Polymer flexible conductive film and preparation method thereof

A flexible conductive and polymer technology, used in magnetic films, equipment for manufacturing conductive/semiconducting layers, and cable/conductor manufacturing, etc. and other problems, to achieve the effect of low material cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

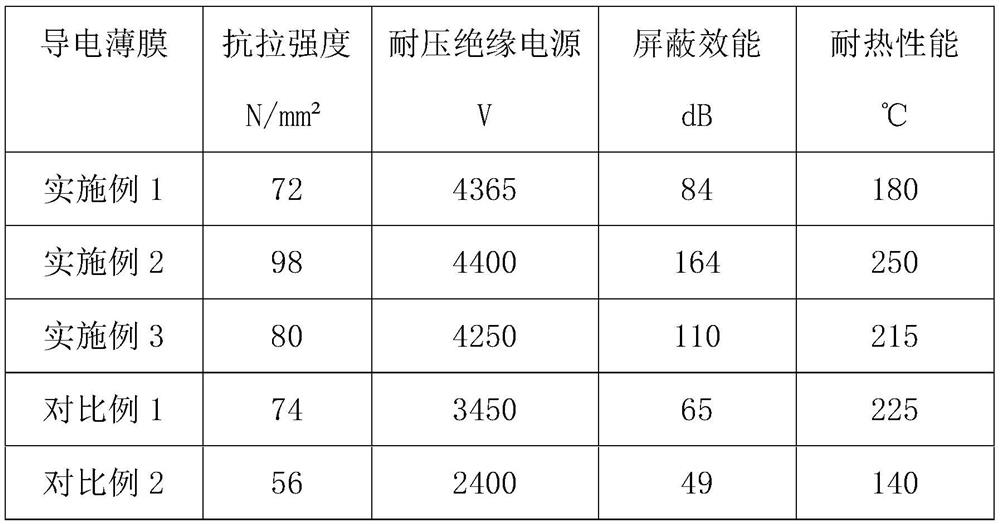

Examples

Embodiment 1

[0028] A polymer flexible conductive film, comprising a generation layer and a molding layer,

[0029] The resulting layer mainly includes the following components according to the mass fraction ratio: 3 parts of 3,4-ethylenedioxythiophene; 5 parts of polystyrenesulfonic acid; 5 parts of ferric oxide; 2 parts of tin oxide; 1 part of indium oxide; Magnesium 3 parts;

[0030] The molding layer mainly includes the following components: 8 parts of organic salt solution; 3 parts of reinforcing agent.

[0031] The organic salt solution is specifically 4-pyridine acetate hydrochloride,

[0032] The reinforcing agent is specifically a graphite molecular solution.

[0033] A method for preparing a polymer flexible conductive film, comprising the steps of:

[0034] S1: Clean and dry the surface of the substrate;

[0035] S2: After uniformly mixing 3,4-ethylenedioxythiophene, polystyrene sulfonic acid and ferric oxide particles, prepare a basic film on the surface of the collection b...

Embodiment 2

[0045] A polymer flexible conductive film, comprising a generation layer and a molding layer,

[0046] The resulting layer mainly includes the following components according to the mass fraction ratio: 8.5 parts of 3,4-ethylenedioxythiophene; 7 parts of polystyrenesulfonic acid; 9 parts of ferric oxide; 5 parts of tin oxide; 3 parts of indium oxide; Magnesium 4 parts;

[0047] The molding layer mainly includes the following components: 10 parts of organic salt solution; 5.5 parts of reinforcing agent.

[0048] The organic salt solution is specifically 4-pyridine acetate hydrochloride.

[0049] The reinforcing agent is specifically a graphite molecular solution.

[0050] A method for preparing a polymer flexible conductive film, comprising the steps of:

[0051] S1: Clean and dry the surface of the substrate;

[0052] S2: After uniformly mixing 3,4-ethylenedioxythiophene, polystyrene sulfonic acid and ferric oxide particles, prepare a basic film on the surface of the collec...

Embodiment 3

[0062] A polymer flexible conductive film, comprising a generation layer and a molding layer,

[0063] The resulting layer mainly includes the following components according to the mass fraction ratio: 10 parts of 3,4-ethylenedioxythiophene; 9 parts of polystyrenesulfonic acid; 12 parts of ferric oxide; 8 parts of tin oxide; 5 parts of indium oxide; Magnesium 6 parts;

[0064] The molding layer mainly includes the following components: 12 parts of organic salt solution; 8 parts of reinforcing agent.

[0065] The organic salt solution is specifically 4-pyridine acetate hydrochloride.

[0066] The reinforcing agent is specifically a graphite molecular solution.

[0067] A method for preparing a polymer flexible conductive film, comprising the steps of:

[0068] S1: Clean and dry the surface of the substrate;

[0069] S2: After uniformly mixing 3,4-ethylenedioxythiophene, polystyrene sulfonic acid and ferric oxide particles, prepare a basic film on the surface of the collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com