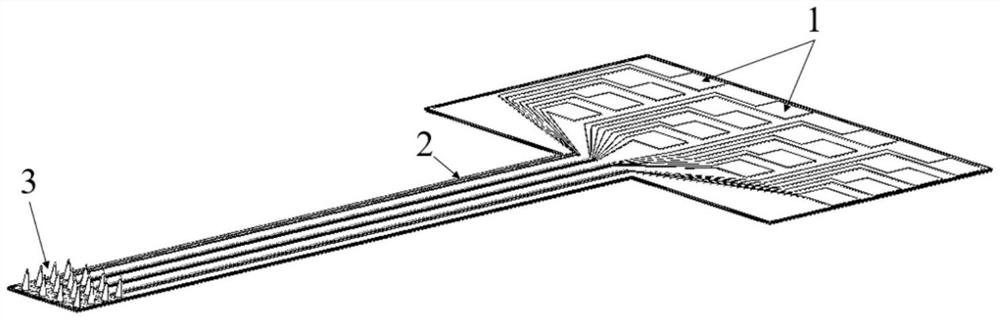

High-density self-insulating flexible microneedle electrode and preparation method thereof

A high-density, micro-needle technology, used in medical science, sensors, diagnostic recording/measurement, etc., can solve problems such as inability to achieve phosphor stimulation, avoid metal etching problems, avoid lithography patterning, and improve spatial resolution. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as Figure 5 As shown, the specific steps of the preparation method of the high-density self-insulating flexible microneedle electrode are as follows:

[0045] 1) if Figure 5 As shown in part a, use a quartz glass plate as the substrate, place the substrate in acetone, ethanol and deionized water for 5 minutes, and then blow dry it with nitrogen and bake it on a hot plate at 180°C for 15 minutes .

[0046] 2) if Figure 5 As shown in part b of , use CVD (Chemical Vapor Deposition) to deposit a layer of paryleneC with a thickness of 10 microns as the lower insulating layer.

[0047] 3) if Figure 5 As shown in part c, use a glue spinner to spin coat a layer of SU-8 photoresist with a thickness of 10 microns on the lower insulating layer and perform photolithographic patterning on the front side to form microneedle bosses and wire bosses with inverted trapezoidal longitudinal sections. Mesa 10 and pad boss 7 structure.

[0048] 4) if Figure 5 As shown in par...

Embodiment 2

[0056] Such as Figure 5 As shown, the specific process of the steps is as follows:

[0057] 1) if Figure 5 As shown in part a, use a quartz glass plate as the substrate, place the substrate in acetone, ethanol and deionized water for 5 minutes, and then blow dry it with nitrogen and bake it on a hot plate at 180°C for 15 minutes .

[0058] 2) if Figure 5 Shown in part b of the quartz glass, spin-coat one deck of PMMA (polymethyl methacrylate) on the quartz glass as a sacrificial layer, then spin-coat a layer of 5 micron thick PI (polyimide glue) on the PMMA sacrificial layer and After curing, it is used as the lower insulating layer.

[0059] 3) if Figure 5 As shown in part c, spin-coat a layer of SU-8 photoresist with a thickness of 10 microns on the lower insulating layer using a glue spinner and perform photolithographic patterning on the front side to form microneedle bosses, wire bosses and pad bosses structure.

[0060] 4) if Figure 5 As shown in part d, a l...

Embodiment 3

[0068] Such as Figure 5 As shown, the specific process of the steps is as follows:

[0069] 1) if Figure 5 As shown in part a, use a quartz glass plate as the substrate, place the substrate in acetone, ethanol and deionized water for 5 minutes, and then blow dry it with nitrogen and bake it on a hot plate at 180°C for 15 minutes .

[0070] 2) if Figure 5 As shown in part b of the above, use CVD (chemical vapor deposition system) to deposit a layer of 5 micron thick paryleneC on the quartz glass as a sacrificial layer, and then spin coat a layer of 5 micron thick PI (polyimide) on the paryleneC sacrificial layer. Glue) and cured as the lower insulating layer.

[0071] 3) if Figure 5 As shown in part c, spin-coat a layer of SU-8 photoresist with a thickness of 10 microns on the lower insulating layer using a glue spinner and perform photolithographic patterning on the front side to form microneedle bosses, wire bosses and pad bosses structure.

[0072] 4) if Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com