Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1187 results about "Stick resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

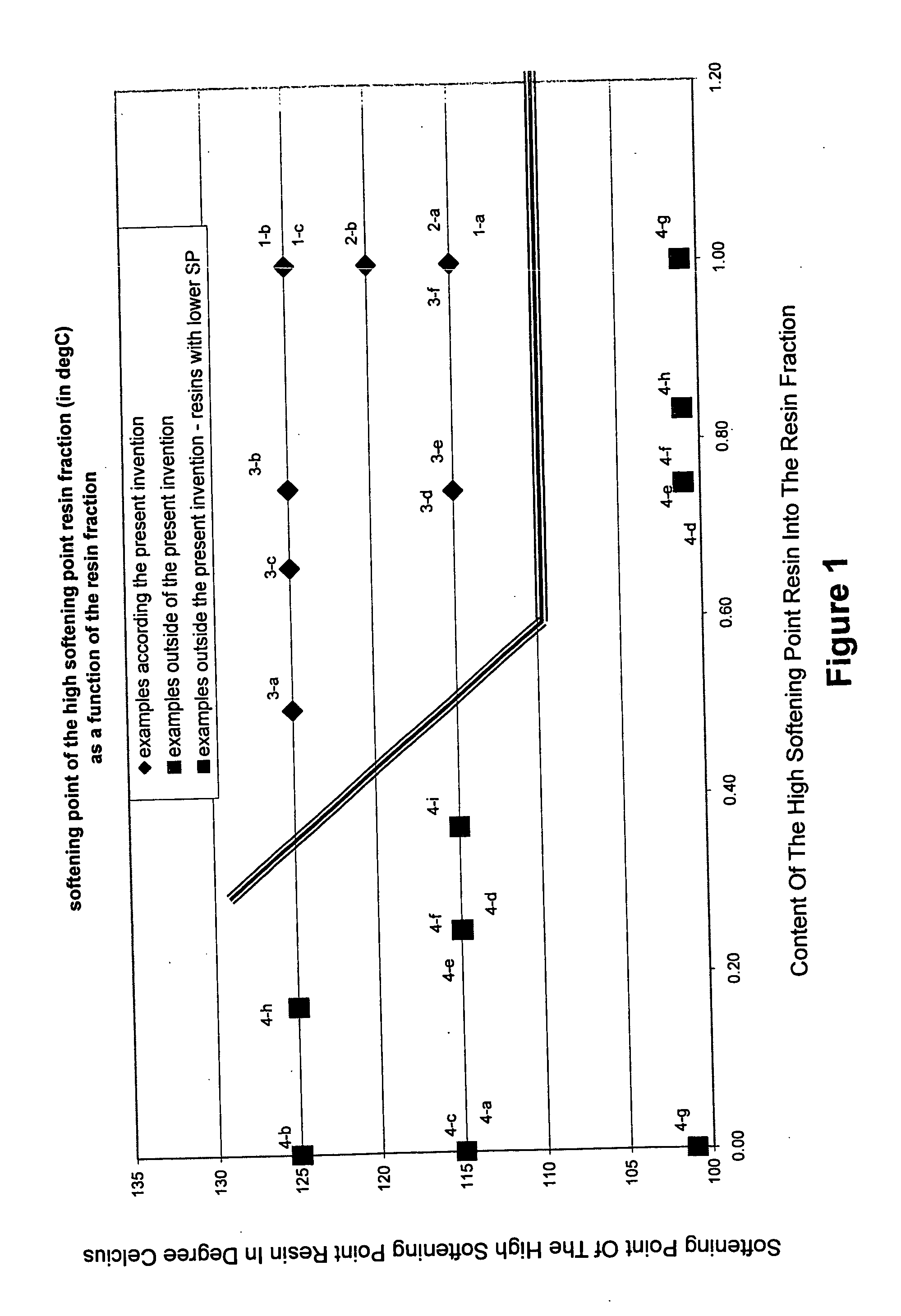

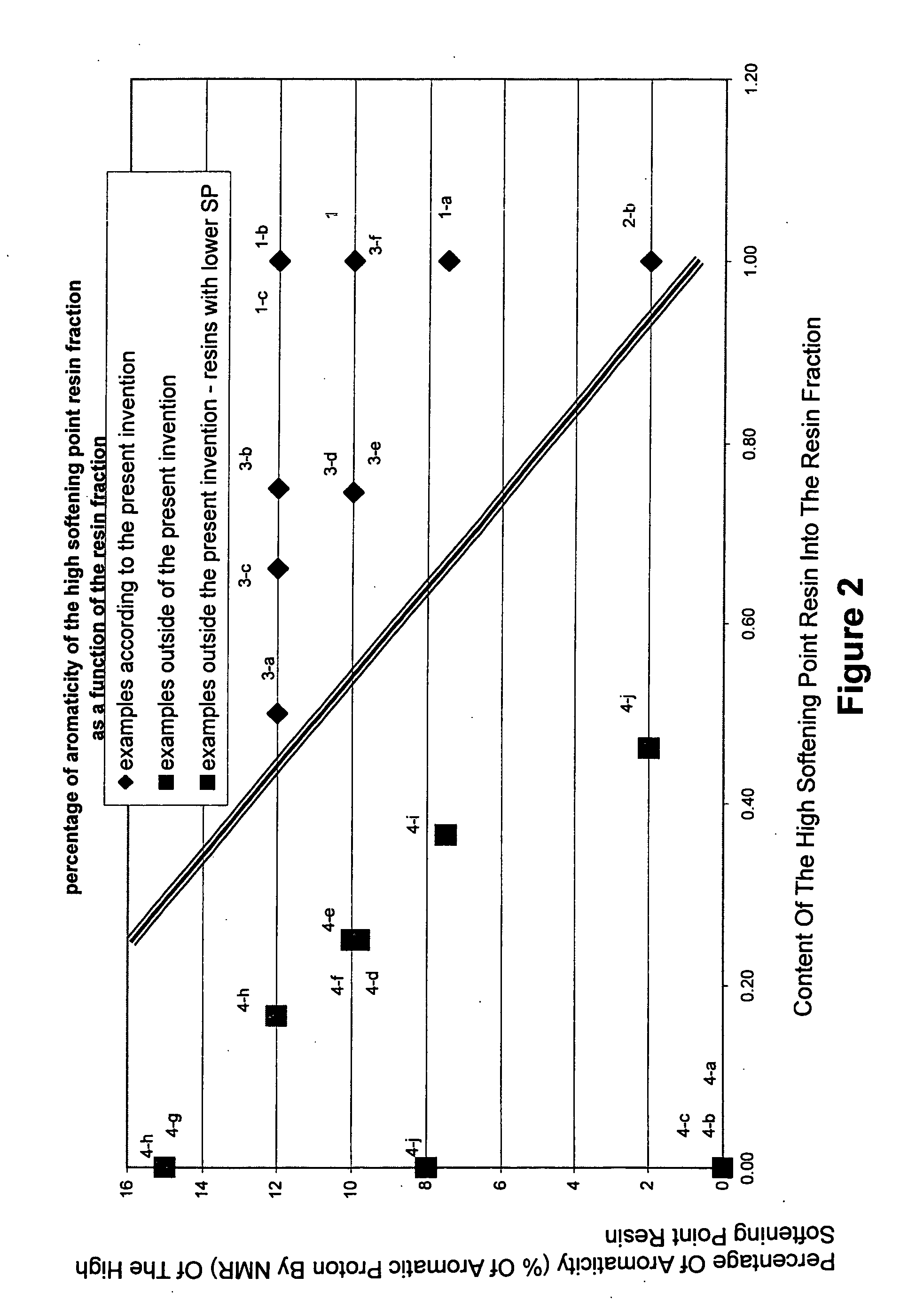

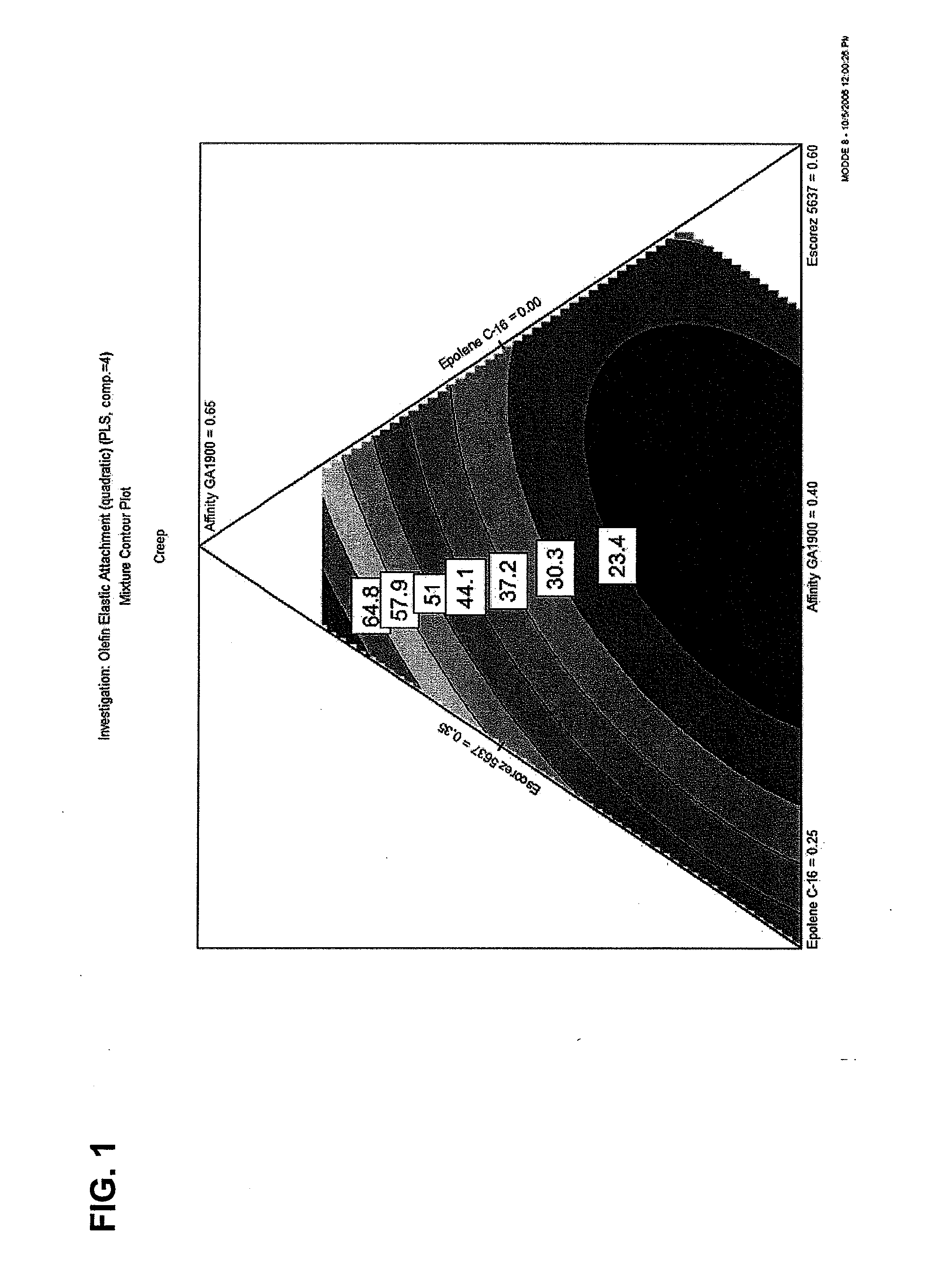

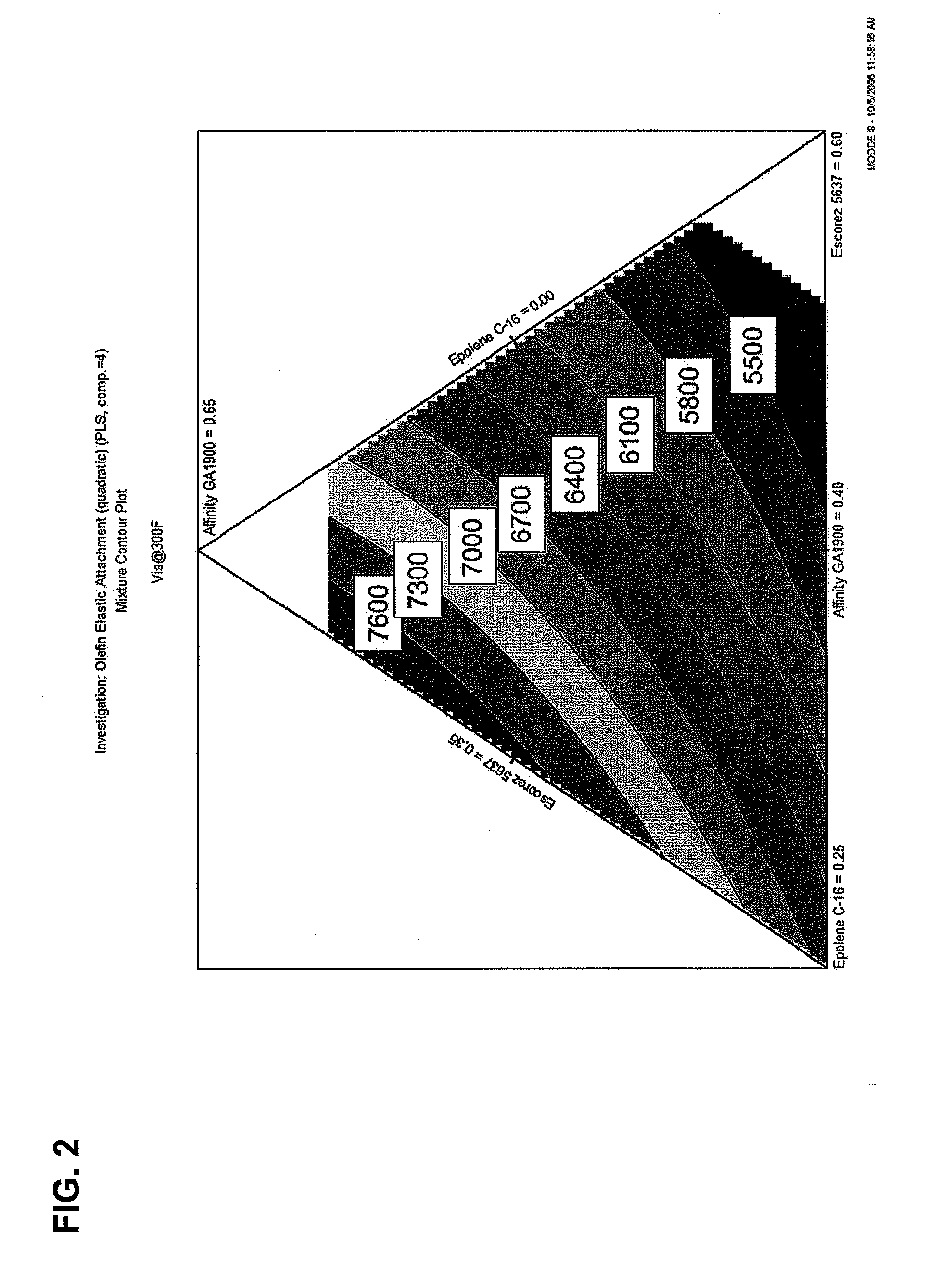

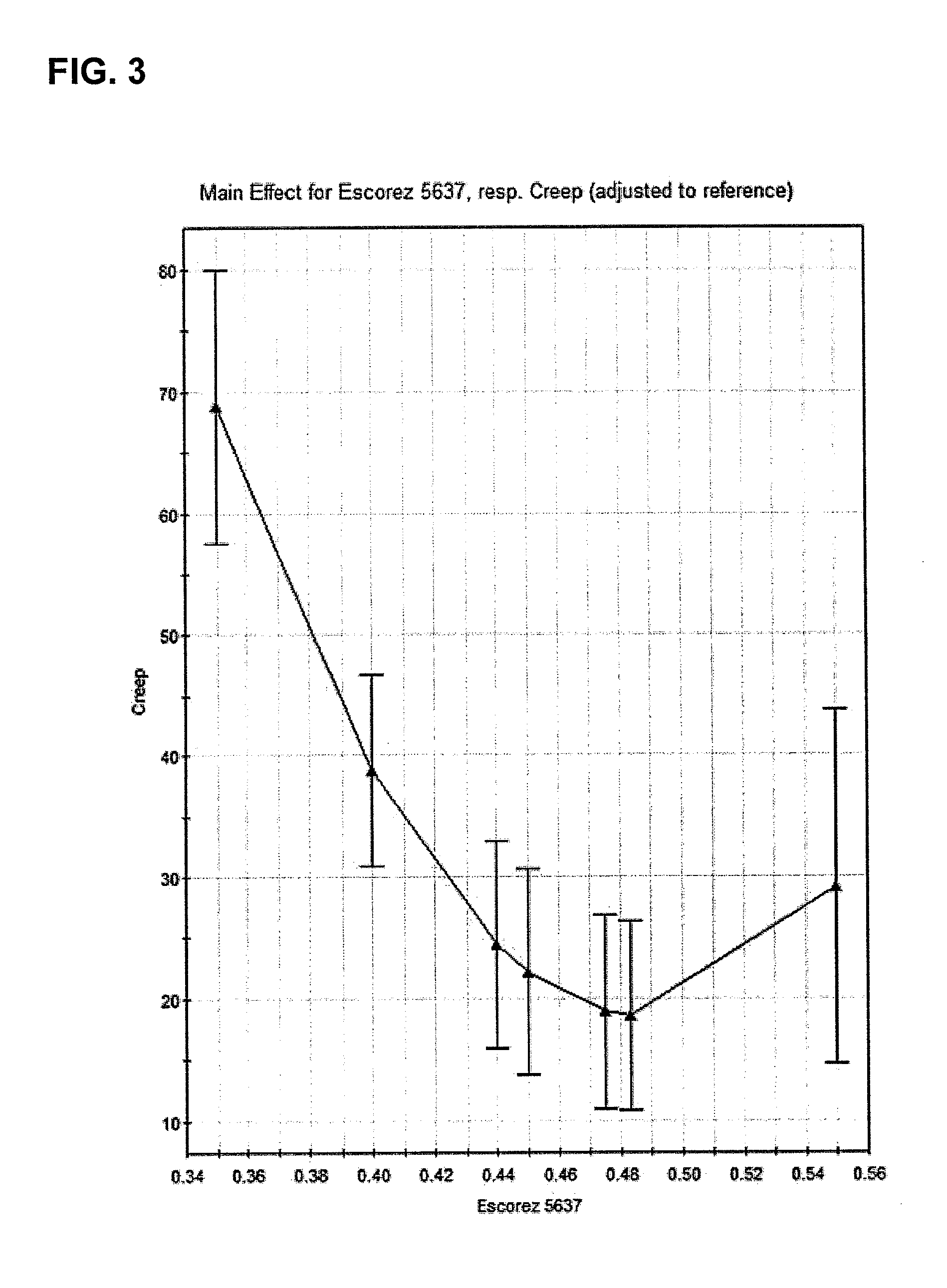

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

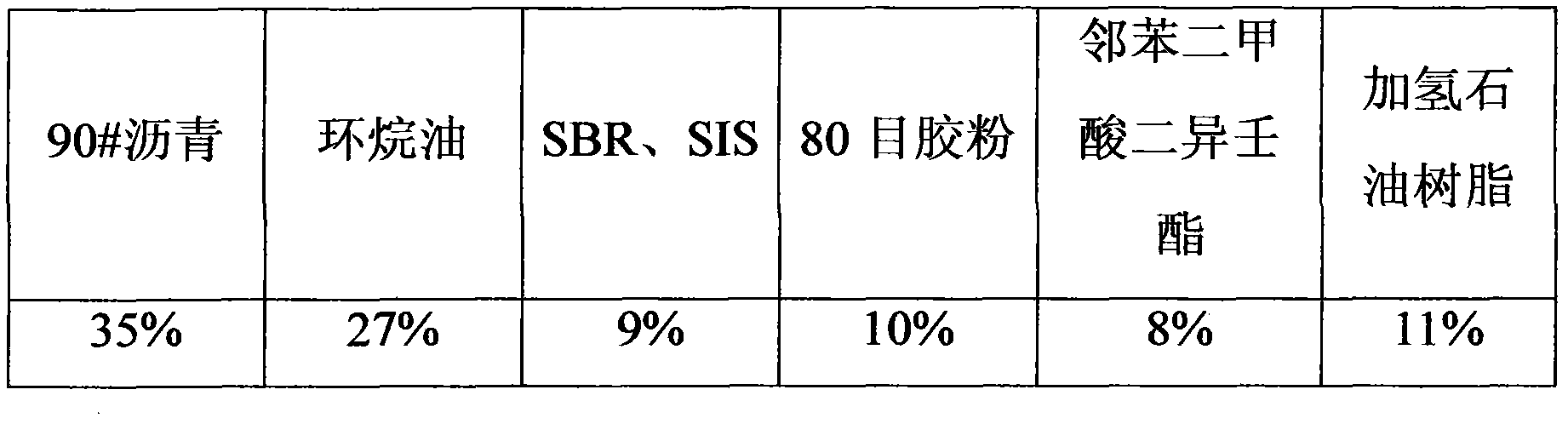

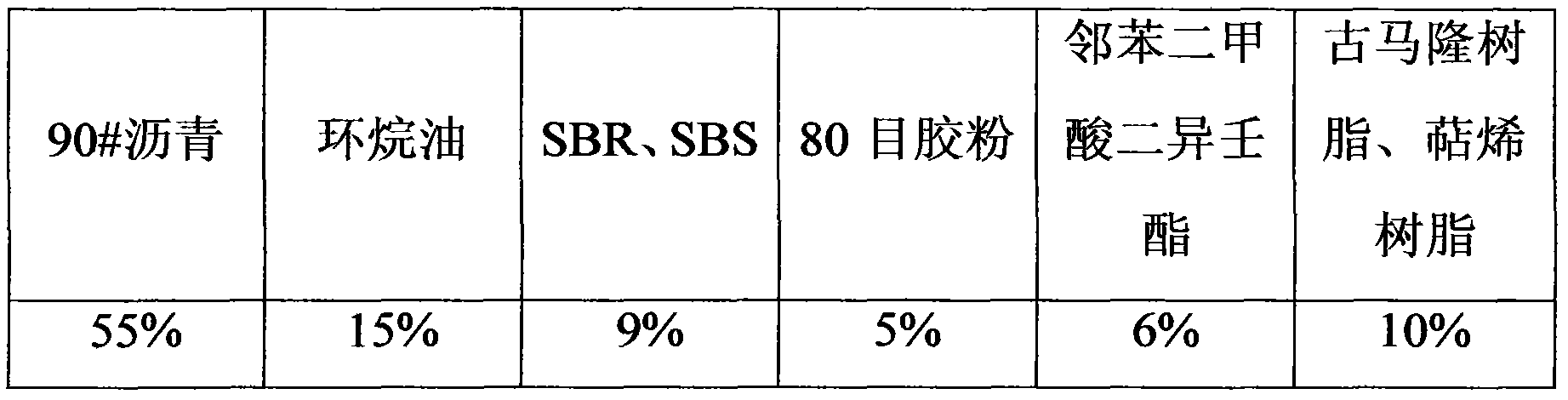

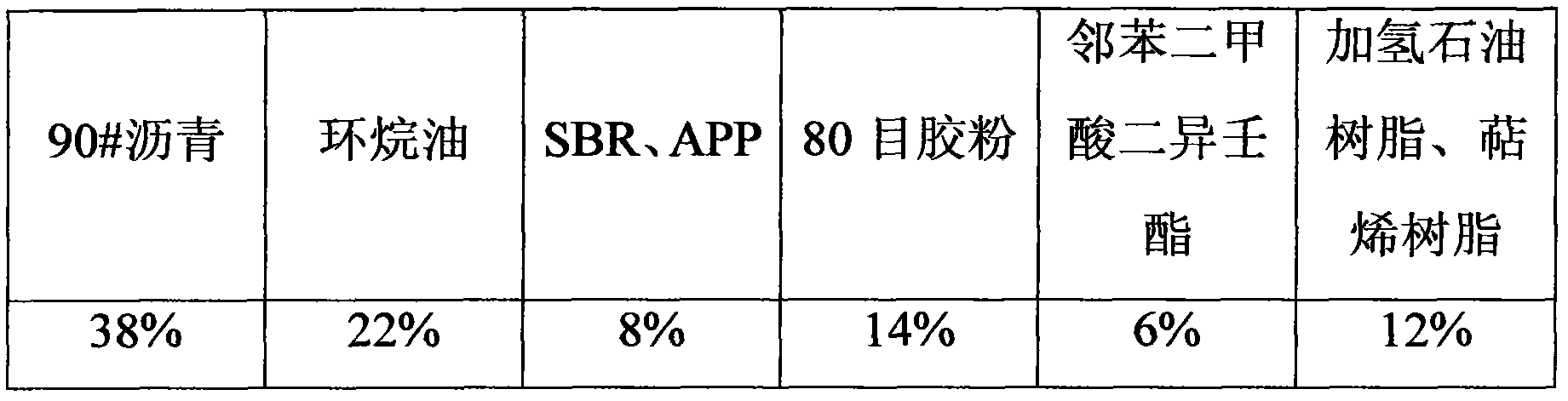

Non-cured asphalt mastic

The invention requests to protect non-cured asphalt mastic comprising the following components in percentage by