Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84results about "Evaporation application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

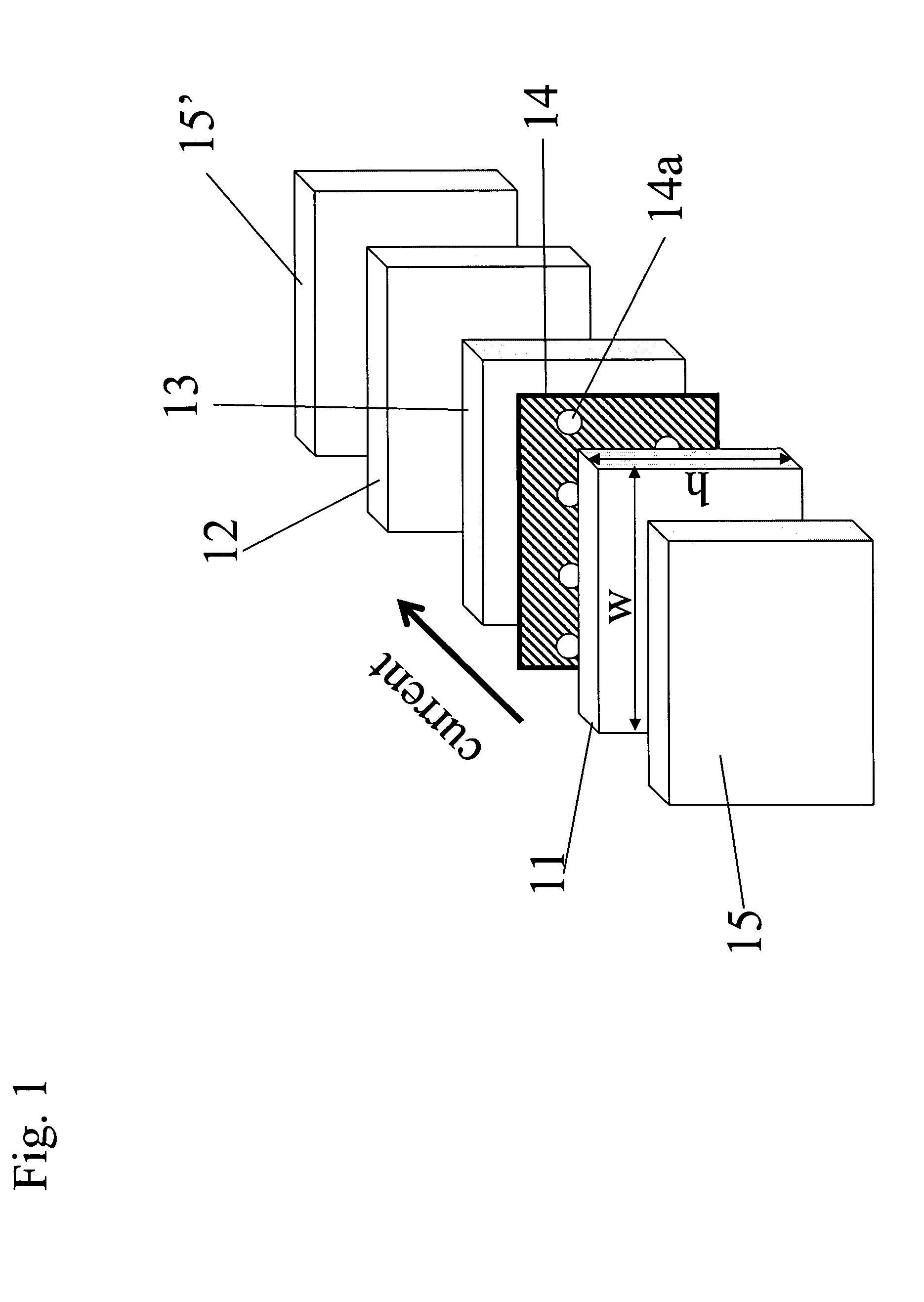

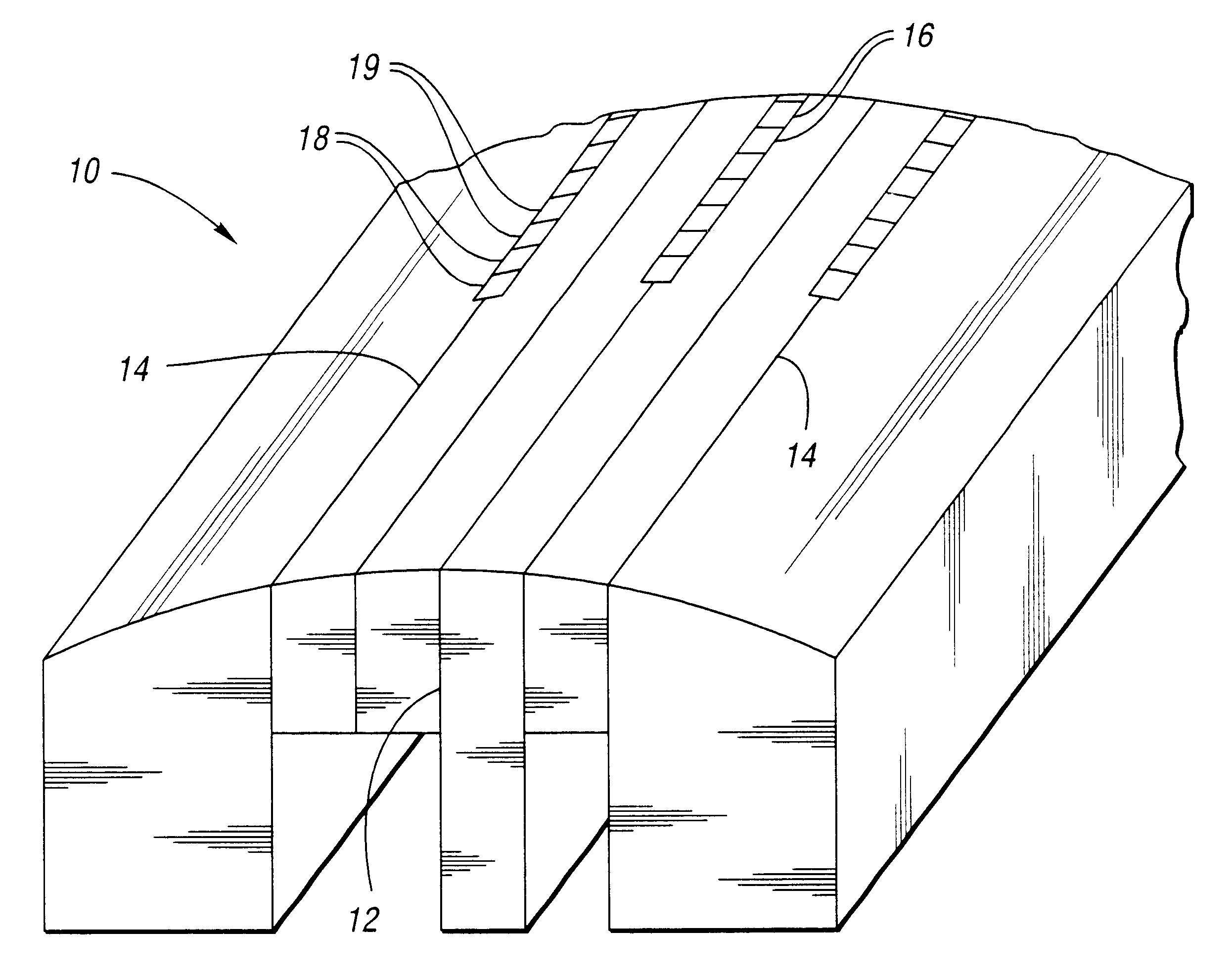

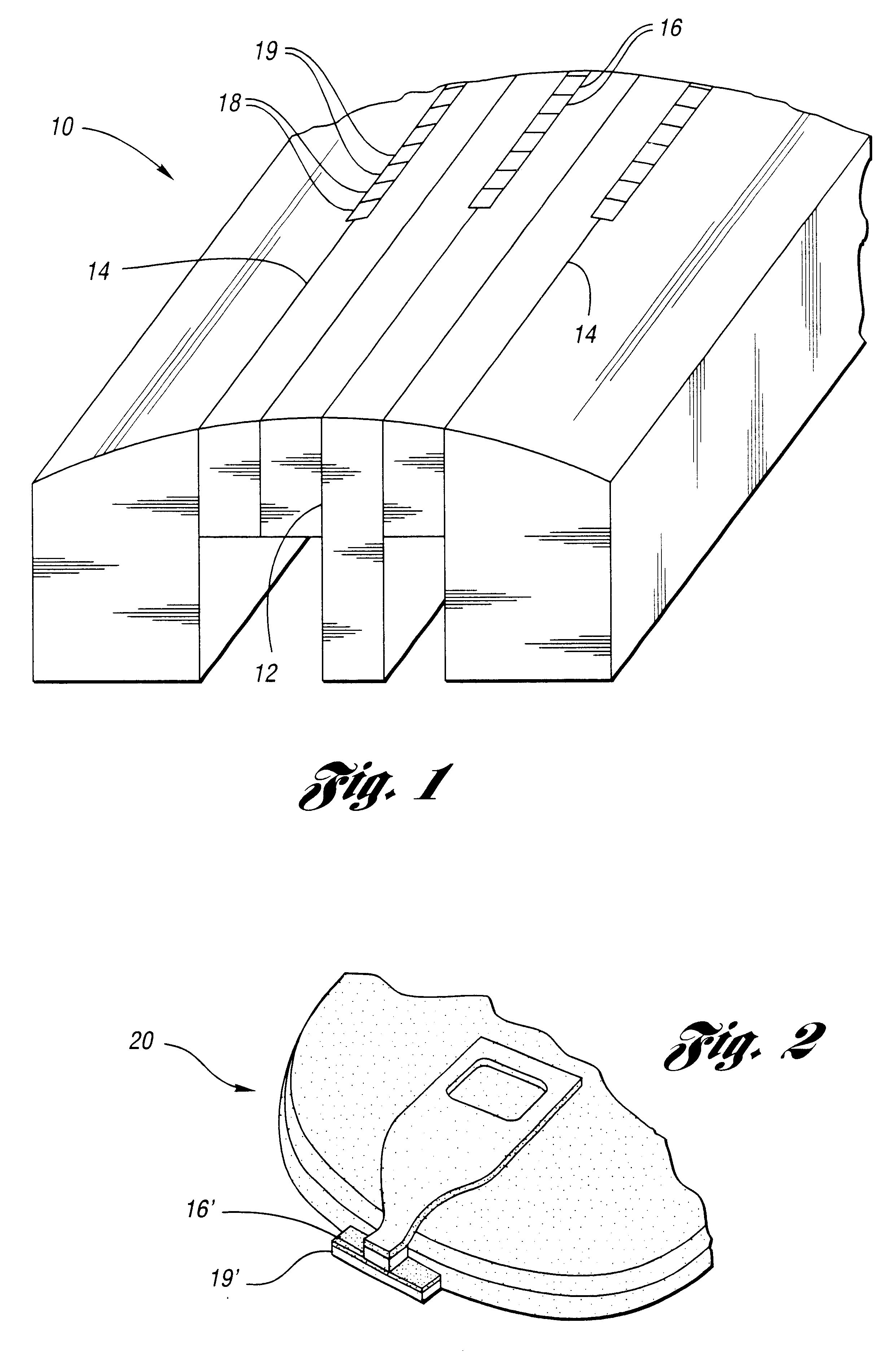

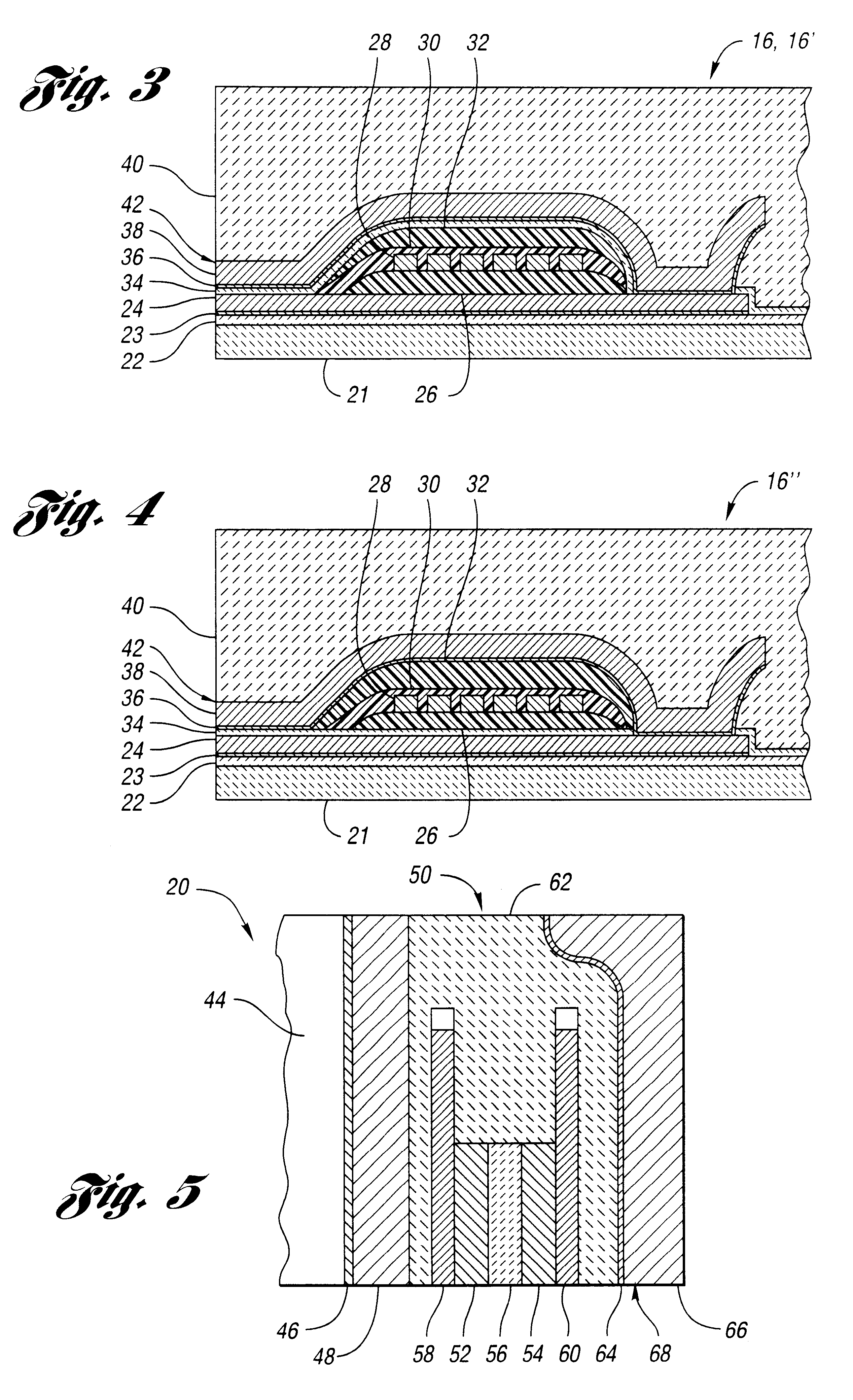

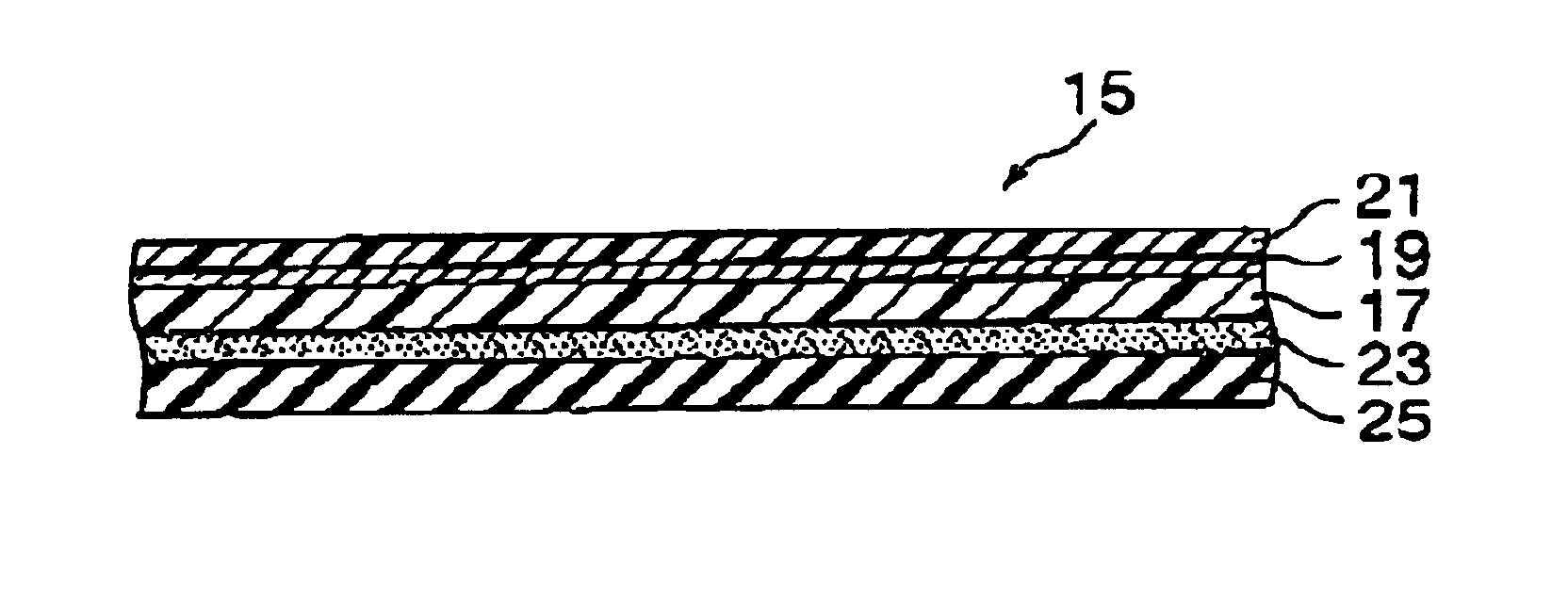

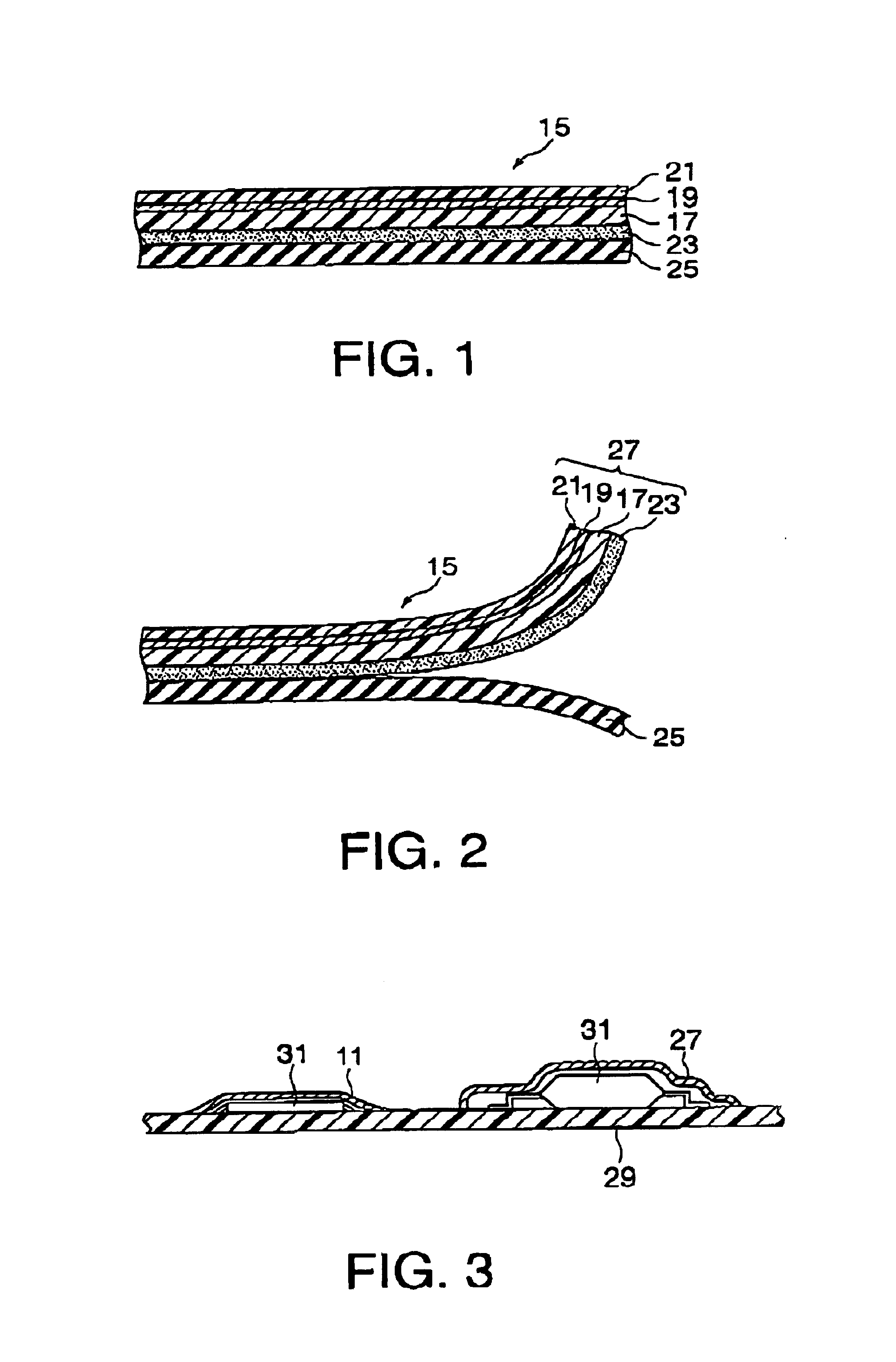

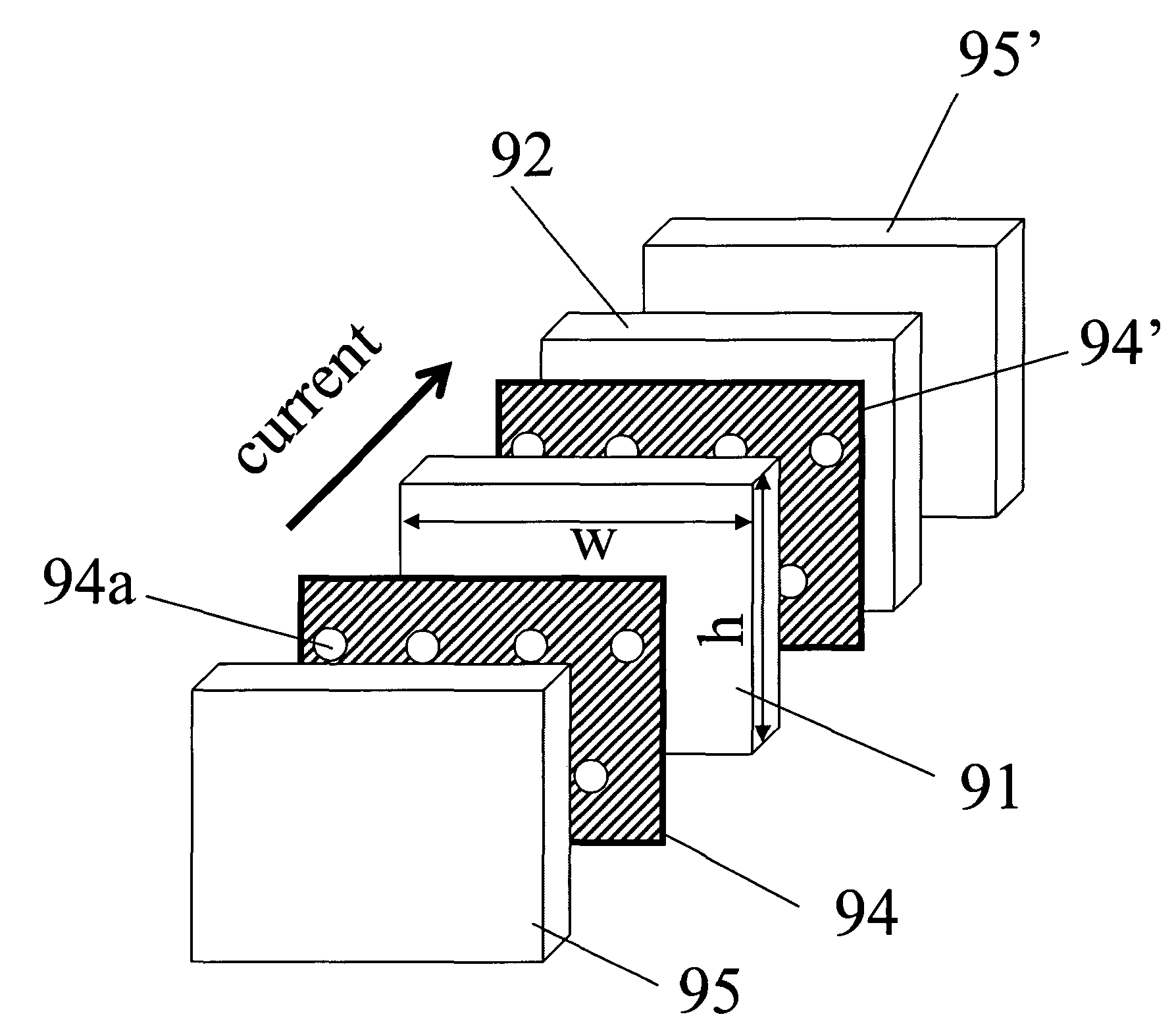

CPP spin-valve element

InactiveUS20050002126A1Increase resistanceLower average currentMagnetic-field-controlled resistorsSolid-state devicesCurrent limitingCoupling

A CPP spin-valve element formed on a substrate including a free layer structure including at least one ferromagnetic layer and a pinned layer structure including at least one ferromagnetic layer. The free layer is magnetically softer than the pinned layer. A thin non-magnetic spacer layer structure configured to separate the free layer and the pinned layer is provided in order to prevent a magnetic coupling between the free and pinned layer structures, and to allow an electric current to go there through. At least two current-confining (CC) layer structures including at least two parts having significantly different current conductivities are incorporated therein.

Owner:UNIVERSITY OF ALABAMA +1

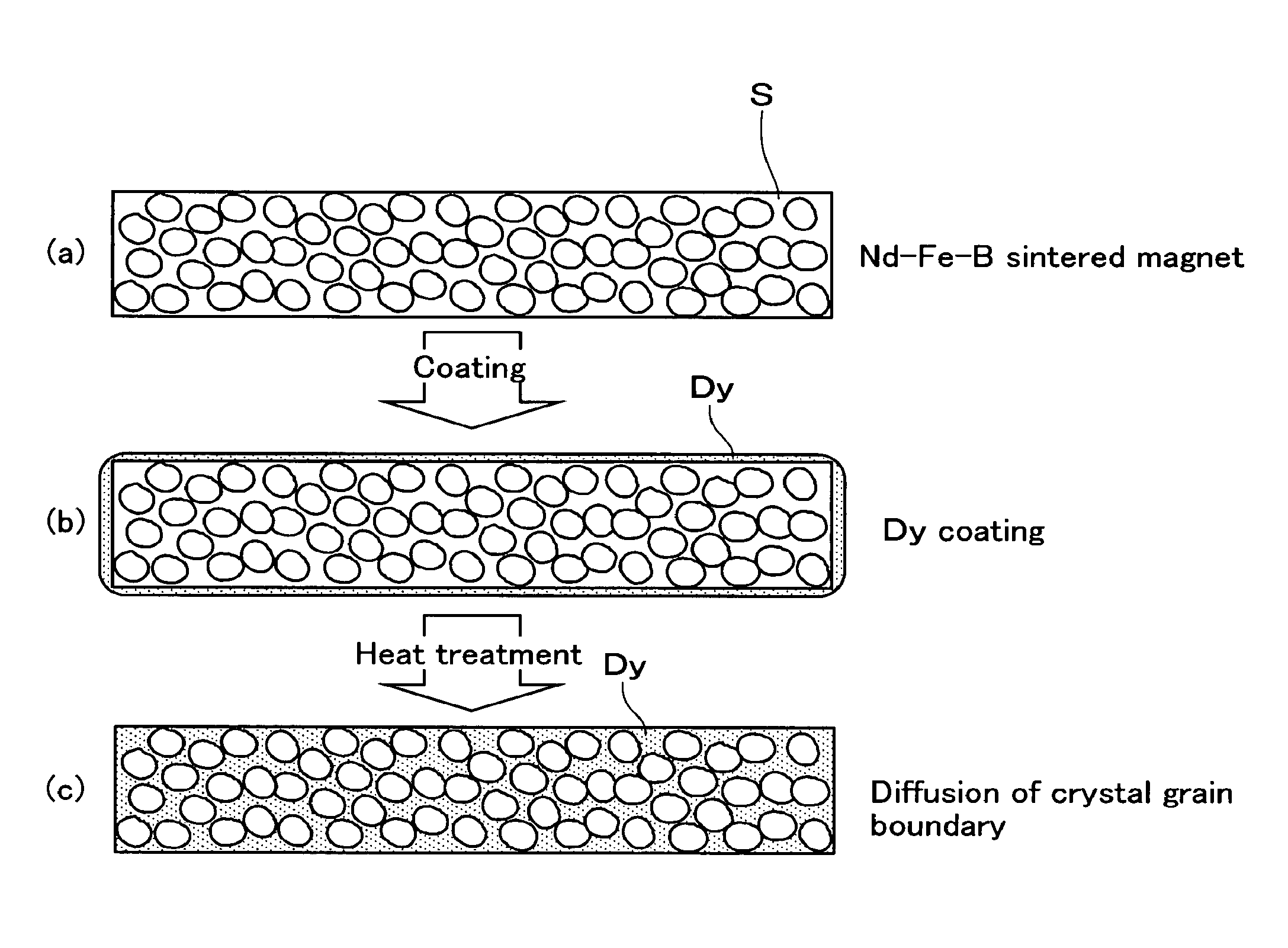

Rare earth sintered magnet and process for producing the same

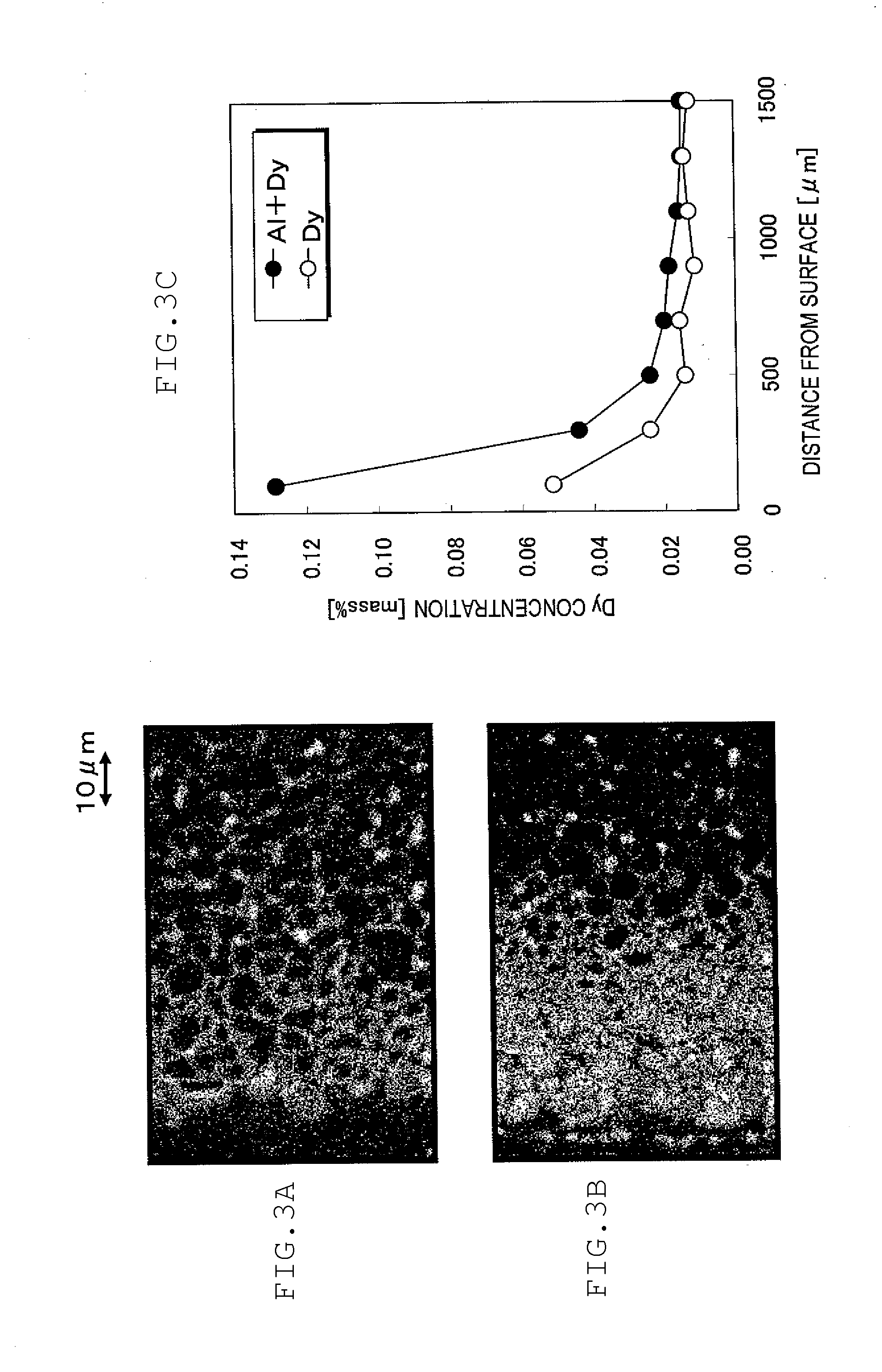

ActiveCN101006534APhenomena that promote grain boundary diffusionEfficient replacementLiquid applicationPermanent magnetsRare-earth elementSintered magnets

