Non-evaporable type adsorption pump utilizing electric heating activation

An adsorption pump and non-evapotranspiration technology, which is applied in the direction of heating element materials, heating element shapes, pumps, etc., can solve the problems that the low-temperature condensation pump cannot be coupled and installed, the pumping area cannot be directly installed, and the vacuum degree cannot be maintained, etc. The time to achieve is short , high efficiency and low heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

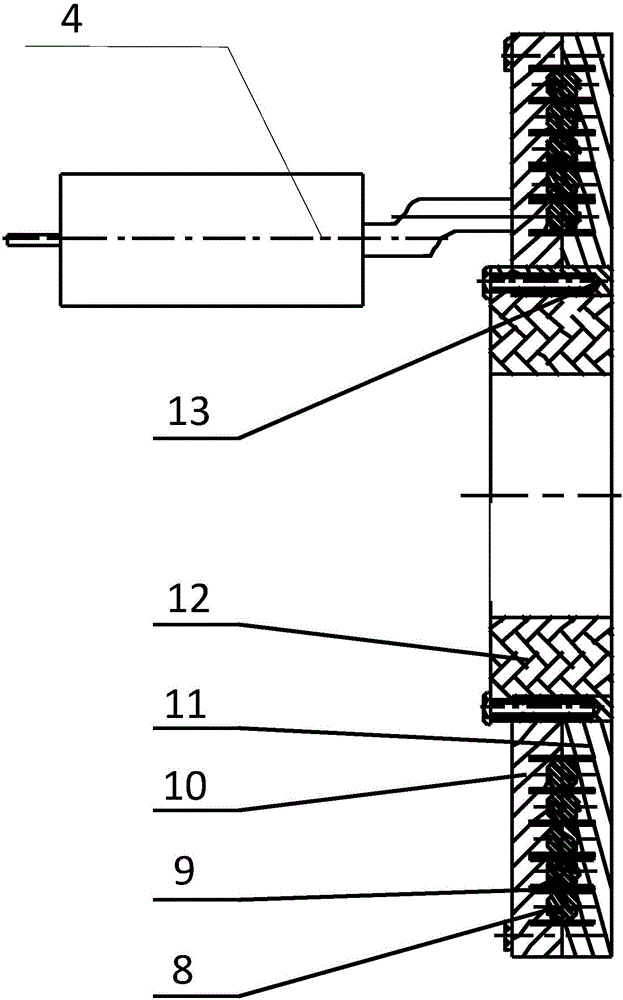

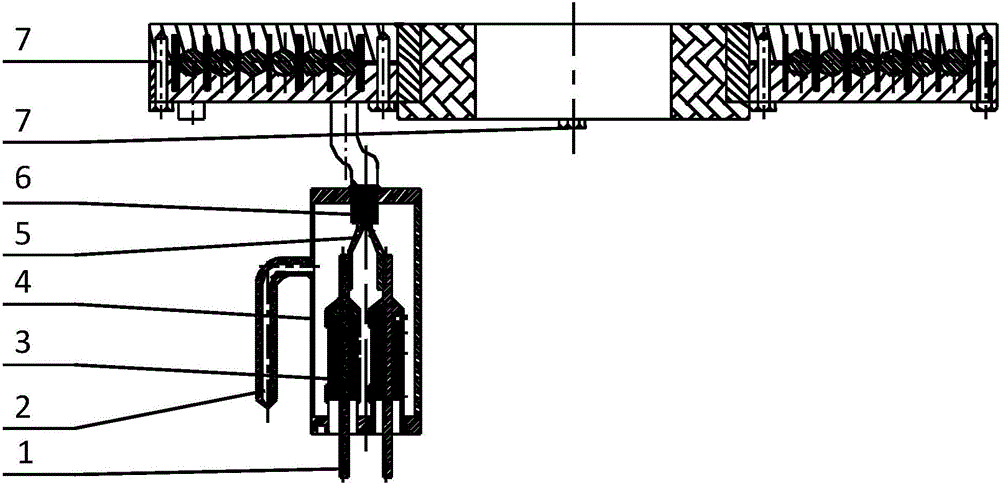

[0030] Such as Figure 1~3 As shown, a non-evaporable adsorption pump activated by electric heating, the adsorption pump mainly includes an adsorption unit, a heater and an installation interface 4;

[0031] Wherein, the adsorption unit is composed of an adsorption belt 9 and an adsorption material attached to the adsorption belt 9; the installation interface 4 is a vacuum-sealed hollow structure, and an electrical connector 3 is arranged in the cavity;

[0032] The adsorption unit is spaced apart from the heater, and the adsorption unit interferes with the heater; the heating element 5 of the heater is electrically connected to the electrical connector 3 in the installation interface 4 .

[0033] Further, the adsorption pump also includes a support assembly, which is composed of a heat insulation ring 12, a support ring 13, an upper support rib 10 and a lower support rib 11; wherein, the upper support rib 10 and the lower support rib 11 are Processed with installation holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com