Vacuum evaporation coating method and rare earth magnet covered with evaporation coating

A technology of vacuum evaporation and rare earth magnets, which is applied in the field of magnet manufacturing, can solve the problems of excessive oxidation, poor protection effect, peeling, etc., and achieve the effects of preventing excessive oxidation, overcoming oxidative damage, and overcoming weak binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

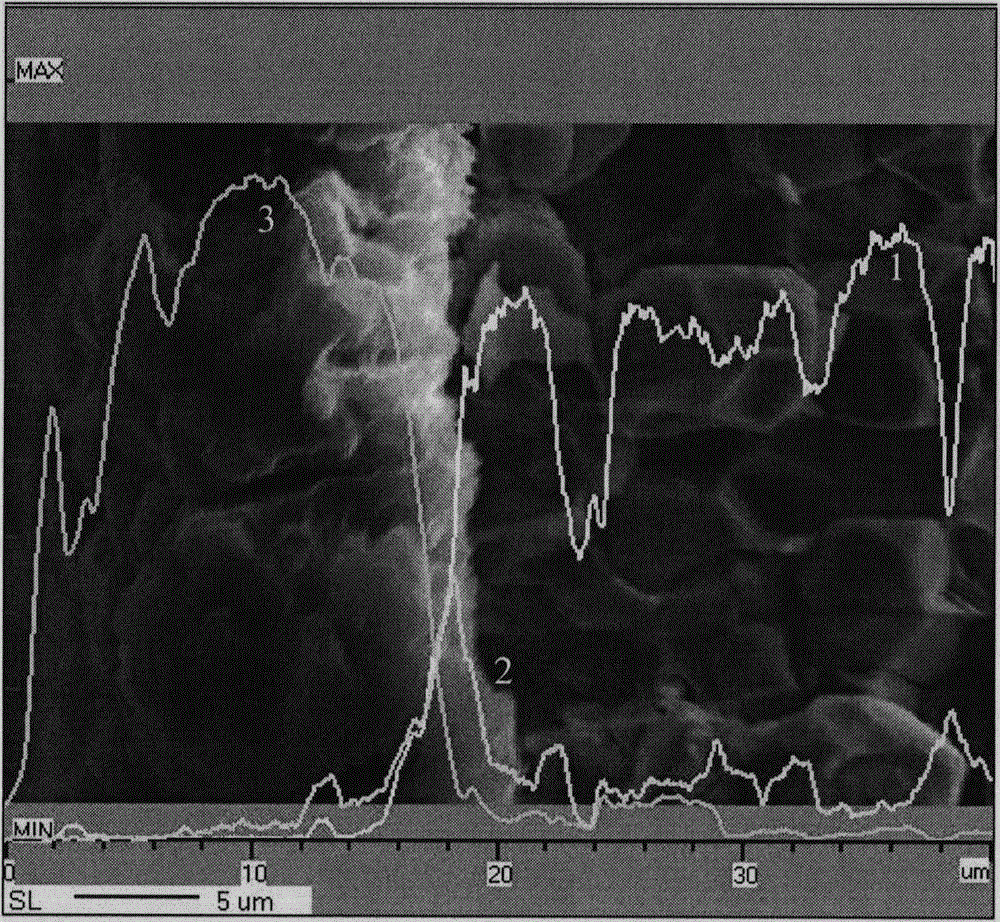

Image

Examples

Embodiment 1

[0052] A rare earth magnet sintered body was prepared, the sintered body had the following atomic composition: Dy was 5, Lu was 0.2, Er was 0.2, Nd was 8.5, Tm was 0.5, Y was 0.1, Co was 1, C was 0.05, and B was 7 , Cu is 0.2, Mn is 0.2, Ga is 0.2, Bi is 0.1, Ti is 0.3, and Fe is the balance. It is produced according to the existing procedures of smelting, flake flakes, hydrogen crushing, jet milling, pressing, sintering and heat treatment of rare earth magnets.

[0053] The heat-treated sintered body is processed into a magnet of 30mm×30mm×5mm, and the direction of 5mm is the orientation direction of the magnetic field. Set of magnets (10 pieces).

[0054] Take another group of magnets (10 pieces) with clean surface as a blank example.