Owner:HITACHI METALS LTD

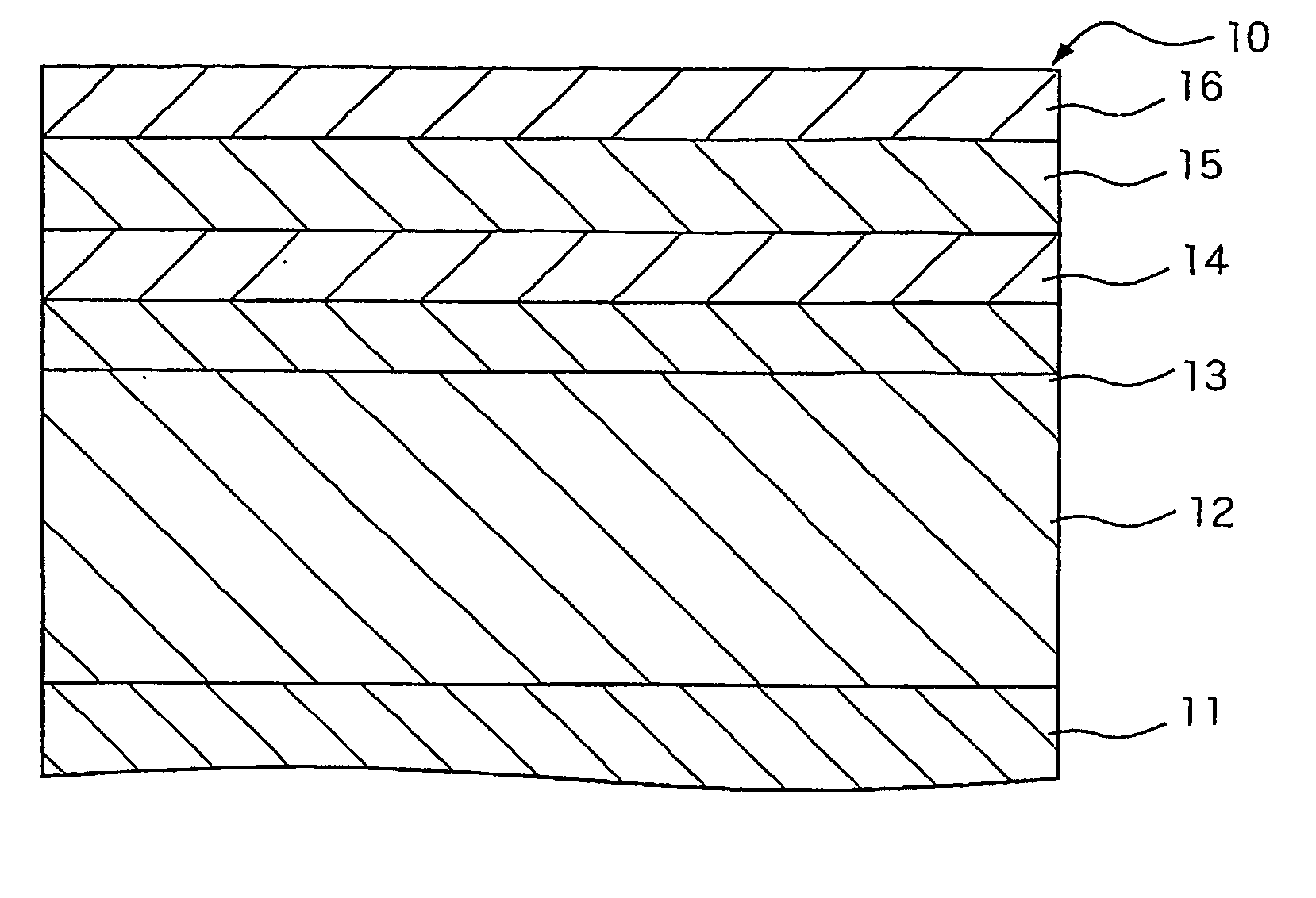

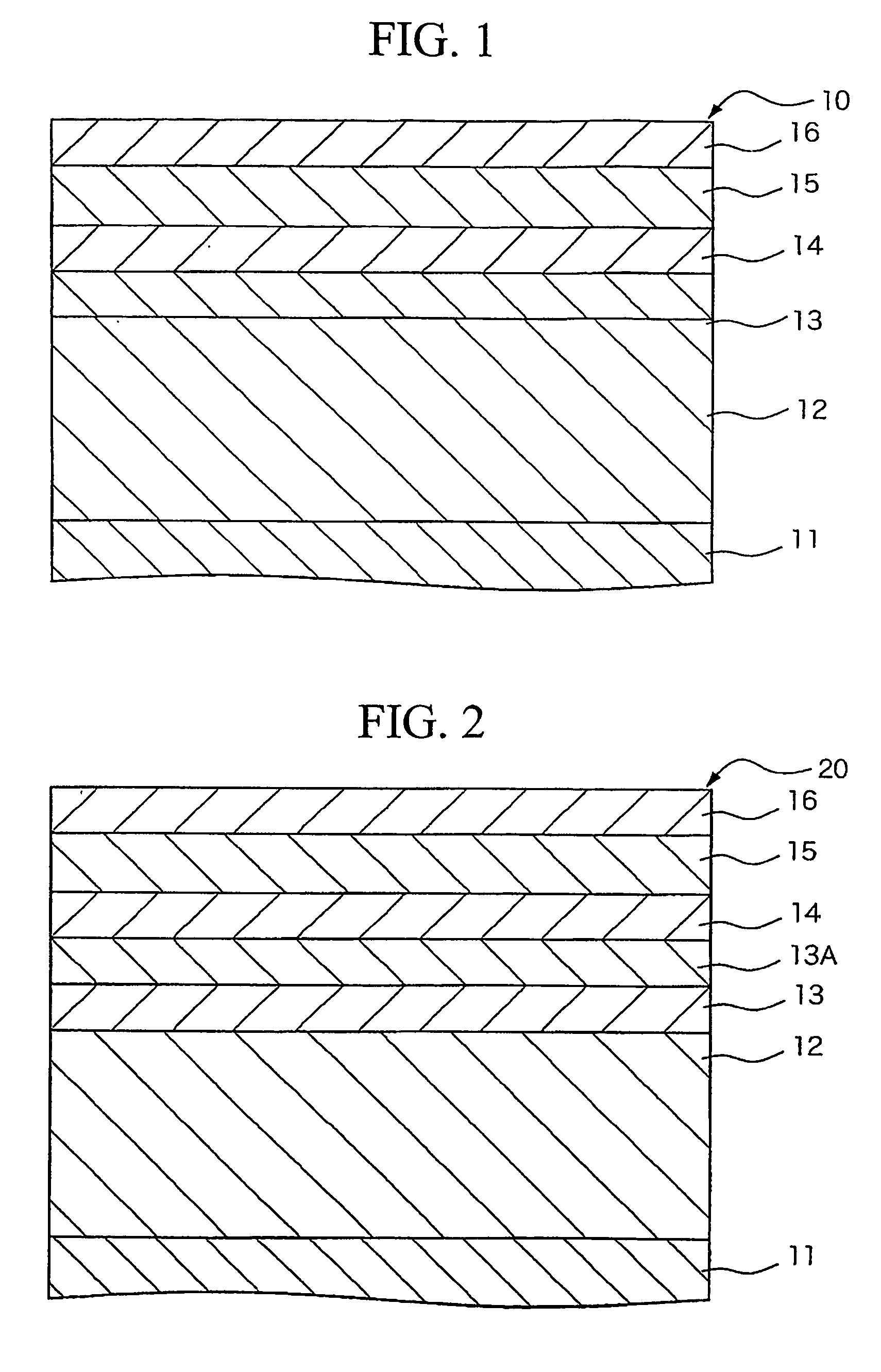

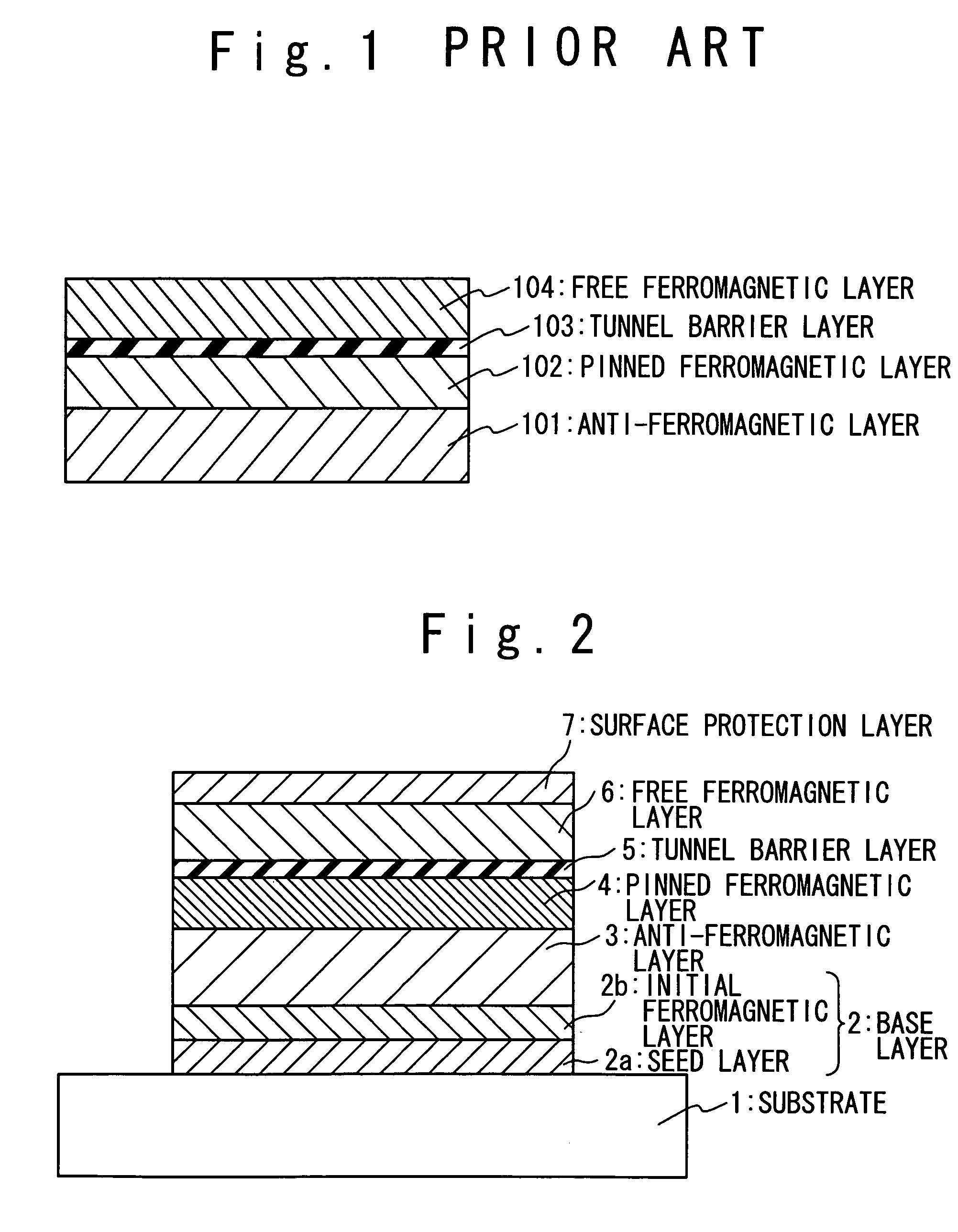

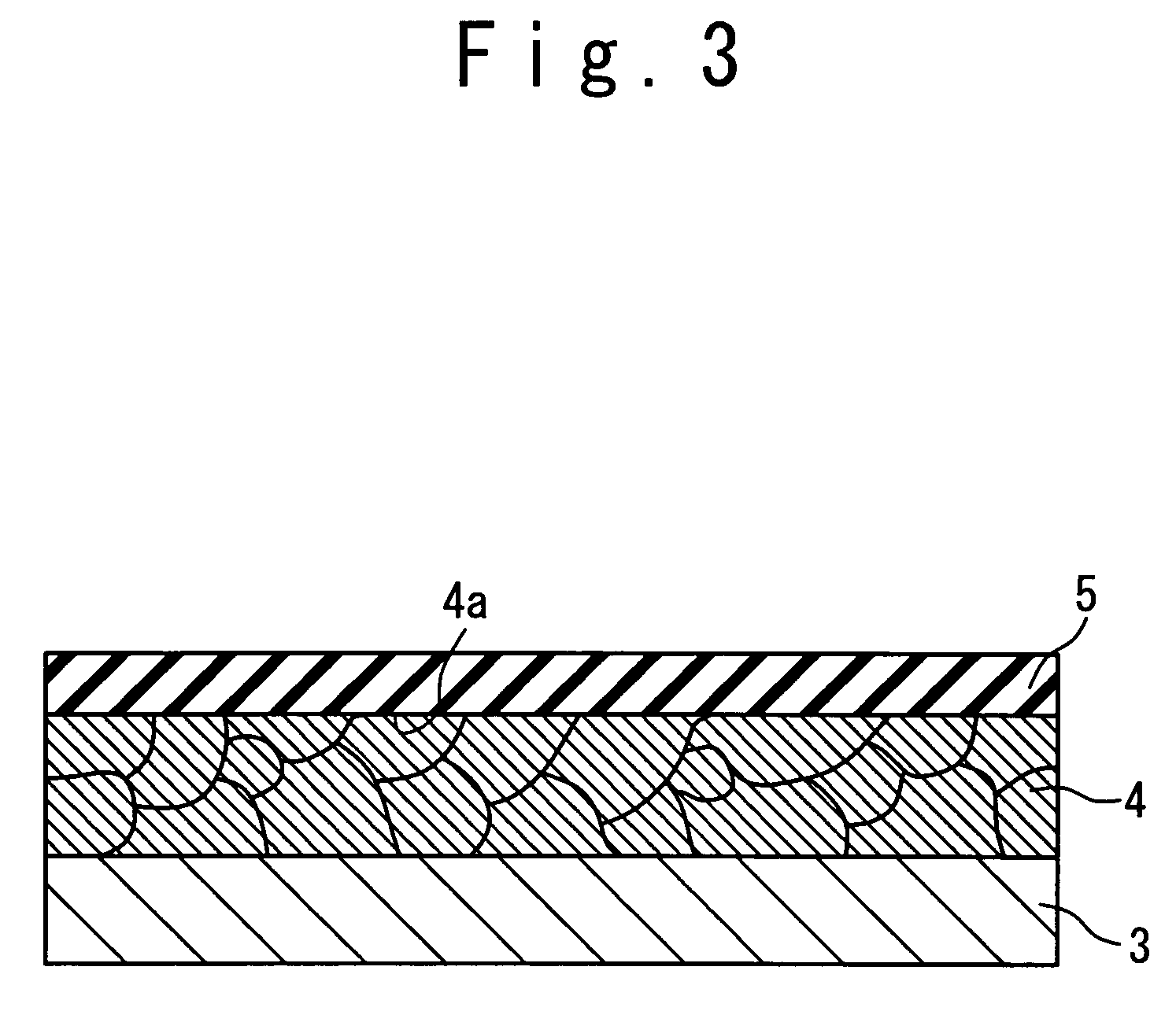

Magnetoresistive device and method for manufacturing same

ActiveUS20050219769A1Improve heat resistanceInhibitionNanomagnetismNanoinformaticsHeat resistanceMagnetic reluctance

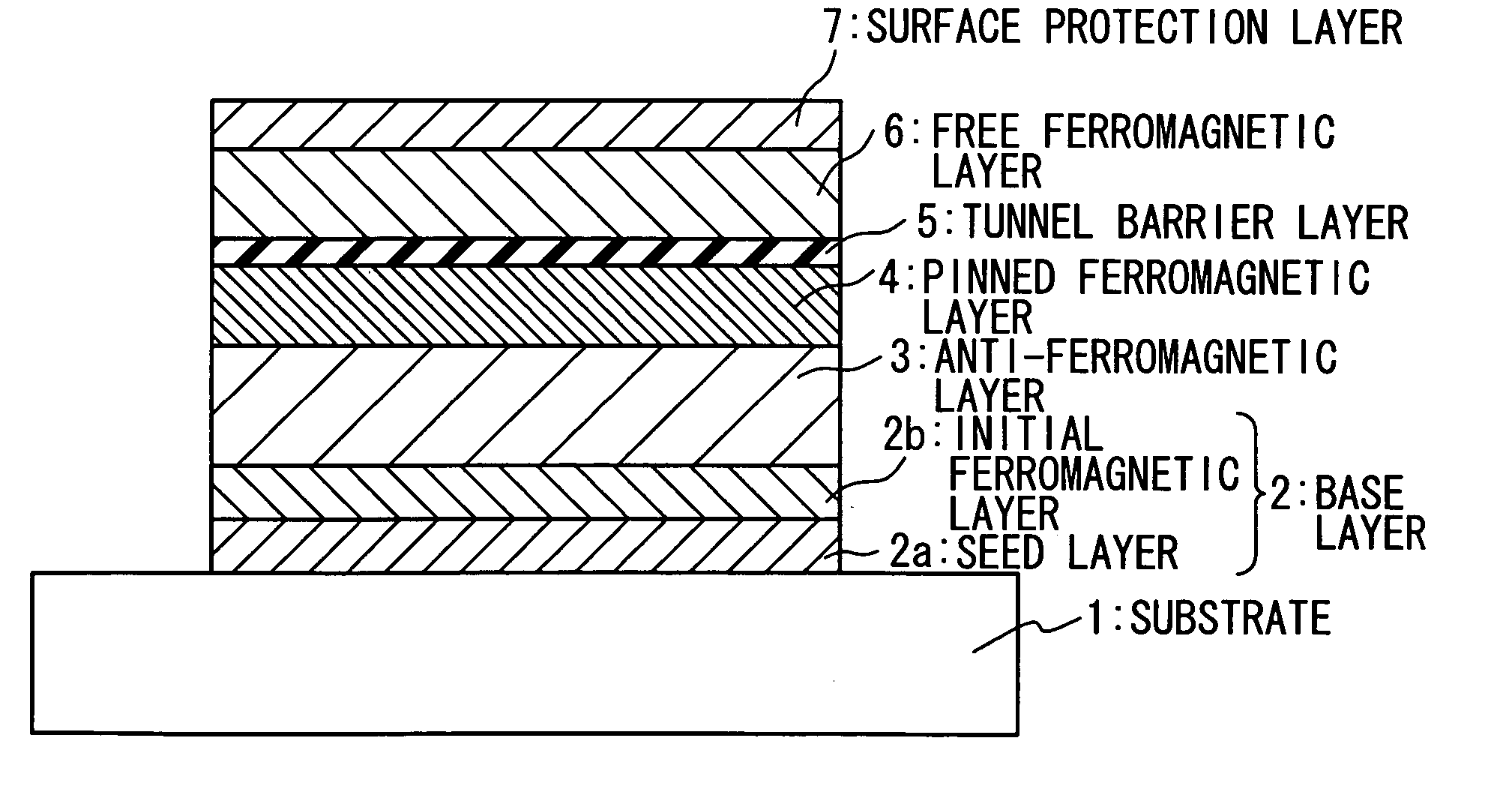

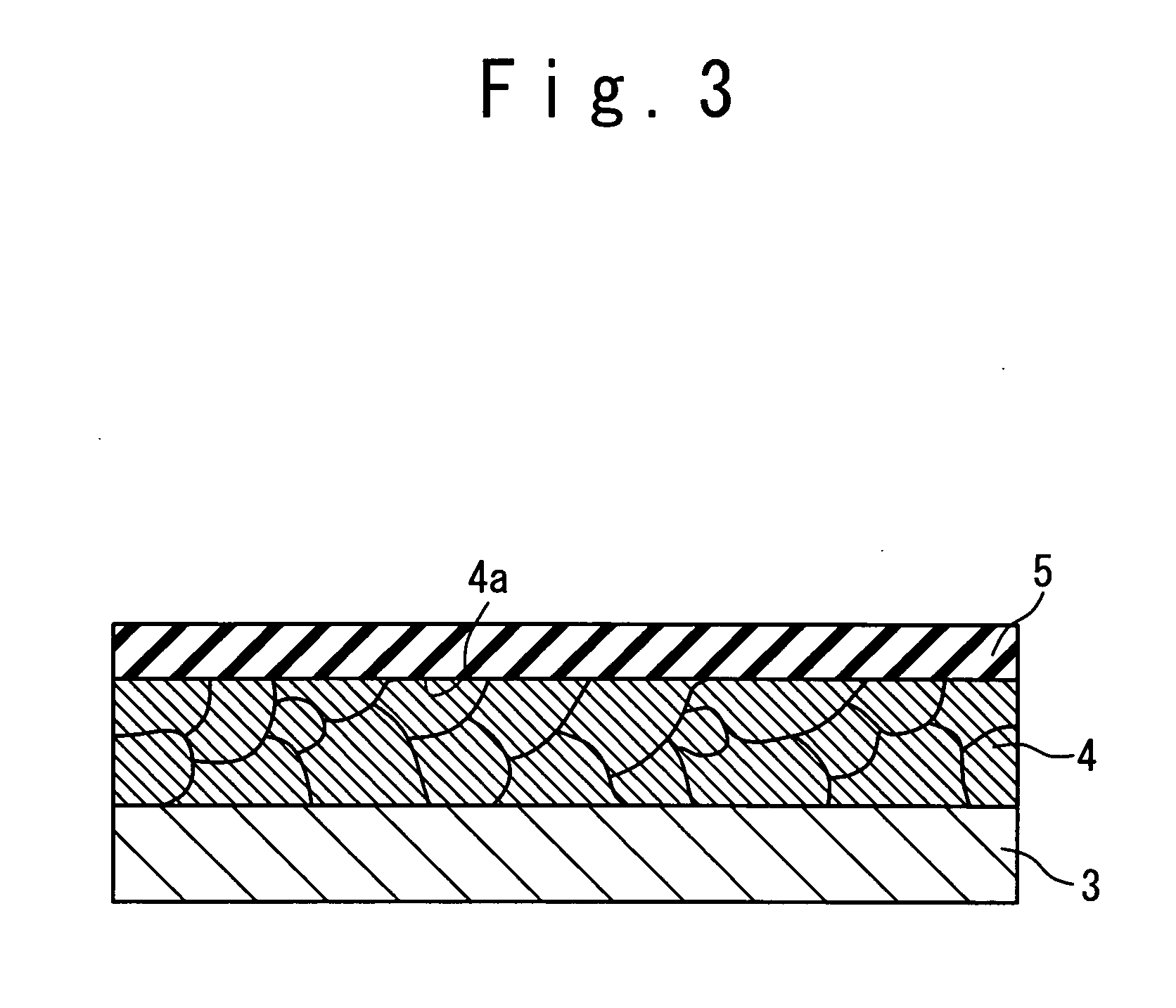

The heat resistance of a magnetic resistance device utilizing the TMR effect is improved. Also, the Neel effect of the magnetic resistance device utilizing the TMR effect is restrained. The magnetic resistance device includes a first ferromagnetic layer formed of ferromagnetic material, a non-magnetic insulative tunnel barrier layer coupled to the first ferromagnetic layer, a second ferromagnetic layer formed of ferromagnetic material and coupled to the tunnel barrier layer, and an anti-ferromagnetic layer formed of anti-ferromagnetic material. The second ferromagnetic layer is provided between the tunnel barrier layer and the anti-ferromagnetic layer. A perpendicular line from an optional position of the surface of the second ferromagnetic layer passes through at least two of the crystal grains of the second ferromagnetic layer.

Owner:NEC CORP

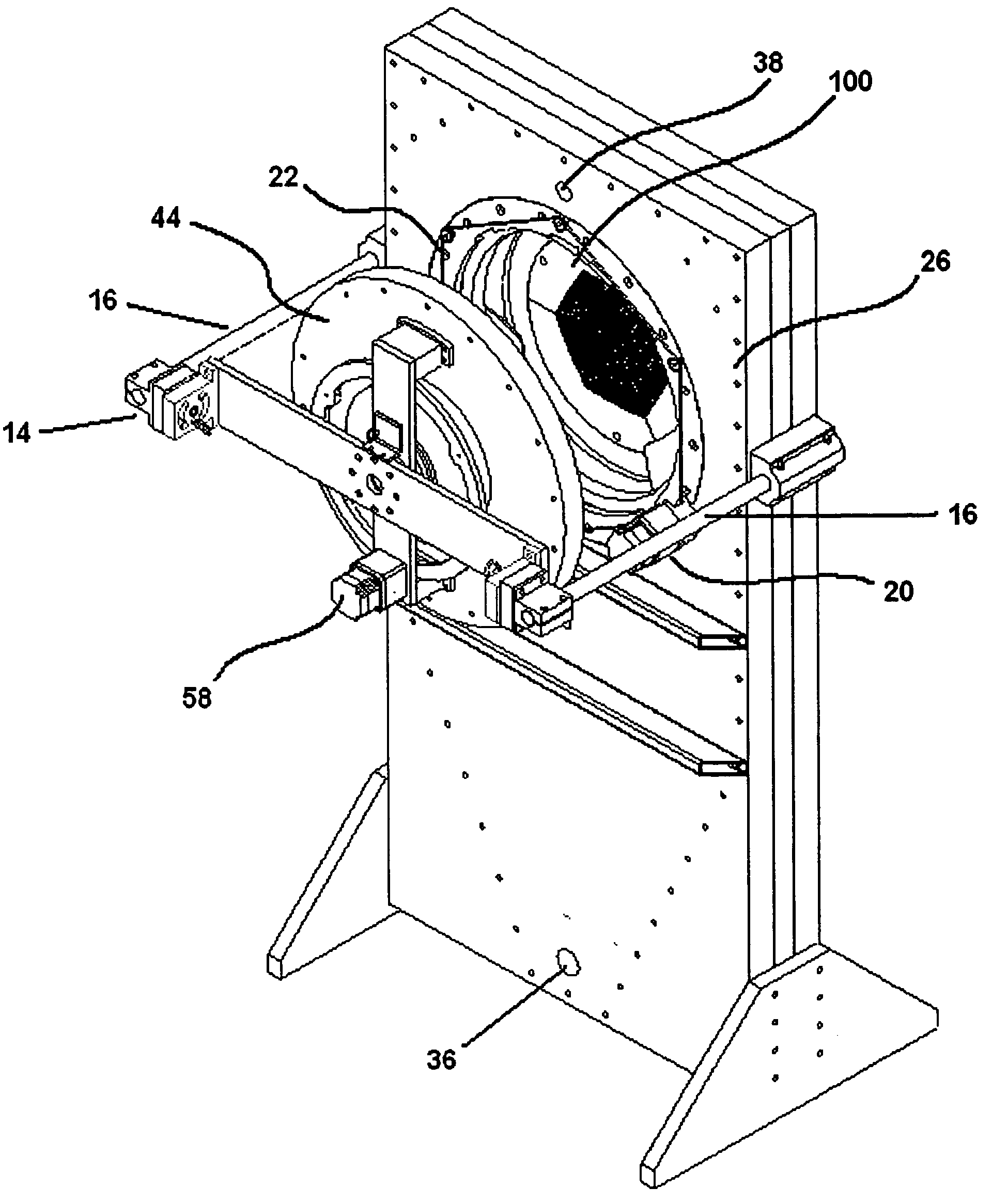

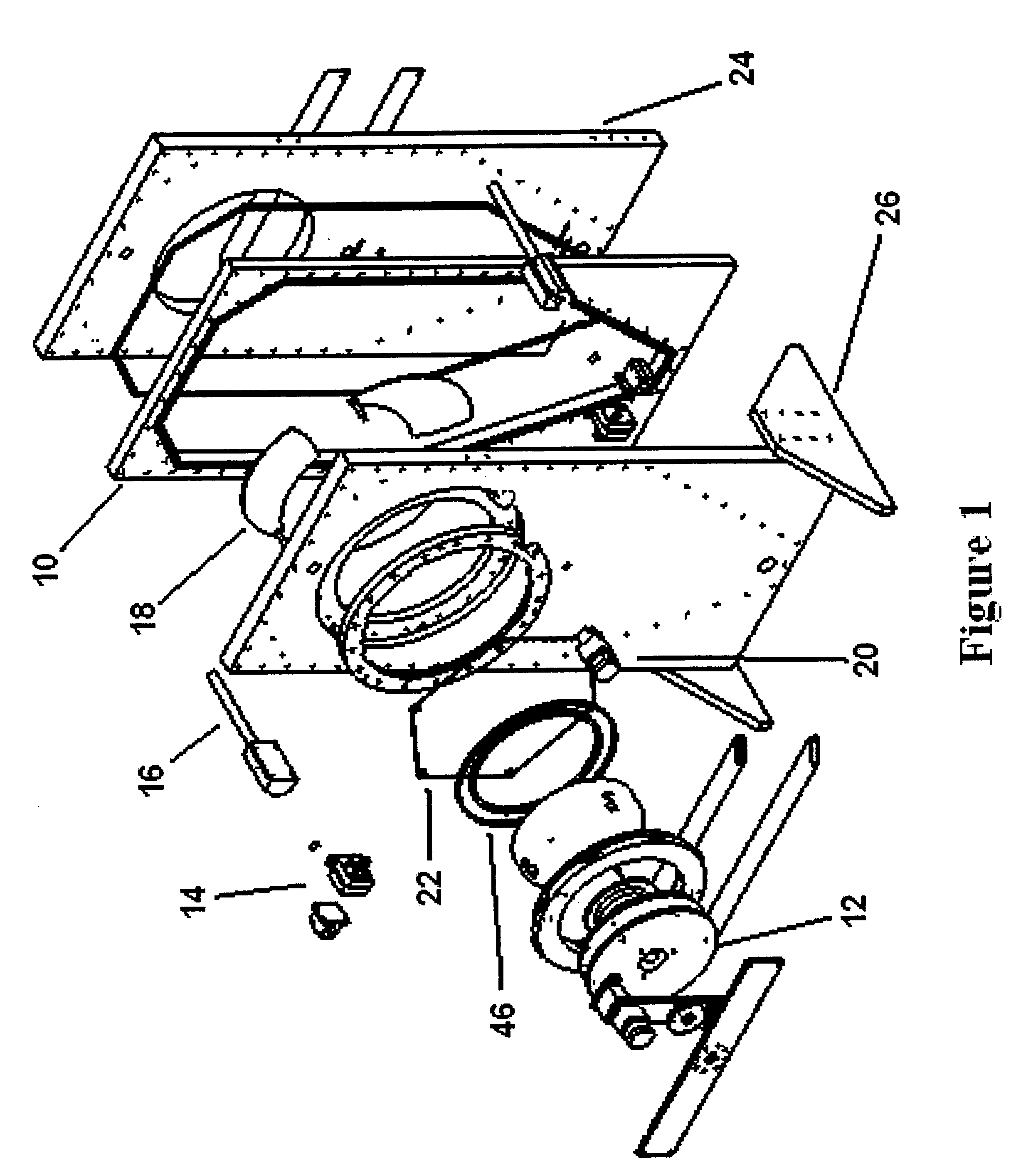

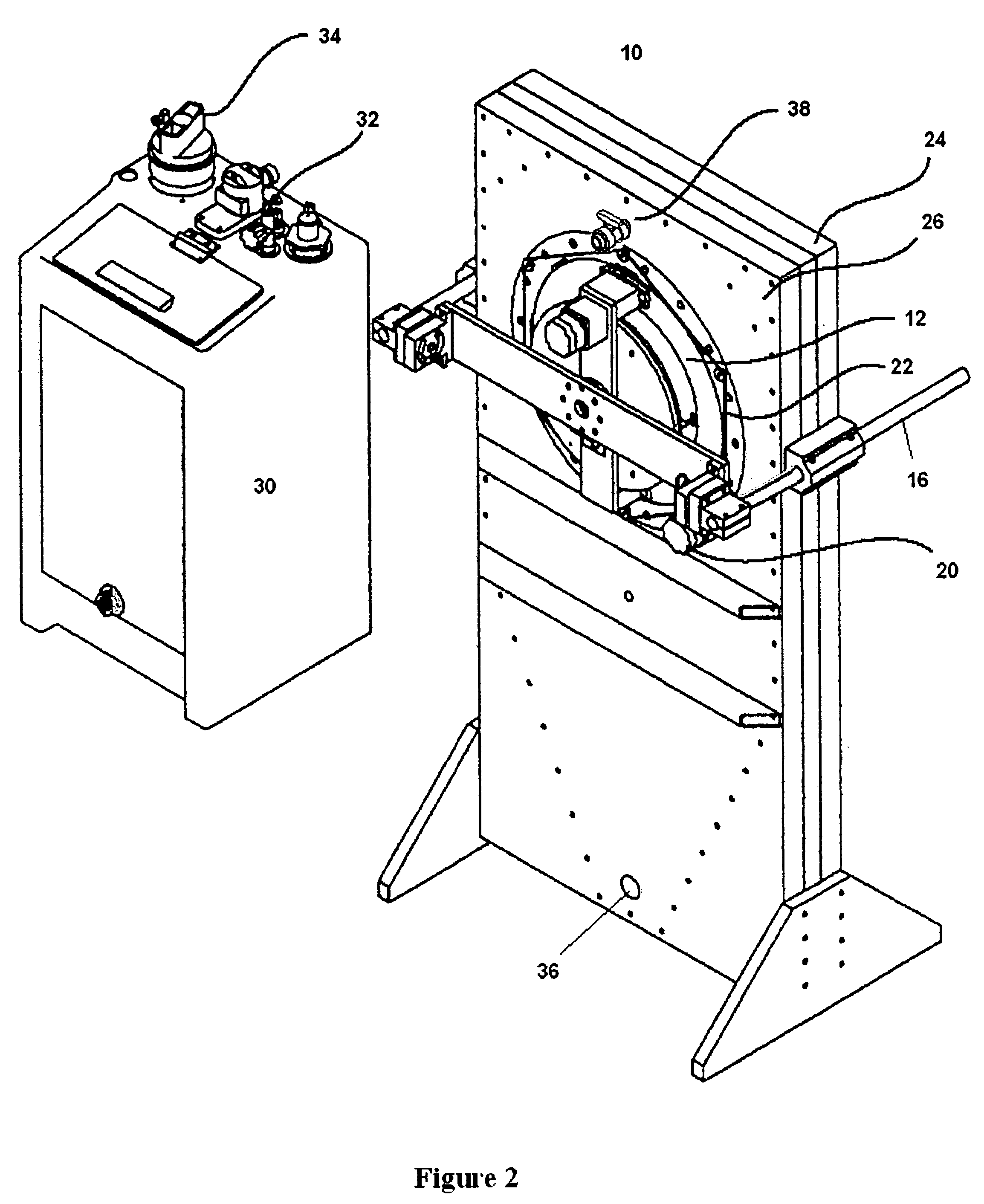

Apparatus and method for highly controlled electrodeposition

An apparatus and method for highly controlled electrodeposition, particularly useful for electroplating submicron structures. Enhanced control of the process provides for a more uniform deposit thickness over the entire substrate, and permits reliable plating of submicron features. The apparatus includes a pressurized electrochemical cell to improve plating efficiency and reduce defects, vertical laminar flow of the electrolyte solution to remove surface gases from the vertically arranged substrate, a rotating wafer chuck to eliminate edge plating effects, and a variable aperture to control the current distribution and ensure deposit uniformity across the entire substrate. Also a dynamic profile anode whose shape can be varied to optimize the current distribution to the substrate. The anode is advantageously able to use metallic ion sources and may be placed close to the cathode thus minimizing contamination of the substrate.

