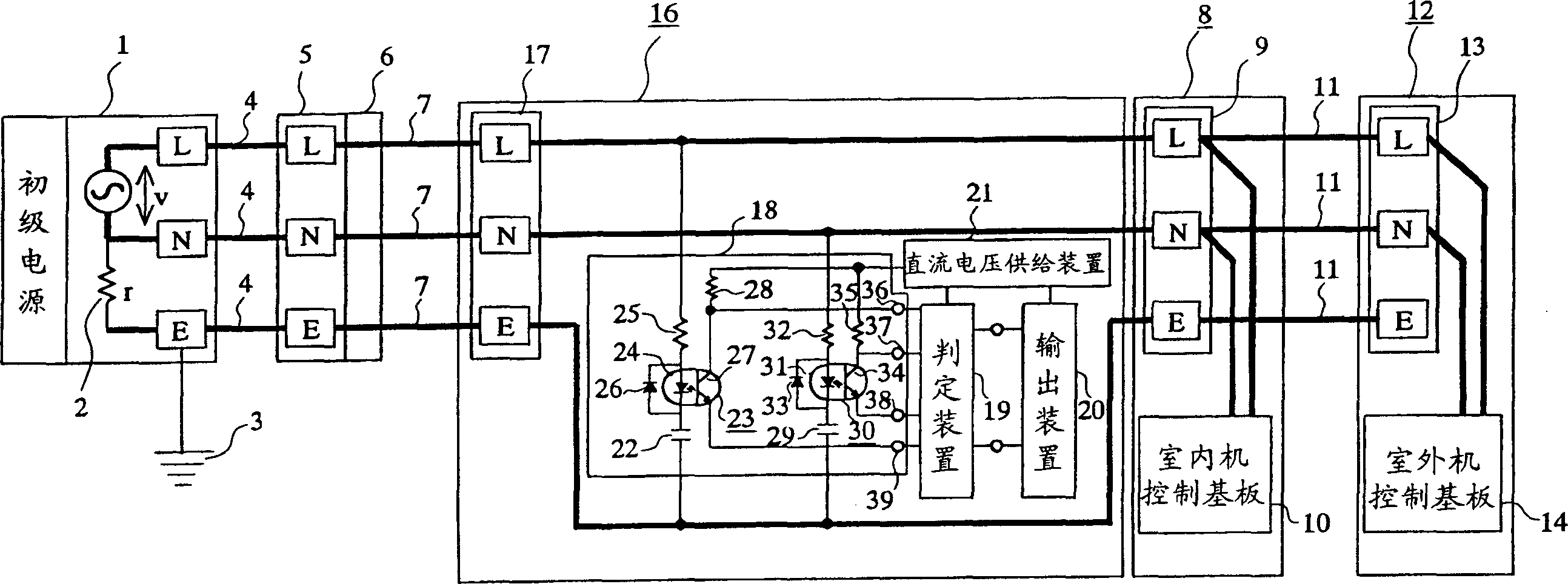

Error wiring detector for air conditioner

InactiveCN1444047AAchieve insulationAchieve electrical insulationSpace heating and ventilation safety systemsLighting and heating apparatusOutput deviceNeutral line

Owner:MITSUBISHI ELECTRIC CORP

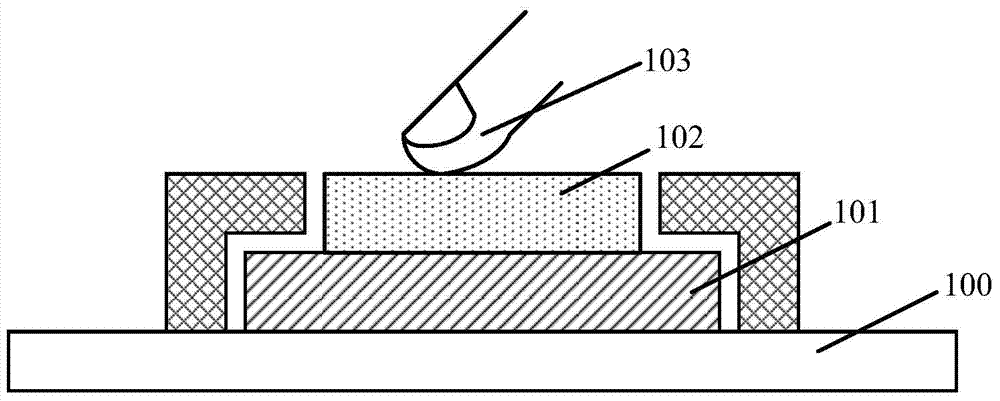

Fingerprint identification chip packaging structure and packaging method

InactiveCN104851813AThe packaging method is simpleReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingEngineering

The invention provides a fingerprint identification chip packaging structure and a packaging method. The packaging method comprises the steps that a substrate is provided; an induction chip is coupled at the surface of the substrate, the induction chip is provided with a first surface and a second surface which is opposite to the first surface, the first surface of the induction chip comprises induction areas, and the second surface of the induction chip is arranged at the surface of the substrate; and a plastic packaging layer is formed at the surfaces of the substrate and the partial induction chip, and the plastic packaging layer is exposed out of the induction areas. Sensitivity of the packaging structure of a fingerprint identification chip is enhanced, the packaging technology is simplified and manufacturing cost is reduced.

