Magnetic composite organic nanometer granule film with magnetoresistance effect and preparation method thereof

A nanoparticle and magnetoresistance technology, which is applied in the fields of magnetic field controlled resistors, the application of magnetic films to substrates, magnetic layers, etc., can solve the problems of high cost and complicated preparation process, and achieve material simplification, broad application prospects, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

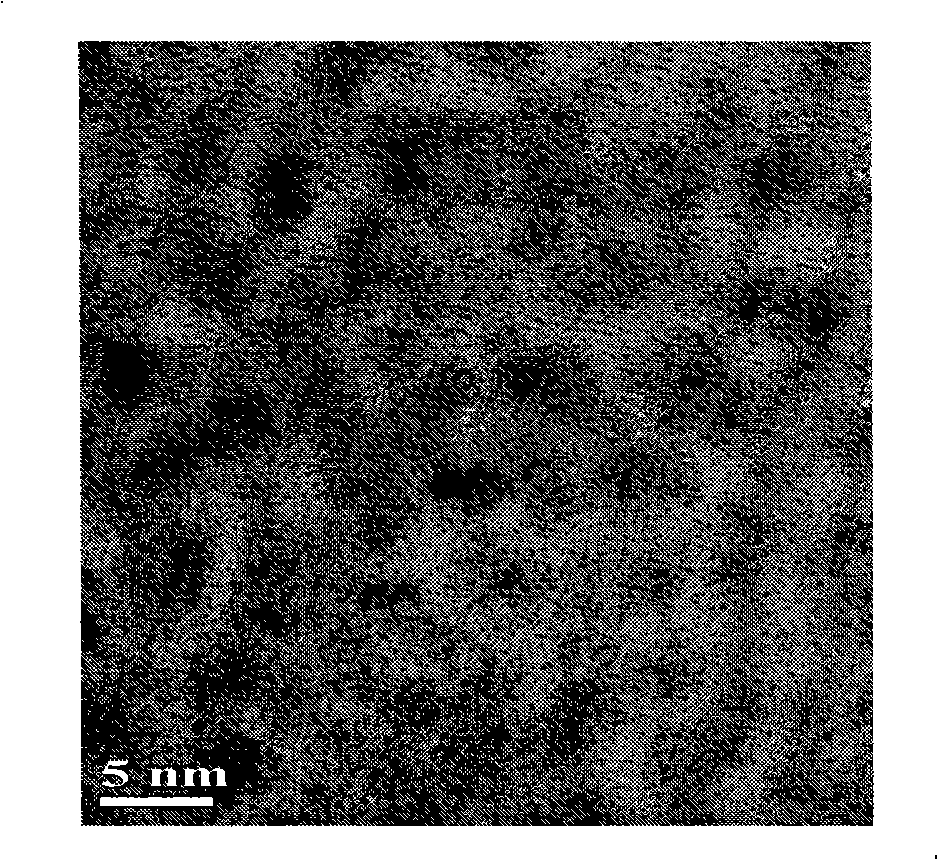

[0022] Co / Alq 3 Preparation of nanoparticle films:

[0023] a. The substrate used for deposition is a glass slide, which is cleaned and dried, and placed in a vacuum chamber.

[0024] b. Use a mechanical pump and a molecular pump to pump the vacuum chamber to a higher vacuum, about 5×10 -4 Pa.

[0025] c. Two evaporation sources are arranged at the bottom of the vacuum chamber—an organic semiconductor source and a magnetic metal material source. The film formation process is controlled by adjusting the heating voltage and temperature, as well as the real-time monitoring of the film thickness meter. The evaporation rate of the magnetic metal is controlled at Between , the rate of the organic material is controlled at Between, and through their relative velocity to control the film composition.