Owner:COOK BIOTECH +1

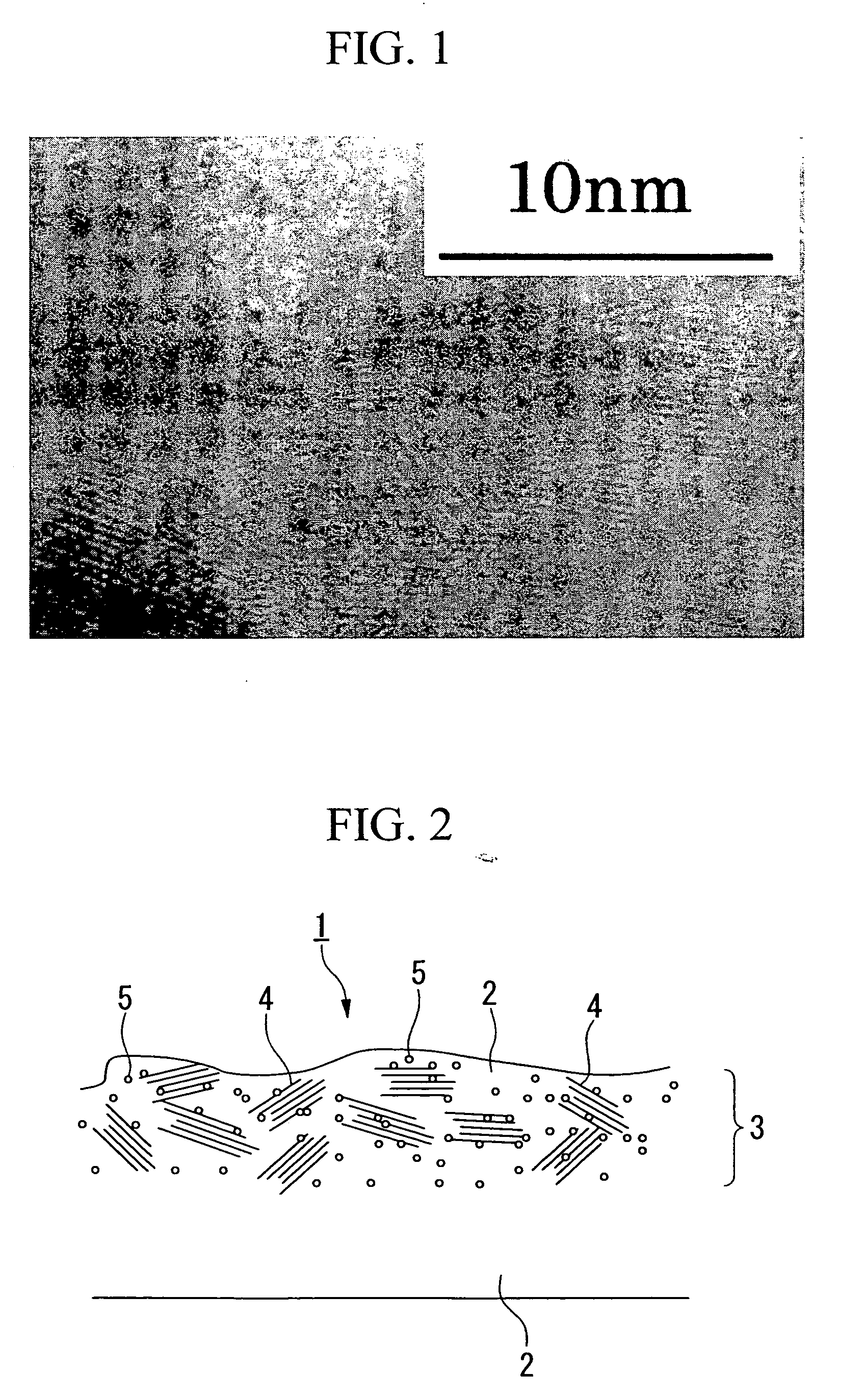

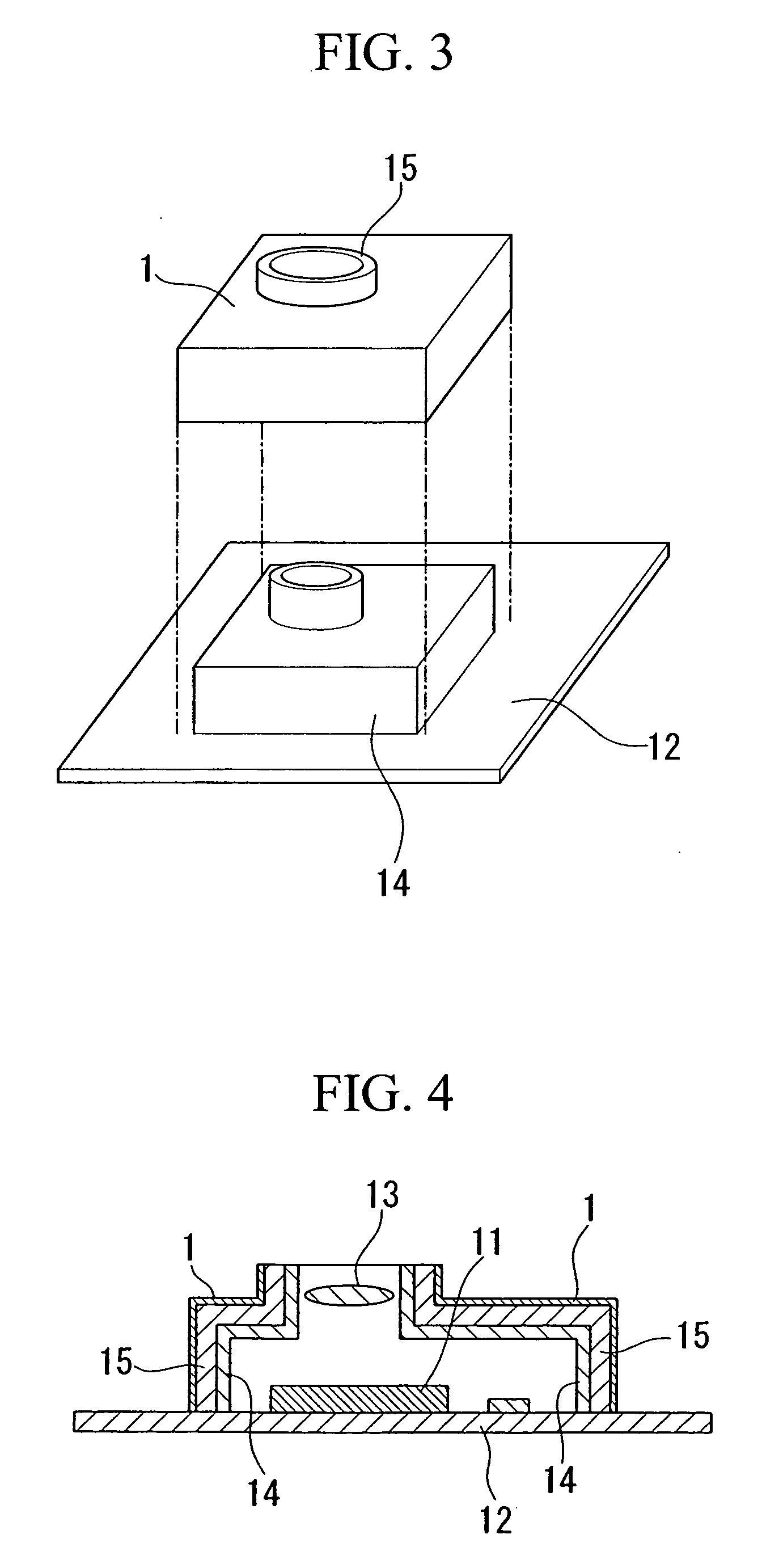

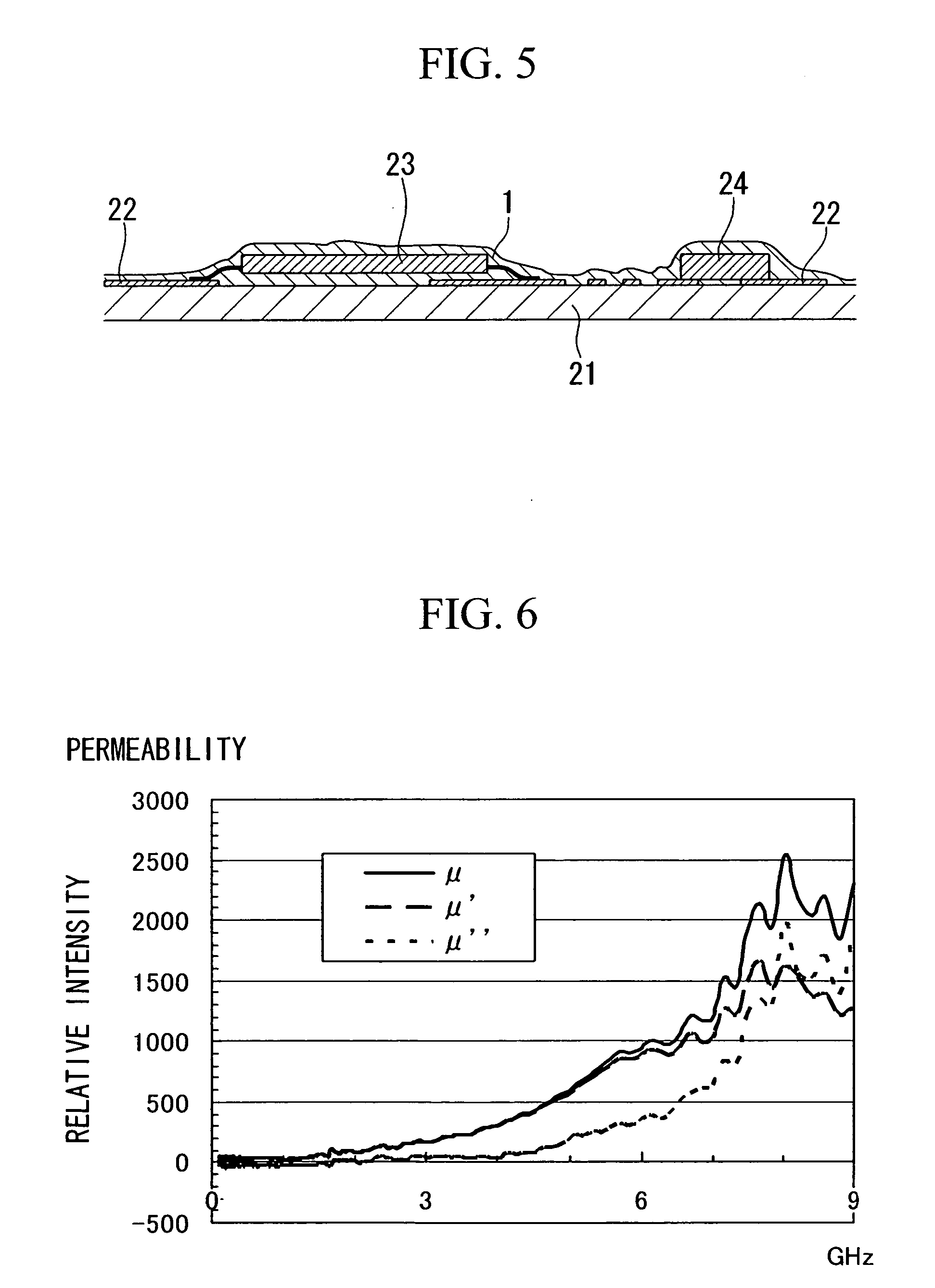

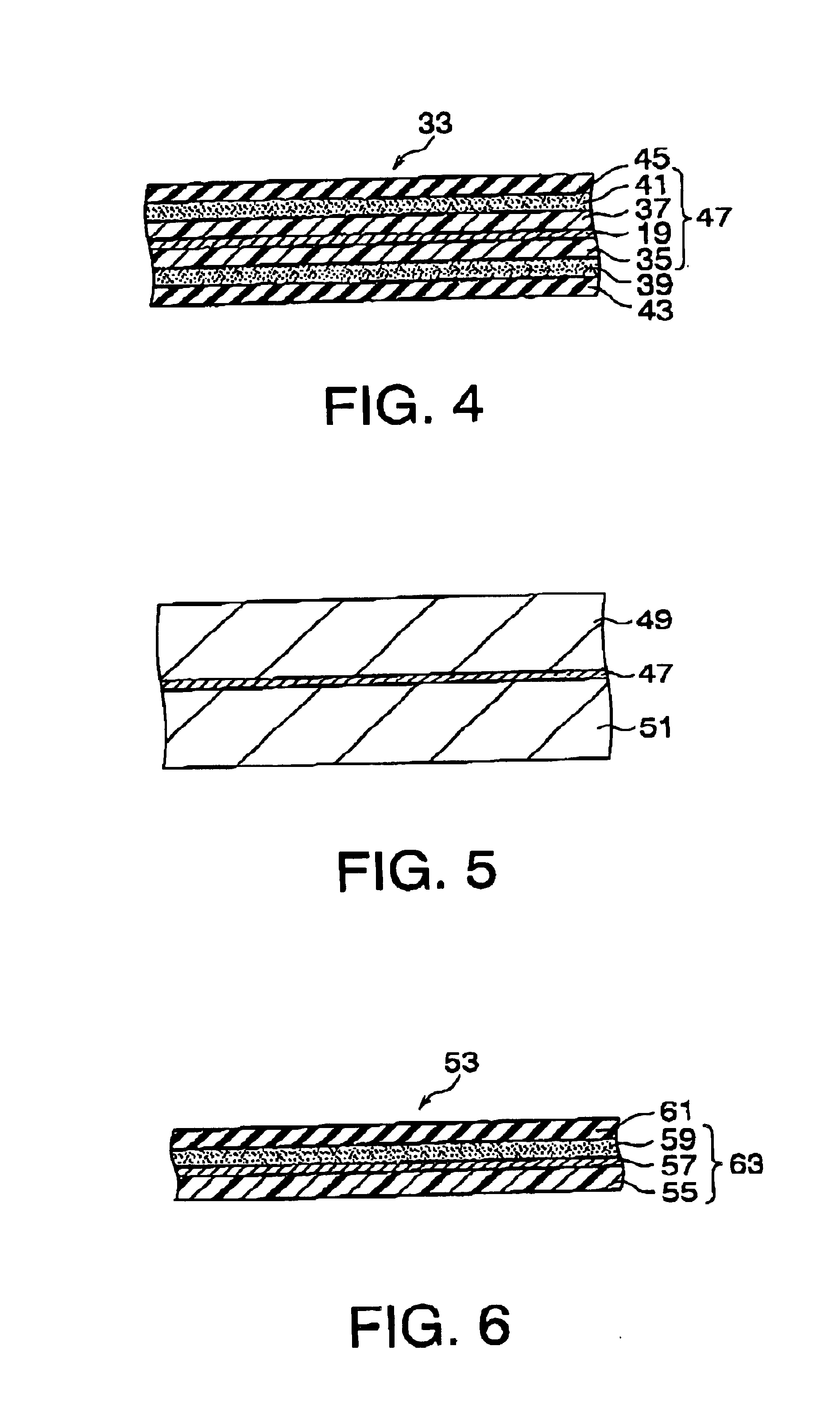

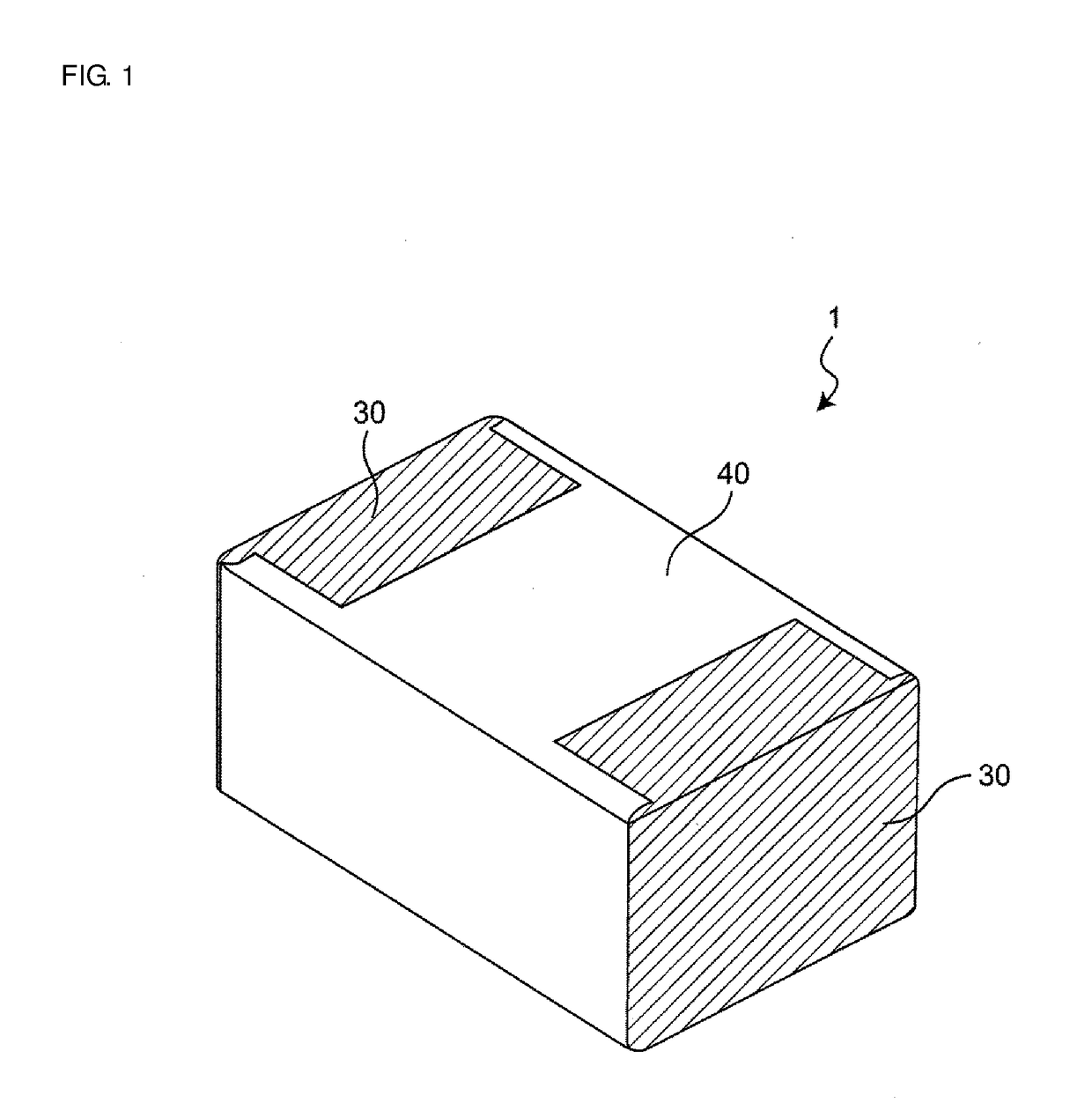

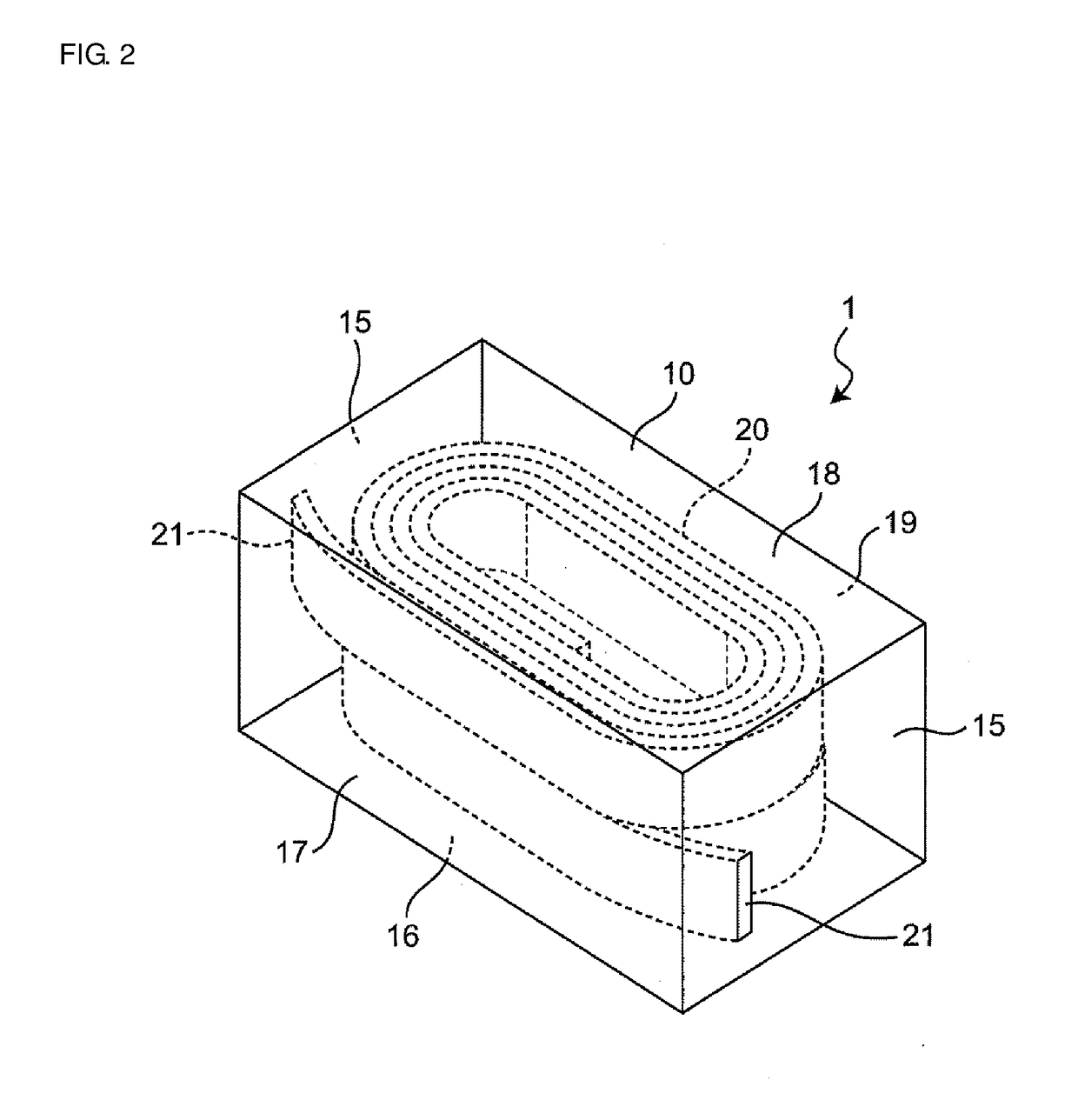

Electromagnetic noise suppressor, structure with electromagnetic noise suppressing function, and method of manufacturing the same

InactiveUS20060038630A1Easy to manufactureSuppress electromagnetic noiseShielding materialsSemiconductor/solid-state device detailsSuppressorResonance

An electromagnetic noise suppressor of the present invention has magnetic resonance frequency of 8 GHz or higher, and the imaginary part μ″H of complex magnetic permeability at 8 GHz is higher than the imaginary part μ″L of complex magnetic permeability at 5 GHz. Such an electromagnetic noise suppressor is capable of achieving sufficient electromagnetic noise suppressing effect over the entire sub-microwave band. The electromagnetic noise suppressor can be manufactured by forming a composite layer 3 on the surface of a binding agent 2 through physical deposition of a magnetic material on the binding agent 2. The structure with an electromagnetic noise suppressing function of the present invention is a printed wiring board, a semiconductor integrated circuit or the like that is covered with the electromagnetic noise suppressor on at least a part of the surface of the structure.

Owner:SHIN-ETSU POLYMER CO LTD

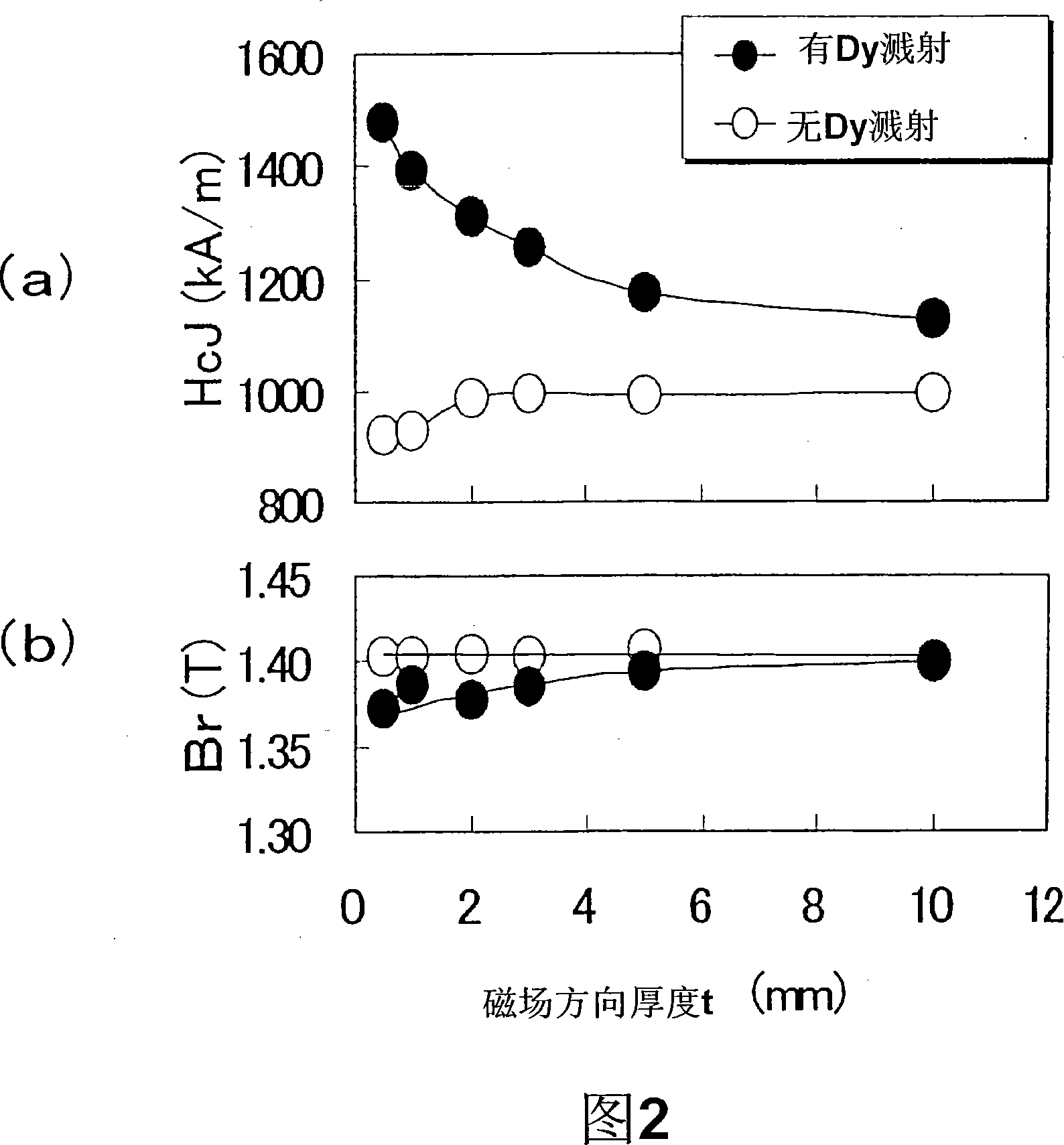

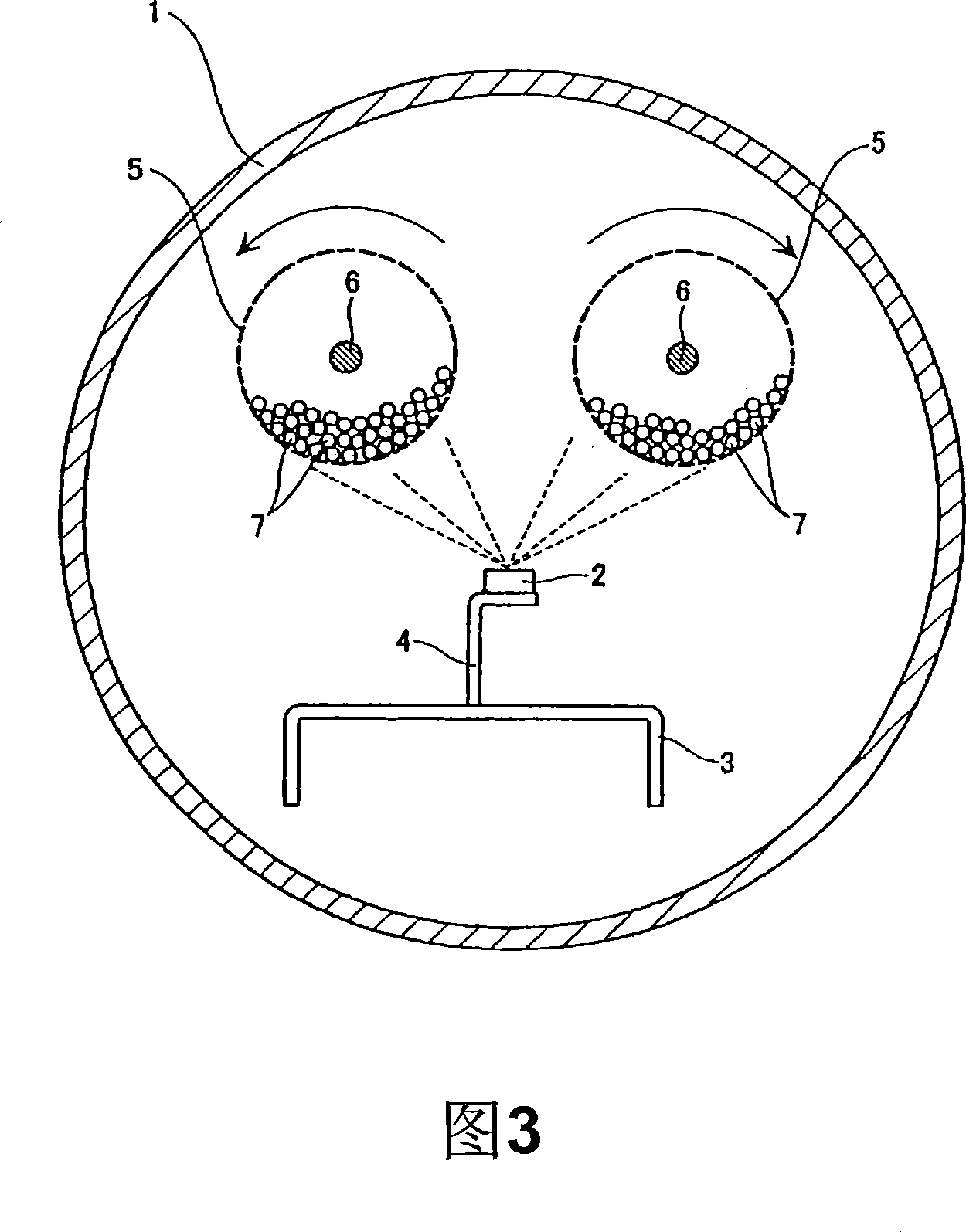

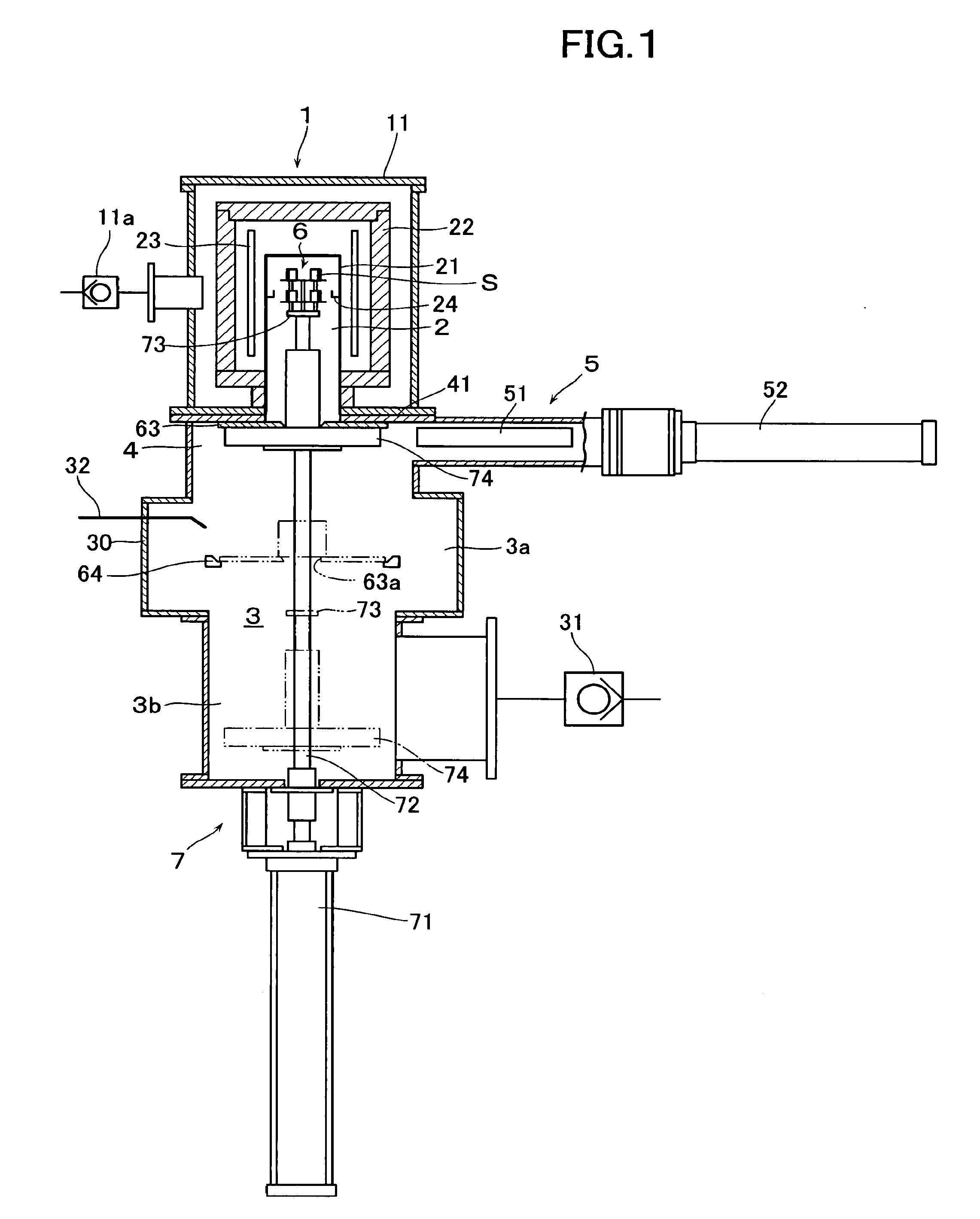

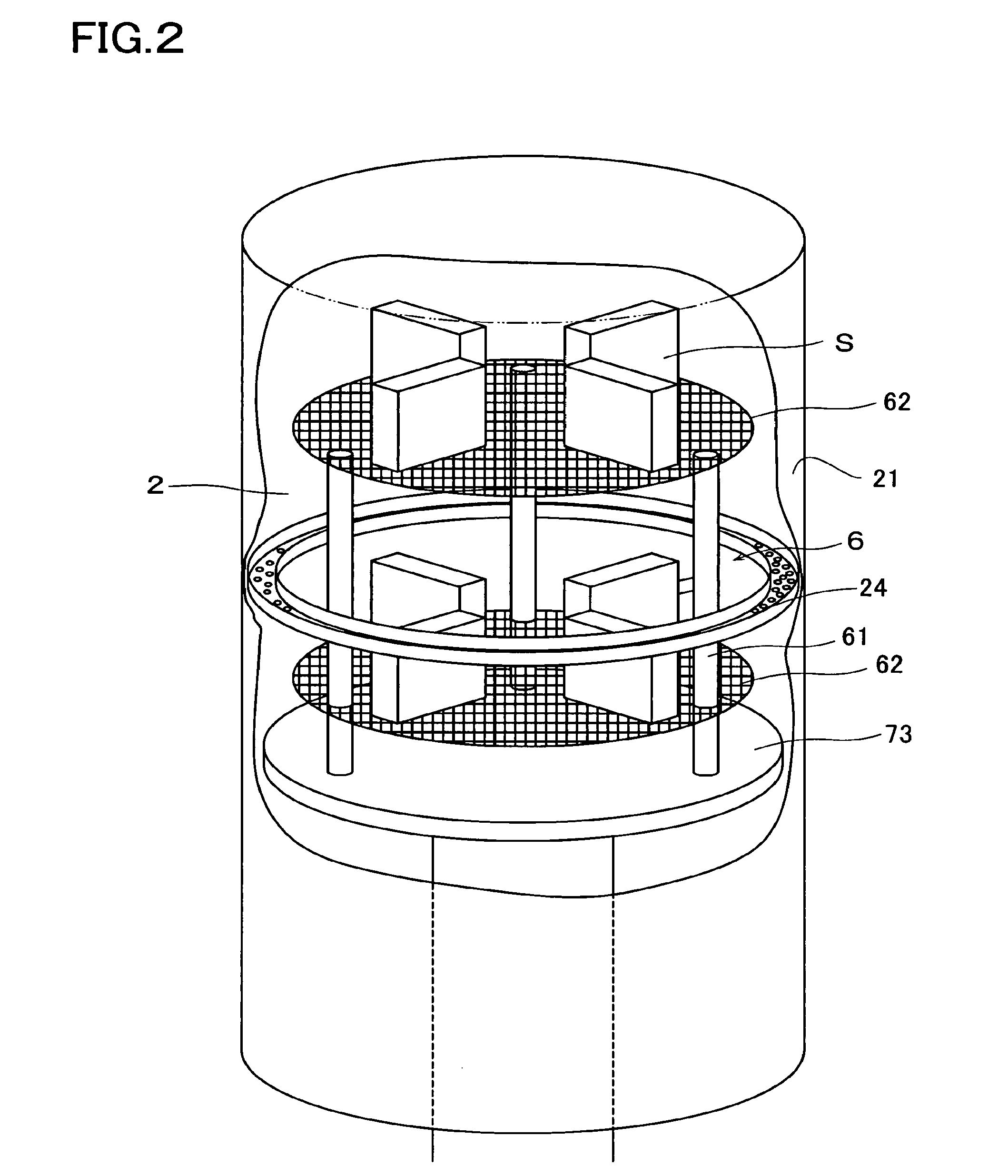

Coating Method and Apparatus, a Permanent Magnet, and Manufacturing Method Thereof

InactiveUS20080257716A1Improve productivityLow costCellsVacuum evaporation coatingHigh rateRare earth

A film is formed at a high rate on the surface of an iron-boron-rare-earth-metal magnet having a given shape, while effectively using dysprosium or terbium as a film-forming material. Thus, productivity is improved and a permanent magnet can be produced at low cost. A permanent magnet is produced through a film formation step in which a film of dysprosium is formed on the surface of an iron-boron-rare-earth-metal magnet of a given shape and a diffusion step in which the magnet coated is subjected to a heat treatment at a given temperature to cause the dysprosium deposited on the surface to diffuse into the grain boundary phase of the magnet. The film formation step comprises: a first step in which a treating chamber where this film formation is performed is heated to vaporize dysprosium which has been disposed in this treating chamber and thereby form a dysprosium vapor atmosphere having a given vapor pressure in the treating chamber; and a second step in which a magnet kept at a temperature lower than the internal temperature of the treating chamber is introduced into this treating chamber and the dysprosium is selectively deposited on the magnet surface based on a temperature difference between the treating chamber and the magnet until the magnet temperature reaches a given value.

