High-acid value rice bran oil esterification depickling process

A high-acid value rice bran oil, esterification and deacidification technology, applied in the direction of fatty acid esterification, fat oil/fat refining, fat production, etc., to achieve the effect of cheap price, good repeatable catalytic ability, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

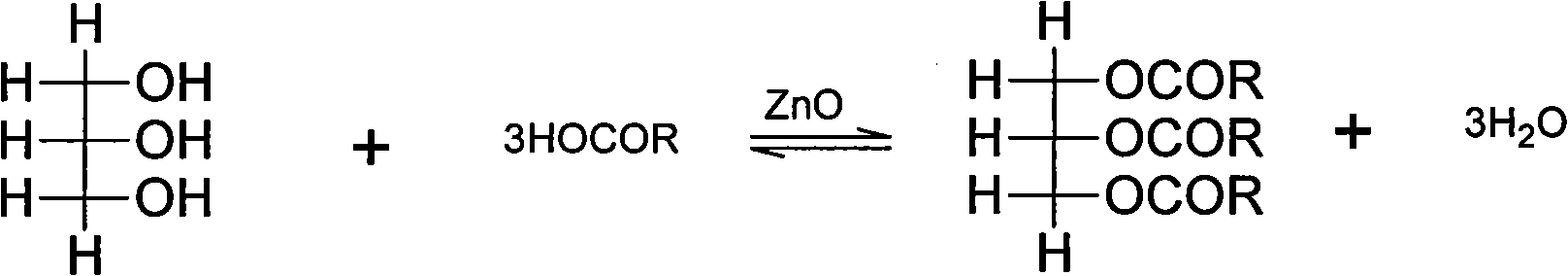

Method used

Image

Examples

Embodiment 1

[0020] The high acid value rice bran oil esterification deacidification process comprises the following process steps:

[0021] A. Grease pretreatment

[0022] (1), degumming

[0023] With 50g of crude rice bran oil (crude rice bran oil refers to refined rice bran oil, that is, rice bran oil that has not been degummed and decolorized), heat it to 70°C with rapid stirring, and add phosphoric acid with a concentration of 85% for conditioning. 0.2% of the amount of rice bran oil, and stirred for 30 minutes, then add sodium hydroxide with a concentration of 2%-2.5%, the amount of sodium hydroxide is 2%-3% of the amount of crude rice bran oil, flocculate and precipitate, and heat to 75°C -78°C, then add water at a temperature of 90°C-95°C and stir for 15 minutes, the amount of water is 8% of the crude rice bran oil, and centrifuge at a speed of 10000r / min for 10 minutes to obtain a degummed product;

[0024] (2), decolorization

[0025] Under the condition of vacuum degree of 0....

Embodiment 2

[0029] Under the condition of a vacuum of 0.09MPa, stir and heat 50g of the decolorized product to 220°C, add 1.042g of glycerin, add 0.3% W / W catalyst zinc oxide, catalyze the reaction for 4 hours, and the acid value can be reduced from 38.14mgKOH / g to 5.32mgKOH / g, low acid value rice bran oil was obtained.

[0030] Other steps are the same as in Example 1.

Embodiment 3

[0032] Under the condition of a vacuum of 0.09MPa, stir and heat 50g of the decolorized product to 200°C, add 1.563g of glycerin, add 0.2% W / W catalyst zinc, and catalyze the reaction for 2 hours, the acid value can be reduced from 38.14mgKOH / g to 6.90 mgKOH / g, low acid value rice bran oil was obtained.

[0033] Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com