Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Organic/organo-metallic films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanodevices for Spintronics and Methods of Using Same

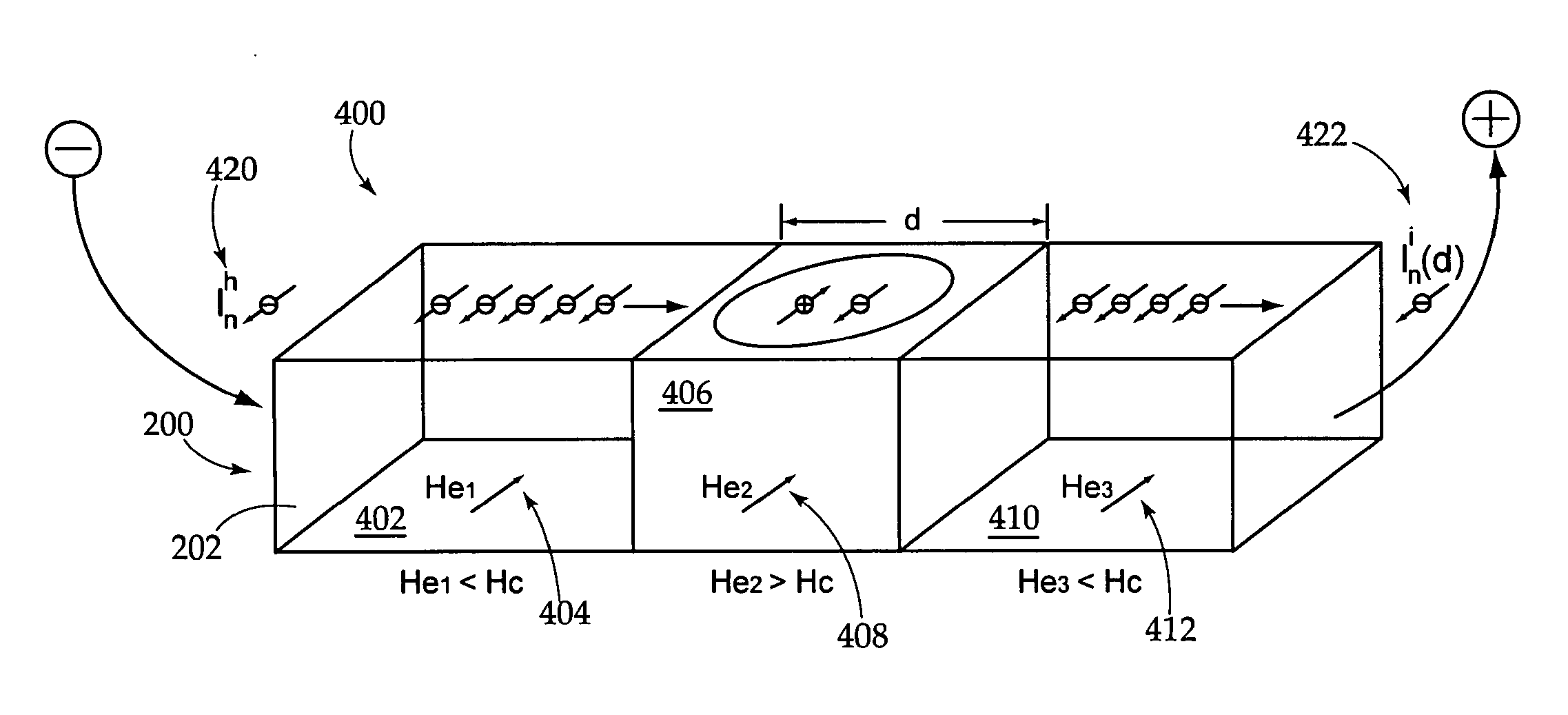

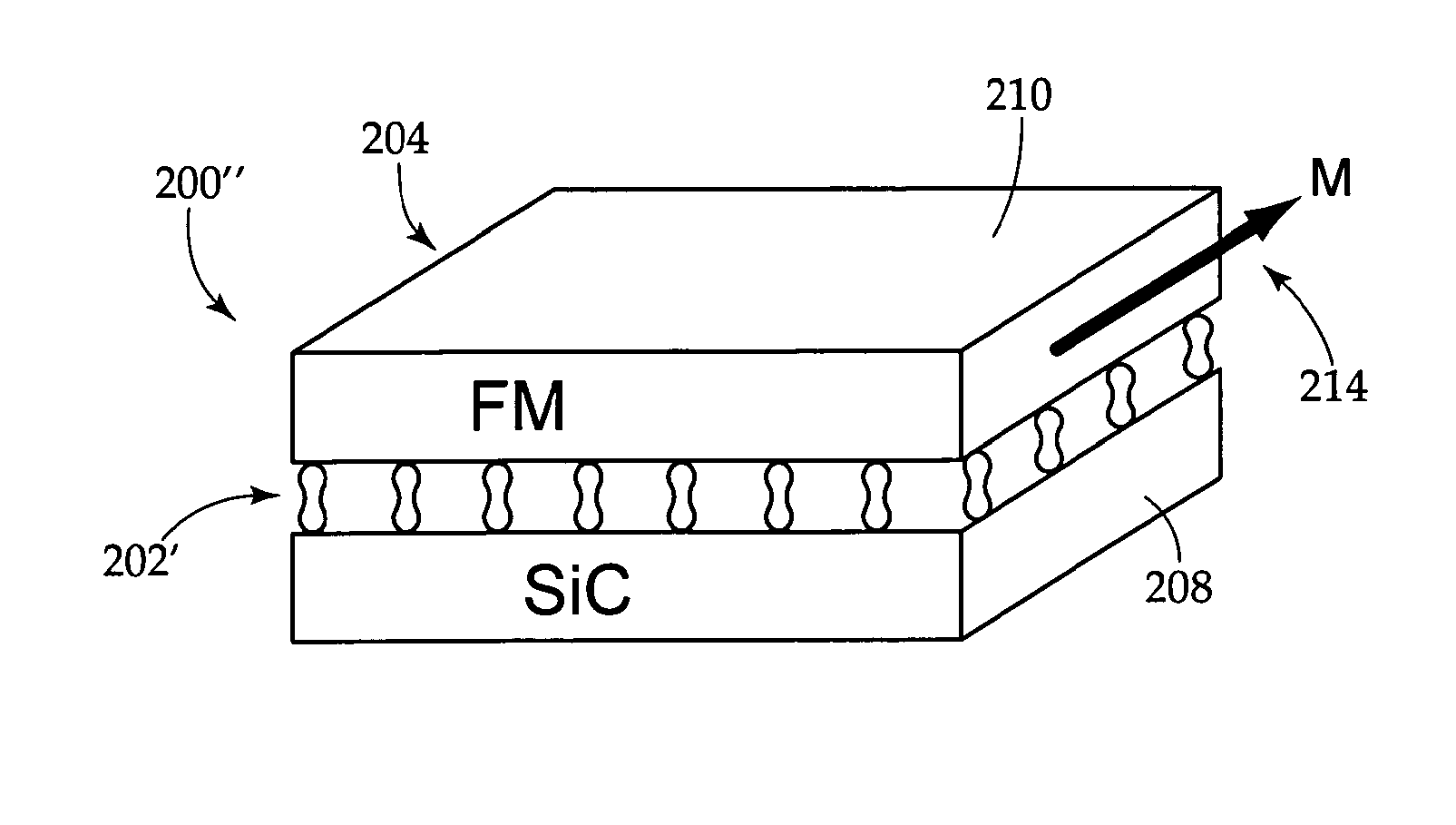

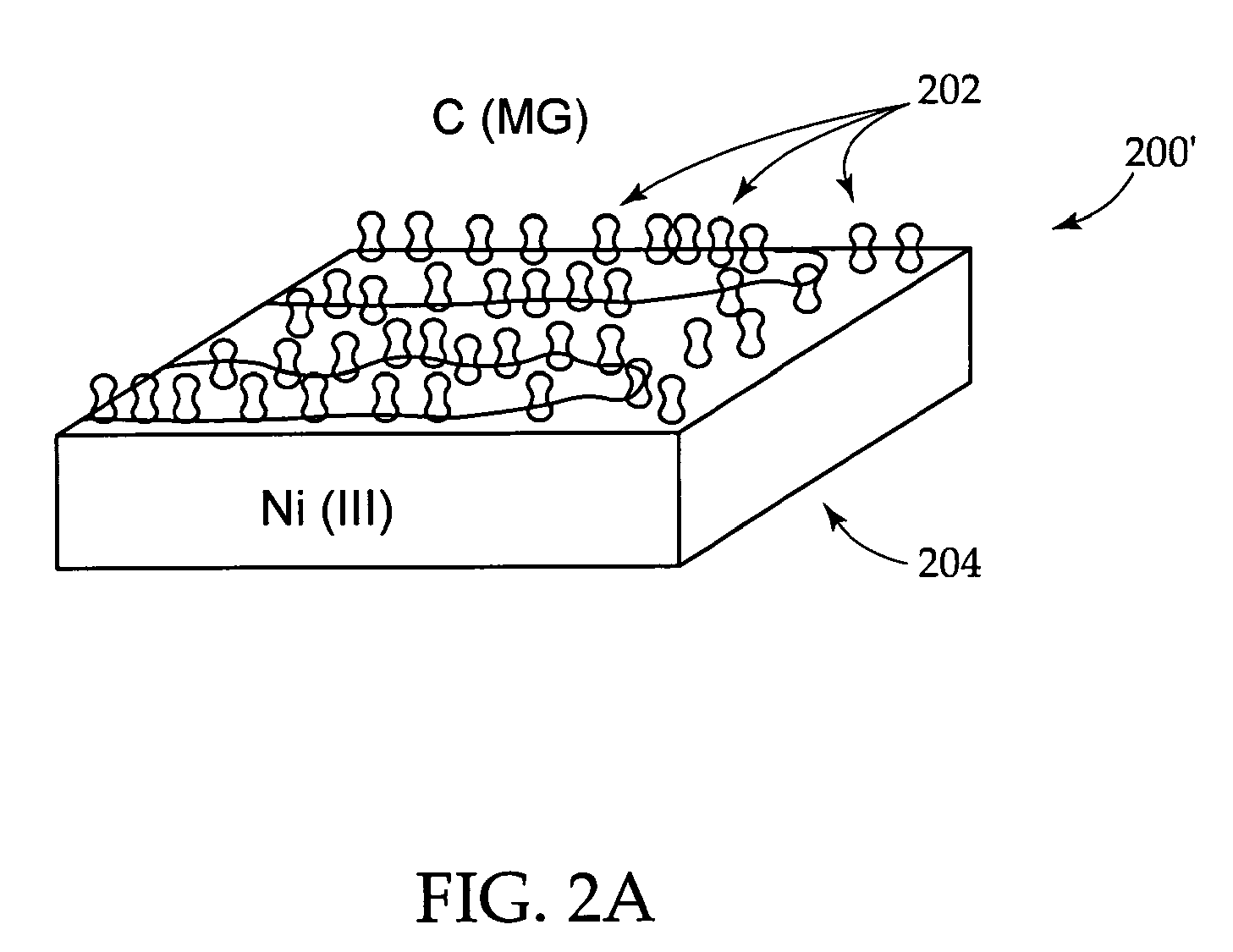

Graphene magnet multilayers (GMMs) are employed to facilitate development of spintronic devices. The GMMs can include a sheet of monolayer (ML) or few-layer (FL) graphene in contact with a magnetic material, such as a ferromagnetic (FM) or an antiferromagnetic material. Electrode terminals can be disposed on the GMMs to be in electrical contact with the graphene. A magnetic field effect is induced in the graphene sheet based on an exchange magnetic field resulting from a magnetization of the magnetic material which is in contact with graphene. Electrical characteristics of the graphene can be manipulated based on the magnetization of the magnetic material in the GMM.

Owner:BROOKHAVEN SCI ASSOCS

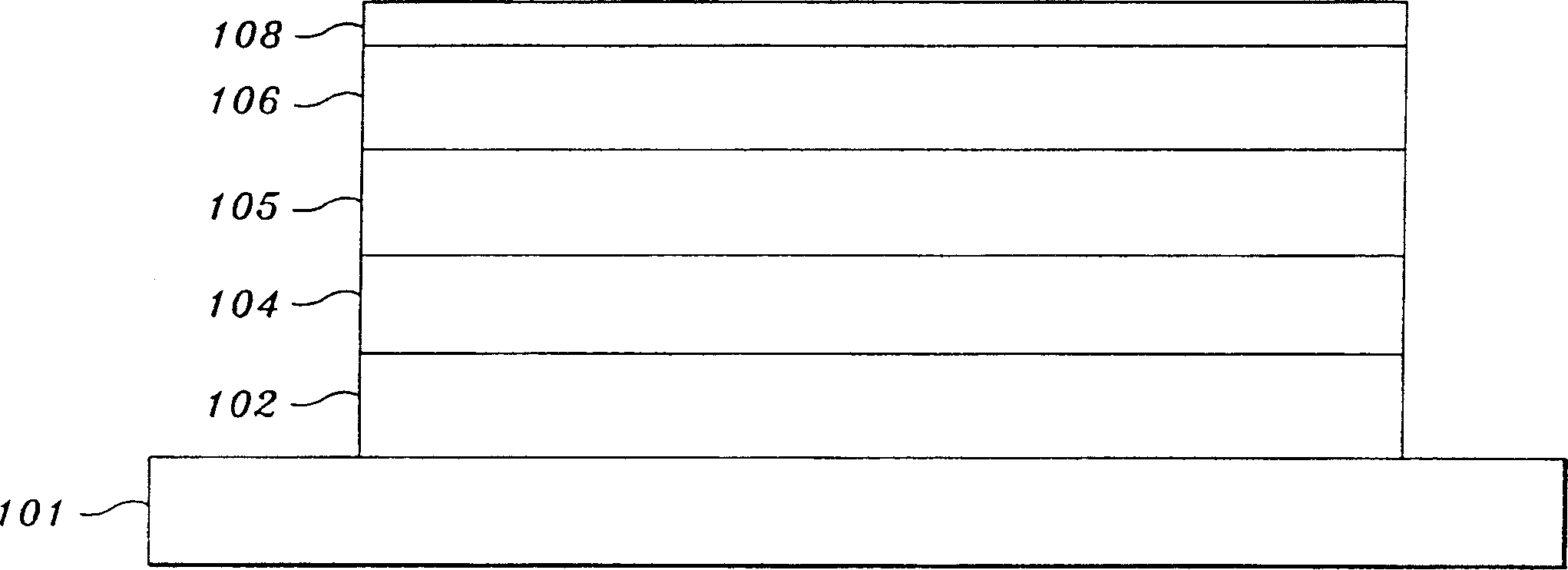

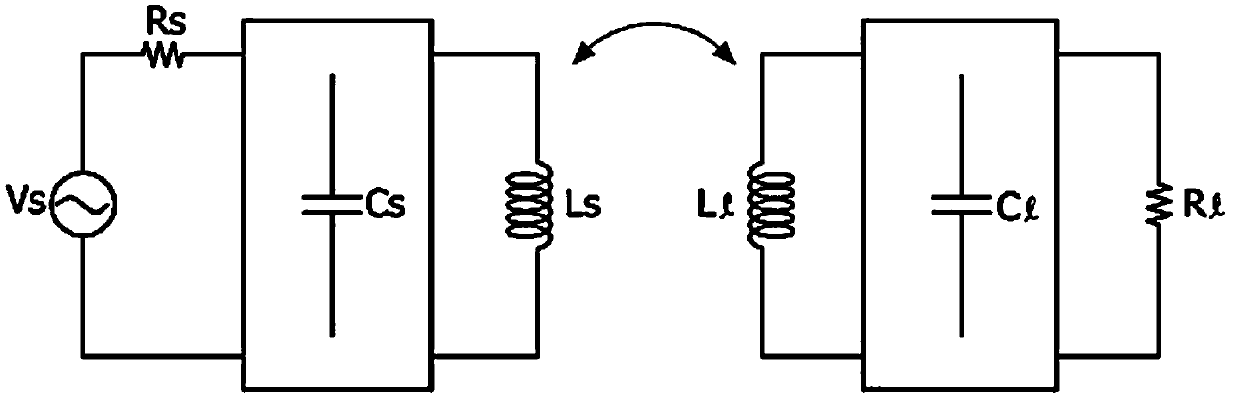

Magnetic thin film, magnetic component that uses this magnetic thin film, manufacturing methods for the same, and a power conversion device

InactiveUS20050094302A1Soft qualityEasy to manufactureNanomagnetismSemiconductor/solid-state device detailsElectric forceElectrical conductor

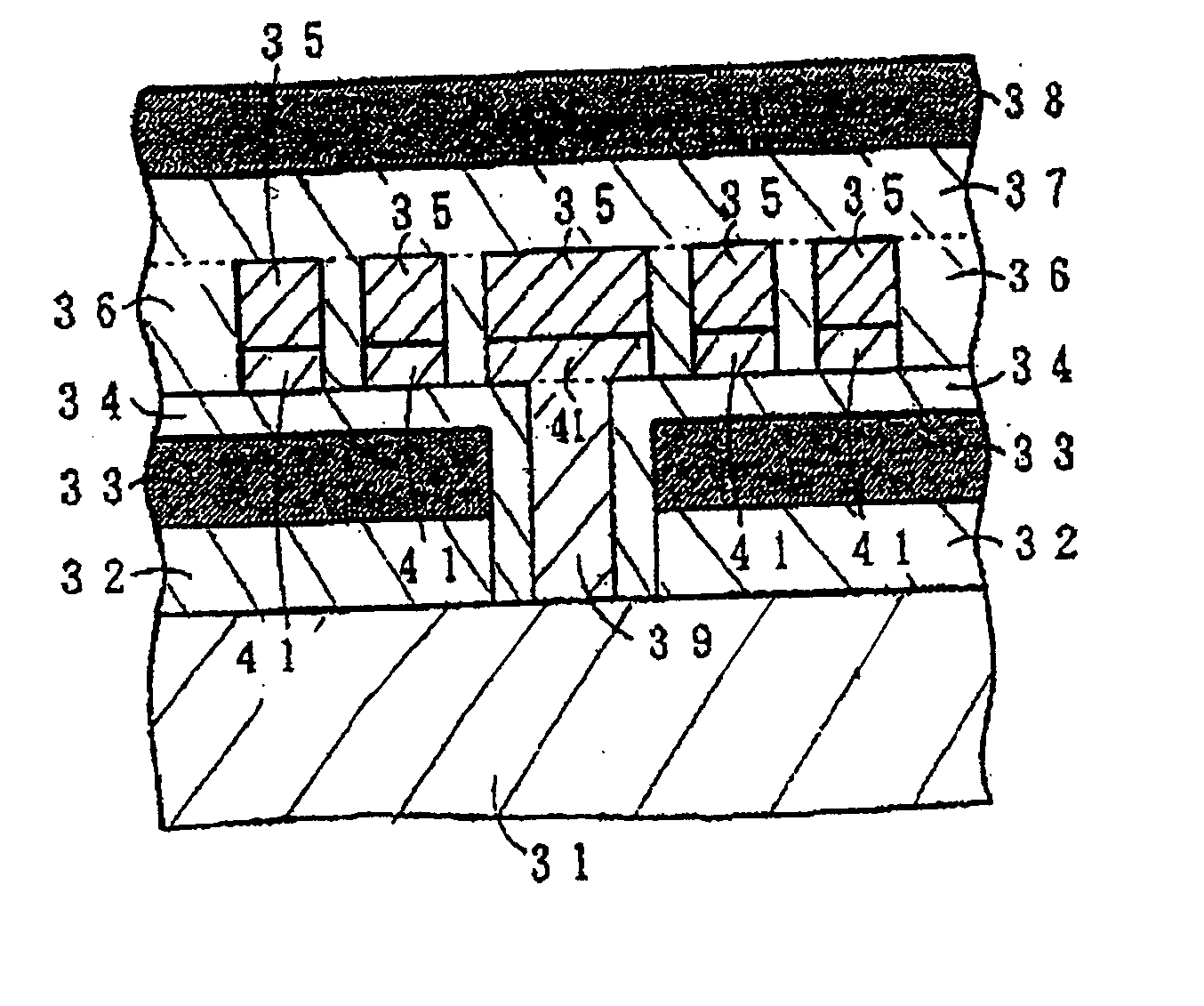

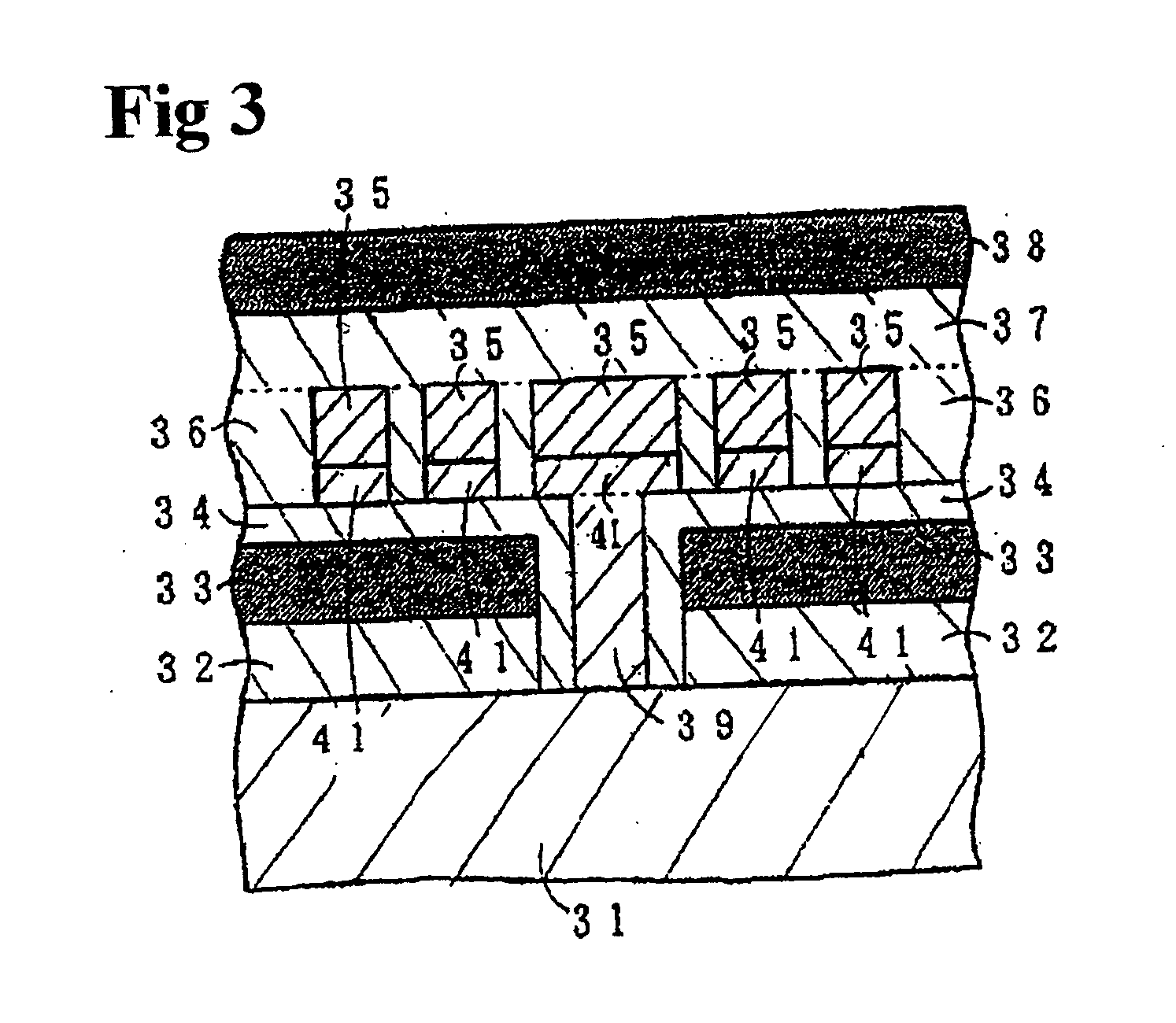

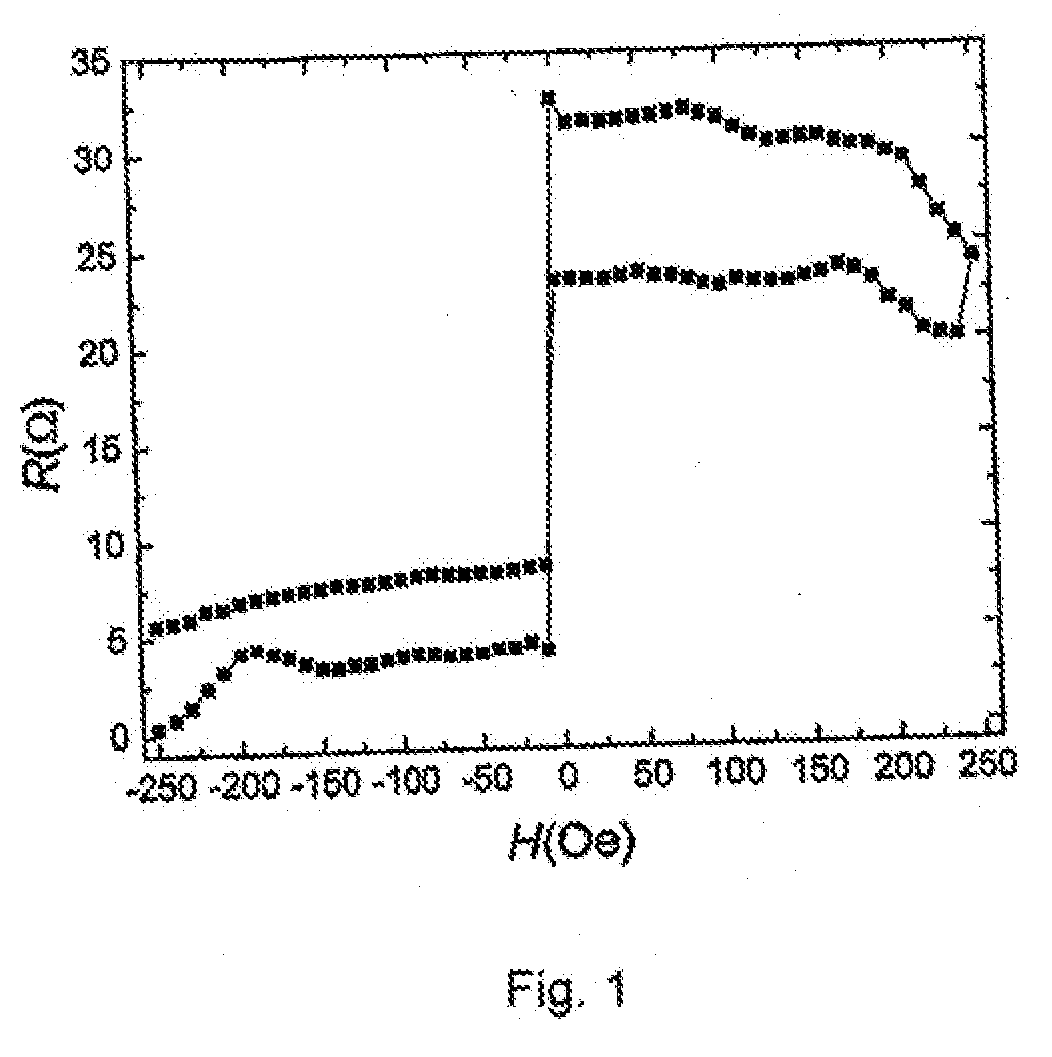

On top of a silicon substrate, a polyimide film with a thickness of 10 μm is formed. On top of this, a magnetic thin film that is a polyimide film containing Fe fine particles and that has a thickness of 20 μm is formed. On top of this magnetic thin film, a patterned Ti / Au film and a Ti / Au connection conductor are formed. On top of this, a polyimide film with a thickness of 10 μm, and a Cu coil with a height 35 μm, width 90 μm, space 25 μm, and a polyimide layer that fills the spaces in the Cu coil are formed. On top of this, via a polyimide film with a thickness of 10 μm, a magnetic thin film that is a polyimide film containing Fe particles and that has a thickness of 20 μm is formed. This thin film inductor has a small alternating current resistance. The present invention provides a magnetic thin film that is well suited for mass production, can be manufactured easily, can be made into a thick film, has soft magnetic qualities, and is inexpensive. The present invention also provides a magnetic component that uses this magnetic thin film, manufacturing methods for these, and a power conversion device.