Owner:ULVAC INC

Method of manufacturing magnetic multilayer film, method of manufacturing magnetic recording medium, magnetic multilayer film and magnetic recording medium

InactiveUS6824817B2Damage suppressionSquareness ratio of the magnetization curveNanostructure applicationNanomagnetismMagnetization curveOptoelectronics

Owner:TDK CORPARATION

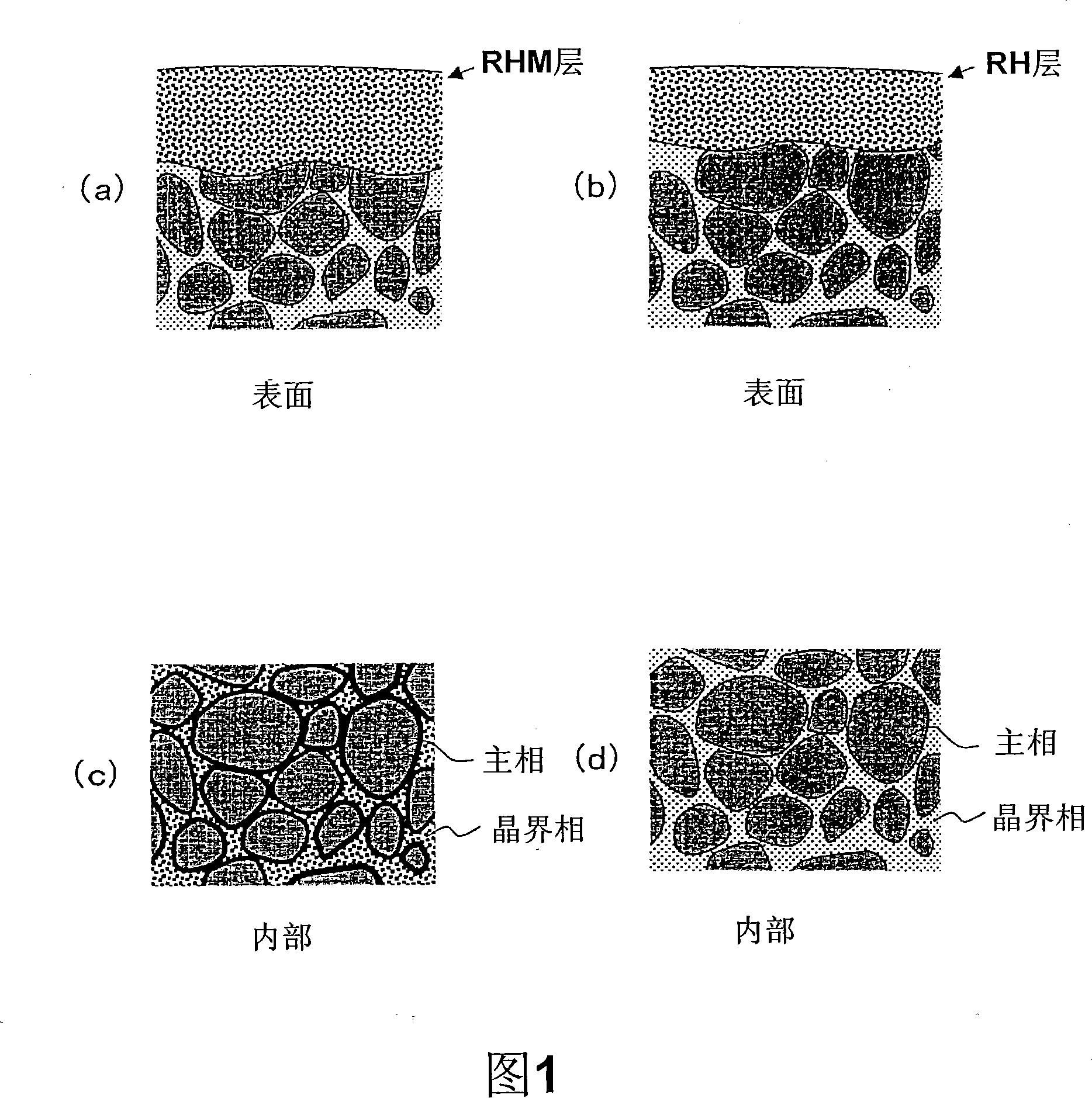

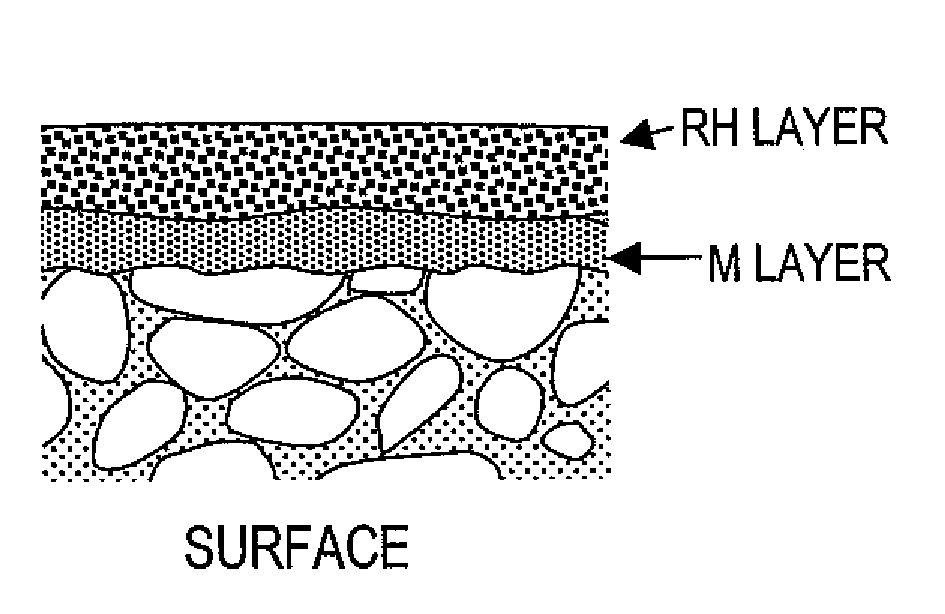

R-Fe-B RARE-EARTH SINTERED MAGNET AND PROCESS FOR PRODUCING THE SAME

ActiveUS20100231338A1Easy to useImprove remanenceVacuum evaporation coatingSputtering coatingRare-earth elementSintered magnets

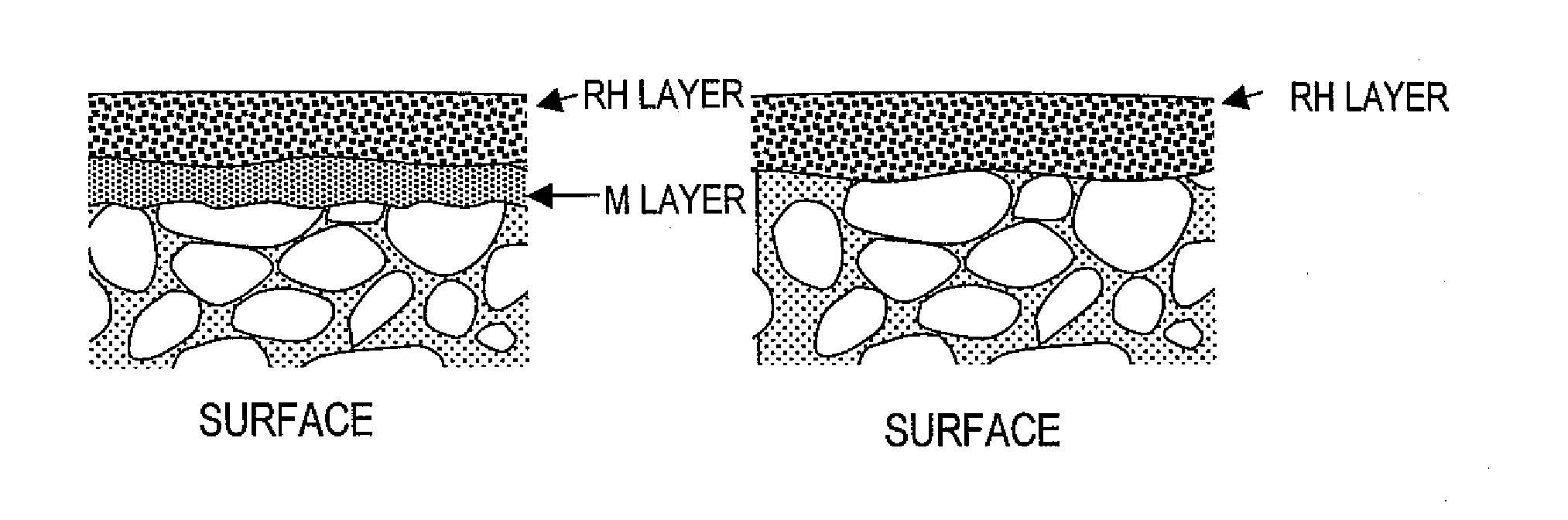

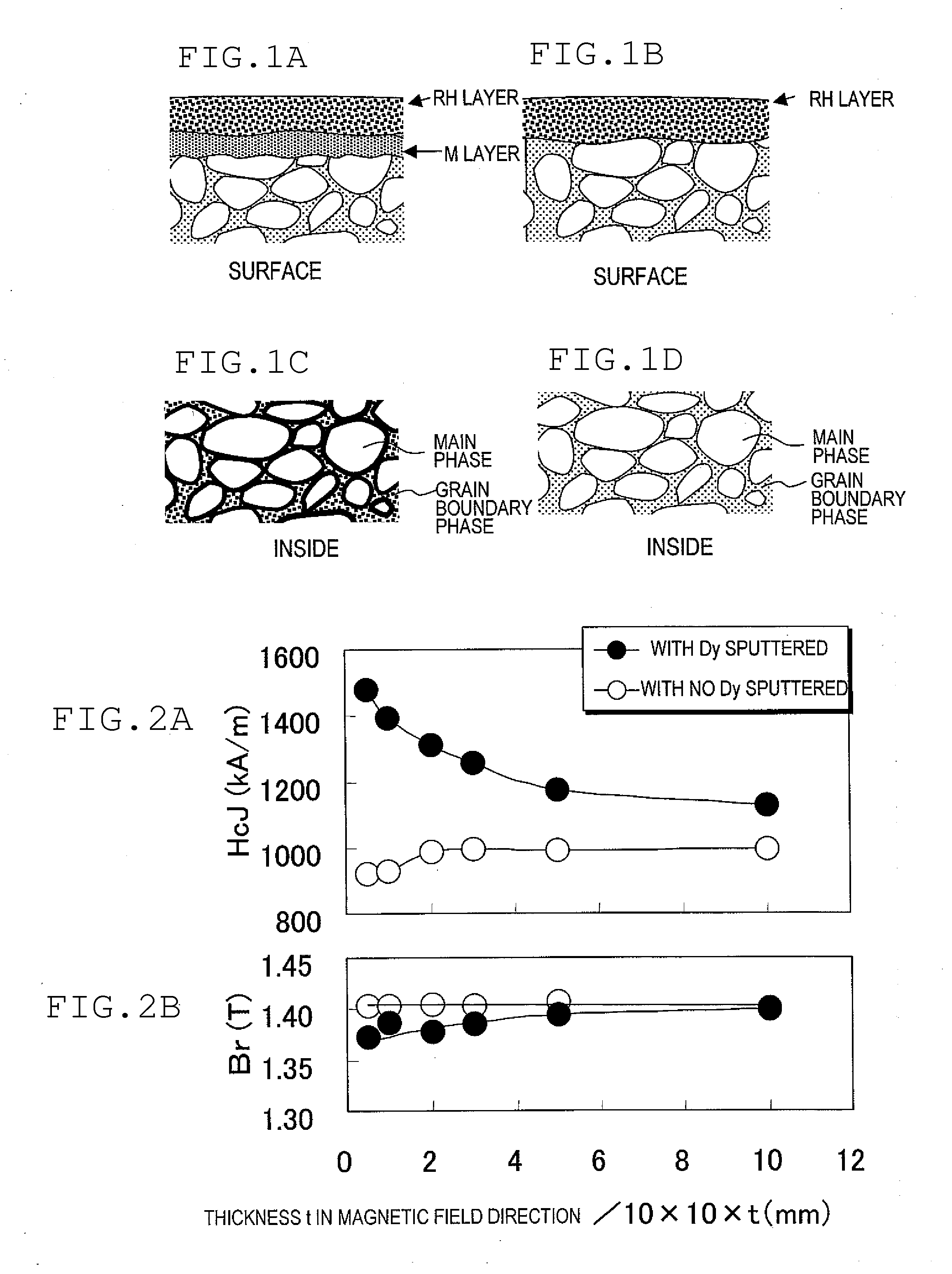

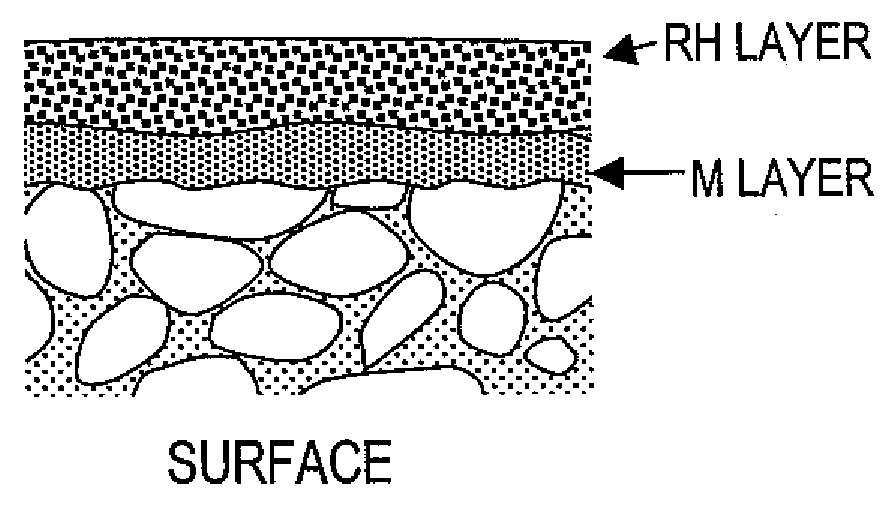

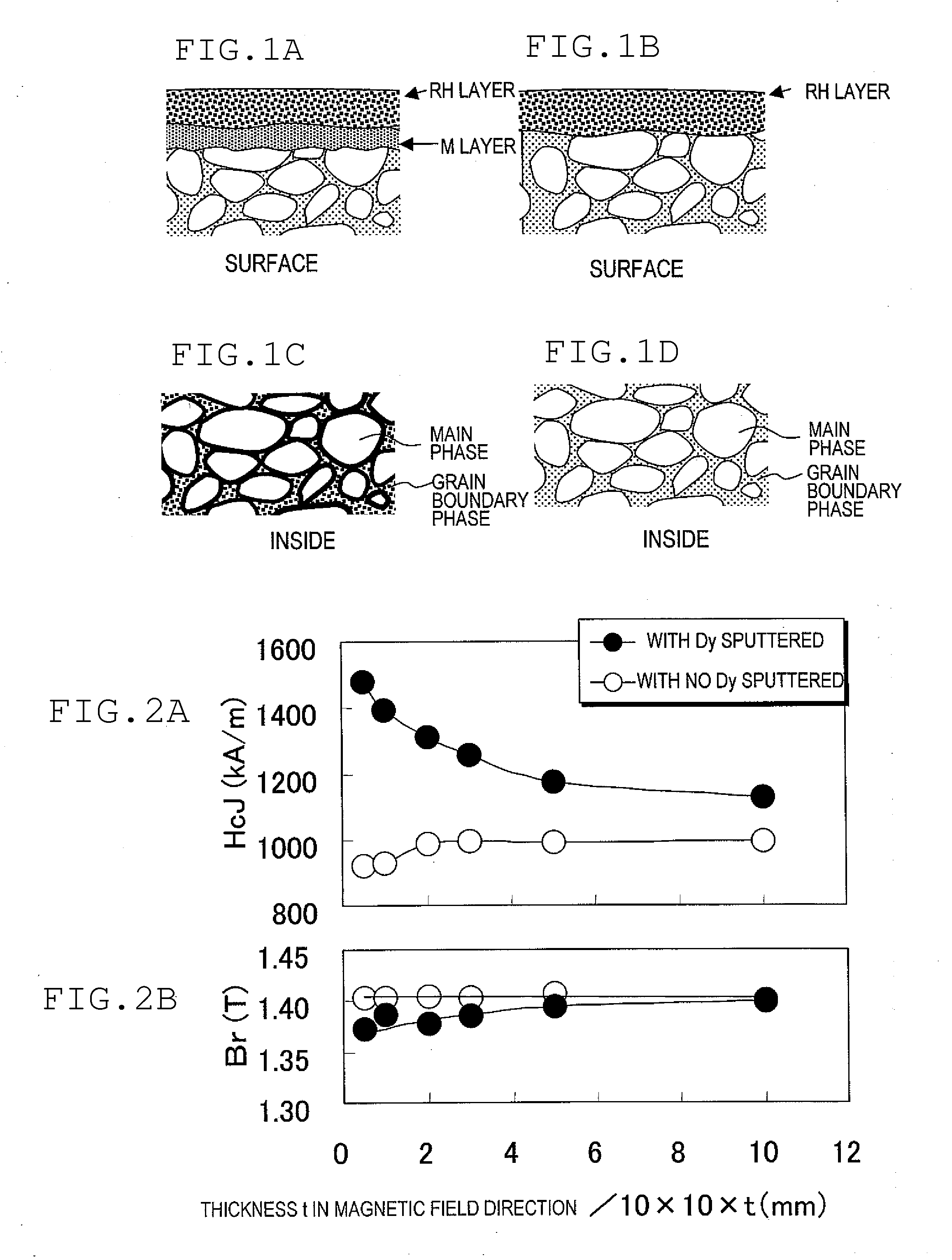

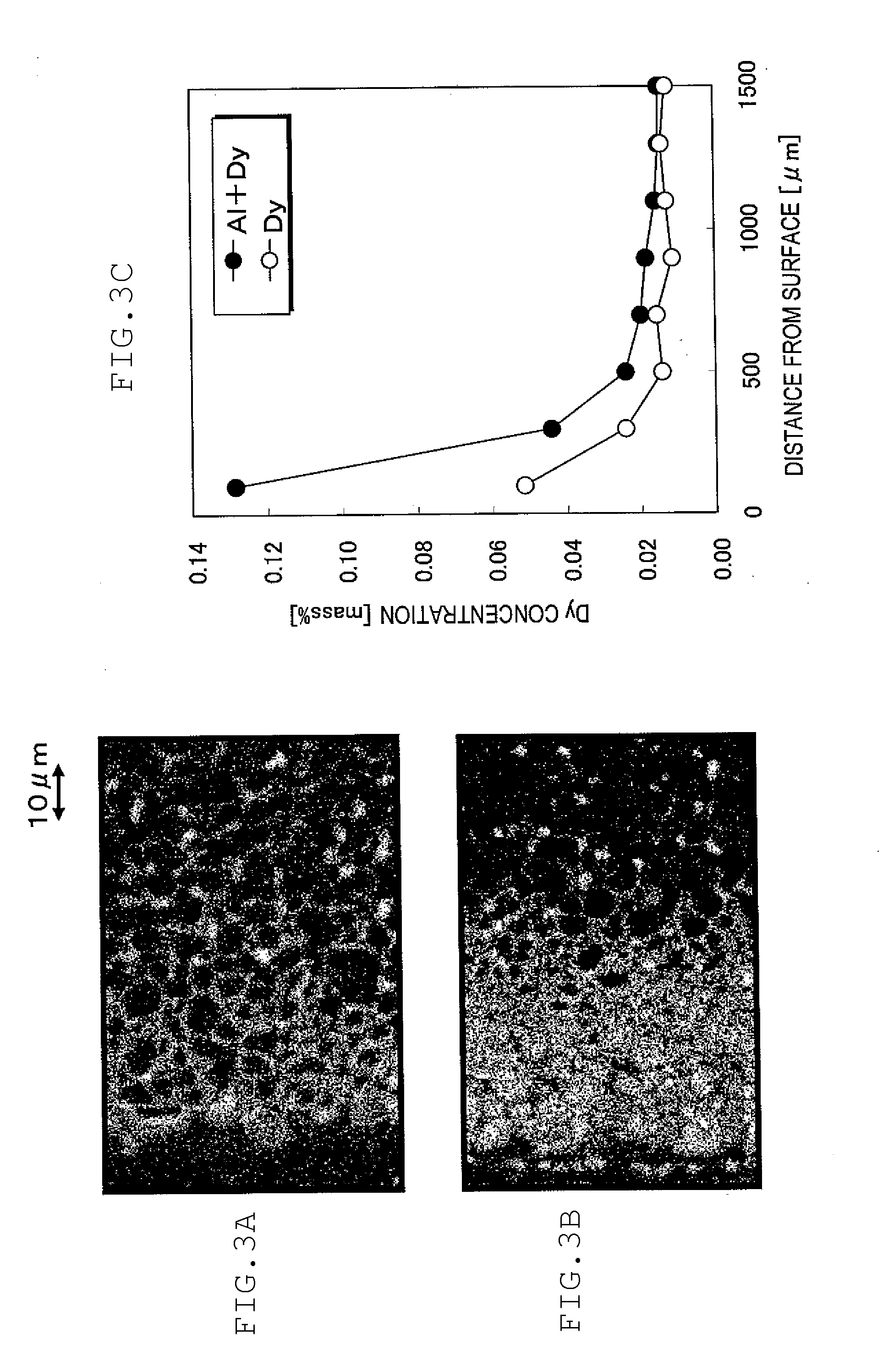

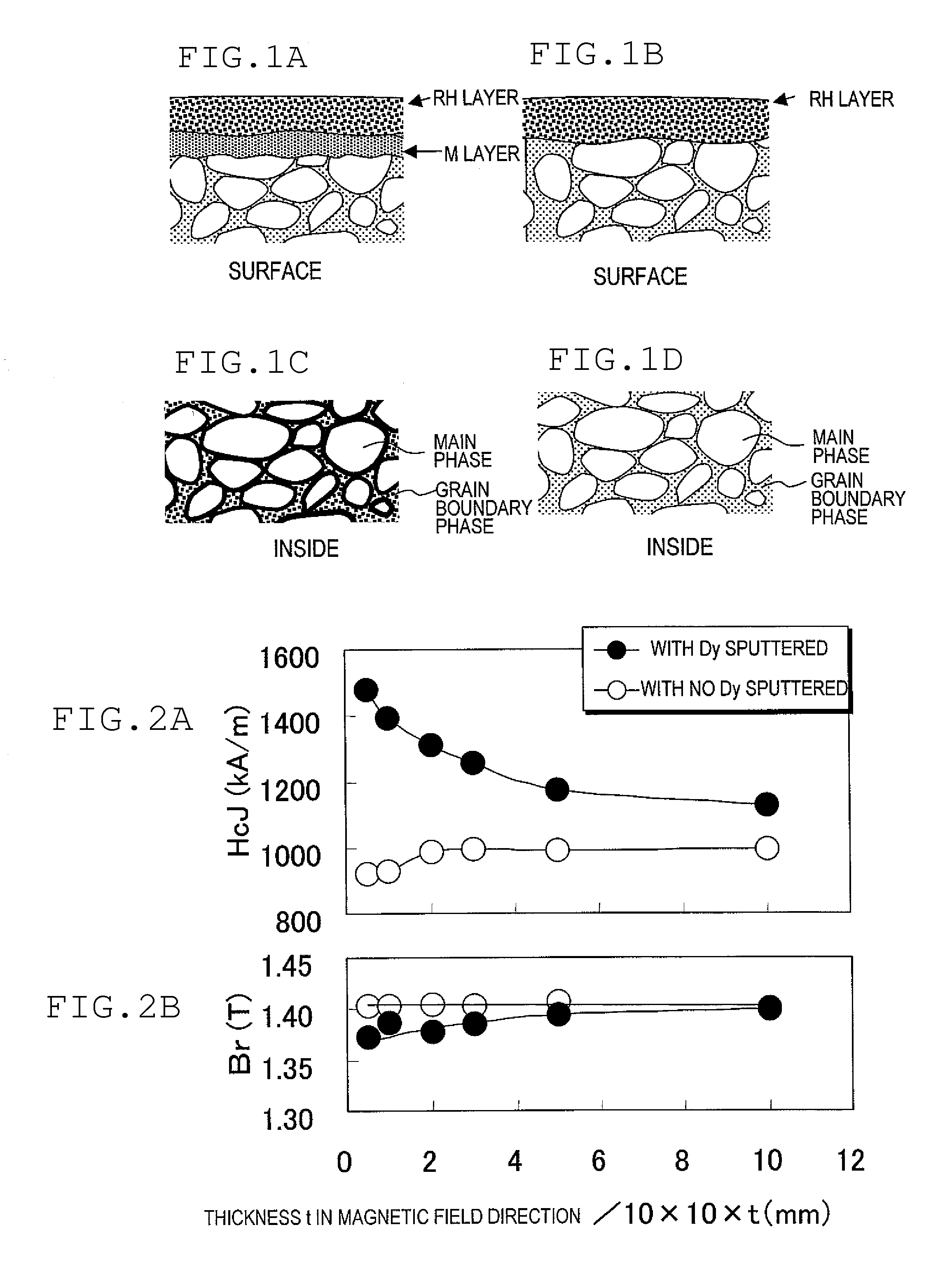

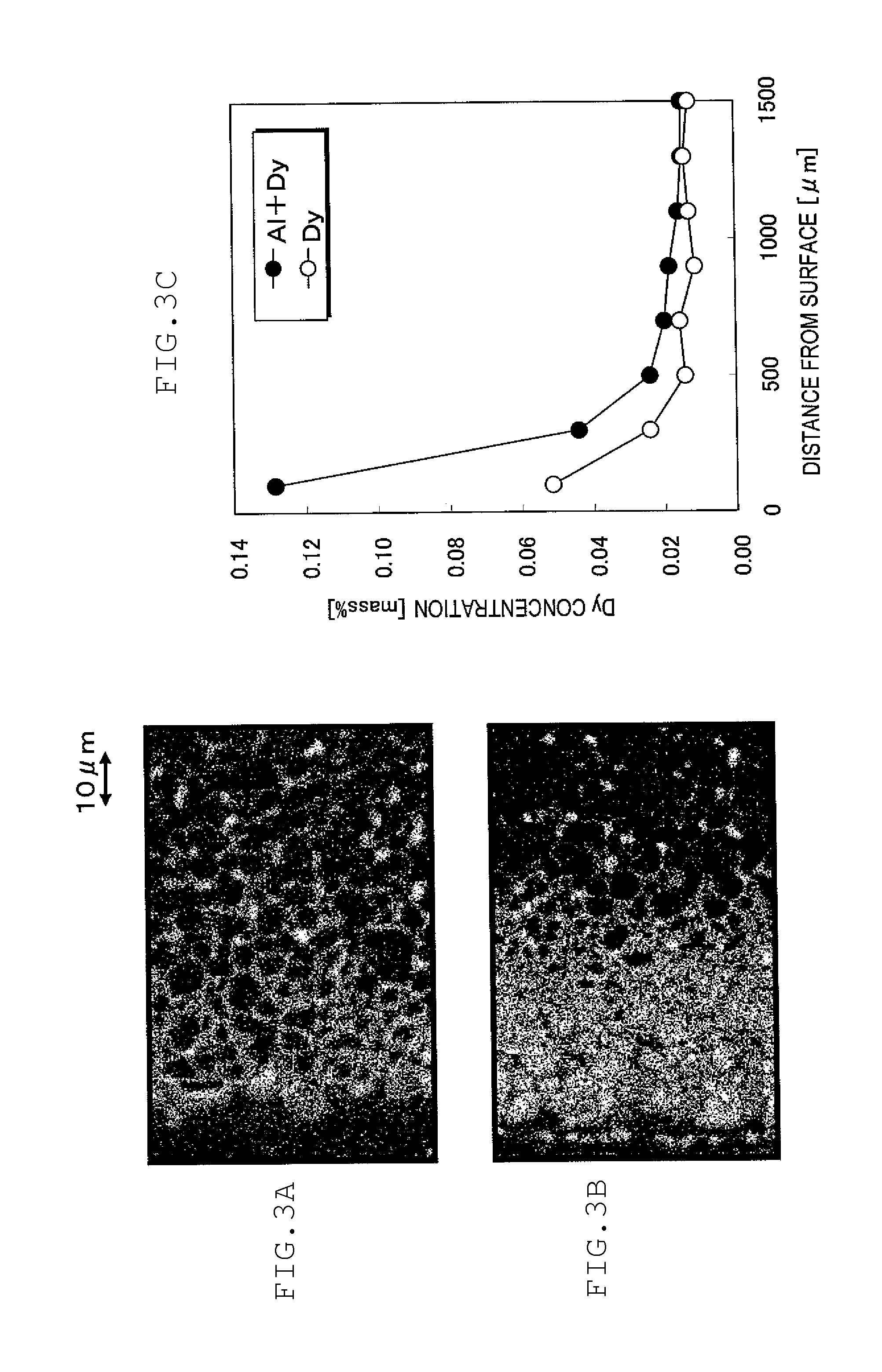

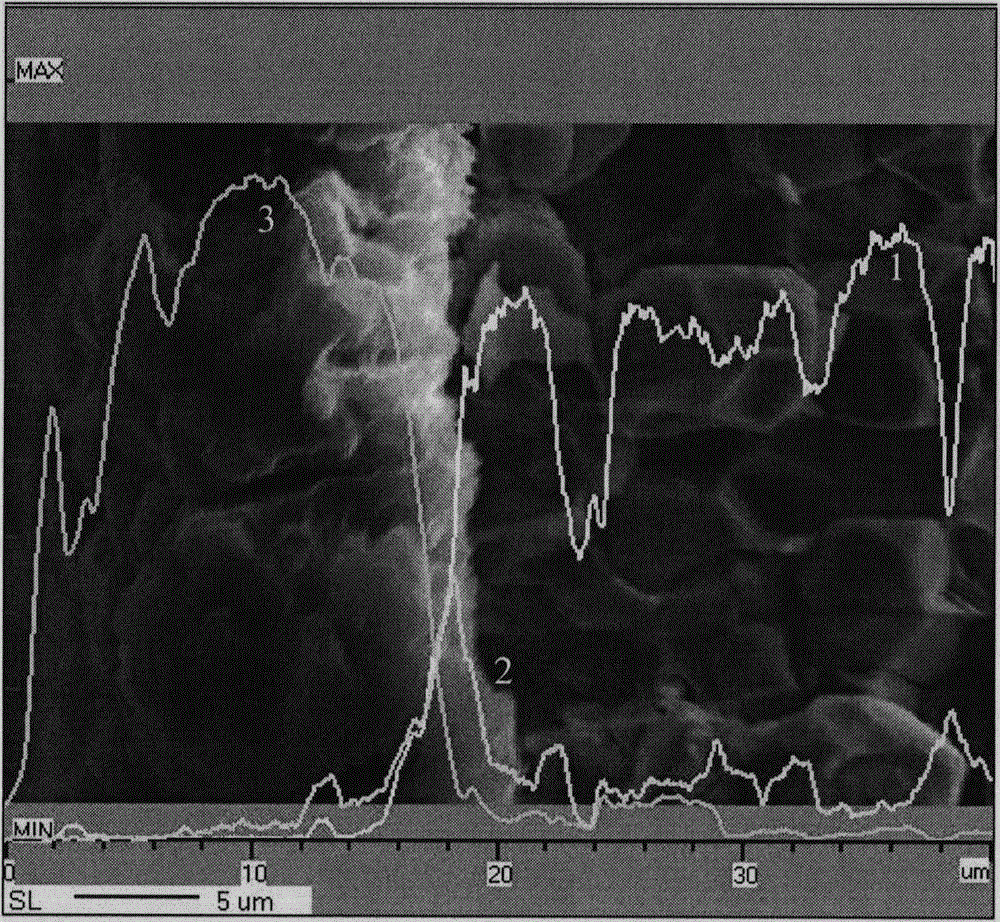

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:HITACHI METALS LTD

Method of making nitrided active elements

InactiveUS6473960B1High resistivityImprove wear resistanceConstruction of head windingsElectrical transducersCelsius DegreeEngineering

A method of manufacturing an active element for use with a magnetic head includes depositing a magnetic material to form a magnetic member, and nitriding the magnetic member after the depositing step. Preferably, the depositing step comprises depositing nickel-iron alloy, and the nitriding step comprises plasma nitriding the magnetic member. Advantageously, plasma nitriding may be performed at a temperature below 300 degrees Celsius to avoid adverse effects to components of the active element, such as organic planars. Active elements manufactured according to the method of the invention are also disclosed.

