Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

228 results about "Temperature Increment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

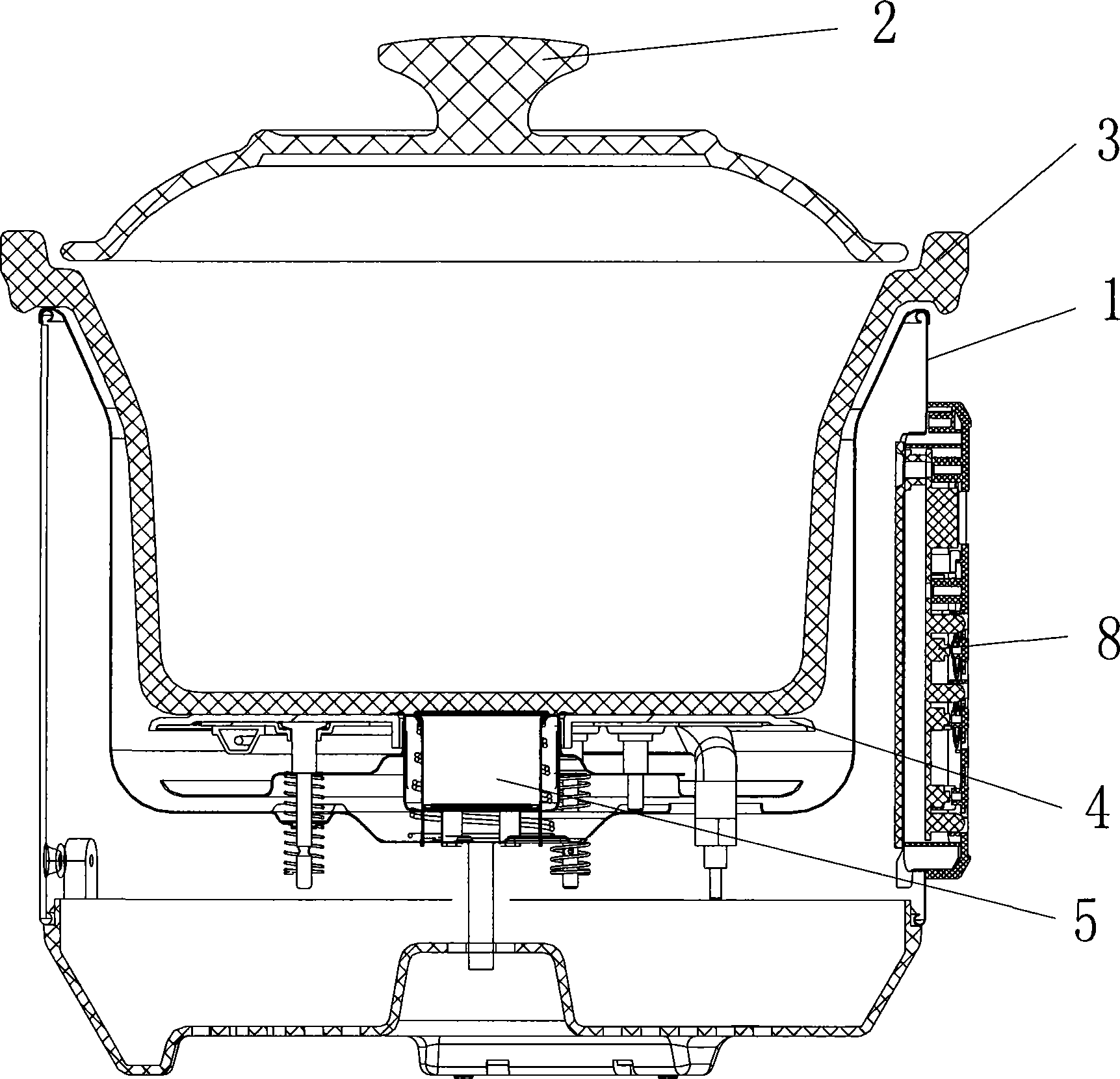

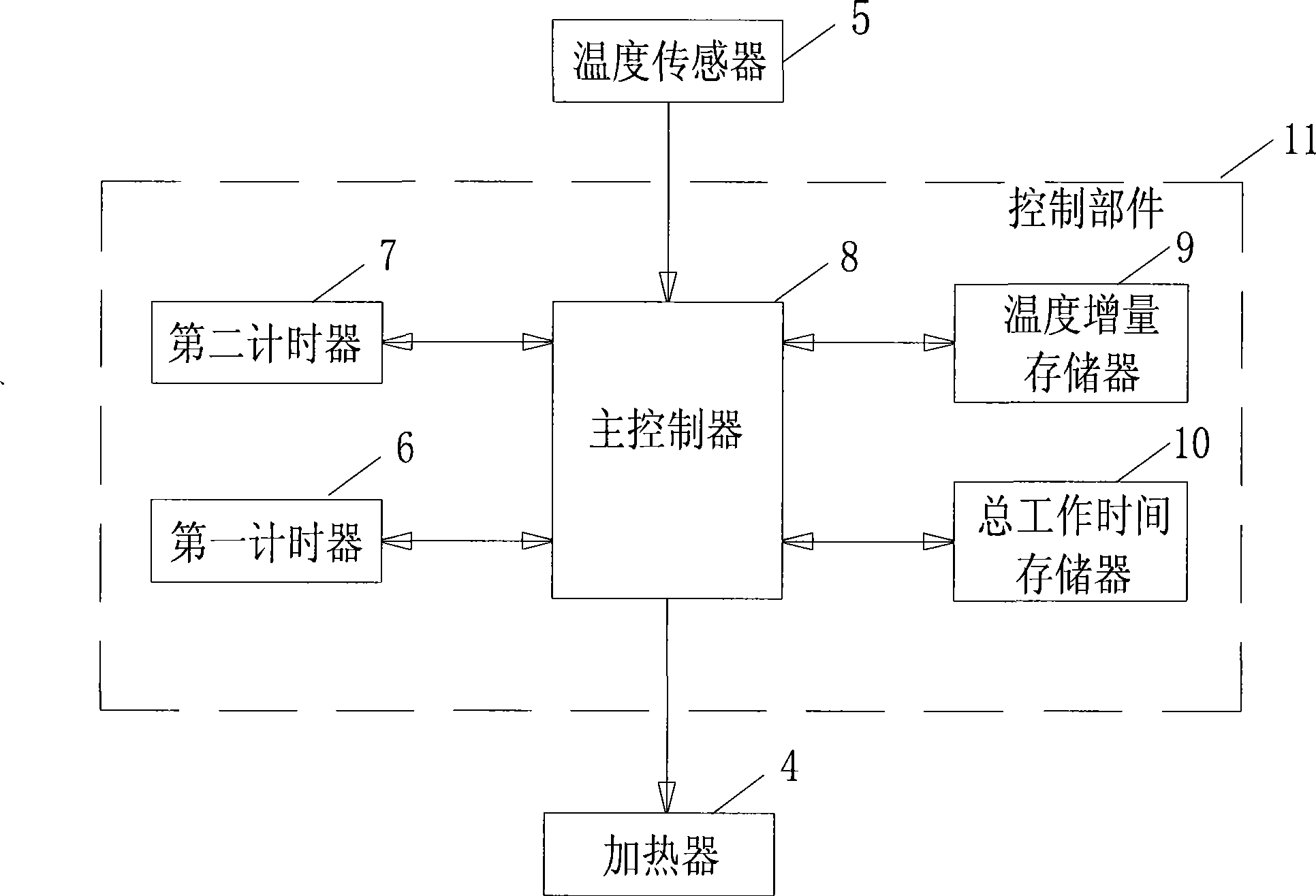

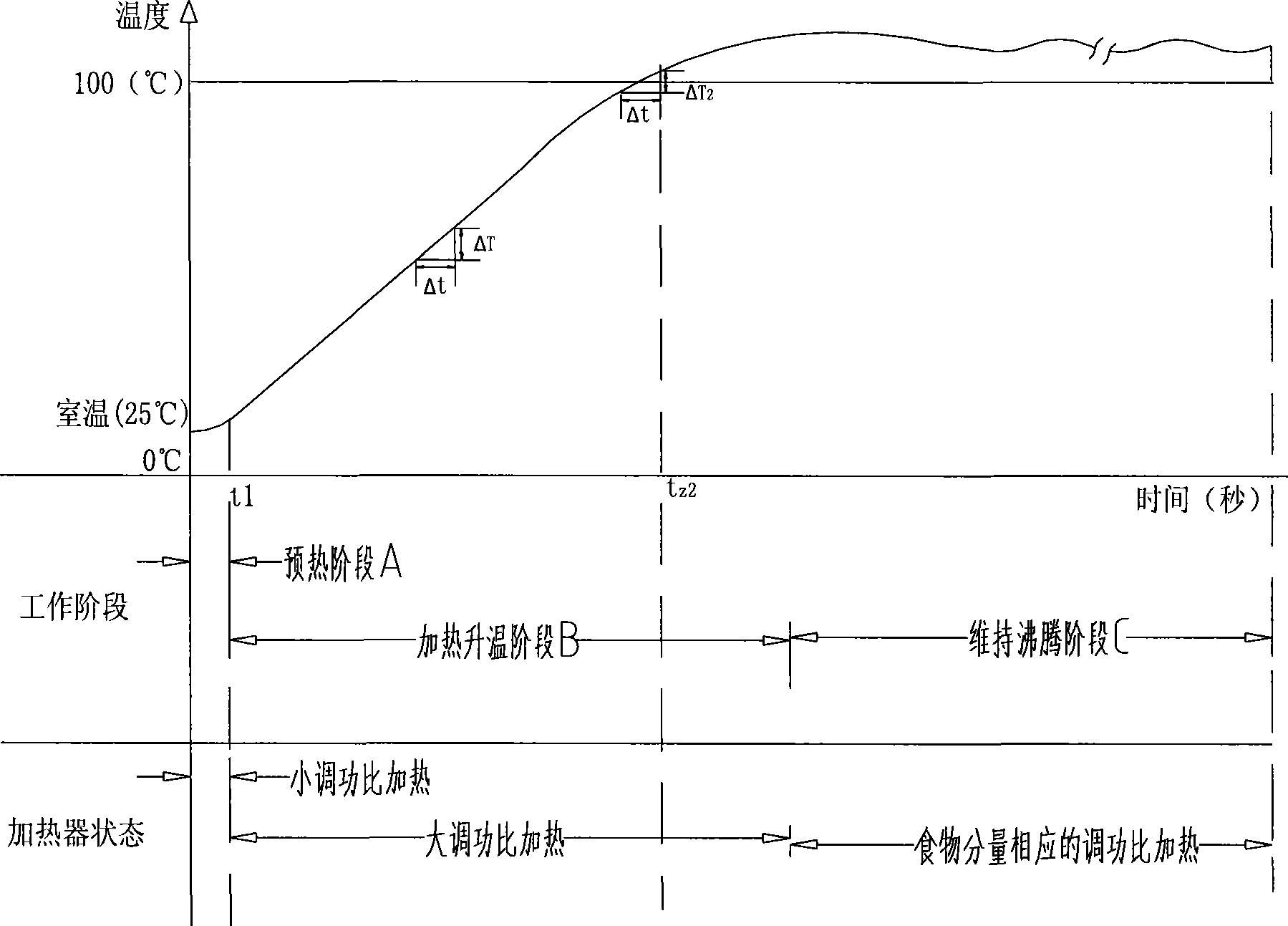

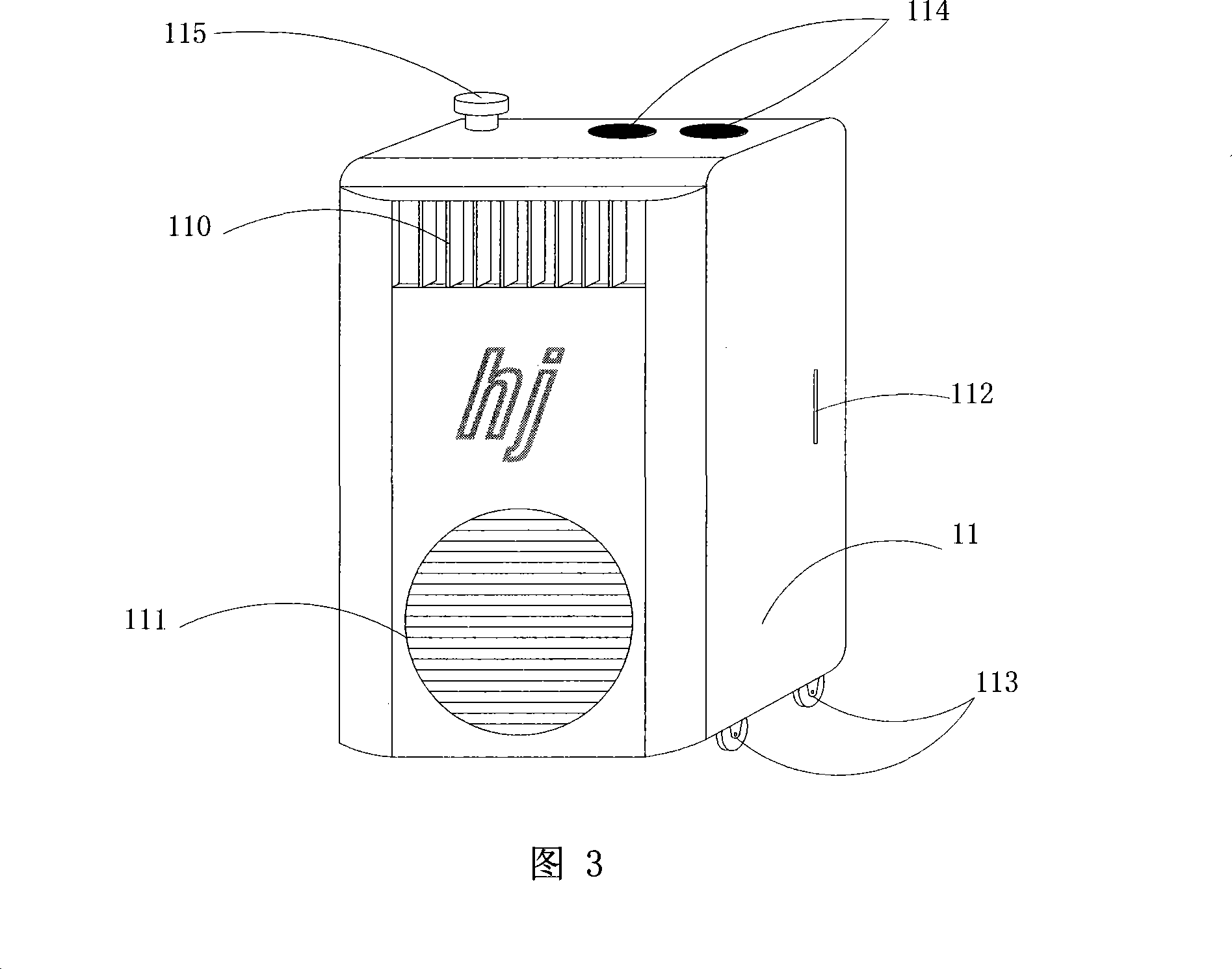

Electric cooker and heating control method thereof

ActiveCN101518409AAccurately judge the serving sizeAccurately judge the statusTemperatue controlTime-controlled ignitorsElectricityPortion size

The invention belongs to the field of household appliances, and in particular relates to an electric cooker and a heating control method thereof. The electric cooker comprises a pot body, a pot cover, an inner pot and a heater arranged under the inner pot; the inside of the pot body is provided with a control part and a temperature sensor; the control part comprises a main controller, a first timer, a second timer, a temperature incremental memory and a total working time memory; and the main controller is electrically connected with the heater, the temperature sensor, the first timer, the second timer, the temperature incremental memory and the total working time memory respectively. The heating control method comprises a preheating stage A and a heating and temperature rising stage B; and in the heating and temperature rising stage B, the main controller controls the heater to continue heating or to finish the heating and temperature rising stage B according to an inner pot temperature increment delta T correspondingly generated in a unit time delta t timed by the second timer, a temperature increment preset in the temperature incremental memory, a total working time t timed by the first timer and a total working time preset in the total working time memory. The method can accurately judge the quantity and boiling state of food in the cooker, has the advantages of simple control and low cost, and is suitable for various electric stewpots and ceramic pots with separated upper covers.