Owner:FUJI ELECTRIC DEVICE TECH CO

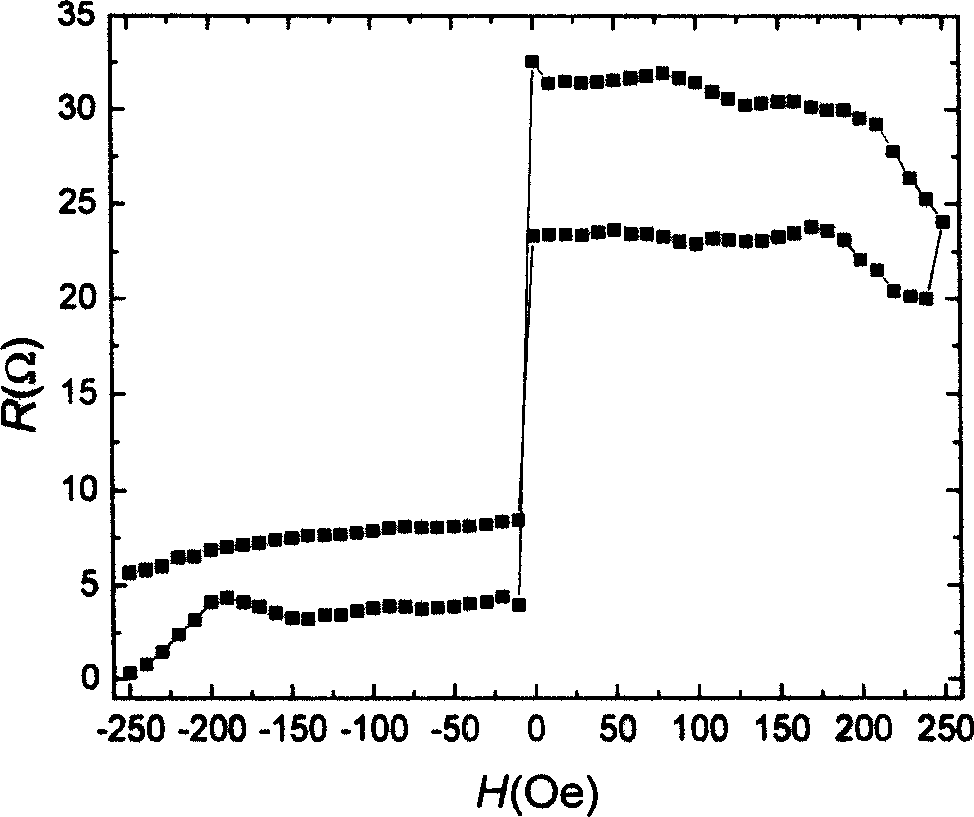

Core Composite Film for a Magnetic/Nonmagnetic/Magnetic Multilayer Thin Film and Its Useage

InactiveUS20090011284A1Low costLow rateNanomagnetismMagnetic materials for record carriersOrganic filmComposite film

The present invention relates to a core composite film for magnetic / nonmagnetic / magnetic multilayer thin film comprising a free magnetic layer, a spacer layer and a pinned magnetic layer. As the core composite film, it may be only the spacer layer is an LB film; and the spacer layer is an organic LB film consisting of materials with insulative, conductive or semiconductive character. As the core composite film, it may also be said free magnetic layer, spacer layer and pinned magnetic layer are all LB films; wherein the pinned magnetic layer and the free magnetic layer are organic films made of magnetic materials. The core composite film can be applied to a magnetic spin valve sensor, which can compose a magnetic induction unit of a magnetic spin valve sensor; and it can also be applied to a magnetic random access memory as a memory cell. Uniformity and consistency can be kept over large areas for the core composite film, and the process thereof is simple and the cost is low; moreover, by use of an LB organic film substituting for conventional spacer layer and magnetic layer, devices are made lighter, thinner, easier to be processed to and integrated.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

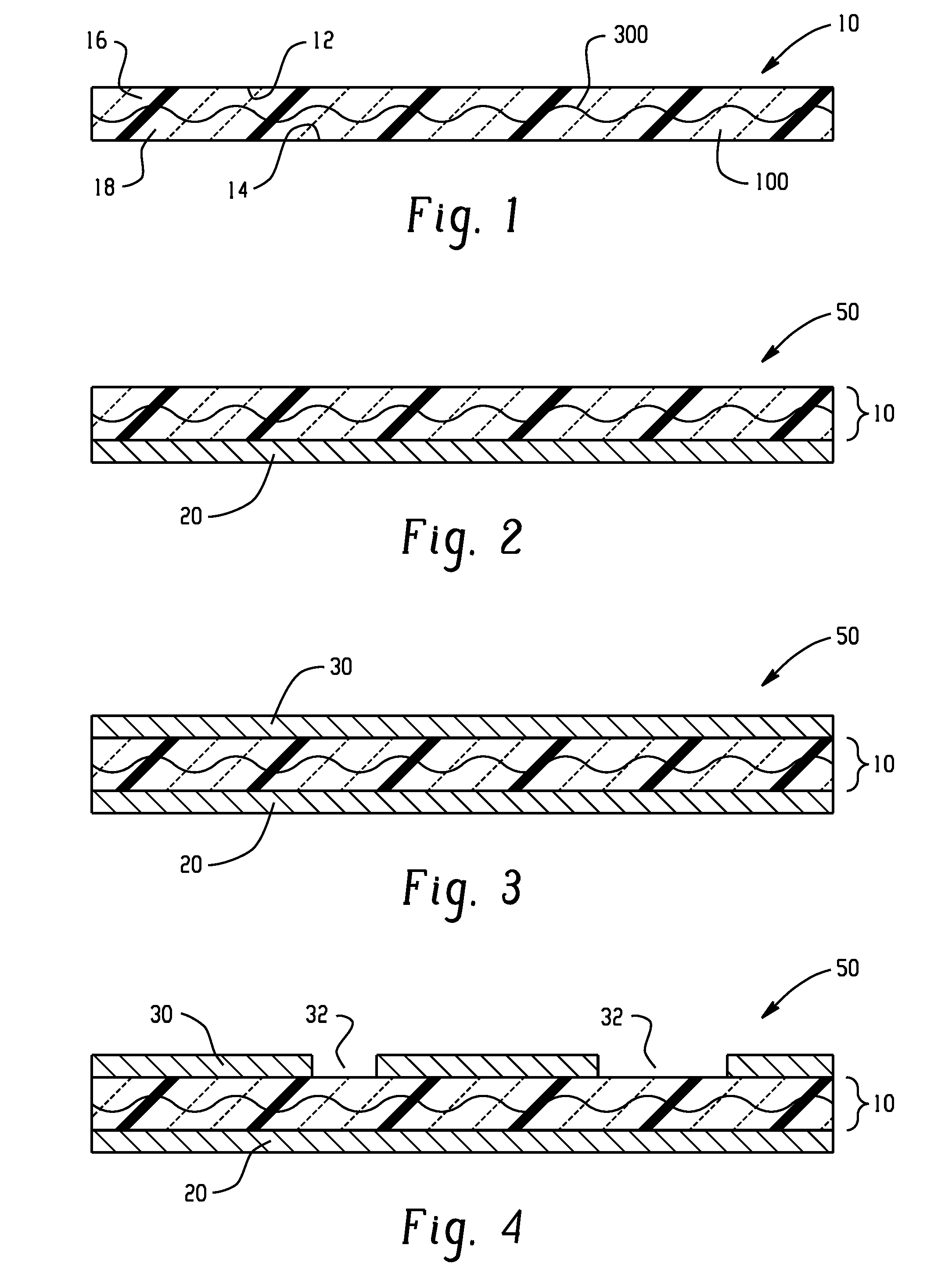

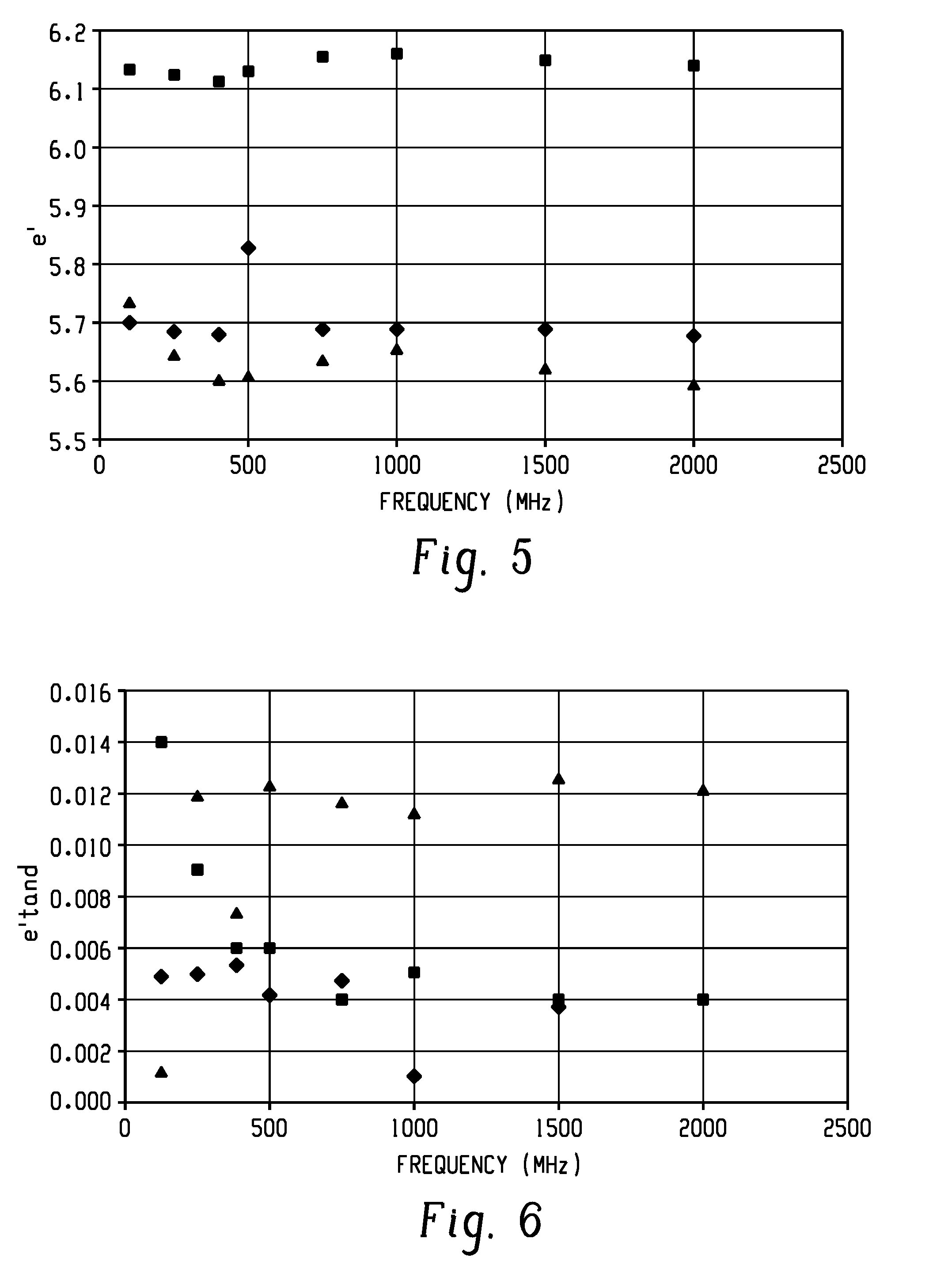

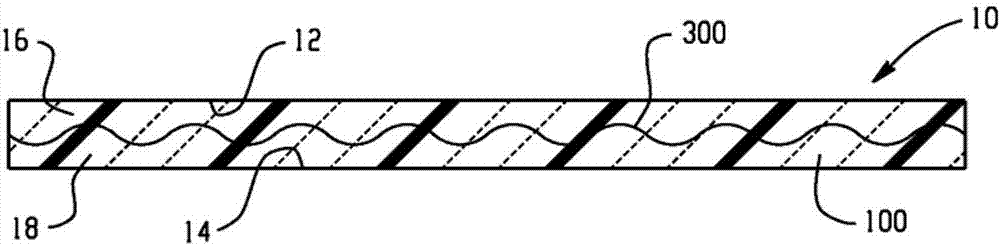

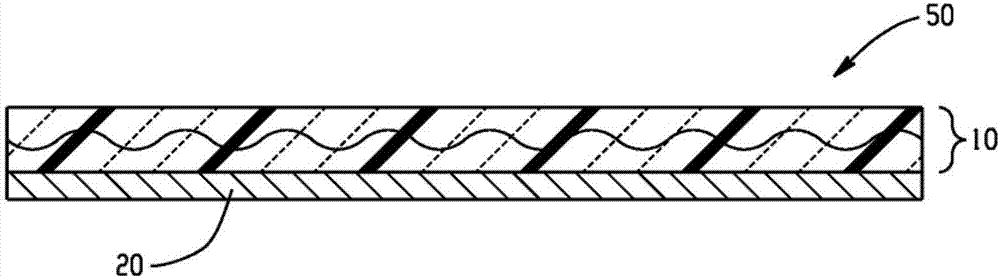

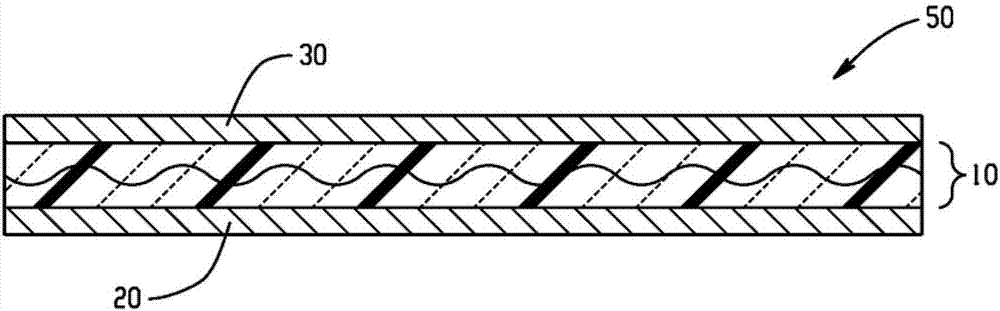

Magneto-dielectric substrate, circuit material, and assembly having the same

InactiveUS20160276072A1Printed circuit aspectsInorganic material magnetismDielectric substrateMagneto

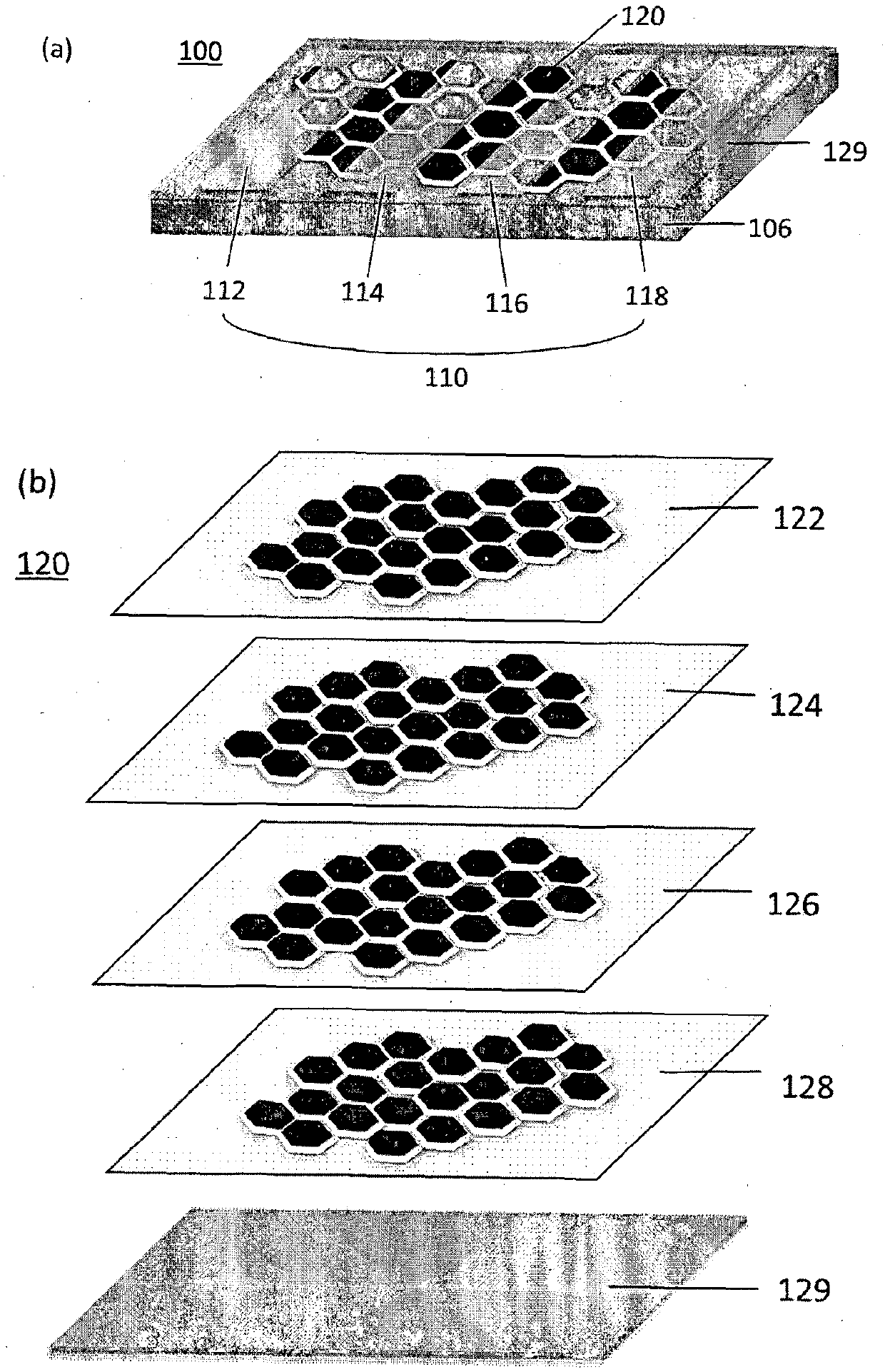

In an embodiment, a magneto-dielectric substrate comprises a dielectric polymer matrix; and a plurality of hexaferrite particles dispersed in the dielectric polymer matrix in amount and of a type effective to provide the magneto-dielectric substrate with a magnetic constant of less than or equal to 3.5 from 500 MHz to 1 GHz, or 3 to 8 from 500 MHz to 1 GHz, and a magnetic loss of less than or equal to 0.1 from 0 to 1 GHz, or 0.001 to 0.07 over 0 to 1 GHz.