weight: 35-55 asphalt, 15-30 naphthenic oil, 3-10 polymer modifying agent, 55-20 gelatin powder, 3-10 diisononyl phthalate and 10-20 tackifying resin. The non-cured asphalt mastic can be independently used or can be used with the matched coil to form a waterproof system and can effectively solve the problem of water leakage caused by the crack of a waterproof layer due to the deformation of a base layer.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Transparent pressure-sensitive adhesive layer

InactiveUS20040137222A1Improve bindingFilm/foil adhesivesThin material handlingPolycarbonatePressure sensitive

The invention refers to a transparent pressure-sensitive adhesive layer the pressure-sensitive adhesive of which comprises: (i) the reaction product obtainable by polymerizing a precursor comprising (a) one or more alkyl(meth)acrylate monomers the alkyl groups of which comprise independently from each other 4 to 20 carbon atoms, and (b) one or more moderately polar Lewis base-functional copolymerizable monomers, and (ii) one or more tackifying resins wherein; the concentration of the alkyl acrylate monomer or monomers and the thickness of the pressure-sensitive adhesive layer are selected so that the pressure-sensitive adhesive layer has a 90° peel adhesion from polycarbonate after a dwell time of 72 as measured according to FINAT method no. 2 of at least 35 N / 1.27 cm.