Owner:MIDEA GRP CO LTD

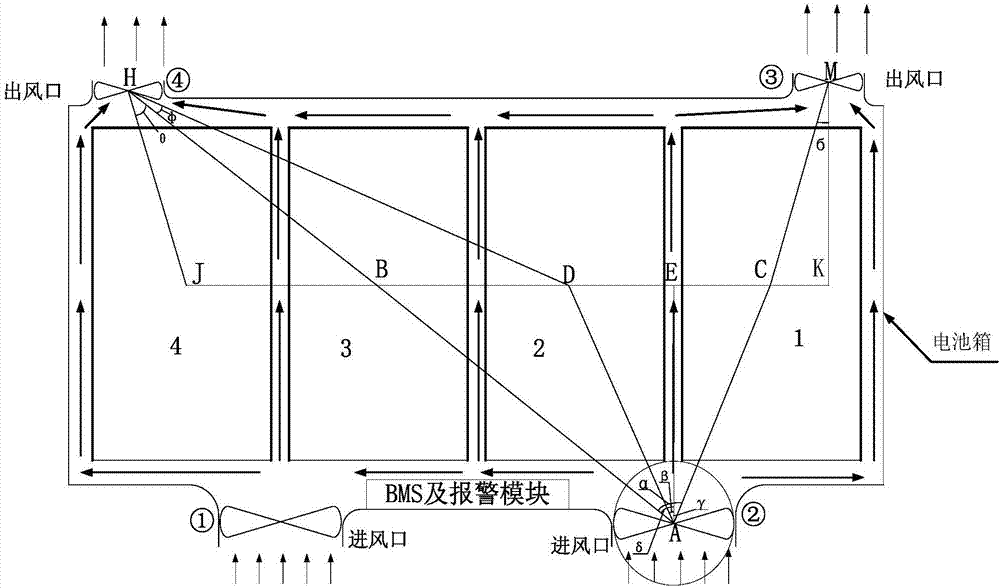

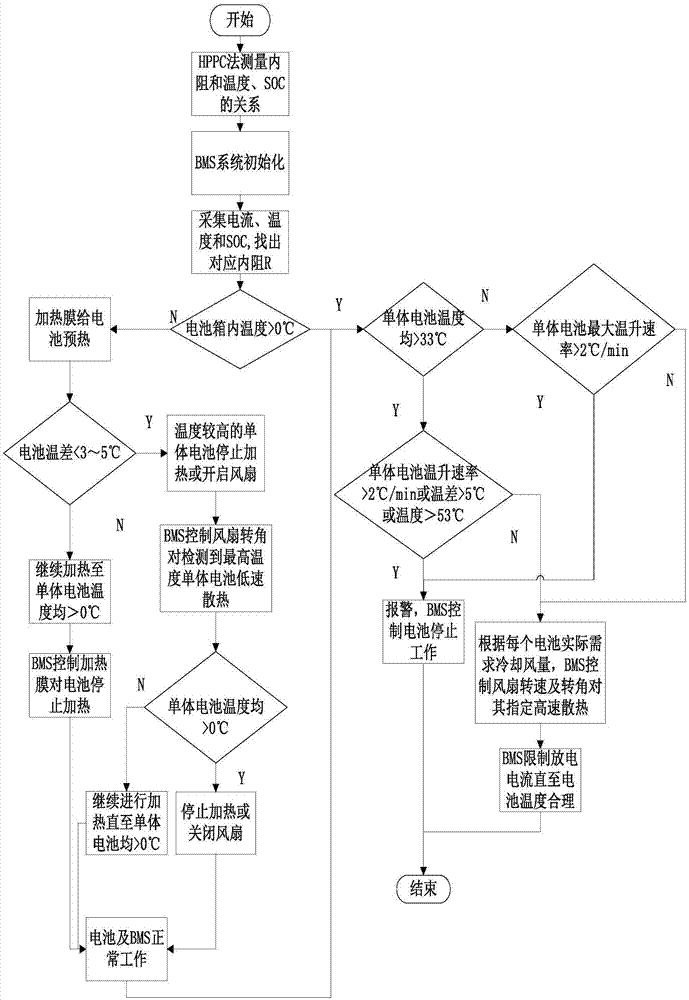

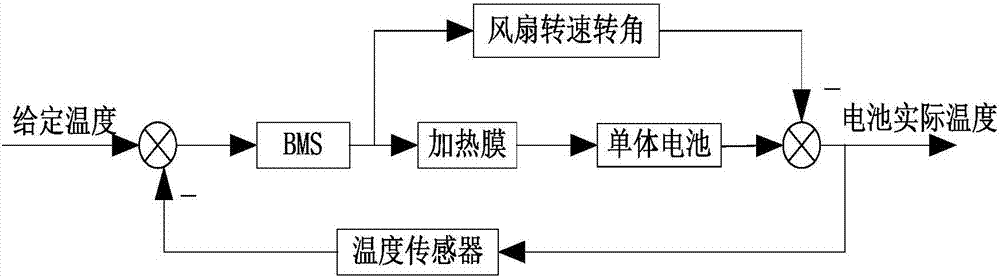

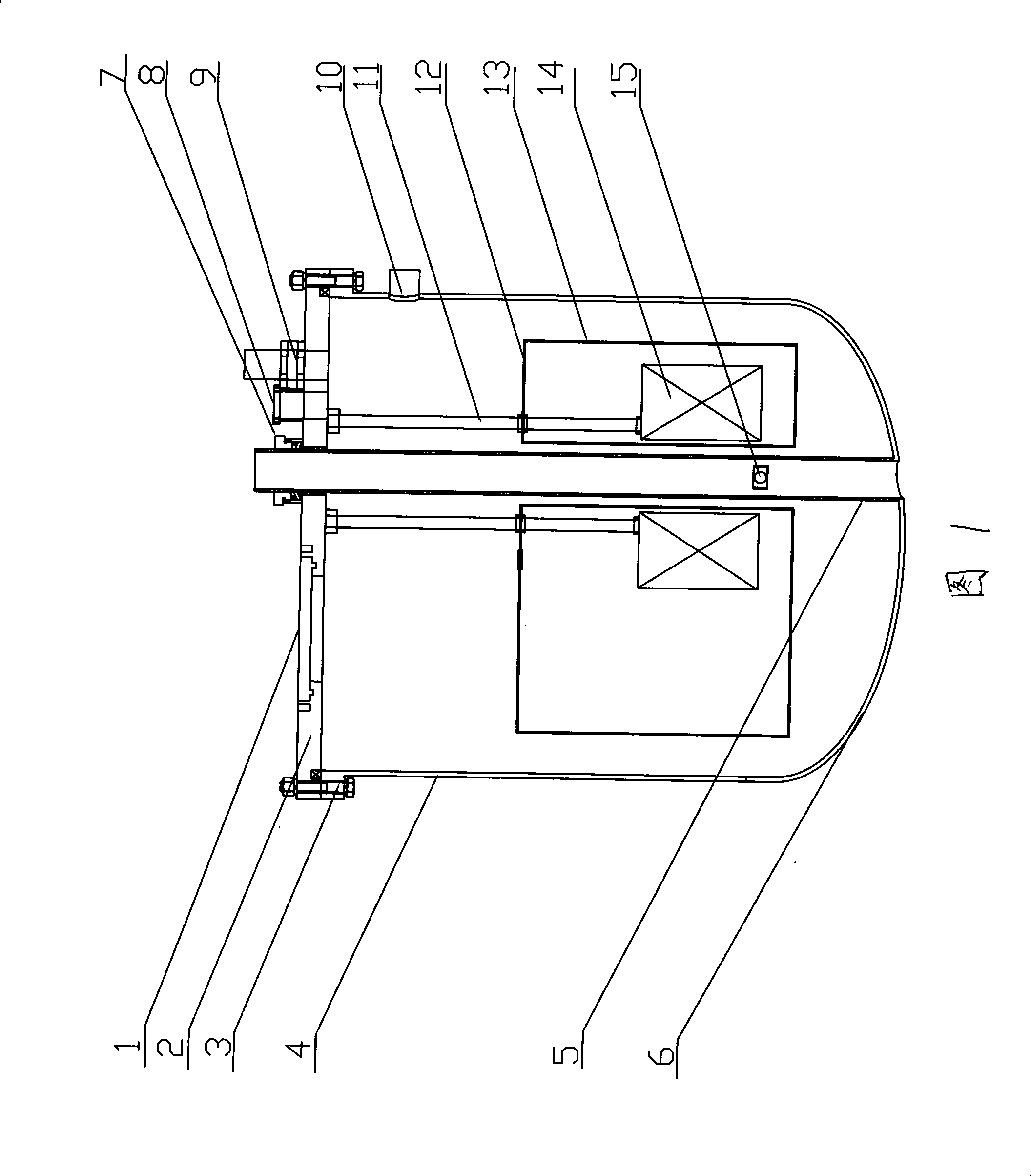

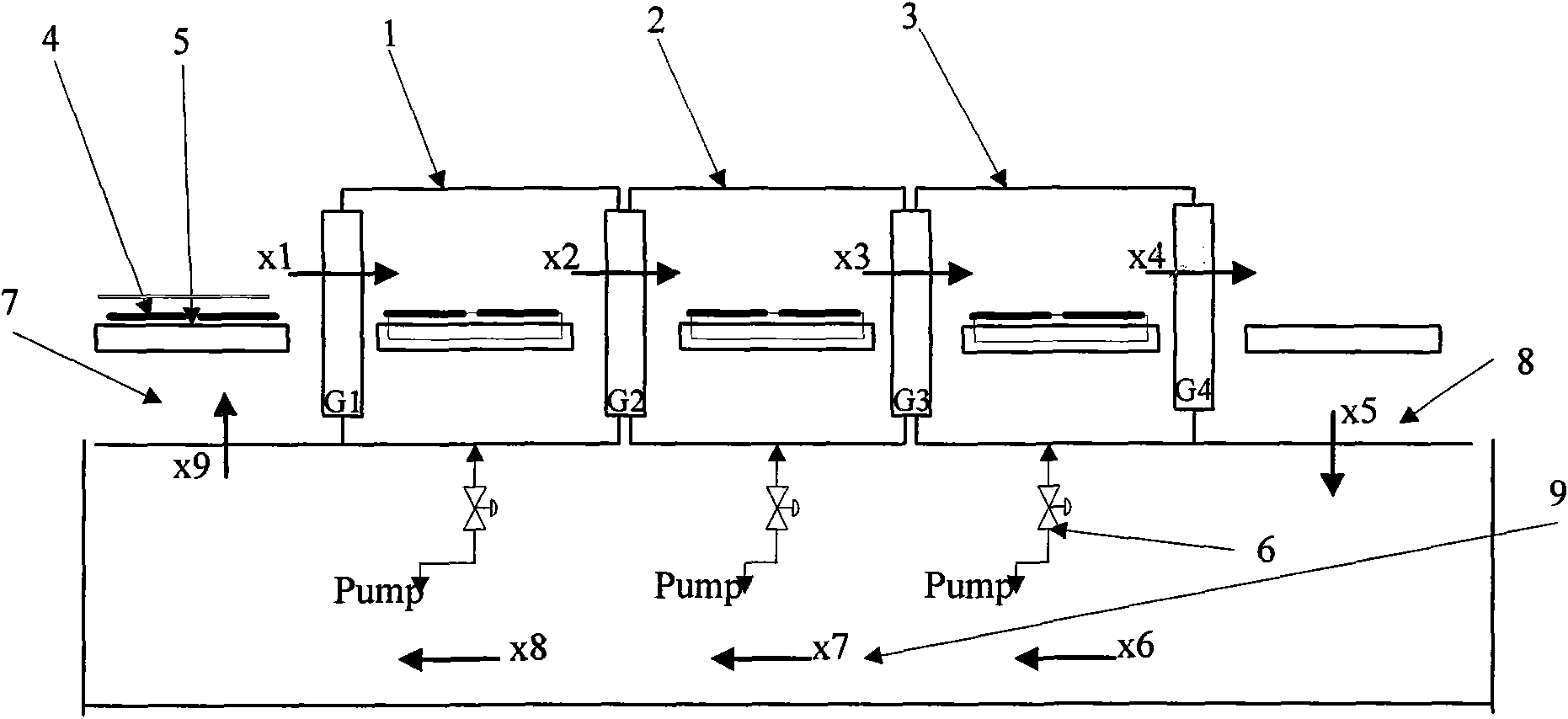

Electric automobile battery pack heat management and temperature balancing control method

ActiveCN107579308AAvoid excessive temperature riseAvoid excessive local temperature differencesSecondary cellsVehicular energy storageTemperature controlHeat management

The invention discloses an electric automobile battery pack heat management and temperature balancing control method. According to the electric automobile battery pack heat management and temperaturebalancing control method, a battery module, a battery box, a BMS and a warning device are provided; a heating film is arranged at the periphery of the battery module; a plurality of temperature sensors are distributed in the battery box equidistantly and a plurality of fans capable of controlling rotation angles are arranged in the battery box; and the BMS evaluates the stage of the battery by monitoring the temperature of the battery pack through the temperature sensors, and performs heat management on the battery pack by taking 0 DEG C, 33 DEG C and 53 DEG C as temperature control thresholdvalues and combining temperature increasing rate and temperature difference as judgment conditions, wherein the temperature of the battery pack is maintained within the work range by the measures of selectively heating the heating film as well as accurately controlling the rotation angle of the fans, the starting time and the cooling air quantity. By the method, too high temperature increment andtoo large temperature difference of the battery are effectively avoided, battery temperature change stability and balanced characteristics are guaranteed and the service life of the lithium battery isprolonged.

Owner:JIANGSU UNIV

Conduction cooling superconducting magnet dewar convenient for loading and unloading

The invention relates to a conduction-cooled superconducting magnet Dewar with easy loading-unloading, comprising a Dewar cylinder. The conduction-cooled superconducting magnet Dewar is characterized in that the Dewar cylinder is a hollow annular cylinder, the middle of the annular cylinder is provided with a room temperature hole, an annular copper cold shield is arranged in the Dewar cylinder, a refrigerator and a superconducting magnet are arranged in the copper cold shield, a vacuum pumping port is arranged on the Dewar cylinder, a measuring device is arranged on an upper cover of the Dewar cylinder and the Dewar cylinder is in a vacuum state. Compared with the prior Dewar container, the conduction-cooled superconducting magnet Dewar is simpler, has small conduction heat leakage, and has the advantages of easy installation and disassembly; the refrigerator is used for conducting and cooling without a low temperature liquid (such as liquid helium and so on) cooling system; because of simple and safe system, a first-level cold junction of the refrigerator is operated under a temperature of 77K, thereby realizing heat sink of the copper cold shield, an electric lead and a support device; the first-level cold junction of the refrigerator adopts soft connection, thereby reducing temperature increment of the magnet due to vibration of the refrigerator; and the conduction-cooled superconducting magnet Dewar has the advantages of easy operation of manufacture, processing and installation, and is applicable to scale production.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

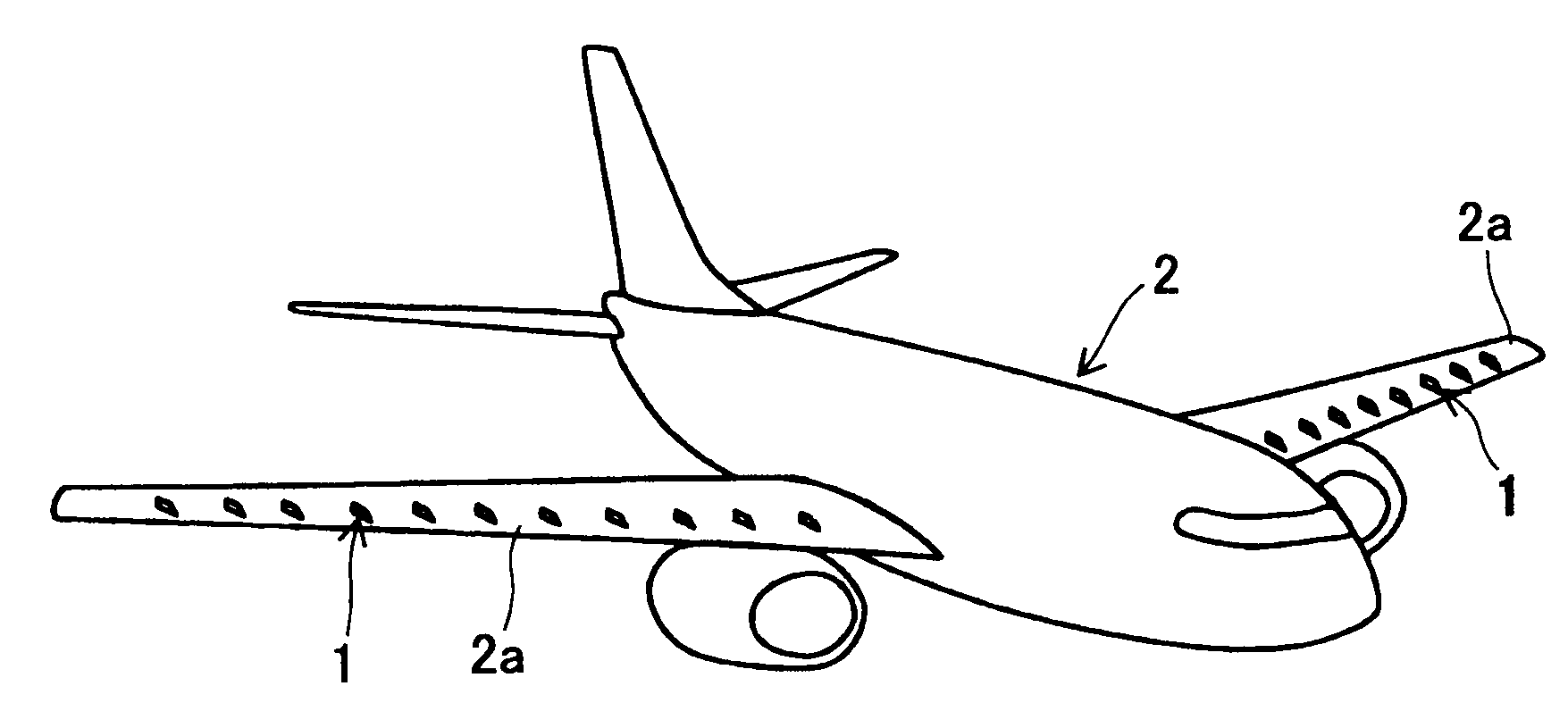

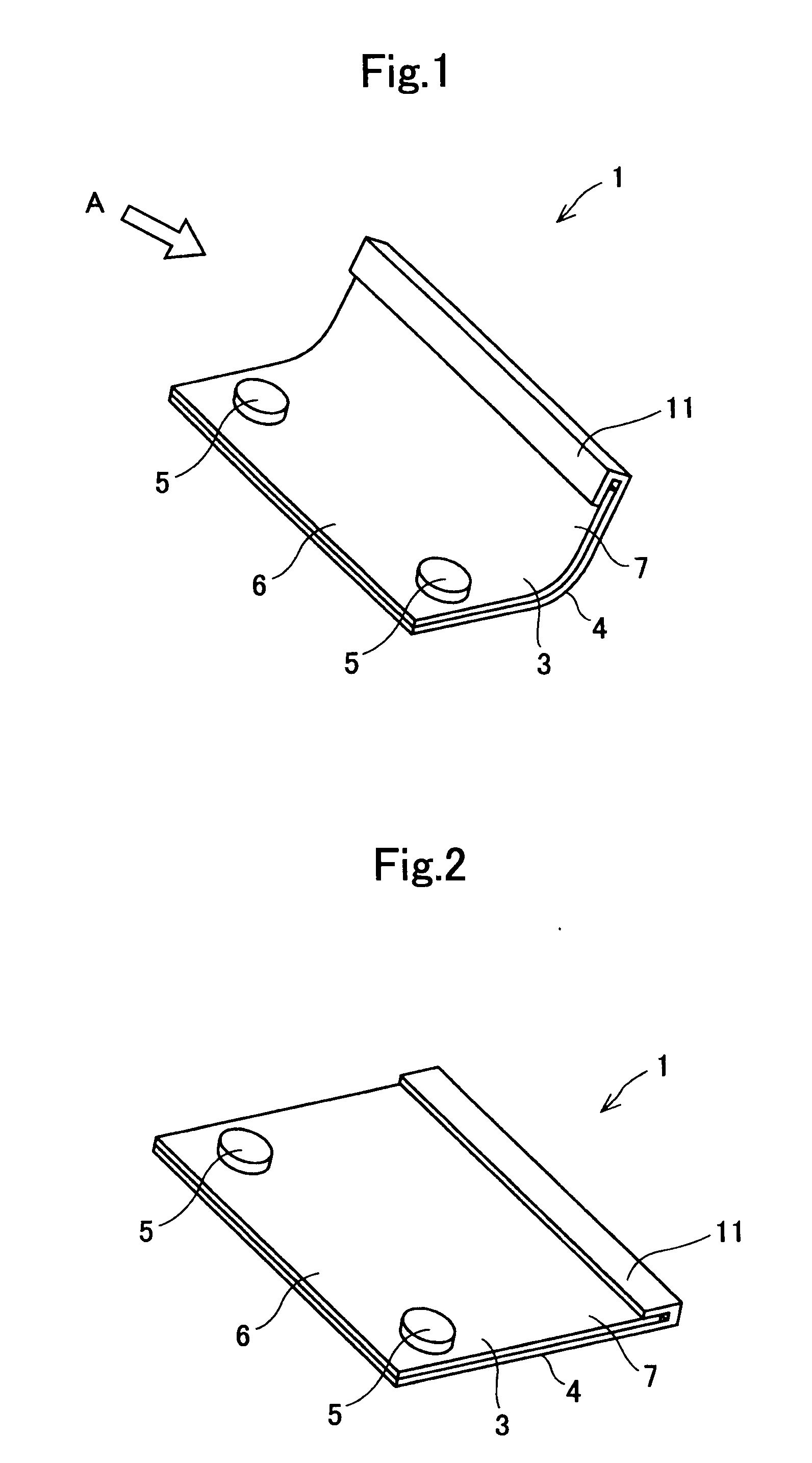

Smart Vortex Generator, and Aircraft, Vessel, and Rotary Machine Being Equipped with the Same

InactiveUS20080217485A1Simple structureEasy to installInfluencers by generating vorticesWatercraft hull designShape-memory alloyEngineering

A smart vortex generator including a main body, disposed on a body surface, such as a main wing of aircraft, making a boundary to a flow of fluid, and at least a part of which includes a shape memory alloy. A form of the main body, depending on a temperature increment / decrement of the fluid, changes between (1) a first form capable of suppressing a flow separation by a vortex generation and (2) a second form capable of suppressing a turbulent flow, by a phenomenon that the shape memory alloy undergoes a phase transformation between a high-temperature-side stable phase and a low-temperature-side stable phase. The smart vortex generator demonstrates a multi-directional characteristic depending on a temperature change, such that no energy supply from the outside is required. The structure is simple, and repairs and maintenance as well as installation to existing wings are easy.

Owner:NAGOYA UNIVERSITY

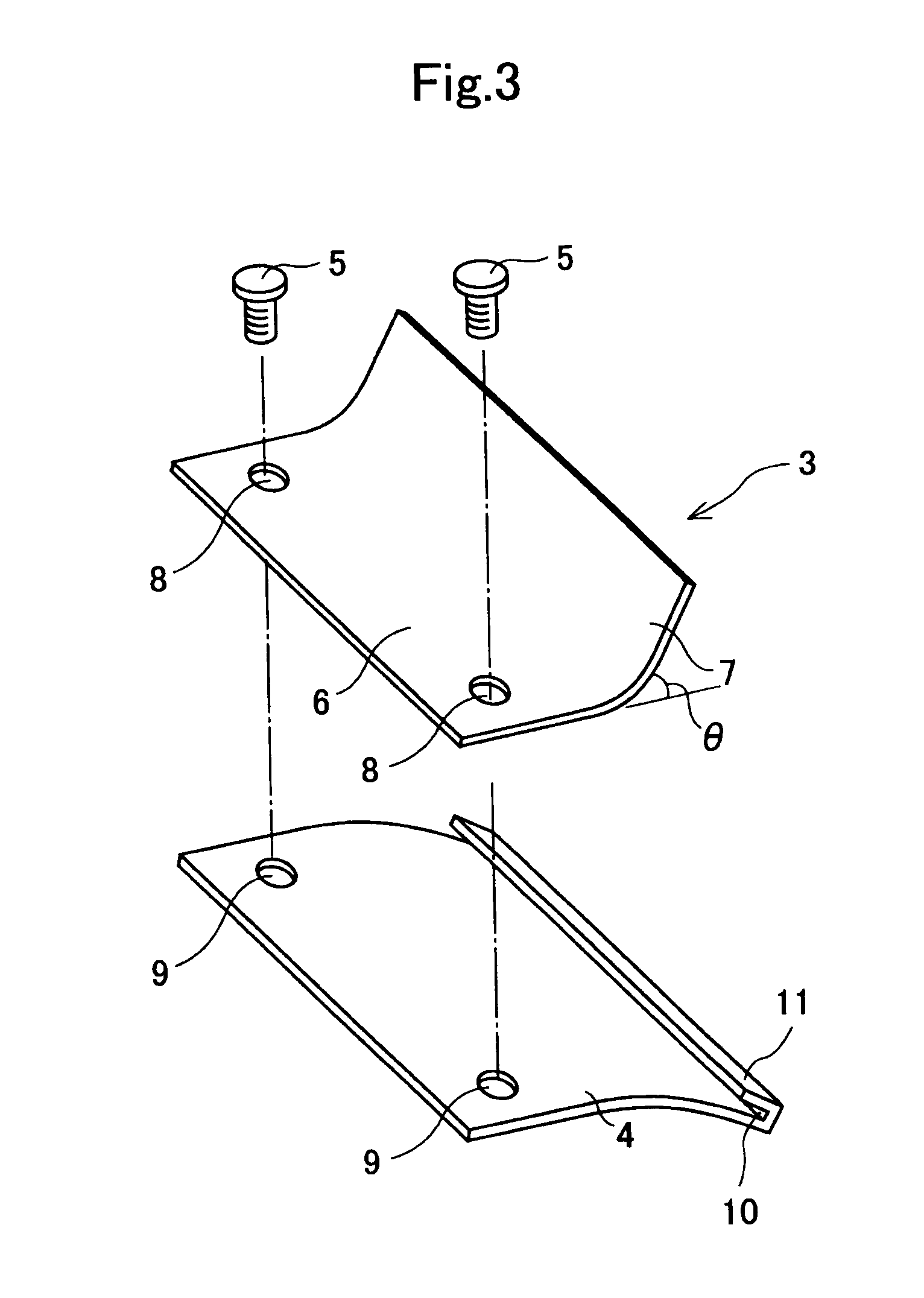

Liquid crystal display device having good heat radiating function

ActiveUS20100165239A1Effective radiationIncrease surface areaNon-linear opticsLiquid-crystal displayEngineering

Disclosed is a liquid crystal display (LCD) device having a good heat radiating function. Surface areas of a lower cover, an upper cover, and a guide panel are increased by forming grooves at the lower cover, the upper cover, and the guide panel. Heat generated from an optical source is rapidly radiated through the lower cover, the upper cover, and the guide panel having increased surface areas. This may prevent temperature increment of a backlight unit.