Owner:ROGERS CORP

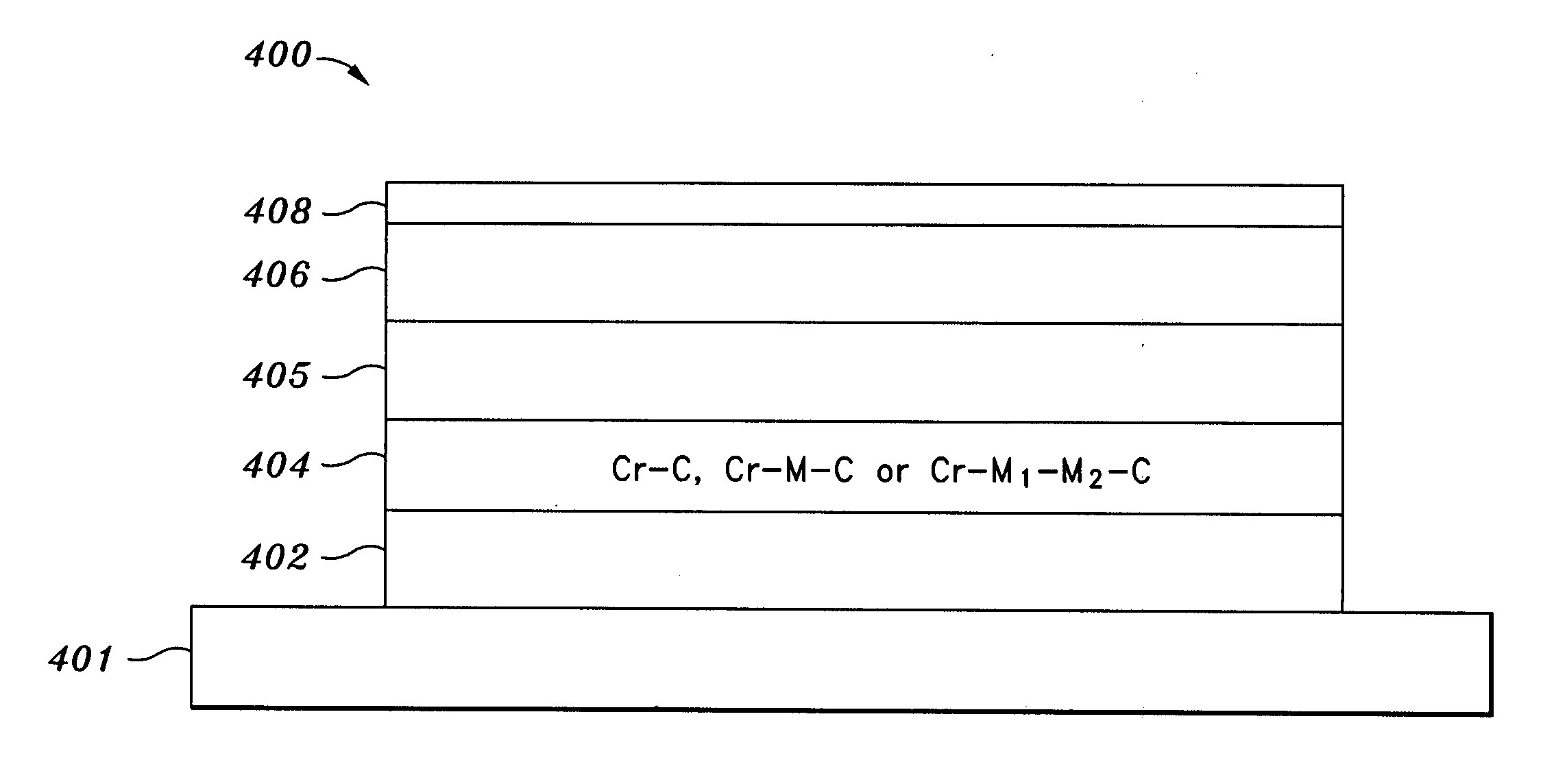

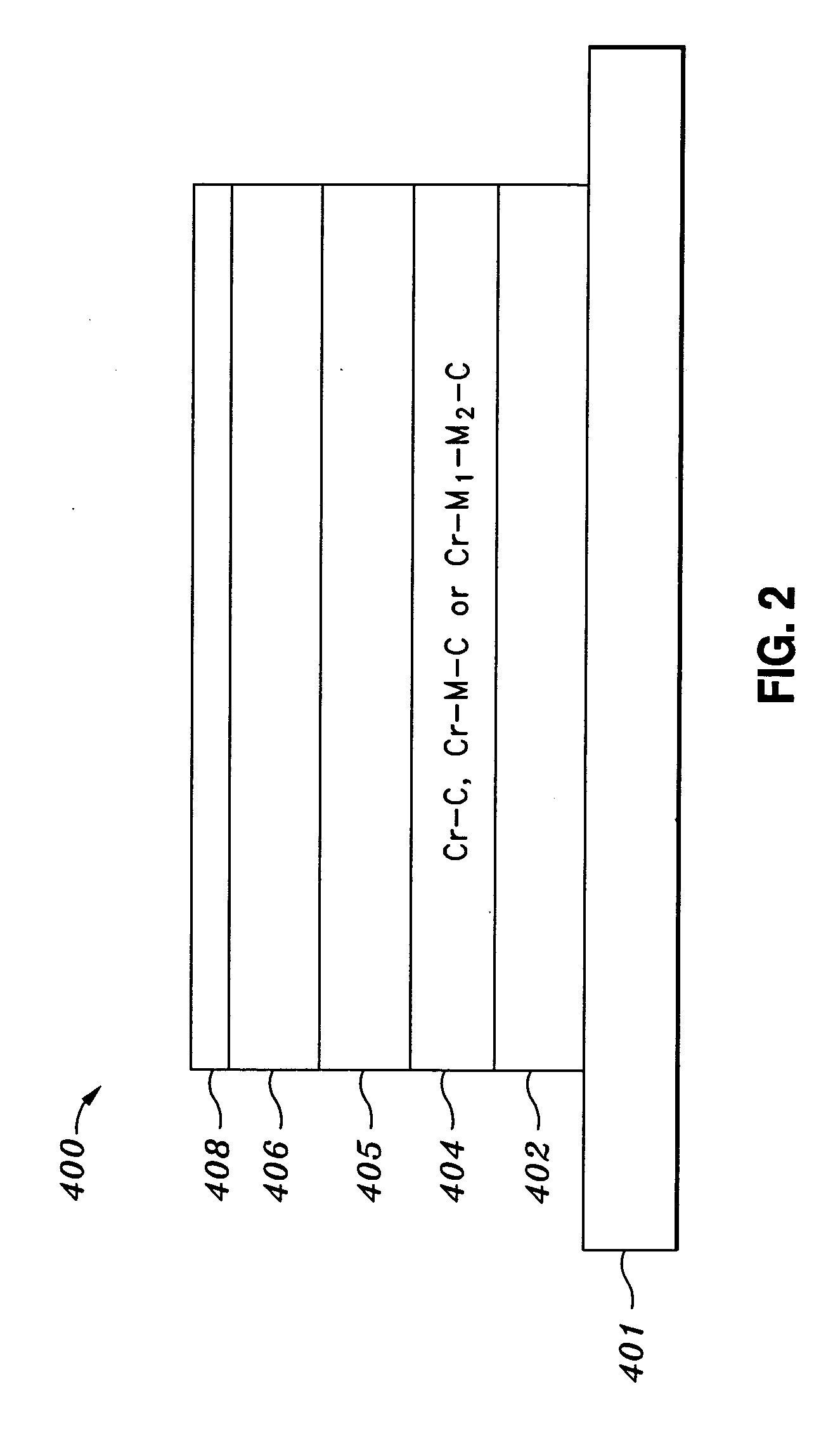

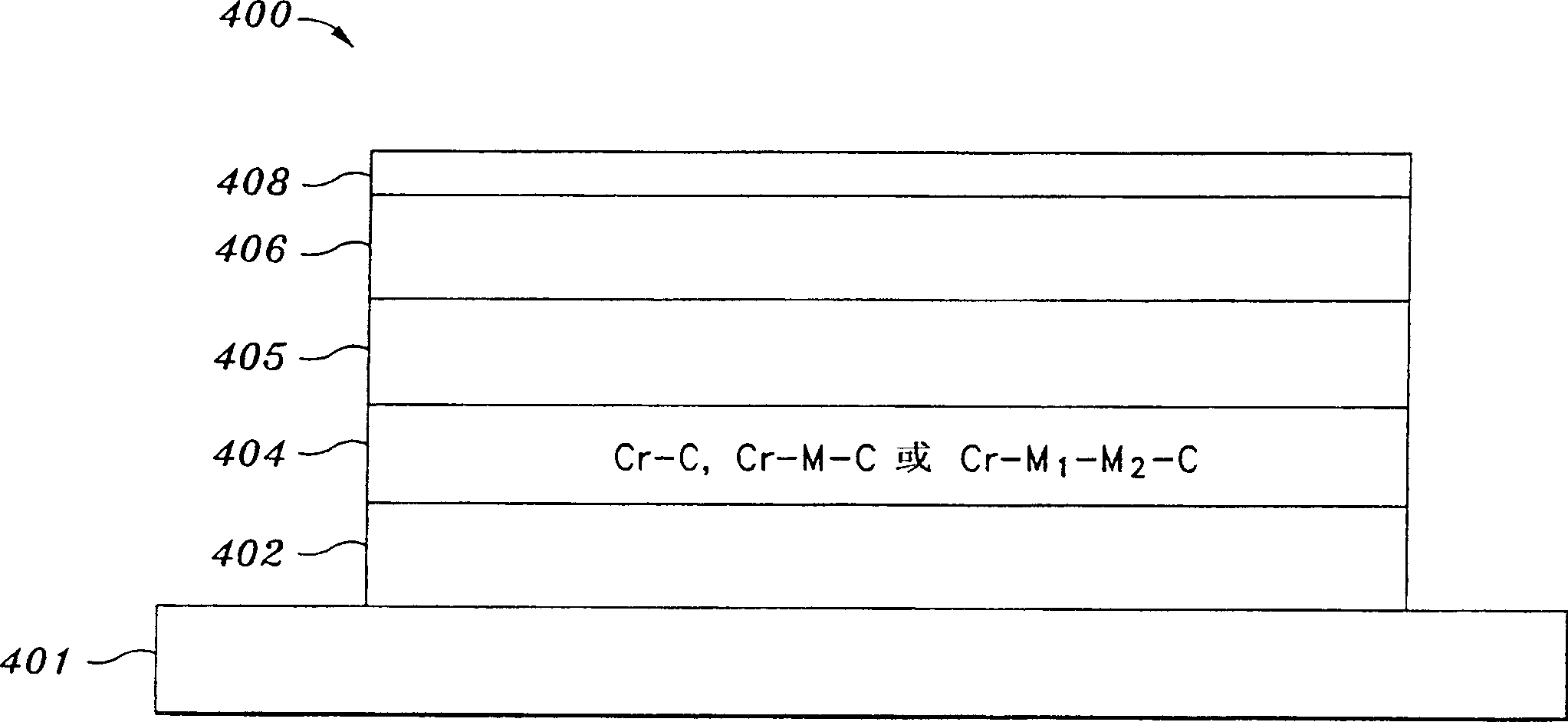

Carbon containing sputter target alloy compositions

InactiveUS20060110626A1Favorable epitaxial growthImprove matchVacuum evaporation coatingSputtering coatingCarbideAg element

The invention provides a sputter target material. The sputter target material comprises an alloy system comprising Cr—C, Cr—M—C or Cr—M1—M2—C, wherein C comprises at least 0.5 and as much as 20 atomic percent; M comprises at least 0.5 and as much as 20 atomic percent and is an element selected from the group consisting of Ti, V, Y, Zr, Nb, Mo, Hf, Ta, and W; M1 comprises at least 0.5 and as much as 20 atomic percent and is an element selected from the group consisting of Ti, V, Zr, Nb, Mo, Hf, Ta, and W, and M2 comprises at least 0.5 and as much as 10 atomic percent and is an element selected from the group consisting of Li, Mg, Al, Sc, Mn, Y, and Te. A magnetic recording medium comprising a substrate and at least an underlayer comprising the sputter target material of the invention also is provided. A method of manufacturing a sputter target material further provided. The method can employ powder materials comprising a combination of elements can include a chromium alloy, a carbide or carbon containing master alloy.

Owner:HERAEUS INC

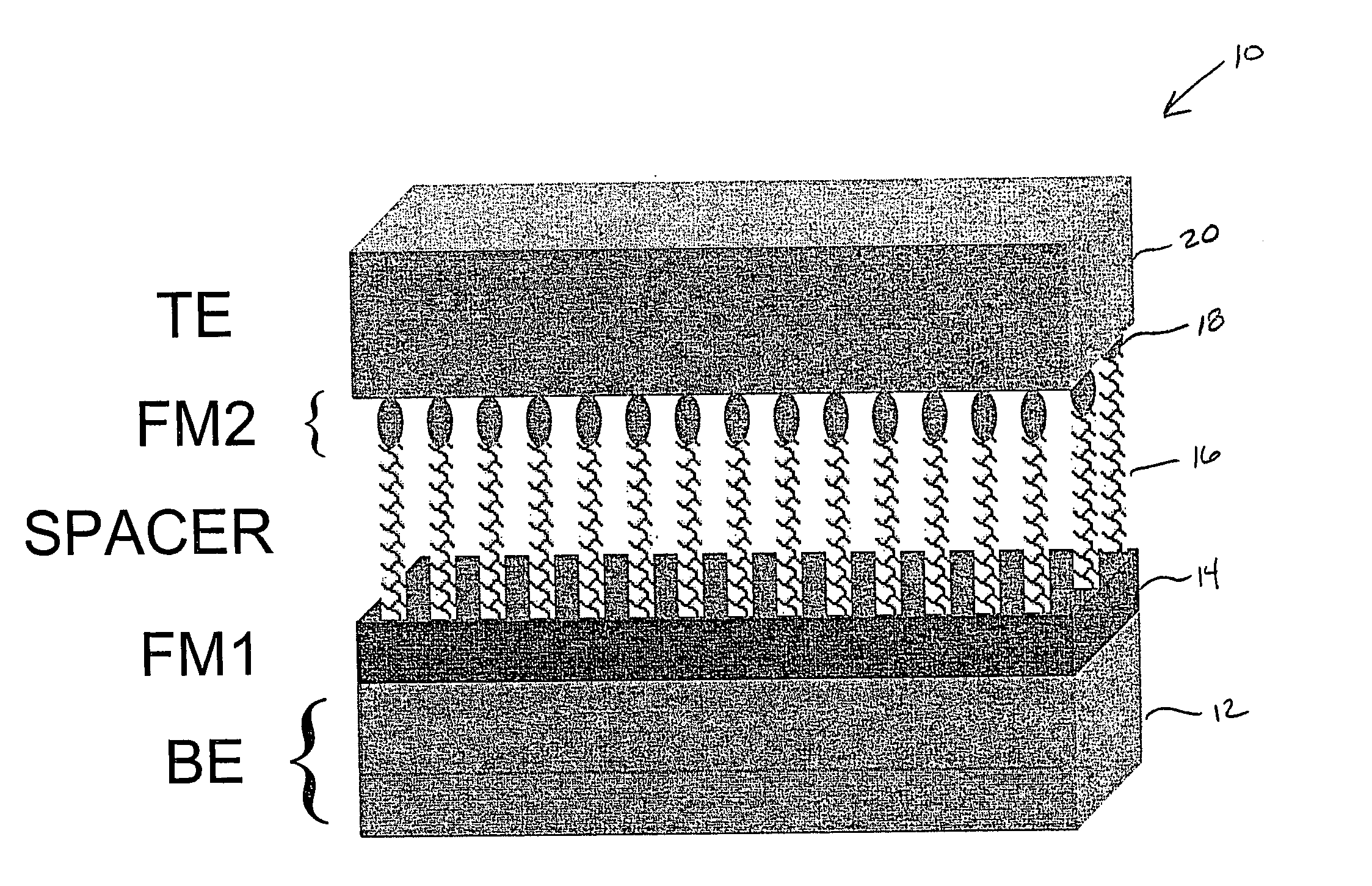

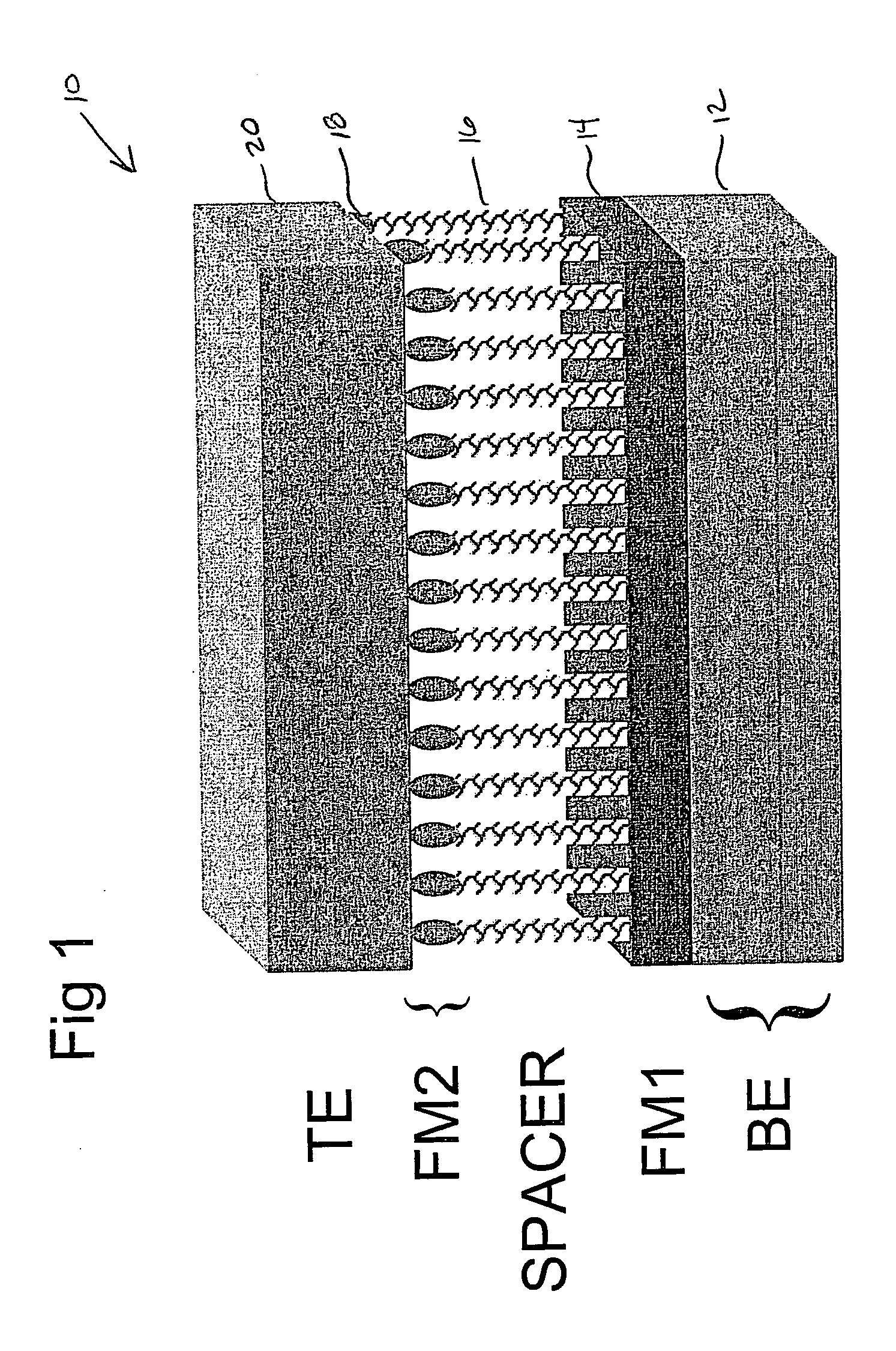

Spintronic device having a carbon nanotube array-based spacer layer and method of forming same

This invention relates to spintronic devices—and electronic devices comprising them, such as spin valves, spin tunnel junctions and spin transistors—which utilize a layer comprised of an array of aligned carbon nanontubes. A spintronic device includes, a bottom electrode, a first ferromagnetic layer, a CNT array, a second ferromagnetic layer and a top electrode.

Owner:THE OHIO STATE UNIV RES FOUND

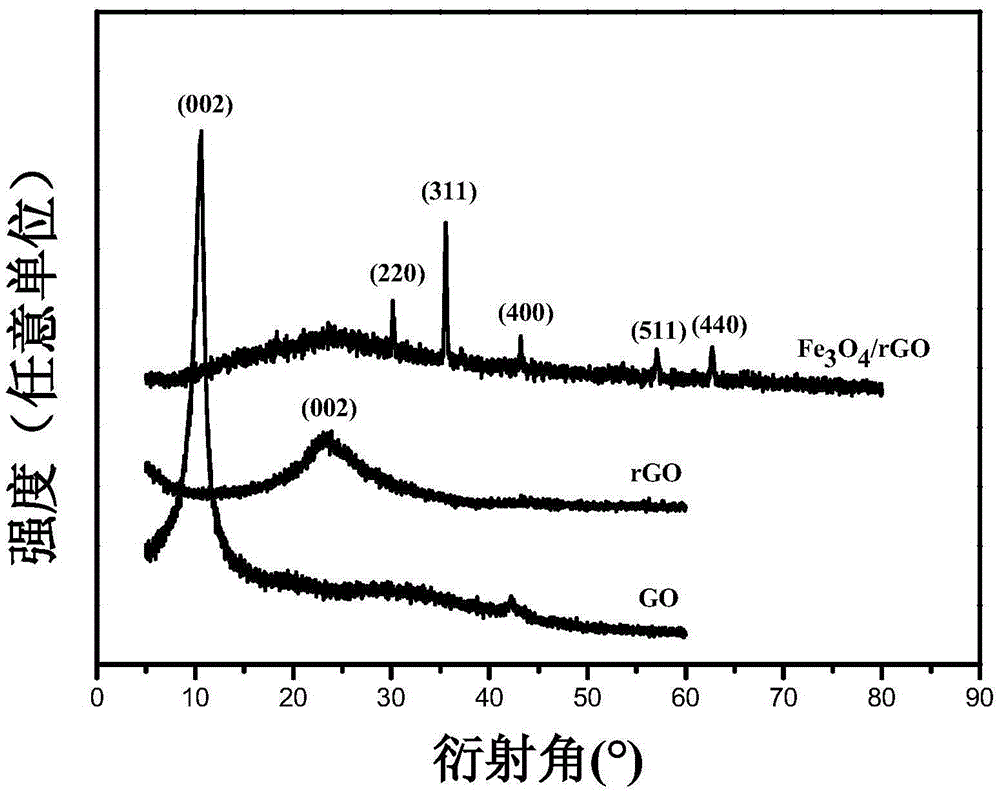

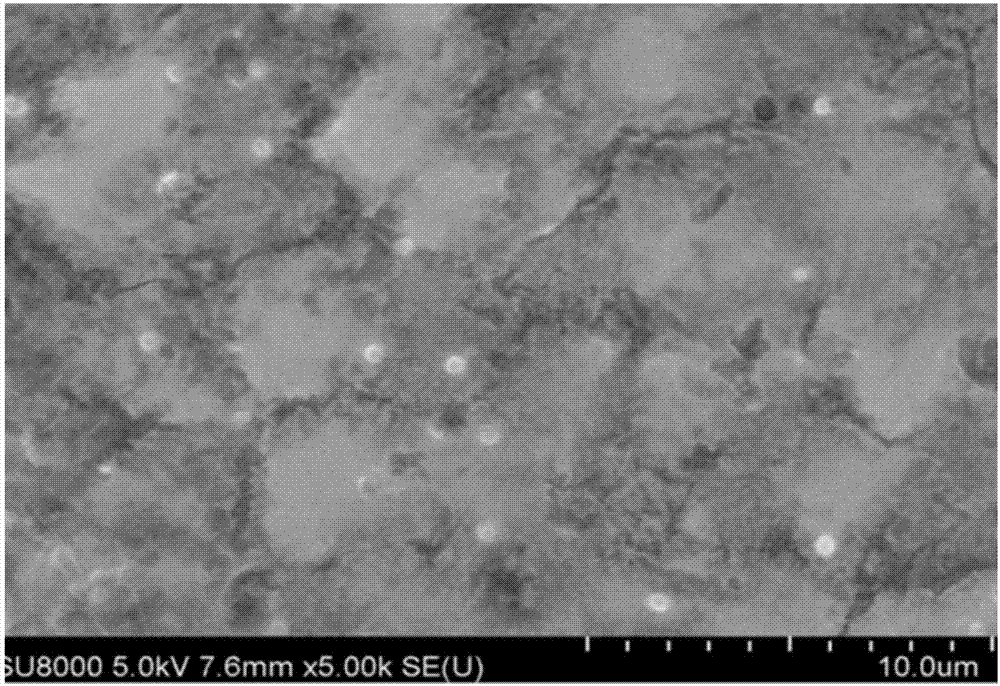

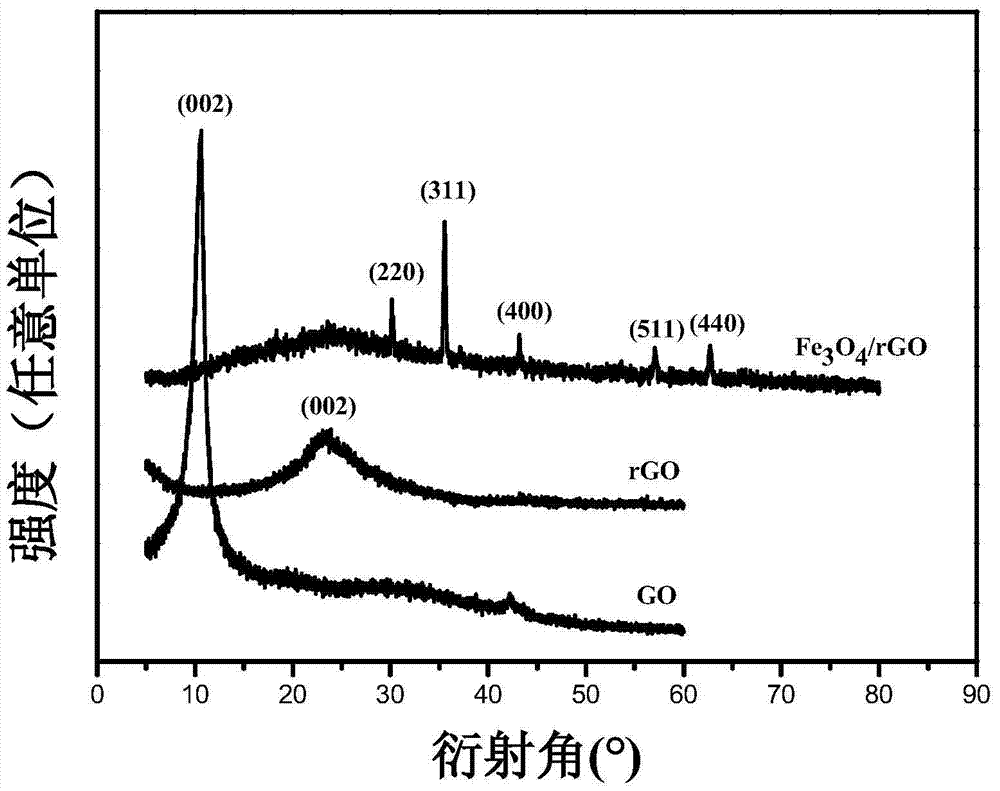

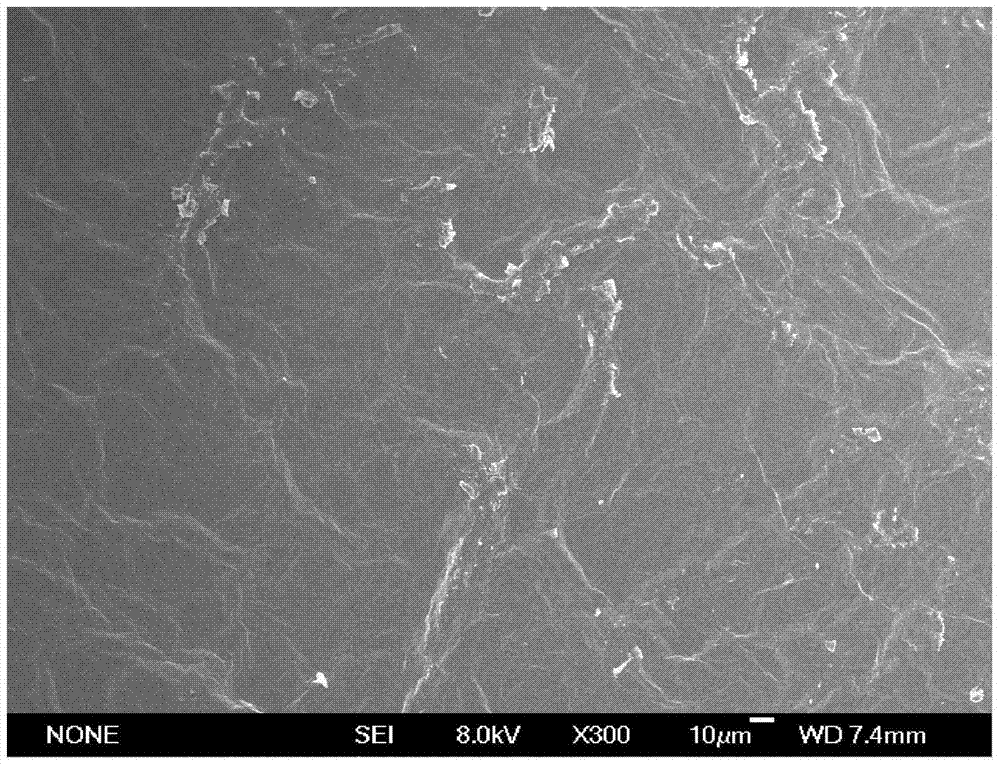

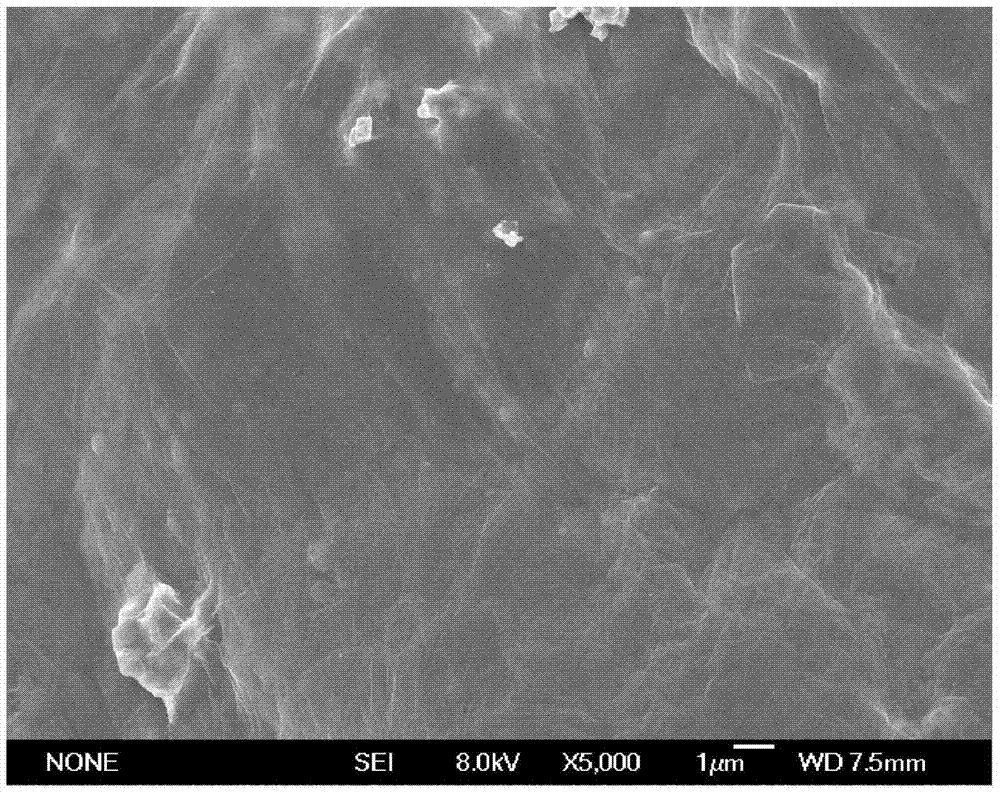

Preparation method of Fe<3>O<4>/graphene composite membrane

InactiveCN105609305ALow costUniformity controllableNanostructure applicationChemical vapor deposition applicationGrapheneElectron

The invention relates to a preparation method of an Fe<3>O<4> / graphene composite membrane. In summary, according to the method, by the process of mixing graphene oxide with Fe<3>O<4> nano-particles at a certain ratio to obtain a mixture solution, the Fe<3>O<4> / graphene composite membrane is prepared under drying and low-temperature stepped heating reduction conditions. The product prepared by the method is good in complex condition; the Fe<3>O<4> nano-particles are uniform to disperse; and the composite membrane has ferromagnetic property. The method disclosed by the invention is simple and easy to control; industrial production is facilitated; and the prepared self-supported composite membrane has a broad application prospect in the fields of information, electrons, energy, biology, military industry and the like.