Owner:CHINA WAFER LEVEL CSP

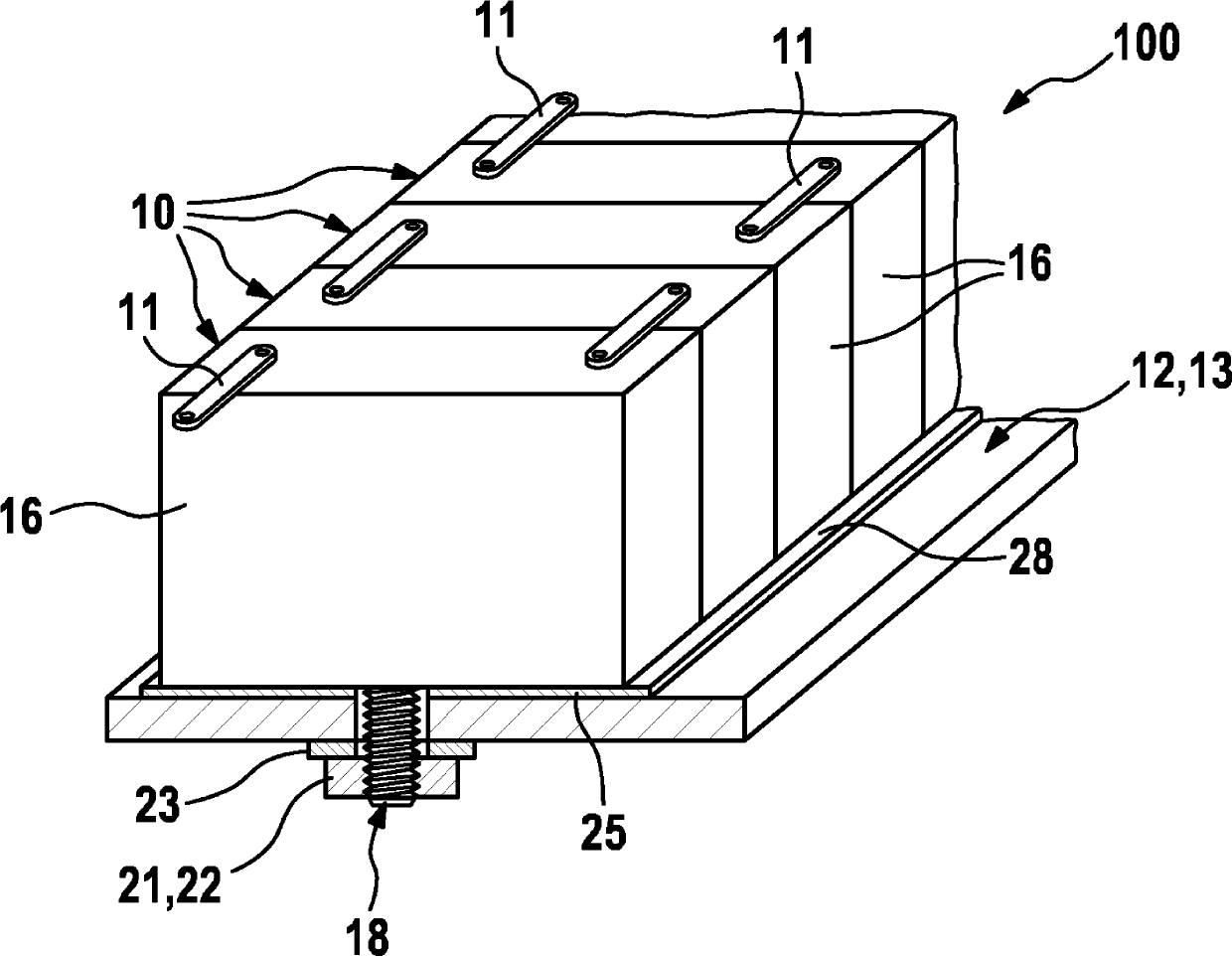

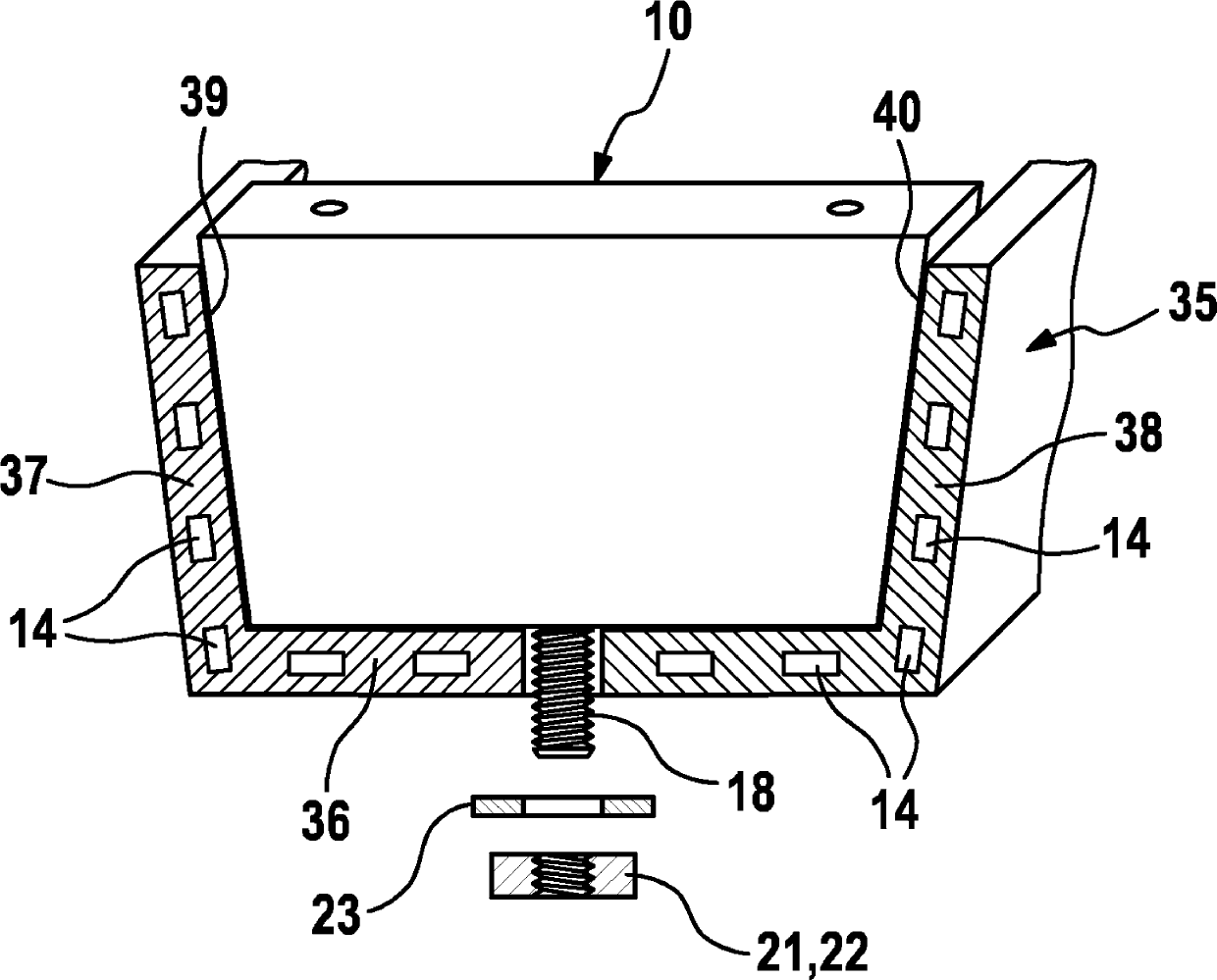

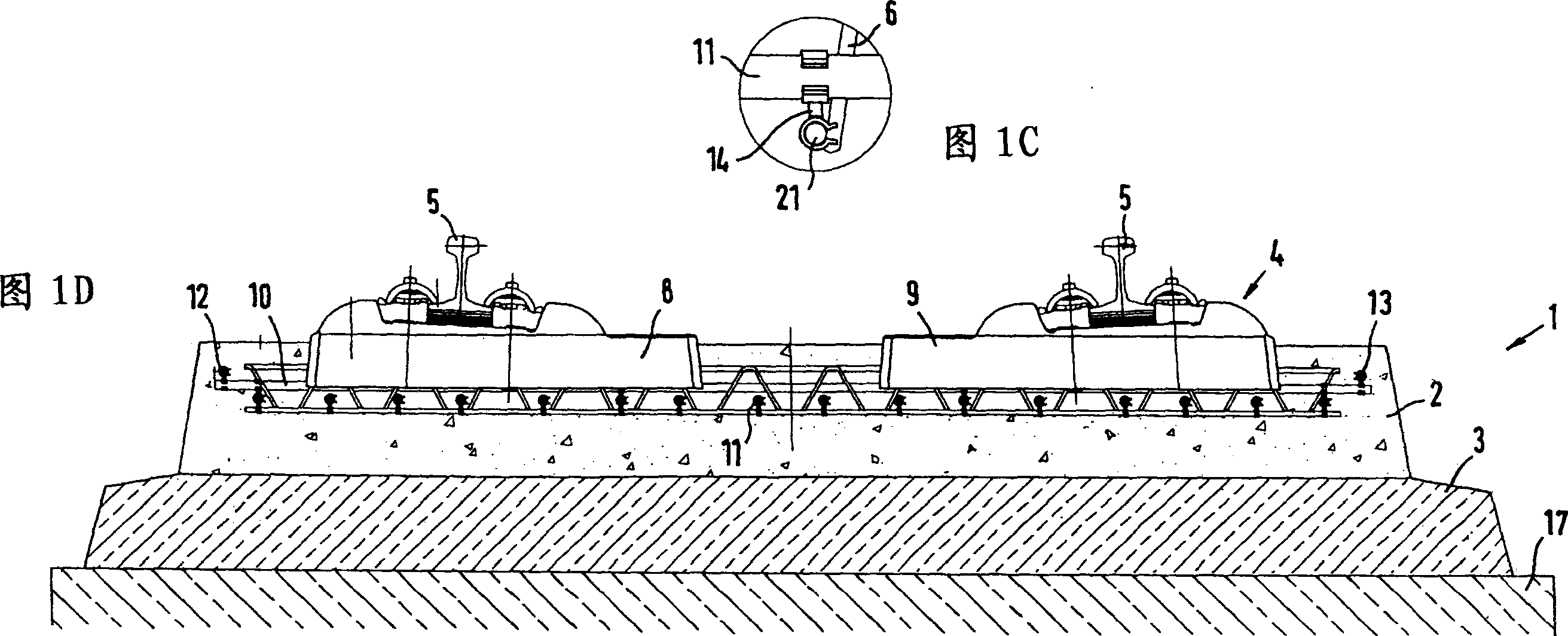

Battery assembly

ActiveCN104272498AGood and reliable electrical insulationImprove thermal conductivityCells cooling/heatingSecondary cellsEngineeringMechanical engineering

The invention relates to a battery assembly (100) consisting of several battery cells (10) which are electrically connected to each other and which respectively comprise a preferably prismatic cell housing (16). Each cell housing (16) comprises at least one fastening projection (18) on the base of the cell (17), said fastening projection protruding through an opening (19) of a cooling element (12) embodied as a cooling plate (13) or as a cooling housing (35) for the cell housings (16). Said fastening projection (18) interacts with a tensioning element (22) which maintains the cell housing (16) against the cooling element (12).