Owner:ORACLE INT CORP

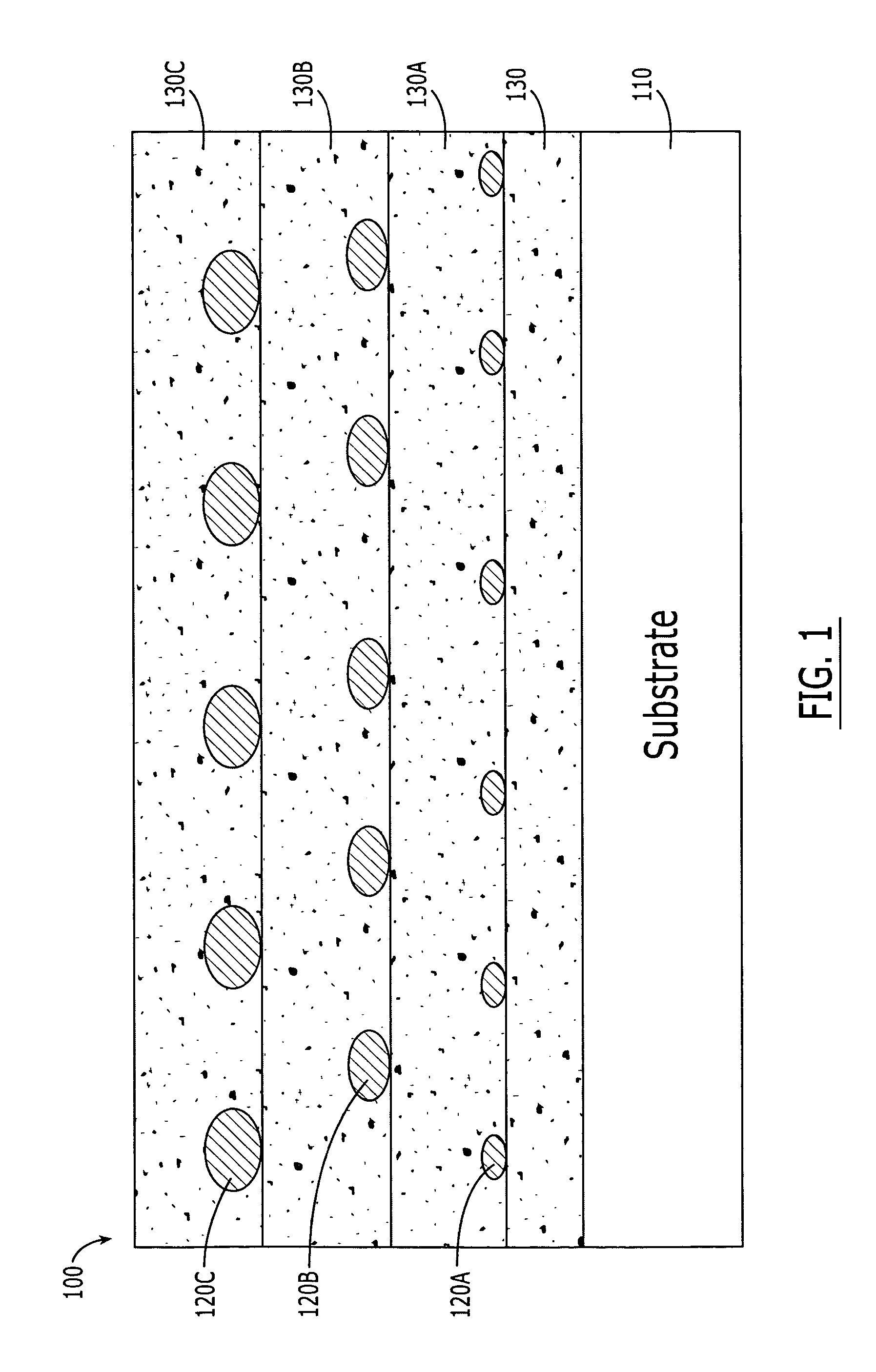

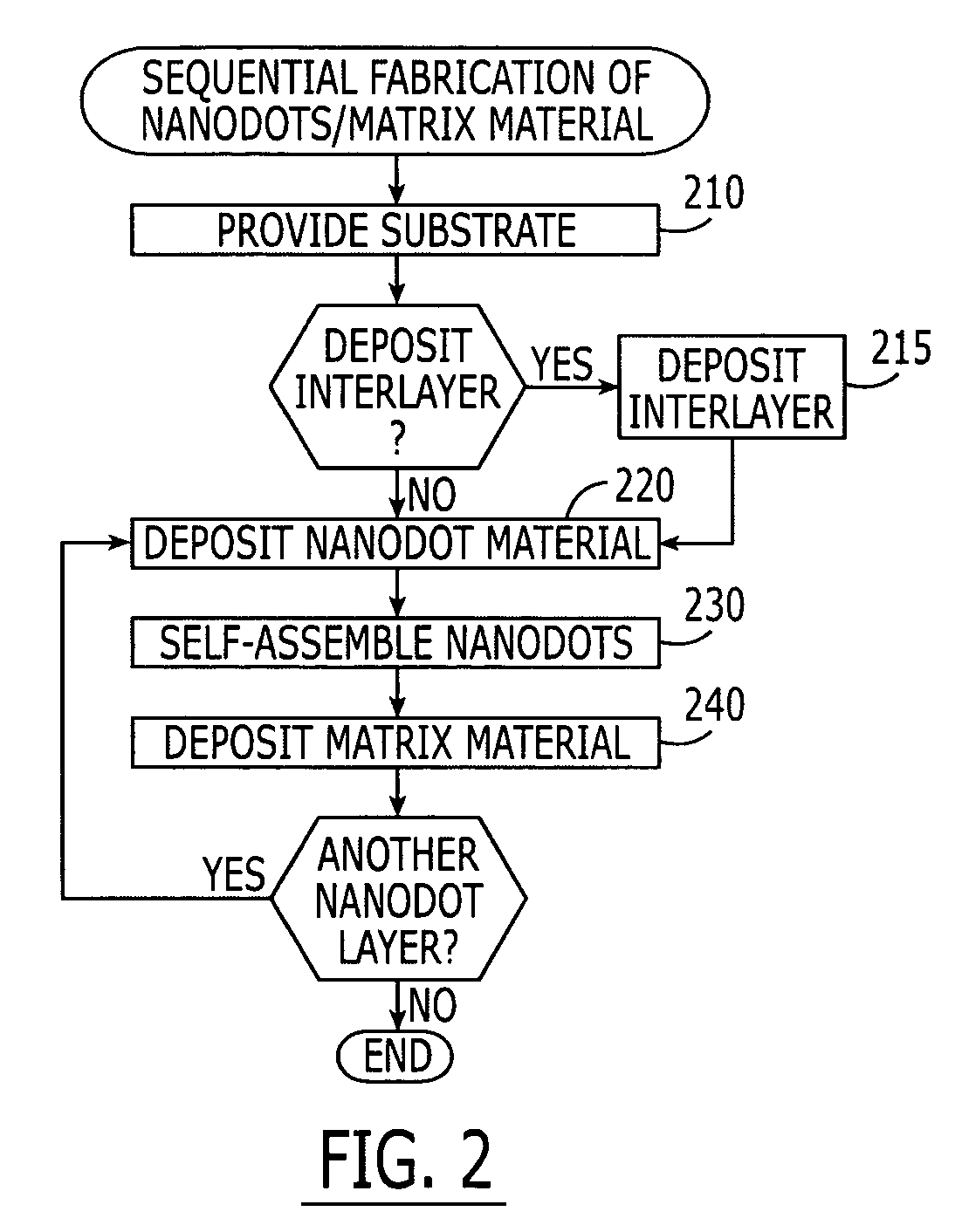

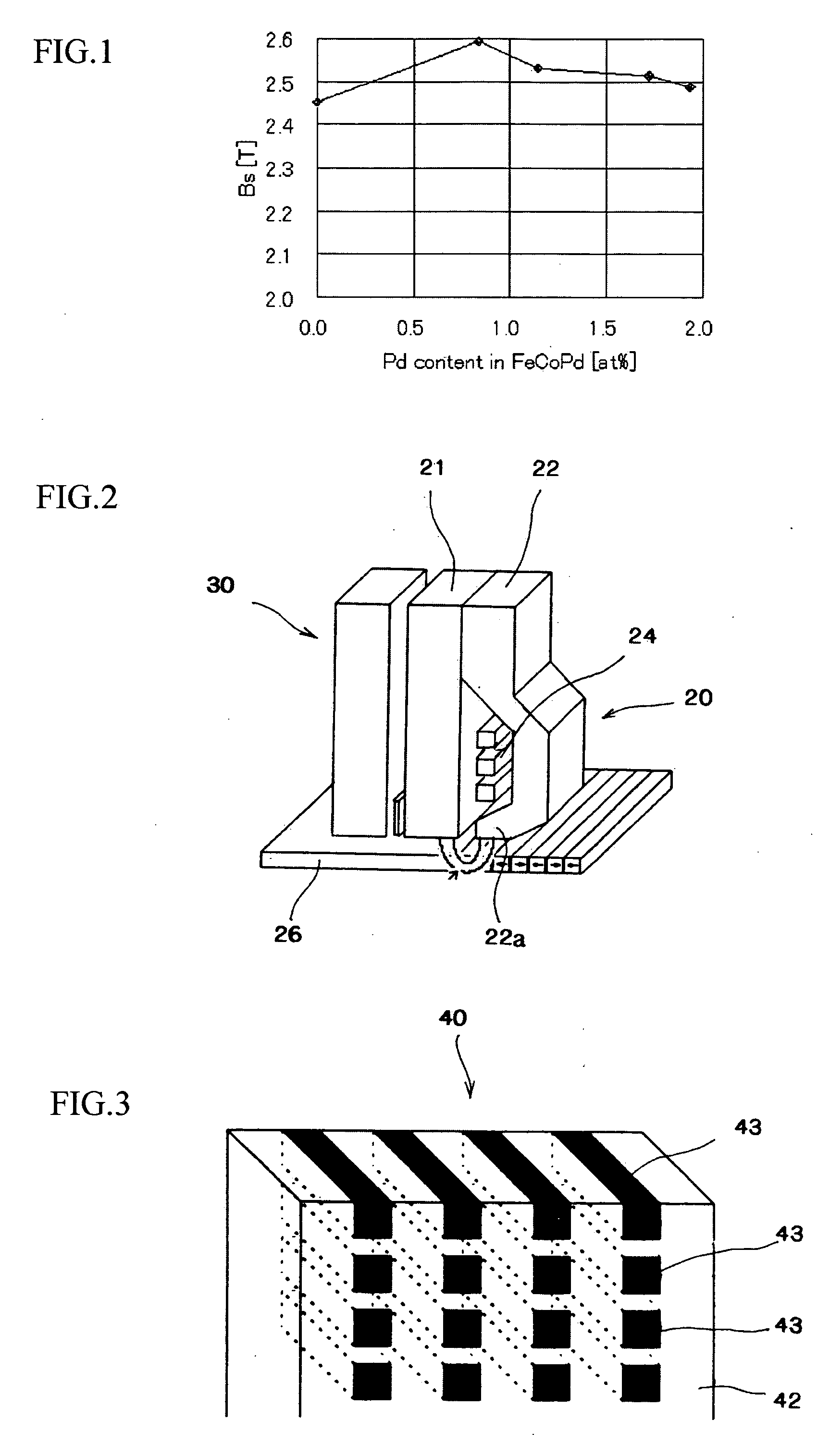

Methods of forming three-dimensional nanodot arrays in a matrix

ActiveUS7105118B2Rapid productionImprove magnetic propertiesNanostructure applicationNanomagnetismNanodotFree energies

Nanostructures and methods of making nanostructures having self-assembled nanodot arrays wherein nanodots are self-assembled in a matrix material due to the free energies of the nanodot material and / or differences in the Gibb's free energy of the nanodot materials and matrix materials.

Owner:NORTH CAROLINA STATE UNIV

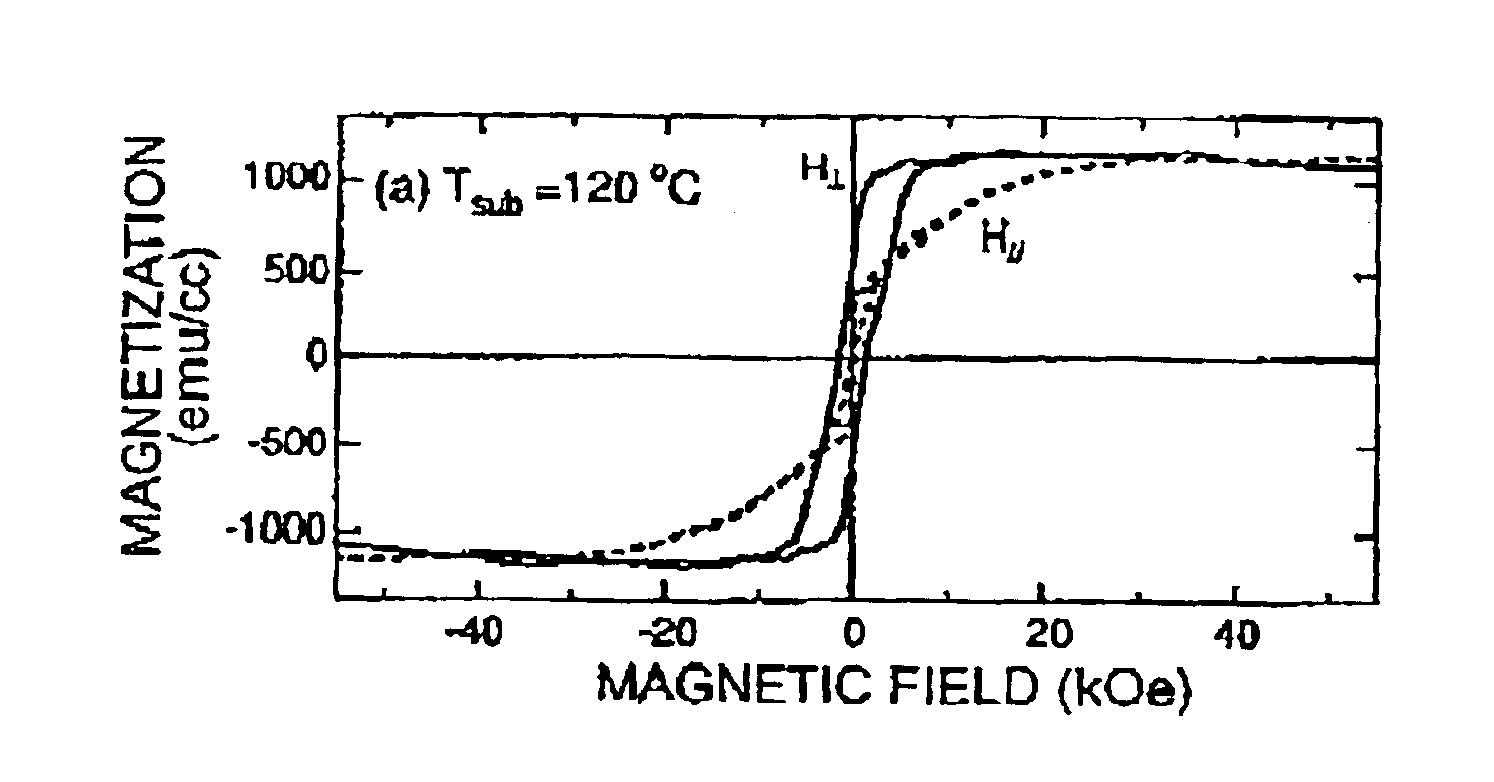

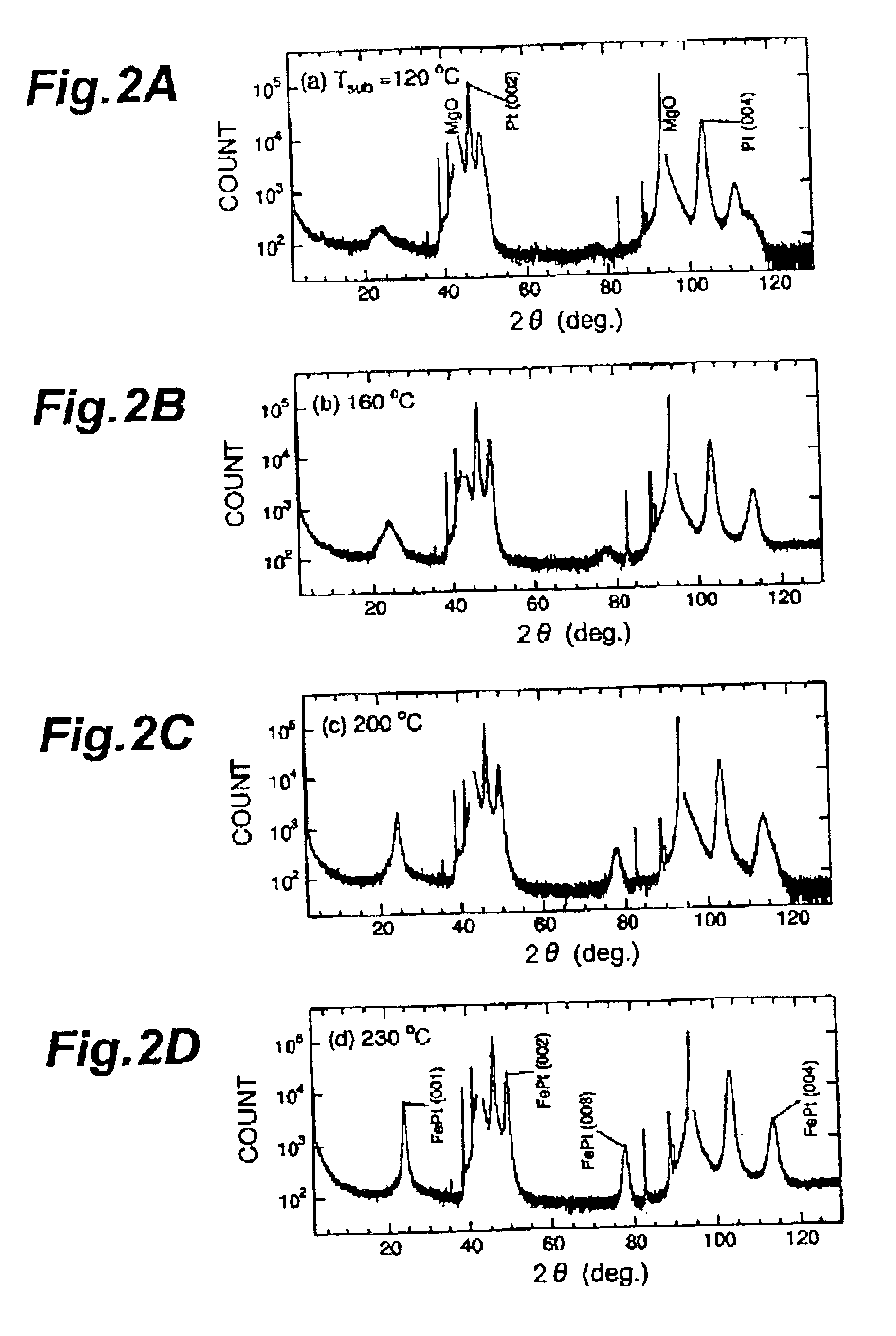

Titanium dioxide cobalt magnetic film and its manufacturing method

InactiveUS20030091500A1High catalytic activitySoldering apparatusVacuum evaporation coatingSemiconductor materialsMagnetization

A titanium dioxide.cobalt magnetic film is provided that is useful to make up a photocatalyst having high catalytic capability, a semiconductor material having an optical, an electrical and a magnetic function all in combination, and a transparent magnet. The titanium dioxide.cobalt magnetic film has a composition expressed by chemical formula: Ti1-xCoxO2 where 0<x<=0.3, wherein a Ti atom at its lattice position is replaced with a Co atom, and the magnetic film is a film epitaxially grown on a single crystal substrate. The magnetic film has either anatase or rutile crystalline structure, has its band gap energy varying in a range between 3.13 eV and 3.33 eV according to the concentration of Co atoms replaced for Ti atoms at their lattice positions, is capable of retaining its magnetization even at a temperature higher than a room temperature, and is also transparent to a visible light. I the manufacture of the titanium dioxide.cobalt magnetic film, a target having TiO2 and Co mixed together at a selected mixing ratio is prepared, placed in a vacuum chamber provided with an atmosphere with a selected oxygen pressure therein, and irradiated in the vacuum chamber with a selected laser light under selected irradiating conditions to cause TiO2 and Co to evaporate from the target and a layer of TiO2.Co to grow in a single crystal substrate that is heated in the vacuum chamber.

Owner:JAPAN SCI & TECH CORP

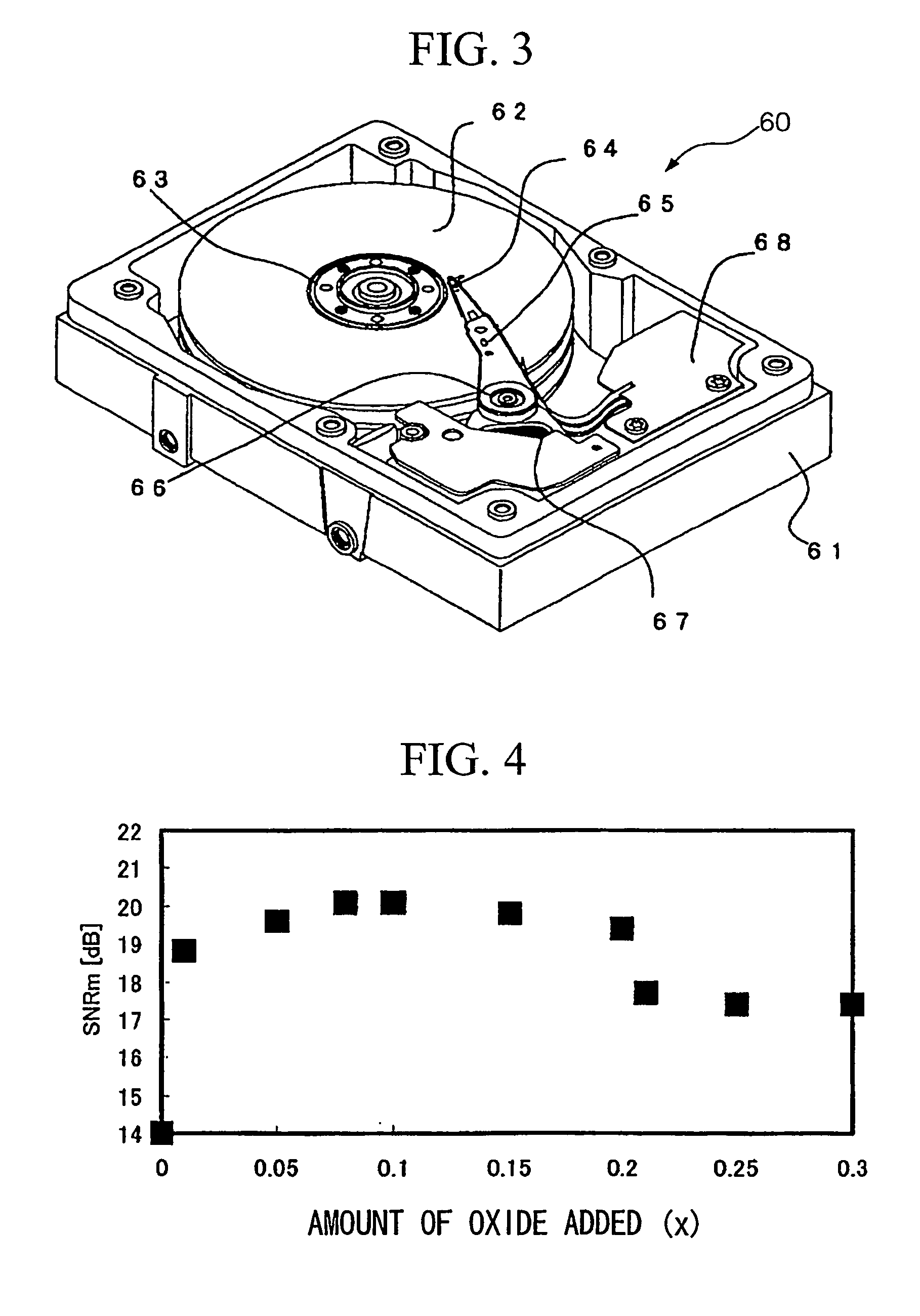

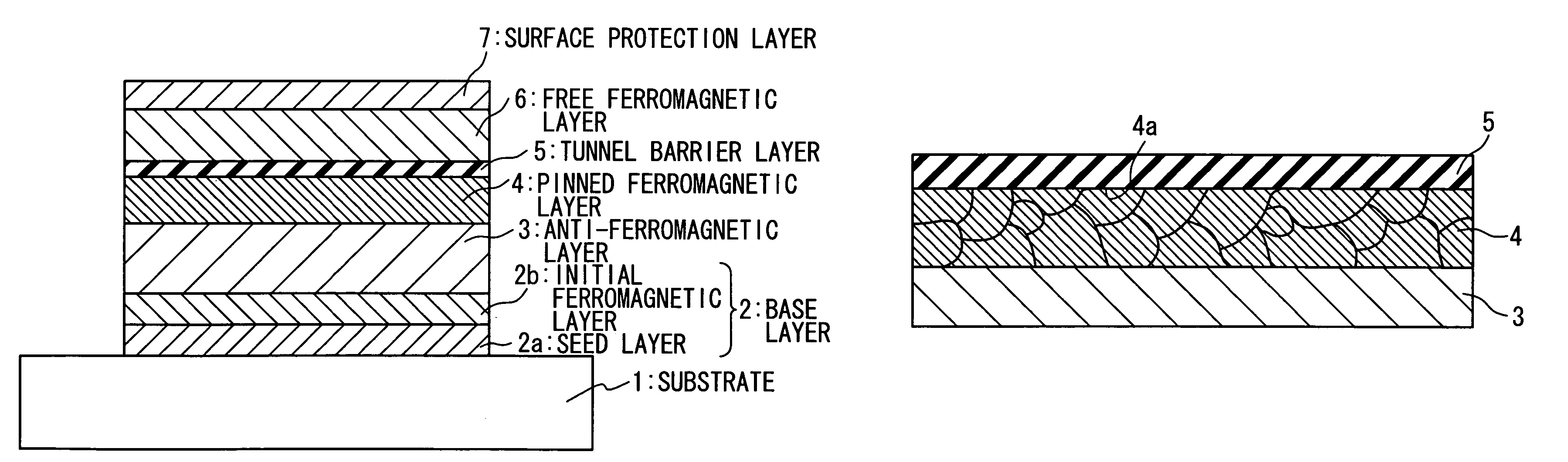

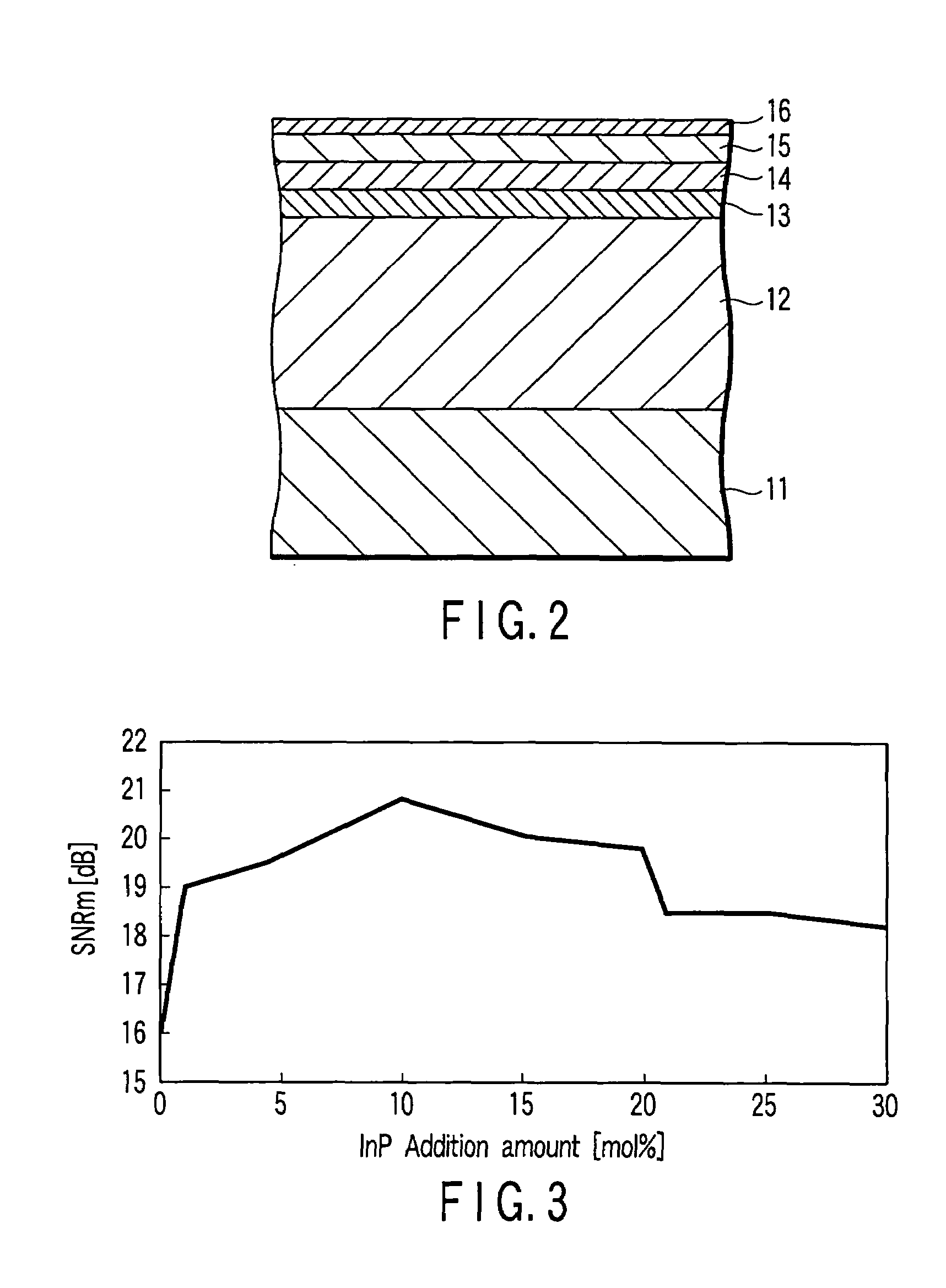

Perpendicular magnetic recording medium, manufacturing method therefor, and magnetic read/write apparatus using the same

InactiveUS20070065955A1Improve signal-to-noise ratioHigh density recordingBase layers for recording layersSemiconductor/solid-state device manufacturingMagnetizationRecording layer

A perpendicular magnetic recording medium includes: a substrate; at least one underlayer formed above the substrate; and a perpendicular magnetic recording layer formed above the at least one underlayer, an easy magnetization axis of the perpendicular magnetic recording layer being oriented perpendicular to the substrate, the perpendicular magnetic recording layer including magnetic crystal particles and grain boundaries surrounding the magnetic crystal particles, wherein the grain boundaries contain an oxide of silicon and at least one element selected from the group consisting of Li, Na, K, Rb, Cs, Ca, Sr, and Ba, and the ratio of a total amount of substance of Si, Li, Na, K, Rb, Cs, Ca, Sr, and Ba in the perpendicular magnetic recording layer is no less than 1 mol % and no more than 20 mol %.

Owner:KK TOSHIBA +1

Magnetoresistive device and method for manufacturing same

ActiveUS7187525B2InhibitionGrowth inhibitionNanomagnetismNanoinformaticsHeat resistanceMagnetic reluctance

The heat resistance of a magnetic resistance device utilizing the TMR effect is improved. Also, the Neel effect of the magnetic resistance device utilizing the TMR effect is restrained. The magnetic resistance device includes a first ferromagnetic layer formed of ferromagnetic material, a non-magnetic insulative tunnel barrier layer coupled to the first ferromagnetic layer, a second ferromagnetic layer formed of ferromagnetic material and coupled to the tunnel barrier layer, and an anti-ferromagnetic layer formed of anti-ferromagnetic material. The second ferromagnetic layer is provided between the tunnel barrier layer and the anti-ferromagnetic layer. A perpendicular line from an optional position of the surface of the second ferromagnetic layer passes through at least two of the crystal grains of the second ferromagnetic layer.

Owner:NEC CORP

High-frequency current suppression body using magnetic loss material exhibiting outstanding complex permeability characteristics

InactiveUS6921573B2Effectively counterSmall volumeTurning machine accessoriesMagnetic/electric field screeningCenter frequencyRelative bandwidth

The present invention is a high-frequency current essentially of M—X—Y, where M is Fe, Co, and / or Ni, X is an element other than M or Y, and Y is F, N, and / or O. The maximum value μ″max of the loss factor μ″ of this material exists at 100 MHz to 10 GHz. A relative bandwidth bwr is not greater than 200% where the relative bandwidth bwr is obtained between two frequencies at which the value of μ″ is 50% of μ″max and normalizing the frequency bandwidth at the center frequency.