Owner:JILIN UNIV

Nuclear composite film for magnetic, nonmagnetic and magnetic multilayer film and use thereof

InactiveCN1836896AQuality improvementImprove uniformityNanomagnetismLayered productsSemiconductor materialsMaterials science

The kernel composite film for multilayer magnetic / non-magnetic / magnetic film includes a free magnetic layer, an isolating layer and a nailed magnetic layer. Of the free magnetic layer, the isolating layer and the nailed magnetic layer in the kernel composite film, at least the isolating layer has LB film layer of insulating, conducting or semiconductor material. The kernel composite film may be used as the magnetic inducing unit in magnetic resistive rotating valve sensor, and as the memory unit in magnetic resistive RAM. It may have great area homogeneity and identity, and has simple preparation process and low cost.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for producing a carbon layer-covering transition metallic nano-structure, method for producing a carbon layer-covering transition metallic nano-structure pattern, carbon layer-covering transition metallic nano-structure, and carbon layer-covering transition metallic nano-structure pattern

InactiveUS20050170181A1Easy to controlMaterial nanotechnologyNanomagnetismCarbon layerNano structuring

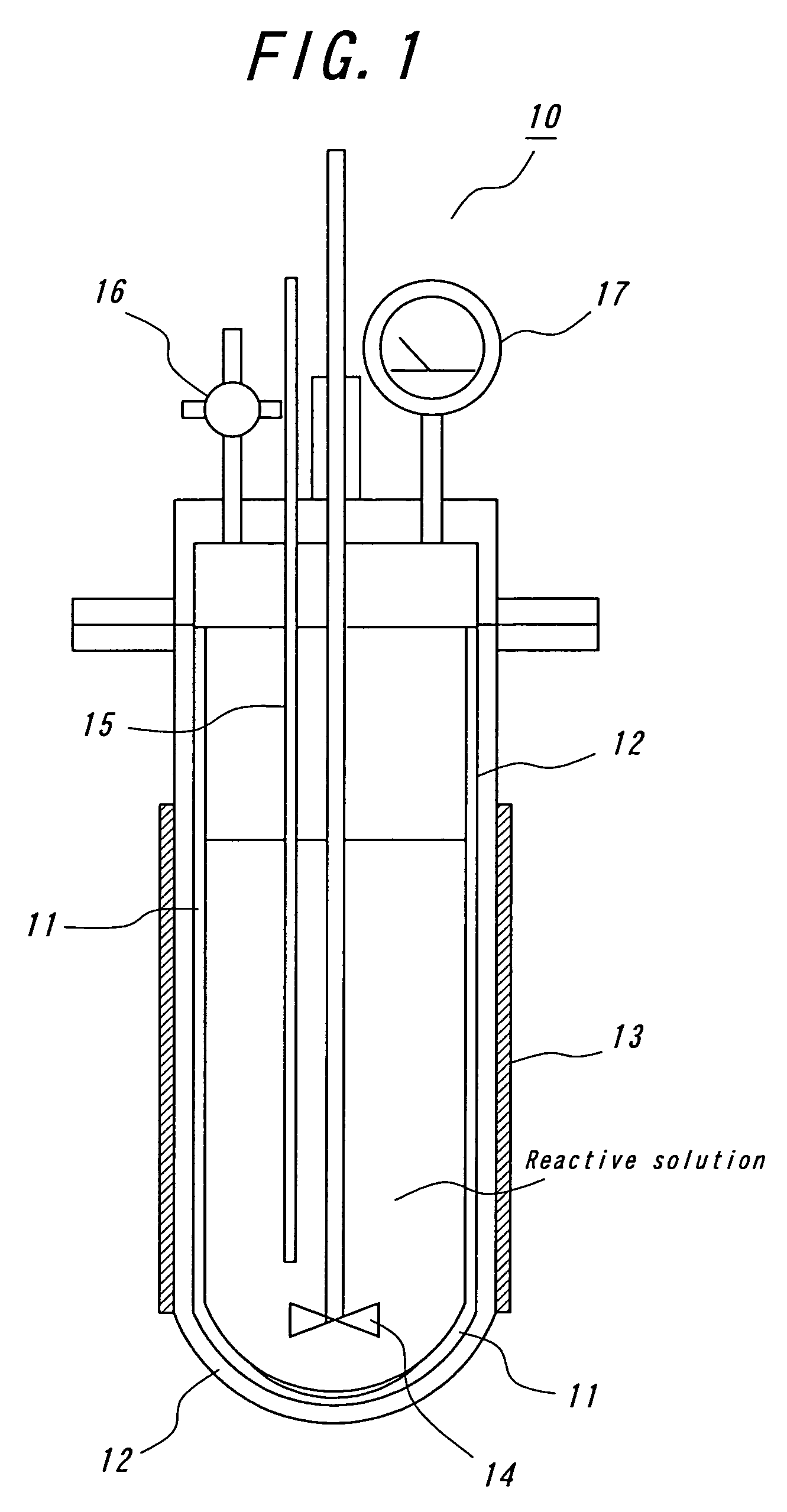

An anhydrous chloride with a formula of MCl2 (M=Fe, Co or Ni) is dissolved into an anhydrous acetonitrile solvent to form a chloride-acetonitrile solution. Then, calcium carbide minute powders are added and dispersed in the chloride-acetonitrile solution to form a reactive solution. Then, the reactive solution is thermally treated (first thermal treatment) to form a nano-powder made of a transition metal acetylide compound having an M-C2-M bond, a tetragonal structure, and a formula of MC2 (herein, M=Fe, Co or Ni). Then, the nano-powder is thermally treated (second thermal treatment) again at a temperature higher than the temperature in the first thermal treatment to form a carbon layer-covering transition metallic nano-structure wherein a metallic core made of the transition metal M is covered with a carbon layer.

Owner:INTER UNIV RES INST NAT INST OF NATURAL SCI

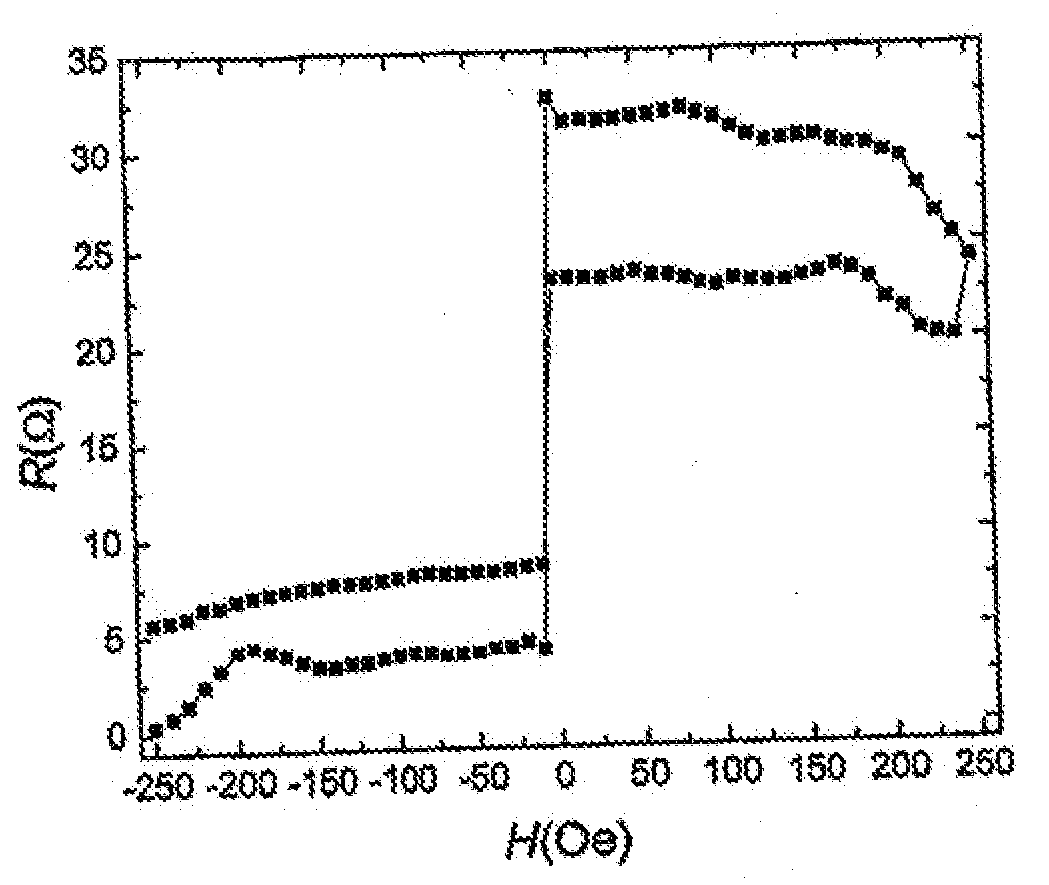

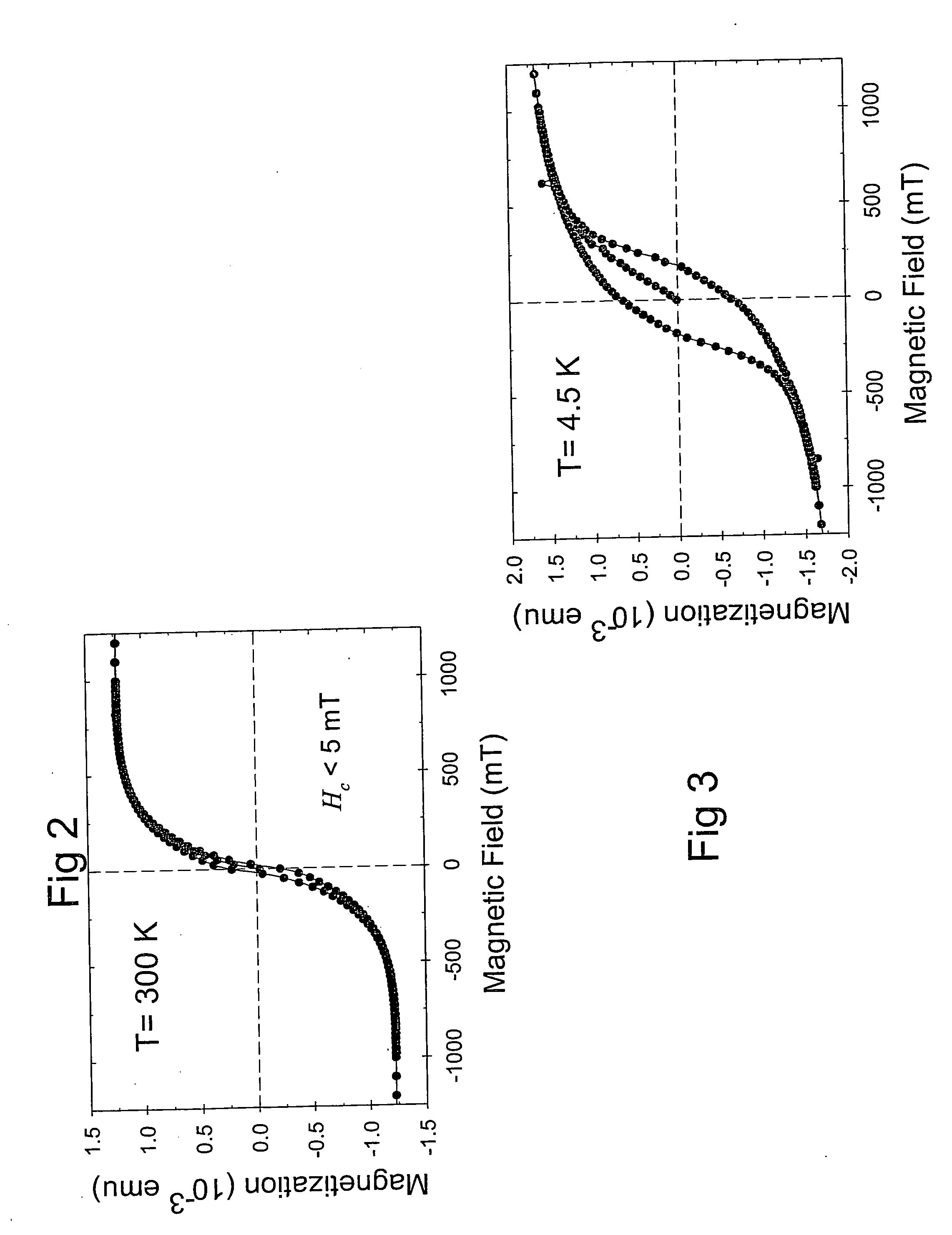

Nanodevices for spintronics and methods of using same

Graphene magnet multilayers (GMMs) are employed to facilitate development of spintronic devices. The GMMs can include a sheet of monolayer (ML) or few-layer (FL) graphene in contact with a magnetic material, such as a ferromagnetic (FM) or an antiferromagnetic material. Electrode terminals can be disposed on the GMMs to be in electrical contact with the graphene. A magnetic field effect is induced in the graphene sheet based on an exchange magnetic field resulting from a magnetization of the magnetic material which is in contact with graphene. Electrical characteristics of the graphene can be manipulated based on the magnetization of the magnetic material in the GMM.

Owner:BROOKHAVEN SCI ASSOCS

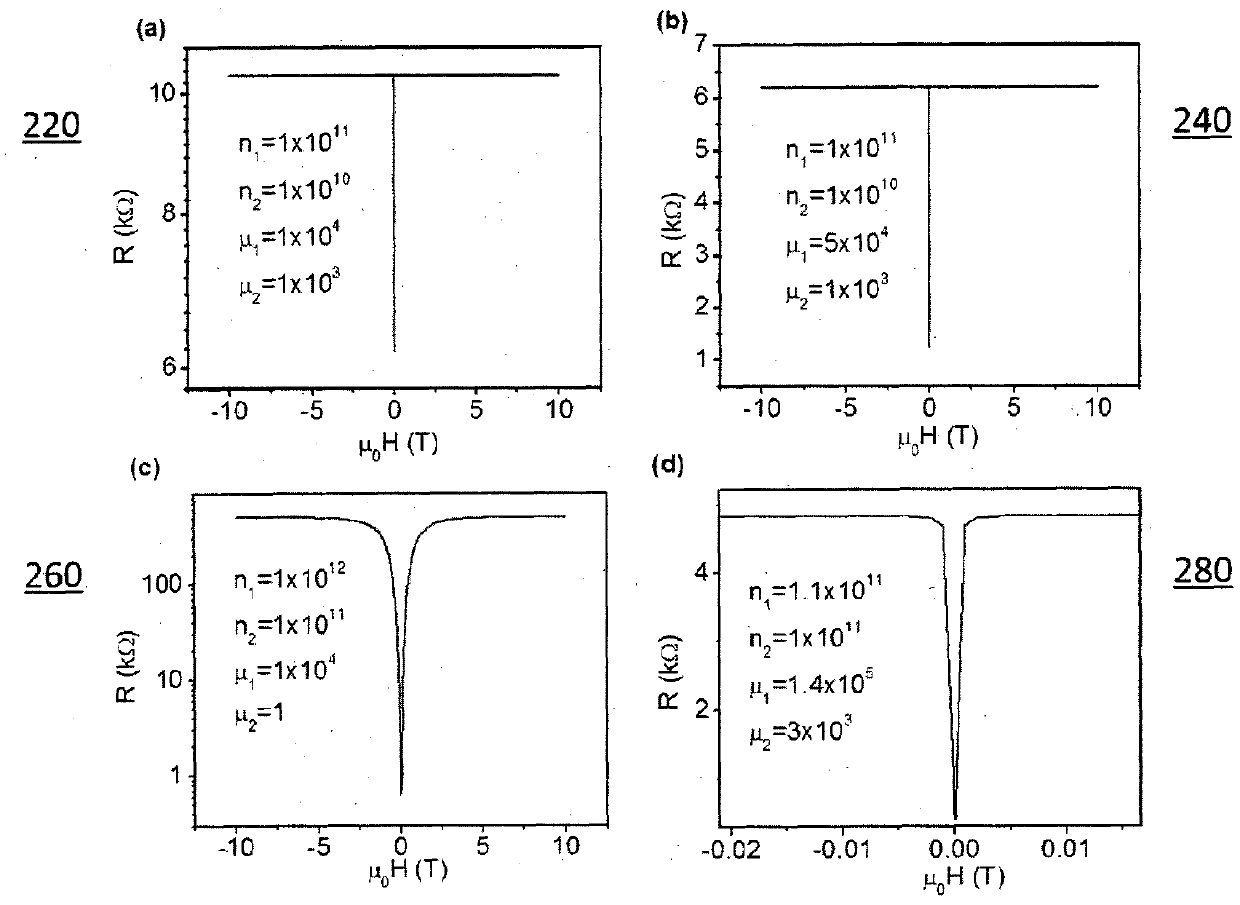

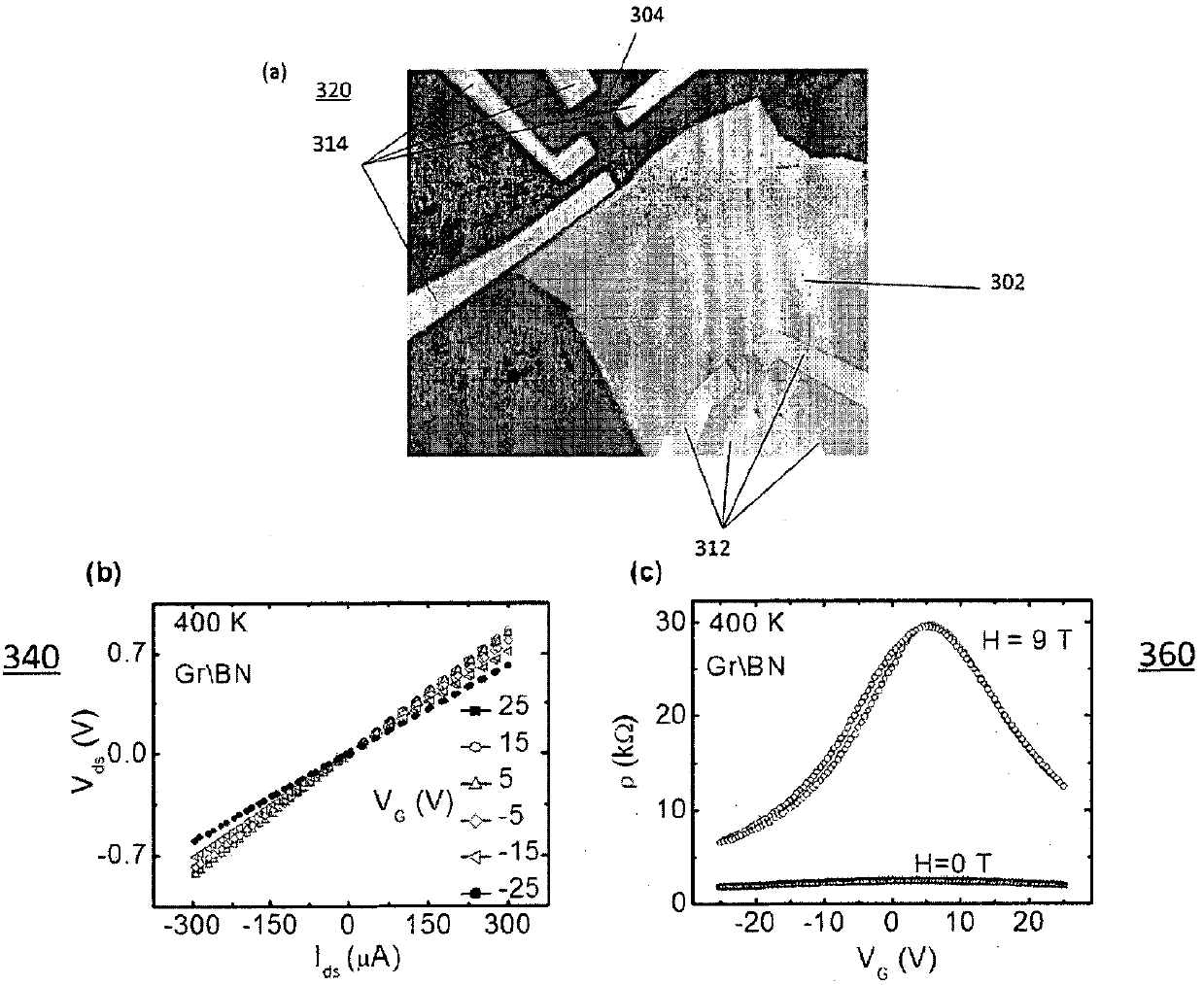

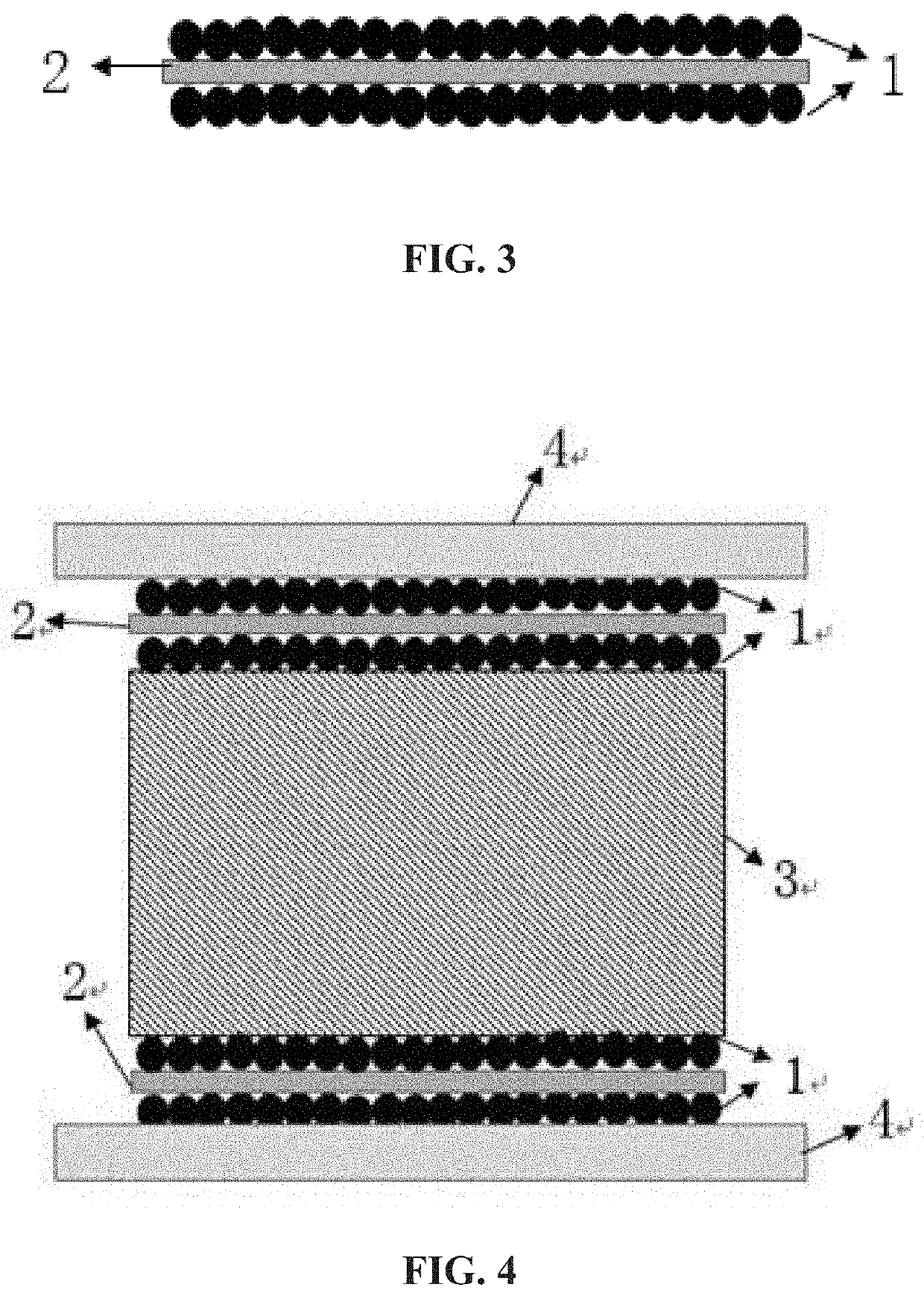

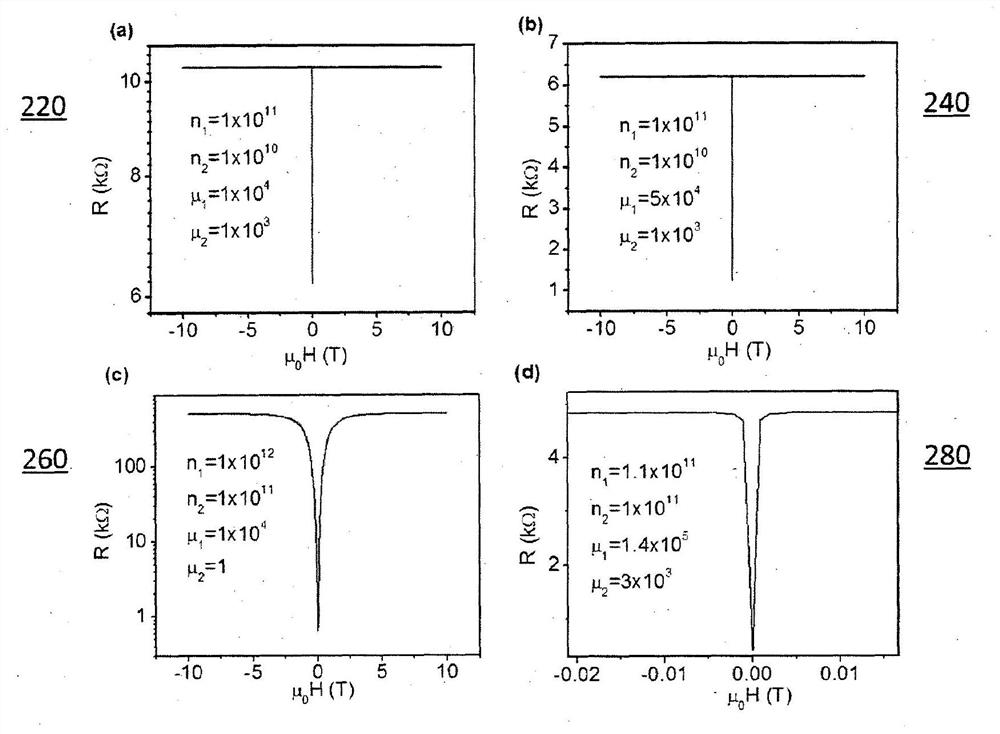

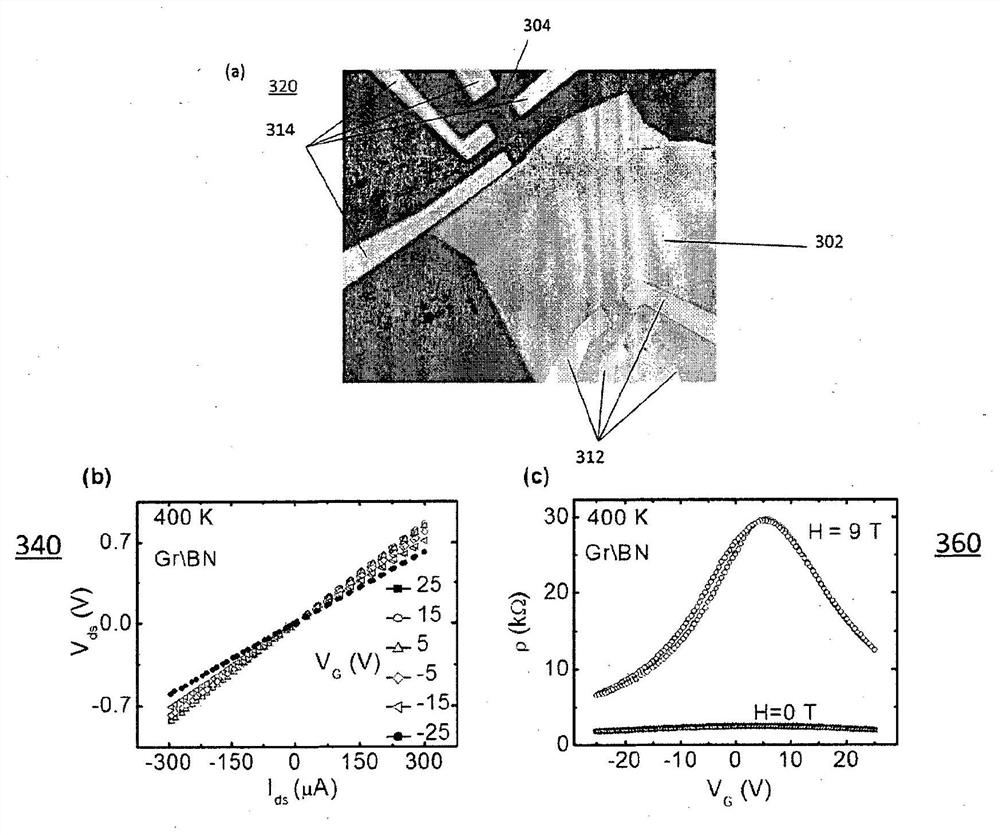

Graphene based magnetoresistance sensors

A graphene structure is provided. The graphene structure comprises a substrate layer and at least two graphene layers disposed on the substrate. The at least two graphene layers comprises a gate voltage tuned layer and an effective graphene layer and the effective graphene layer comprises one or more graphene layers. A magnetoresistance ratio of the graphene structure is determined by a difference in a charge mobility and / or a carrier density between the gate voltage tuned layer and the effective graphene layer. The charge mobility and / or the carrier density of the gate voltage tuned layer is tunable by a gate voltage applied to the graphene structure. A magnetic field sensor comprising the graphene structure is also provided.

