Nuclear composite film for magnetic, nonmagnetic and magnetic multilayer film and use thereof

A multi-layer film, non-magnetic technology, applied in the direction of magnetic film, organic/organic metal film, magnetic objects, etc., can solve the problems of high production cost and low yield, and achieve low price, low cost and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

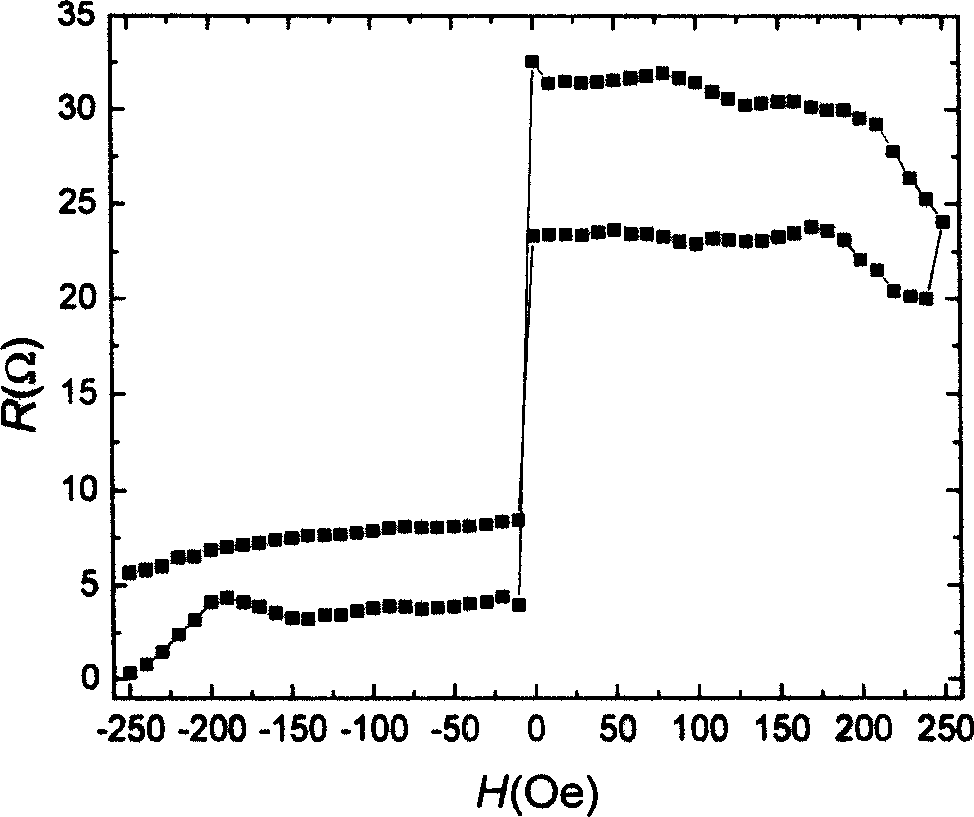

Image

Examples

Embodiment 1

[0039] First, the lower electrode layer and the bottom layers are grown in sequence by magnetron sputtering under high vacuum, and its structure is: Ta(5nm) / Cu(20nm) / Ni-Fe(5nm) / Ir-Mn(10nm) / Co -Fe-B (4nm); then stearic acid (C 17 H 35 COOH)LB film is used as the isolation layer; finally, the upper layers are grown sequentially by magnetron sputtering under high vacuum: Co-Fe-B(4nm) / Ni-Fe(5nm) / Cu(20nm) / Ta(5nm) .

[0040] After the sample is grown, ultraviolet exposure and ion beam etching are used to obtain the required sample unit with a certain shape and size. The unit of the composite magnetic multilayer film can be used for magnetic sensitivity, electric sensitivity, light sensitivity, or gas sensitivity. The device cell of the detector or the storage cell of Magnetic Random Access Memory (MRAM).

Embodiment 2

[0042] First, the lower electrode layer and the bottom layers are grown in sequence by magnetron sputtering under high vacuum, and its structure is: Ta(5nm) / Cu(20nm) / Ni-Fe(5nm) / Ir-Mn(10nm) / Co -Fe(4nm) / Ru(0.9nm) / Co-Fe(4nm); then the fatty acid [CH 3 (CH 2 ) 14 COO] 2 The Cd LB film was used as the isolation layer; finally, the upper layers were grown sequentially by magnetron sputtering under high vacuum: Co-Fe(4nm) / Ru(0.9nm) / Co-Fe(4nm) / Cu(20nm) / Ta (5nm).

[0043] After the sample has grown, the follow-up work is similar to that in Example 1, which is omitted here.

Embodiment 3~13

[0045] According to the methods of Examples 1 and 2, core composite films for magnetic / nonmagnetic / magnetic multilayer films with different LB films as intermediate spacers (functional layers) were prepared. The types and properties of the LB films are listed in Table 1.

[0046] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com