Owner:LG DISPLAY CO LTD

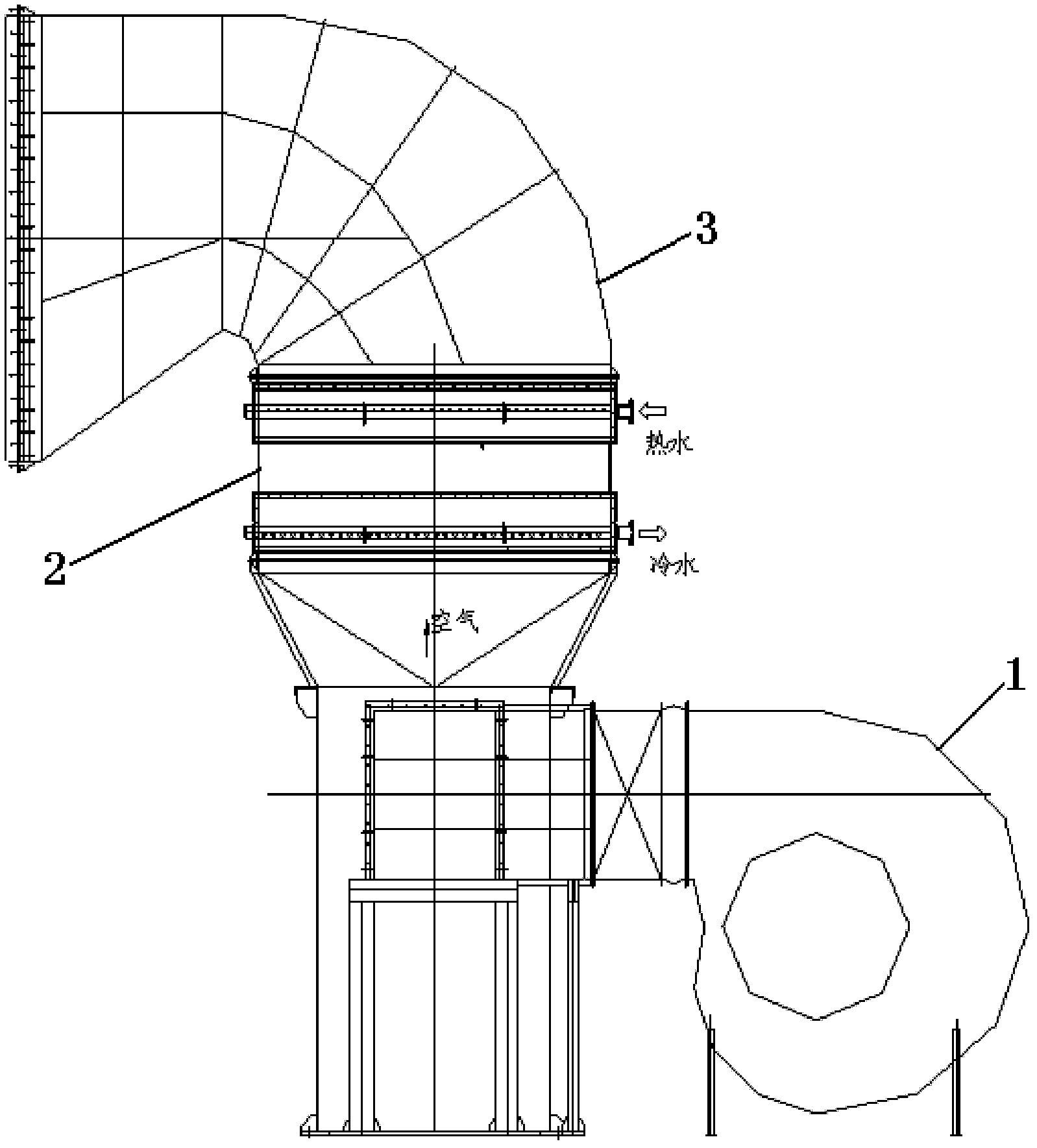

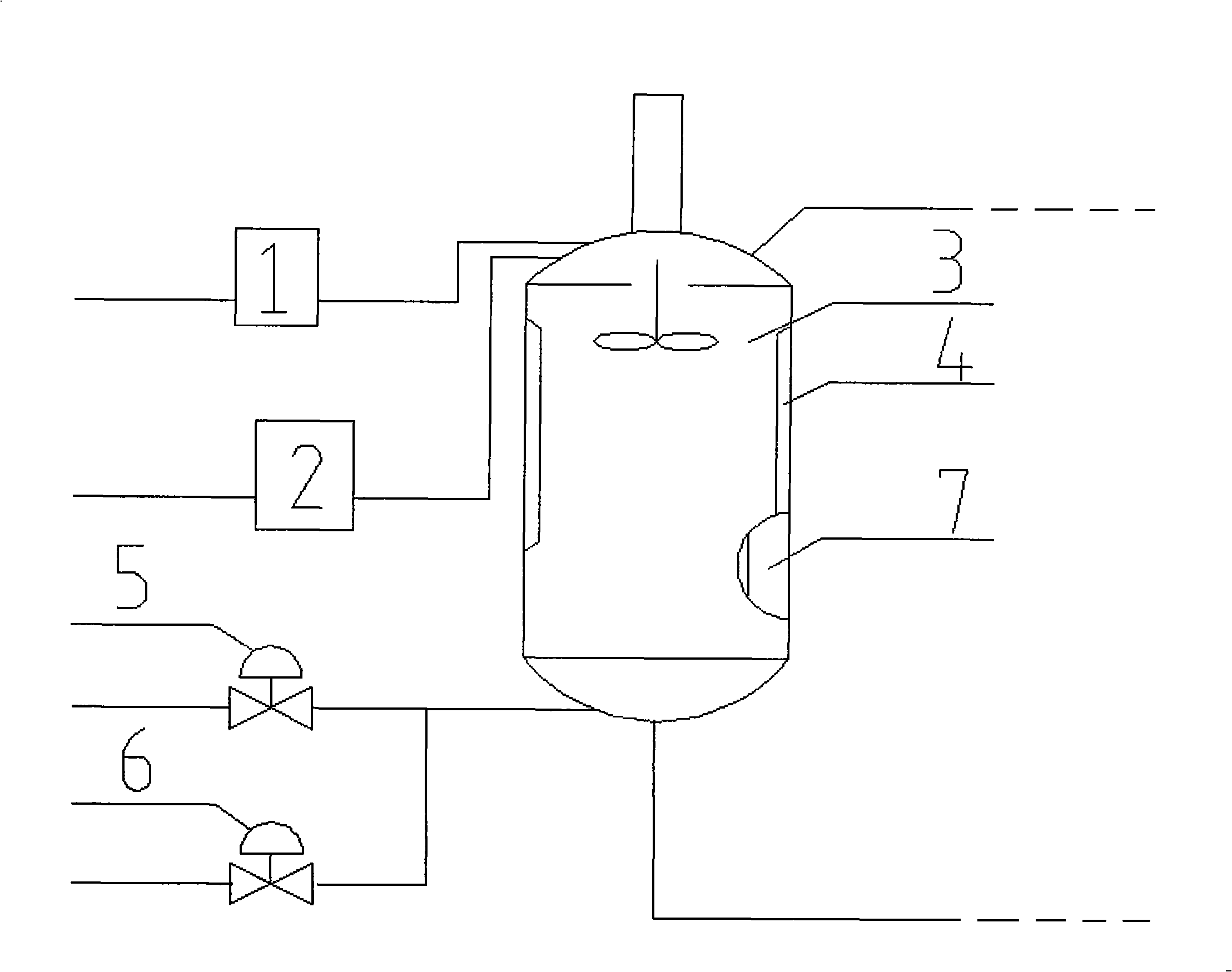

Waste heat recovery system of pipe heater

InactiveCN103185464AIncrease temperatureAvoid dew point corrosion temperatureIncreasing energy efficiencyWaste heat treatmentAir preheaterWaste heat recovery unit

The invention provides a waste heat recovery system of a pipe heater, which comprises a blower, a preposed preheater and an air preheating device, wherein the preposed preheater is arranged at the inlet or the outlet of a blower, the outlet of the preposed preheater is connected with the inlet of the air preheating device, cold air enters into the preposed preheater after entering into the blower, then is discharged after being heated by the preposed preheater, and finally enters into the air preheating device. Therefore, in the invention, by adding the preposed preheater, a heat source is introduced to heat for increasing the temperature of air and the temperature of air entering into the air preheating device is increased. With the temperature increment of a wall at the air inlet part of the air preheating device, heat is transferred to a flue gas outlet part through heat transmission. Therefore, the temperature at the flue gas outlet can be increased, flue gas dew point corrosion temperature can be avoided, and the effect of preventing flue gas dew point corrosion can be achieved.

Owner:LUOYANG HEZONG PETROCHEM ENG

Device for calibrating thermistor voltages to temperature values by using rough and fine lookup tables

InactiveUS6033109AReduce capacityLow costThermometer detailsThermometers using electric/magnetic elementsMultiplexerHeat sensitive

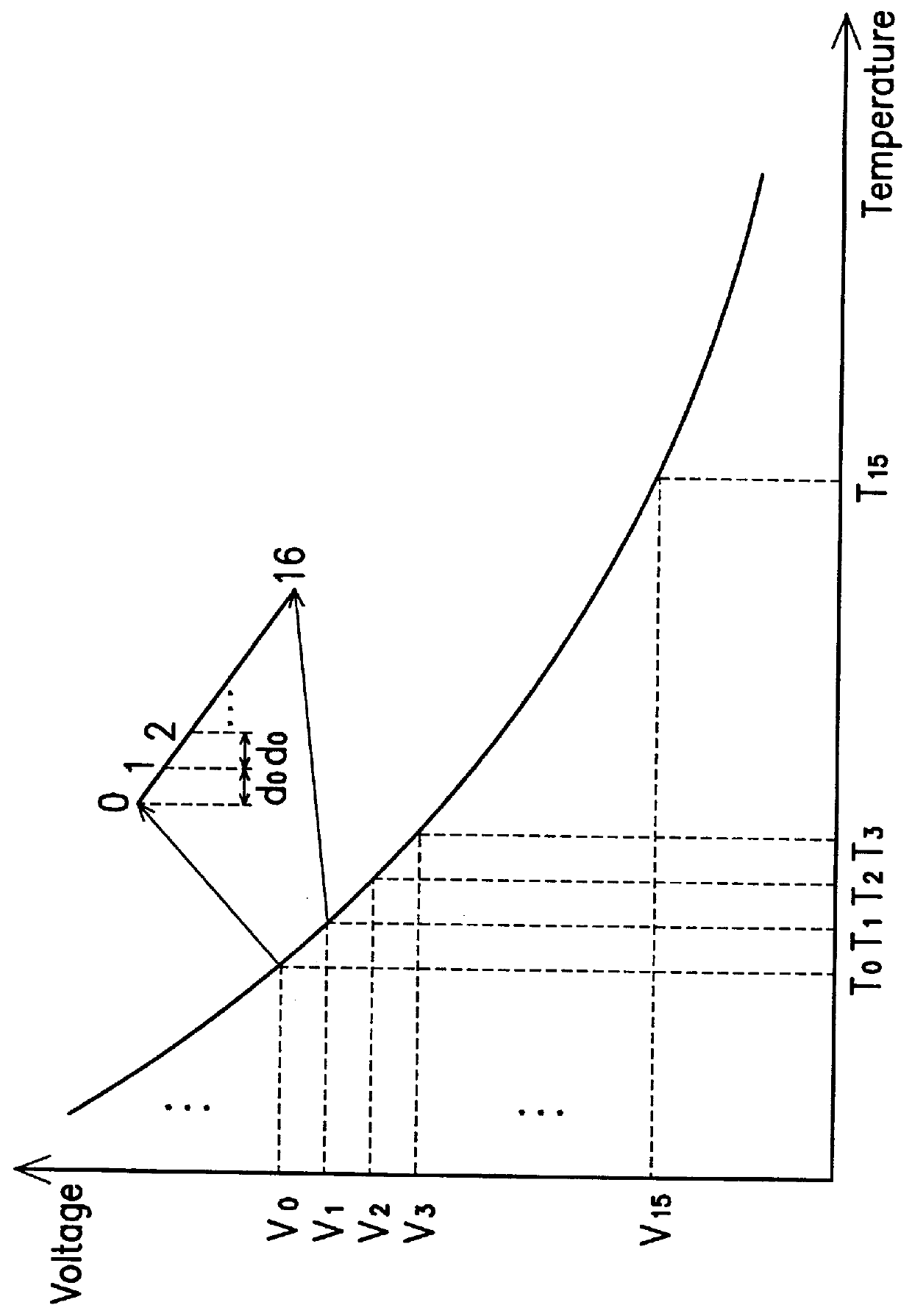

A device appropriate for converting voltages to temperature values by using a thermistor is disclosed. The device according to the present invention utilizes a voltage-temperature cross-reference table and a temperature-increment table to carry out the conversion instead of using the conventional one-to-one voltage-temperature table, thereby reducing the required capacity of RAM and ROM and the fabrication cost. The thermistor is disposed at the place where the temperature is to be measured, and the voltage across the thermistor varies with respect to changes of temperature. An analog-to-digital converter receives the voltage of the thermistor and transforms it into digital output. A first multiplexer decodes the higher bit portion of the digital output thereby selecting a corresponding temperature from a voltage-temperature cross-reference table as a rough temperature. A second multiplexer decodes the higher bit portion of the digital output thereby selecting a corresponding temperature increment from a temperature-increment table as a temperature step. A multiplier multiplies the lower bit portion of the digit output by the temperature step to obtain a fine temperature. An adder adds the fine temperature to the rough temperature to output a practical temperature value.

Owner:WINBOND ELECTRONICS CORP

Method for controlling sleep mode of air conditioner

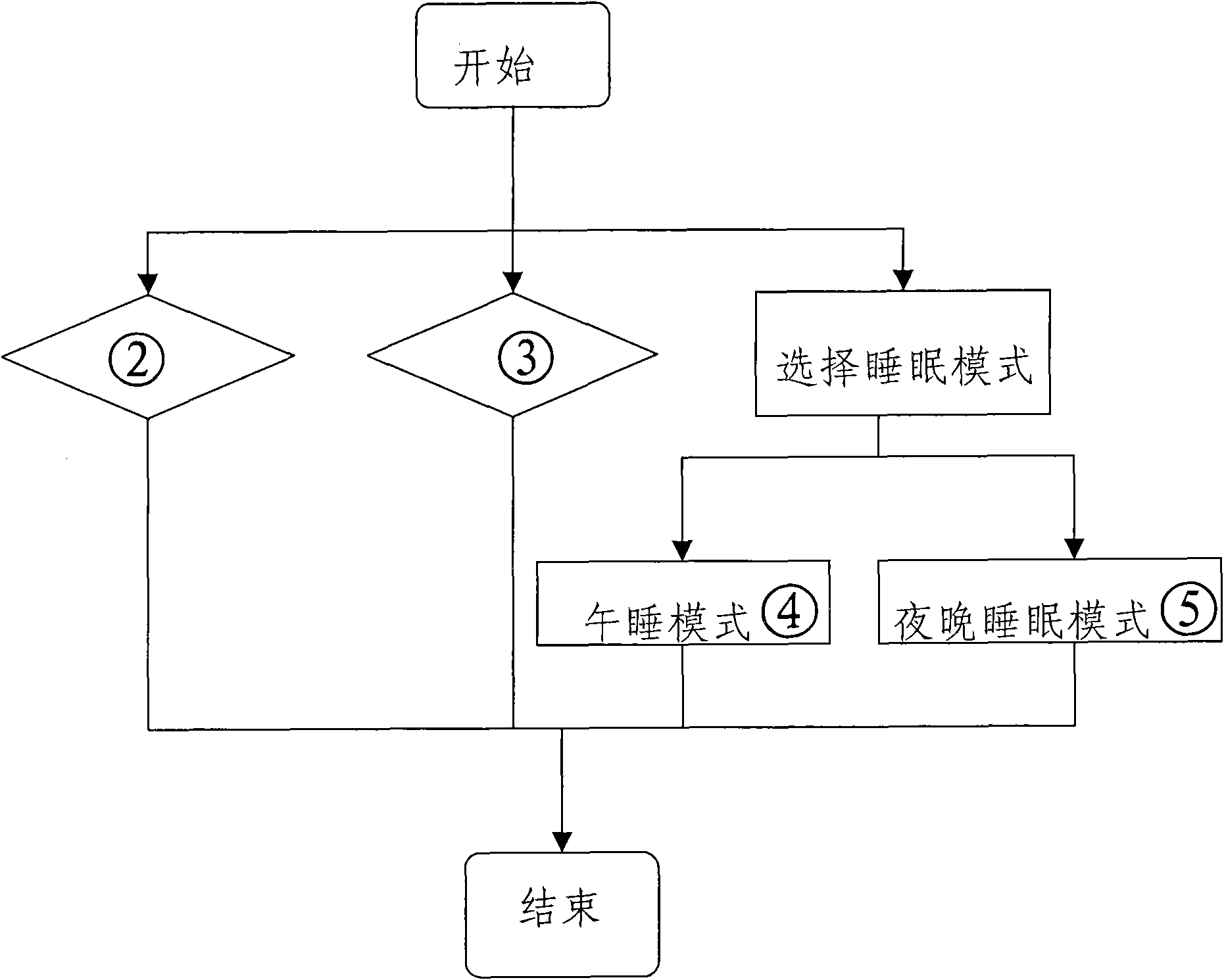

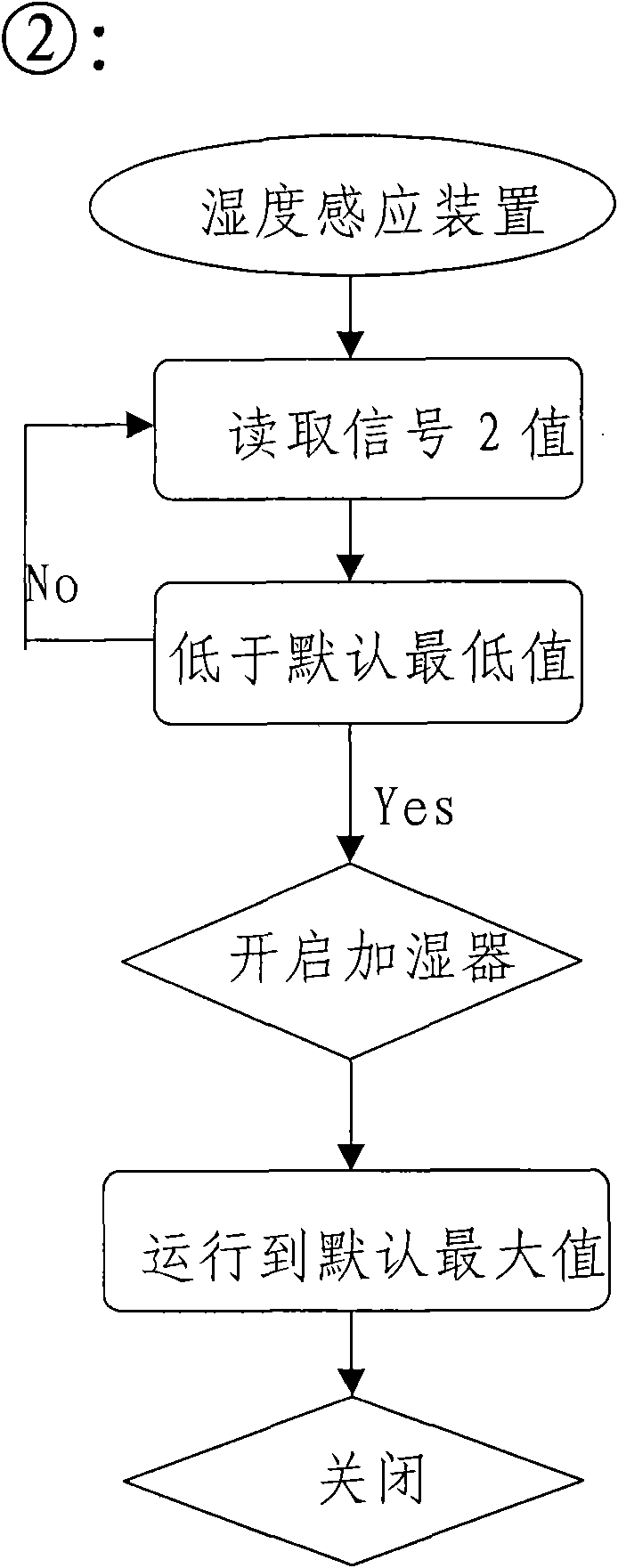

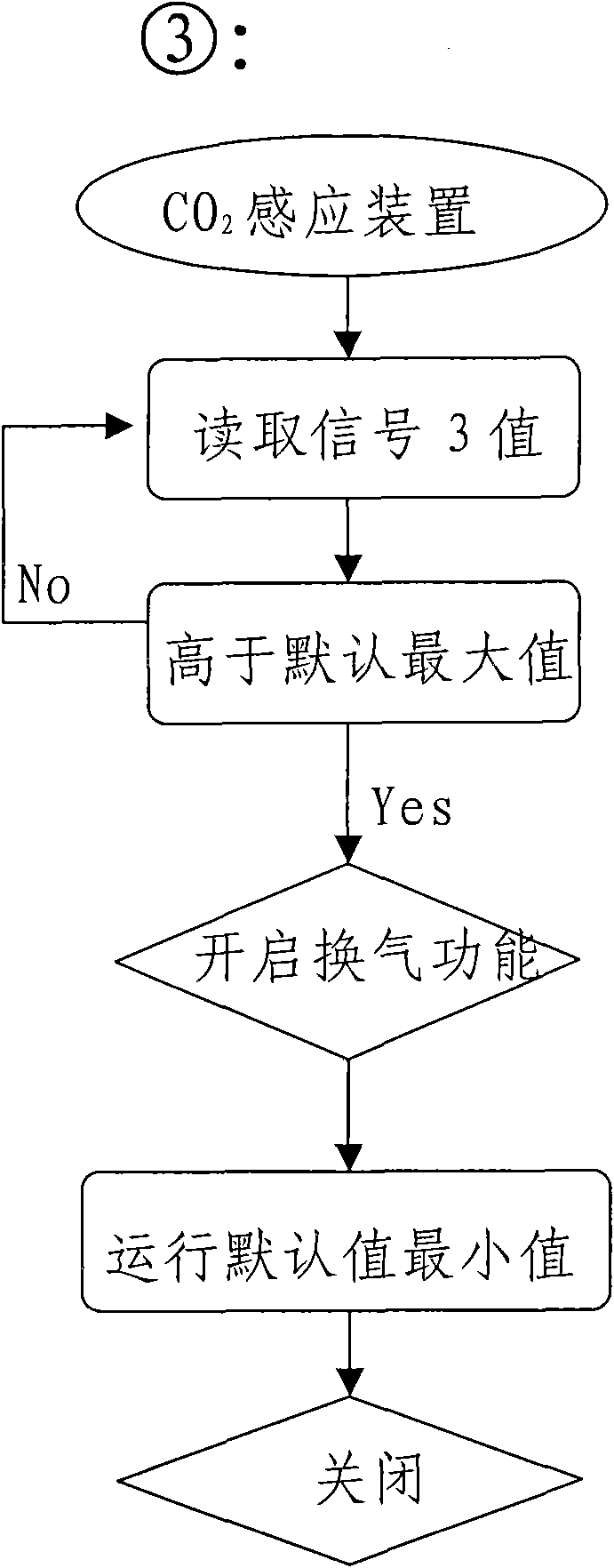

ActiveCN102147138AProper thermal comfortImprove sleep environmentSpace heating and ventilation safety systemsLighting and heating apparatusControl theoryRunning time

The invention discloses a method for controlling a sleep mode of an air conditioner, which comprises an afternoon nap mode and a night sleep mode, wherein the afternoon nap mode is realized by adopting a user-defined control mode or set control mode, in the user-defined control mode, a user sets an air conditioner operating temperature Tset, a temperature increment delta T and an air conditioner operating time t1, the air conditioner operates according to the user set temperature and gradually regulates the temperature to Tset+ / -delta T within the user set time t1; and in the set control mode, the last operating temperature of the air conditioner is read and is enabled to be equal to the set temperature Tset, the temperature is divided into three control ranges by adopting an air conditioner default operating time, and the temperature is controlled in each control range according to a set program. The invention provides a control method of the afternoon nap mode, the air conditioner selects the afternoon nap mode or night sleep mode according to the use demands in an operating process to ensure that the environment can obtain actually required temperature and the user obtains proper heat comfort, and thus better sleep environment can be created and purpose of saving energy can be achieved.