Owner:NAT UNIV OF SINGAPORE

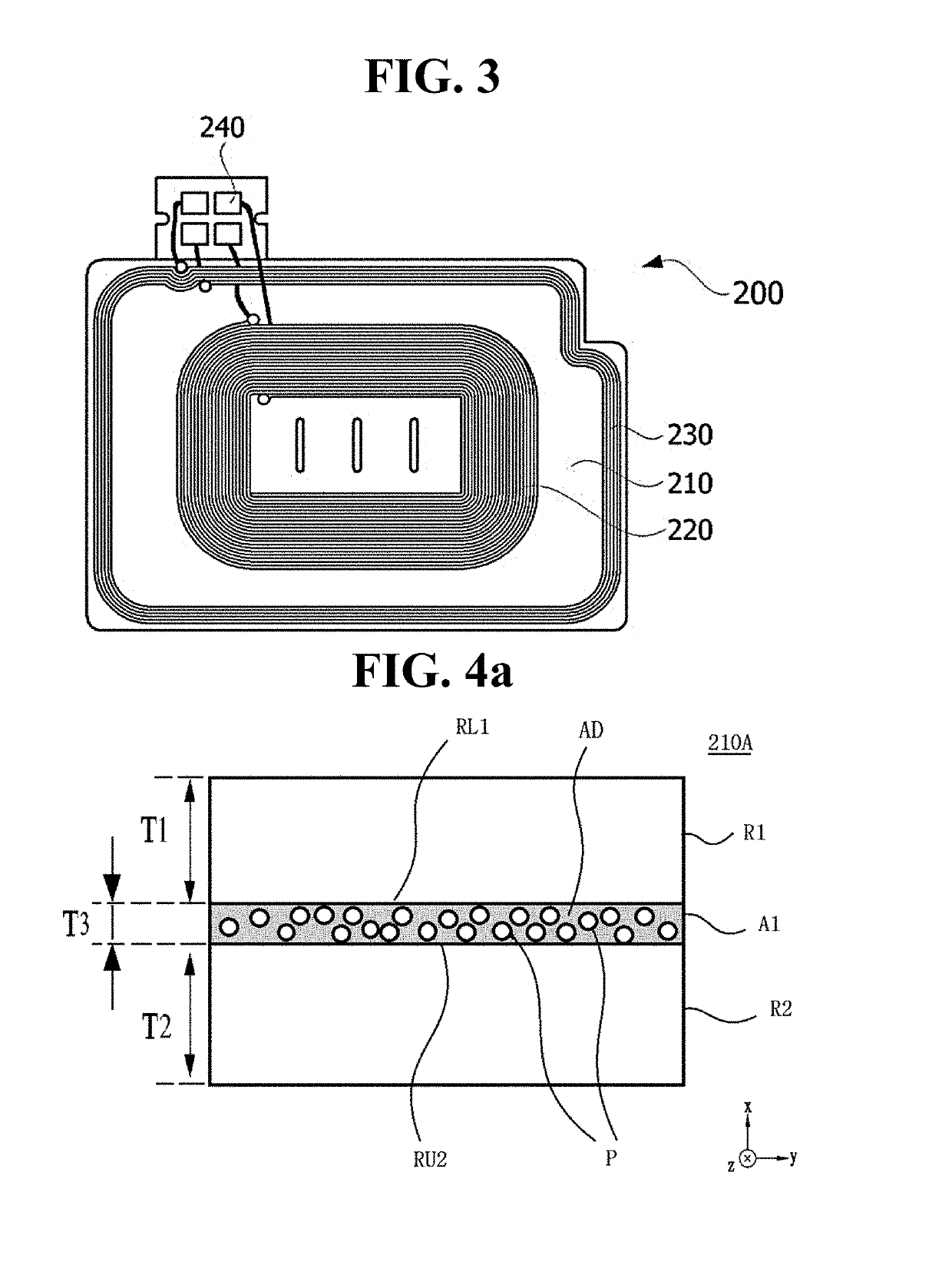

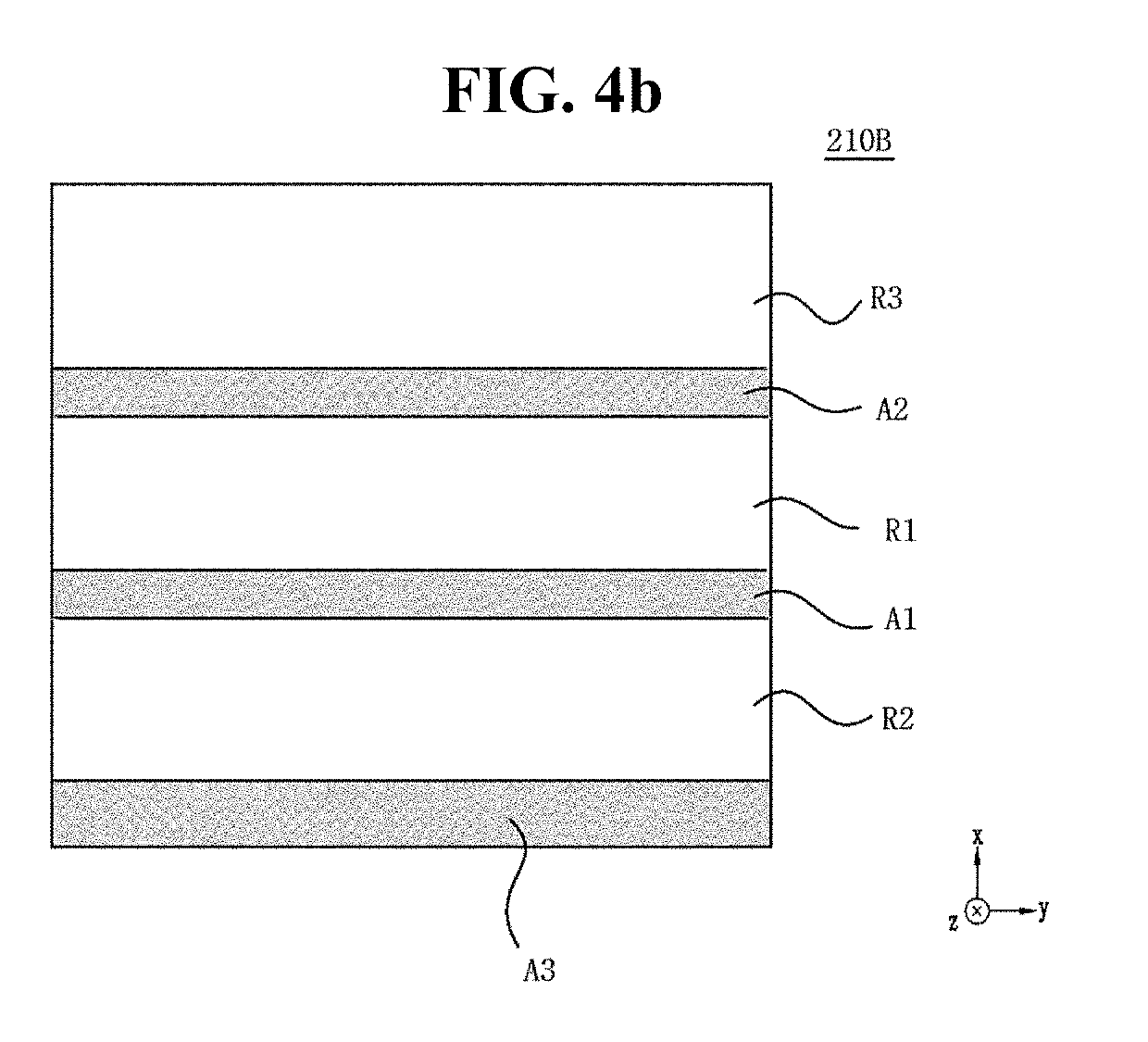

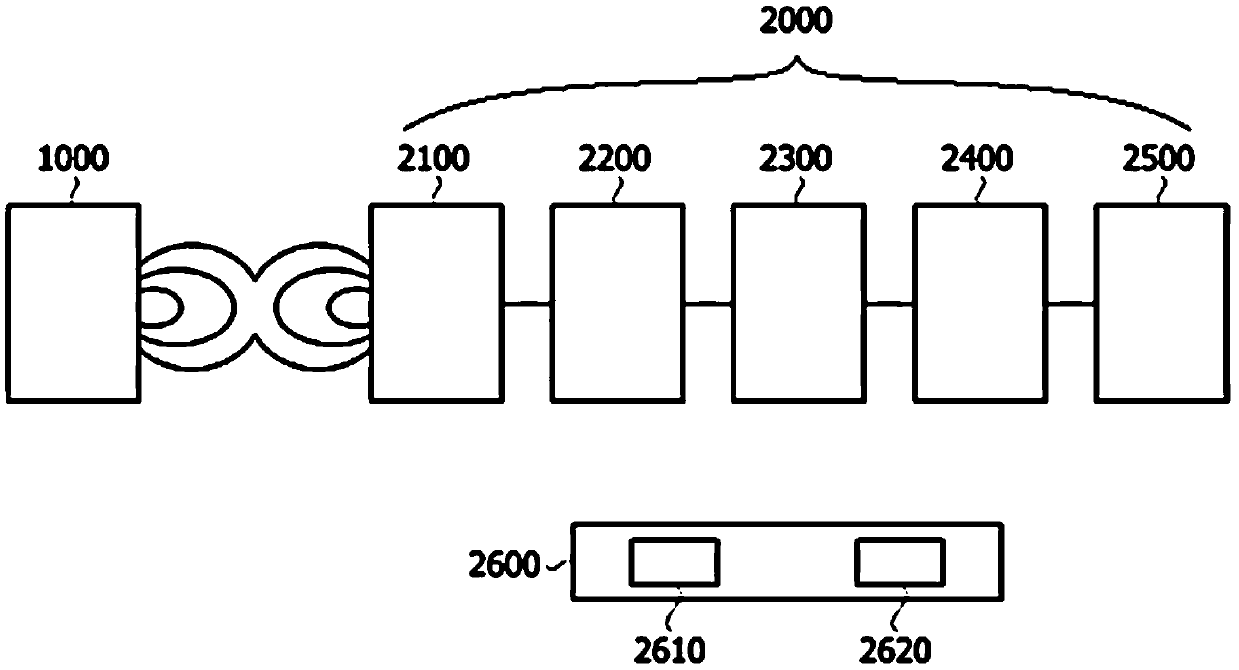

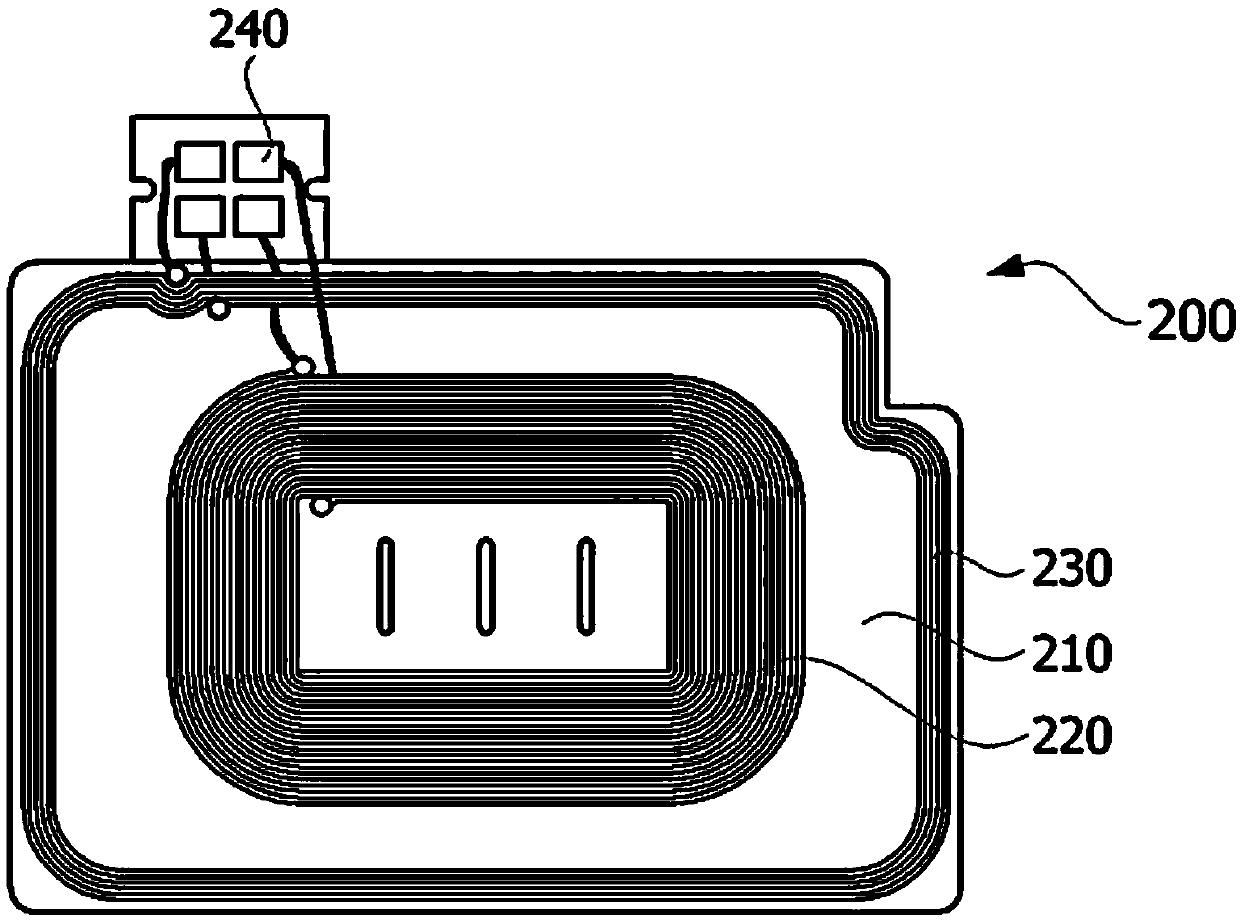

Magnetic sheet and wireless power receiving device comprising same

InactiveUS20190214180A1Strong adhesionImprove transmission efficiencyBatteries circuit arrangementsTransformersEngineeringElectric power

A magnetic sheet according to an embodiment comprises: a first magnetic sheet portion comprising a first surface; a second magnetic sheet portion comprising a second surface that faces the first surface; and an attachment portion arranged between the first surface and the second surface, wherein the attachment portion may comprise a plurality of magnetic particles and a coating layer that is coated with the plurality of magnetic particles and comprises an organic material.

Owner:SCRAMOGE TECH LTD

Magneto-dielectric substrate, circuit material, and assembly having the same

ActiveCN107347258APrinted circuit aspectsInorganic material magnetismDielectric substrateMaterials science

Owner:ROGERS CORP

Carbon containing sputter target alloy compositions

InactiveCN1807679ABest Matched Epitaxial GrowthMatched epitaxial growthBase layers for recording layersVacuum evaporation coatingCarbideChromium Alloys

Owner:HERAEUS INC

Magnetic recording medium, and method for producing the same

InactiveUS20050217760A1Shorten the annealing timeShort annealing timeChemical vapor deposition applicationLiquid applicationFerromagnetic orderAlloy

A magnetic recording medium including: a support; and a magnetic layer provided on the support, the magnetic layer containing a magnetic particle of a CuAu type or Cu3Au type ferromagnetic ordered alloy phase, wherein a content of boron in the magnetic particle is 0 to 0.9 at %, and a content of fluorine in the magnetic particle is 0.09 to 0.3 at %. Also provided is a method for producing a magnetic recording medium including: forming an alloy particle capable of forming a CuAu type or Cu3Au type ferromagnetic ordered alloy phase by a reduction method in which a reducing agent containing a boron atom is used; forming a layer including the alloy particle on a support; heat-treating the alloy particle at a temperature below a transformation temperature of the alloy particle; and annealing the alloy particle at a temperature which is not lower than the transformation temperature of the alloy particle.

Owner:FUJIFILM CORP +1

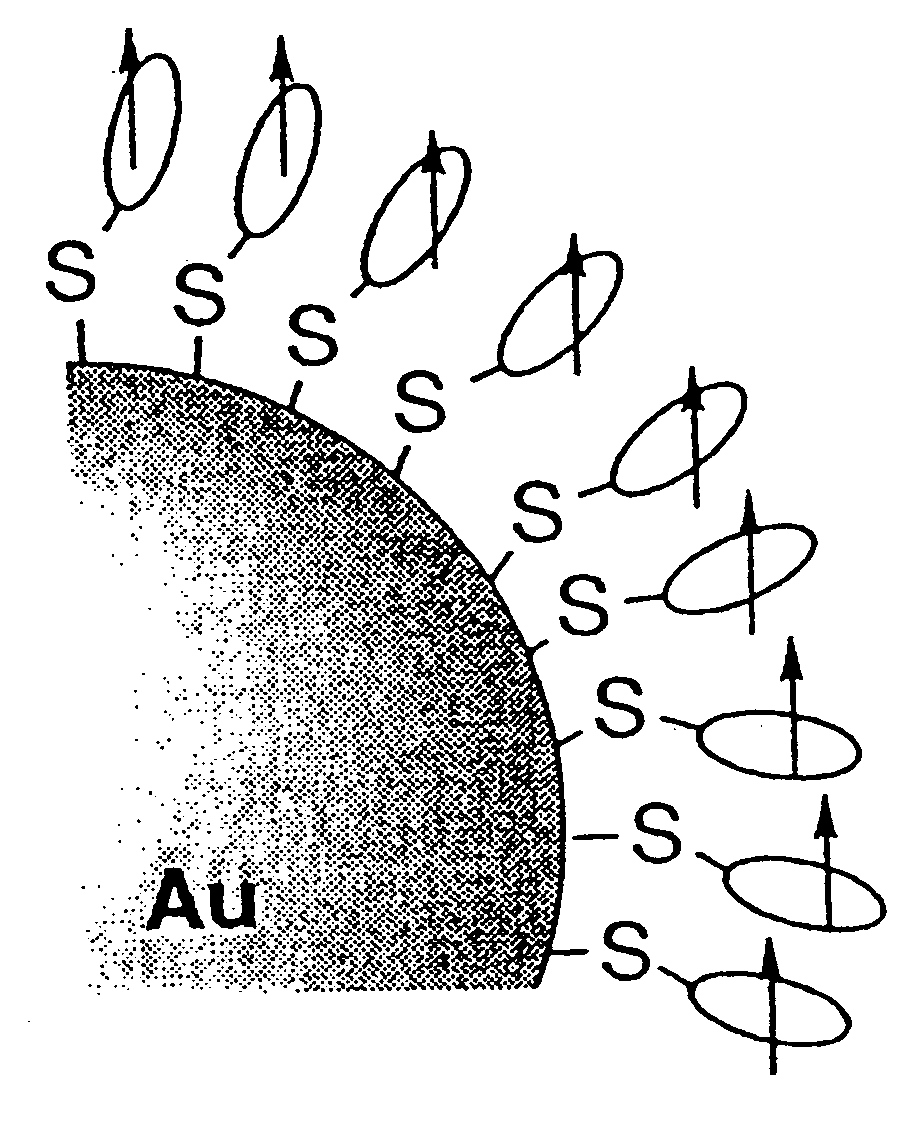

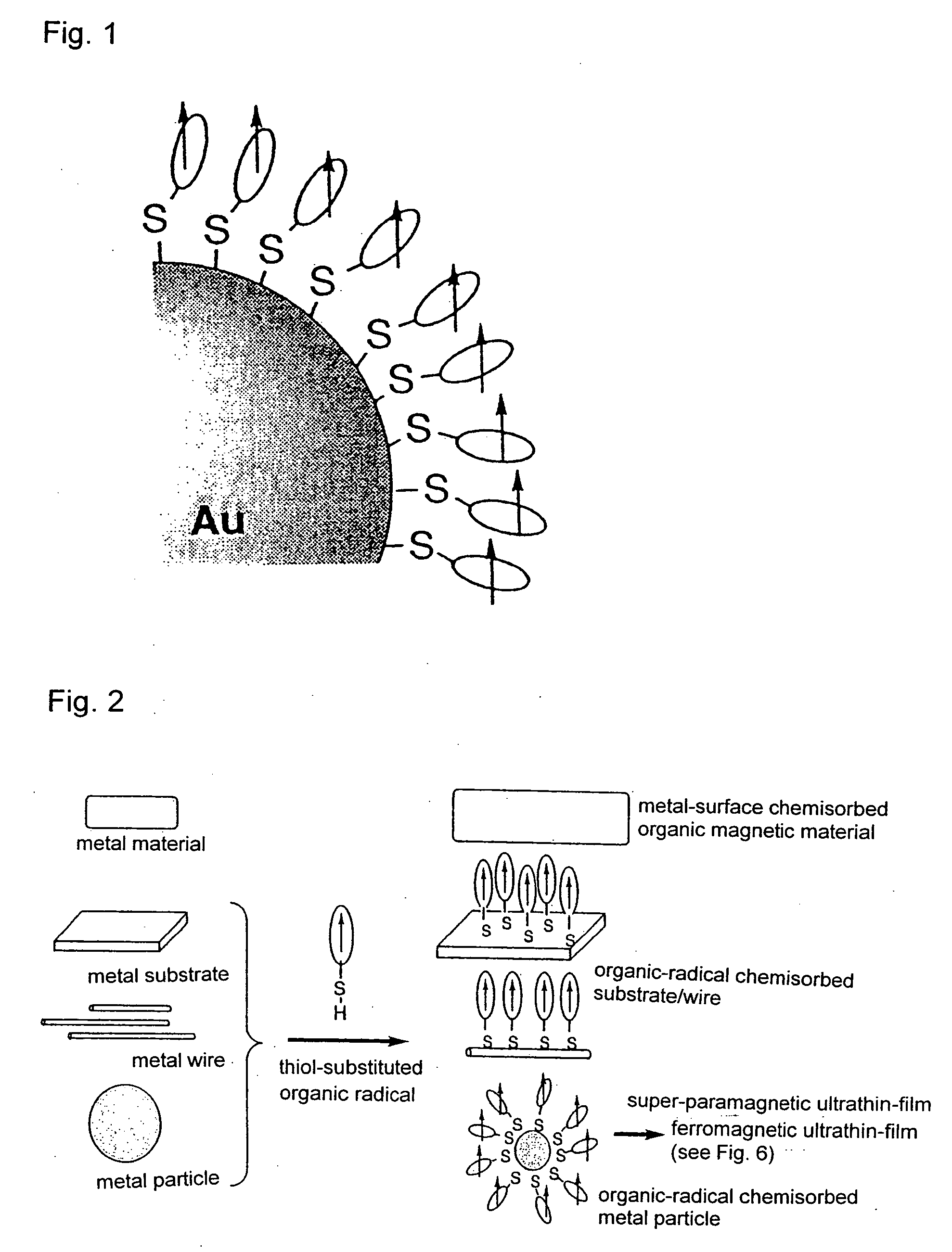

Organic-inorganic compositie magnetic material and method for manufacturing same

InactiveUS20050205851A1Eliminate unevennessNanostructure applicationNanomagnetismThiolSuperparamagnetism

The present invention provided a method for manufacturing an organic-inorganic composite magnetic material which has organic radical molecules chemisorbed on the surface of a metal substance and exhibits super-paramagnetism or ferromagnetism. An ionic salt of a metal allowing thiol to be absorbed thereon is reduced with a reducing agent in the presence of a stabilizing ligand so as to form a soluble metal particle. The stabilizing ligand absorbed on the formed soluble metal particle is exchanged with a thiol-substituted organic radical having an unpaired electron so as to synthesize an organic-radical absorbed metal particle.