Owner:TOKIN CORP

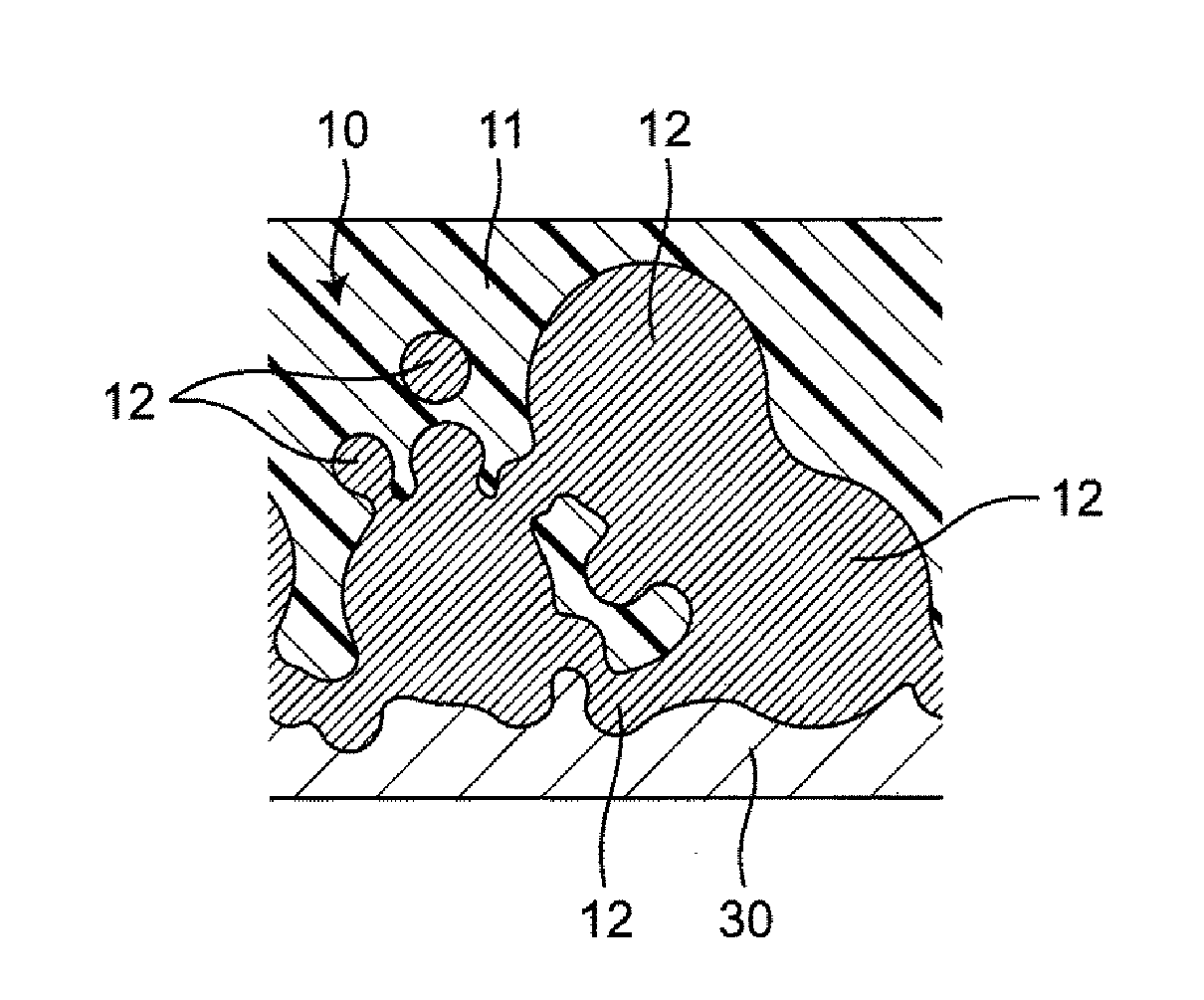

Electronic component and method for manufacturing the same

ActiveUS20180247764A1Low efficiencyIncrease resistanceTransformers/inductances coils/windings/connectionsMetal-working apparatusElectronic componentMetal powder

An electronic component includes an element body made of a composite material of a resin material and metal powder. A plurality of particles of the metal powder are exposed from the resin material and make contact with one another on the outer surface of the element

Owner:MURATA MFG CO LTD

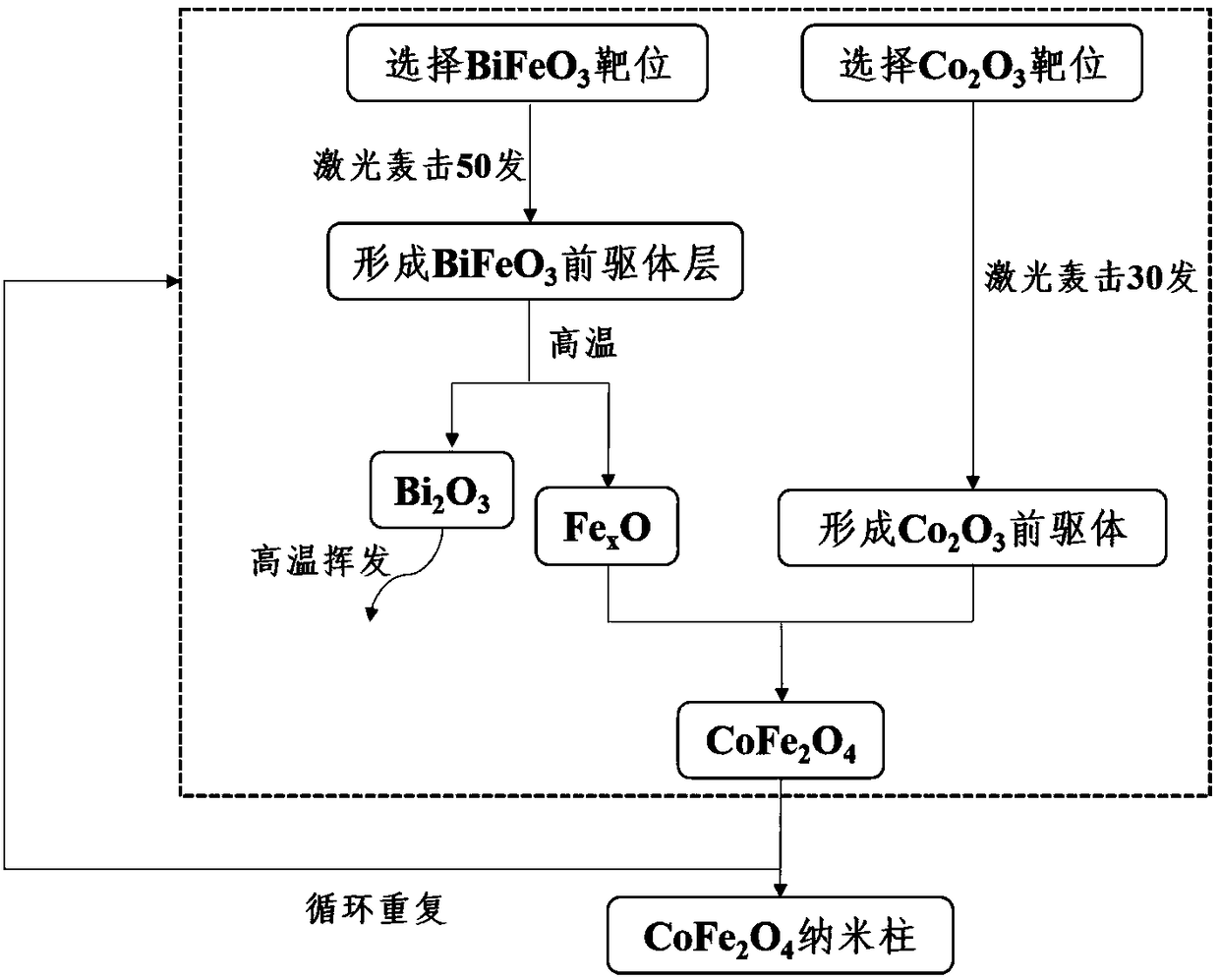

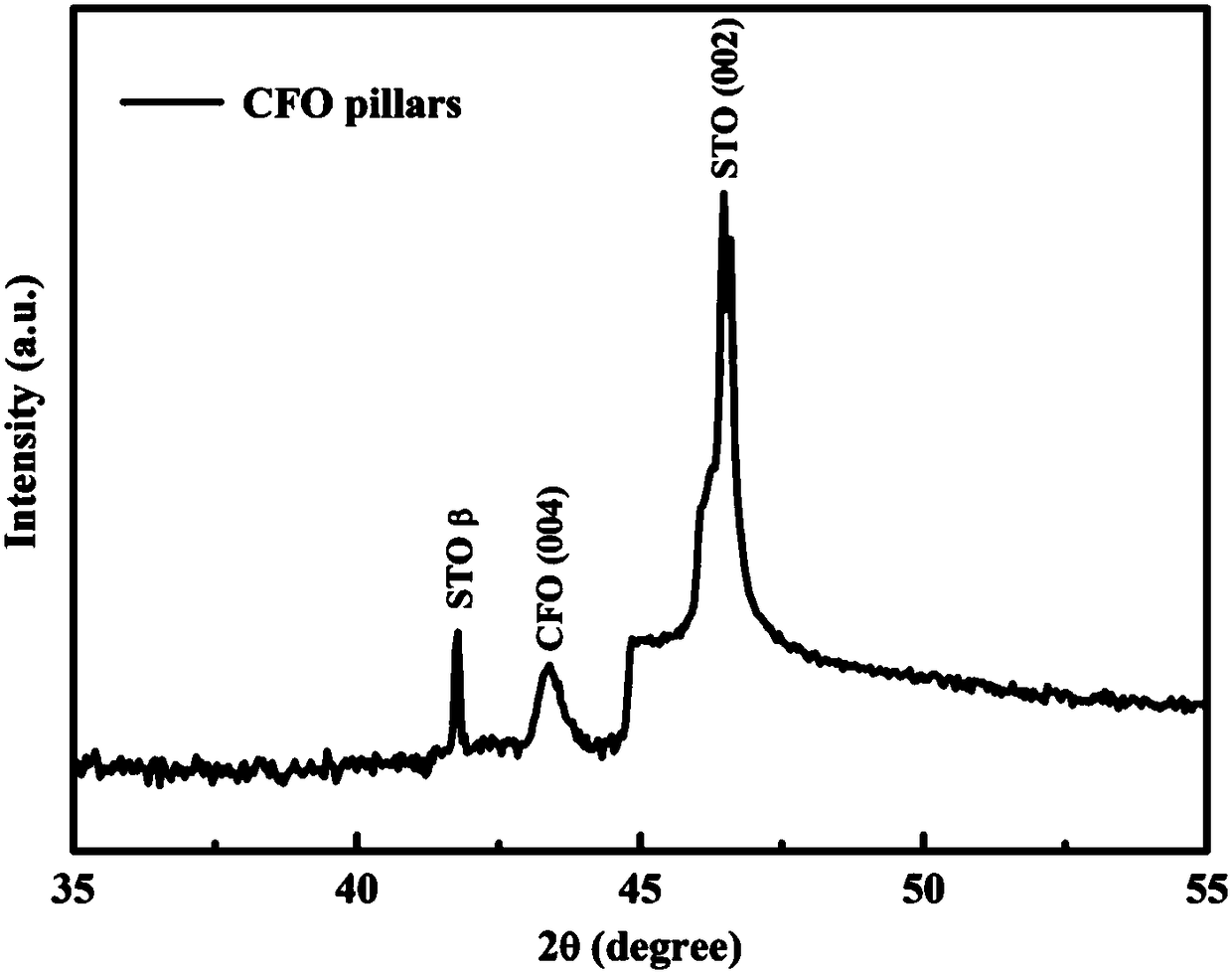

Method of using pulsed laser deposition to prepare independent dispersed cobalt ferrite nano column

ActiveCN108546919AHigh coercive fieldHigh curie temperatureVacuum evaporation coatingSputtering coatingPulsed laser depositionNanotechnology

The invention discloses a method of using pulsed laser deposition to prepare an independent dispersed cobalt ferrite nano column. The method comprises following steps: selecting a substrate, preprocessing the substrate; adopting a pulsed laser deposition system to prepare independent dispersed cobalt ferrite nano columns on the preprocessed substrate by a rapid switching dual target material method; and carrying out a post treatment on the cobalt ferrite nano column sample prepared in the previous step. The disclosed preparation method has the advantages of simple preparation process and highyield, moreover, the whole preparation process can be precisely controlled, the quality of the prepared product is stable, and massive and industrial production can be realized.

Owner:XIANGTAN UNIV

R-Fe-B RARE-EARTH SINTERED MAGNET AND PROCESS FOR PRODUCING THE SAME

ActiveUS20110260816A1Easy to useImprove remanencePermanent magnetsCathode sputtering applicationRare-earth elementSintered magnets

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:PROTERIAL LTD

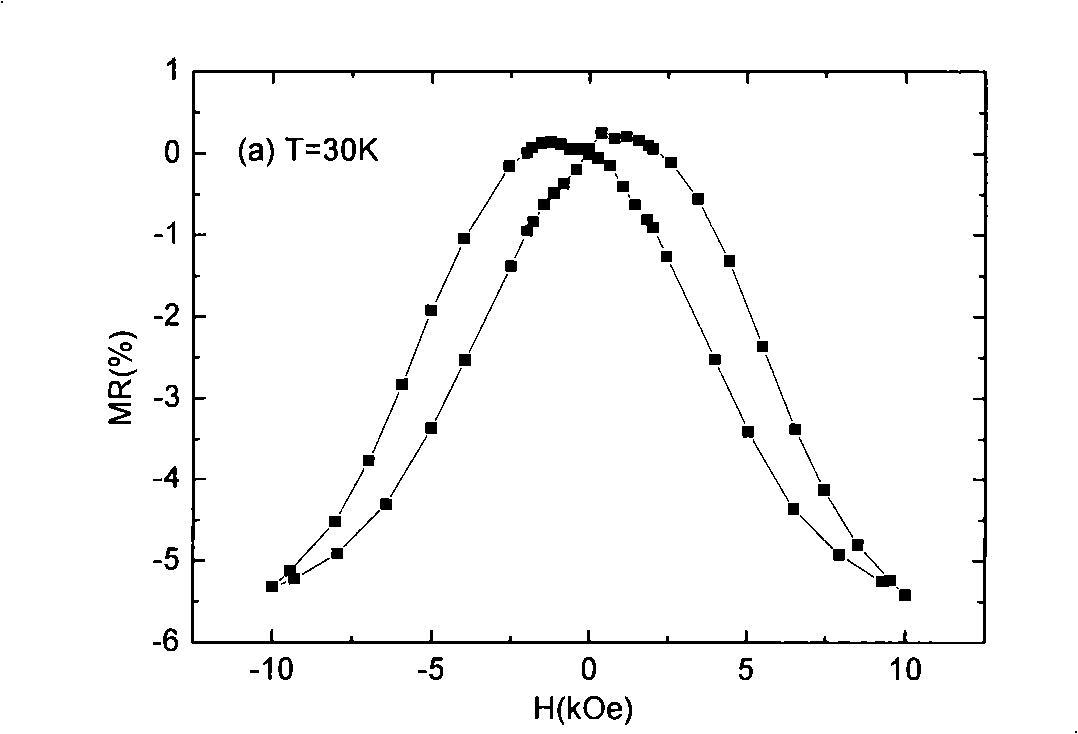

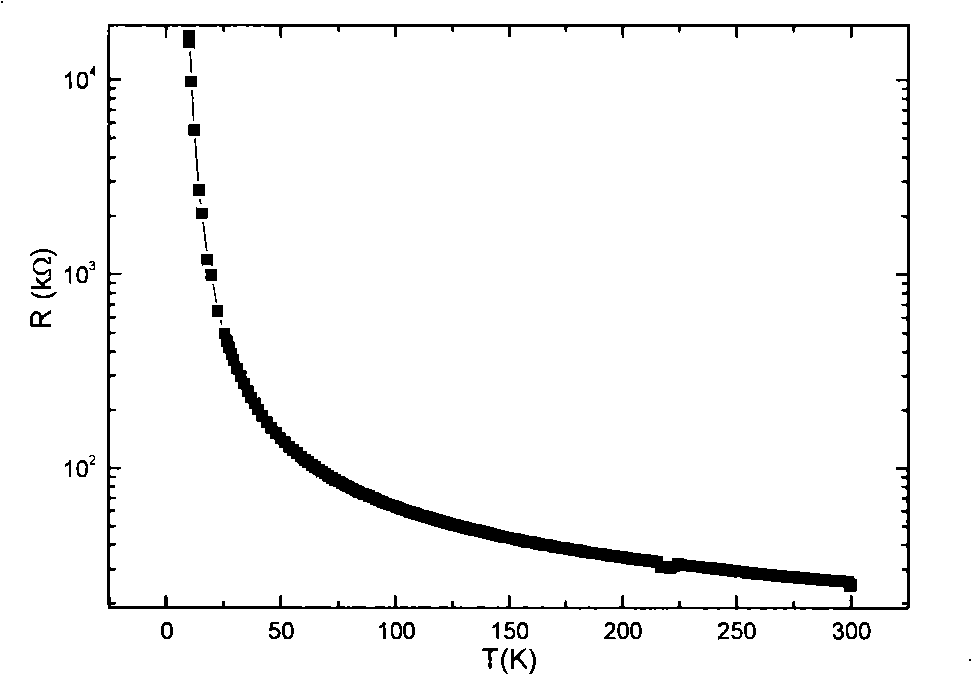

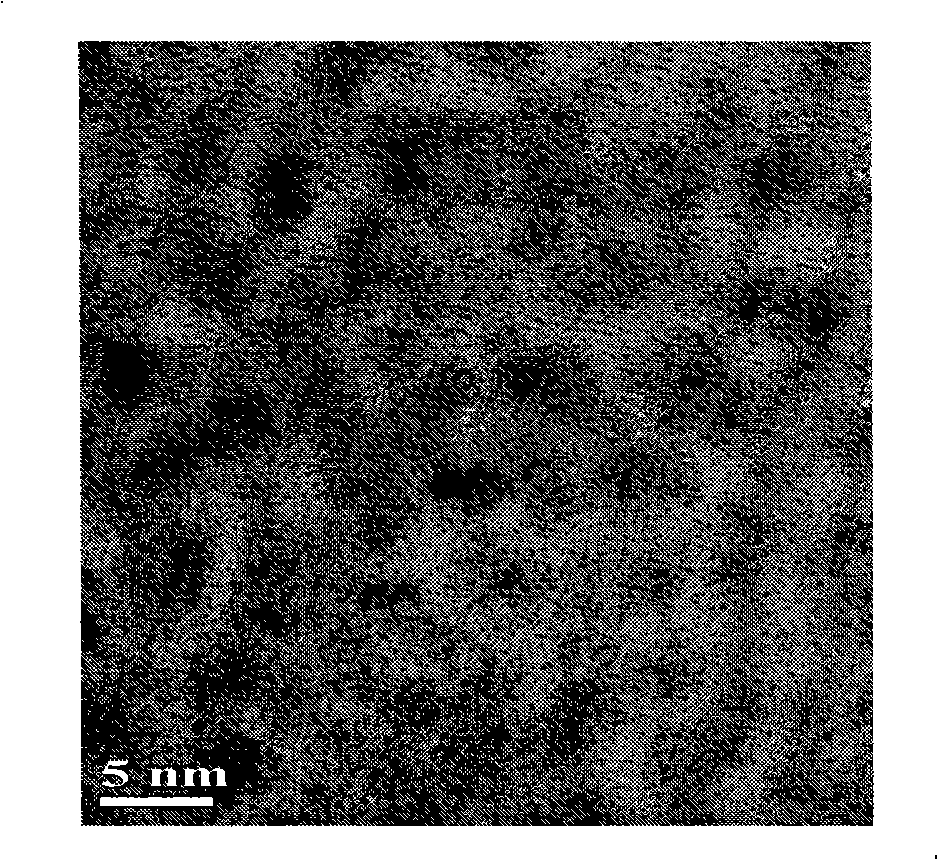

Magnetic composite organic nanometer granule film with magnetoresistance effect and preparation method thereof

InactiveCN101354945AWith giant magnetoresistance effectHigh resistivityMagnetic-field-controlled resistorsGalvano-magnetic material selectionMetallic materialsEvaporation

The invention belongs to the technical field of a magnetic film material, in particular to a magnetic composite organic nanometer granular film with giant magnetic resistance effect and a method for preparing the same. The film material is prepared and obtained from a magnetic metal material and an organic semiconductor material by a co-evaporation method; the nanometer granules of the magnetic metal material are evenly embedded in an organic semiconductor substrate and expressed as: (A)x(B)1-x, x is more than 0.28 and less than 0.56, wherein A is the magnetic metal material; and B is the organic semiconductor material. The film material can be widely used for a magnetic sensor, a magnetic memory, a temperature sensor and other element devices.

Owner:FUDAN UNIV

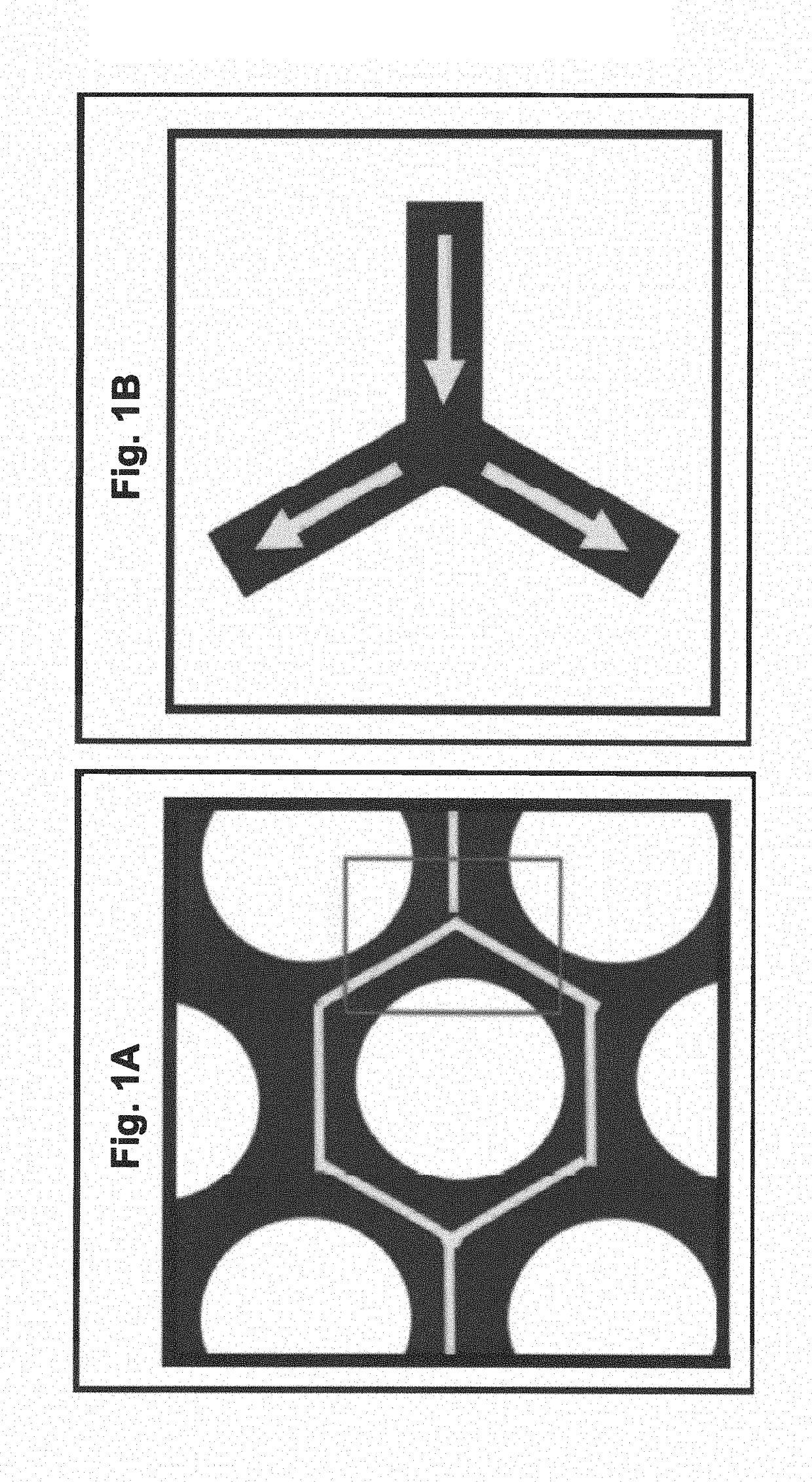

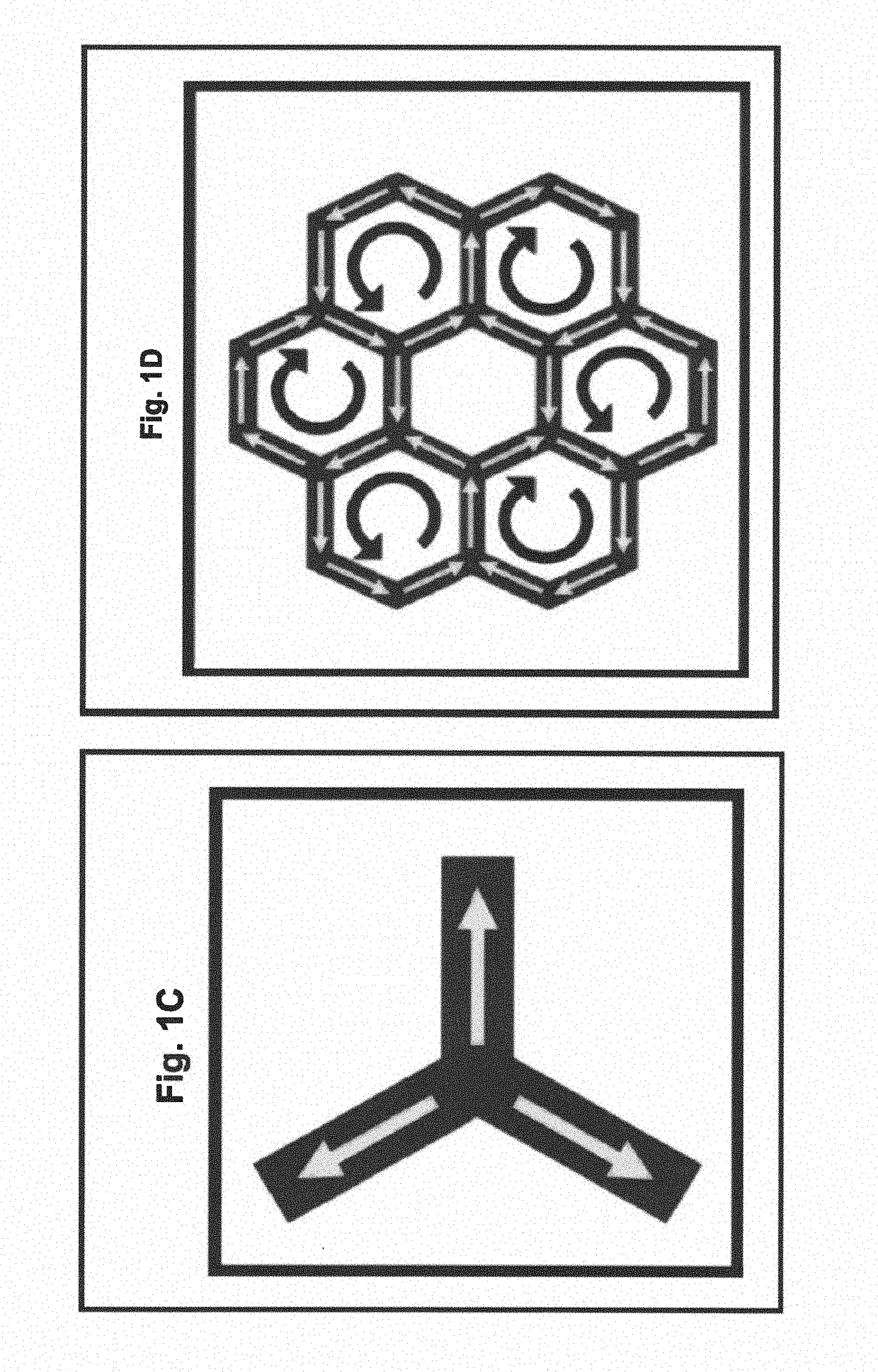

Magnetic Diode in Artificial Magnetic Honeycomb Lattice

ActiveUS20190058110A1Galvano-magnetic material selectionConductive/insulating/magnetic material on magnetic film applicationHoneycombNanometre

A magnetic artificial honeycomb lattice comprising a multiplicity of connecting elements separated by hexagonal cylindrical pores, wherein:(a) the hexagonal cylindrical pores:(i) have widths that are substantially uniform and an average width that is in a range of about 15 nm to about 20 nm; and(ii) are substantially equispaced and have an average center-to-center distance that is in a range of about 25 nm to about 35 nm; and(b) the connecting elements comprise a magnetic material layer, and the connecting elements have:(i) lengths that are substantially uniform and an average length that is in a range of about 10 nm to about 15 nm;(ii) widths that are substantially uniform and an average width that is in a range of about 4 nm to about 8 nm; and(iii) a thickness of the magnetic material layer that is substantially uniform and an average thickness that is in a range of about 2 nm to about 8 nm; and(c) the magnetic artificial honeycomb lattice has a surface area, disregarding the presence of the hexagonal cylindrical pores, that is in a range in a range of about 100 mm2 to about 900 mm2.

Owner:UNIVERSITY OF MISSOURI

Magnetic film for magnetic device

InactiveUS20050271901A1Improve recording densityHigh saturationNanomagnetismHeads using thin filmsMagnetizationEvaporation

Owner:FUJITSU LTD

CPP spin-valve element

InactiveUS7538987B2Increase resistanceLower average currentMagnetic-field-controlled resistorsSolid-state devicesCurrent limitingCoupling

A CPP spin-valve element formed on a substrate including a free layer structure including at least one ferromagnetic layer and a pinned layer structure including at least one ferromagnetic layer. The free layer is magnetically softer than the pinned layer. A thin non-magnetic spacer layer structure configured to separate the free layer and the pinned layer is provided in order to prevent a magnetic coupling between the free and pinned layer structures, and to allow an electric current to go there through. At least two current-confining (CC) layer structures including at least two parts having significantly different current conductivities are incorporated therein.

Owner:UNIVERSITY OF ALABAMA +1

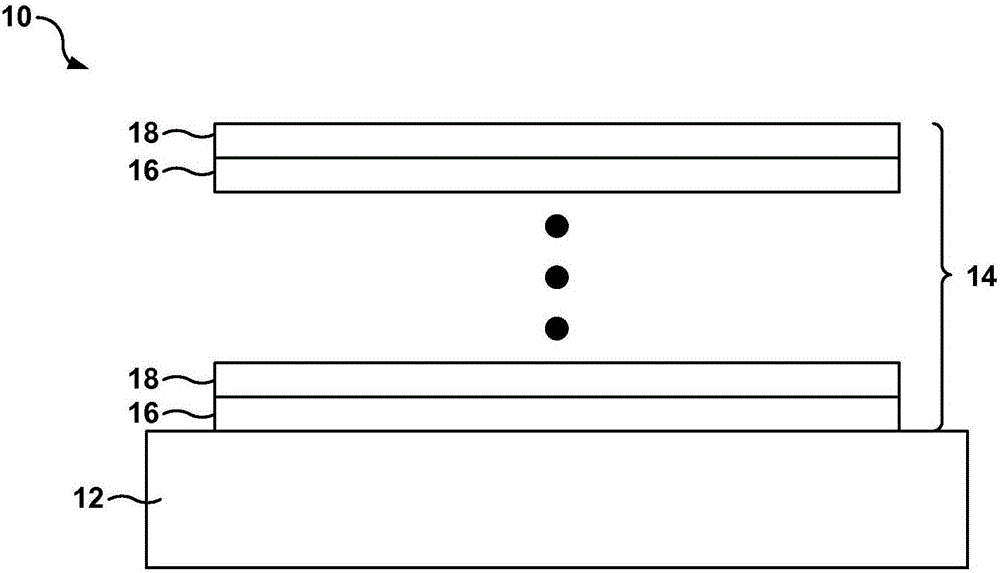

Multilayer iron nitride hard magnetic materials

The disclosure describes multilayer hard magnetic materials including at least one layer including alpha"-Fe16N2 and at least one layer including alpha"-Fe16(NxZ1-x)2 or a mixture of alpha"-Fe16N2 and alpha"-Fe16Z2, where Z includes at least one of C, B, or O, and x is a number greater than zero and less than one. The disclosure also describes techniques for forming multilayer hard magnetic materials including at least one layer including alpha"-Fe16N2 and at least one layer including alpha"-Fe16(NxZ1-x)2 or a mixture of alpha"-Fe16N2 and alpha"-Fe16Z2 using chemical vapor deposition or liquid phase epitaxy.

