Self-cleaning and fireproof multifunctional coating for steel structure and preparation method of self-cleaning and fireproof multifunctional coating

A self-cleaning, steel structure technology, applied in the direction of fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of dust and gas pollution, increased self-weight, unsightly steel structure materials, etc., to achieve good heat resistance and mechanical Performance, increasing hydrophobicity, improving self-cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

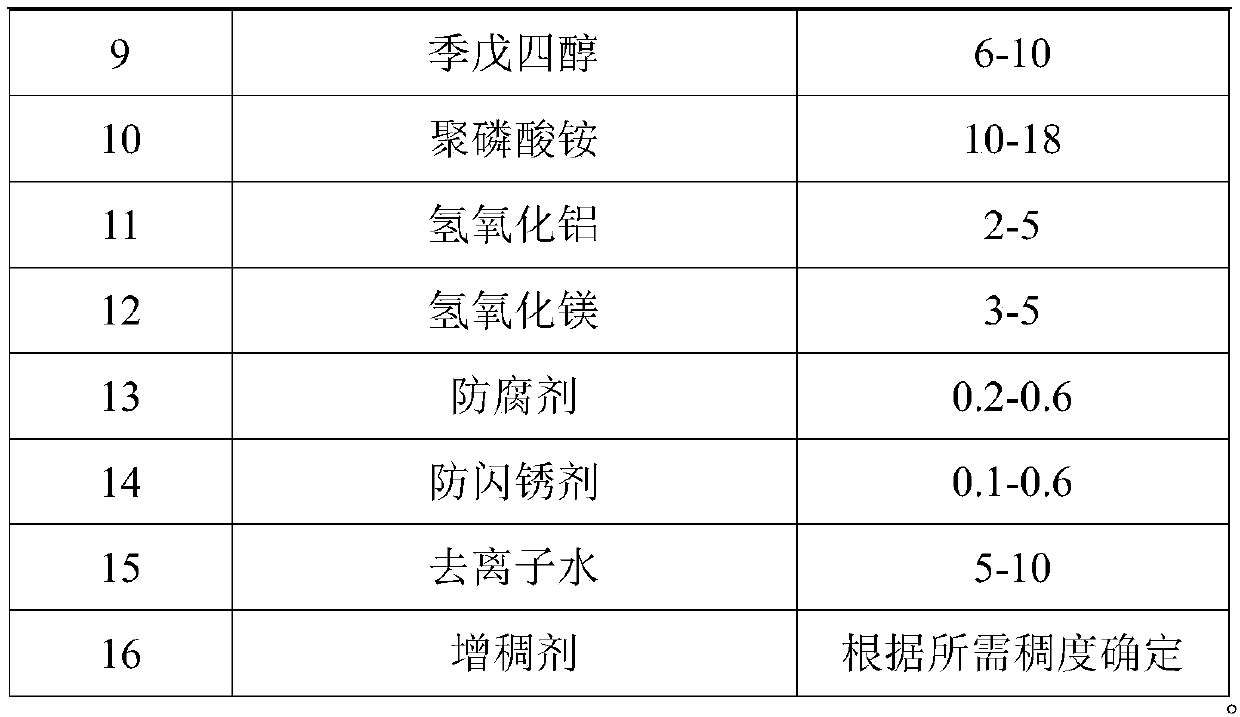

[0041] The production formula of coating component A is shown in Table 1:

[0042] Table 1

[0043]

[0044]

[0045] Component B: Bayhydrol 110 waterborne polyurethane curing agent. The mass ratio of component A and component B is 5:1, and the coating is cured by mixing during use.

[0046] Coating component A production steps:

[0047] Add component 1 into the dispersion tank and stir at a high speed of 1000-1200r / min to disperse evenly, and add component 2 to adjust the pH value to 9.5-10. Add components 3-4 while stirring, and disperse evenly at 1000-1200r / min. Add components 5-14 while stirring, 1200-1500r / min high-speed stirring and grinding until the fineness is below 20 microns, adjust the consistency with component 15 during the addition process, and adjust the consistency with a thickener after grinding. The outflow time of 4 cups is 50-60 seconds, and the material is packaged. Note: The temperature should not exceed 50 °C during the entire production proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com