Owner:JAPAN SCI & TECH CORP

Regularly Arrayed Nanostructured Material

InactiveUS20080206546A1Low costEfficient use ofMaterial nanotechnologyNanomagnetismNanoparticleNanostructured materials

Owner:FUJIFILM CORP

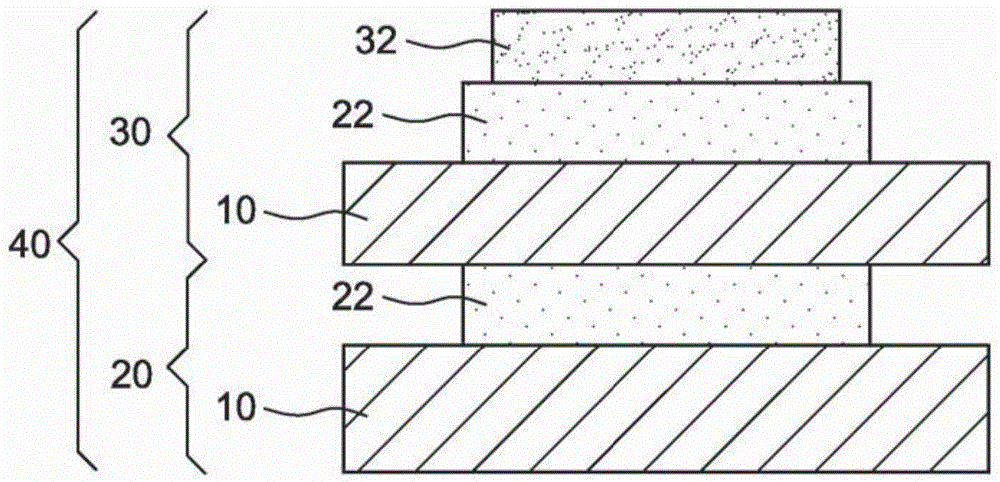

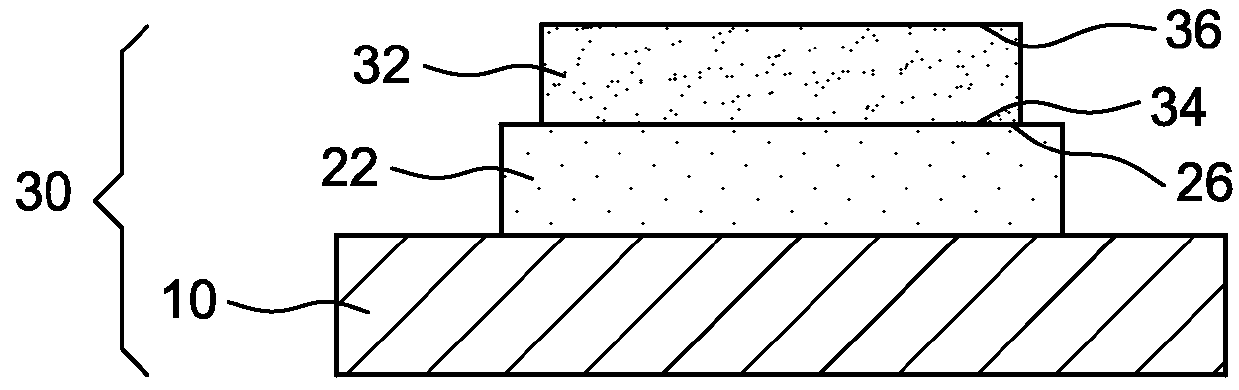

Spin injector device comprising a protection layer at the centre thereof

ActiveCN104380399AComposition is variableReduced spintronic performanceGalvano-magnetic material selectionConductive/insulating/magnetic material on magnetic film applicationElectronic statesOrganic layer

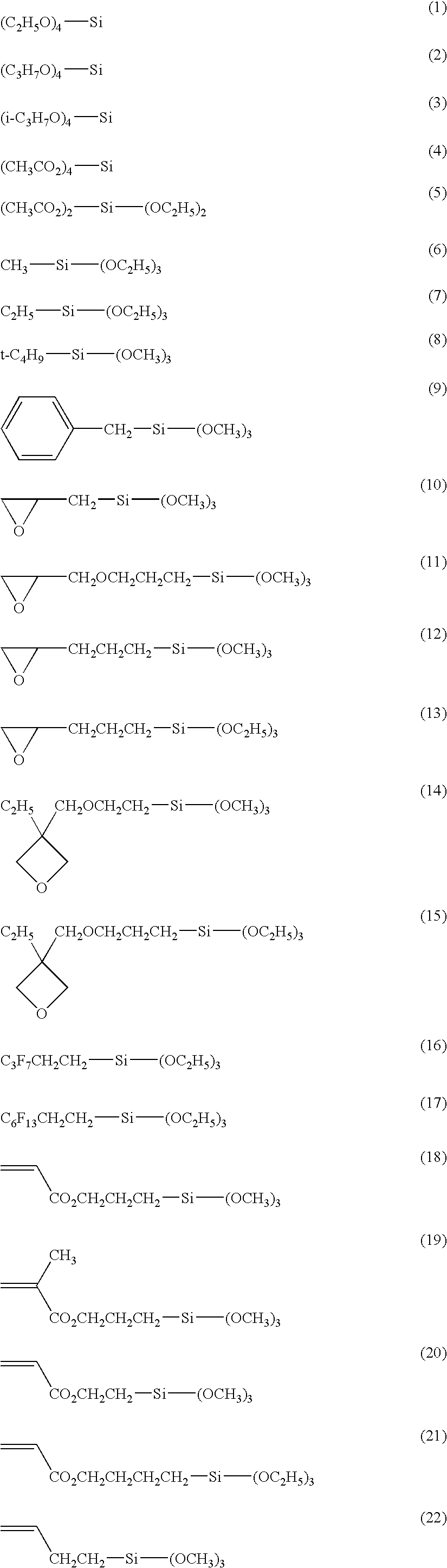

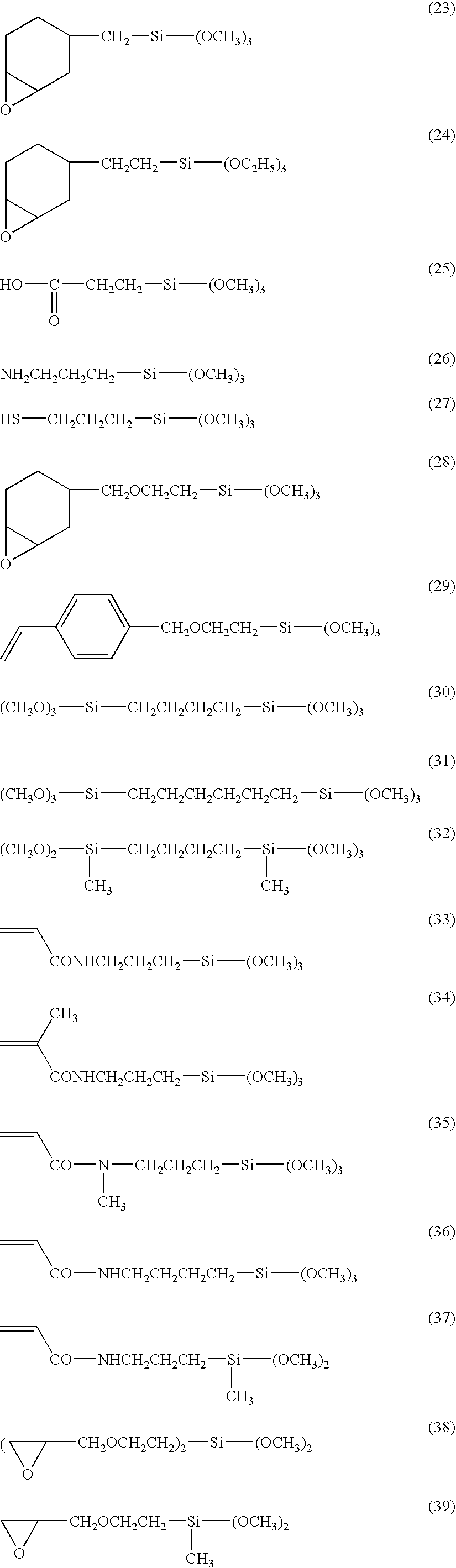

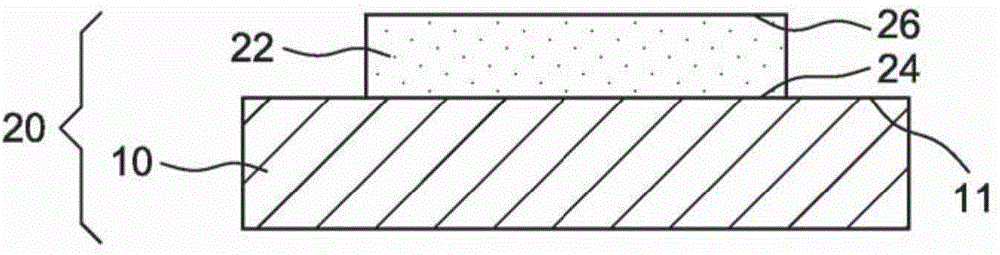

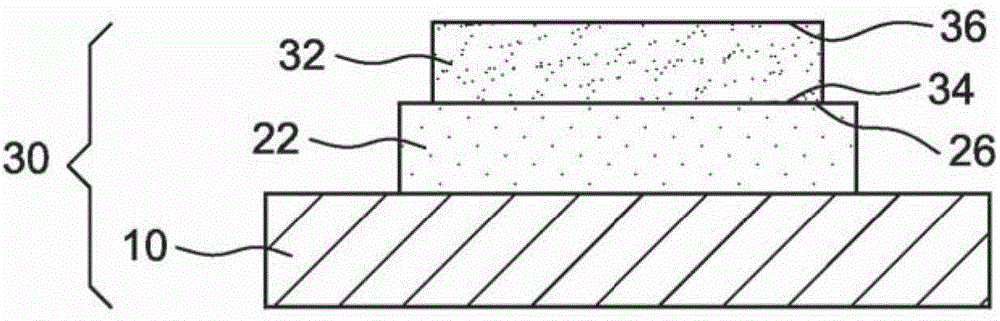

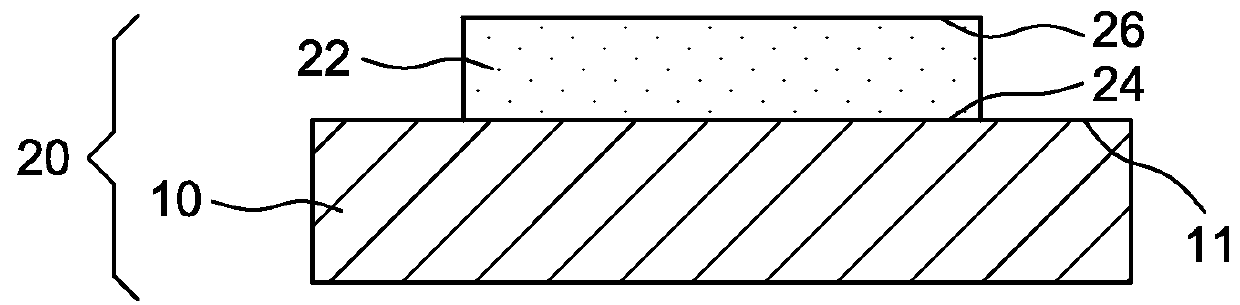

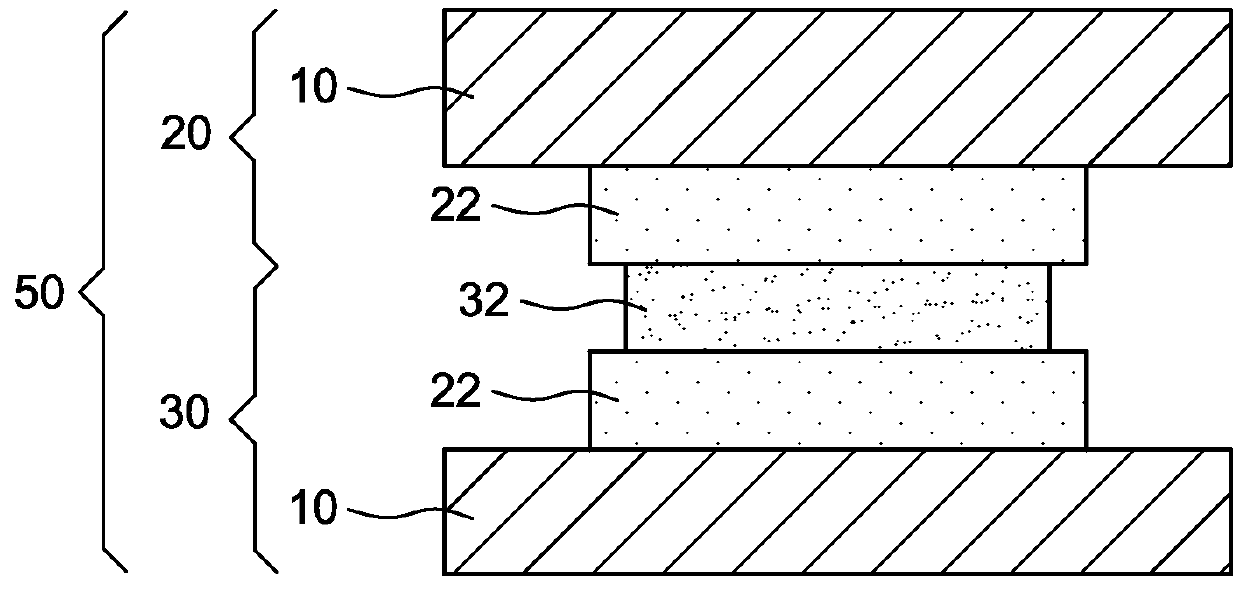

The invention relates to a method for producing a spin injector device (30), comprising the following steps: a) formation of a metal protection layer (22) on a surface (11) of a substrate (10) such as to limit or prevent the oxidation and / or contamination of the surface by its environment, said surface being magnetic and electroconductive, the protection layer being naturally diamagnetic or paramagnetic; and b) formation of an upper layer (32) on the protection layer, which can stimulate a spin polarization, at close to the Fermi level, of the electronic states of the interface between the protection layer and the upper layer using an amplitude and a spin referential defined by the magnetism of the substrate and / or of the surface of the substrate, the upper layer being an organic layer and at least one of the molecular sites of said organic layer having a paramagnetic moment upon contact with the protection layer.

Owner:CENT NAT DE LA RECH SCI (C N R S) +1

Method of increasing the coercivity of a sintered nd-fe-b permanent magnet

ActiveUS20200027655A1Increase in coercivityReduce the amount requiredPermanent magnetsInductances/transformers/magnets manufactureOrganic filmRare-earth element

A method of increasing coercivity of an Nd—Fe—B sintered permanent magnet includes a step of providing an organic film. A powder, containing at least one heavy rare earth elements, is uniformly deposited on the organic film forming a diffusion source. Then, a sintered Nd—Fe—B magnet block having a pair of block surfaces extending perpendicular to a magnetization direction is provided. Next, the diffusion source is deposited on at least one of the block surfaces with the powder being in abutment relationship with at least one of the block surfaces. After depositing the diffusion source, the sintered Nd—Fe—B magnet block containing the diffusion source is pressed allowing the powder of the diffusion source to be in close contact with the block surface. The diffusion source is then diffused into the sintered Nd—Fe—B magnet block to produce a diffused magnet block. Next, the diffused magnet block is aged.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

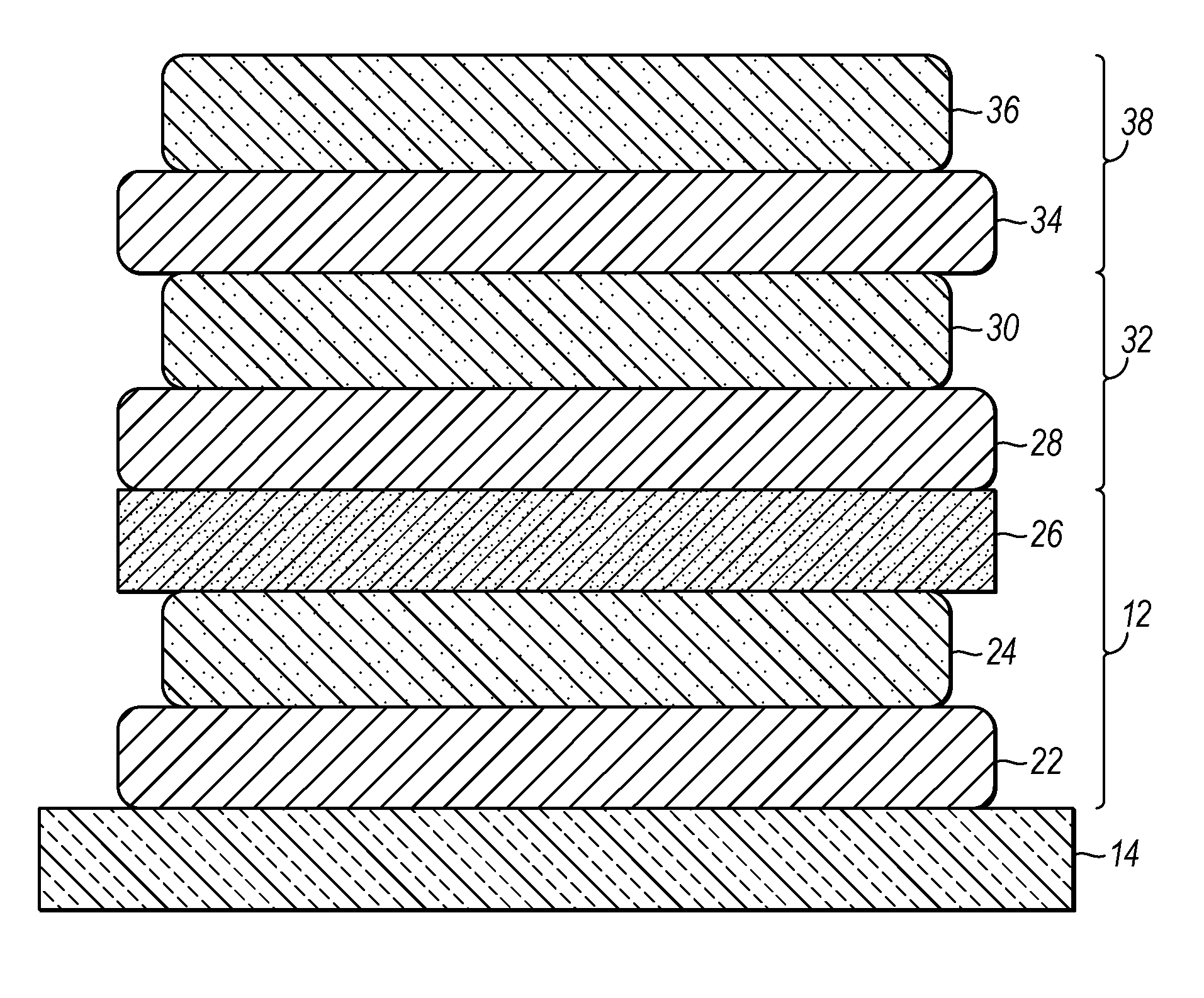

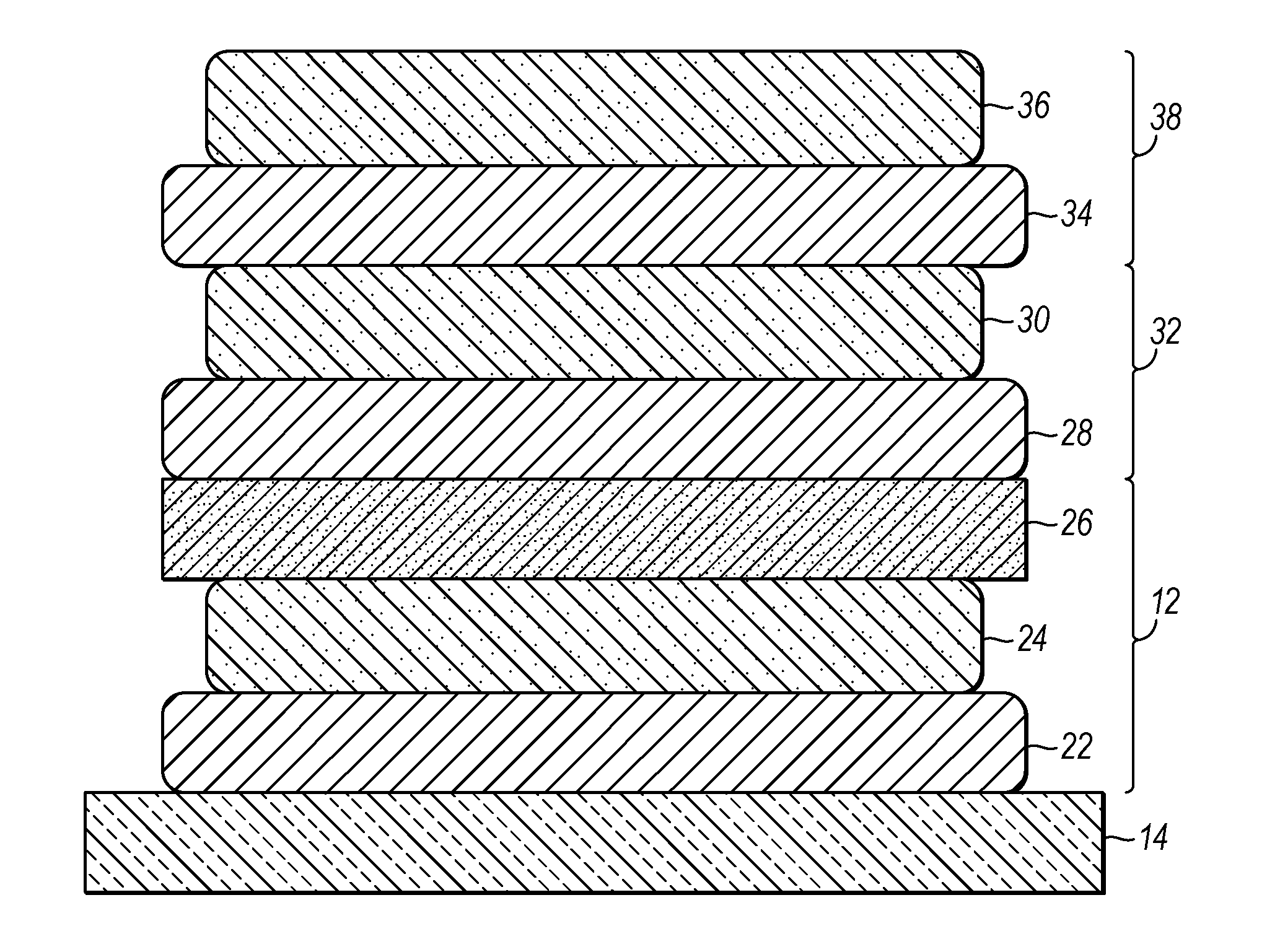

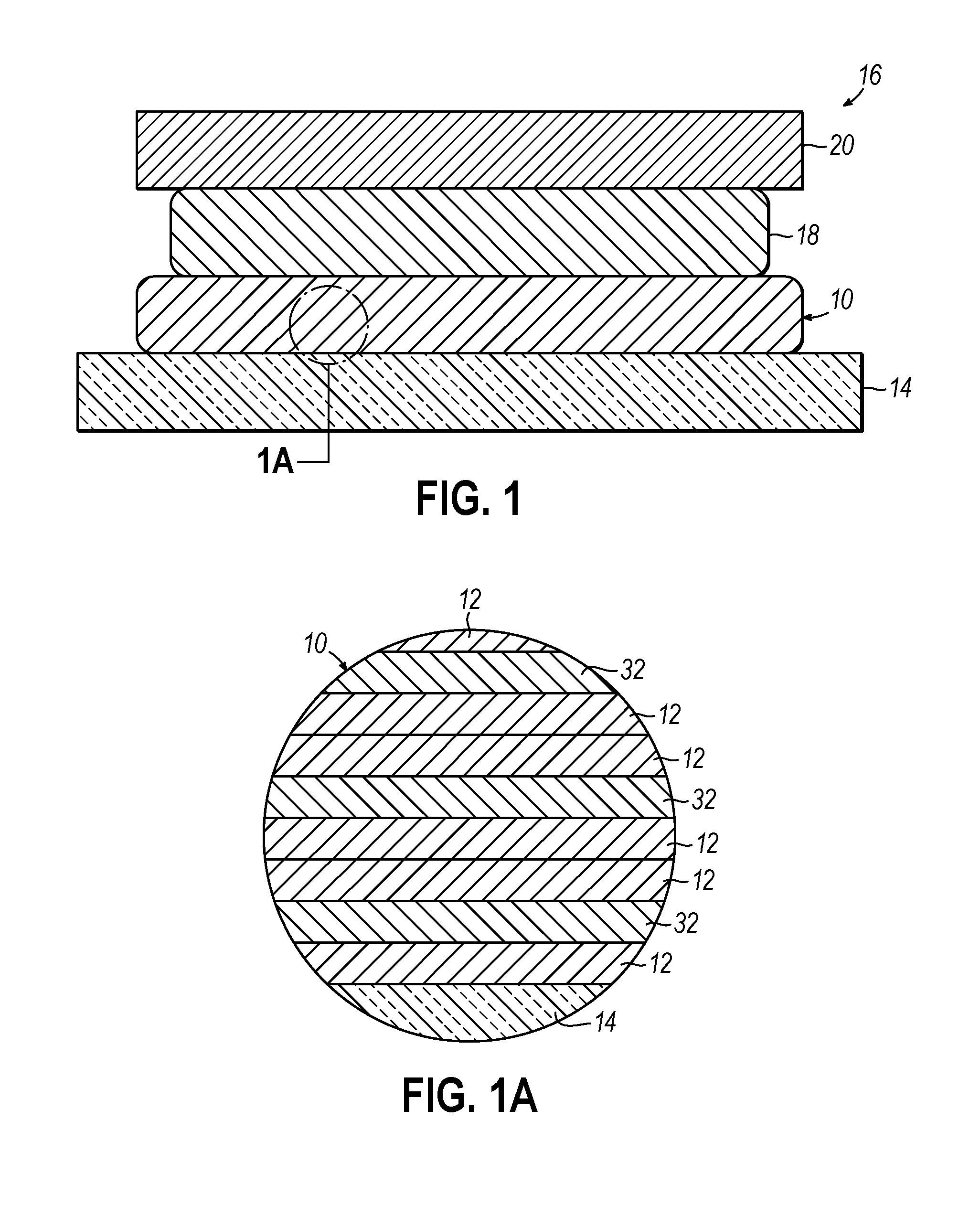

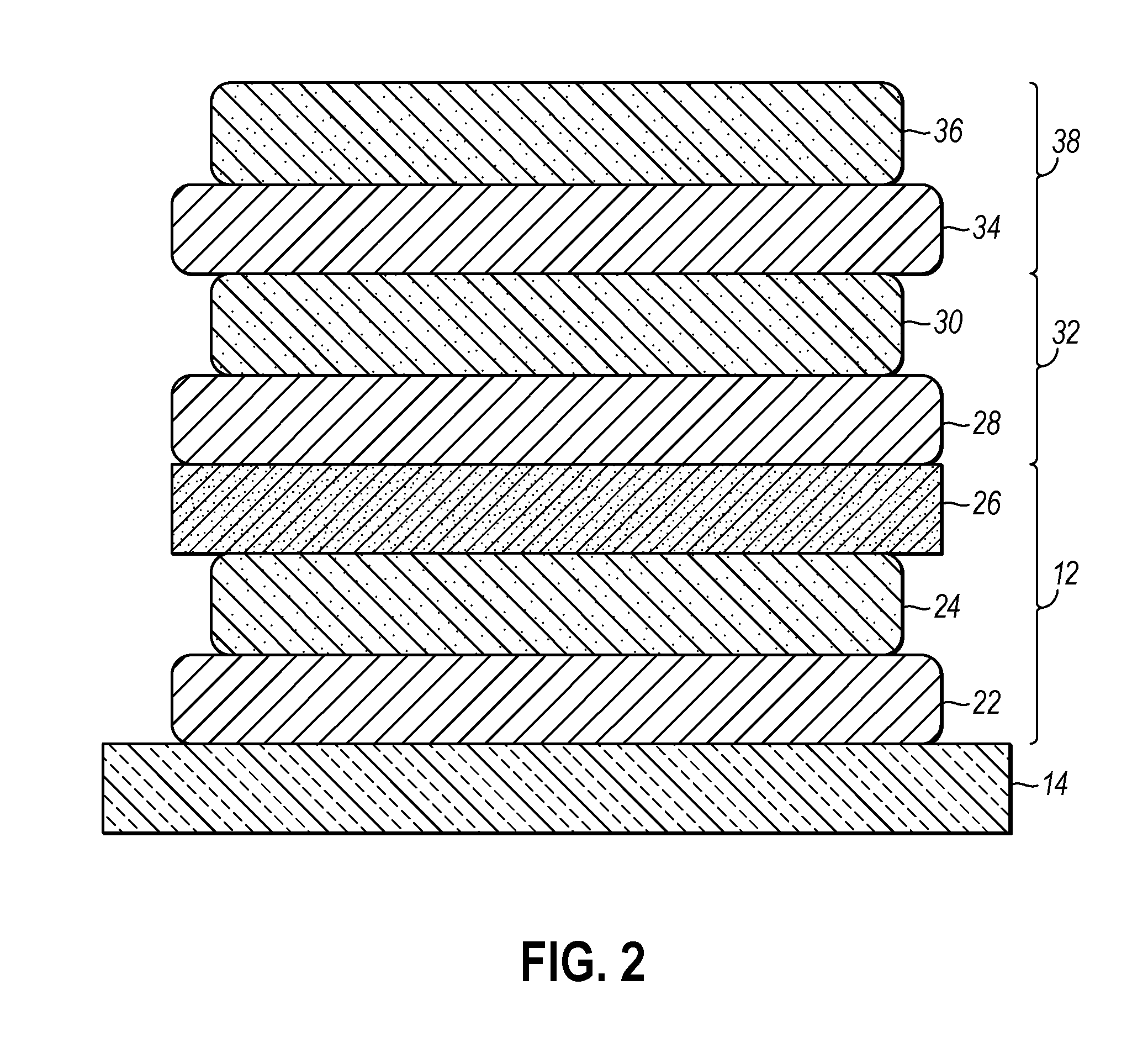

Laminate composite and method for making same

ActiveUS8808861B2Shielding materialsChemical vapor deposition applicationSimple Organic CompoundsMagnetization

