Heat treatment method for steel plate used for extremely thick non-quenched and tempered ocean engineering

A heat treatment method and marine engineering technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of poor rolling capacity of rolling mills, small compression ratio, and no obvious improvement in the quality of continuous casting slabs, etc., to achieve wide applicability , excellent mechanical properties and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

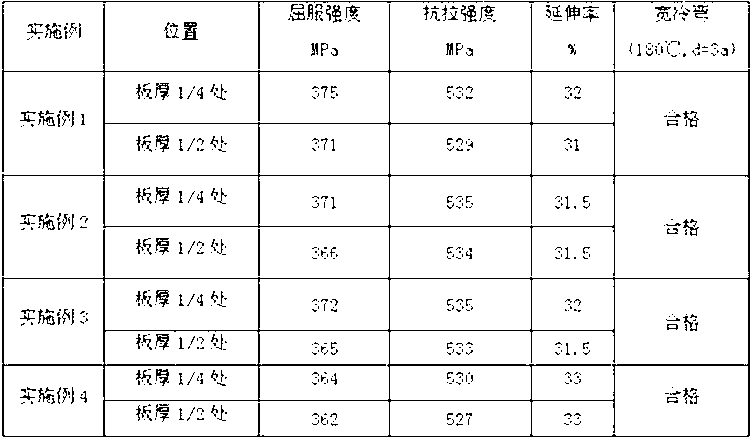

Embodiment 1-4

[0022] Implementation 1-4 is the heat treatment method of 50-100mm thick non-quenched and tempered marine engineering steel:

Embodiment 1

[0023] The heat treatment method of the 50mm thick ocean engineering E36-Z35 steel plate of embodiment 1 is specifically as follows:

[0024] The first normalizing process: the first stage is heated at 600°C, with a temperature rise coefficient of 1.6min / mm, and then kept for 20 minutes after reaching the temperature; the second stage is heated at 900°C, with a temperature rise coefficient of 1.5min / mm, and held for 20 minutes after reaching temperature; Secondary normalizing process: heating at 600°C in the first stage, with a temperature rise coefficient of 1.6min / mm, and holding for 30 minutes after reaching the temperature; heating in the second stage at 880°C, with a temperature rise coefficient of 1.5min / mm, and holding for 20 minutes after reaching the temperature; tempering The process is: the tempering temperature is 550°C, and the total tempering time is 2.5 min / mm. Obtain 50mm thick E36-Z35 steel plate for ocean engineering.

Embodiment 2

[0025] The heat treatment method of the 70mm thick ocean engineering E36-Z35 steel plate of embodiment 2 is specifically as follows:

[0026] The first normalizing process: the first stage is heated at 650°C, with a temperature rise coefficient of 1.3 min / mm, and then kept for 30 minutes after reaching temperature; the second stage is heated at 950°C, with a temperature rise coefficient of 1.2min / mm, and held for 30 minutes after reaching temperature; Secondary normalizing process: heating in the first stage at 650°C, with a temperature rise coefficient of 1.3 min / mm, and holding for 30 minutes after reaching the temperature; heating in the second stage at 930°C, with a temperature rise coefficient of 1.2min / mm, and holding for 30 minutes after reaching temperature; tempering The process is: the tempering temperature is 640°C, and the total tempering time is 2.0 min / mm. A 70mm thick E36-Z35 steel plate for marine engineering was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com