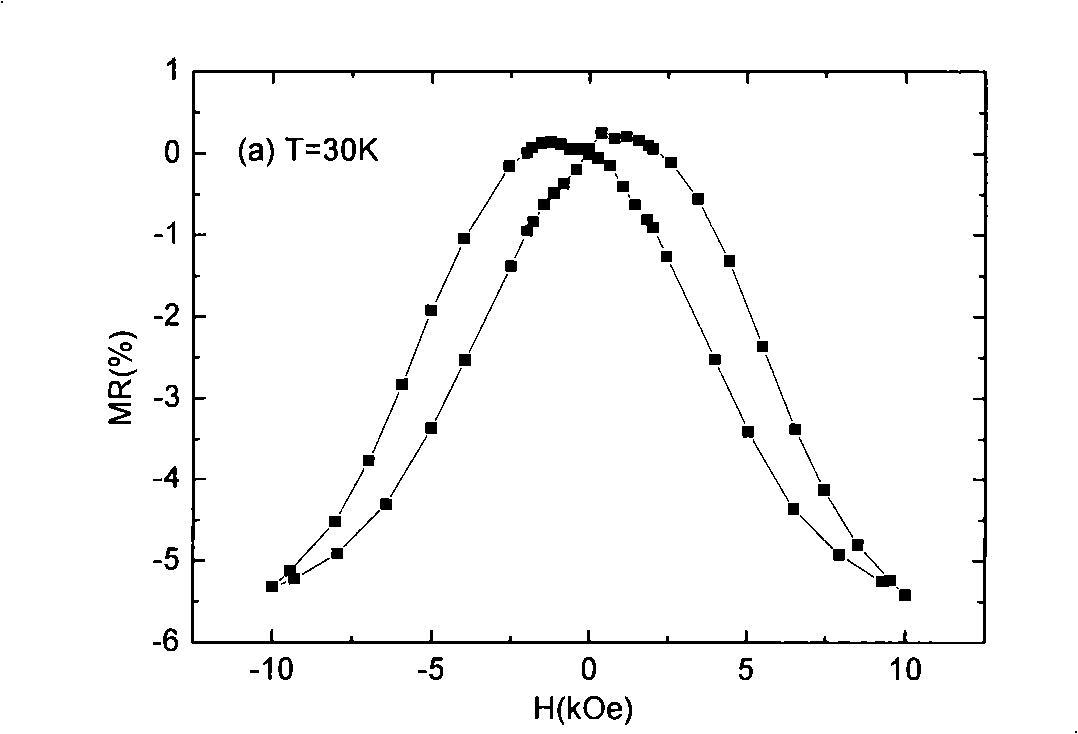

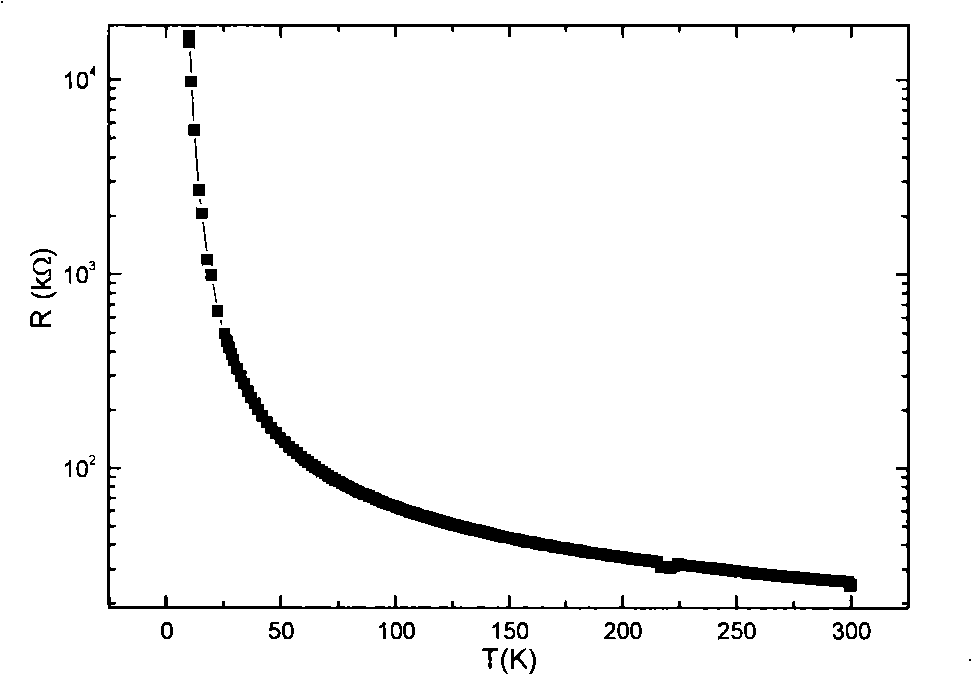

[0026] d. Using the physical property testing system (PPMS) to test the magnetoresistance of the sample, it is found that the magnetic composite organic nanoparticle film increa...

Embodiment 2

[0031] Preparation of Co / TPD nanoparticle film:

[0032] a. The substrate used for deposition is a glass slide, which is cleaned and dried, and placed in a vacuum chamber.

[0033] b. Use a mechanical pump and a molecular pump to pump the vacuum chamber to a higher vacuum, about 5×10 -4 Pa.

[0034] c. There are two evaporation sources at the bottom of the vacuum chamber—organic source and metal source. The film formation process is controlled by adjusting the heating voltage and temperature, as well as the real-time monitoring of the film thickness meter. The evaporation rate of the magnetic metal is controlled at Between , the rate of the organic material is controlled at Between, and through their relative velocity to control the film composition.

[0035] d. The magnetoresistance test was carried out on the sample by using a physical property testing system (PPMS), and the giant magnetoresistance effect reached -1.1% (T=4.2K) in the sample with x=0.28.

[0036] e. ...

Embodiment 3

[0039] Fe / Alq 3 Preparation of nanoparticle films:

[0040] a. The substrate used for deposition is a glass slide, which is cleaned and dried, and placed in a vacuum chamber.

[0041] b. Use a mechanical pump and a molecular pump to pump the vacuum chamber to a higher vacuum, about 5×10 -4 Pa.

[0042] c. There are two evaporation sources at the bottom of the vacuum chamber—organic source and metal source. The film formation process is controlled by adjusting the heating voltage and temperature, as well as the real-time monitoring of the film thickness meter. The evaporation rate of the magnetic metal is controlled at Between , the rate of the organic material is controlled at Between, and through their relative velocity to control the film composition.

[0043] d. The magnetoresistance test was carried out on the sample by using a physical property testing system (PPMS), and the giant magnetoresistance effect reached -0.13% (T=30K) in the sample with x=0.56.

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com