Owner:GREE ELECTRIC APPLIANCES INC

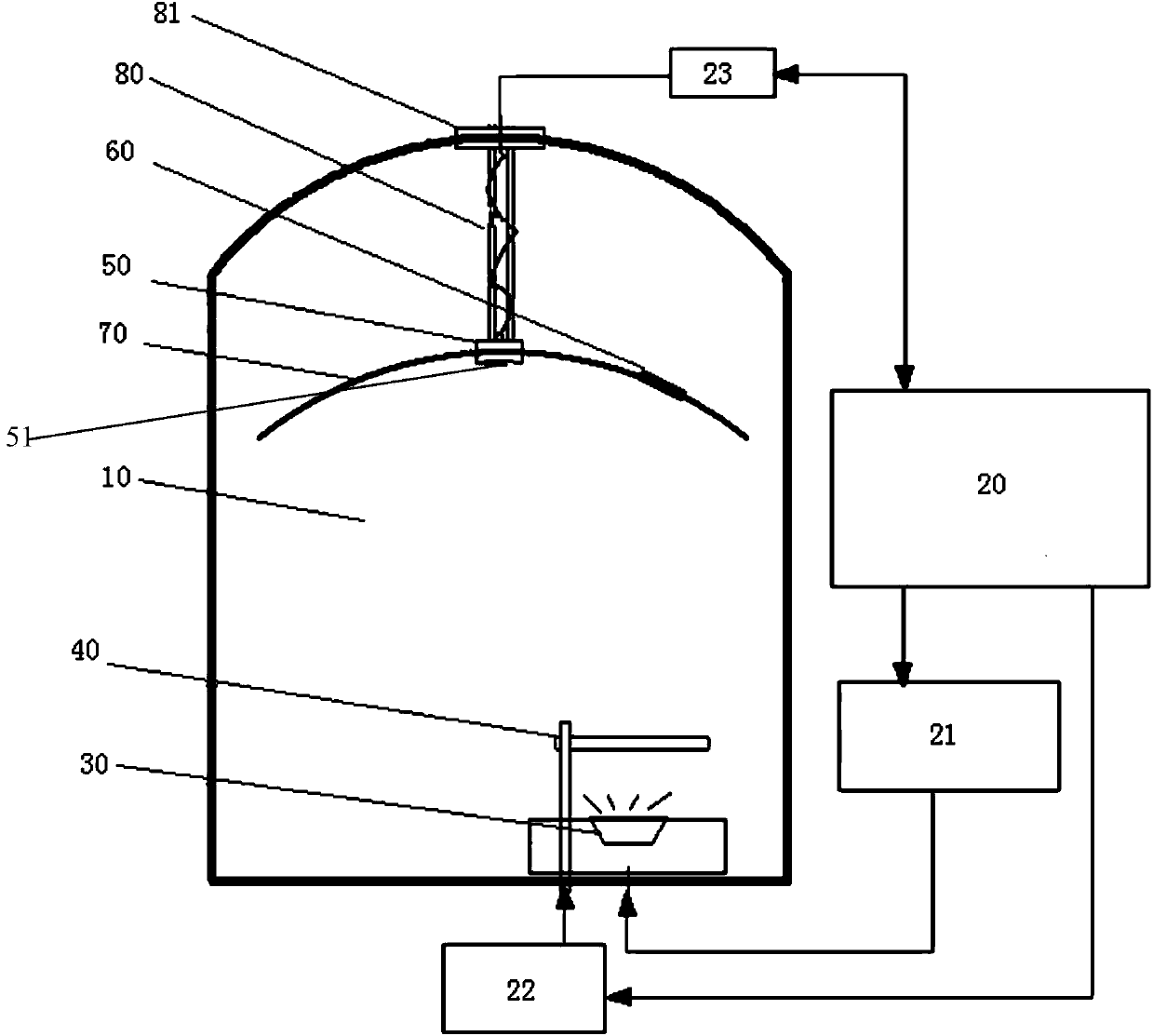

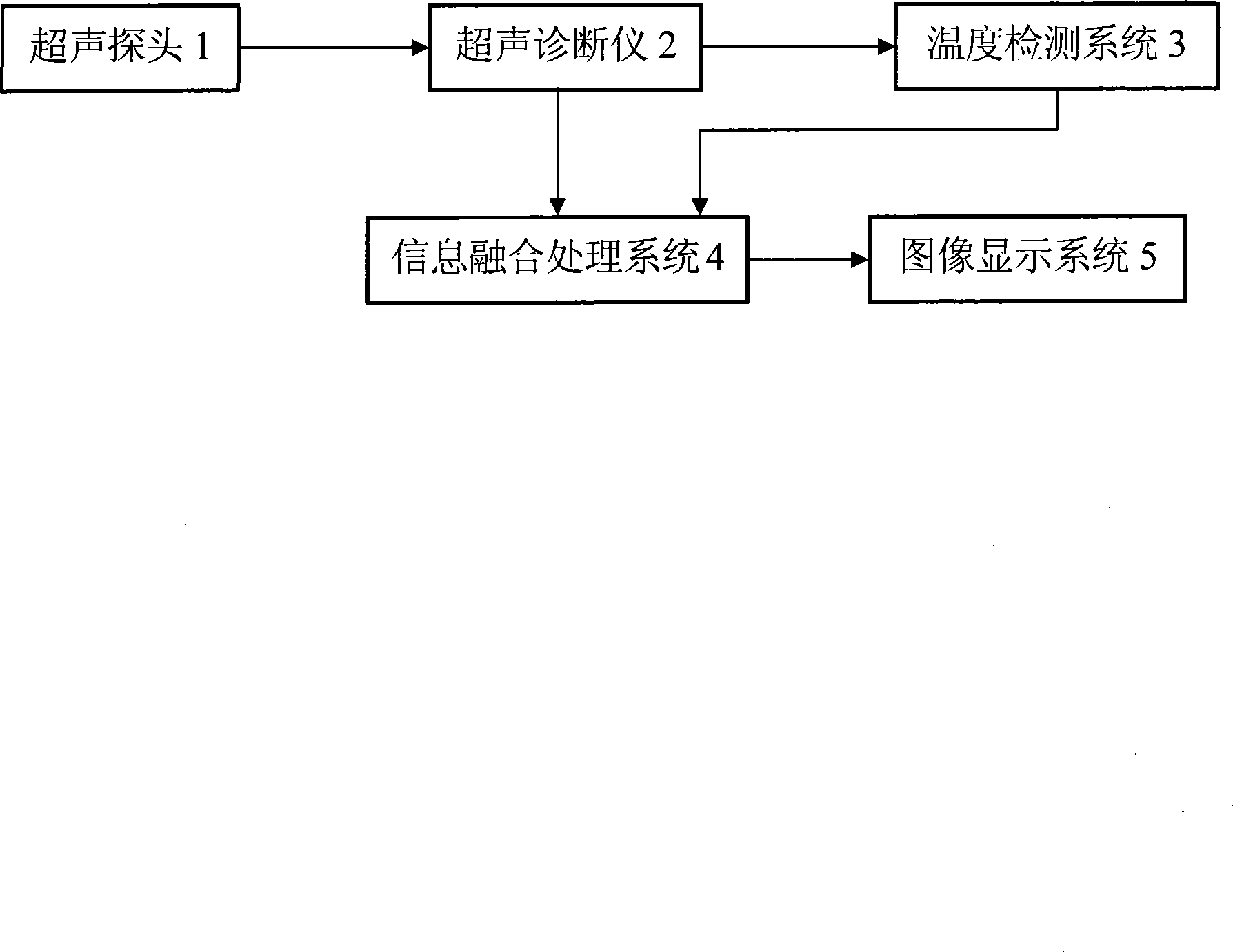

Control method of coating thickness of quartz crystal and coating device of quartz crystal

ActiveCN103469172AHigh thickness accuracySolve Thickness ProblemsVacuum evaporation coatingSputtering coatingHuman–machine interfaceControllability

The invention provides a control method of coating thickness of a quartz crystal, wherein the coating thickness is calculated according to the initial oscillation frequency of the quartz crystal before coating and the oscillation frequency of the quartz crystal after coating. The control method is characterized in that thickness measurement errors caused by rise of the oscillation frequency of the quartz crystal due to temperature increment of the quartz crystal are reduced. The coating device of the quartz crystal, provided by the invention, is convenient to operate, and the work efficiency is improved. A film thickness controller of the quartz crystal provided by the invention adopts a human-machine interface and is convenient for operators to monitor the coating process in real time and analyze the film forming data, thereby improving the controllability of the coating process. By adopting the control method and the device provided by the invention, the error on the coating thickness can be reduced to below 1 / 4 of the error in the prior art, so that the precision on the coating thickness is greatly improved.

Owner:SHANGHAI MOLIN TECH CO LTD

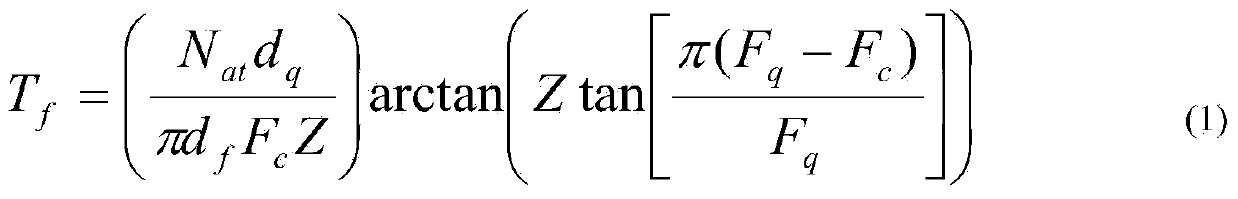

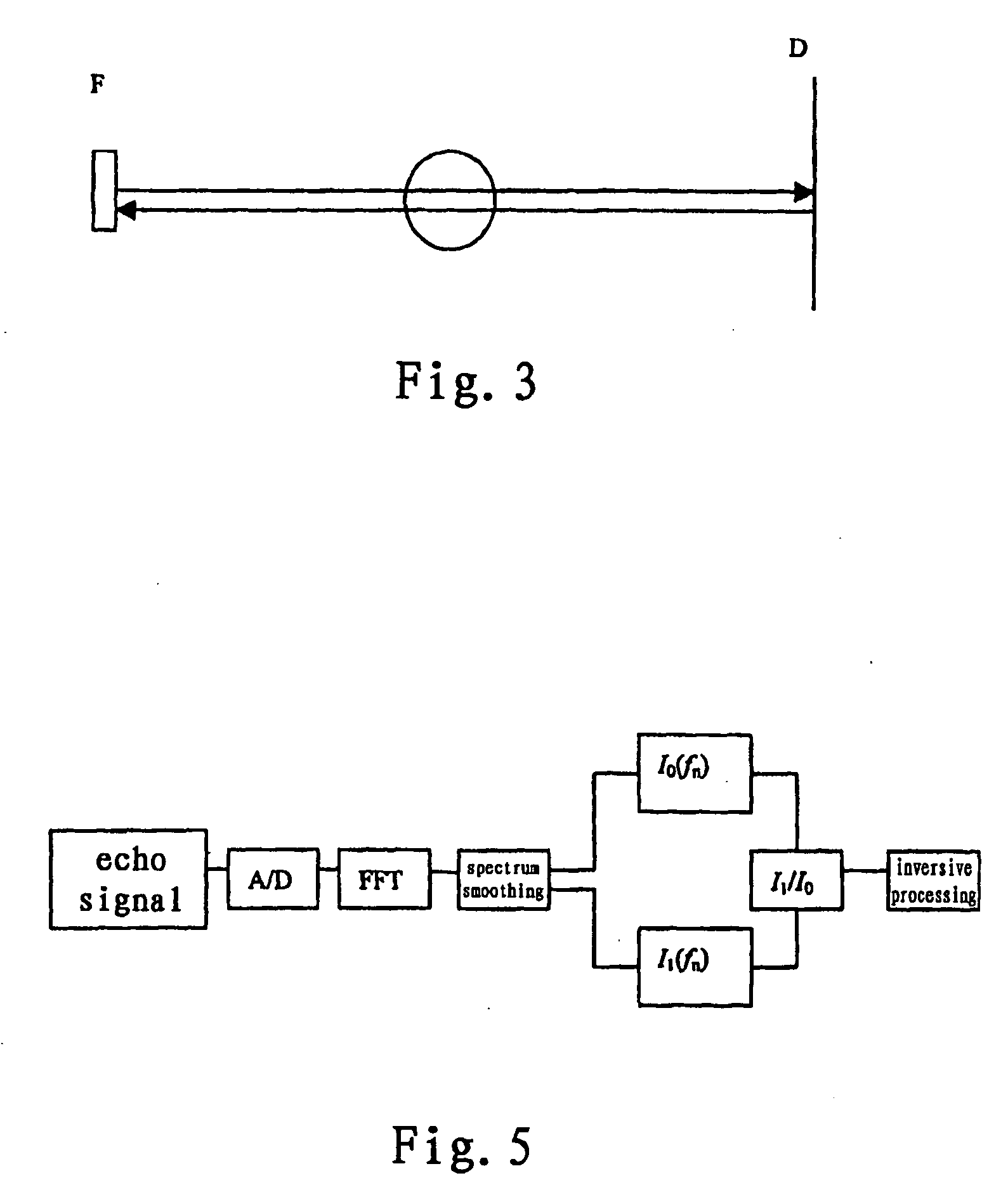

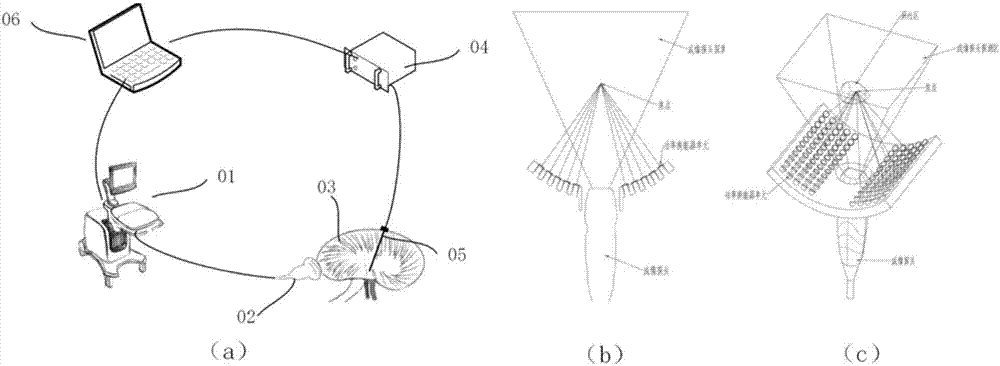

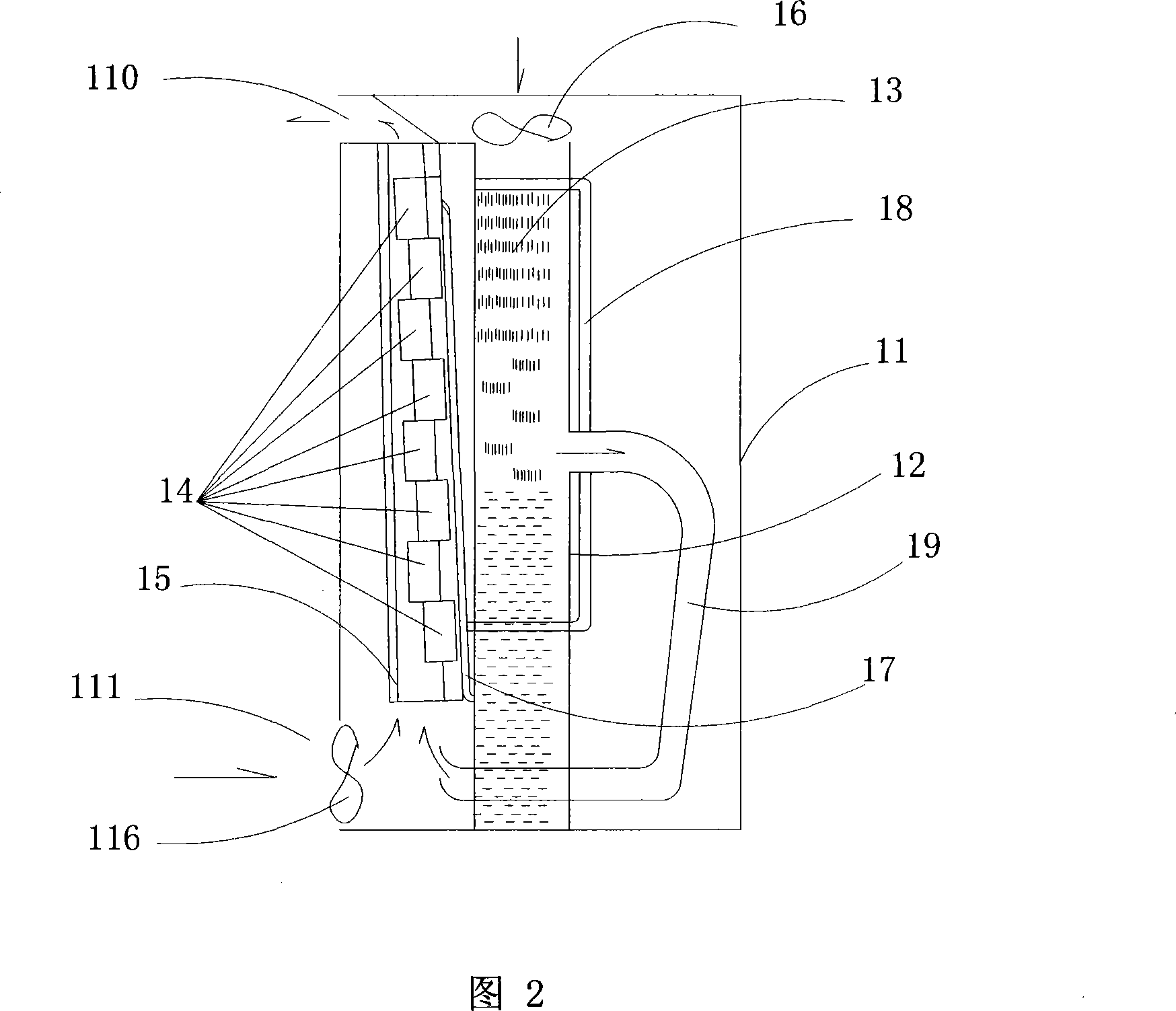

Ultrasonic real time harmless human body temperature-measuring device and temperature-measuring method

InactiveCN101125088ASolve the difficulty of variable temperature characteristic parametersSolve changing difficultiesUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringRelational modelBody temperature measure

The present invention relates to an ultrasonic real-time nondestructive body temperature measuring device and the temperature measurement method; the present invention establishes a relationship model of the temperature increment and the echo signal in the time domain or the frequency domain based on that the thermal characteristics of the human tissues and the ultrasound beams which pass through the human tissues thereof have better correlation with the temperature increment on the beam path during the slow change, furthermore, the present invention uses the numerical calculation method (such as, finite element / finite difference method) which is based on the nonlinear medical ultrasonic field to carry out the real-time dynamic calibration of the thermal coefficient of the deep tissue by establishing a Pennes biological heat conduction equation (BHTE) in a human structural model, so as to solve the difficulties that the characteristic parameters of the tissue temperature are too changeable ; the present invention uses the combination method of the numerical calculation and the ultrasonic detection to eliminate the problem of the heat-acoustic lens and adopts the fusion imaging method of the temperature information and the tissue structure information to visually display the temperature distribution and the structure distribution in the body.

Owner:XI AN JIAOTONG UNIV

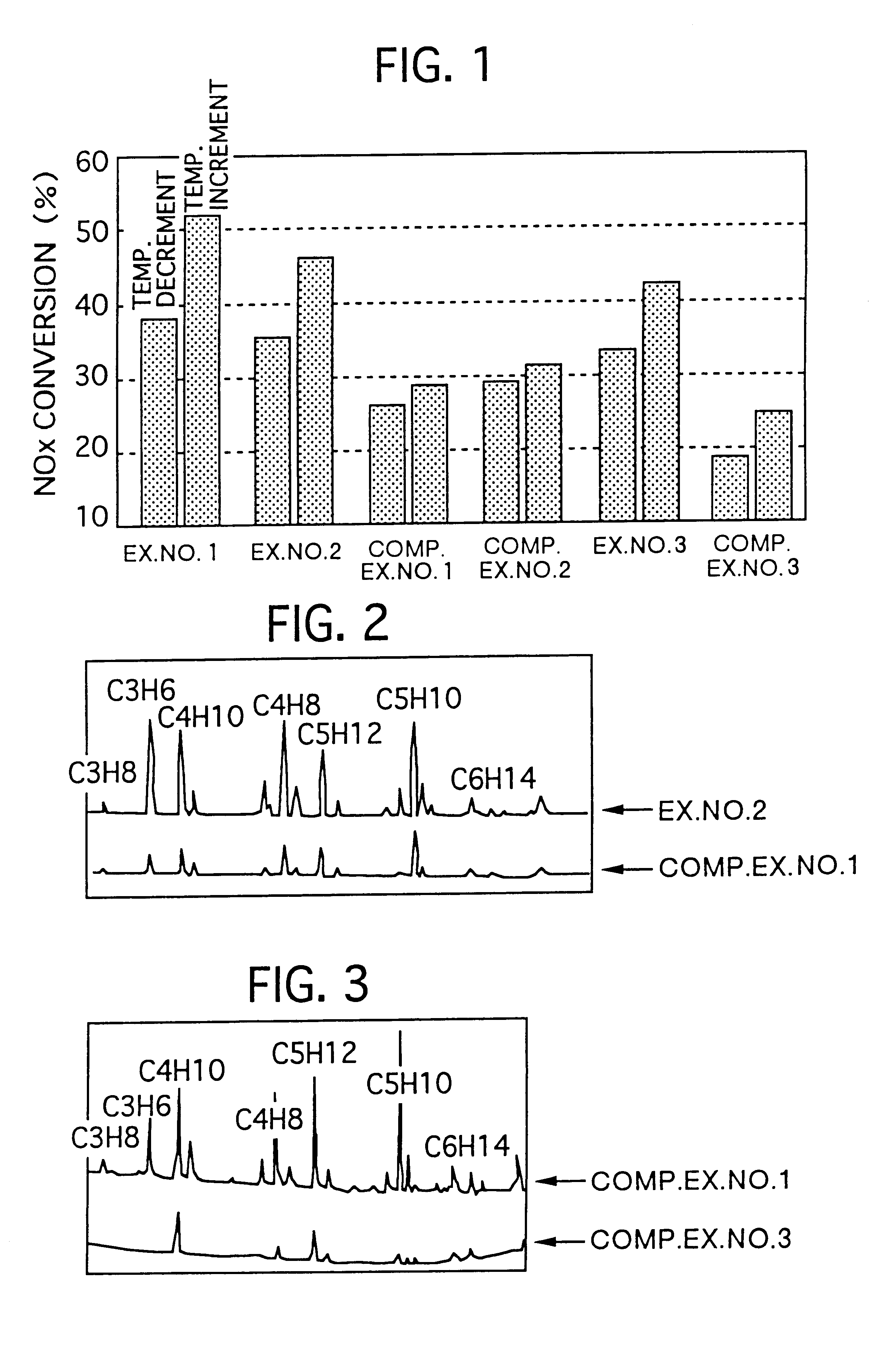

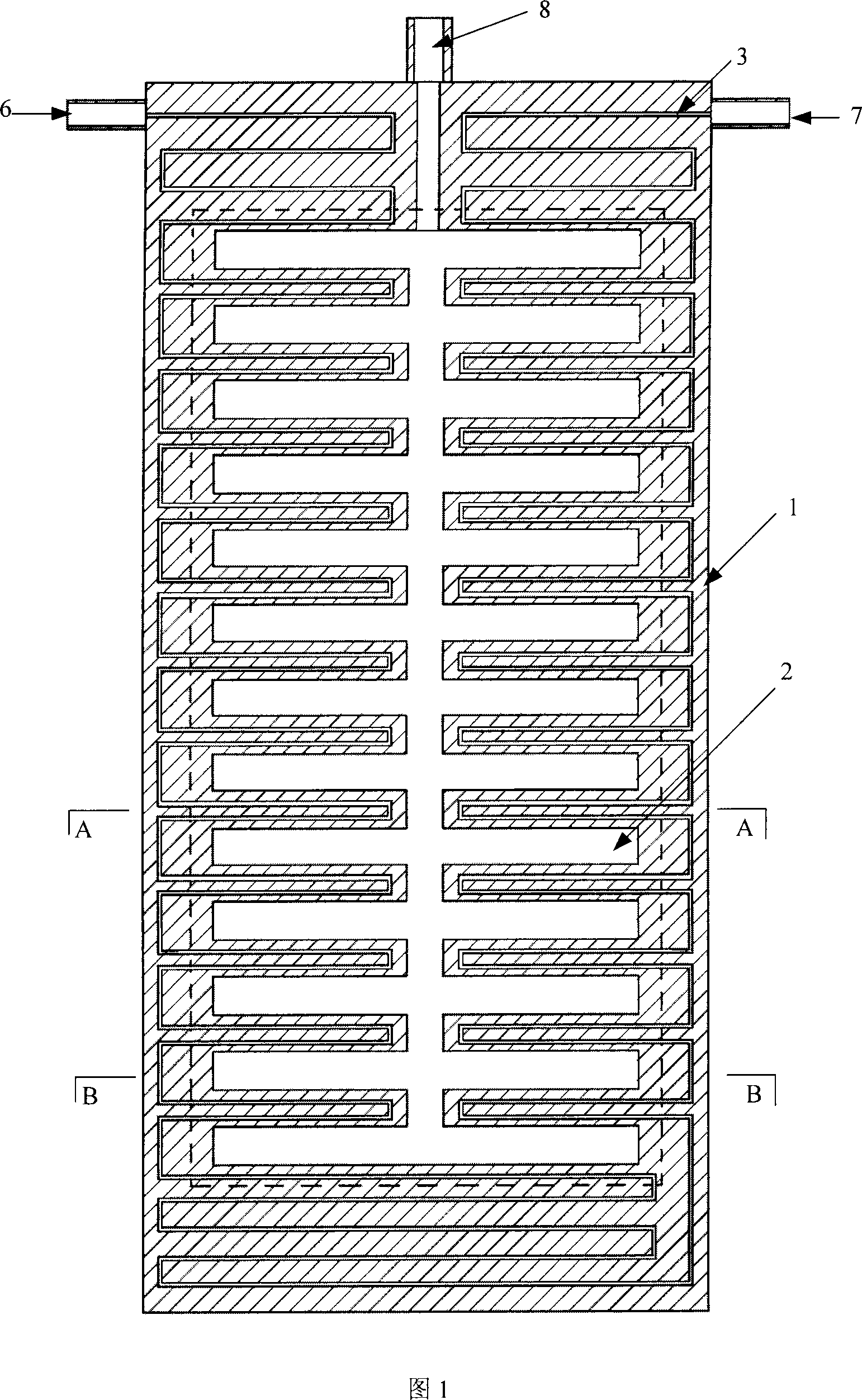

Method of purifying exhaust gas and catalyst for purifying exhaust gas

InactiveUS6191061B1Speed up the conversion processReducing and purifying the nitrogen oxides in the exhaust gasMolecular sieve catalystsDispersed particle separationComposite oxideReducing agent

In an exhaust gas in an oxygen-rich atmosphere, a method of purifying an exhaust gas and a catalyst for purifying an exhaust gas, which can exhibit a high NOx conversion securely, are provided. Disclosed is a method of purifying an exhaust gas that reduces and purifies NOx in an exhaust gas in an oxygen-rich atmosphere. Here, as a catalyst for purifying an exhaust gas, a loading layer comprising zeolite is loaded with alumina sulfate and cerium sulfate-zirconium composite oxide, and Pt is loaded on these. And, in a temperature range where HC are not oxidized, the HC are adsorbed and held by the zeolite, the HC, which the zeolite releases at the temperature increment, are subjected to cracking by the zeolite, the alumina sulfate and the cerium sulfate-zirconium composite oxide, and the thus produced low-grade HC are turned into reducing agents, thereby reducing and purifying the NOx in the exhaust gas.