Owner:RGT UNIV OF MINNESOTA

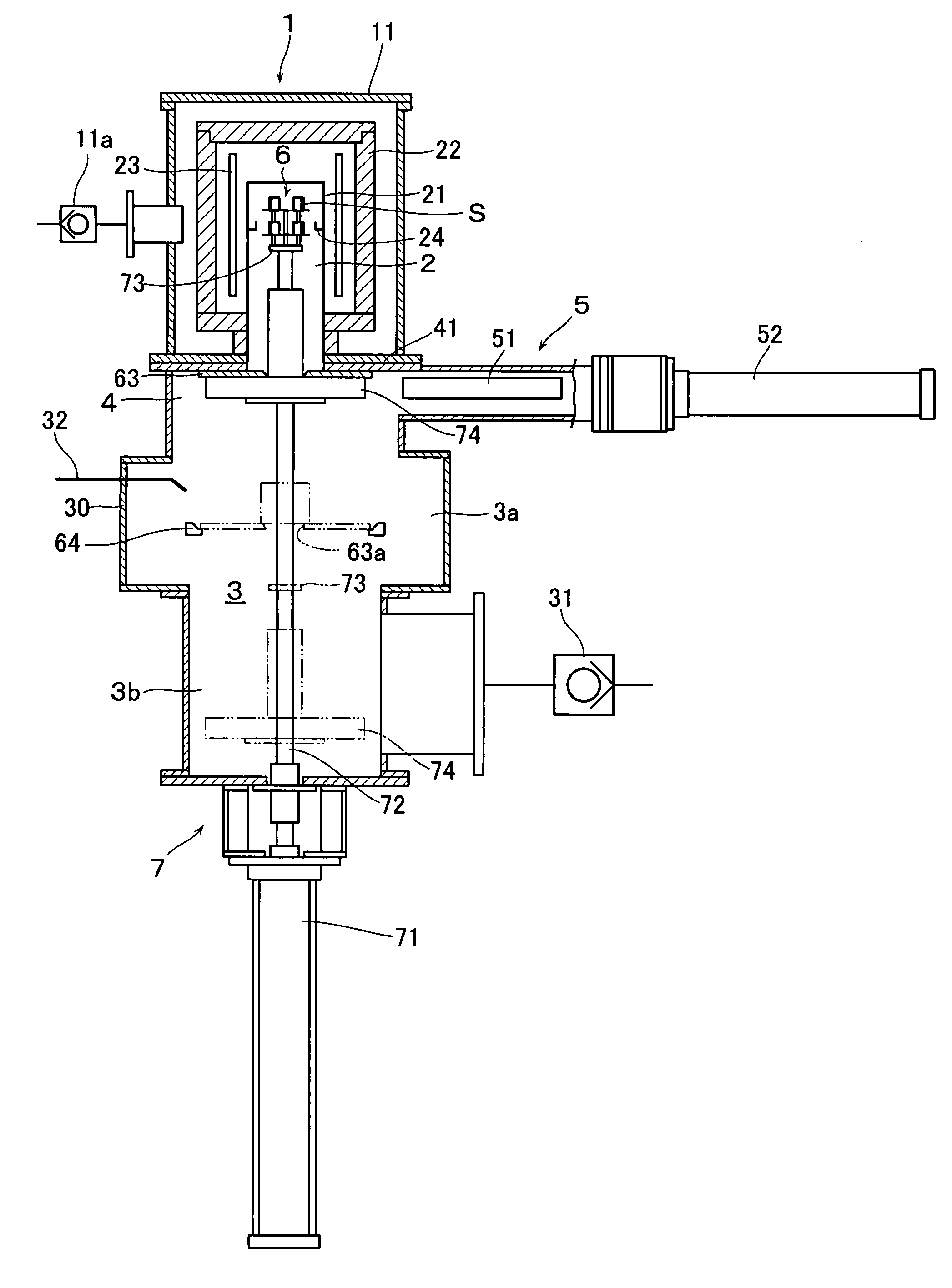

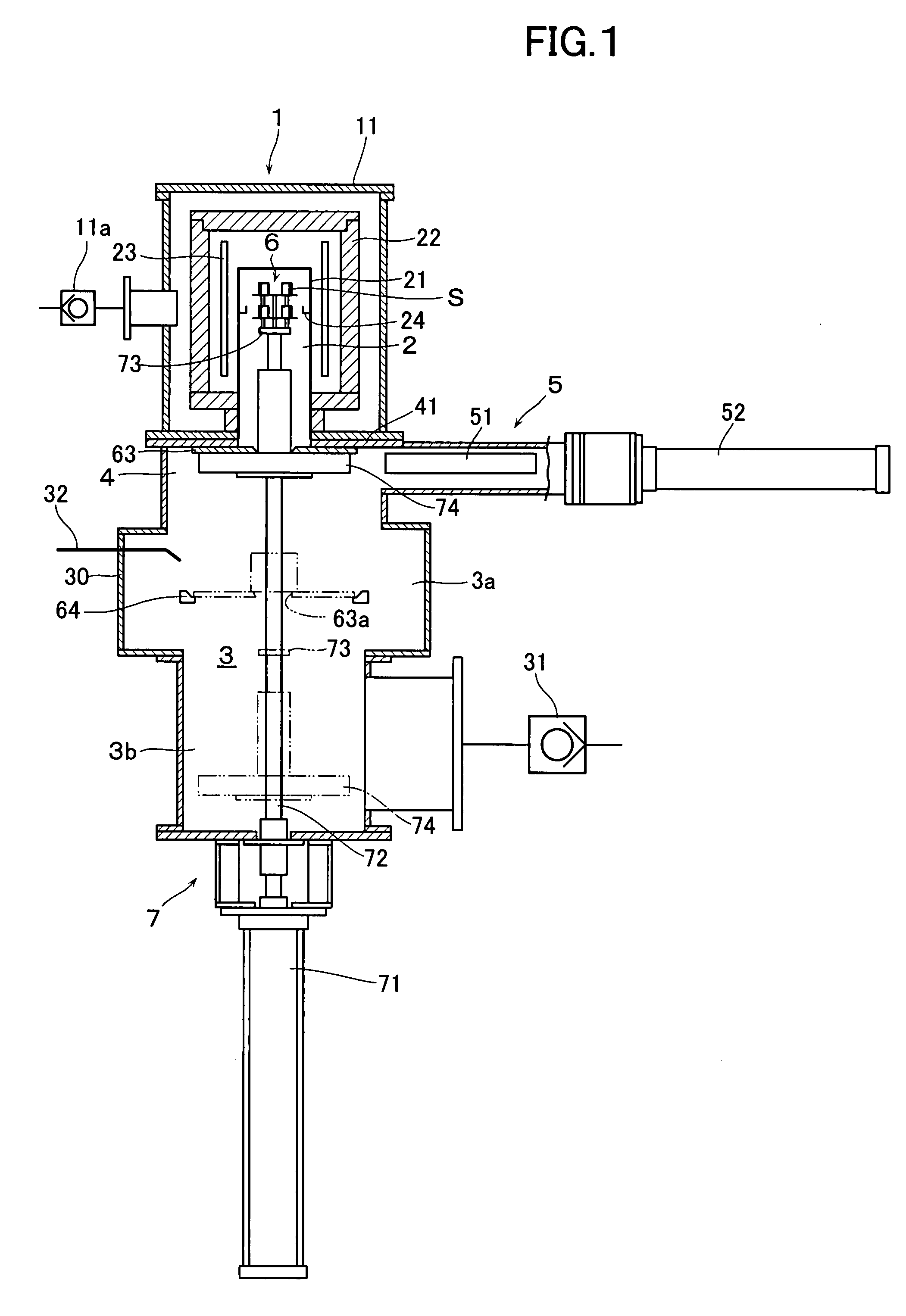

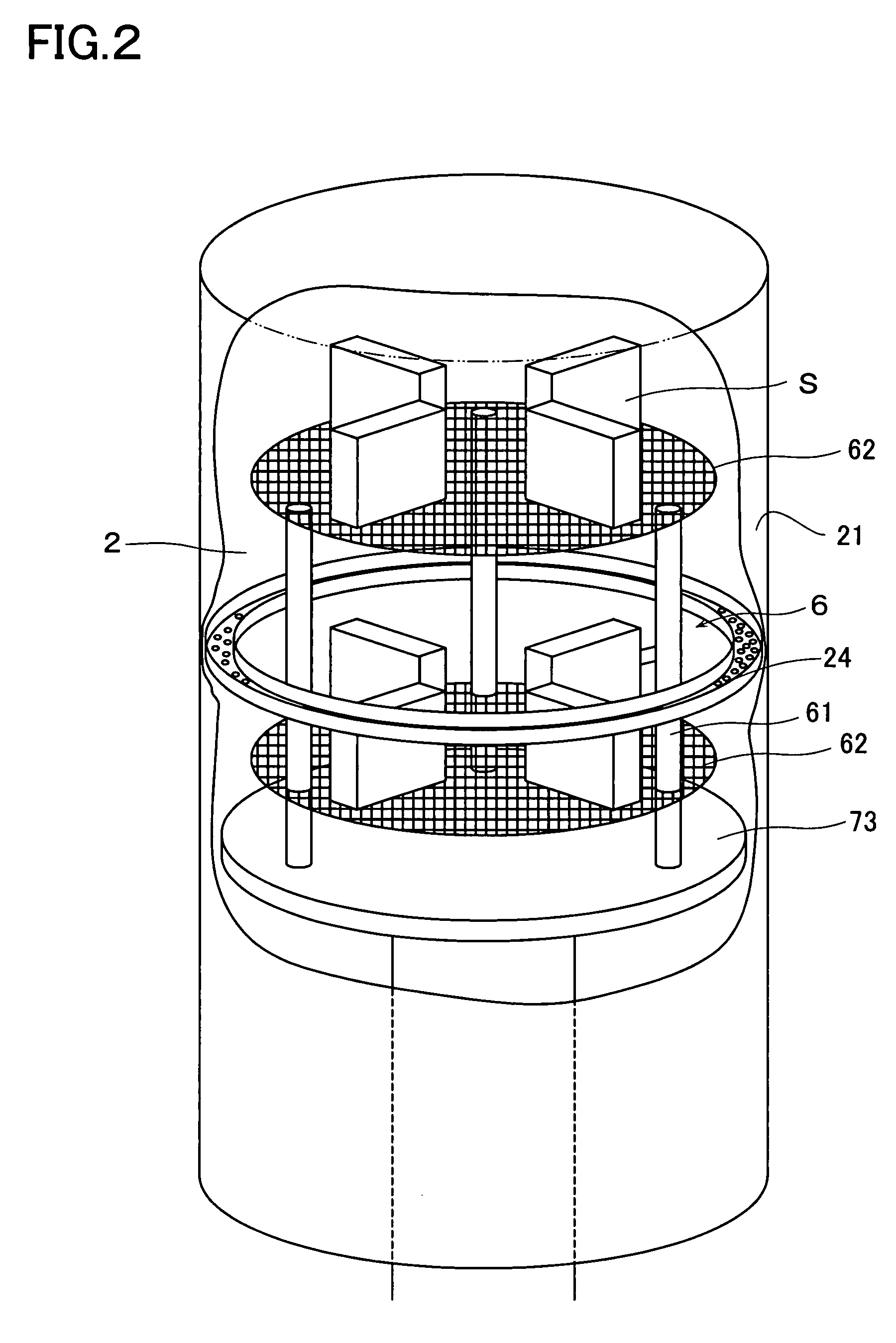

Coating method and apparatus, a permanent magnet, and manufacturing method thereof

ActiveUS20100159129A1Improve productivityLow costVacuum evaporation coatingSputtering coatingRare-earth elementProduction rate

The object of the present invention is to improve the productivity of a permanent magnet and to manufacture it at a low cost by effectively coating Dy and Tb on a surface of the magnet of Fe—B-rare earth elements having a predetermined configuration. The permanent magnet of the present invention is manufactured by a coating step for coating Dy on the surface of the magnet of Fe—B-rare earth elements having a predetermined configuration and a diffusing step for diffusing Dy coated on the surface of the magnet into crystal grain boundary phases of the magnet with being heat treated at a predetermined temperature. In this case, the coating step comprises a first step for heating a process chamber used for carrying out the coating step and generating metallic vapor atmosphere within the process chamber by vaporizing vaporizable metallic material previously arranged within the process chamber, and a second step for introducing into the process chamber the magnet held at a temperature lower than that within the process chamber and then selectively depositing the vaporizable metallic material on a surface of the magnet by an effect of temperature difference between the temperature within the process chamber and that of the magnet by the magnet reaches a predetermined temperature.

Owner:ULVAC INC

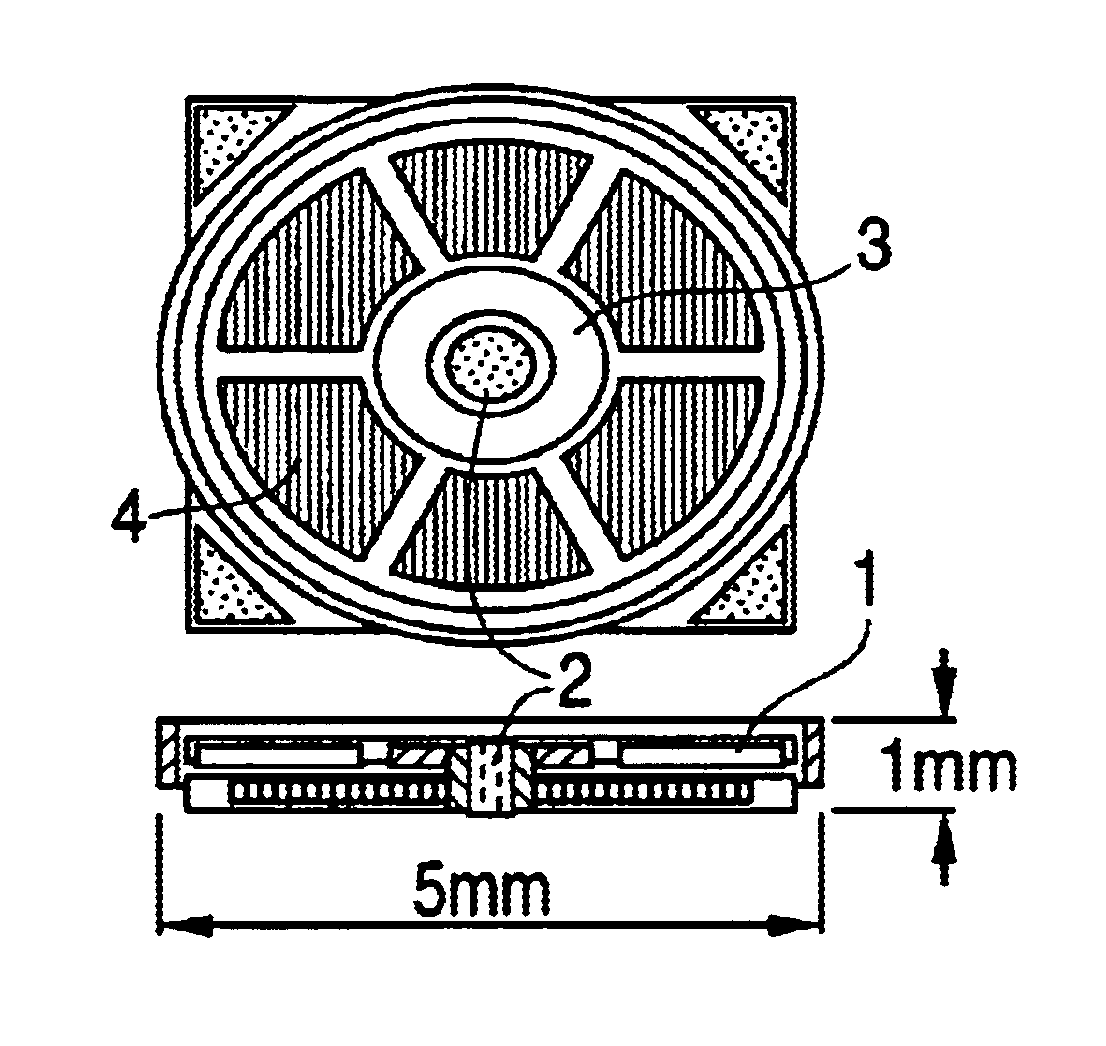

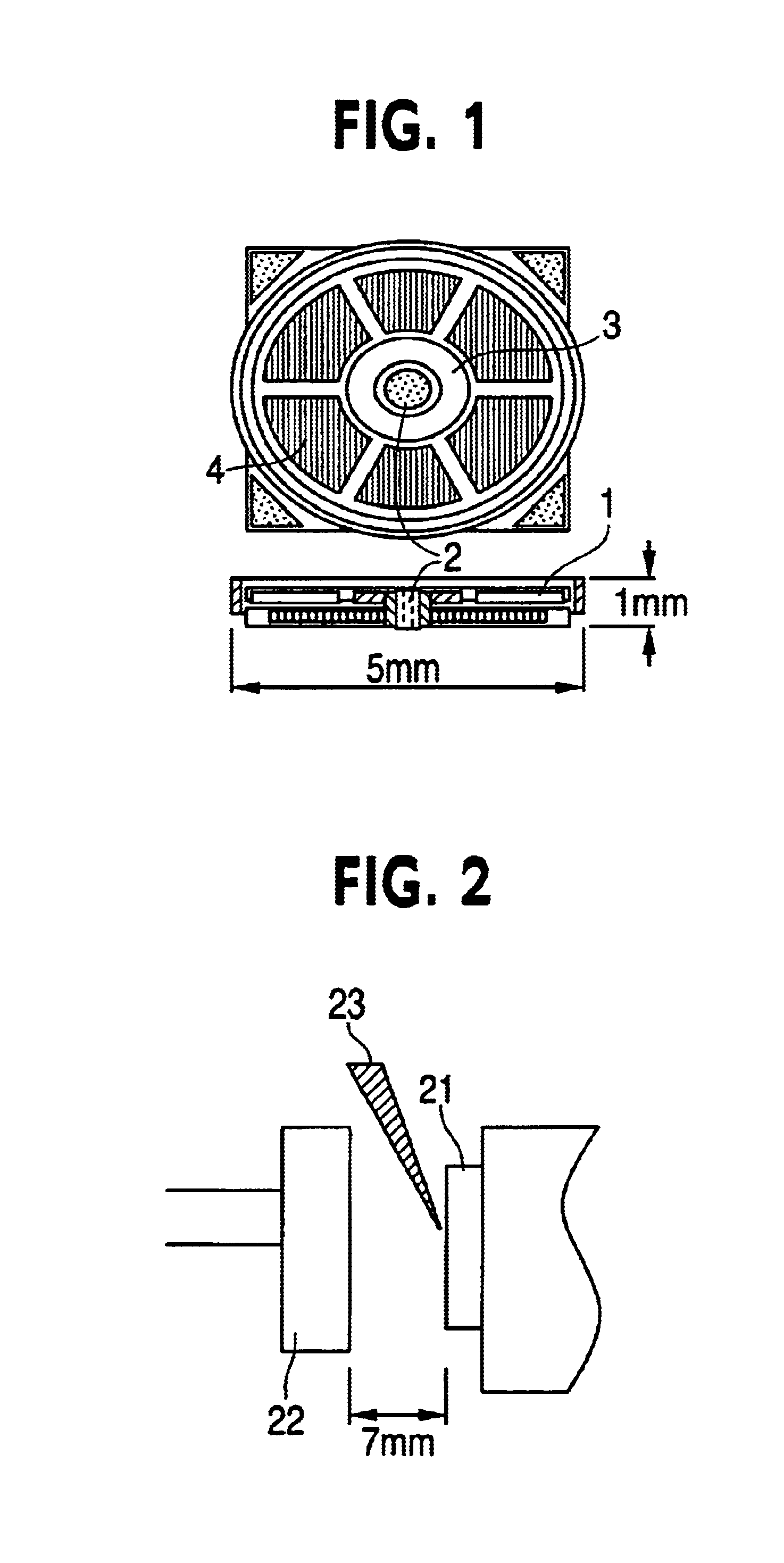

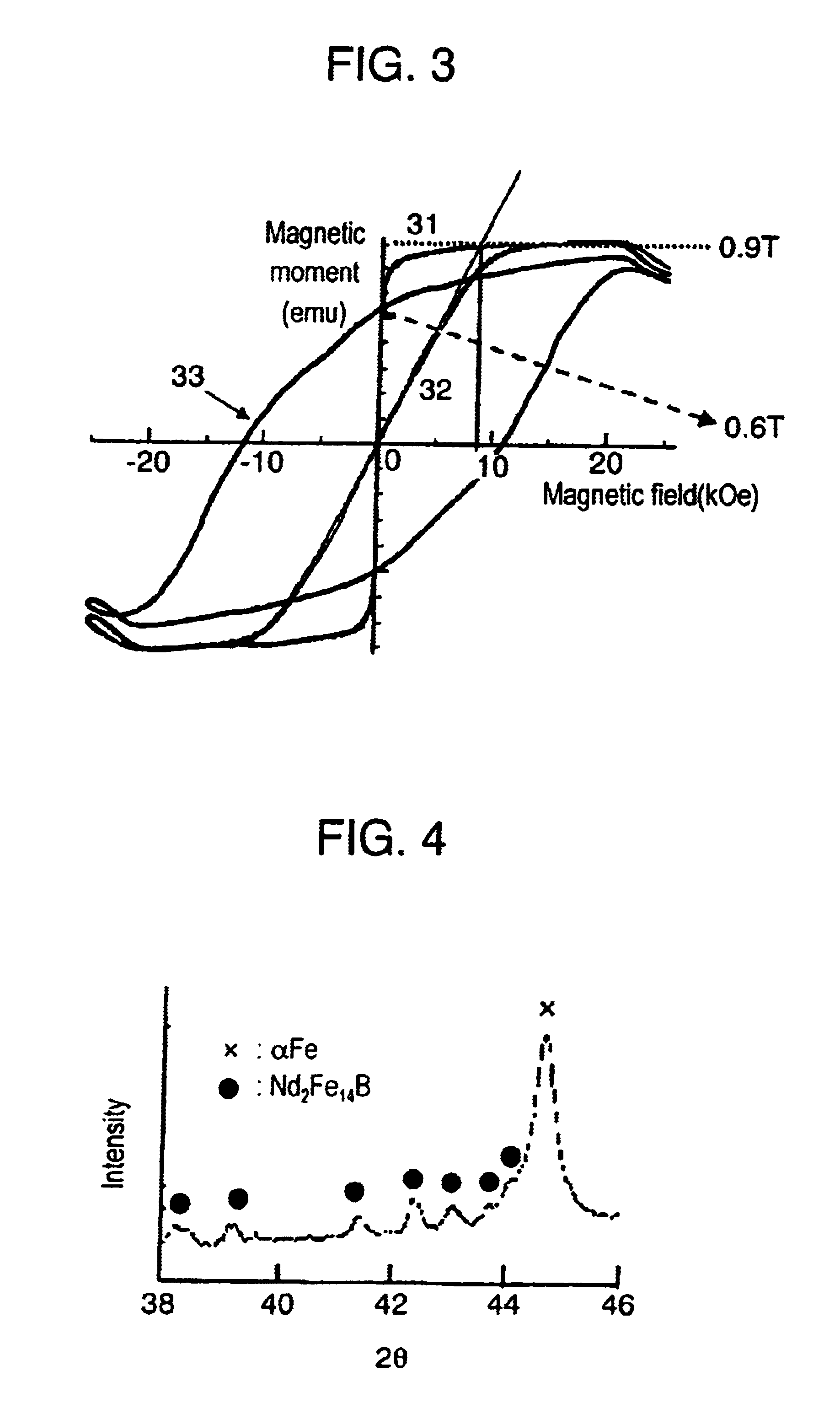

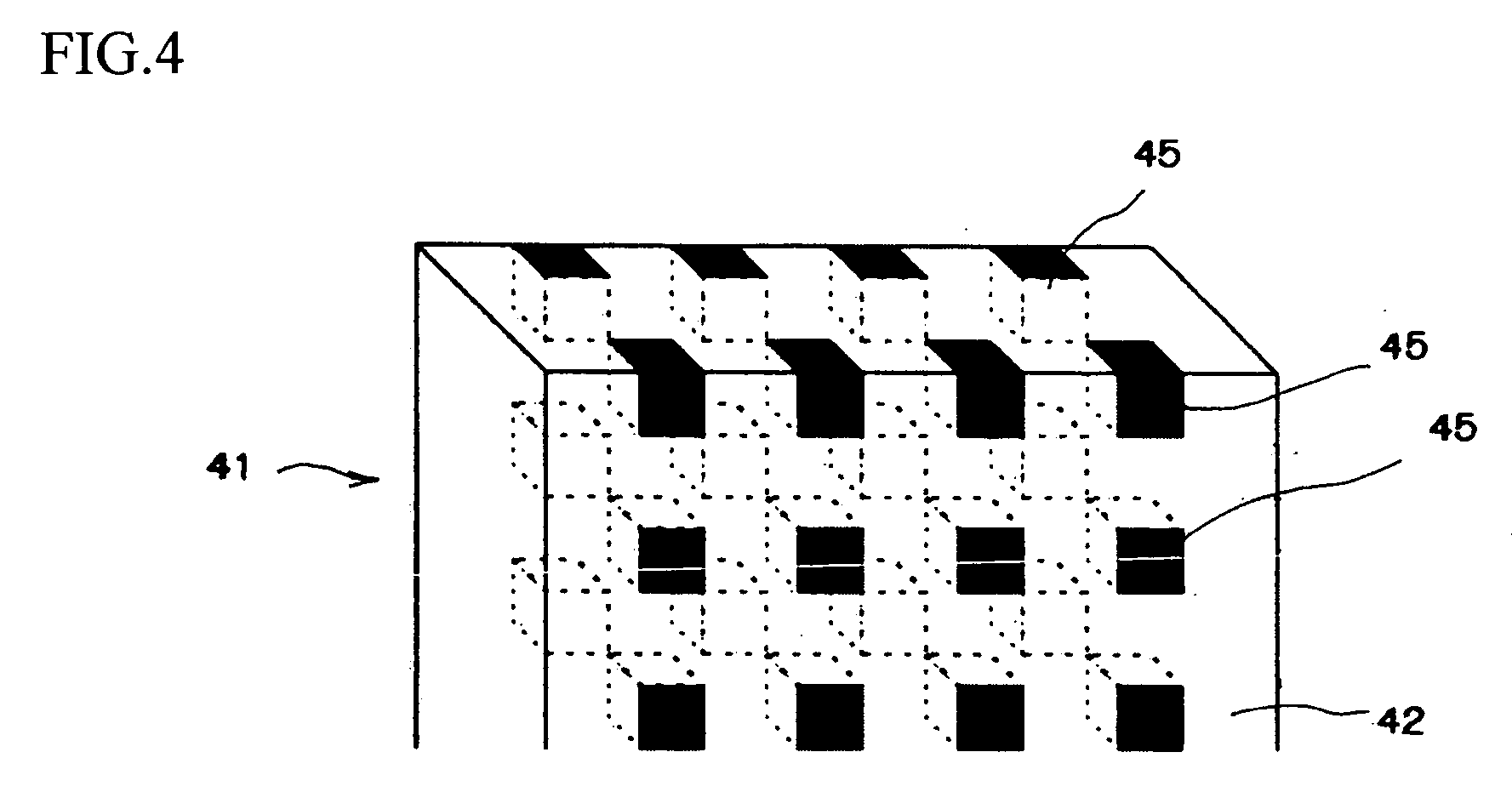

Method of manufacturing a motor comprising a rare earth thick film magnet

InactiveUS6941637B2Easy to assembleSmall sizeElectromagnets without armaturesEvaporation applicationRare-earth elementAlloy

The method of manufacturing rare earth thick film magnet comprising a step of forming an alloy layer of 30-100 μm thick having a general formula RXBYTMZ on a substrate by a physical deposition process, and a step of heat-treating the alloy layer to form a thick film magnetic layer having R2TM14B phase as a main phase. In the general formula, R is at least one of rare earth elements, B is boron, TM is iron or its alloy partly substituted by cobalt. X is 0.1-0.2, Y is 0.05-0.2 and Z=1-X-Y. Further, the method of the present invention includes a step of laminating a plurality of alloy layers formed on a substrate together with the substrate. A motor comprising rare earth thick film magnet of the present invention is extremely small while obtaining high output.

Owner:PANASONIC CORP

R-Fe-B rare-earth sintered magnet and process for producing the same

ActiveUS8038807B2Easy to useImprove remanenceVacuum evaporation coatingPermanent magnetsRare-earth elementSintered magnets

First, an R—Fe—B based rare-earth sintered magnet body including, as a main phase, crystal grains of an R2Fe14B type compound that includes a light rare-earth element RL, which is at least one of Nd and Pr, as a major rare-earth element R is provided. Next, an M layer, including a metallic element M that is at least one element selected from the group consisting of Al, Ga, In, Sn, Pb, Bi, Zn and Ag, is deposited on the surface of the sintered magnet body and then an RH layer, including a heavy rare-earth element RH that is at least one element selected from the group consisting of Dy, Ho and Tb, is deposited on the M layer. Thereafter, the sintered magnet body is heated, thereby diffusing the metallic element M and the heavy rare-earth element RH from the surface of the magnet body deeper inside the magnet.

Owner:HITACHI METALS LTD

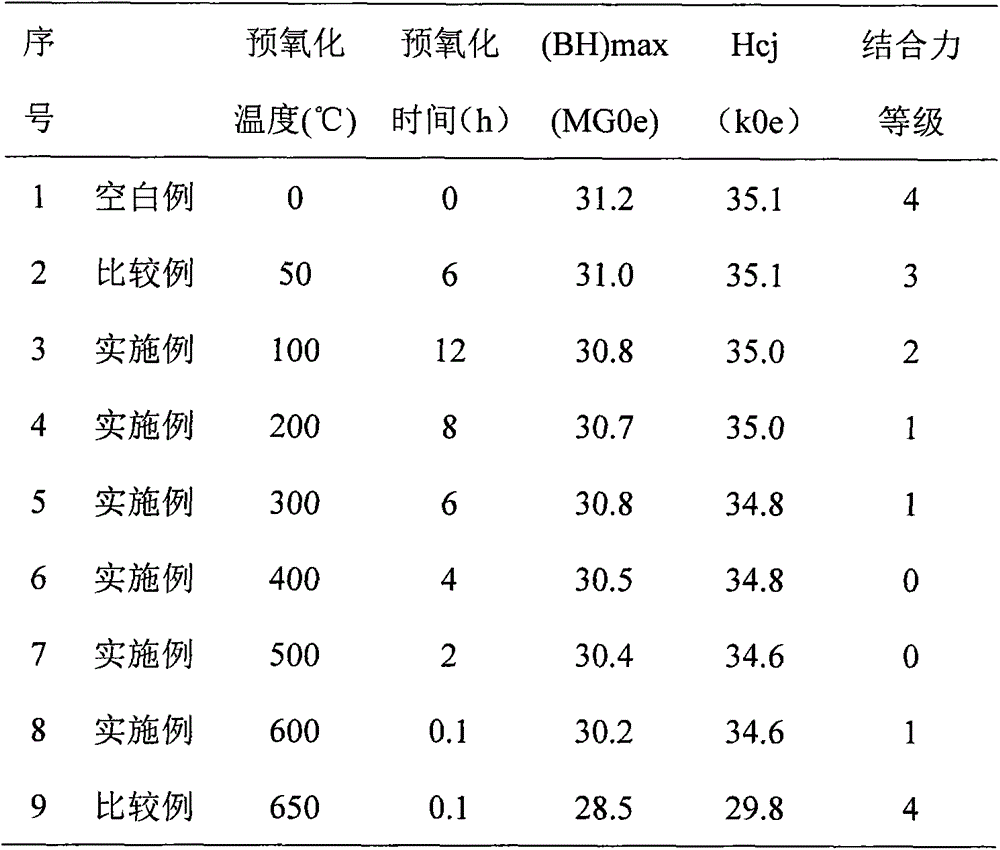

Vacuum evaporation coating method and rare earth magnet covered with evaporation coating

ActiveCN104032263AAvoid excessive oxidationOvercoming the problem of weak bindingVacuum evaporation coatingSputtering coatingRare-earth elementThin layer

The invention discloses a vacuum evaporation coating method and a rare earth magnet covered with an evaporation coating. The method includes steps of: 1) installing a rare earth magnet workpiece to a workpiece rest before pretreatment; 2) sending the workpiece rest into a reaction chamber, and performing preoxidation; 3) sending the workpiece rest to a coating chamber, vacuumizing, heating a meta evaporating material M to an evaporation temperature, and subjecting the rare earth magnet workpiece to evaporation coating; and 4) cooling, restoring to normal pressure and taking the workpiece out. According to the method, the rare earth magnet is subjected to trace oxidation in advance and is subjected to replacement by feeding M steam, thus preventing excessive oxidation of the rare earth magnet, and obtaining a dense MO distribution thin layer and an M layer firmly connected to the MO distribution thin layer.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