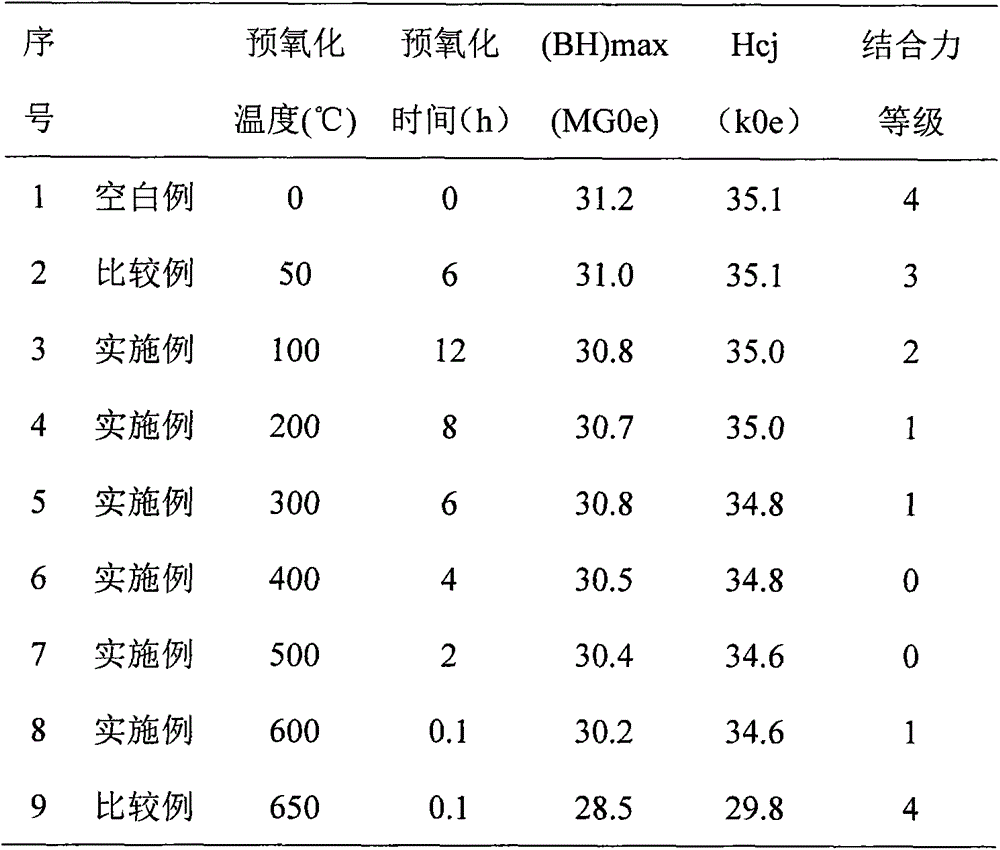

[0055] Send the workpiece racks fixed with magnets into different coating chambers, and move to each coating chamber at a distance of 0.5m 3 Oxygen is introduced at a rate of / hr, and heated to 50-650°C respectively, and pre-oxidized for 0...

Embodiment 2

[0068] A rare earth magnet sintered body was prepared, the sintered body had the following atomic composition: Dy was 5, Lu was 0.2, Er was 0.2, Nd was 8.5, Tm was 0.5, Y was 0.1, Co was 1, C was 0.05, and B was 7 , Cu is 0.2, Mn is 0.2, Ga is 0.2, Bi is 0.1, Ti is 0.3, and Fe is the balance. It is produced according to the existing procedures of smelting, flake flakes, hydrogen crushing, jet milling, pressing, sintering and heat treatment of rare earth magnets.

[0069] The heat-treated sintered body is processed into a 30mm×30mm×8mm magnet, and the 8mm direction is the orientation direction of the magnetic field. After the processed magnet is sandblasted, purged, and cleaned, the surface is finally installed on the workpiece frame, and installed on each workpiece frame. A set of magnets (10 pieces).

[0070] Take another group of magnets (10 pieces) with clean surface as a blank example.

[0071] Send the workpiece racks fixed with magnets into different coating chambers, ...

Embodiment 3

[0082] A rare earth magnet sintered body was prepared, the sintered body had the following atomic composition: Dy was 5, Lu was 0.2, Er was 0.2, Nd was 8.5, Tm was 0.5, Y was 0.1, Co was 1, C was 0.05, and B was 7 , Cu is 0.2, Mn is 0.2, Ga is 0.2, Bi is 0.1, Ti is 0.3, and Fe is the balance. It is produced according to the existing procedures of smelting, flake flakes, hydrogen crushing, jet milling, pressing, sintering and heat treatment of rare earth magnets.

[0083] The heat-treated sintered body is processed into a 30mm×30mm×8mm magnet, and the 8mm direction is the orientation direction of the magnetic field. After the processed magnet is sandblasted, purged, and the surface is cleaned, it is then installed on the workpiece holder, and 10 pieces are installed on the workpiece holder. magnet.

[0084] Send the workpiece frame fixed with the magnet into the coating chamber, and move 1.0m away from the coating chamber. 3 Oxygen is fed at a rate of / hr, and heated to 200°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com