Owner:TOYOTA JIDOSHA KK

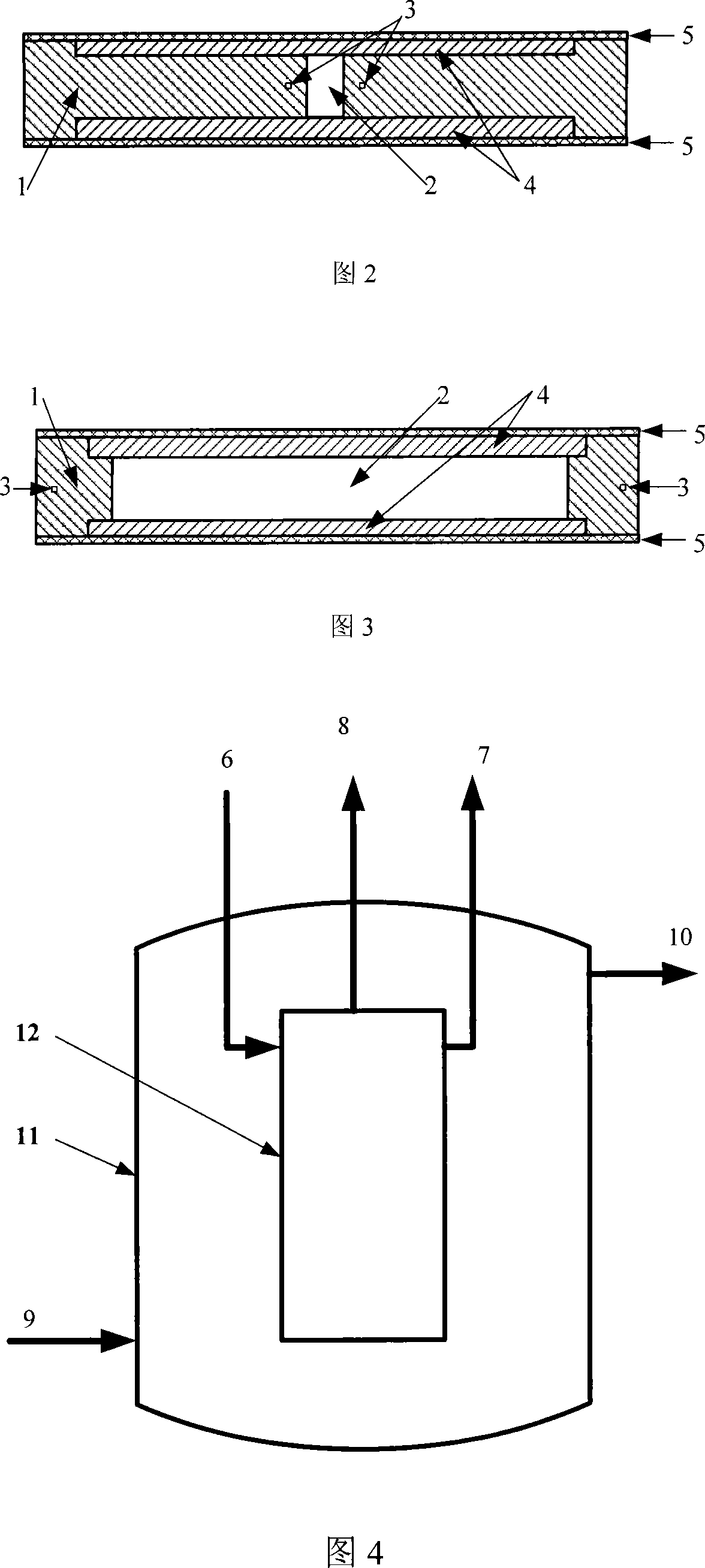

Quick start-up palladium membrane components transferring heat by small-scale passage

InactiveCN101181975AHeating up fastReduce metal contentHydrogen separation using solid contactWorking temperatureAlloy

The invention discloses a fast starting Pd alloy membrane component which transfers heats through small passage, comprising a membrane-supporting frame, a porous metal-supporting body and a Pd alloy membrane; two porous metal-supporting bodies and the Pd alloy membrane are respectively arranged at the two sides of the membrane supporting frame where a purified hydrogen passage and a small passage are arranged; the small passage is an airflow passage for heating passing through the interior of the membrane supporting frame, with the section of rectangle and the section dimension of 0.2-1.0mm multiplied by 0.2-1.0mm; a passage inlet and a passage outlet connected with the small passage are arranged on the membrane supporting frame; the hydrogen flow passage on the supporting body is in rectangle tooth shape; an air guide outlet is arranged on the upper end of the supporting frame. The component can quickly lead the temperature of the Pd alloy membrane component to rise to requirement working temperatures by using the flowing heat conduction of the heat fluid in the small passage, thus reducing the metal content of the Pd alloy membrane component and further reducing the temperature increment time.

Owner:SOUTH CHINA UNIV OF TECH

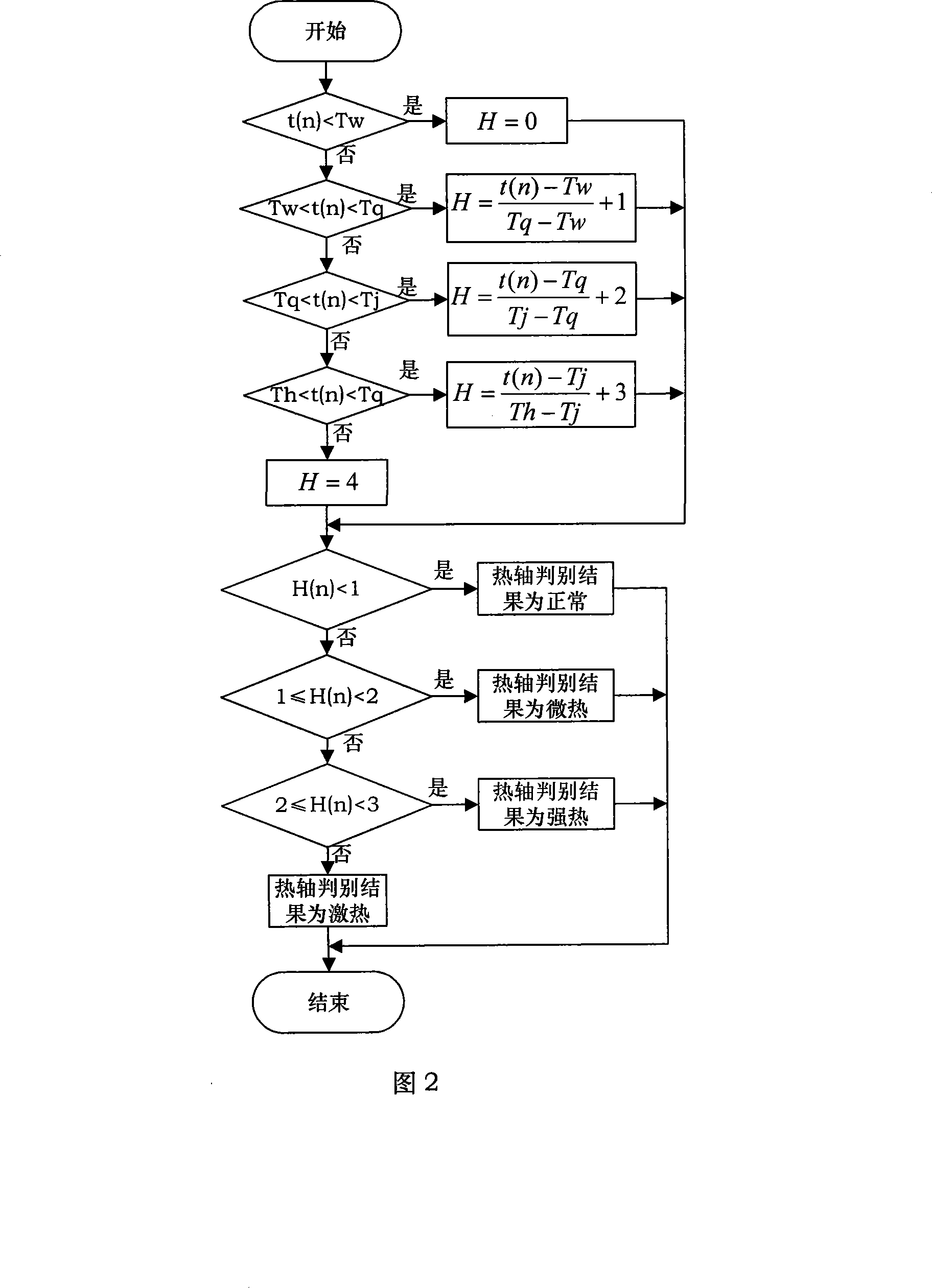

Hotbox distinguishing method for train infrared shaft-temperature detecting system

InactiveCN101181901ASimple calculationThe judgment result is accurateRailway auxillary equipmentRailway profile gaugesPhotonTemperature Increment

The invention provides a hot shaft distinguishing method for a train infrared shaft temperature probing system. The hot shaft temperatures are abnormal values of the train shaft temperatures which are statistically distributed; therefore, the hot shaft has great distance away from the average value; the distance from the shaft temperature to the average shaft temperature can be taken as a criterion for the hot shaft distinguishing. All the shaft temperatures on the same side of the train are taken as a group of samples; by adopting the temperature increment and the revin temperature increment variance, the vehicle temperature increment variance or the temperature increment and the revin temperature increment variance and the vehicle temperature increment as the criterion of the hot shaft distinguishing; by taking all the shaft temperatures on the same side of the train as a group of samples, the physical meaning is definite, the calculation is simple and the distinguishing result is exact. The method can be adopted to the train infrared shaft temperature probing system which adopts a photon probe, or can be adopted to the train infrared shaft temperature probing system which adopts other train shaft temperature probing system.

Owner:BEIJING CTROWELL INFRARED TECHN

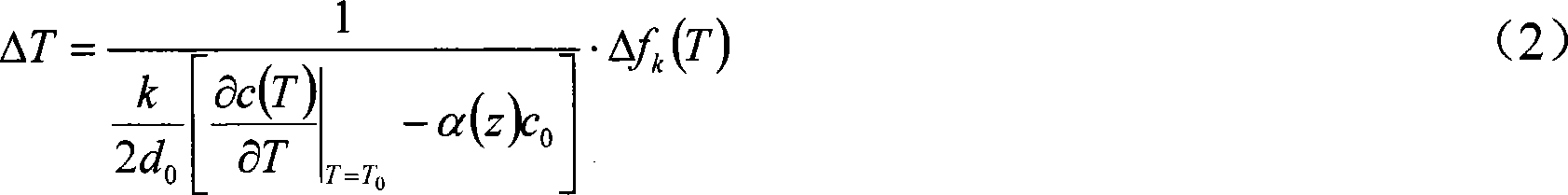

Method for measuring the temperature in the body of human or animal with acoustic inversion

InactiveUS20050281313A1Effective and practicalThe method is practical and effectiveUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyObject functionInversion methods

A method for measuring the local temperature in the body of human or animal is provided. In the method, a first ultrasonic wave is transmitted to a region to be measured, which has temperature T, under the guiding of M-type ultrasound. The reflected ultrasonic wave from a particular reflection surface is received to obtain a first parameter. Then the temperature of the region to be measured is modified to T+ΔT. A second ultrasonic wave is transmitted to the region to be measured. The reflected ultrasonic wave from the second ultrasonic wave reflected by a particular reflection surface is received to obtain a second parameter. A ratio of the measured value of 2nd parameter to that of 1st parameter can be obtained. On the other hand, a theoretical ratio of the second parameter to the first parameter can also be obtained through theoretical calculation. The objection function which involves the differences between the theoretical ratio and measured ratio can be minimized by an optimization method. The local temperature increment ΔT of the region to be measured will be obtained with an inversion method.

Owner:HAIFUNING HIFU TECH BEIJING

Preparation method of propylene hydroximic acid

ActiveCN102584629AHigh yieldAvoid decomposition and volatilizationOrganic chemistryHydroxylamineDistillation

The invention discloses a preparation method of propylene hydroximic acid, wherein the temperature of the reaction is controlled by a thermostatic waterbath, a certain amount of methyl acrylate and pure water are added into a reaction vessel, the quality of the pure water is 3-4 times that of the methyl acrylate, the mixture is quickly stirred to enable the methyl acrylate to be uniformly dispersed, then hydroxylamine hydrochloride with the weight being 1.2-1.5 times that of the methyl acrylate is added into a three-opening round bottomed flask, the mixture is constantly stirred to dissolve the mixture, when the system temperature is kept stable at 20 DEG C, ionic membrane caustic soda liquid with the weight being equal to that of hydroxylamine hydrochloride,is added into the mixture by using a dripping method so as to enable the reaction to perform smoothly, meanwhile, the temperature of a reaction system is kept to be not more than 25 DEG C, low-pressure distillation is performed after the reaction to remove dissociated unreacted hydroxylamine and a by-product methyl alcohol, cooling and suction filtration are performed to remove the precipitated salinity, and the final product is a water solution of propylene hydroximic acid. The reaction is controlled to be carried out slowly by adopting a method of dripping ionic membrane caustic soda liquid, so that the dissociated hydroxylamine is prevented from being decomposed and volatilized due to rapid temperature increment, and the utilization ratio of raw materials is further improved.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

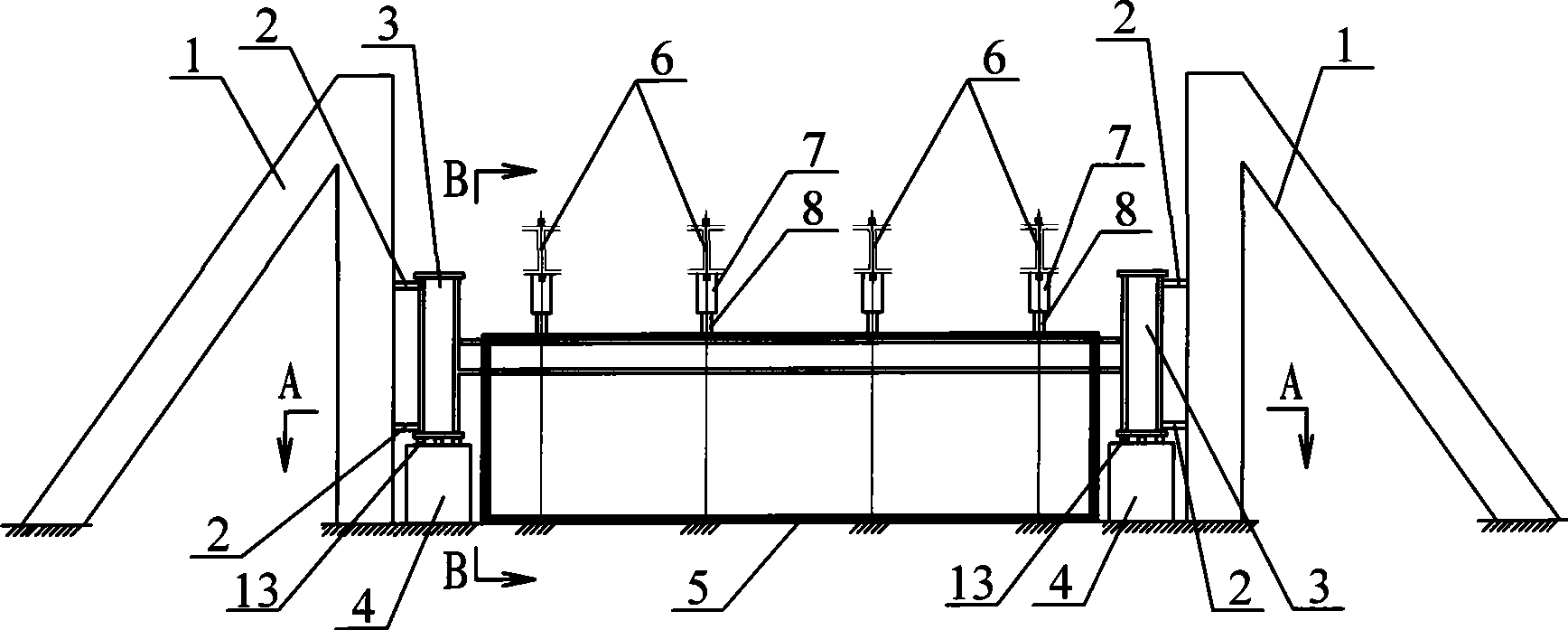

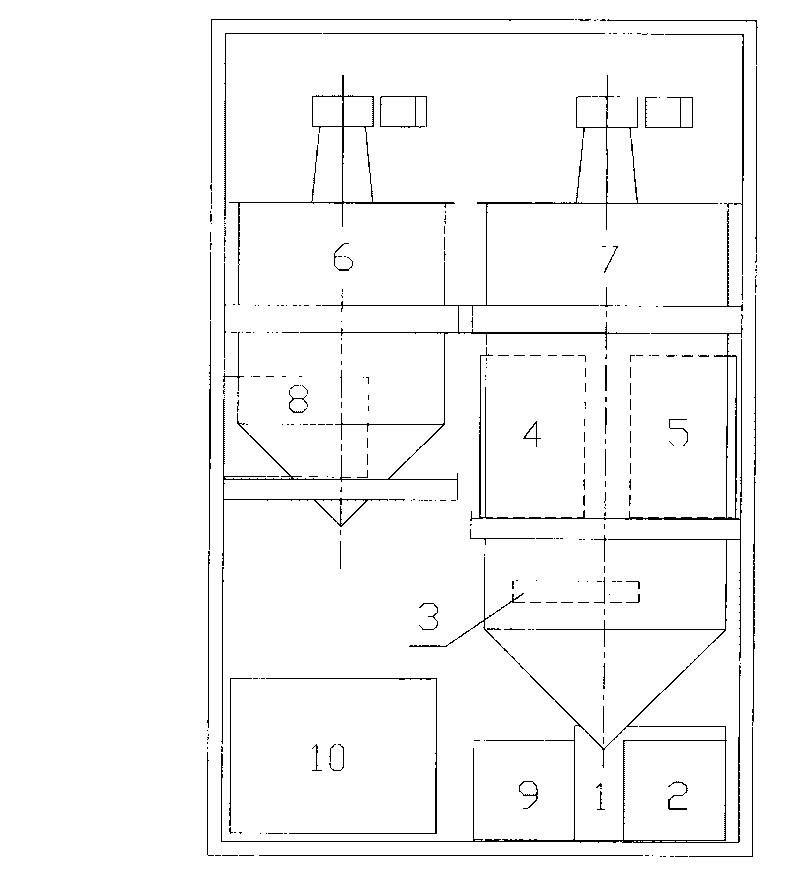

Anti-fire test device of restrained beam

InactiveCN101413937AImprove performanceHigh simulationStructural/machines measurementMaterial testing goodsTension compressionFire test

The invention relates to a fire-resistance testing device, in particular to a fire-resistance testing device used for a restrained beam. The invention aims at solving the problem that the existing testing device can not test the fire-resistance performance of the restrained beam. Two sample supporters are longitudinally arranged on the ground surface; two reaction frames are positively arranged on the ground surface at the external side of the two sample supporters; a restraining steel column is vertically arranged on a rolling shaft; a tension-compression sensor is arranged between the reaction frame and the restraining steel column; a furnace body is arranged on the ground surface between the two sample supporters; two anchor rods on a vertical-loading device are transversely arranged at two sides of the furnace body; a jack and a weighing sensor are respectively arranged at the upper part and the lower part of the lower surface of a reaction steel beam; a nozzle is arranged at a sprout; an oil pump is connected with the nozzle; the oil pump is connected with an oil tank; a fan is communicated with the sprout; the furnace body is provided with a flue; the thermocouple is arranged on the furnace body wall; in the invention, the testing device is provided for the fire-resistance test of the restrained beam, and the test requirements required by the test such as temperature increment, boundary constrains, reaction measurement, loading, and the like are met.