Owner:ROBERT BOSCH GMBH

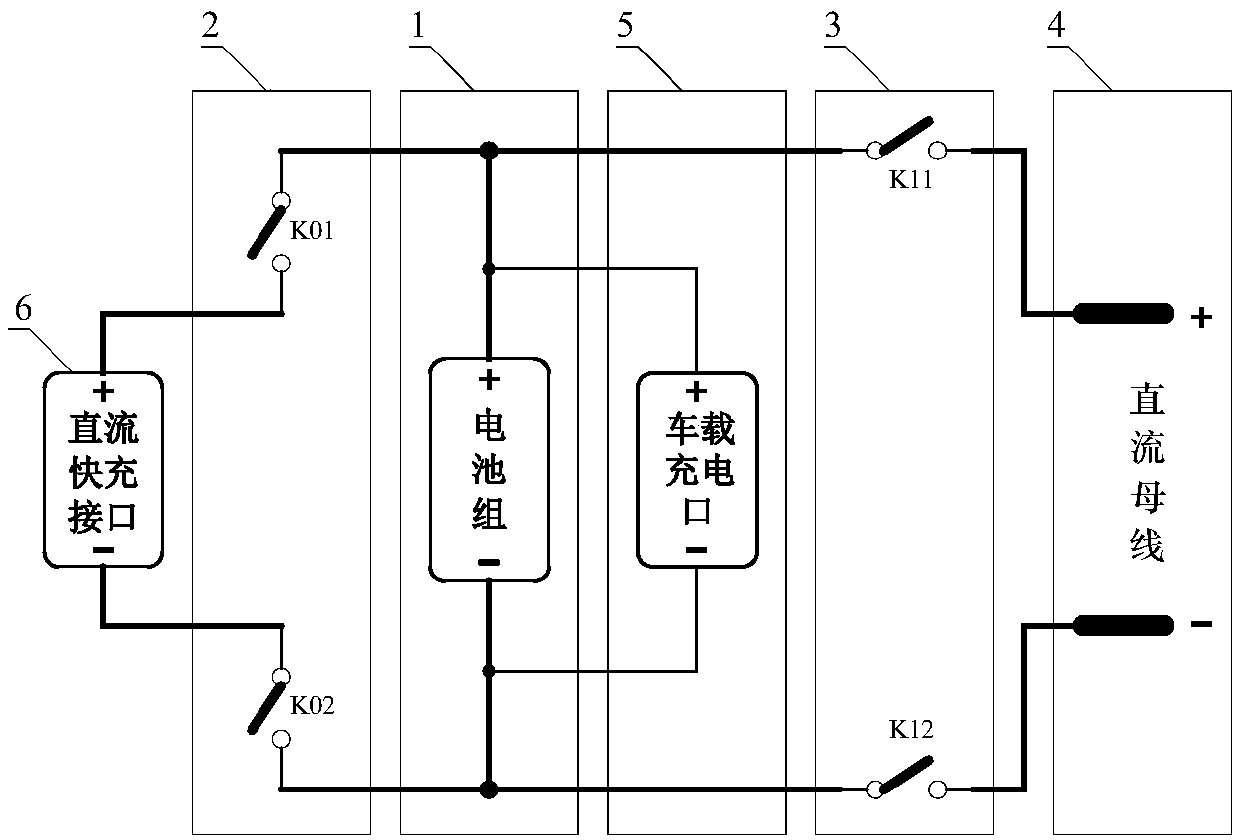

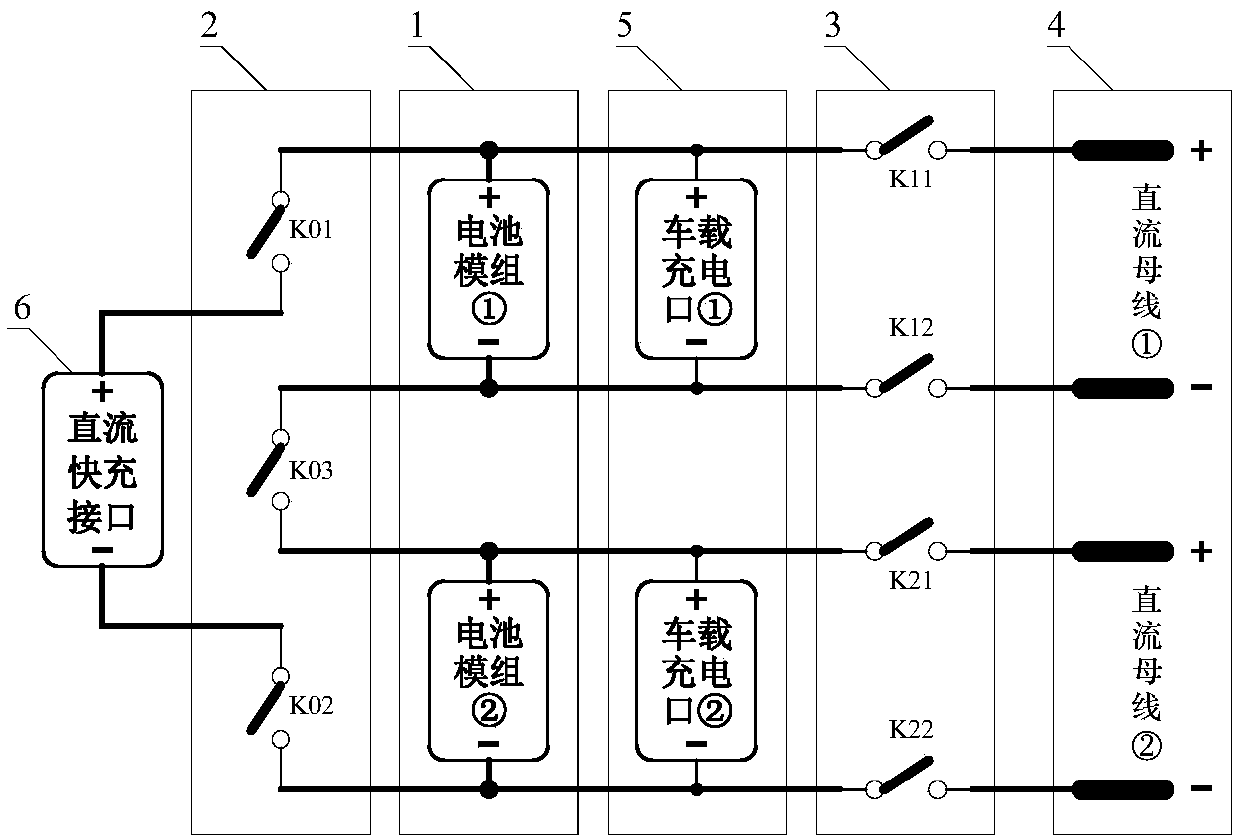

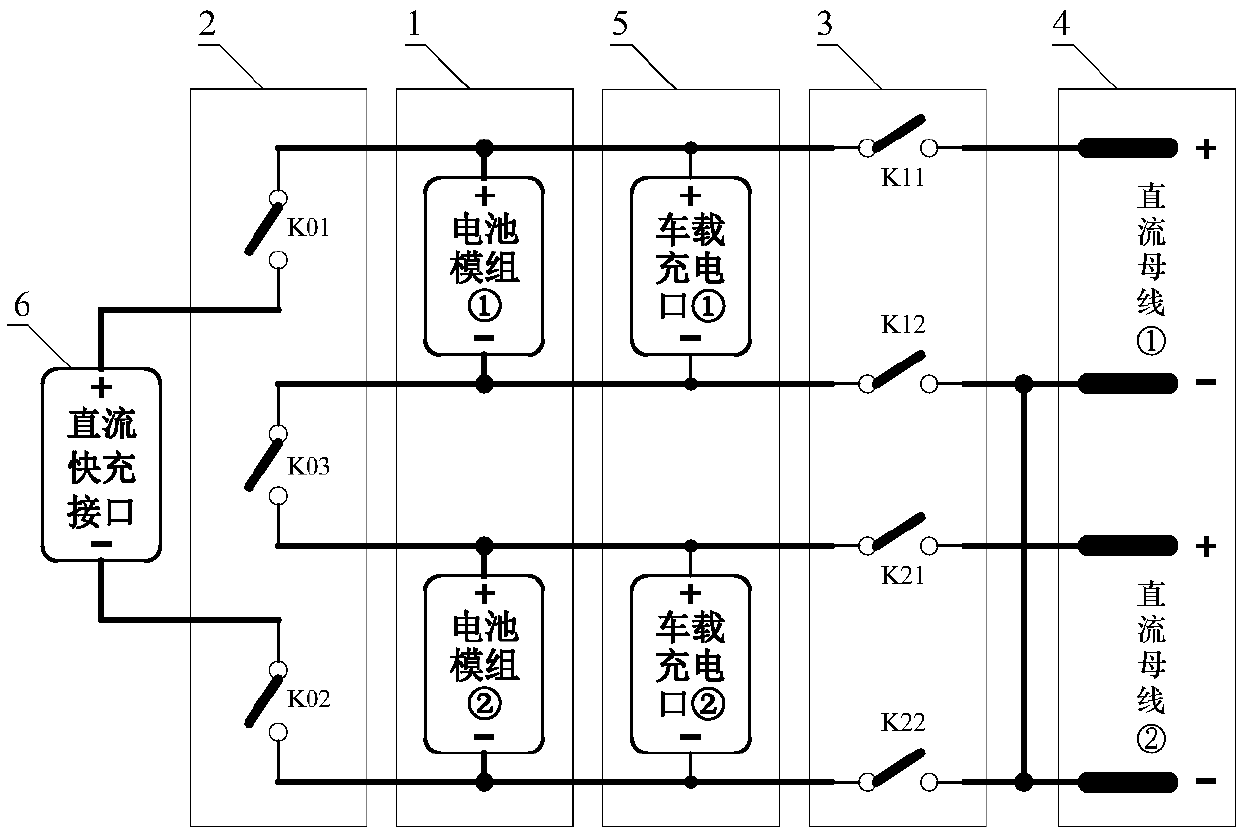

Electric vehicle battery pack electrical structure capable of achieving rapid charging

PendingCN110014880AAchieve active balancingAchieve electrical insulationCharging stationsElectric devicesElectrical batteryAutomotive battery

The invention relates to an electric vehicle battery pack electrical structure capable of achieving rapid charging. The electric vehicle battery pack electrical structure comprises a battery unit, a charging switch unit, a discharging switch unit, a direct-current bus unit, a vehicle-mounted charging unit and a direct-current rapid charging interface. Three charging switches and four discharging switches are all electrical switches. The electric vehicle battery pack electrical structure is characterized in that the battery unit is provided with two battery modules, the vehicle-mounted chargingunit is provided with two vehicle-mounted charging interfaces, and the direct-current bus unit is provided with two sets of direct-current buses; the discharging switches are turned off and the charging switches are turned on, thus the two battery modules are in series connection, and rapid charging is conducted through the direct-current rapid charging interface; the charging switches are turnedoff and the discharging switches are turned on, thus the two battery modules are discrete, and the two sets of direct-current buses conduct discharging independently (or in a common-ground mode or parallelly); and after a vehicle is parked, all the discharging switches and the charging switches are turned off, and the two battery modules can be charged slowly through the two vehicle-mounted charging interfaces. The electric vehicle battery pack electrical structure has the advantages of 1, series high-voltage rapid charging and discrete low-voltage safety discharging, and 2, electric energy redundancy and power supply redundancy, convenient driving of redundancy, and active equalization.

Owner:张朝辉

Integrated packaging microwave device array parallel welding apparatus and method

ActiveCN104966678AImprove seam welding efficiencyReduce labor intensity and operation timeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMicrowave

The invention discloses an integrated packaging microwave device array parallel welding apparatus and method. The front side of a positioning clamp is provided with a plurality of welding chambers arranged in arrays; insulation heat dissipation substrates are welded in the welding chambers, and are level with the front side of the positioning clamp; a clamp cover plate is provided with a plurality of fixing through holes arranged in arrays; the fixing through holes match the frame dimension of a device to be welded; a clamp insulating layer covers the back side of the clamp cover plate; a cover plate insulating layer covers the front surface of the positioning clamp except the welding chambers. The apparatus and method can rapidly dissipate great heat generated in the array parallel welding process of an integrated packaging microwave device, and avoid the problems of device temperature rapid rising, device internal welding flux remelting, rubber aging and bare chip loss caused by heat diffusion in successive covering processes of array devices.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