Owner:THE OHIO STATES UNIV

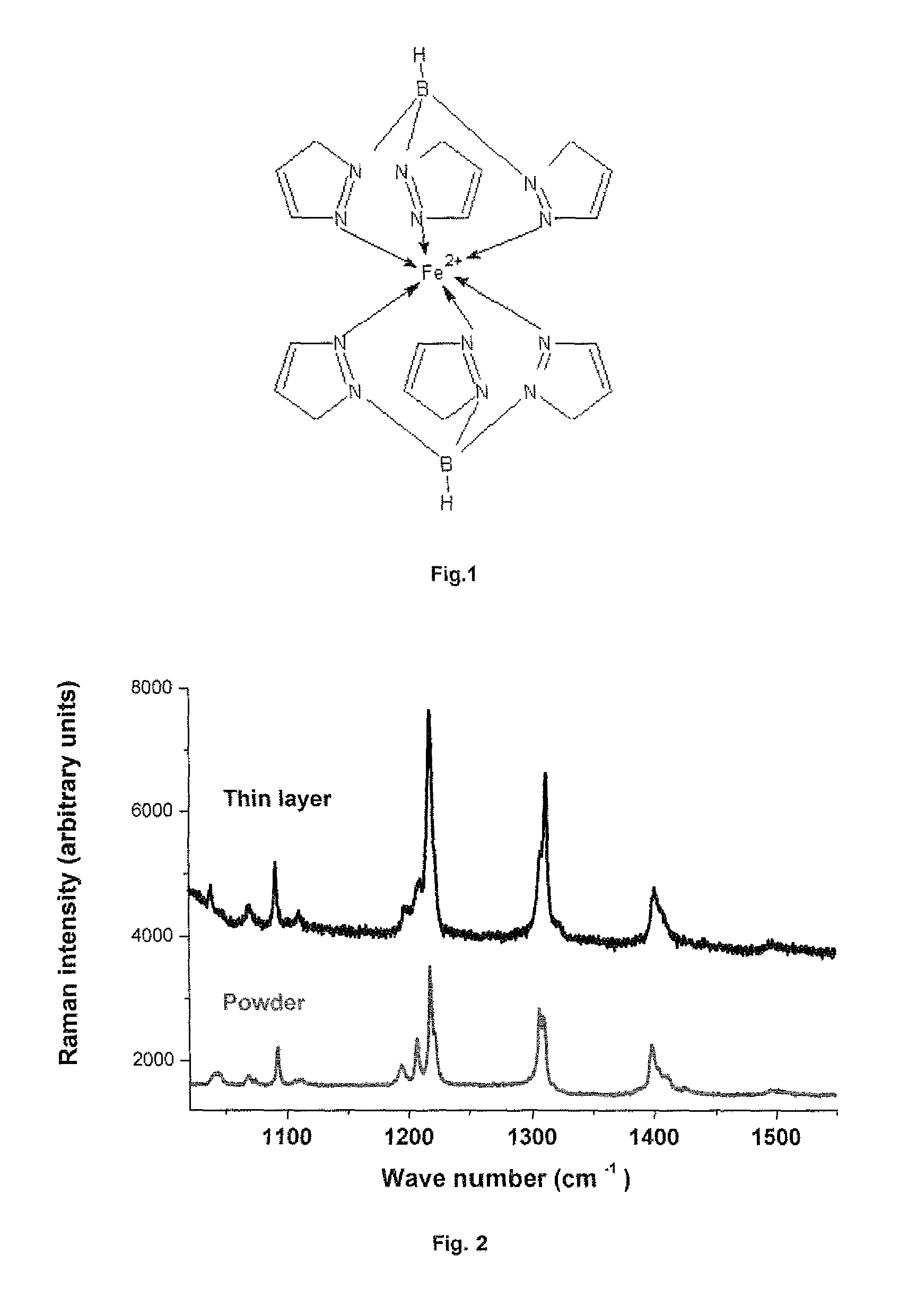

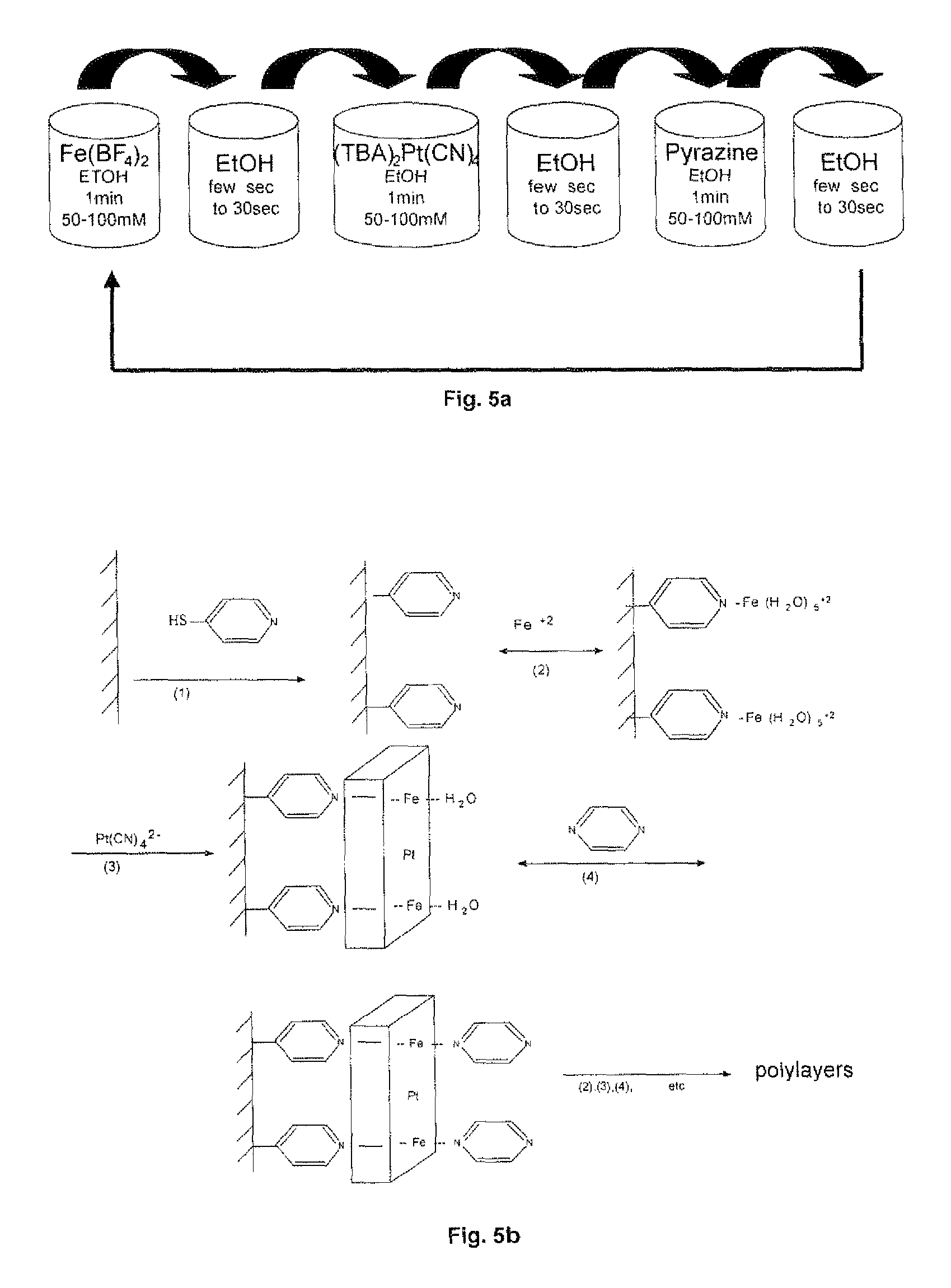

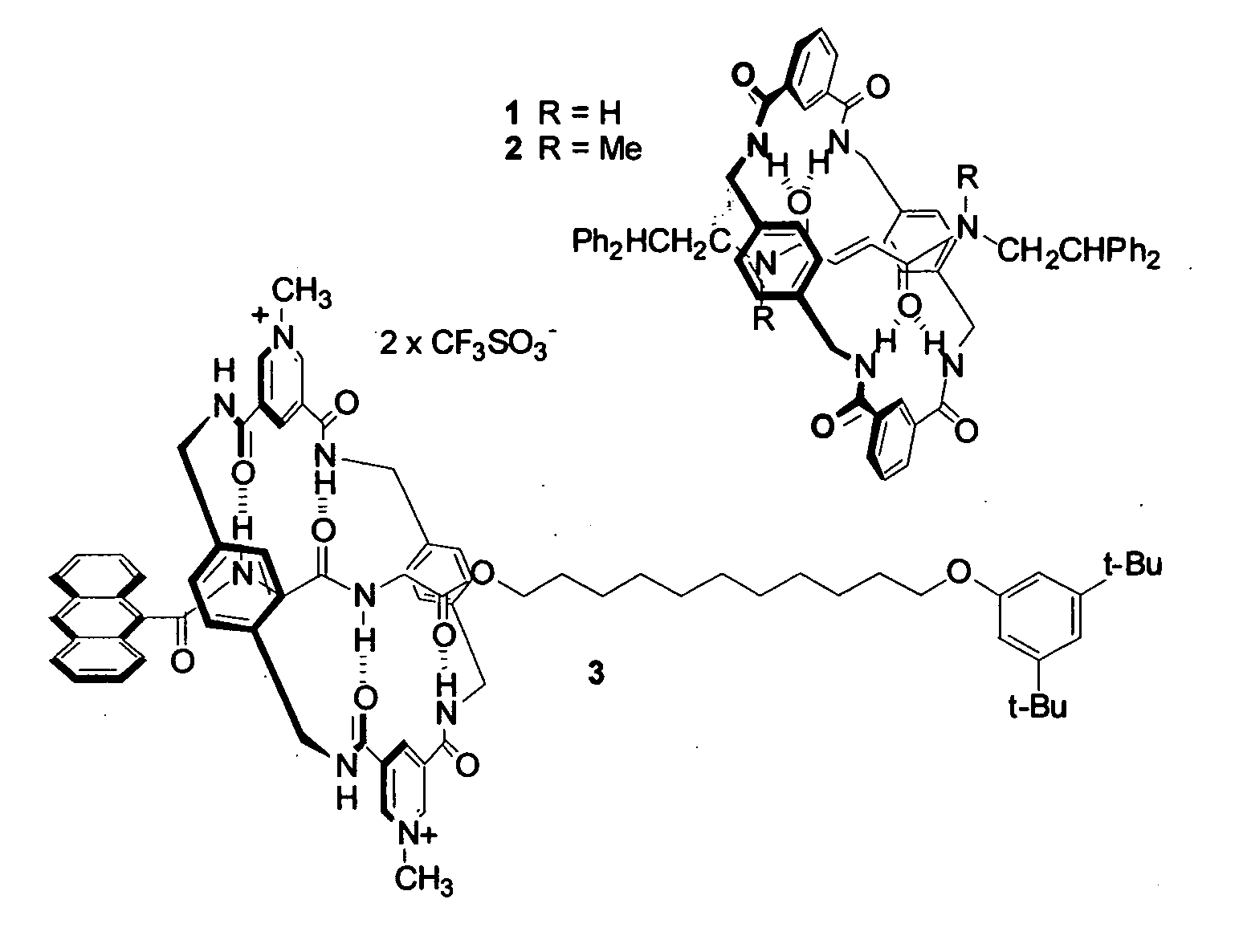

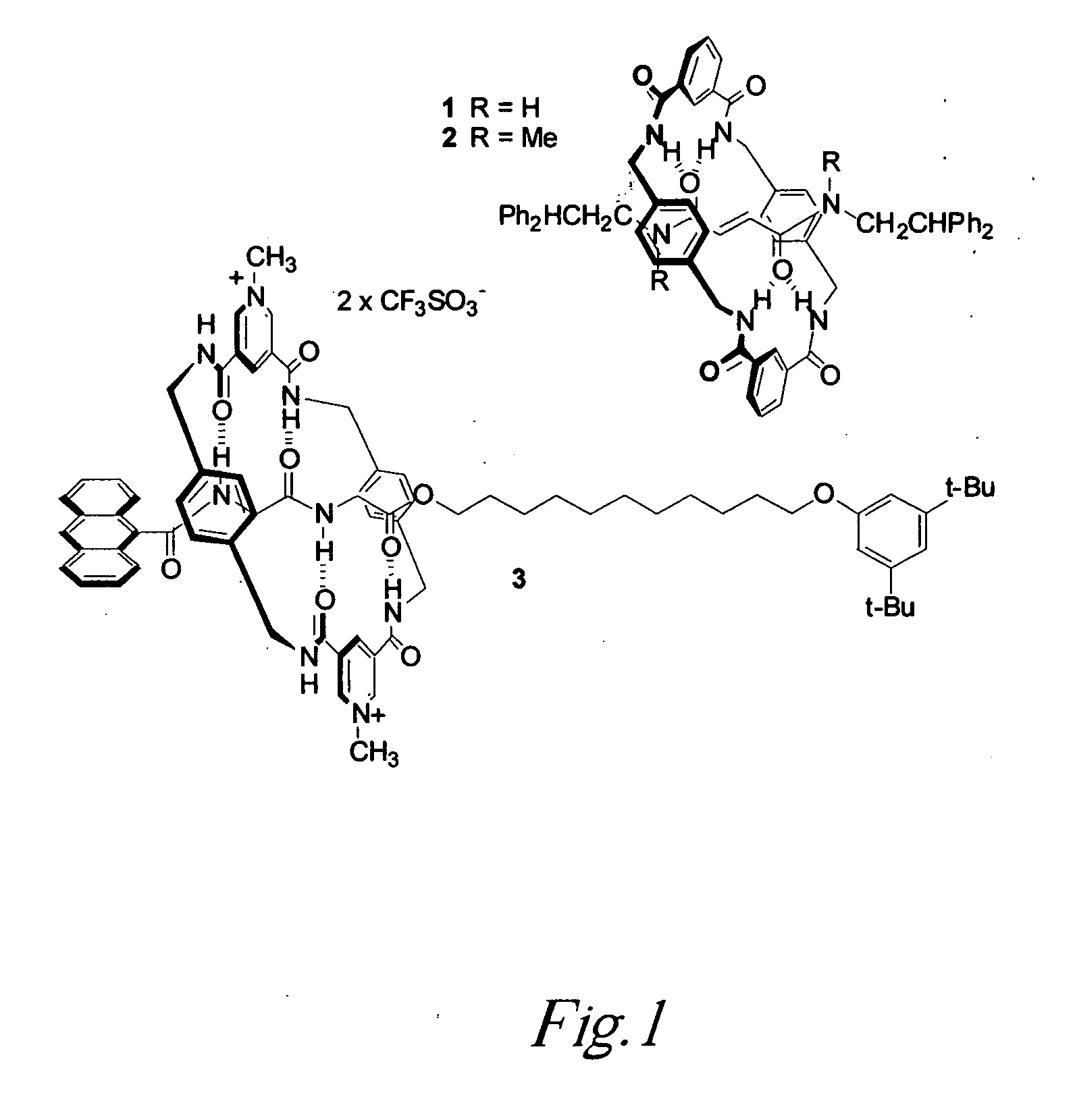

Process for the application of spin transition molecular materials in thin layers

This application relates to a process for the application of thin layers of substantially pure spin transition molecular materials while maintaining the hysteresis properties of the material. The process makes it possible to obtain a dense uniform surface with very low roughness.

Owner:CENT NAT DE LA RECH SCI C N R S - 90 PART INTEREST +1

Spin injector device comprising a protection layer at the centre thereof

ActiveUS9362488B2Restrict and prevent oxidation and contaminationIncreased susceptibilityGalvano-magnetic material selectionConductive/insulating/magnetic material on magnetic film applicationOrganic layerEngineering

A method for manufacturing a spin injector device, comprising the following steps of:a) forming a metal protection layer on a face of a substrate, so as to restrict or prevent oxidation and / or contamination of said face by its environment, the face being magnetic and electrically conductive, the protection layer being of a diamagnetic or paramagnetic nature;b) forming an upper layer onto the protection layer, able to promote a spin bias of electronics sates in the vicinity of the Fermi level of the interface between the protection layer and the upper layer according to an amplitude and a spin referential frame which are defined by the magnetism of the substrate and / or of the face of the substrate, the upper layer being an organic layer of which one or more molecular sites have, in contact with the protection layer, a paramagnetic moment.

Owner:CENT NAT DE LA RECHERCHE SCI +1

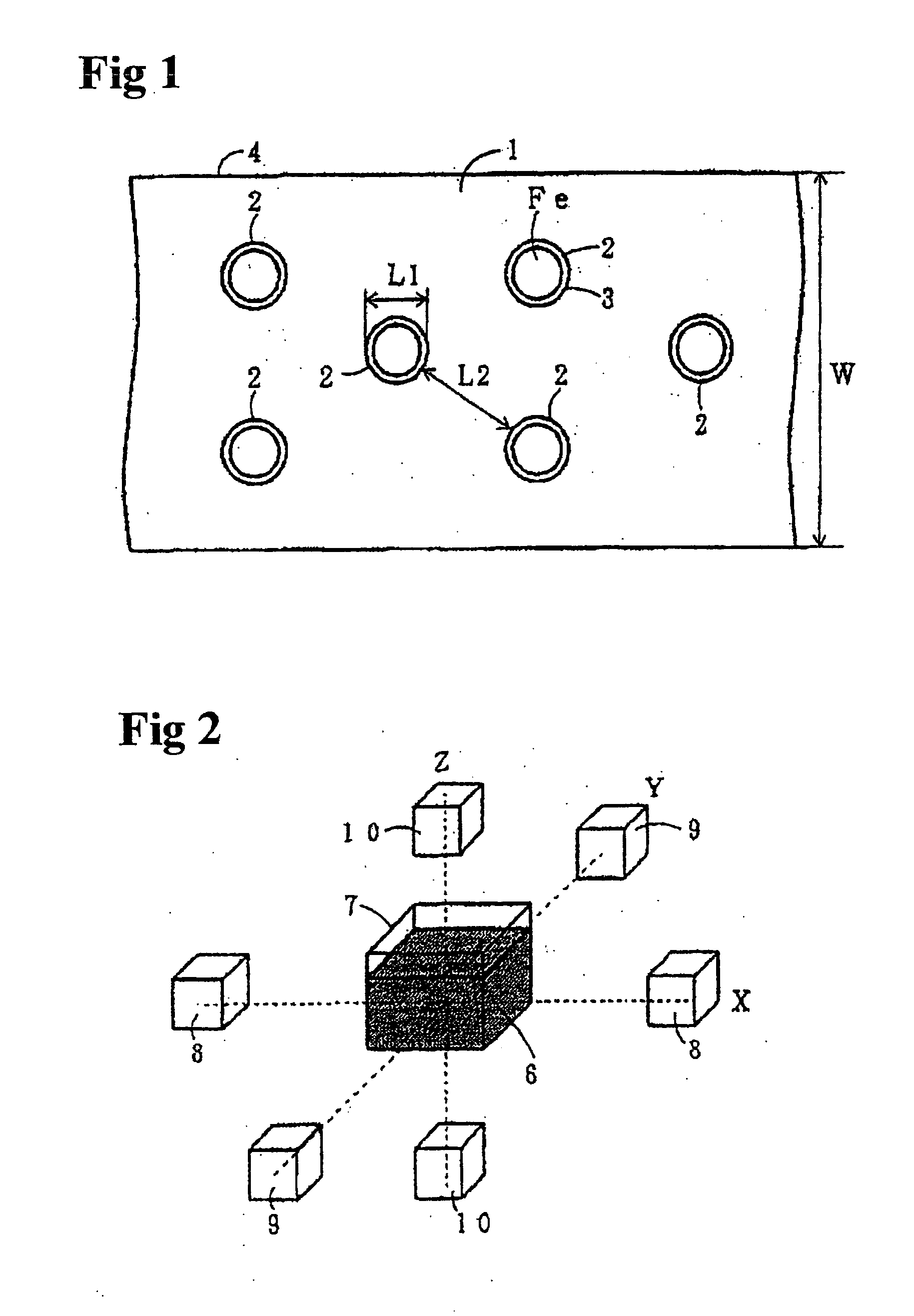

Process for obtaining spatially-organised nanostructures on thin films

InactiveUS20060019439A1Increase areal densityGood effectNanomagnetismNanoinformaticsMorphological transformationNanostructure

A process for forming nanostructures comprising the step of applying on localised regions of a smooth thin film of bistable or multistable molecules an external perturbation with preset magnitude thereby said film undergoes a collective morphological transformation and nanostructures are formed by selforganisation of said molecules, said nanostructures having preset number, size, interspacing and shape. The nanostructures can be used as storage medium in storage devices.

Owner:SCRIBA NANOTECNOLOGIE SRL

Ethylene glycol-based magnetic fluid composite film and preparation method thereof

InactiveCN107346697AHigh crystallinityImprove dispersion stabilityChemical vapor deposition applicationMagnetic liquidsWater basedMagnetic susceptibility

The invention provides an ethylene glycol-based magnetic fluid composite film and a preparation method thereof, which relate to the technical field of magnetic composite materials and are mainly prepared from the following components in parts by mass: ethylene glycol-based magnetic fluid 90-110 15-25 parts of polyvinyl alcohol, 70-90 parts of deionized water, among which, the ethylene glycol-based magnetic fluid is mainly prepared from nano ferric oxide, ethylene glycol and a dispersion stabilizer, which relieves the existing magnetic fluid Among them, the carrier liquid matrix is water-based or oil-based, so that the degree of dispersion of magnetic nanoparticles has not been significantly improved, resulting in the technical problem that the performance of the magnetic fluid composite film is limited. The ionic water cooperates with each other to make the magnetic particles evenly distributed in the composite film, so that the composite film can maintain good paramagnetic properties, the saturation magnetization is larger, the magnetic susceptibility per unit mass is higher, and the strain capacity is better. The technical effect of better magnetic properties.