Owner:HARBIN INST OF TECH

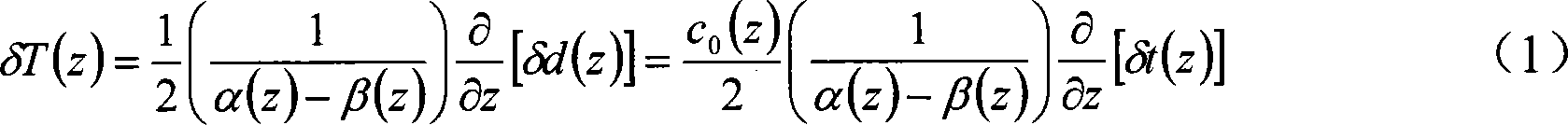

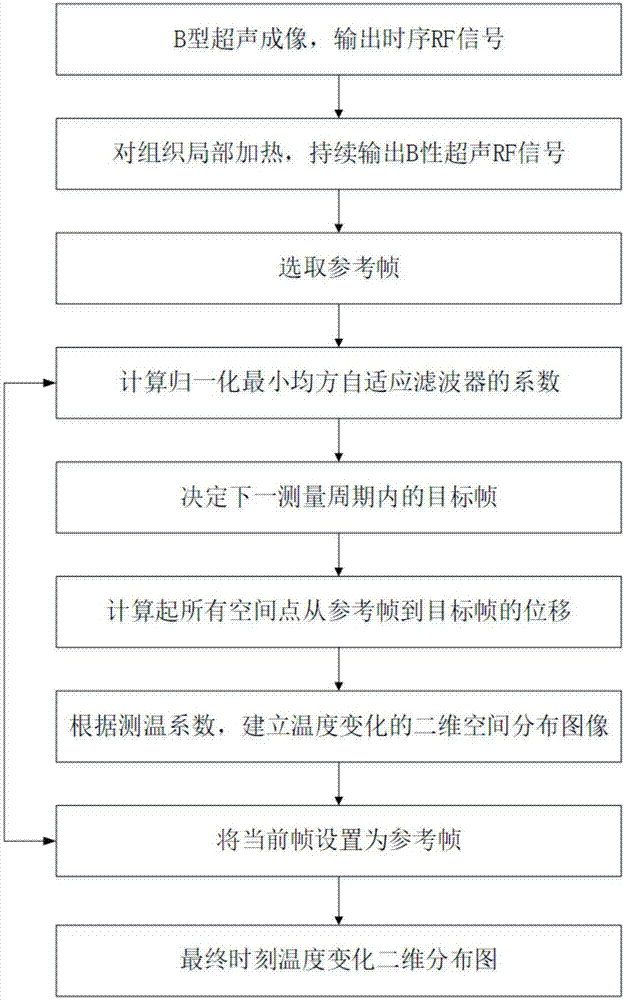

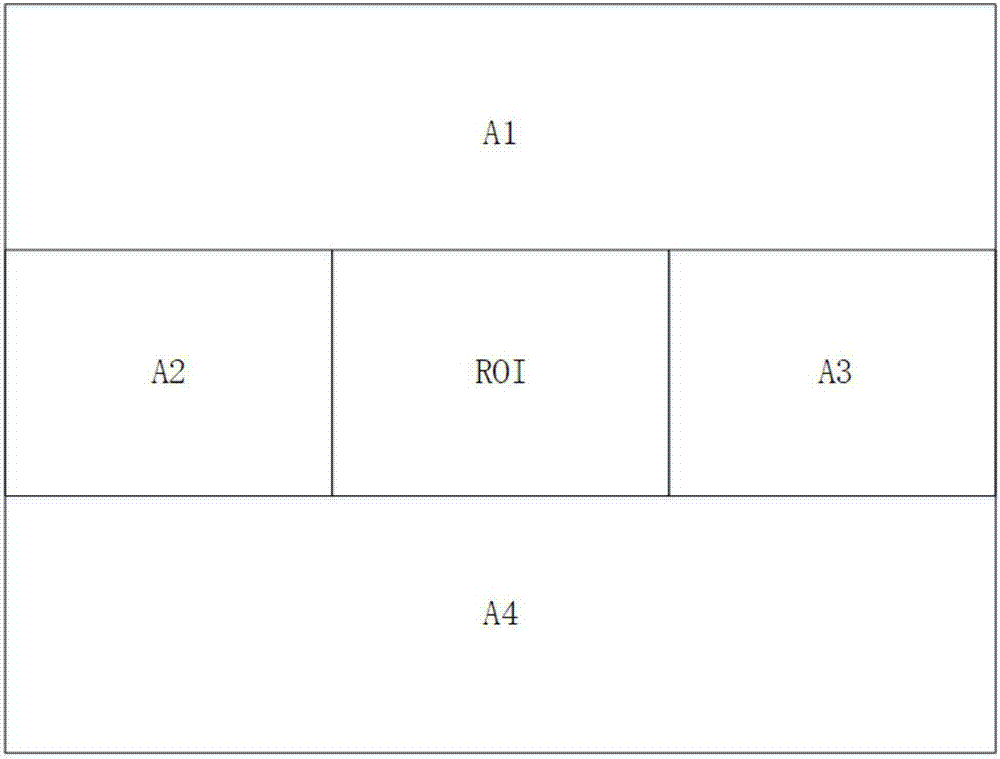

Ultrasonic method for measuring temperature change of biological tissue based on thermal expansion and gating algorithm

ActiveCN107569256ALow costEasy to deploy at scaleOrgan movement/changes detectionInfrasonic diagnosticsDiseaseTissue heating

The invention discloses an ultrasonic method for measuring temperature change of biological tissue based on thermal expansion and gating algorithm. Aiming at the problem that temperature increment ofa target area cannot be effectively monitored in methods for treating diseases based on various current body tissue heating modes, a method for evaluating the temperature change of the biological tissue by using B-mode ultrasound RF signals is established. According to the method, methods such as focused ultrasound, radio frequency and microwave are used for locally heating the biological tissue,B-mode ultrasound is used for imaging the target area and collecting the RF signals of the target area, a target frame is selected based on B-mode ultrasound timing sequence images, time delay imagesthat ultrasound passes through the tissue are calculated, and accordingly temperature change images are obtained; according to images outside a heating area, the coefficient of a self-adaption filteris calculated, and the obtained temperature change images are subjected to noise suppression. According to the ultrasonic method, the error in the temperature increment range of 18 DEG C is smaller than or equal to 2 DEG C, the temperature increment monitoring technology of B-mode ultrasound is promoted to be applied to thermal therapy, and the safety and effectiveness of the thermal therapy can be remarkably improved.

Owner:NANJING GUANGCI MEDICAL TECH

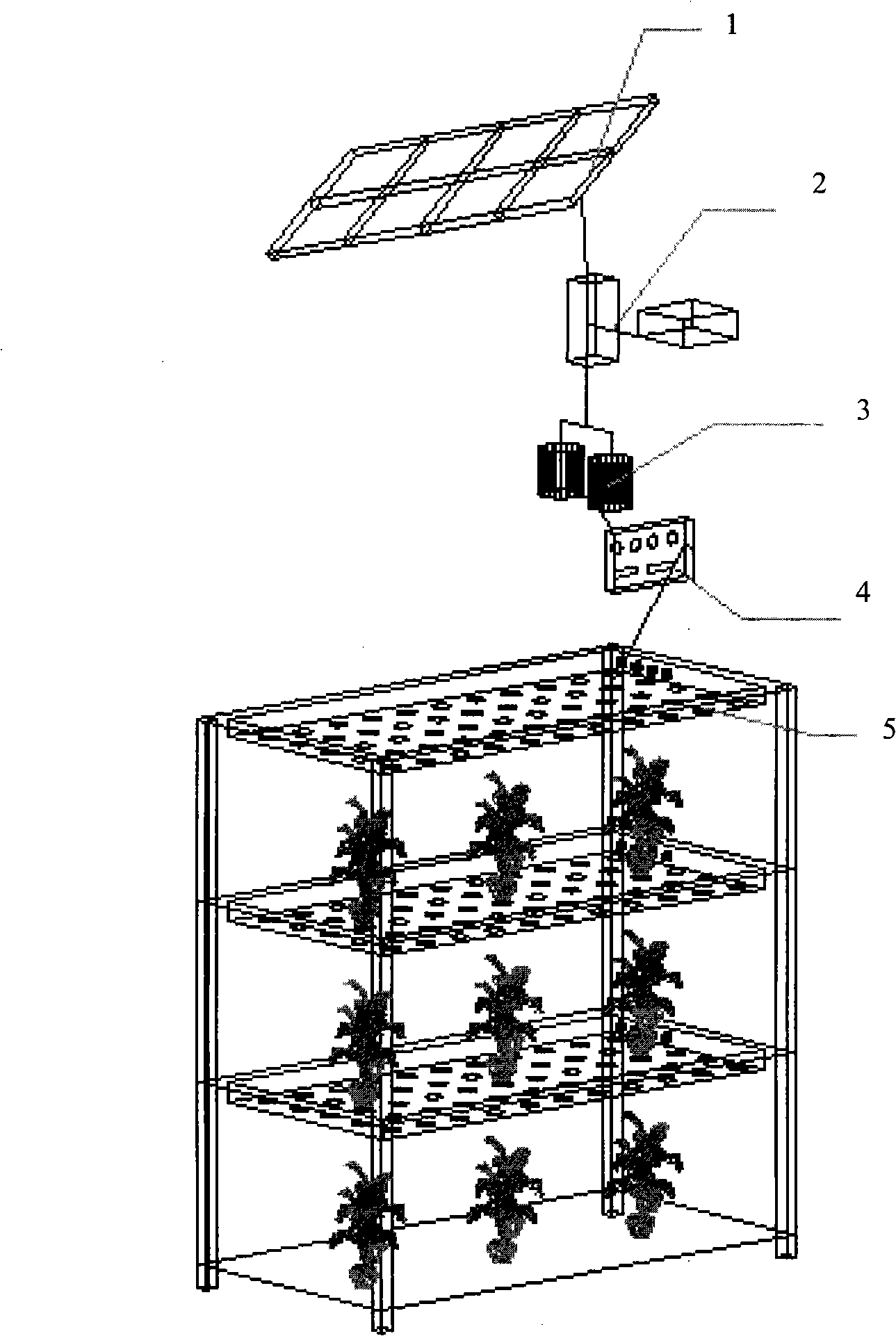

Solar energy driven plant growth lamp

InactiveCN101285564AReasonable structurePrecise control of opening/closing timeBatteries circuit arrangementsPoint-like light sourceFar-redEngineering

The invention provides a plant growth lamp driven by solar energy, in particular to a plant growth lamp with specific spectrum wavelength particularly designed for growing development of plant, belonging to agricultural engineering technical field. The invention discloses a plant growth lamp driven by solar energy, comprising a solar battery module, a light source panel consisting of three LED semiconductor light sources, and a light quality regulating and controlling device, wherein, the light source panel consists of a red LED semiconductor light source with wavelength of 630nm, a blue LED semiconductor light source with wavelength of 460nm and a far-red LED semiconductor light source with wavelength of 730nm which are in cross combined distribution. The LED light sources have an improving function to the growth of plant, can reduce the temperature increment brought by heating of a common light source, and can reduce manufacturing cost; the LED light sources also can sufficiently use the solar energy to provide energy for plant production under man-made environment, and can reduce dependence to conventional energy and electric energy.

Owner:AGRI ENVIRONMENT & SUSTAINABLE DEV INST CAAS

Integral forming method for sewing enhanced cross connector made of fiber reinforced resin matrix composite

The invention discloses an integral forming method for a sewing enhanced cross connector made of fiber reinforced resin matrix composites. The method comprises five main steps: 1, preparing cross fiber performing body; 2, allowing the cross fiber performing body to be subjected to sewing enhancement through sewing fiber threads; 3, putting the obtained performing body in a die, followed by positioning and die closing; 4, vacuum-pumping, pouring resin and curing through temperature increment; 5, performing die opening, and taking out cured and formed the sewing enhanced cross connector made of the fiber reinforced resin matrix composite. According to the method, a composites RTM forming process method and a sewing enhancement method are integrated, so that the interlayer strength of the cross connector is improved.

Owner:BEIHANG UNIV

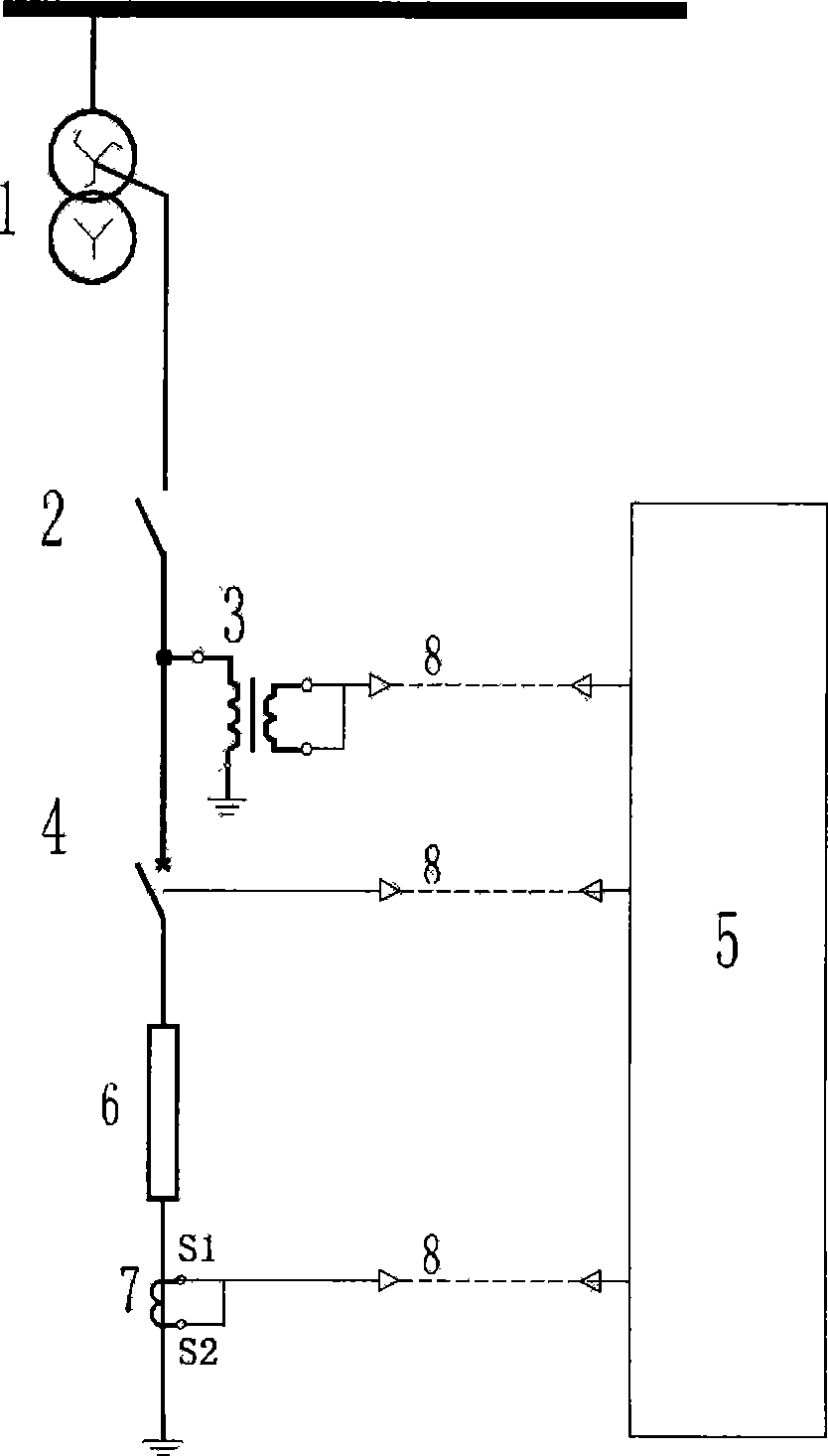

Neutral point grounding resistor plant for electrical power system

ActiveCN101499655ASolve agingExtend your lifeResistorsEmergency protective arrangements for automatic disconnectionElectric power systemTime delays

The invention provides a neutral point grounding resistor integrated device for a power system, belonging to the field of power system distribution network technology. The integrated device comprises a grounding transformer, an isolation switch, a voltage transformer, a circuit breaker, a controller, a grounding resistor and a current transformer. When the grounding does not occur, the grounding resistor is not accessed and no current passes by the grounding resistor, thus completely solving the ageing problem caused by the temperature increment during the normal running process and greatly prolonging the service life of the equipment; and after the grounding occurs, the grounding resistor is accessed with time delay, thus avoiding the transient grounding. Compared with the prior art, the integrated device can reduce the shutdown time by about a half; after the grounding resistor is accessed, the grounding resistor is cut off after a certain time, thus preventing the grounding resistor from being burned and ensuring the safety of the equipment.

Owner:JIANGSU ELECTRIC POWER CO +1

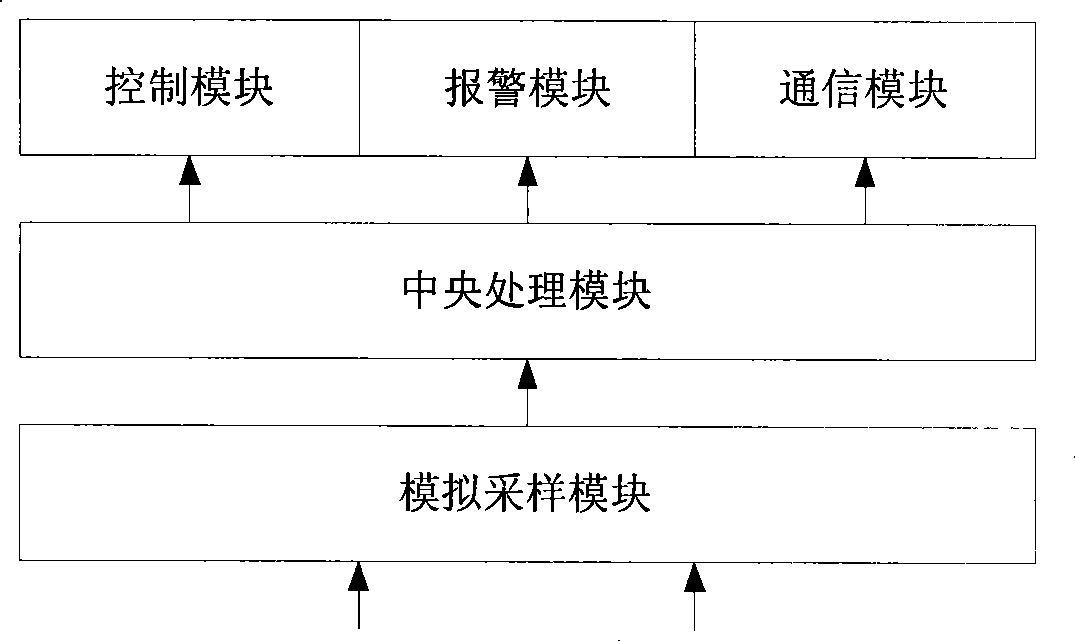

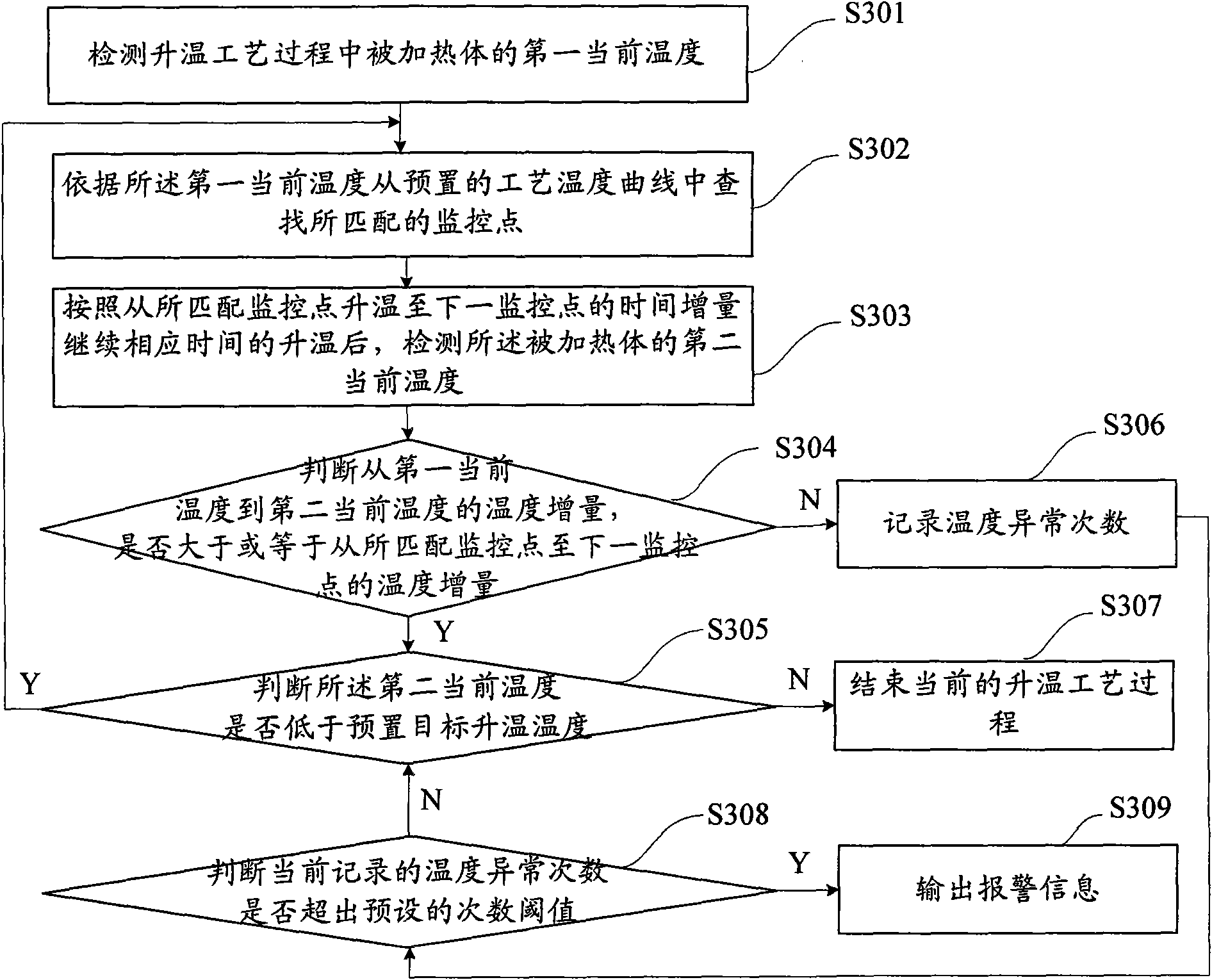

Temperature monitoring method and device of production line device

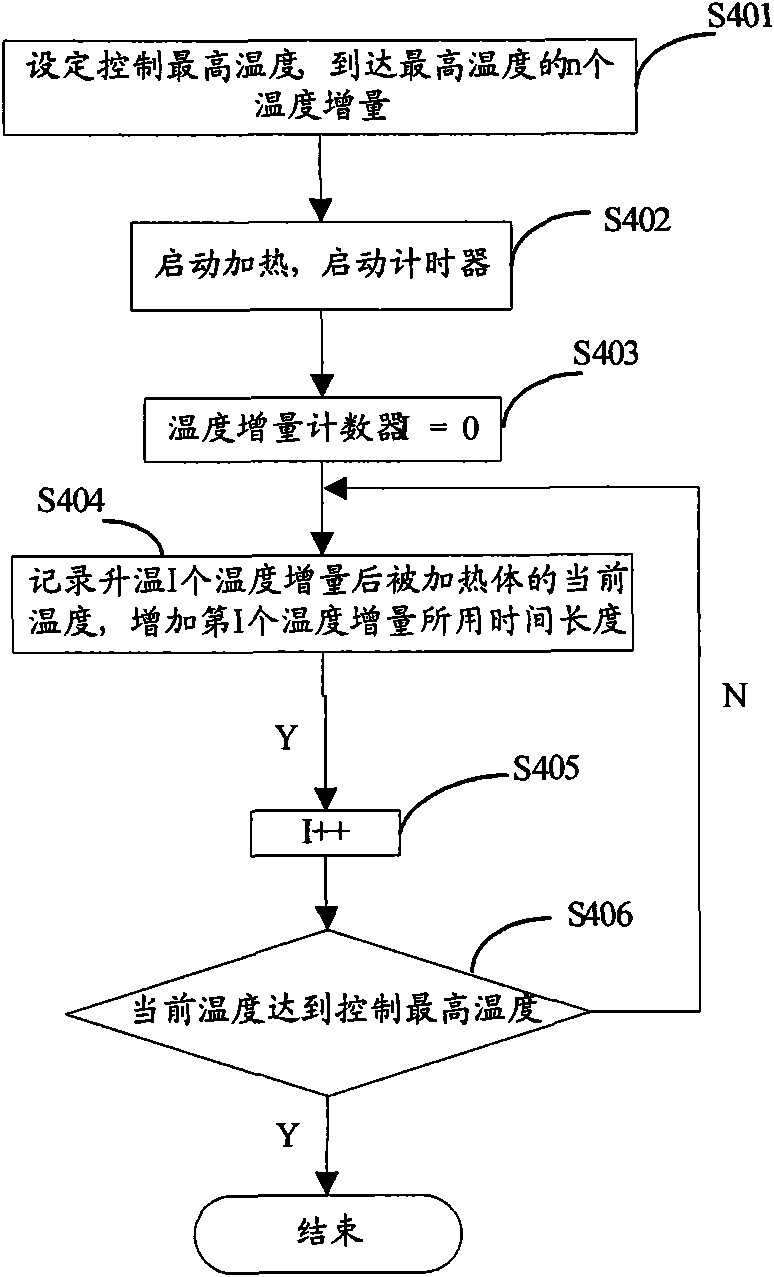

ActiveCN101620448AAffect uniformityReduce damage rateTemperature control using electric meansAlarmsTemperature curveMatched control

The invention discloses a temperature-rise monitoring method of a production line device, which comprising steps as follow: S11, detecting a first current temperature of a heated object; S12, searching out a matched control point from a preset process temperature curve according to the first current temperature; S13, detecting a second current temperature of the heated object after keeping risingtemperature according to the time increment generated when the temperature rises from the matched monitoring point to the next monitoring point; S14, judging whether the temperature increment generated when temperature rises from the first current temperature to the second current temperature is larger than or equal to the temperature increment generated when the temperature rises from the matched monitoring point to next monitoring point; if so, executing S15; if not, recording the abnormal information of temperature; S15, judging whether the second current temperature is lower than the preset objective temperature-rise temperature or not; if so, taking the second current temperature as the first current temperature and going back to S12; if not, finishing the operation. The invention can monitor temperature in real time during the temperature adjustment of the production line device on the bases of improving product percent of pass and lowing cost.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Supersonic inverting method for measuring temperature of human or animal body

InactiveCN1584524AUltrasonic/sonic/infrasonic diagnosticsUltrasound therapySonificationThermodynamics

A method for measuring local temperature in human body or animal body includes emitting the first ultrasonic ray on measured region of temperature T, receiving reflected echo for obtaining the first parameter, changing temperature at measured region to be T+delta T and emitting the second ray for obtaining the second parameter, solving out measuring ratio and theoretical ratio of the two parameters, optimizing deviation between the two ratios for reverting out local temperature increment delta T of measured region.