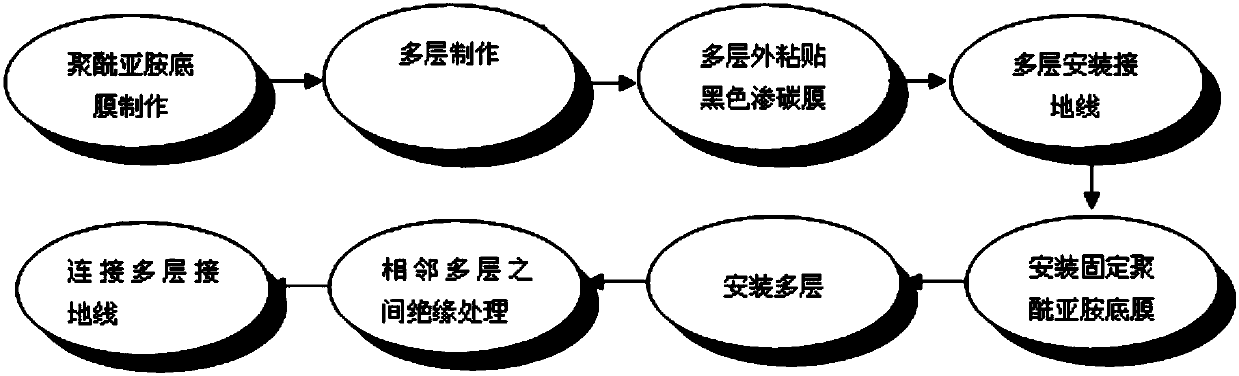

Method for thermal control multilayer coating of induction type magnetometer

ActiveCN107894574ASolve the problem that it is difficult to coat the dendritic structure multi-layer thermal insulation materialSolve problems where closed conductive loops are not allowedMagnitude/direction of magnetic fieldsEquipotentialEngineering

The invention discloses a method for the thermal control multilayer coating of an induction type magnetometer. The method includes manufacturing a polyimide bottom film, manufacturing multiple layers,pasting a black carburization film outside the multiple layers, installing grounding wires on the multiple layers, installing and fixing the polyimide bottom film, installing the multiple layers, performing insulation processing between adjacent multiple layers, and connecting the grounding wires of the multiple layers. According to the invention, the problem that a traditional method is difficult to carry out coating on a multilayer heat insulation material of a dendritic structure is solved, and the effect that the thermal control multilayer coating meets the requirements of heat insulation, insulation and equipotential of the induction type magnetometer product is achieved.

Owner:AEROSPACE DONGFANGHONG SATELLITE

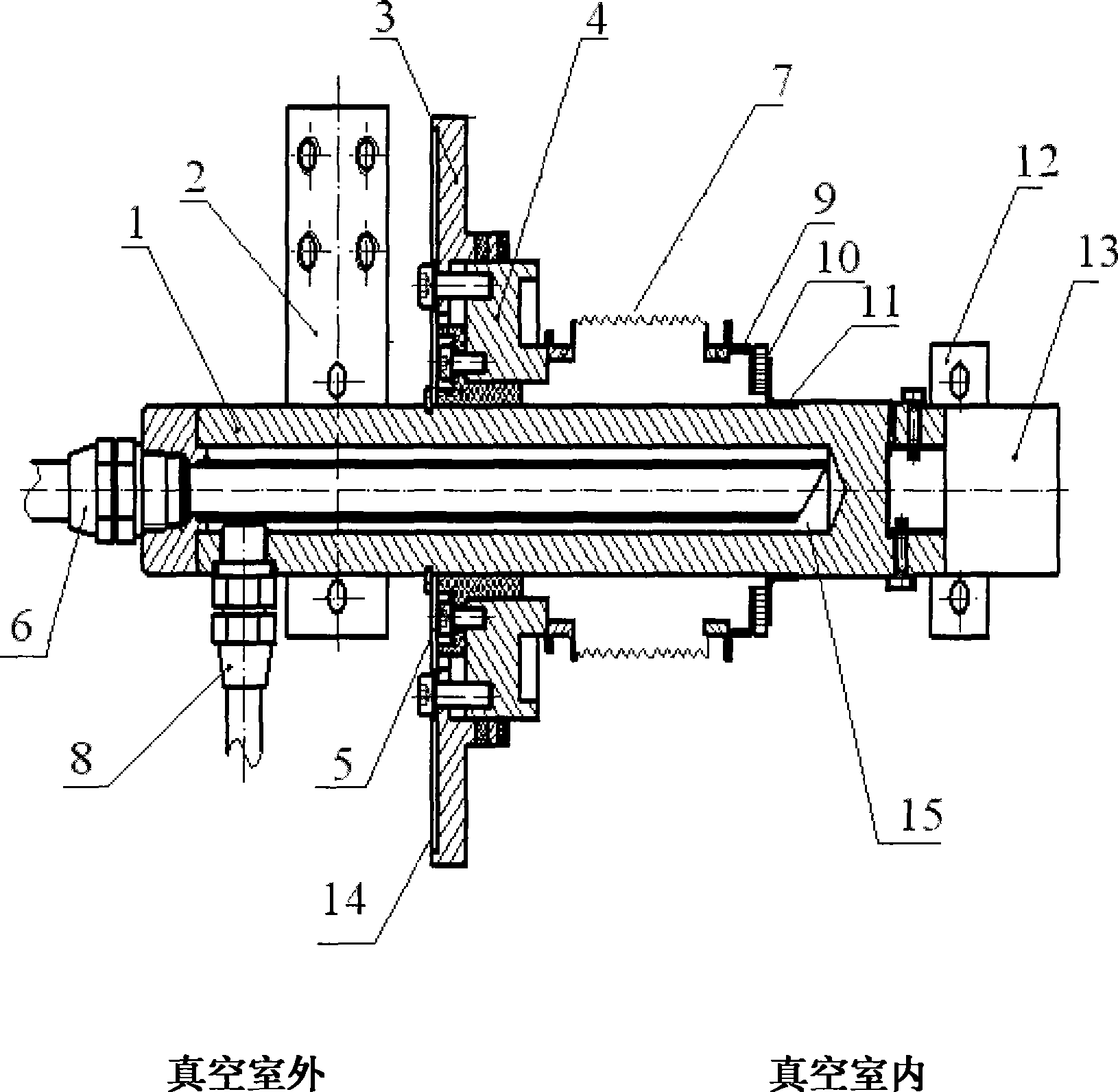

Retractable electrode for tungsten rhenium thermocouple calibration device

ActiveCN101393056AGuaranteed vacuumAchieve electrical insulationThermometer testing/calibrationRheniumEngineering

The invention relates to a telescopic electrode for a tungsten rhenium thermocouple calibration device, which comprises an electrode, wherein the electrode sequentially passes through an insulating sliding seat, a round seat, a corrugated pipe, a transition cap, an insulating ring and a transition ring; one end of the corrugated pipe is welded with the round seat, and the other end of the round seat is connected with the insulating sliding seat; the other end of the corrugated pipe is welded with the transition cap, the other end of the transition cap is welded with the insulating ring, and the other end of the insulating ring is welded with the transition ring; and the other end of the transition ring is welded and fixed on the electrode. The telescopic electrode fully can meet the requirements that the temperature of a tungsten tube reaches 3,000 DEG C, and the expansion amount reaches 20 millimeters to the maximum. A telescopic component, namely the corrugated pipe works in a non-high temperature state, which prolongs the service life.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

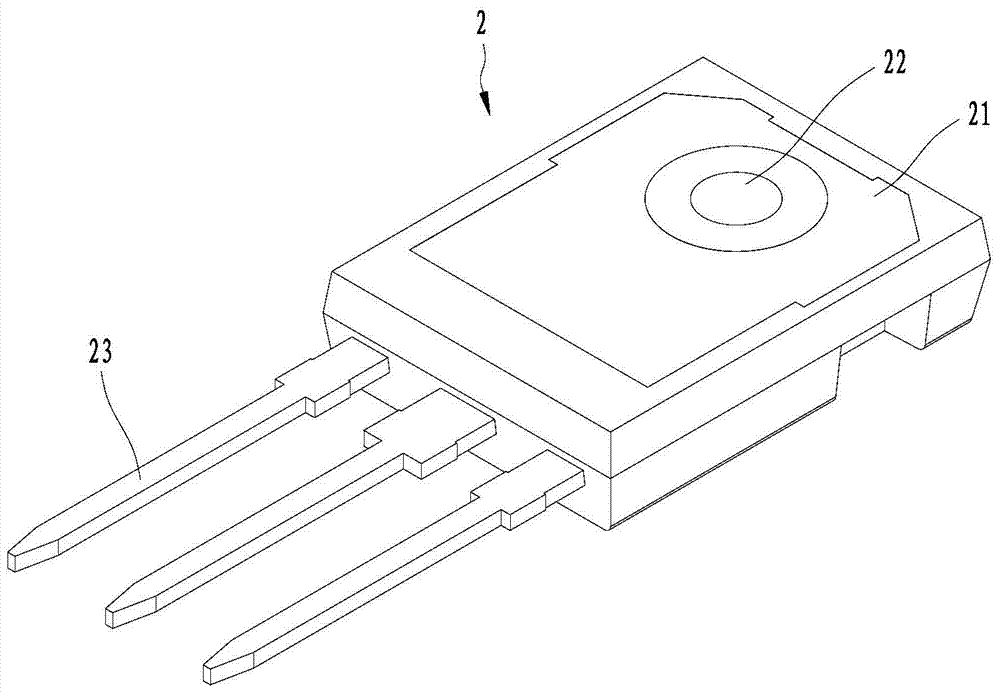

Combined screw

InactiveCN103697039ASimple structureAchieve electrical insulationSemiconductor/solid-state device detailsSolid-state devicesInsulation layerHeat sink

The invention discloses a combined screw. The combined screw is used for fixing a chip on a heat radiating base; one side surface of the chip is provided with a heat radiating sheet which is attached with the heat radiating base, and the chip is provided with a fixing hole penetrating through the heat radiating sheet. The combined screw comprises a head part, a rod part and an insulation layer, wherein the insulation layer is arranged on the outer wall of one end, near the head part, of the rod part in a coating manner. When the combined screw penetrates through the fixing hole to fix the chip on the heat radiating base, the insulation layer is positioned between the heat radiating sheet and the rod part. The combined screw has the beneficial effects that by adopting the structure of the insulation layer arranged on the outer wall of one end, near the head part, of the rod part in a coating manner, the electric insulation between the combined screw and the heat radiating sheet is realized, and a longer creepage distance is realized; the structure is simple; when the chip is assembled with a thread connection method, the operation is easy and convenient, and the automatic production is favorably realized.