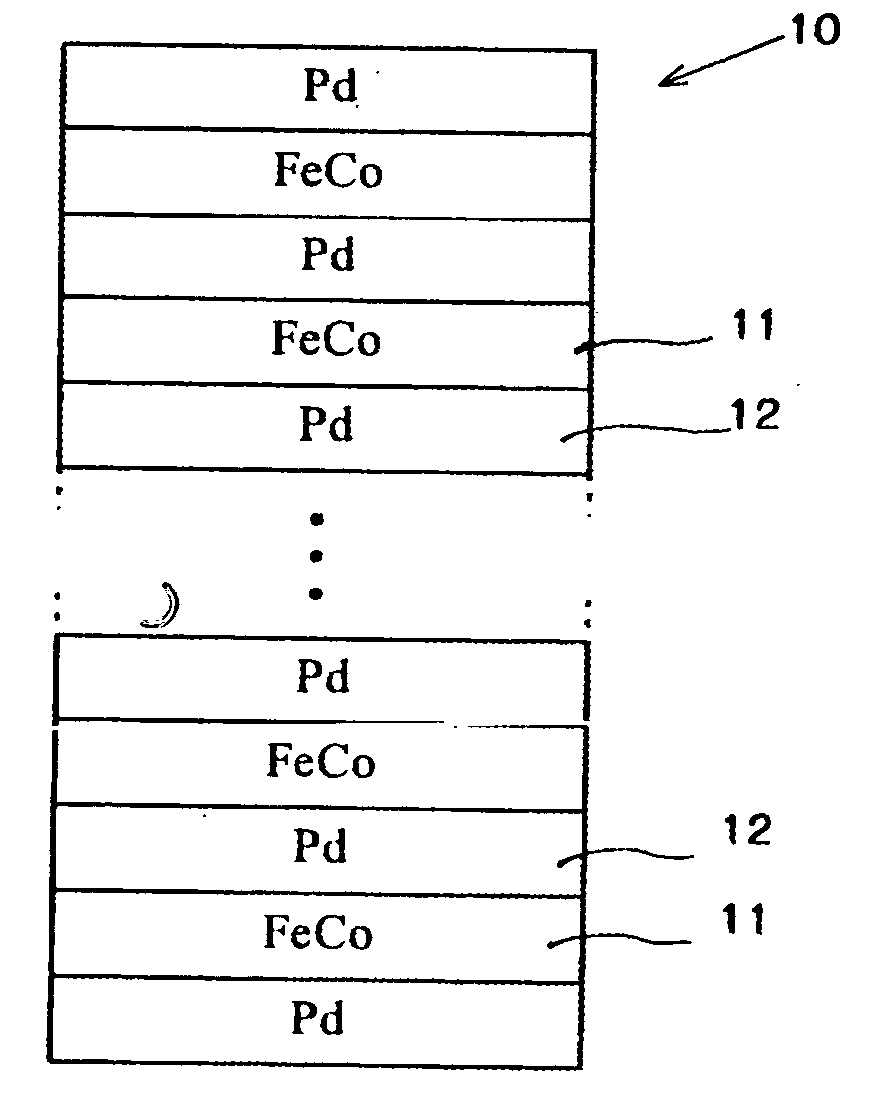

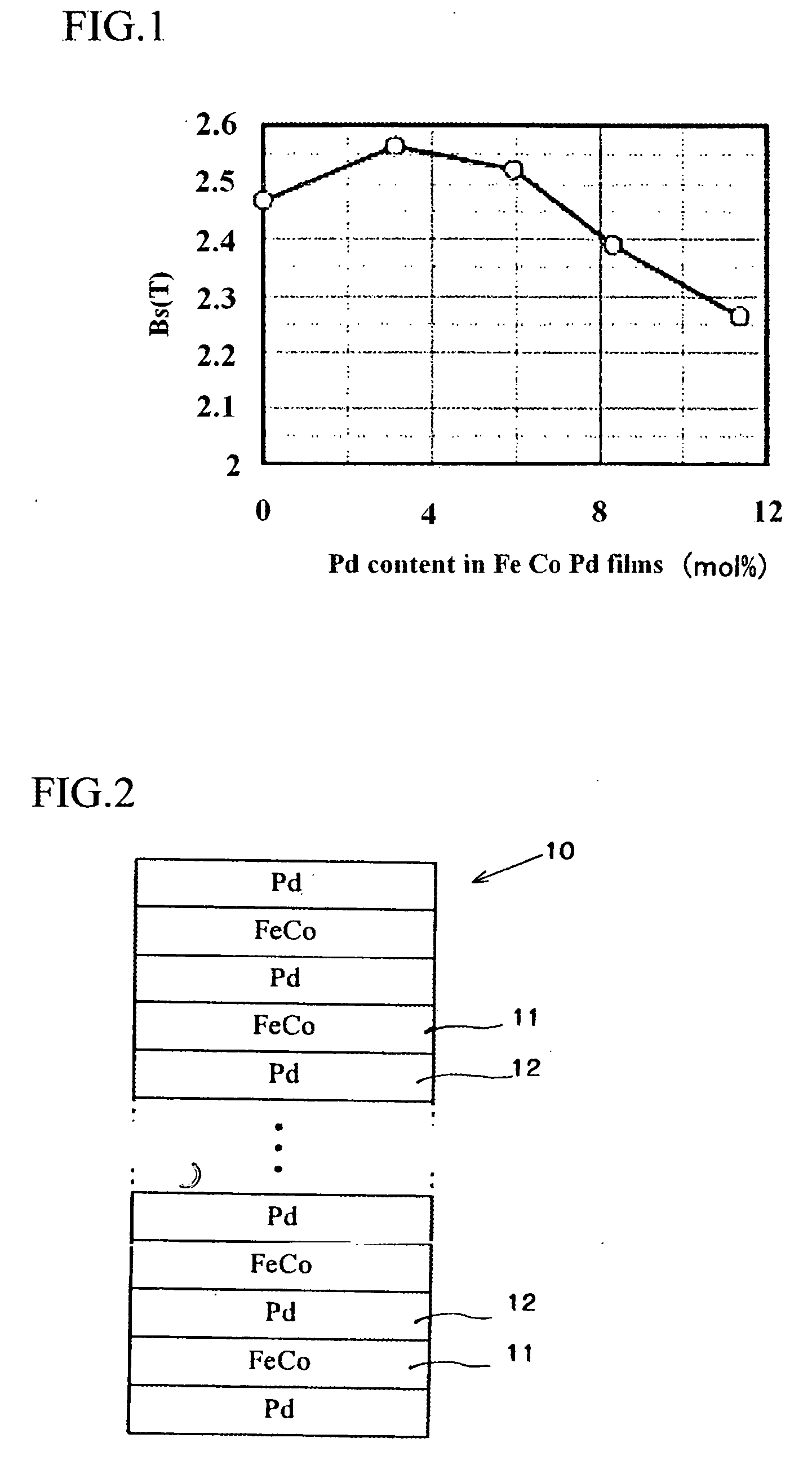

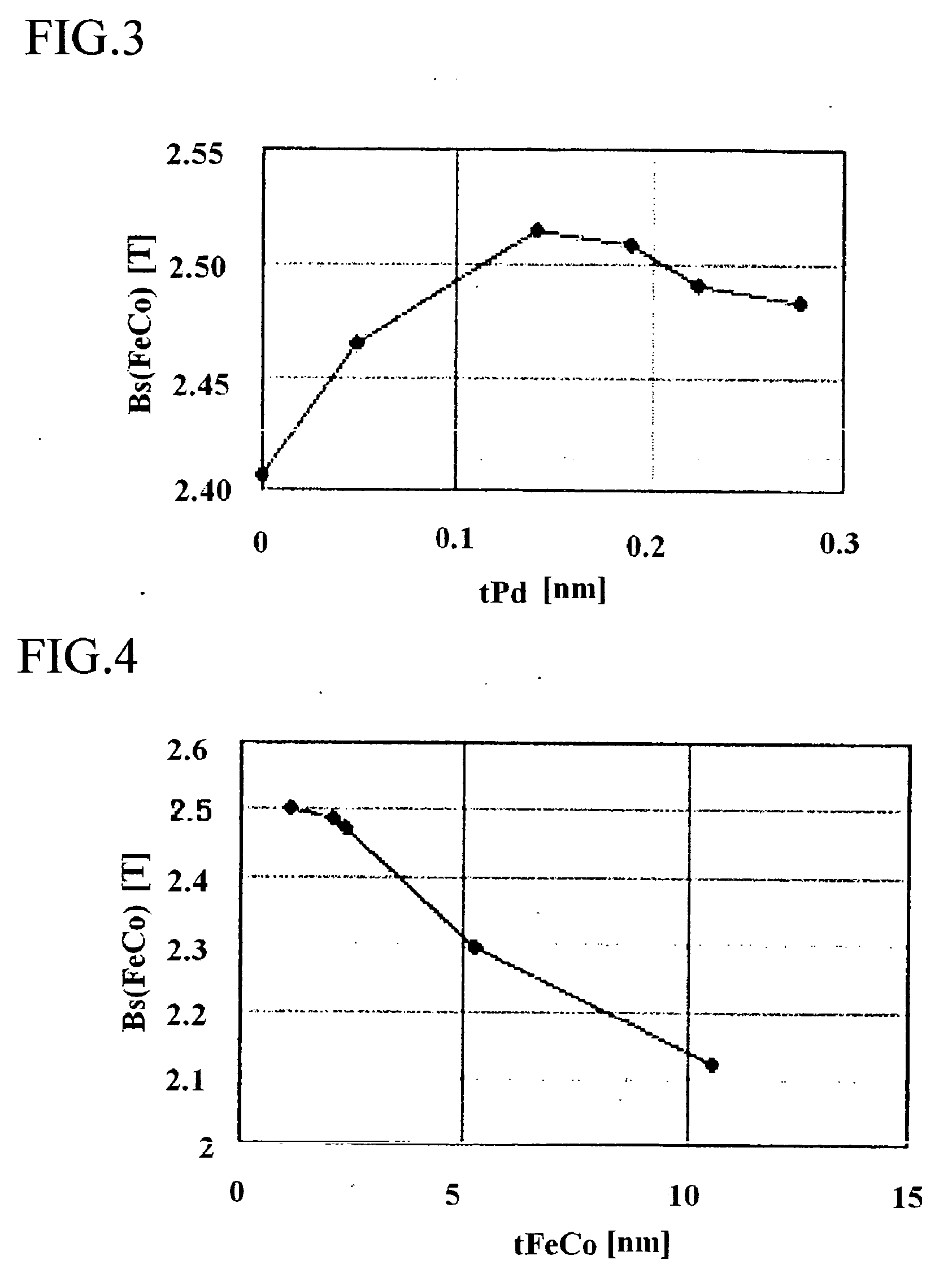

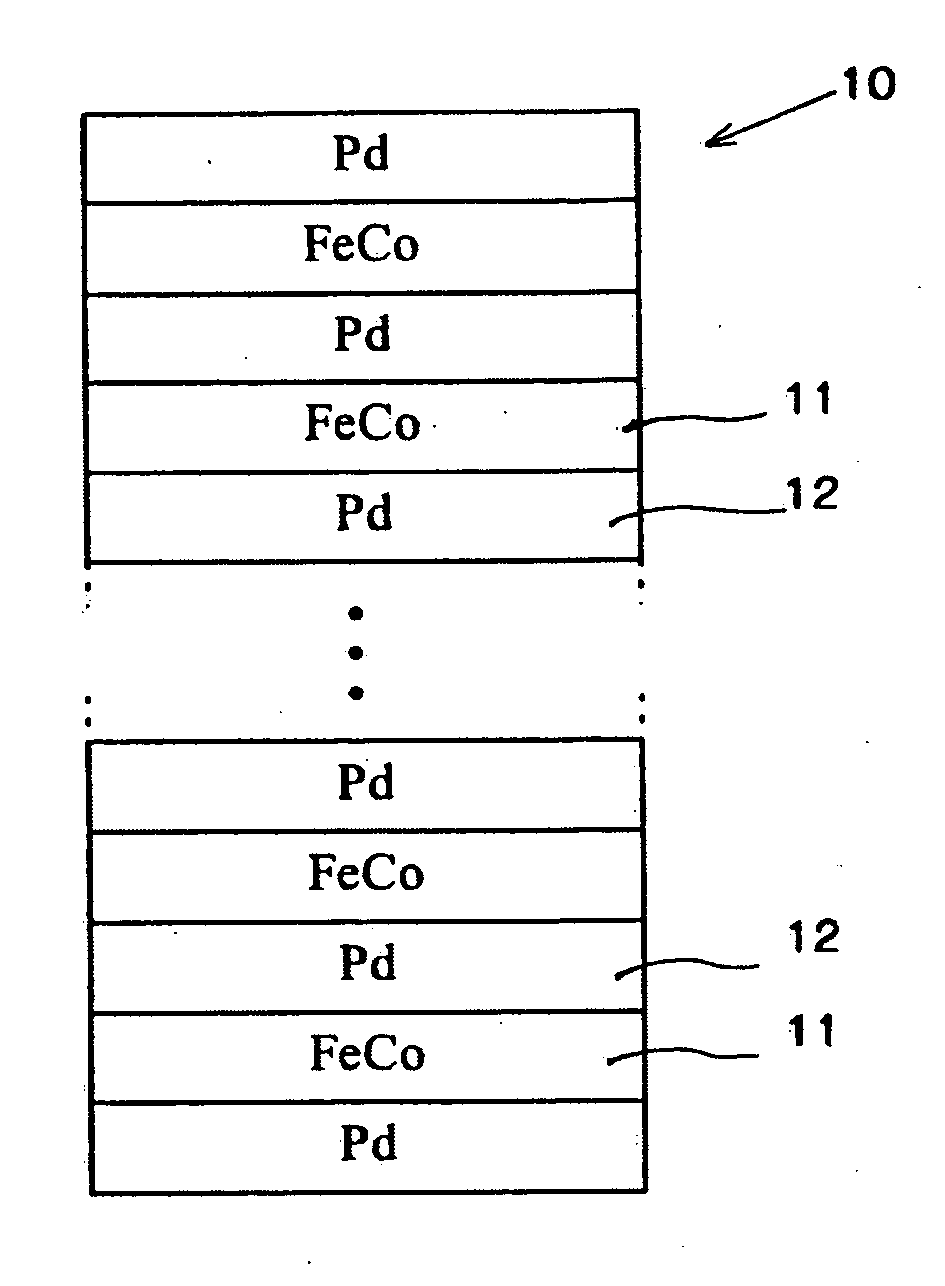

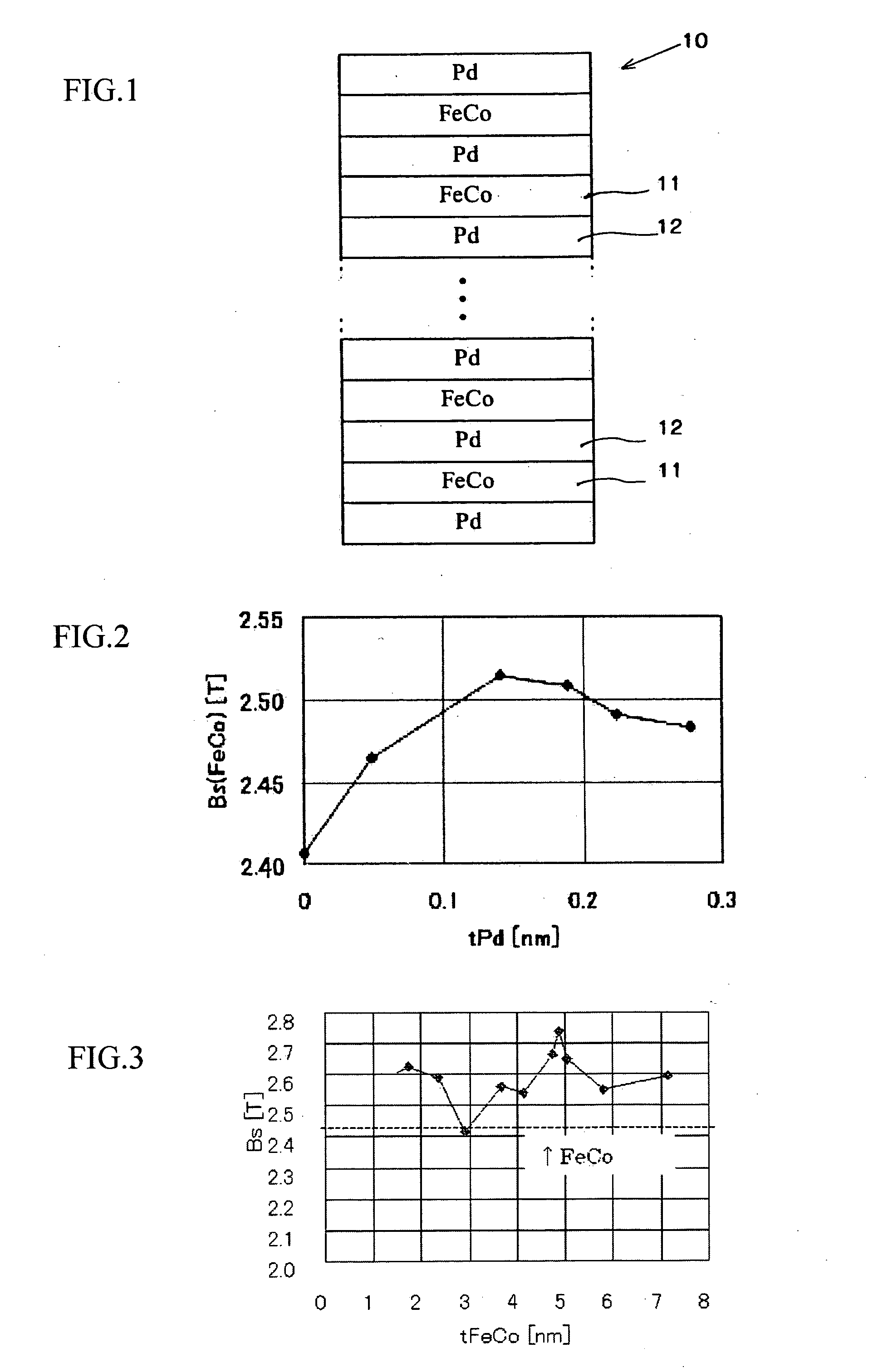

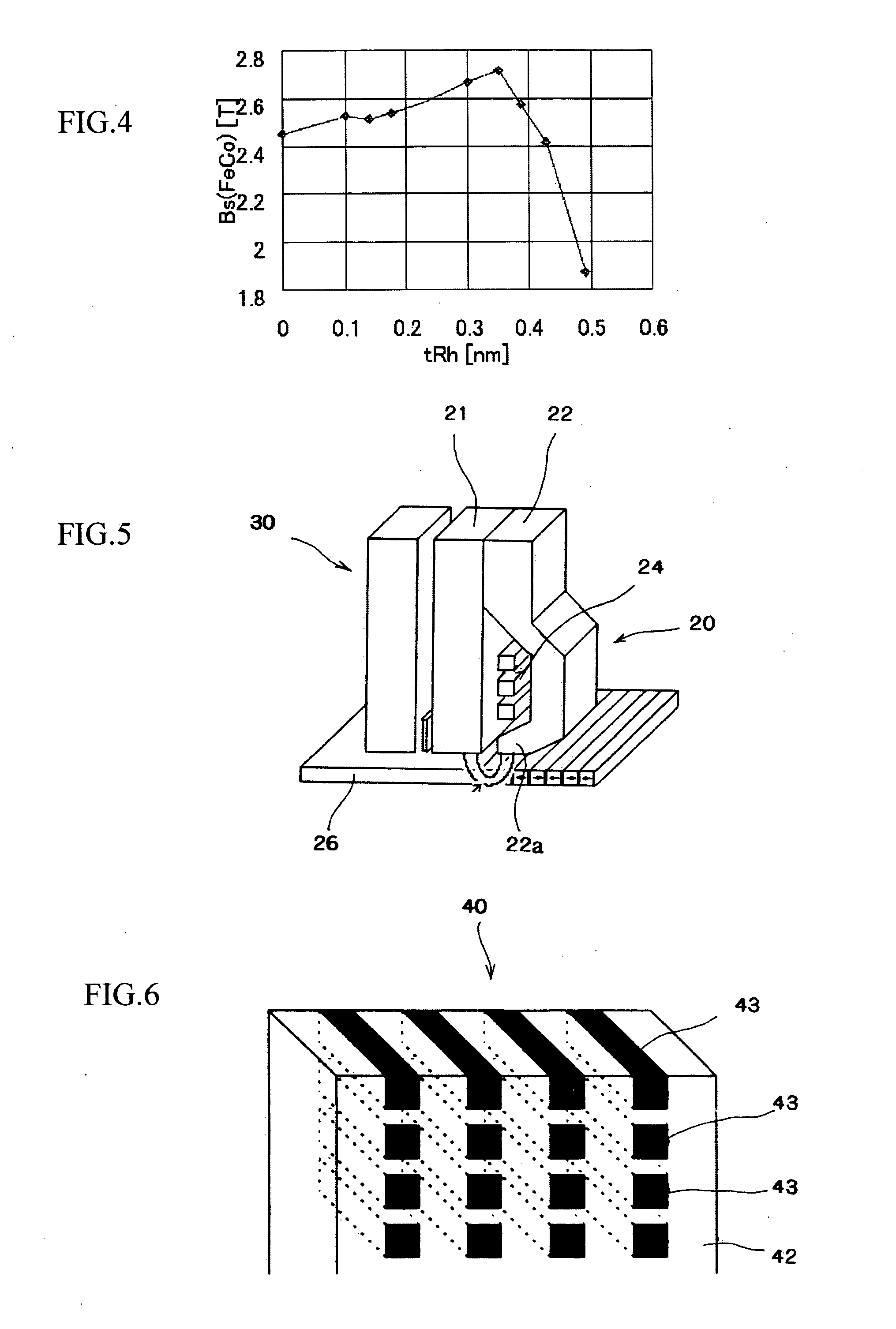

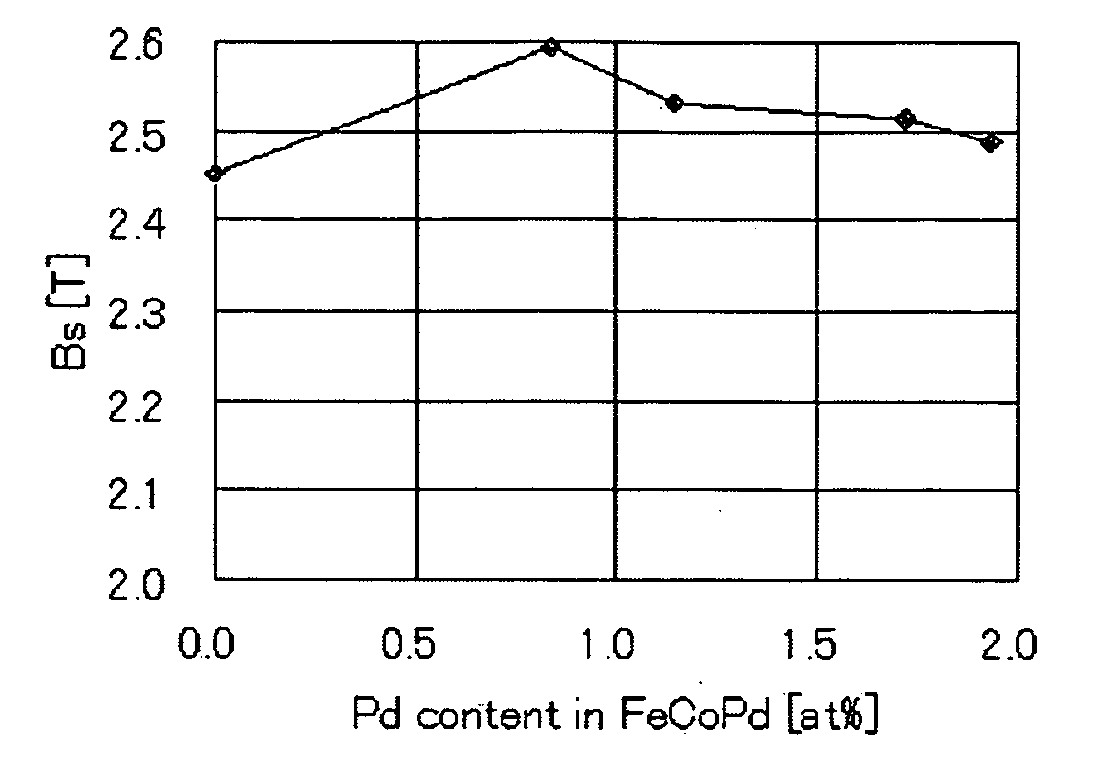

Magnetic film for a magnetic device, magnetic head for a hard disk drive, and solid-state device

InactiveUS20060083950A1NanomagnetismChemical vapor deposition applicationHard disc driveVolumetric Mass Density

There is provided a magnetic material with a high saturation magnetization of 2.46 teslas or above. By using this magnetic material in a recording head, it is possible to record information with a higher density on a recording medium. The magnetic material can also be applied to various kinds of solid-state devices. A magnetic film for a magnetic device is composed of a multilayer film where ferromagnetic films and palladium films or alloy films including palladium are alternately laminated. The laminated palladium films or alloy films including palladium have a main crystal structure that is a body-centered cubic structure, and the multilayer film is formed by dry processing.

Owner:FUJITSU LTD

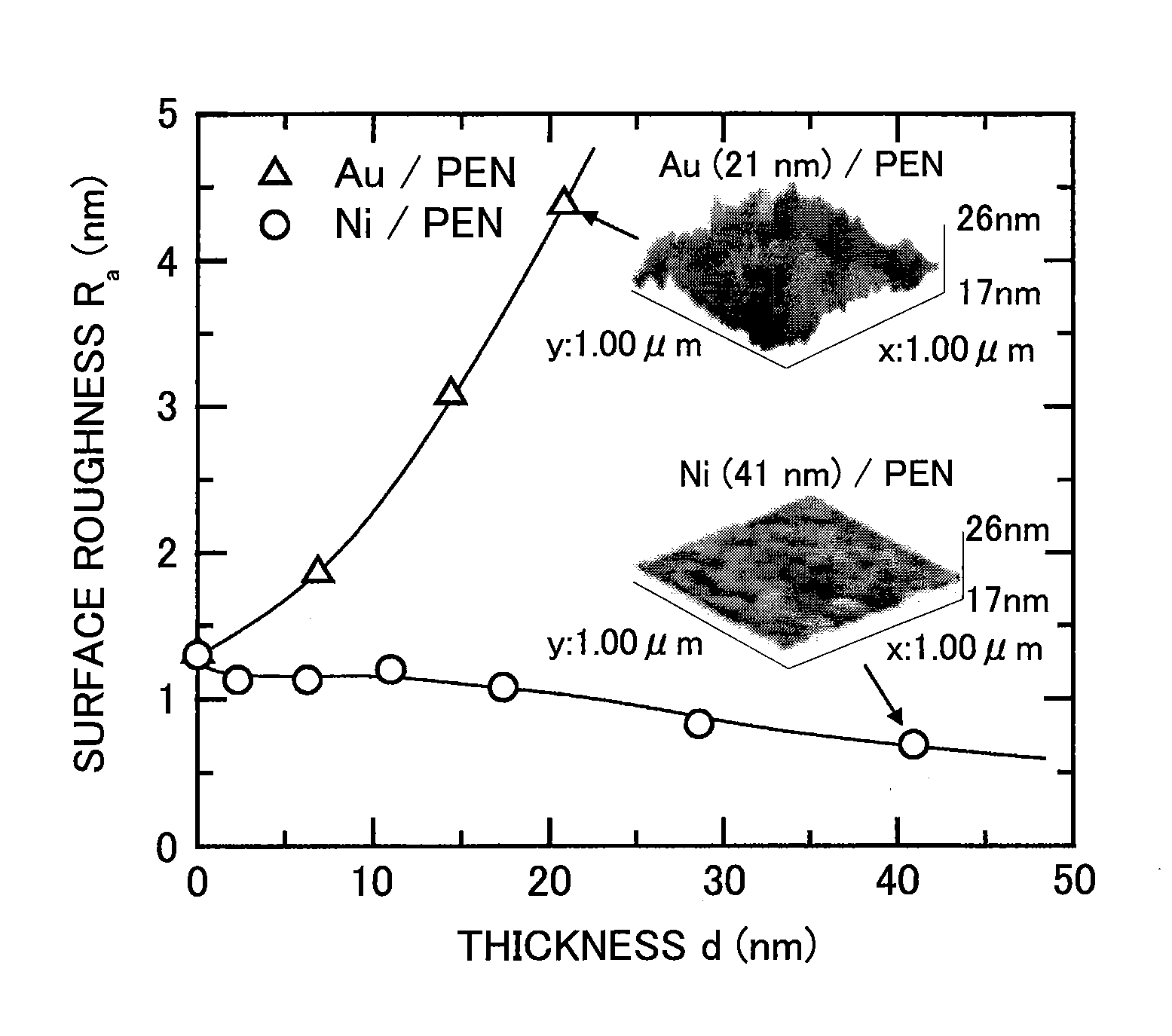

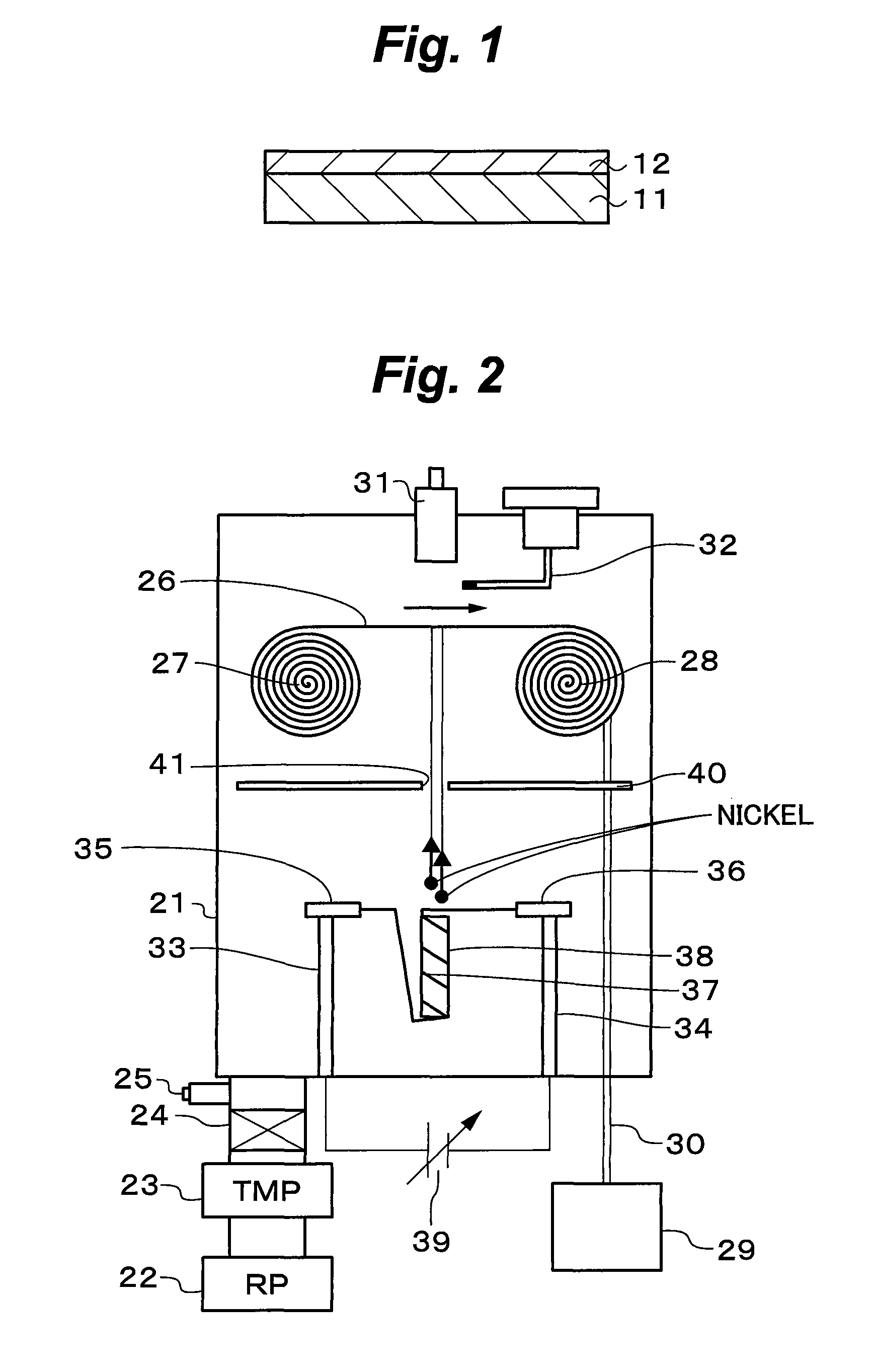

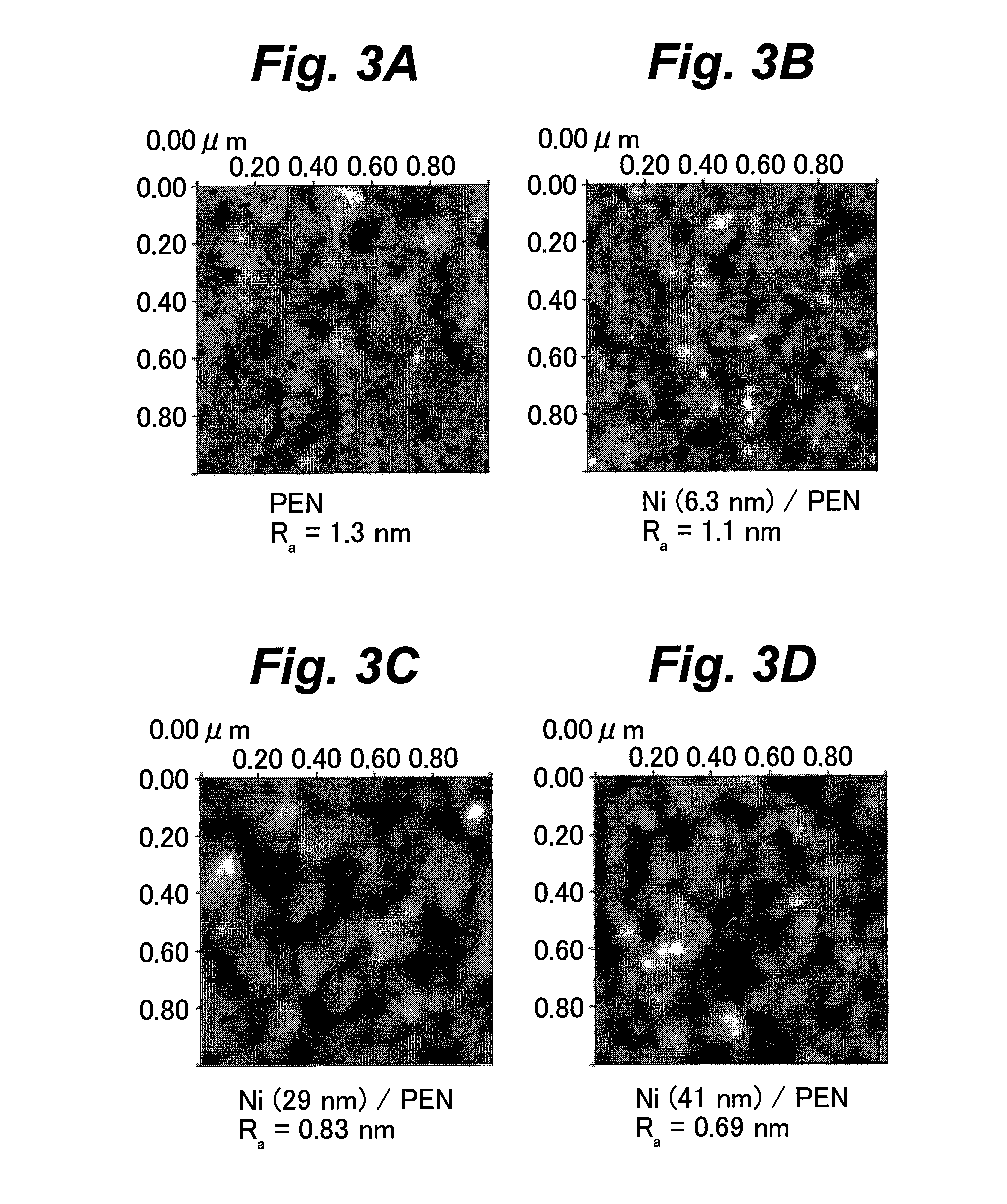

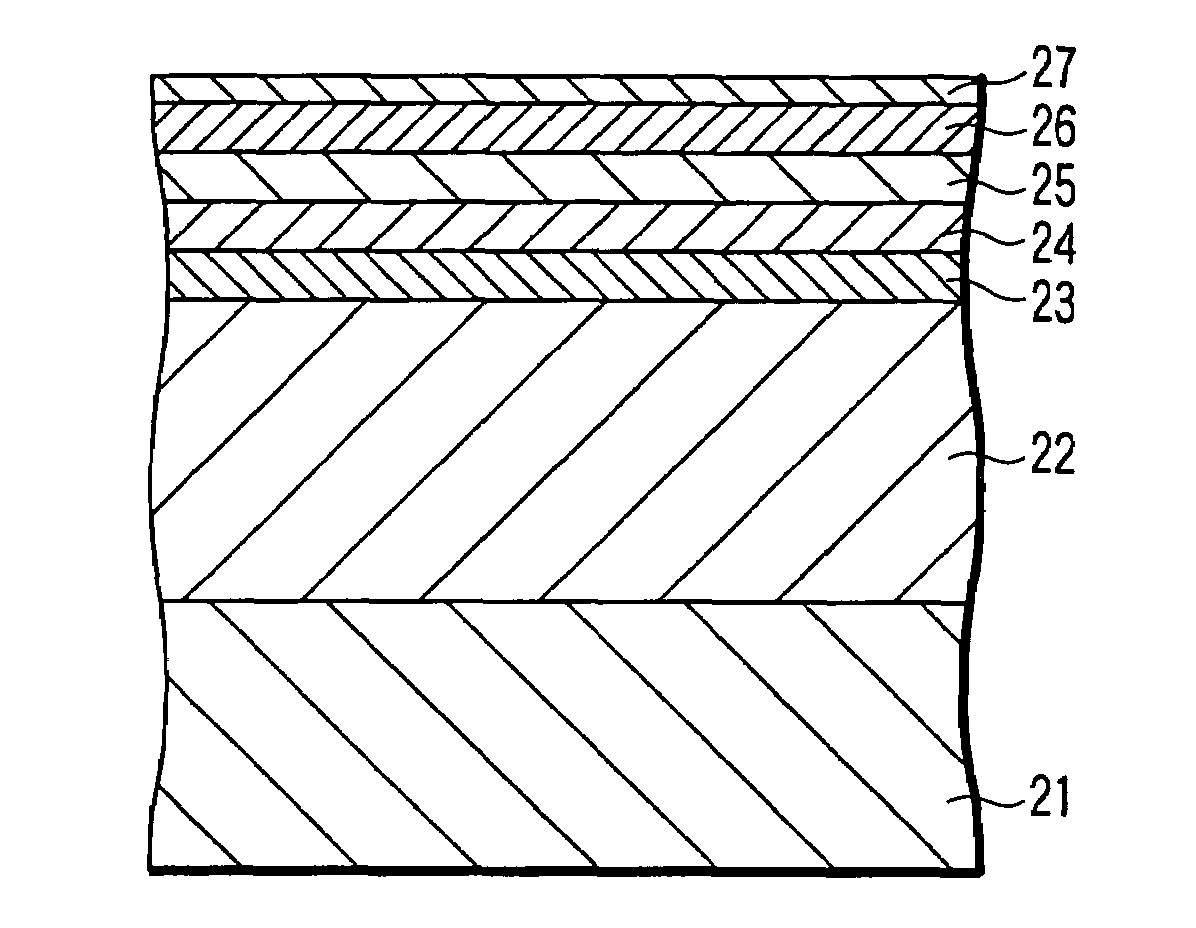

Nickel thin film, method for formation of the nickel thin film, ferromagnetic nano-junction element, method for producing the ferromagnetic nano-junction element, thin metallic wire, and method for formation of the thin metallic wire

InactiveUS8795856B2Surface roughnessReduce surface roughnessVacuum evaporation coatingSputtering coatingPolyethylene naphthalateNanometre

A nickel thin film is formed, for example, to a thickness of 2 nm or more on a polyethylene naphthalate substrate by a vacuum evaporation method. A magnetoresistance effect element using ferromagnetic nano-junction is comprised by using two laminates each comprising a nickel thin film formed on a polyethylene naphthalate substrate, and joining these two laminates so that the nickel thin films cross to each other in such a manner that edges of the nickel thin films face each other.

Owner:HOKKAIDO UNIVERSITY

Perpendicular magnetic recording medium, method for manufacturing the same, and magnetic recording/reproducing apparatus

InactiveUS7289298B2Guaranteed uptimeLittle influenceDifferent record carrier formsRecord information storageRecording layerMaterials science

Disclosed is a magnetic recording medium which includes a substrate, an underlayer, and a perpendicular magnetic recording layer, and in which this perpendicular magnetic recording layer contains magnetic crystal grains and a matrix surrounding the magnetic crystal grains, and the matrix contains an element selected from Zn, Cd, Al, Ga, and In, and a component selected from P, As, Sb, S, Se, and Te.

Owner:KK TOSHIBA +1

Magnetic film for a magnetic device, magnetic head for a hard disk drive, and solid-state device

InactiveUS20060078762A1High magnetizationChemical vapor deposition applicationHeat treatment applicationHard disc driveAlloy

There is provided a magnetic material with a high saturation magnetization of 2.46 teslas or above. By using this magnetic material in a recording head, it is possible to record information with a higher density on a recording medium. The magnetic material can also be applied to various kinds of solid-state devices. The magnetic material is composed of an alloy film made of iron, cobalt, and palladium, wherein a mole percentage content of palladium is set equal to 0.7% or greater but less than 1.0%, and the magnetic material is formed by dry processing.

Owner:FUJITSU LTD

Popular searches

Manufacture of flux-sensitive heads Substrate/intermediate layers Spin-exchange-coupled multilayers Heads for perpendicular magnetisations Semiconductor devices Inorganic material magnetism Galvano-magnetic device manufacture/treatment Magnetic layers Electrolytic coatings Transportation and packaging

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com