Owner:BEIJING YUANDE BIO MEDICAL ENG

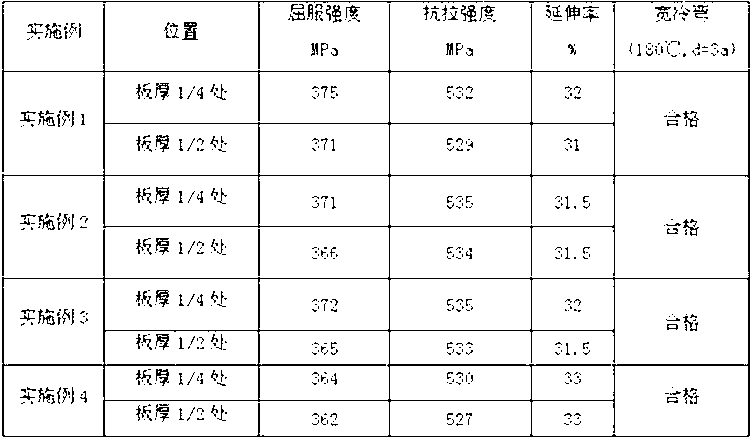

Heat treatment method for steel plate used for extremely thick non-quenched and tempered ocean engineering

InactiveCN103074477ASuitable for productionWide applicabilityFurnace typesHeat treatment process controlTemperingHeat conservation

The invention provides a heat treatment method for a steel plate used for extremely thick non-quenched and tempered ocean engineering. Two times of normalizing and tempering process are adopted, in the first normalizing: in the first stage, the temperature ranges from 600 to 650 DEG C, the temperature increment coefficient is 1.3 to 1.6 min / mm, warm is kept for 20 to 30 min, in the second stage, the temperature ranges from 890 to 950 DEG C, the temperature increment coefficient is 1.2 to 1.5 min / mm, and the warm is kept for 20 to 30 min; in the second normalizing: in the first stage, the temperature ranges from 600 to 650 DEG C, the temperature increment coefficient is 1.3 to 1.6 min / mm, the warm is kept for 20 to 30 min, in the second stage, the temperature ranges 880 to 930 DEG C, the temperature increment coefficient is 1.2 to 1.3 min / mm, and the warm is kept for 20 to 30 min; and in the tempering: the temperature ranges from 550 to 640 DEG C, the total tempering time ranges from 2.0 to 2.5 min / mm. The steel plate used for extremely thick non-quenched and tempered ocean engineering has the characteristics of high strength, high plasticity, excellent Z-direction lamellar tearing resisting performance, uniform thickness directionality and the like.

Owner:NANJING IRON & STEEL CO LTD

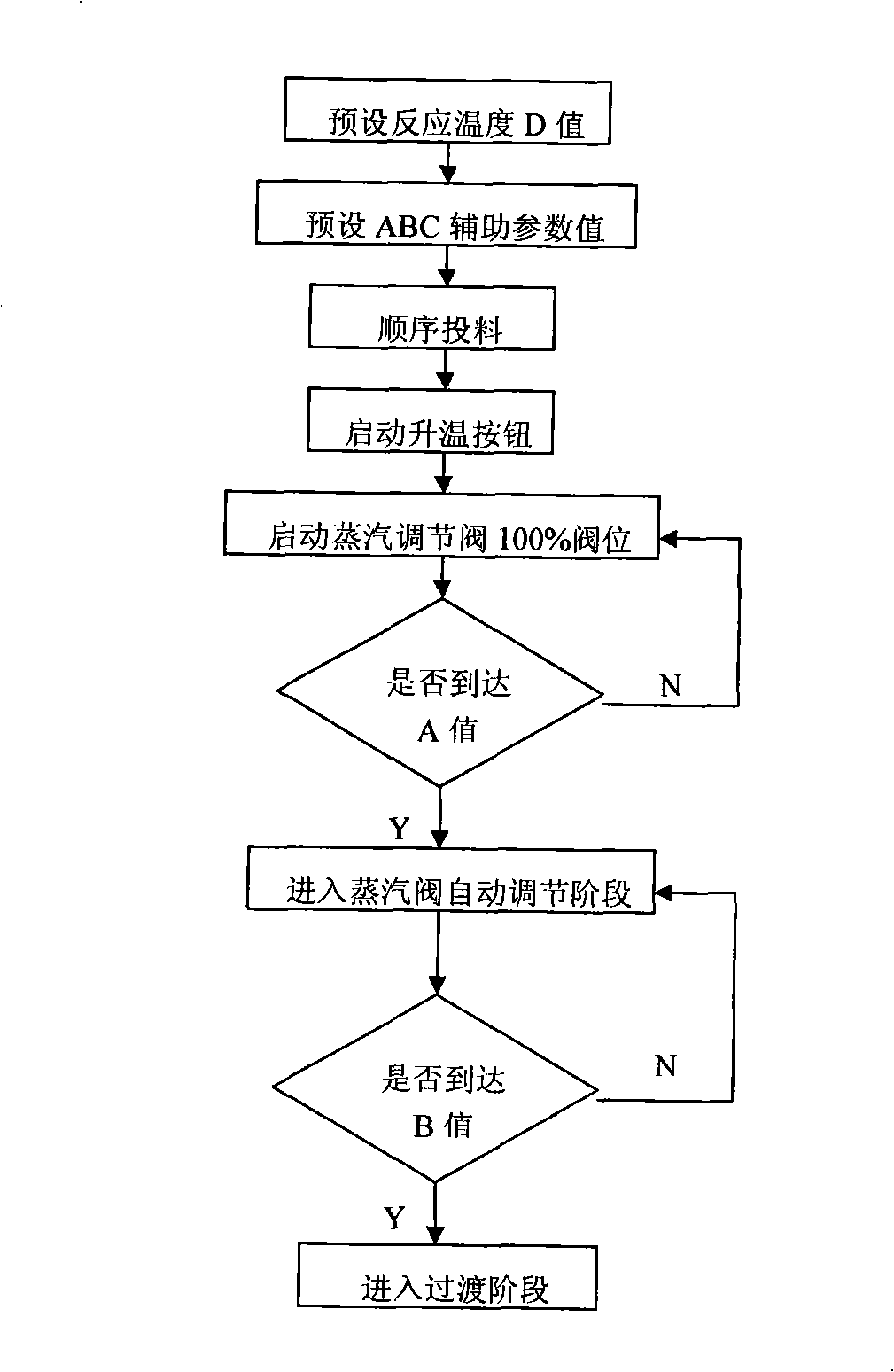

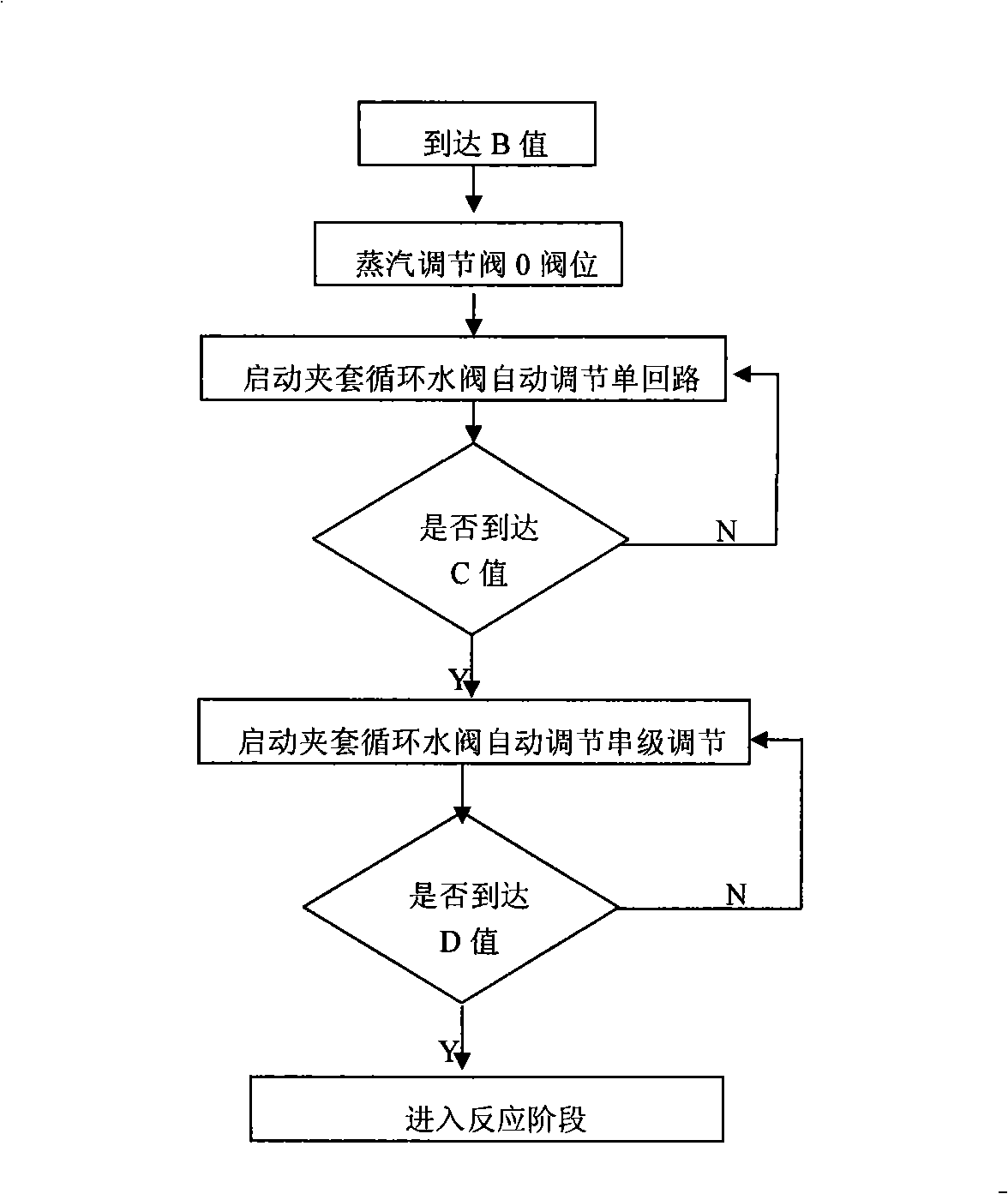

Polychloroethylene production reaction temperature control method for small-sized polymerization kettle DCS

ActiveCN101334676AReduce labor intensityRealize automatic controlTemperature control using electric meansTransition stageAutomatic control

The invention discloses a control method for the reaction temperature of polyvinyl chloride production by a small polymerizing pot DCS; the DCS controls the processes of the polymerizing pot such as temperature increasing, transition, temperature keeping and pot stopping; a steam shut-off value in front of the reaction pot is changed into an adjusting valve; during the temperature increment stage, the DCS control comprises the sequences as follows: reaction time D value is prearranged, three auxiliary parameter values A, B and C are prearranged, sequential material pouring is carried out, then the steam adjusting valve is opened to specific valve position control, and the judgment of A and B is carried out by program; the transition stage is carried out if the B value is achieved; during the transition stage, the programs closes the steam adjusting valve firstly, and starts a reaction pot jack circulation water valve single circuit, and the judgment of C and D value is carries out by the program; the reaction stage is carried out if the D value is achieved. The relationship of the values A, B, C and D is that A is less than B which is less than C which is less than D; the D value is 52-65 DEG C. Therefore, the reaction temperature can achieve ideal control standard, thus leading the reaction to be stable and ensuring and optimizing the product quality; simultaneously, the control method has the advantages of convenient and quick operation, overcoming the effects of the artificial factors on the product quality, reducing the accident incidence rate, realizing the automatic control of the key procedure of aggregated production, and improving the process parameter detection precision and control precision, etc.

Owner:XINJIANG TIANYE GRP

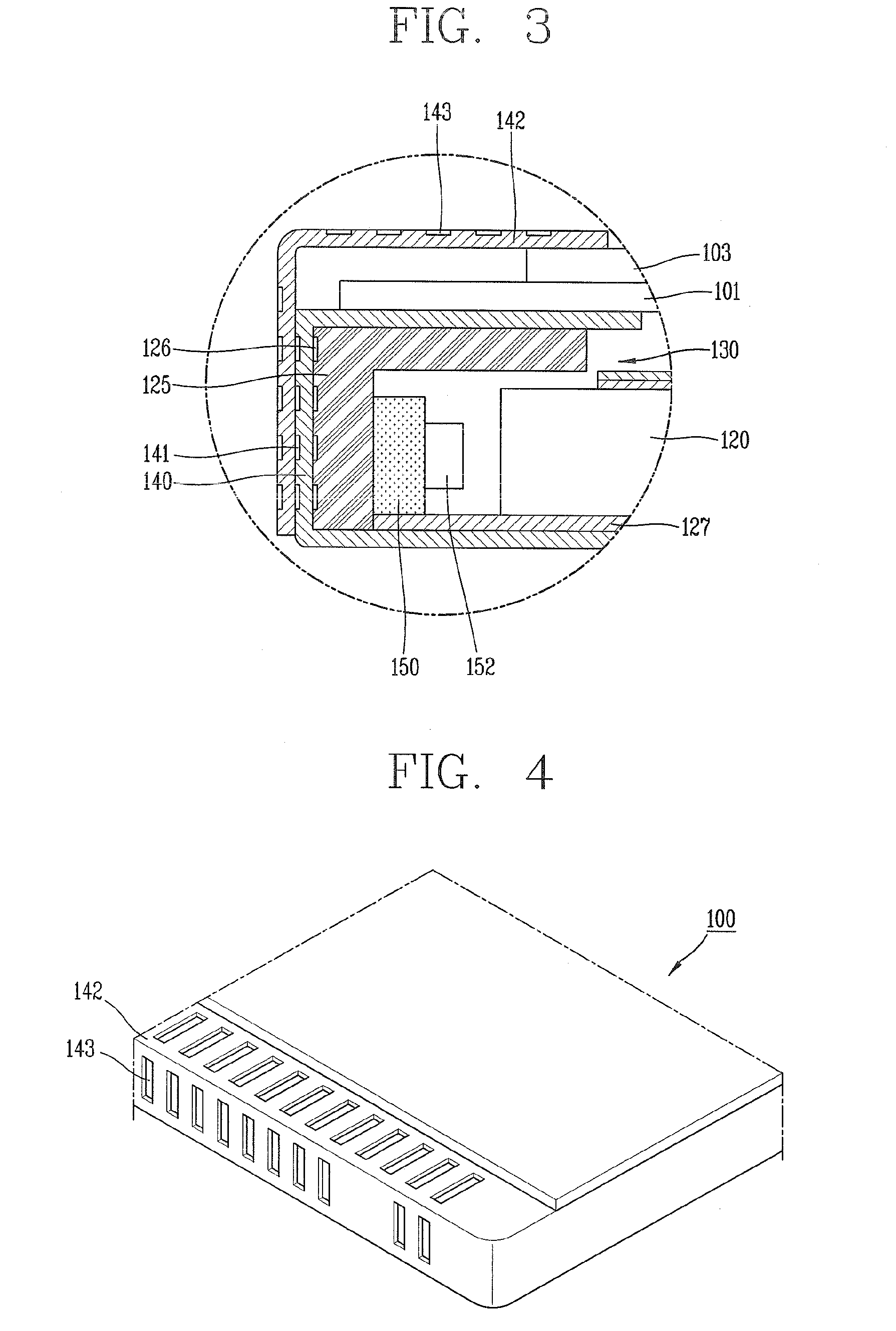

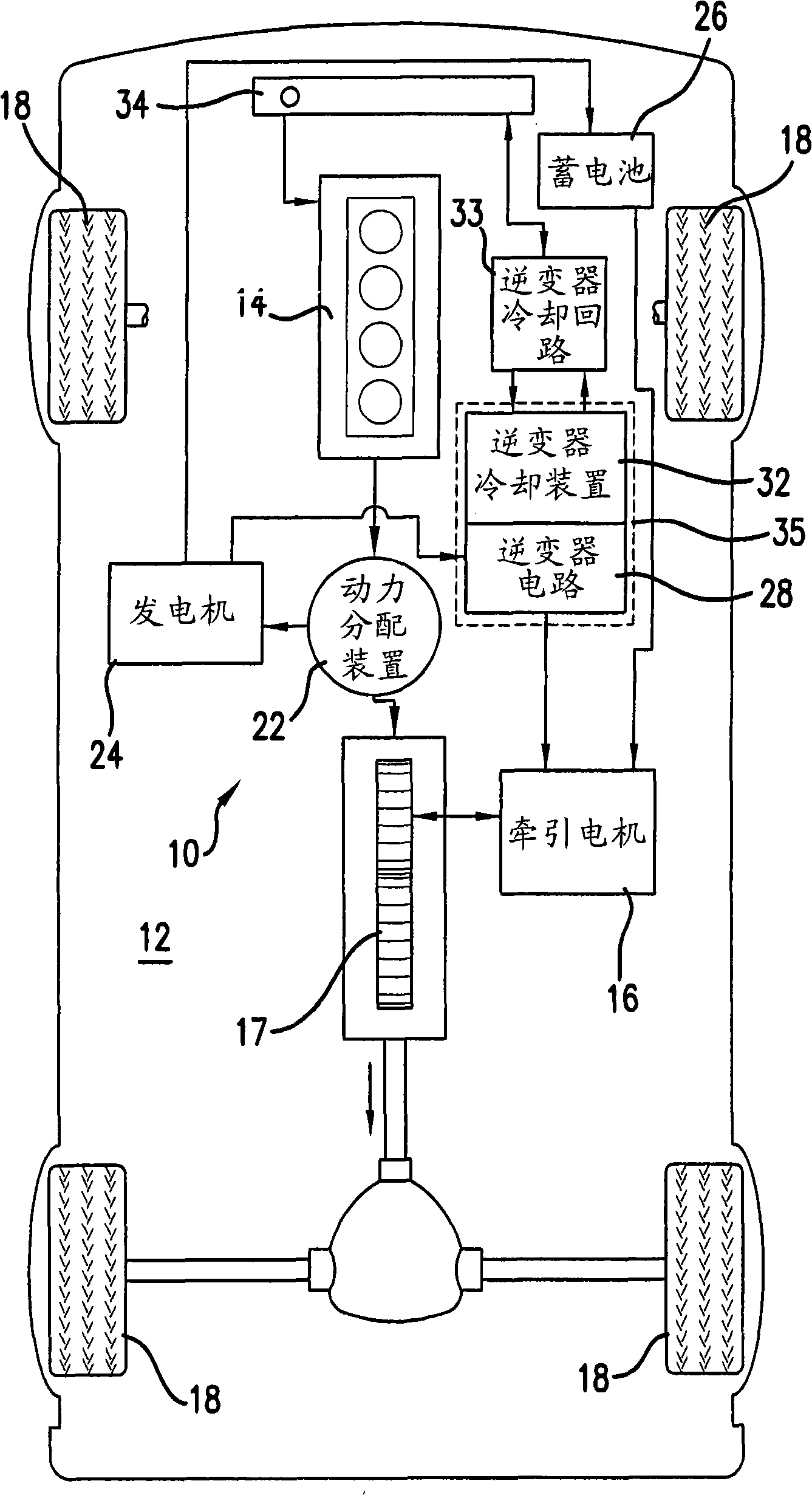

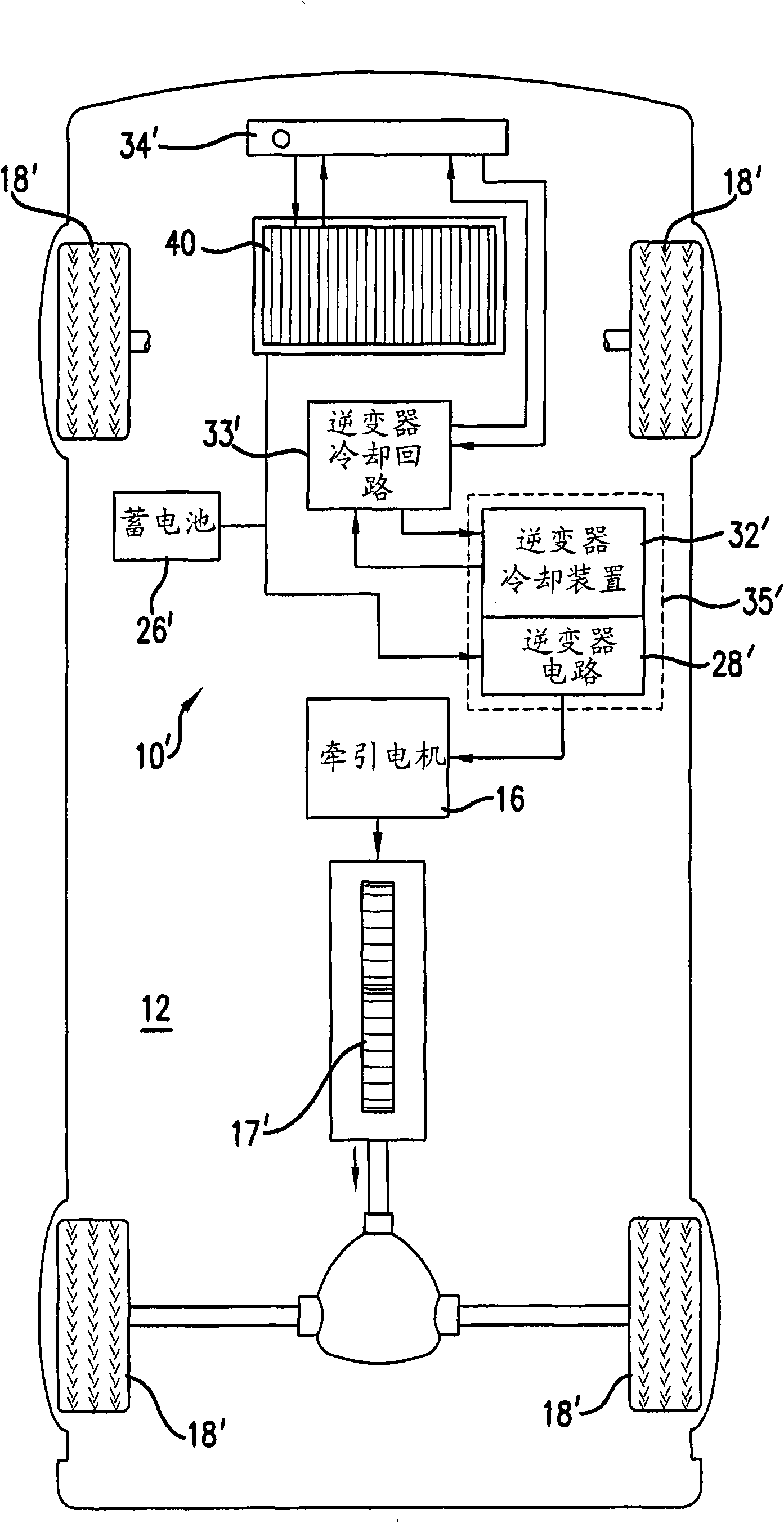

Apparatus and method for cooling phase transition of electric and electronic equipment

