Control method of coating thickness of quartz crystal and coating device of quartz crystal

A quartz crystal, thickness control technology, applied in sputtering plating, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of increasing the difficulty and cost of film formation, lack of monitoring means for thin layers, etc., and achieve convenient operation , Improve controllability, improve the effect of film thickness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

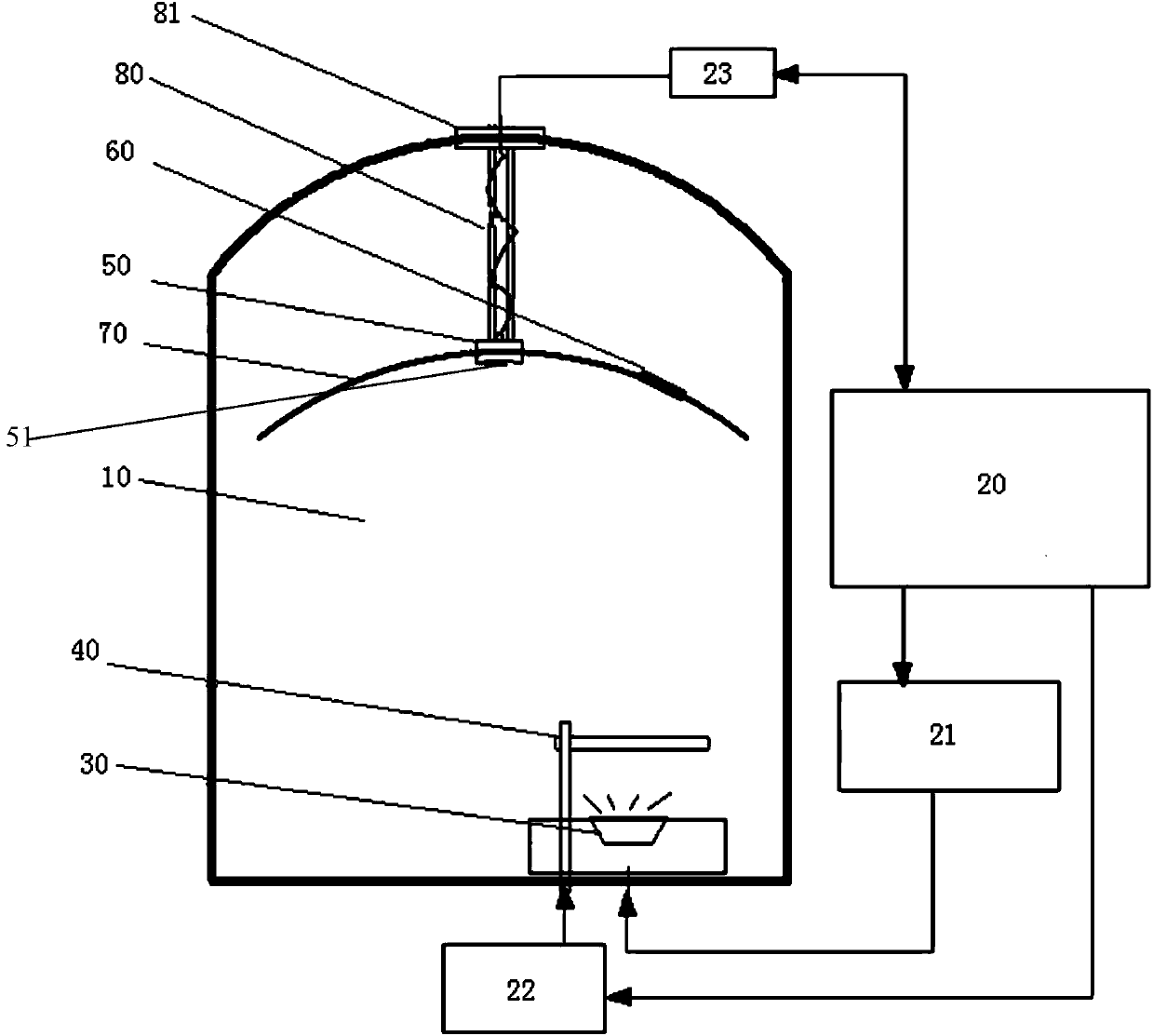

[0040] Such as figure 1 Shown is a quartz crystal coating device, which includes a vacuum chamber 10 and a controller 20 . The bottom of the vacuum chamber 10 is provided with an evaporating container 30 which can contain coating materials. The crystal controller 20 is communicatively connected with the evaporation container 30 through the evaporation container controller 21 . A movable baffle 40 is arranged above the evaporation container 30 . The crystal controller 20 communicates with the baffle 40 through the baffle controller 22 . The upper part of the vacuum chamber 10 is provided with a crystal oscillator probe 50 and a bracket 70 for fixing the sample sheet 60 . The crystal oscillator probe 50 is provided with a quartz crystal plate 51 . The crystal oscillator probe 50 is in contact with the cooling water circulation device 80 . The cooling water circulation device 80 is installed in the upper part of the vacuum chamber 10 through the vacuum flange 81 . The cryst...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 lies in the method for determining the frequency compensation value, and the rest are the same as Embodiment 1.

[0051] The method for determining the frequency compensation value in this embodiment is: when the coating stops, record the frequency of the coated crystal; The difference between the frequency values at these two temperatures is used as the frequency compensation value.

[0052] After the coating is completed, the evaporation source is turned off, and the temperature of the crystal probe starts to drop from the highest point until the temperature does not change any more. There is a temperature difference between the two equilibrium states. The so-called temperature time constant in this embodiment refers to the length of time required for the temperature of the crystal oscillator probe to drop from the highest temperature until it drops by 63% of the temperature difference. That is, assuming that ...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is that the coating thickness is displayed through the calculation of the crystal controller 20 . The frequency compensation value is converted into a thickness compensation value by the crystal controller 20 . The thickness compensation value is added to the film layer thickness converted from the front and back frequencies of the quartz crystal plate 51 detected by the crystal controller 20, and the actual thickness value is directly output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com