Owner:SHENZHEN SINE ELECTRIC

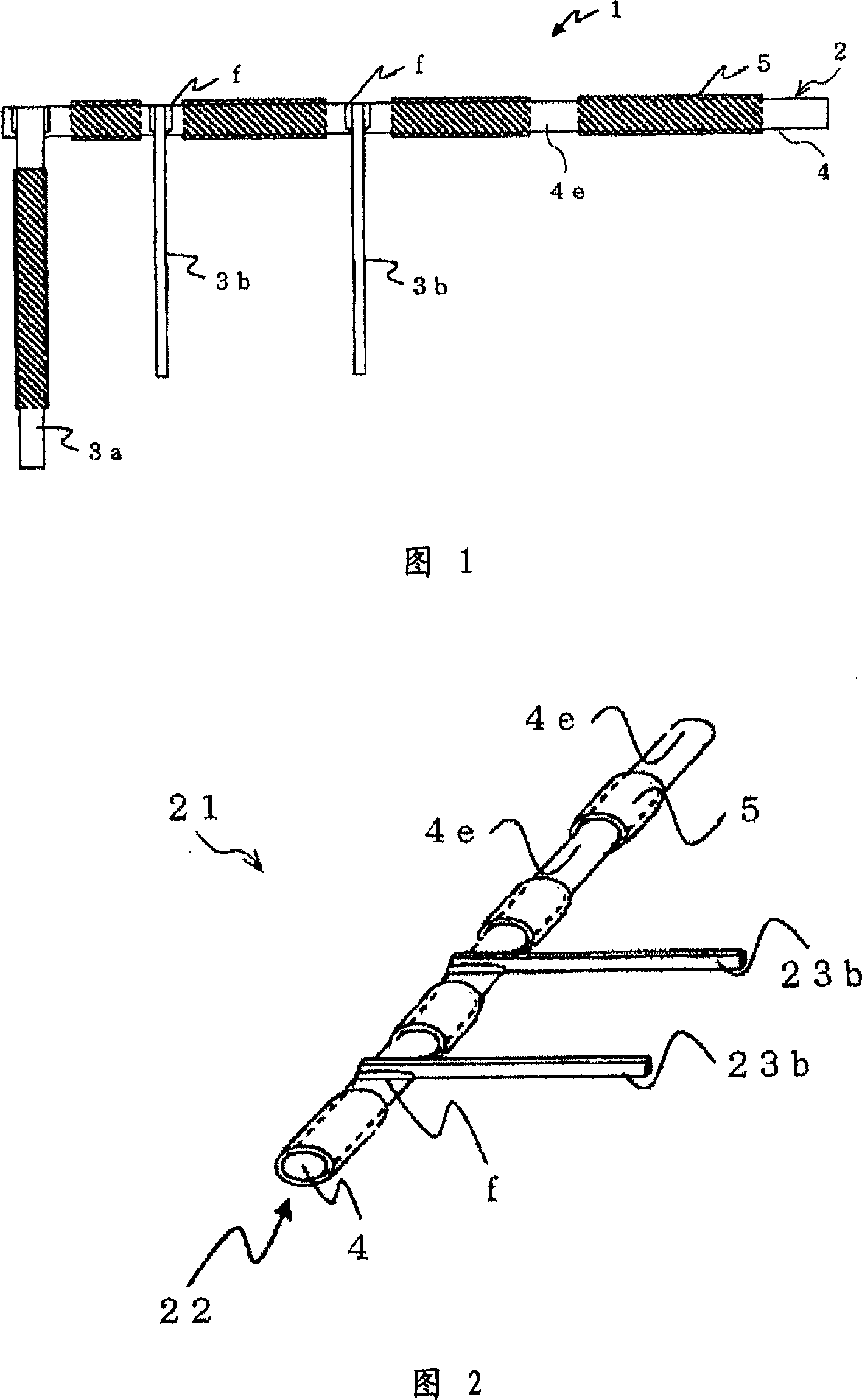

Connecting lead wire, method for fabricating same, and solar battery module using the connecting lead wire

InactiveCN101106166AAchieve electrical insulationReduce production processPhotovoltaic energy generationSemiconductor devicesElectricityProduction rate

A connecting lead wire is used for a solar battery module in which a plurality of solar battery cells connected in series by an inter-connector are arranged. The connecting lead wire is provided with a trunk portion and one or more branch portions. In the trunk portion, an enamel coating layer is provided on a conductor. In each of the branch portions, a solder plating layer is provided on a conductor. The branch portion protrudes from the trunk portion in a lateral direction, and connected to an electrode of each of the solar battery cells. The branch portion connects the solar battery cells with each other.

Owner:HITACHI CABLE

Cooling plate for electrical energy storage element

InactiveCN106463799AImprove mechanical stabilityImprove sealingFuel and secondary cellsSecondary cellsMetal sheetCooling channel

The invention relates to a cooling plate for an electric energy storage element, said cooling plate comprising at least two non-detachably interconnected metal sheets and at least one plastic covering. The joined metal sheets comprise at least one cooling channel which can be created by separating means.

Owner:ROBERT BOSCH GMBH

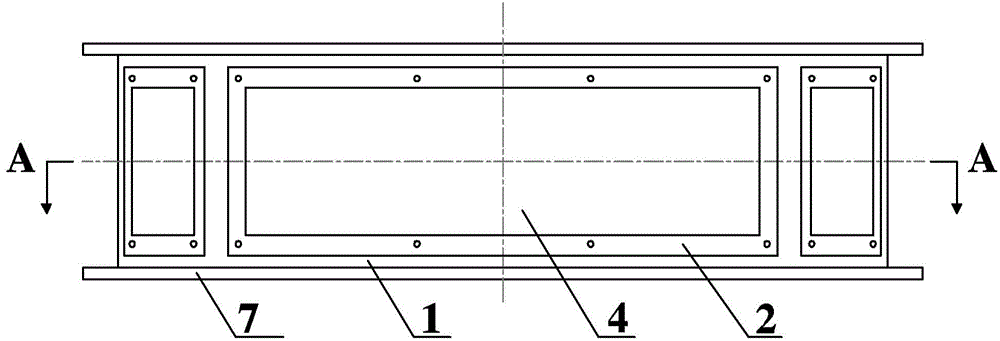

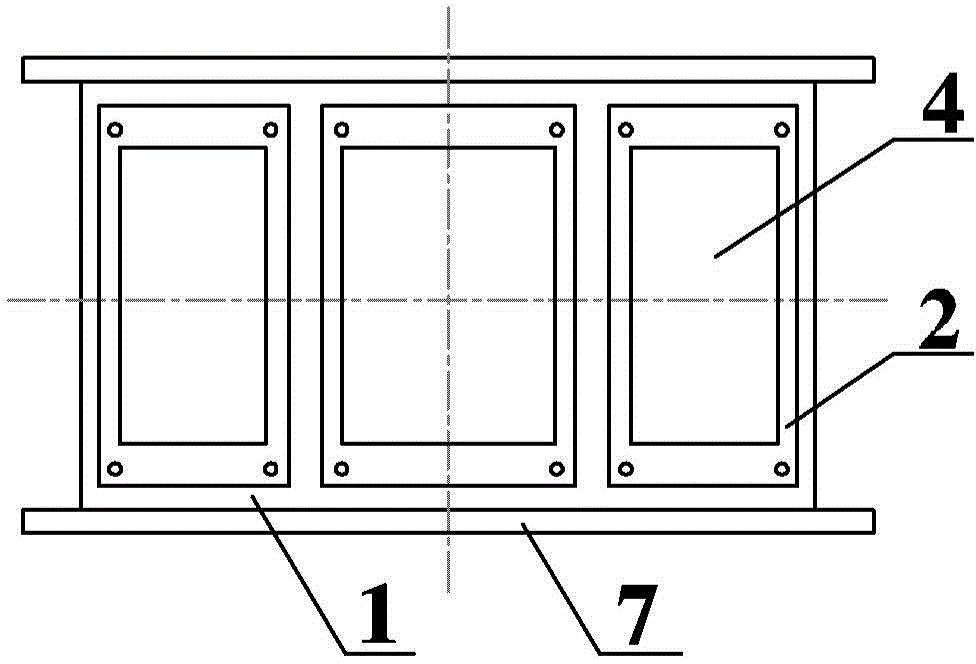

Thermoelectric generation device for vehicle

ActiveCN103758617AOvercome the characteristics of large volume and complex structureImprove heat utilization efficiencyInternal combustion piston enginesExhaust apparatusElectricityUtilization rate

The invention provides a thermoelectric generation device for a vehicle. The device comprises a box arranged on an exhaust pipeline of the vehicle, multiple hollow pipes arranged in the box in parallel, and a thermoelectric device arranged on the pipes in a sleeved mode and of an annular structure, wherein the box is provided with an air inlet and an air outlet, tail gas from an engine flows into the air inlet and is exhausted from the air outlet, and the distribution direction of the pipes is vertical to the airflow direction in the box. The thermoelectric generation device is simple in structure, compact in size and high in heat utilization rate, the structure of the bottom of the vehicle is kept as much as possible, and waste heat of the tail gas of the vehicle can be converted into electricity more effectively.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Fixed carriageway for rail vehicles and method of manufacturing the same