InactiveCN101282075ASemiconductor/solid-state device detailsSolid-state devicesCycle rateEngineering

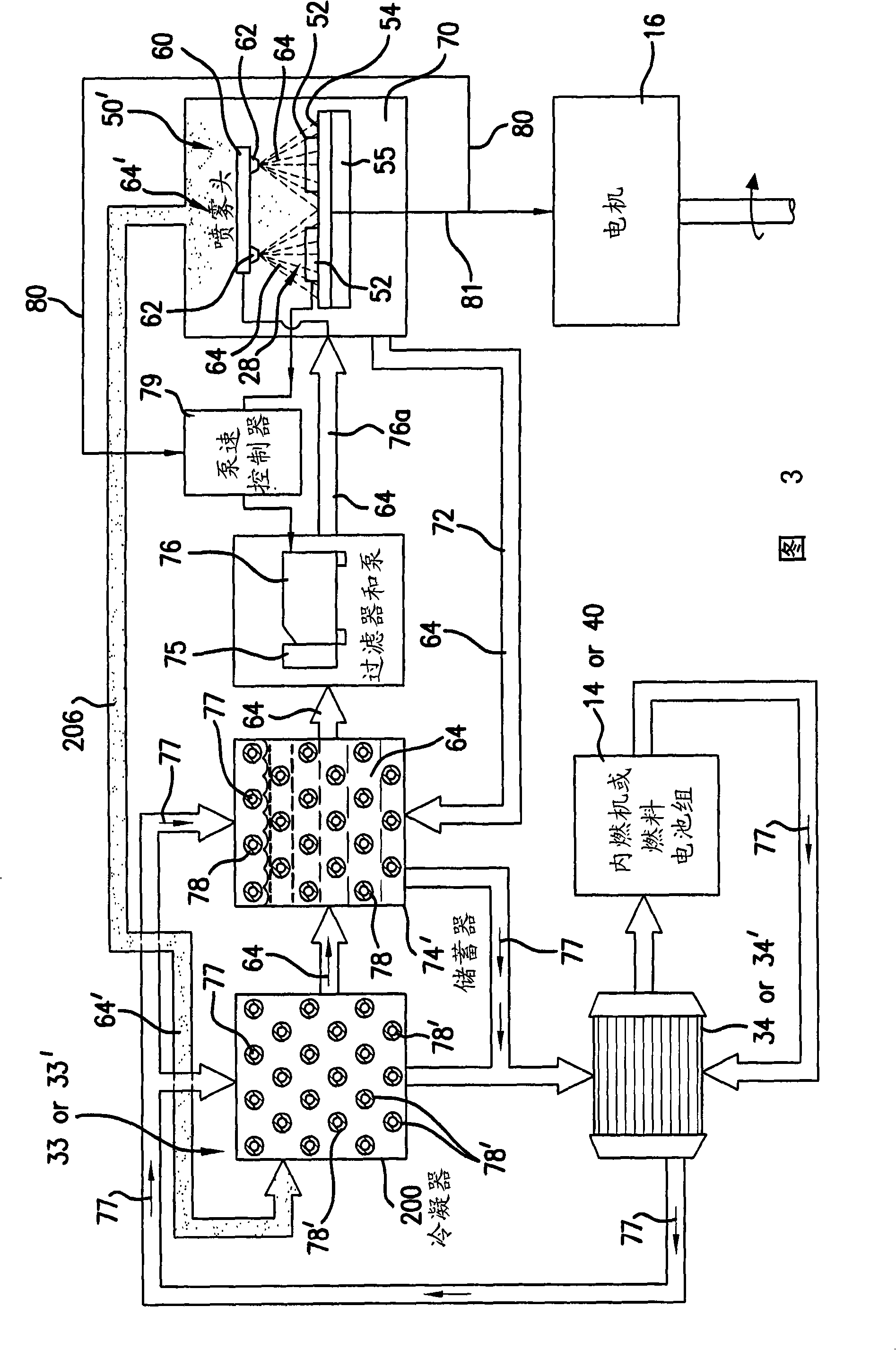

A power electronic equipment of traction motor for driving vehicle is cooled in the closing system by directly injecting the dielectric liquid coolant on the inverter circuit. The liquid coolant generates phase change and evaporates when the inverter circuit inclduing the power electronic equipment is heated from the power transistor. The generated steam is condensated into liquid in the heat exchanging device which has a pipe transporting a second coolant from the radiator which is used for cooling a motor or fuel cell stacks. The overspray coolant keeping in the liquid state can be cooled by the heat exchanging device. The recycle rate of the coolant can be increased by using the latent heat of vaporization of the dielectric liquid coolant when the power output is increased, the temperature increment in the power electronic equipment is controlled.

Owner:GM GLOBAL TECH OPERATIONS LLC

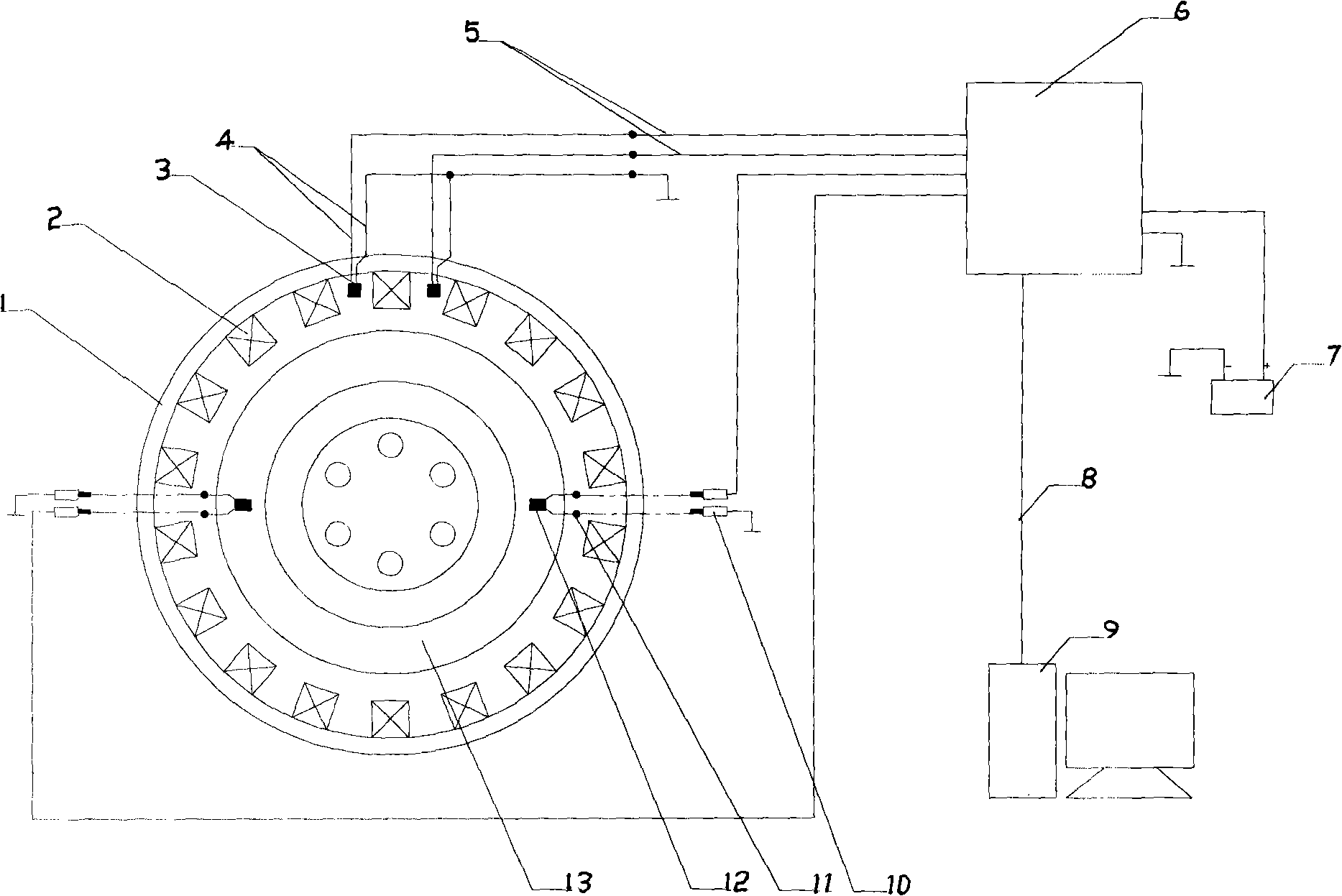

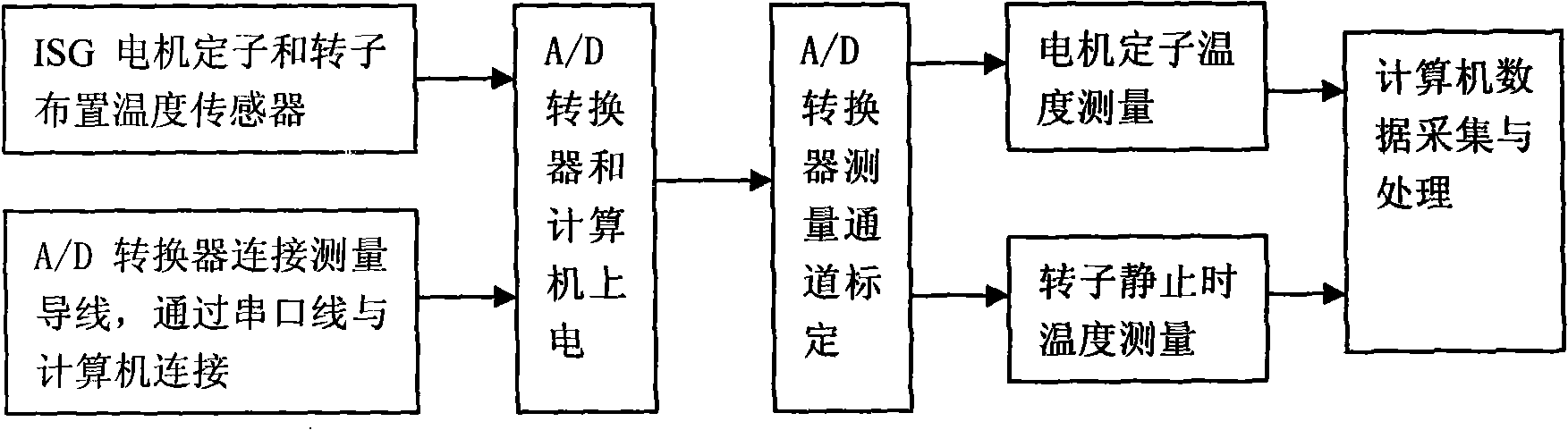

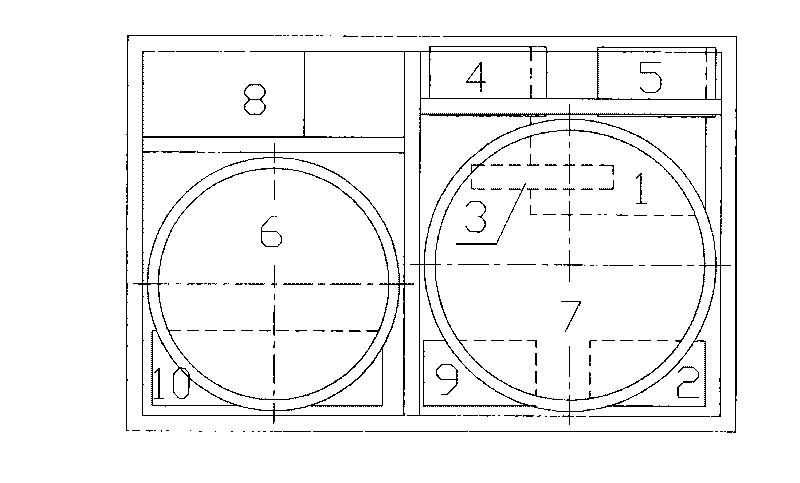

Hybrid power automobile start-up energy production integrated electric motor temperature field measuring systems

InactiveCN101261162ASolving temperature field measurement problemsExtended service lifeThermometers using electric/magnetic elementsUsing electrical meansElectric machineField tests

The invention discloses a stator and rotor temperature field measurement system of a starting and generating integrated motor used for a hybrid vehicle. Patch-typed stator temperature sensors are arranged in different winding coil clearances of an ISG motor stator; signal output leads of the patch-typed stator temperature sensors are connected with an A / D converter by which the patch-typed stator temperature sensors are connected with a computer; patch-typed rotor temperature sensors are arranged in magnetic steel sheets of the ISG motor rotor, with signal output wires connected with signal output contacts of the external edge of the motor rotor; the signal is input into the A / D converter by a measurement probe and is then transmitted into the computer. The temperature increment curve of the stator winding and rotor magnetic steel sheets can be output by an ISG motor temperature field test when the ISG motor outputs fixed power; meanwhile, the temperature distribution of the ISG motor can be measured under the output states of various rotation speeds and various powers.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

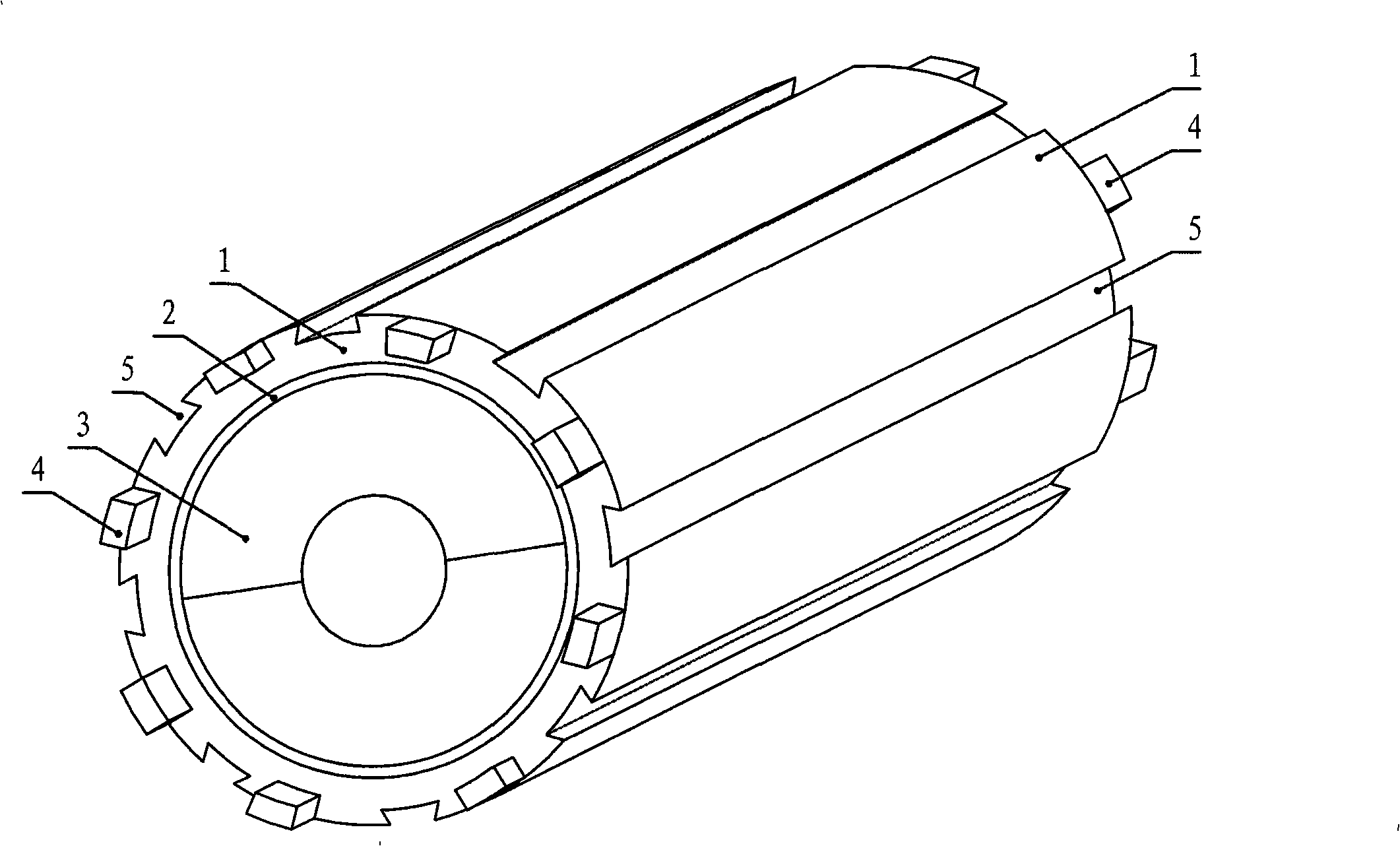

High speed permanent magnet motor rotor

ActiveCN101316057APrevent direct deliveryBlock deliveryMagnetic circuit rotating partsInsulation layerElectric machine

The invention relates to a high-speed permanent magnetic motor rotor, belonging to the field of motor. The high-speed permanent magnetic motor rotor solves the problems that the eddy current loss is comparatively large which leads to the temperature increment of the solid rotor to be excessively high easily and the permanent magnet beside the rotor to generate irreversible high-temperature loss of field when a protection sleeve is added beside the rotor in the existing high-speed permanent magnetic motor. The high-speed permanent magnetic motor rotor comprises a rotor protection sleeve (1), a permanent magnet (3), and an insulation layer (2) which is arranged between the rotor protection sleeve (1) and the permanent magnet (3). A plurality of concave troughs (5) which are parallel to the central axis line of the rotor are uniformly distributed on the rotor protection sleeve (1) along the circumference of the external surface of the rotor protection sleeve (1); two end surfaces of the rotor protection sleeve (1) are uniformly and fixedly provided with a plurality of bulges (4). The high-speed motor rotor of the invention is applicable to the existing high-speed permanent motors.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

Method and device for on-line regeneration of sulfuric acid pickling waste liquid

The invention discloses a method and a device for on-line regeneration of sulfuric acid pickling waste liquid. The method mainly comprises the following steps: 1) adding a certain amount of concentrated sulfuric acid into the pickled low-concentration waste acid liquid to adjust the waste acid liquid to the required acid concentration; 2) adding cooling liquid into the solution to sharply cool the acid pickling liquid obtained in the step 1) so as to quickly reduce the temperature of the acid pickling liquid to between 5 DEG C below zero and 15 DEG C below zero and separate out ferrous sulphate; and 3) performing solid-liquid separation for the solution obtained in the step 2) through solid-liquid separation equipment, conveying the produced regenerative acid after heat exchange and temperature increment to a pickling system to be recycled. The device is provided with the pickling system to prepare waste acid and concentrated acid into acid liquid with the required concentration, then the acid liquid is conveyed to a heat exchange system connected with the pickling system to exchange heat and reduce temperature, a crystallizing system is connected with the heat exchange system to separate out crystals in the acid liquid, the crystals and the acid liquid are separated through a separation system, and the acid liquid is conveyed to the heat exchange system to be recycled. The device has the advantages of short process, less equipment investment, low power consumption and low operating expense, has no three-waste emission, and greatly reduces environment pollution.

Owner:TONGJI UNIV +1

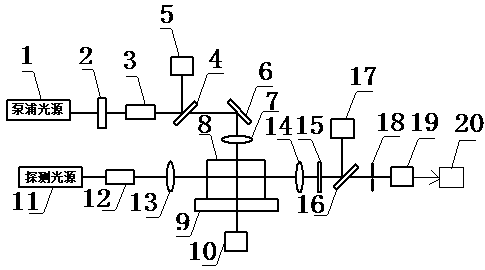

Method and device for detecting three-dimensional distribution of absorption characteristics in transparent optical material body

ActiveCN103712993AImprove resolutionHigh sensitivityMaterial analysis by optical meansThree-dimensional spaceLight energy

The invention provides a method and a device for detecting three-dimensional distribution of absorption characteristics in a transparent optical material body. The method and the device are characterized in that a beam of strong pump light is focused into the transparent optical material, the focus position of the pump light causes the local temperature increment of the transparent optical material due to the absorption of the light energy, so that the local physical characteristics inside the transparent optical material body are changed; a beam of weak detection light with the spreading direction being orthogonal with the spreading direction of the pump light is also focused into the transparent optical material body to be overlapped with the focus of the pump light, and the local physical characteristics variation of the transparent optical material caused by the pump light is detected, so that the absorption characteristics of the pump light focus position in the transparent optical material body can be obtained, and the three-dimensional space distribution of the absorption characteristics and defects in the transparent optical material body can be obtained by changing the position of the pump light focus in a sample body through scanning. The method and the device have the advantages of high resolution, high sensitivity and the like.

Owner:WUXI LIVERMORE INSTR

Solar automobile temperature regulator

InactiveCN101216226AIncrease temperatureAchieve step-by-step coolingMachines using electric/magnetic effectsTemperature controlEngineering

The invention discloses a temperature regulator for solar automobiles, which comprises a solar photovoltaic and heat-concentration converting board for taking full advantage of solar energy, a thermo-semiconductor power generation module, a cooling box, a charging circuit, an accumulator, and a refrigerator, wherein the heating terminal of the thermo-semiconductor power generation module is connected with the solar photovoltaic and heat-concentration converting board, the cold terminal of the solar photovoltaic and heat-concentration converting board is connected with the cooling box, the output end of the thermo-semiconductor power generation module is sequentially connected with the charging circuit, the accumulator, a temperature control device, and the refrigerator. The solar photovoltaic and heat-concentration converting board is used as a movable adhering board for automobile rear glass, and the thermo-semiconductor power generation module is connected in parallel and in series and used for converting solar energy to electric energy and then refrigerating with the obtained electric energy, so as to prevent temperature increment inside the automobile due to vertical incident solar rays.

Owner:汤益波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com