Owner:XINJIANG UNIVERSITY

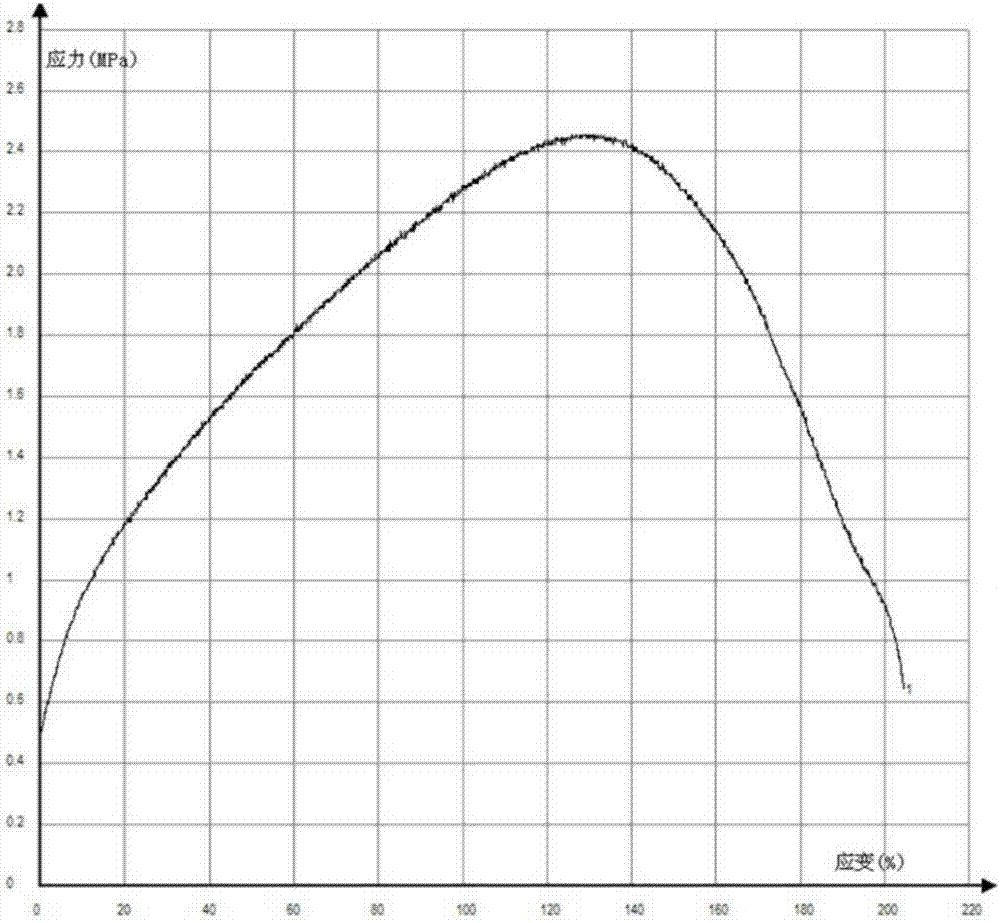

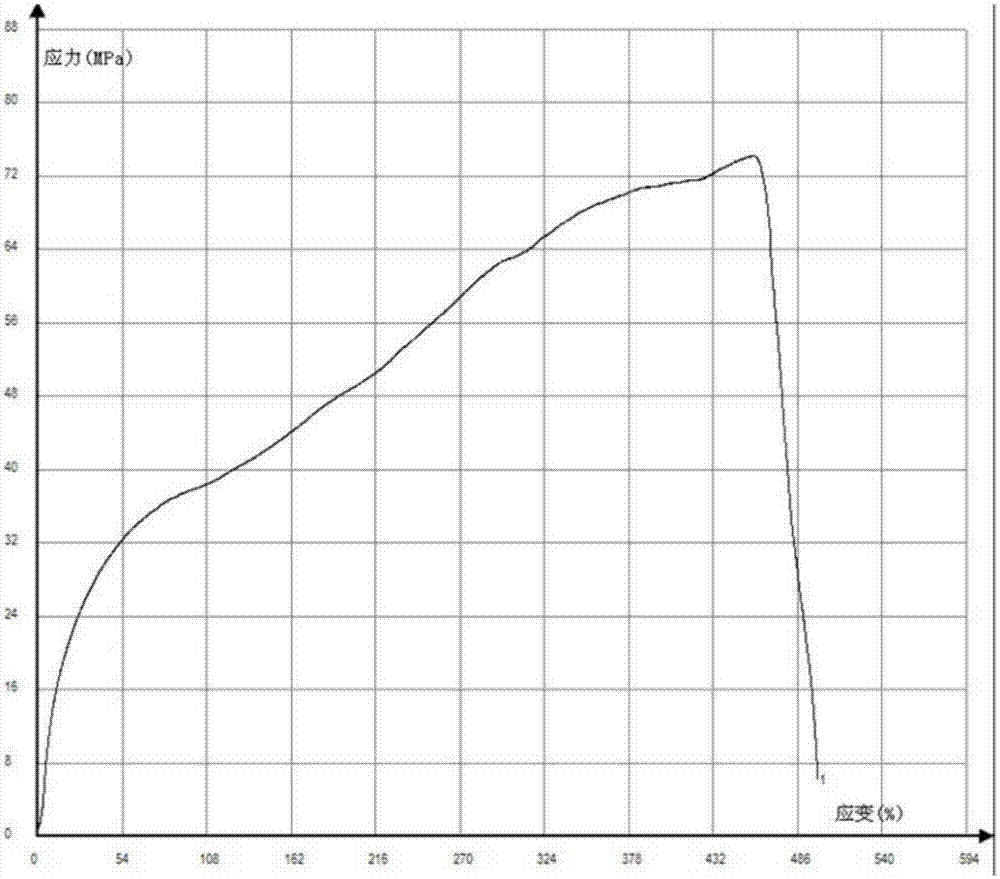

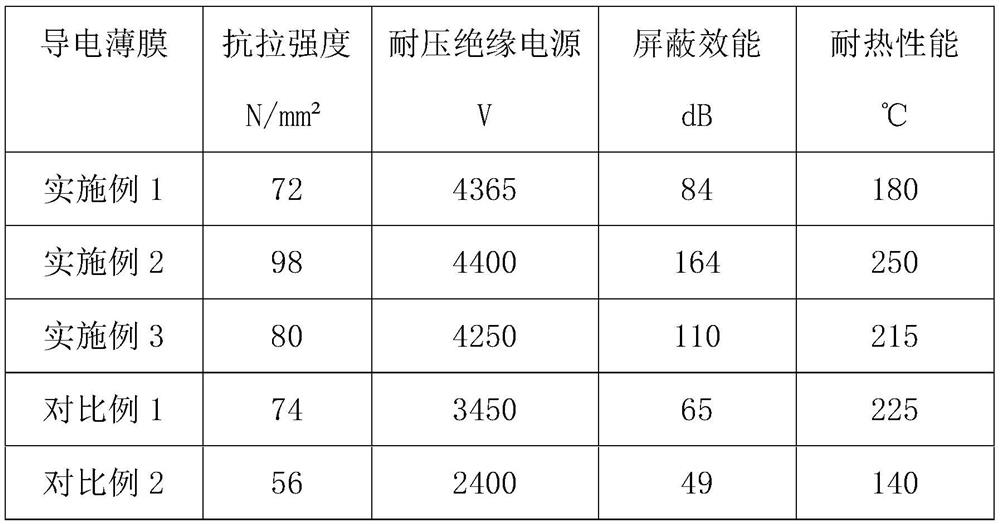

Polymer flexible conductive film and preparation method thereof

ActiveCN112185606ALow costLow resistivityConductive layers on insulating-supportsMagnetic/electric field screeningIndiumPolystyrene

The invention discloses a polymer flexible conductive film and a preparation method thereof, and belongs to the technical field of polymer material preparation. The polymer flexible conductive film comprises a generation layer and a forming layer, and the generation layer mainly comprises the following components: 3, 4-ethylenedioxythiophene; polystyrene sulfonic acid; ferroferric oxide; tin oxide; indium oxide; magnesium hydroxide; the forming layer mainly comprises the following components: an organic salt solution; and a reinforcing agent; according to the invention, the tensile property and the shielding effectiveness of the produced film are effectively improved by utilizing the sputtering spraying reaction of magnesium hydroxide and graphite, and the problem of low overall conductivity caused by magnesium hydroxide is neutralized by tin oxide and indium oxide; and the organic salt solution of 4-pyridine acetate hydrochloric acid can effectively enhance the flexibility and heat resistance of the polymer flexibility.

Owner:深圳市法鑫忠信新材料有限公司

Graphene-based magnetoresistive sensors

A graphene structure is provided. The graphene structure includes a substrate layer and at least two graphene layers arranged on the substrate layer. The at least two graphene layers include a gate voltage tuning layer and an effective graphene layer, and the effective graphene layer includes one or more graphene layers. The magnetoresistance ratio of the graphene structure is determined by the difference in charge mobility and / or carrier density between the gate voltage tuning layer and the effective graphene layer. The charge mobility and / or carrier density of the gate voltage tuning layer can be tuned by the gate voltage applied to the graphene structure. Also provided is a magnetic field sensor including a graphene structure.

Owner:NAT UNIV OF SINGAPORE

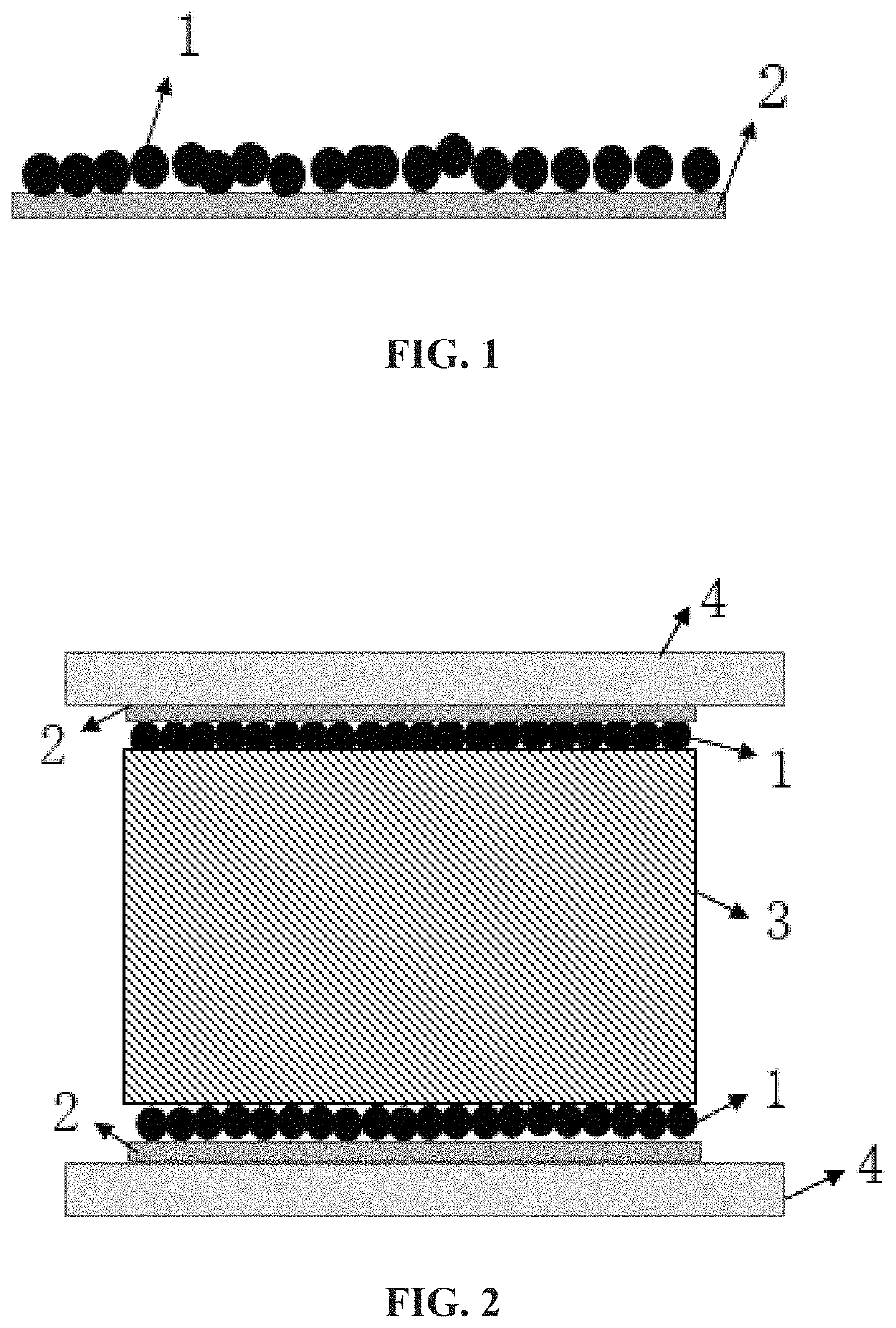

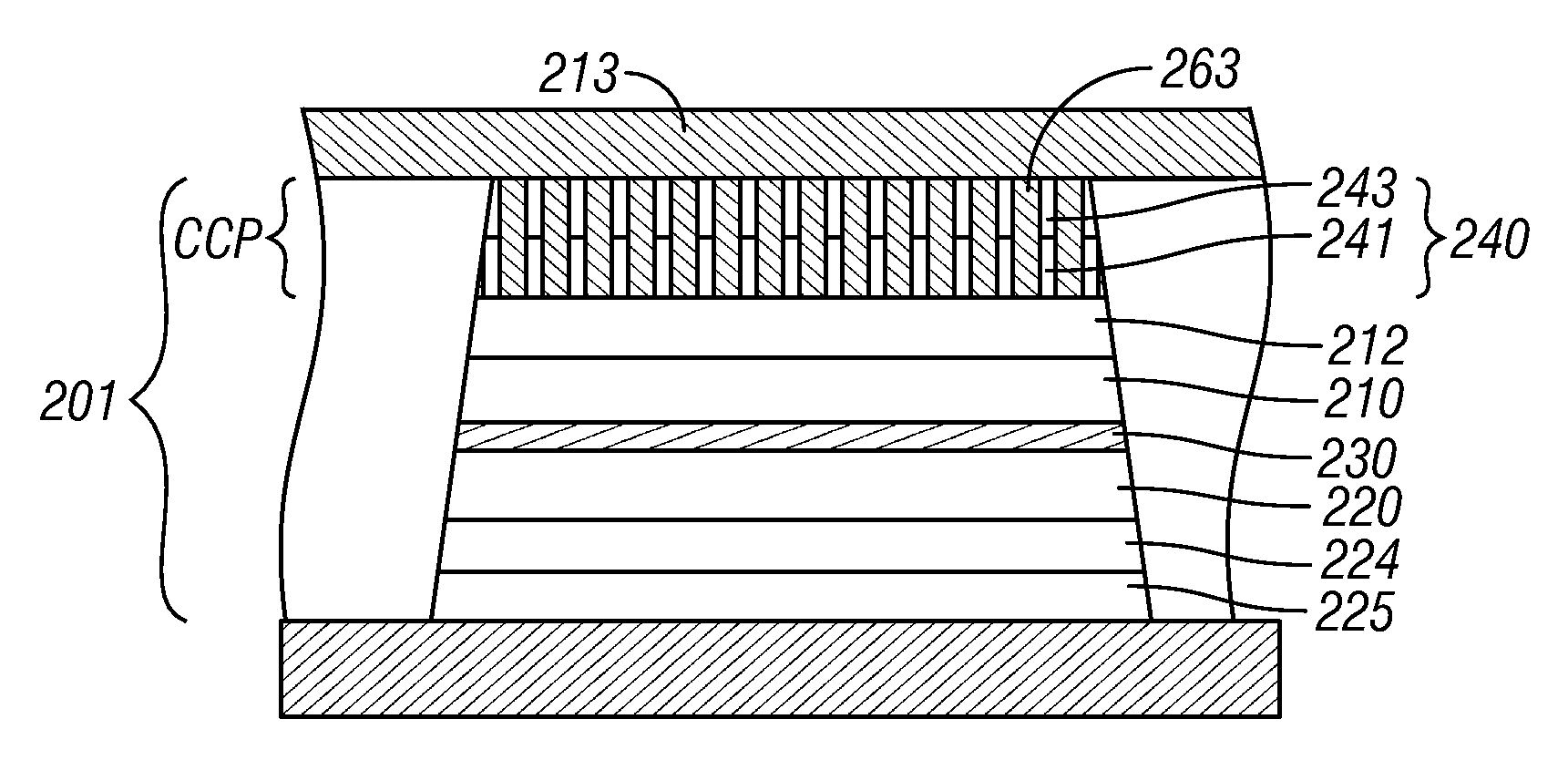

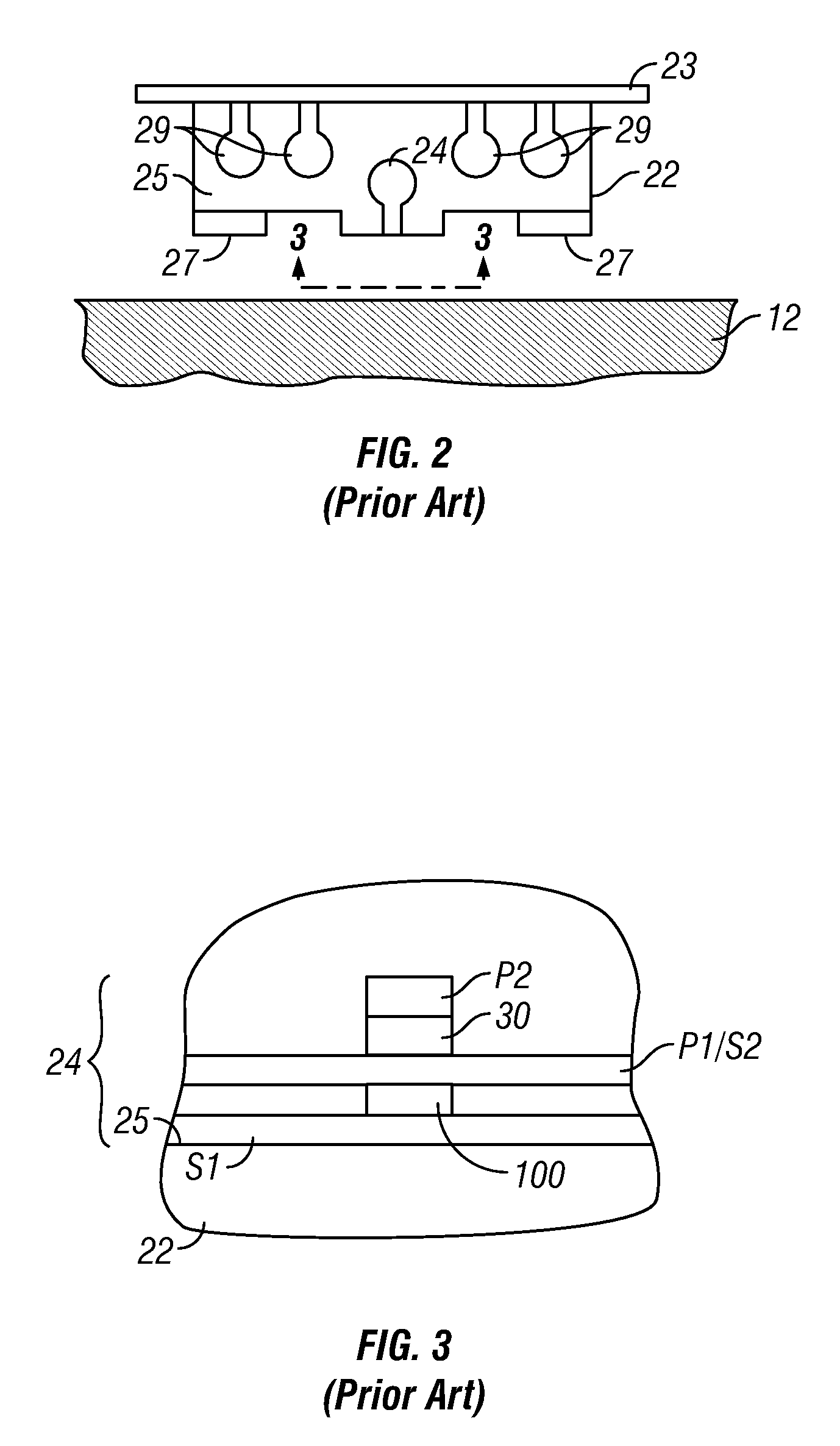

Method for making a current-perpendicular-to-the-plane giant magnetoresistance (cpp-gmr) sensor with a confined-current-path (CCP)

InactiveUS20090297700A1Material nanotechnologyNanomagnetismGiant magnetoresistanceInorganic particle

A method of making a current-perpendicular-to-the-plane giant magnetoresistive (CPP-GMR) sensor with a confined-current-path (CCP) layer uses an array of self-assembled ferritin protein molecules with inorganic cores to make the CCP layer in the sensor stack. In one embodiment, the ferritin molecules with cores of insulating oxide particles are deposited on an electrically conductive support layer and the ferritin molecules are dissolved, leaving an array of insulating oxide particles. An electrically conducting layer is deposited over the oxide particles and into the regions between the oxide particles to form the CCP layer. In another embodiment, the ferritin molecules with inorganic particles in their cores are deposited on an electrically insulating support layer and the ferritin molecules are dissolved, leaving an array of inorganic particles that function as an etch mask. The insulating support layer is then etched through the mask to form vias down to the underlying layer on which the support layer is formed. An electrically conducting layer is then deposited to form the CCP layer.

Owner:WESTERN DIGITAL TECH INC

a fe 3 o 4 The preparation method of/graphene composite film

InactiveCN105609305BLow costUniformity controllableNanostructure applicationChemical vapor deposition applicationNanoparticles dispersionGraphene

The invention relates to a preparation method of an Fe<3>O<4> / graphene composite membrane. In summary, according to the method, by the process of mixing graphene oxide with Fe<3>O<4> nano-particles at a certain ratio to obtain a mixture solution, the Fe<3>O<4> / graphene composite membrane is prepared under drying and low-temperature stepped heating reduction conditions. The product prepared by the method is good in complex condition; the Fe<3>O<4> nano-particles are uniform to disperse; and the composite membrane has ferromagnetic property. The method disclosed by the invention is simple and easy to control; industrial production is facilitated; and the prepared self-supported composite membrane has a broad application prospect in the fields of information, electrons, energy, biology, military industry and the like.

Owner:JILIN UNIV

Laminate composite and method for making same

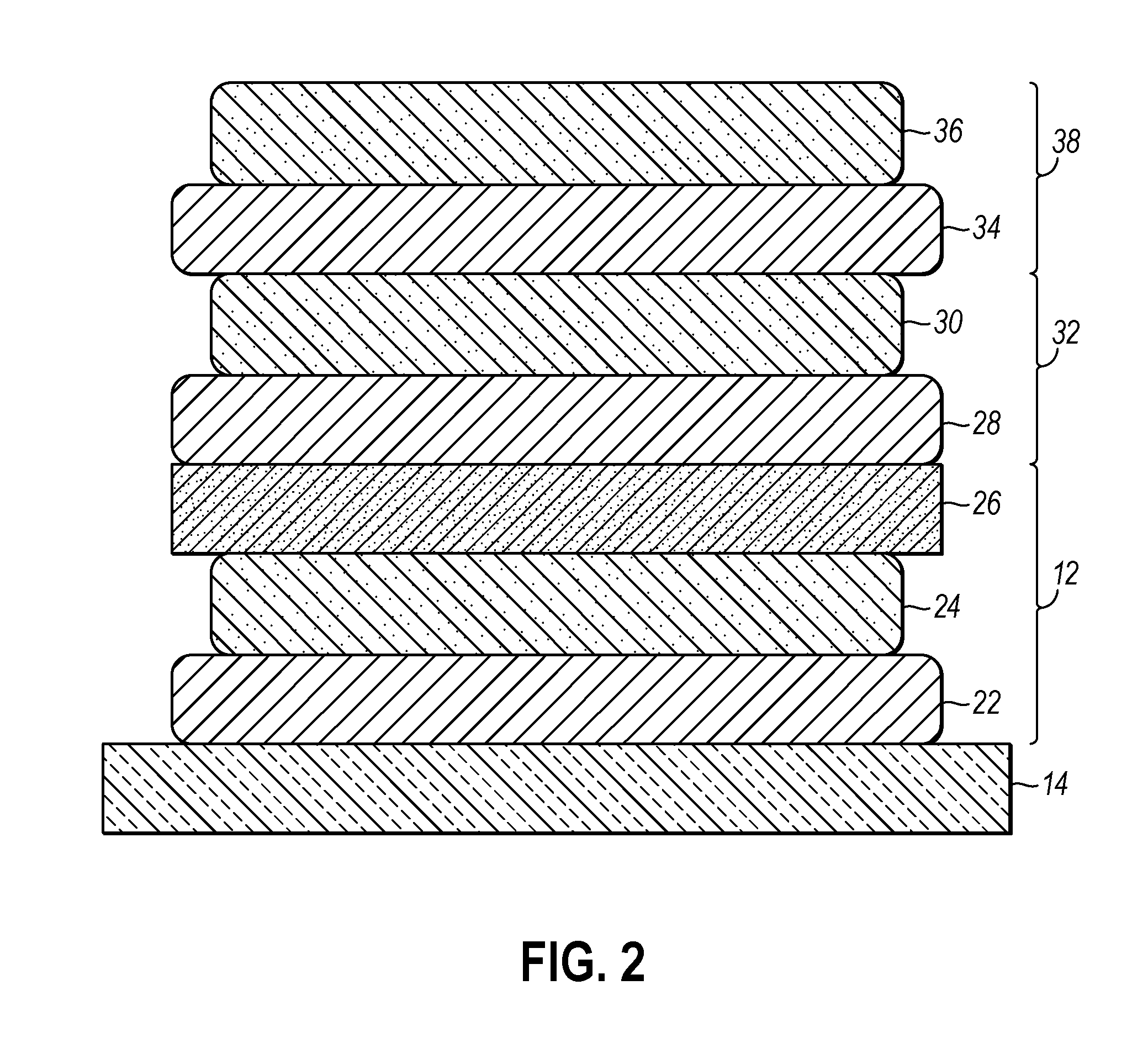

ActiveUS20120126920A1Shielding materialsChemical vapor deposition applicationSimple Organic CompoundsOrganic base

An organic-based magnet is formed by molecular layer deposition (MLD) of a first compound and MLD of a second compound. The first or second compound containing a metal-containing compound. The first and second compounds being reactive with each other to form a first layer organic-based magnet. A laminate composite includes a first monolayer including a metal bonded to a magnet forming organic compound. A second monolayer may be in direct contact with the first monolayer. One of the first monolayer and the second monolayer having an induced magnetization when exposed to a magnetic field. A device includes the laminate composite and a nonmagnetic film thereon. A method of making an organic magnet on a substrate in a vacuum chamber includes depositing a first layer of metal-containing compound on the substrate by MLD.

Owner:THE OHIO STATES UNIV

Magnetic sheet and wireless power receiving device comprising same

InactiveCN109690707AImprove adhesionImprove permeabilityBatteries circuit arrangementsTransformersElectric forceEngineering

A magnetic sheet according to an embodiment comprises: a first magnetic sheet portion comprising a first surface; a second magnetic sheet portion comprising a second surface that faces the first surface; and an attachment portion arranged between the first surface and the second surface, wherein the attachment portion may comprise a plurality of magnetic particles and a coating layer that is coated with the plurality of magnetic particles and comprises an organic material.

Owner:SCRAMOGE TECH LTD

Popular searches

Semiconductor/solid-state device manufacturing Digital storage Bulk negative resistance effect devices Pulse shaping Galvano-magnetic device manufacture/treatment Organic/organo-metallic films Semiconductor devices Record information storage Recording/reproducing/erasing methods Substrate/intermediate layers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com