Owner:RAIL ONE GMBH

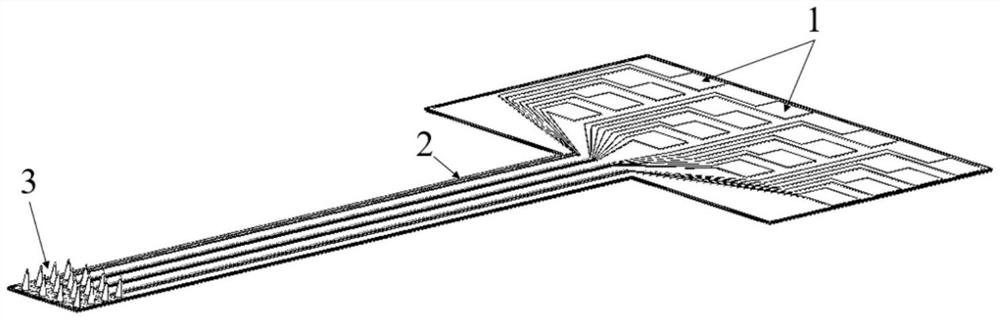

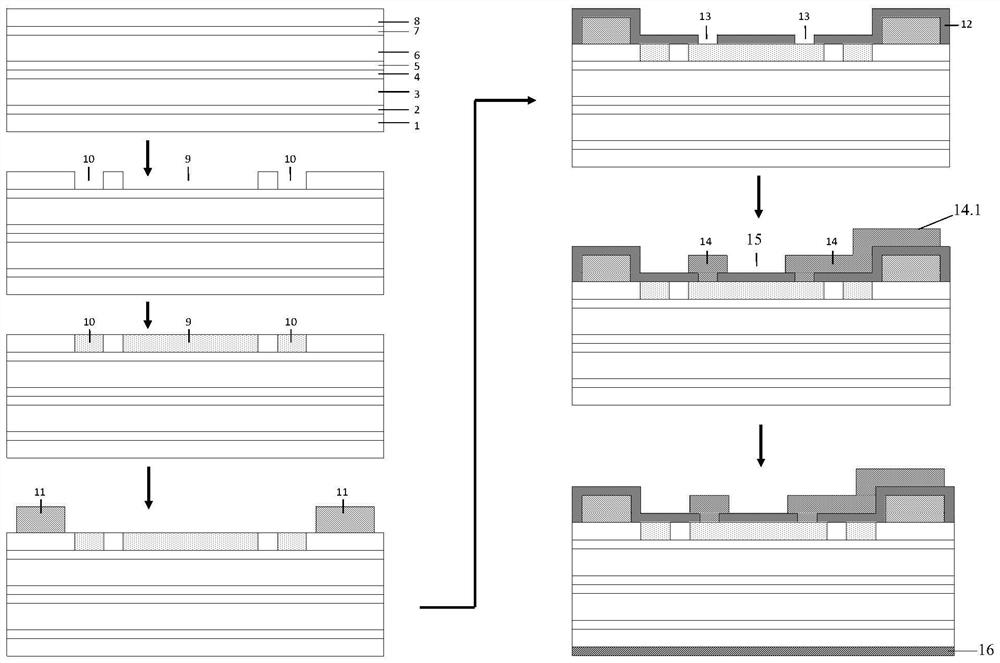

High-density self-insulating flexible microneedle electrode and preparation method thereof

PendingCN114010198AAchieve electrical insulationPrecise exposureDiagnostic recording/measuringSensorsHigh densityElectrode array

The invention discloses a high-density self-insulating flexible microneedle electrode and a preparation method thereof. An existing flexible cerebral cortex electrode has the problems of low stimulation and recording spatial resolution and incapability of being implanted into the cortex. In addition, the existing hesitant electrode or similar hesitant electrode also has the problems of complex preparation process and high cost. The flexible microneedle electrode comprises a lower insulating layer, an SU-8 boss arranged on the lower insulating layer, and metal conductive pads, metal wires and a flexible microneedle electrode array which are arranged on the SU-8 boss. The longitudinal sections of different positions of the SU-8 boss are inverted trapezoidal. The plurality of metal conductive pads, the plurality of metal wires and the flexible microneedle electrode array are all arranged on the SU-8 boss. By using the microneedle structure, the electrode points of the microneedle electrode array can penetrate into the tissue to realize stimulation and recording with high temporal-spatial resolution. The preparation method has the advantages of simple preparation process and low cost, and also has excellent mechanical matching performance.

Owner:杭州电子科技大学温州研究院有限公司 +1

Sealing device used for 10(-8)Pa ultra-high vacuum round plane magnetron sputtering target

InactiveCN100564582CEasy maintenanceEasy to replaceEngine sealsVacuum evaporation coatingUltra-high vacuumMaterials science

The present invention discloses one kind of sealing device for 6x10<-8> Pa aultra high vacuum circular planar magnetically controlled sputtering target. The sealing device includes one water cooling cavity with soft iron and magnetic steel, one water cooling cavity sealing flange with metal O-ring, one water inlet pipe and one water outlet pipe welded to the water cooling cavity sealing flange, one target supporting seat with one electrode insulating layer and two groups of O-rings, one installing flange welded to the target supporting seat and other parts. The present invention can ensure vacuum degree as high as 6x10<-8> Pa.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Non-evaporable type adsorption pump utilizing electric heating activation

ActiveCN106224202AShort activation temperatureReduce heating power consumptionPositive displacement pump componentsHeating element shapesElectricityEngineering

The invention discloses a non-evaporable type adsorption pump utilizing electric heating activation, and belongs to the field of vacuum obtaining and maintaining. The adsorption pump comprises an adsorption unit, a heater and a mounting interface; the adsorption unit is composed of an adsorption belt and an adsorption material attached on the adsorption belt; the mounting interface is a vacuum sealed hollow structure; an electric connector is arranged in a cavity of the mounting interface; the adsorption unit and the heater are arranged in a spaced manner, and the adsorption unit abuts against the heater; and a heating element of the heater is electrically connected to the electric connector in the mounting interface. According to the adsorption pump disclosed by the invention, the adsorption unit and the heater are arranged in the spaced manner, so that the adsorption material is in sufficient contact with a hating tube, and therefore, time for reaching a needed activation temperature is short, heating power loss is low and efficiency is high.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

