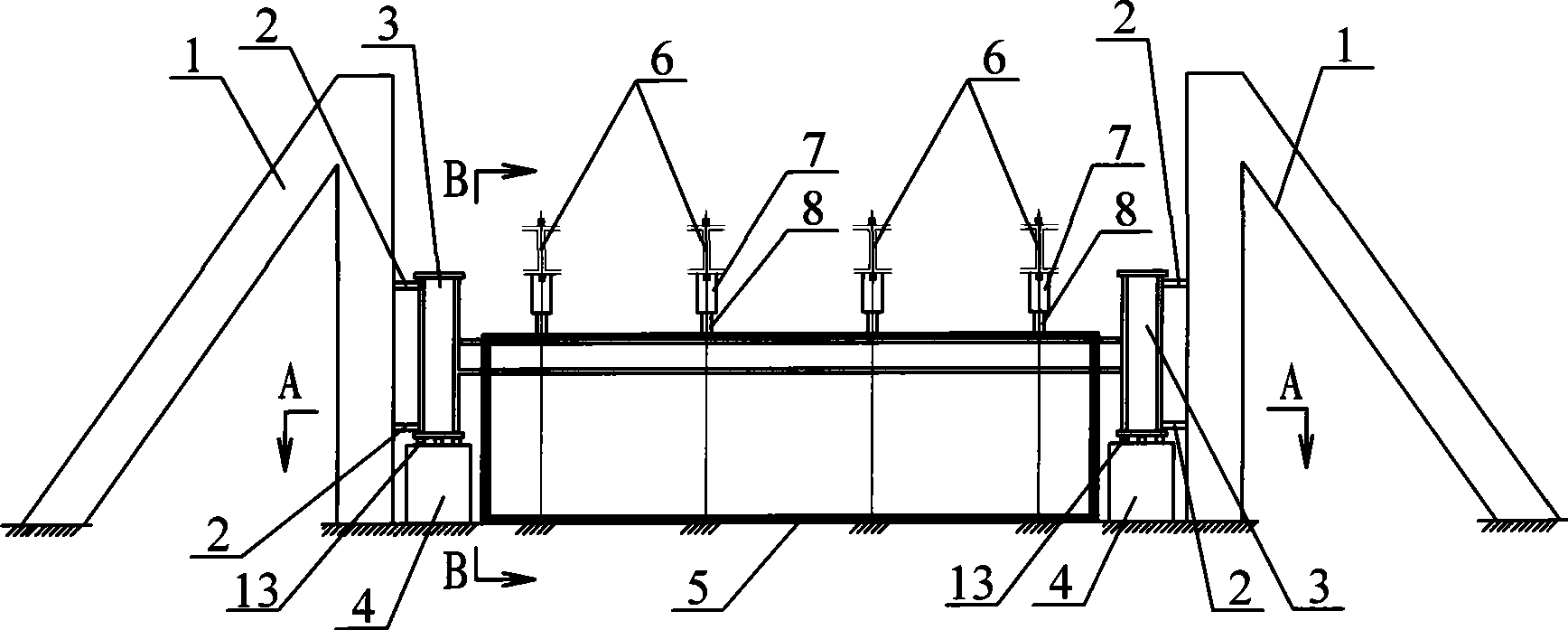

Anti-fire test device of restrained beam

A technology for testing devices and restraining beams, which is applied in measuring devices, testing of machine/structural components, material inspection products, etc., and can solve problems such as fire resistance performance tests of beams that cannot be restrained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 5 Describe this embodiment, this embodiment includes two reaction force frames 1, four tension and pressure sensors 2, two restraining steel columns 3, two specimen supports 4, furnace body 5, at least one vertical loading device 6, At least one jack 7, at least one load cell 8, oil pump 9, oil tank 10, blower fan 11, at least two thermocouples 12, at least four rollers 13 and at least one nozzle 14, two specimen supports 4 are arranged longitudinally on On the ground, two reaction frames 1 are arranged on the outer ground of the two test piece supports 4 facing each other, and at least two rollers 13 are arranged on the upper end surface of each test piece support 4, and two restraining steel columns 3 are respectively vertically arranged on the rollers 13 on the two test piece supports 4, every two tension and pressure sensors 2 are arranged up and down between the reaction force ...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Figure 6 Describe this embodiment, the furnace body wall around the furnace body 5 of this embodiment is formed by refractory bricks, the furnace body wall around the furnace body 5 is formed by common red bricks, and the furnace body wall around the furnace body 5 Refractory fibers are filled between the outer wall and the furnace body 5, and the bottom of the furnace body 5 is made of two layers of refractory bricks. This design makes the furnace body 5 have a good thermal insulation effect, simple structure and low cost.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 2 and Figure 5 Describe this embodiment, the furnace body wall of the flue 5-2 side of the furnace body 5 of this embodiment is provided with the observation hole 5-3. The observation hole 5-3 is convenient for observing the combustion situation in the furnace body 5 and the changes of the test components during the test process. The observation hole 5-3 can also be used to connect some data measurement wires required in the test to the outside of the furnace body 5 data acquisition or processing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com