Implementing method for interconnected structure of RF MEMS switch

A technology of interconnection structure and realization method, which is applied in the direction of circuits, waveguide devices, electrical components, etc., can solve the problems of reducing the reliability of switches, complicated switch processing technology, warping and deformation of switch structures, etc., and achieves the improvement of mechanical strength and reliability , The method and structure are simple and practical, and the effect of avoiding warping and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] The schematic diagram of the planar structure of the interconnection structure is shown in Fig. 1 . Structures 1, 2, and 3 are drive structures, interconnect structures, and contact structures, respectively, and structures 4 and 5 are signal lines and anchor points, respectively. The entire switch structure is formed by one polysilicon deposition with a thickness of 2um.

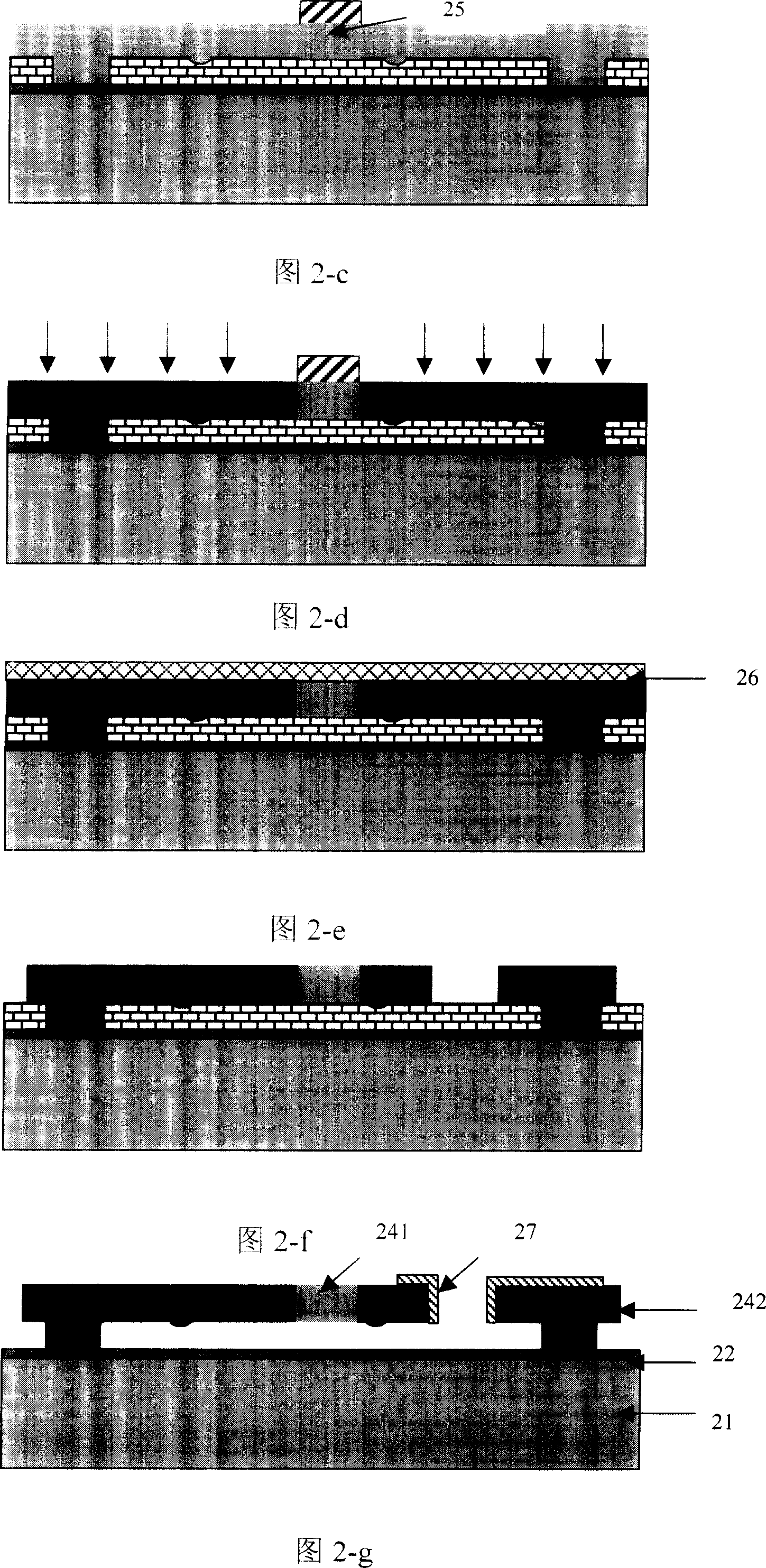

[0048] Referring to Figure 2, the process flow of the switch is as follows:

[0049] 1) An N Si sheet is selected as the Si substrate 21 with a thickness of 400um and a diameter of 4 inches. A silicon nitride insulating layer 22 is deposited by LPCVD to a thickness of 1000 angstroms. A SiO2 sacrificial layer 23 is deposited by LPCVD with a thickness of 2um. Photolithography, and use RIE etching to pattern the sacrificial layer structure;

[0050] 2) Deposit polysilicon 24 with a thickness of 2um by LPCVD;

[0051] 3) Spin the glue and perform photolithography, using the remaining photoresist afte...

example 2

[0057] The schematic diagram of the planar structure of the interconnection structure is shown in Fig. 1 . Structures 1, 2, and 3 are drive structures, interconnect structures, and contact structures, respectively, and structures 4 and 5 are signal lines and anchor points, respectively. The thickness of the whole switch structure is 4um.

[0058] The process flow of the switch is as follows:

[0059] 1) Select N Si sheet as the Si substrate, with a thickness of 400um and a diameter of 4 inches. A silicon nitride insulating layer is deposited by LPCVD to a thickness of 500 angstroms. The SiO2 sacrificial layer is deposited by LPCVD method with a thickness of 2um. Photolithography, and use RIE etching to pattern the sacrificial layer structure;

[0060] 2) Deposit polysilicon with a thickness of 4um by LPCVD method;

[0061] 3) Deposit SiO2 with a thickness of 2um as a mask layer by LPCVD method, and use photolithography and RIE etching to pattern the SiO2 film;

[0062] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com