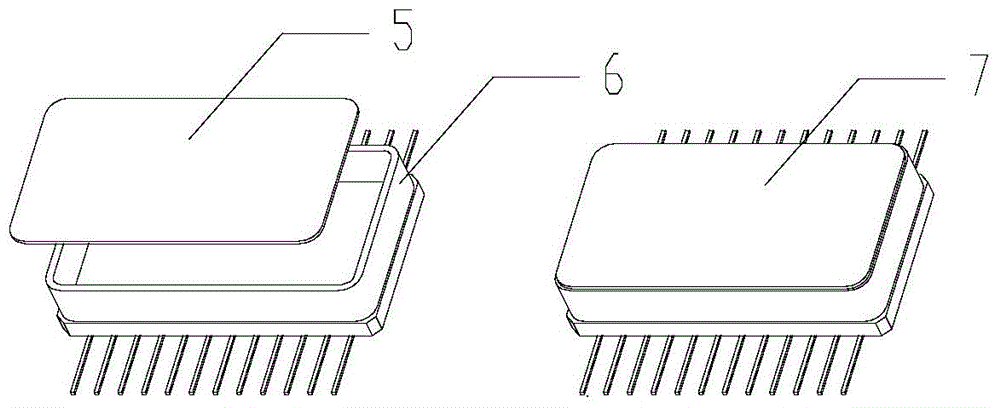

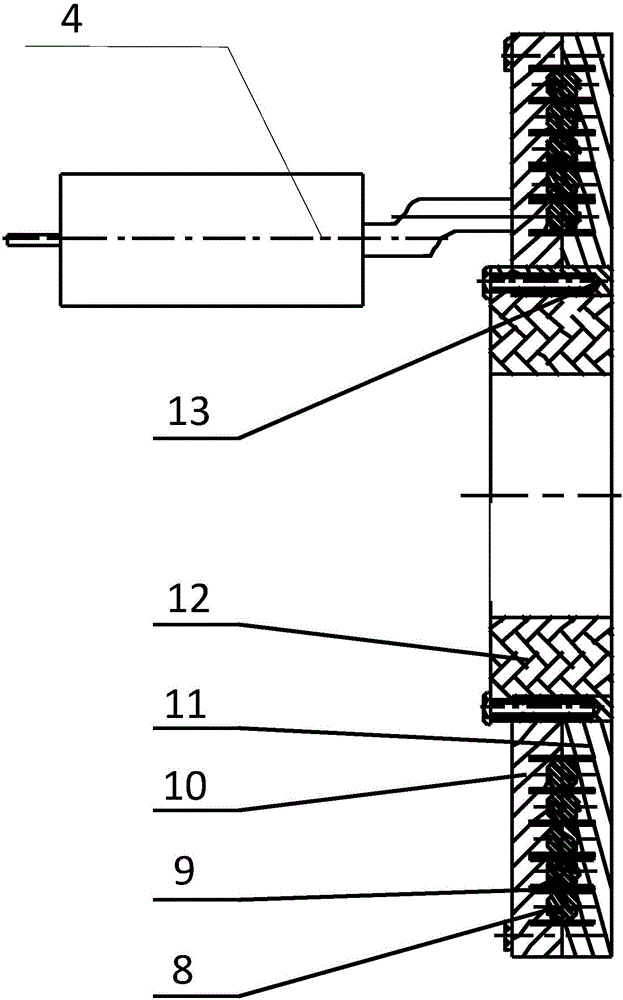

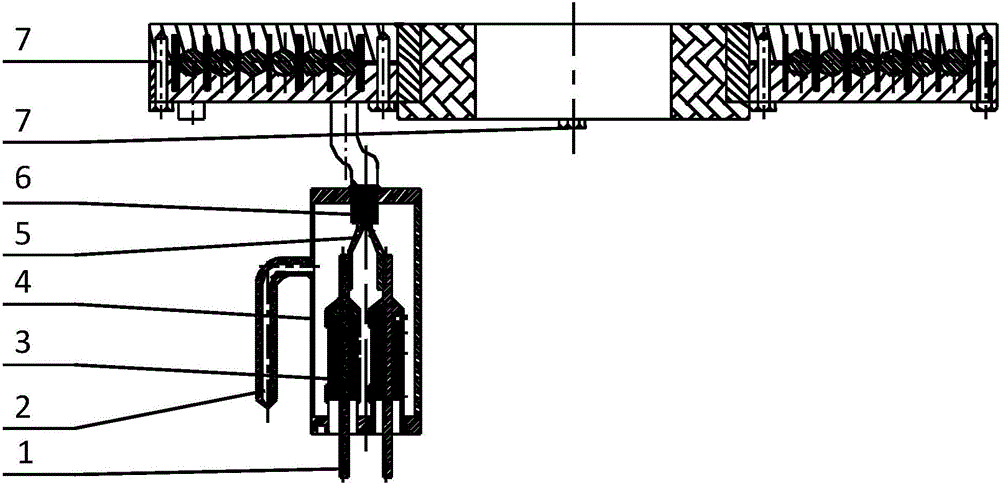

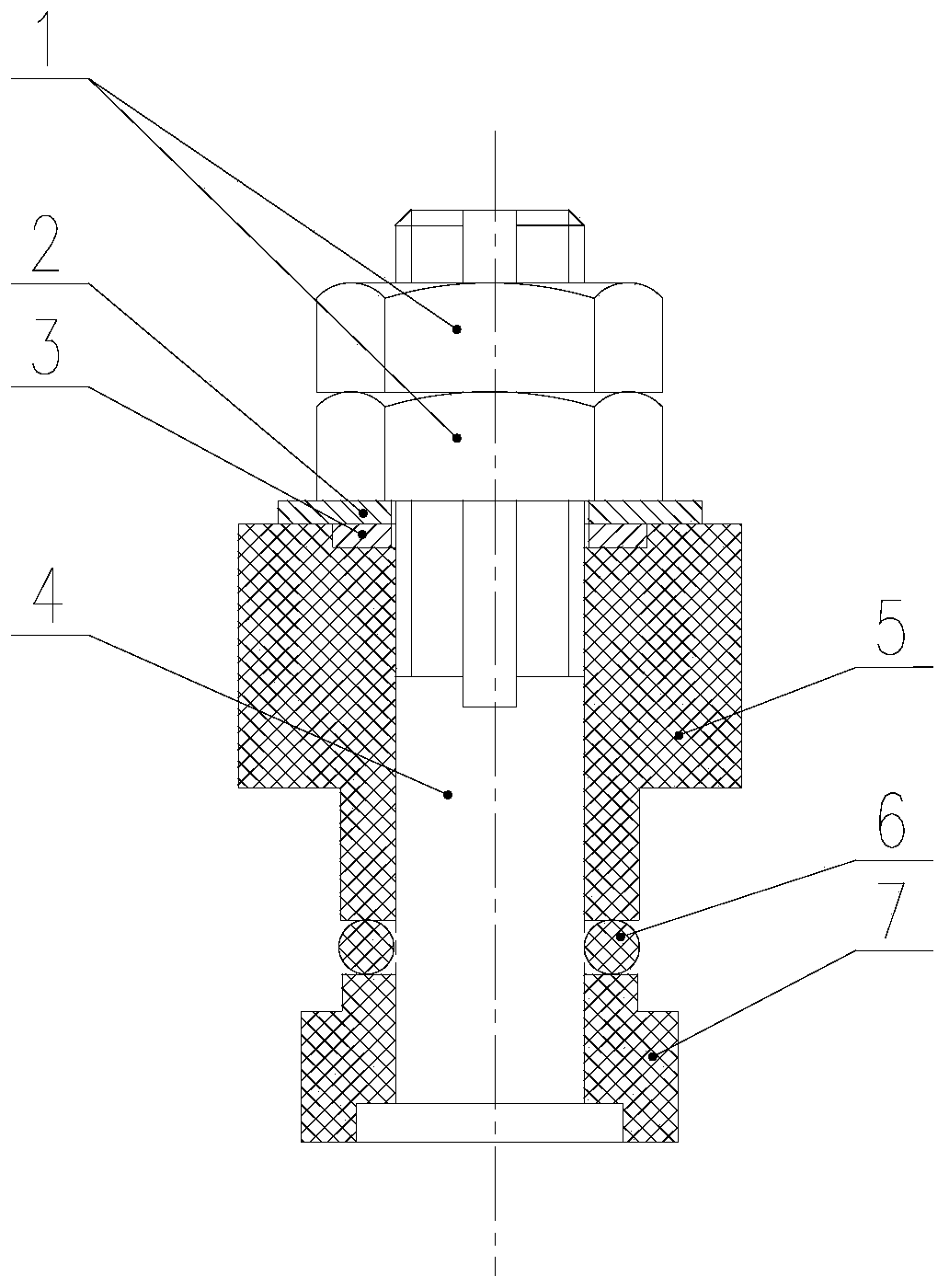

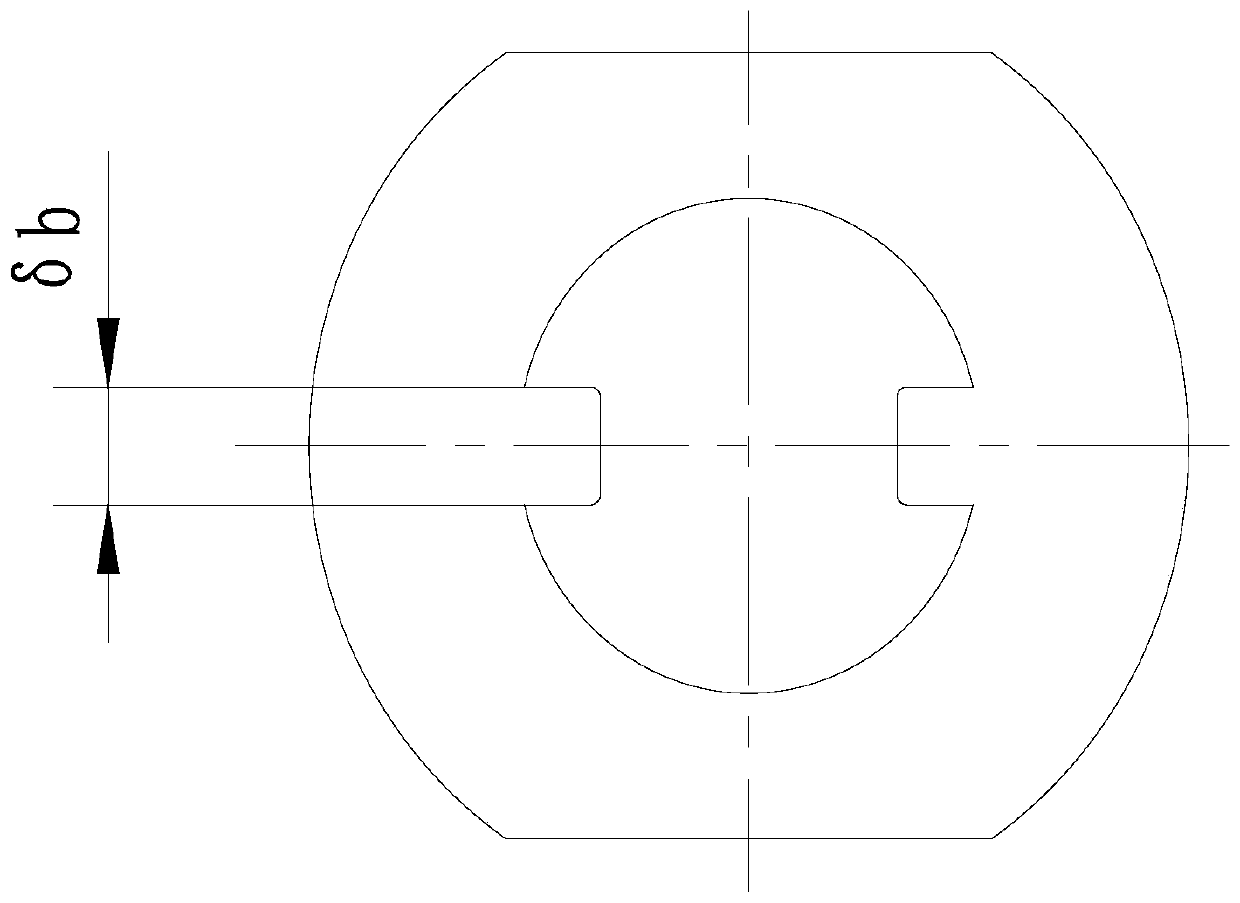

Electrical insulation sealing structure of oil-cooled permanent magnet motor and assembly method

ActiveCN110311497ASimple structureReduce volumeWindings insulation shape/form/constructionManufacturing dynamo-electric machinesRubber ringCooling effect

The invention belongs to the technical field of motors, and relates to an electrical insulation sealing structure of an oil-cooled permanent magnet motor and an assembly method. The electrical insulation sealing structure comprises two compression nuts (1), a metal flat gasket (2), a positioning backing plate (3), a slotted lead terminal (4), a positioning insulator (5), an O-shaped rubber ring (6) and an inner insulator (7). The electrical insulation sealing structure of the oil-cooled permanent magnet motor is applicable to a stator oil immersed high-speed permanent magnet motor, and the motor adopting the structure has the advantages of simple shell structure, small volume, light weight and good stator cooling effect; and the electrical insulation structure of the oil-cooled permanent magnet motor has a function of preventing a lead terminal from rotating, not only can realize the electrical insulation of a stator lead-out wire and the shell, but also can realize the good sealing ofcooling oil in a stator inner cavity.

Owner:HARBIN DONGAN ENGINE GRP

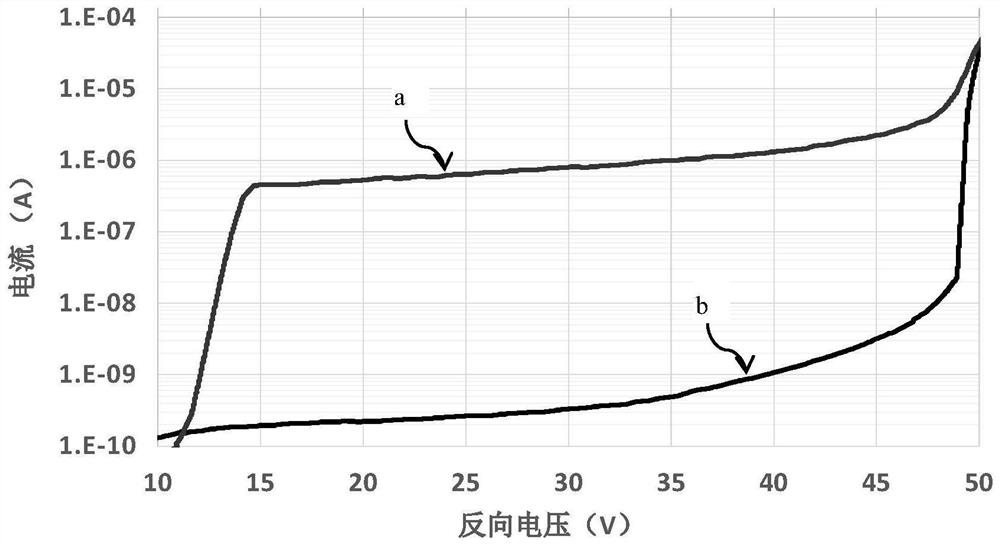

Preparation method of avalanche photodetector

PendingCN114122191AReduce accumulationQuick responseFinal product manufactureSemiconductor devicesPhotodetectorElectric field

The invention discloses a preparation method of an avalanche photodetector. The preparation method comprises the following steps: firstly, sequentially growing a p-type InP buffer layer, an In < 0.53 > Ga < 0.47 > As absorption layer, an In < 1-x-y > Al < x > Ga < y > As bandwidth gradient layer, a p-type In < 0.52 > Al < 0.48 > As charge control layer, an In < 0.52 > Al < 0.48 > As multiplication layer, an In < x > Ga < 1-x > As < y > P < 1-y > corrosion cut-off layer and a p-type InP cover layer on a p-type InP substrate; then corroding the p-type InP cover layer, wherein the corroded region comprises a central region and one or more annular regions surrounding the central region; carrying out secondary epitaxy on n-type InP in the corroded region to form an n-type InP central collector region and an n-type InP electric field protection ring; then depositing a SiO2 layer, and etching off SiO2 in a partial region to form a circle of annular SiO2 isolation layer; depositing an optical anti-reflection film and forming a metal contact window on the optical anti-reflection film above the central collector region; then constructing an upper electrode, wherein the upper electrode is in contact with the central collector region through the metal contact window; and finally, preparing a back electrode on the back surface of the InP substrate.

Owner:北京英孚瑞半导体科技有限公司

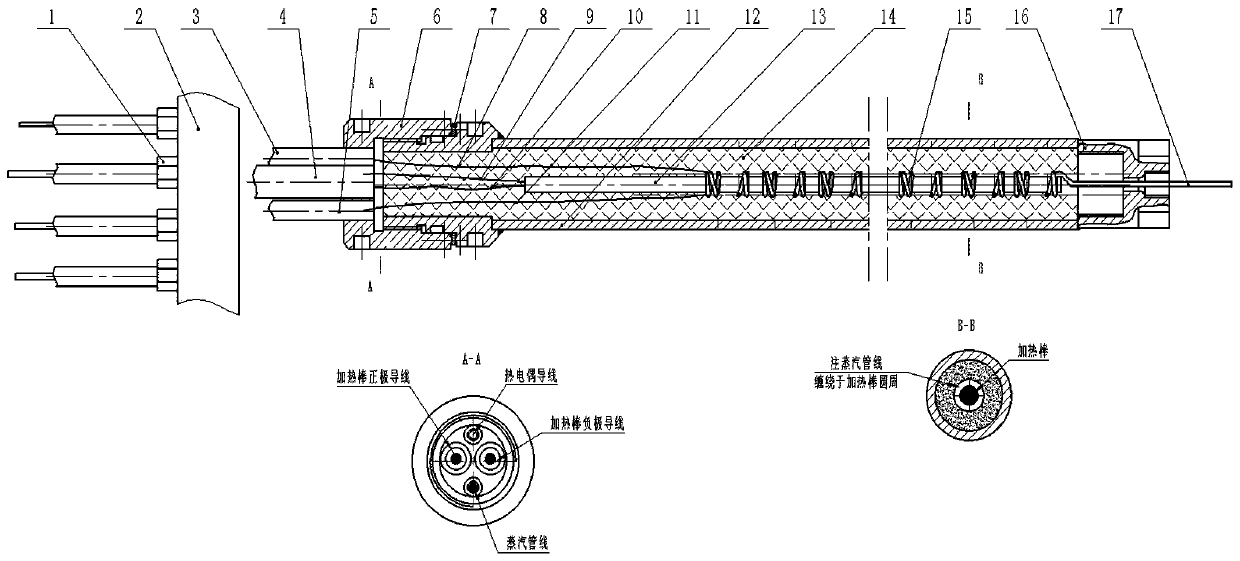

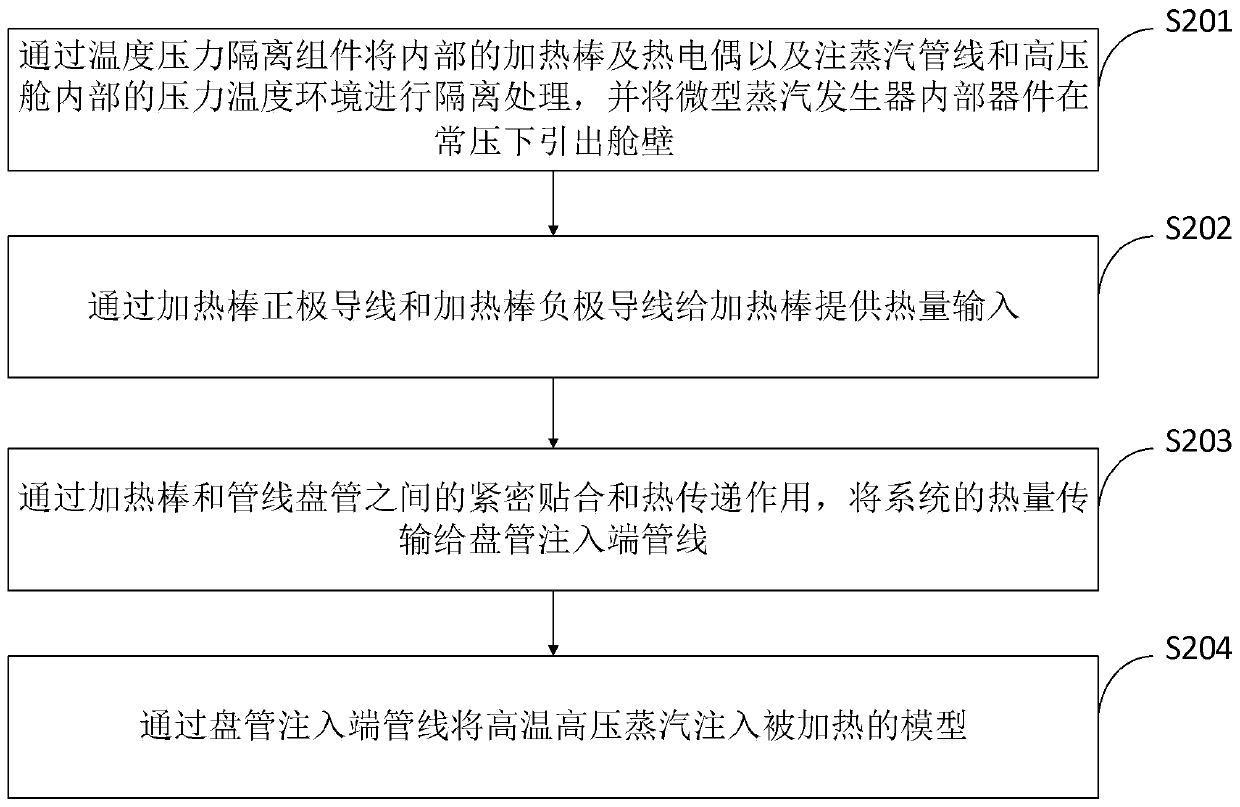

Implantable miniature steam generator

ActiveCN110173679AAchieve electrical insulationAchieve the effect of injectionSteam generation heating methodsBoiler controlTemperature stressEngineering

The invention belongs to the technical field of experimental equipment in the fields of petroleum, chemical engineering and energy resources and discloses an implantable miniature steam generator. Forthe implantable miniature steam generator, isolating treatment is performed on an internal heating rod and a thermocouple as well as pressure temperature environments in a steam injection pipeline and a high-pressure cabin through a temperature and pressure isolation assembly, and devices in a miniature steam generator are led out of the cabin wall at a normal pressure; heat input is provided tothe heating rod through a heating rod positive wire and a heating rod negative wire; heat of a system is transmitted to a pipeline at the injection end of a coil pipe through tight fit and the heat transfer effect between the heating rod and the pipeline coil pipe; and high-temperature and high-pressure steam is injected into a heated die through the coil pipe injection end pipeline. For the implantable miniature steam generator, miniature steam pipeline injection can be performed in a high-pressure vessel under the high-temperature and high-pressure environment; and secondary heating can be performed to compensate for the defect that heat cannot be supplemented due to large pipeline distance of a conventional steam generator.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A Plasma Sealing Structure of Discharge Chamber of Annular Magnetic Steel Annular Tangent Field Ion Thruster

ActiveCN111005849BGuaranteed long-term insulation capabilityEnsure electrical insulationMachines/enginesUsing plasmaEngineeringStructural engineering

The invention provides a plasma sealing structure for a discharge chamber of an annular magnetic steel ring cutting field ion thruster. The plasma sealing structure comprises a ceramic ring, a shielding cover and a Z-shaped sealing ring; peripheral equipment comprises a grid assembly, an anode, an insulation supporting assembly and a supporting ring of the ion thruster, and the anode is of a stepped cylinder structure and comprises a large-diameter cylinder and a small-diameter cylinder; the shielding cover is installed on the outer wall of the upper end of the small-diameter cylinder of the anode, the ceramic ring is located below the shielding cover and fixed to the end face between the large-diameter cylinder and the small-diameter cylinder of the anode, and the shielding cover shieldspart of the end face of the ceramic ring and the inner wall face of the ceramic ring to realize shielding and realize electric insulation between the anode and the grid assembly; and the horizontal end face of one side of the Z-shaped sealing ring is fixed to the bottom face of the grid assembly, and the horizontal end face of the other side is compressed at the top end of the ceramic ring to complete plasma sealing of the discharge chamber. The problems of electric insulation between the grid assembly and the anode of the ion thruster in a long-term plasma environment and plasma sealing of the discharge chamber are solved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com