Owner:3M INNOVATIVE PROPERTIES CO

Road-surface asphalt modified additive at normal temperature and its production

ActiveCN101074321ASimple production processNo pollution in the processBuilding insulationsCross-linkPolymer science

A road surface asphalt modified additive at normal temperature and its production are disclosed. It consists of high-molecular polymer 5-15 proportion, filling oil 20-40 proportion, light distillates 35-70 proportion, viscosity-increasing resin 3-12 proportion, fire-retardant agent 1-3 proportion, and cross-linking agent 0.1-0.5 proportion. The process is carried out by dissolving asphalt, modifying asphalt and blending with stone material at normal temperature. It's safe, has better stability, weather and temperature resistances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

Resin composition

ActiveUS20120283375A1Reduce thermal degradationReduce heatElectrical apparatusElectroluminescent light sourcesEpoxyPolymer science

Owner:AJINOMOTO CO INC

High strong adhesive and method for preparing same

The powerful adhesive includes neoprene, grafting monomer, thickener, dispersant, adhesion promoter, catalyst, antioxidant, solvent, stuffing, etc. The present invention also discloses the preparation process of the adhesive, and the preparation includes introducing grafting monomer to neoprene molecule chain to raise the adhesion strength, selecting proper adhesion promoting resin to increase the initial adhesion force, and adopting mixed solvent to form high adhering performance. The adhesive has high solid content and excellent environment protecting performance, and has also excellent antiageing performance, high resistance to heat, oil, chemical and corrosion, high weather resistance, good mildew-proof performance, antibiotic performance, etc. and may be used for adhering timber, concrete, rubber, metal, gypsum board, brick and other building material.

Owner:GUANGZHOU GLORYSTAR CHEM

Acrylic pressure-sensitive adhesive, acrylic pressure-sensitive adhesive layer and acrylic pressure-sensitive adhesive tape or sheet

ActiveUS20110070434A1Improve adhesionLittle changeImpression capsFilm/foil adhesivesPolymer scienceMeth-

The present invention relates to an acrylic pressure-sensitive adhesive including: a) an acrylic polymer containing, as a monomer unit, an alkyl (meth)acrylate including an alkyl group having 1 to 20 carbon atoms in an amount of 50% by weight or more; and b) a tackifier resin, in which the acrylic polymer a) contains two kinds of monomer units having a difference in solubility parameter (SP value) of 0.2 (MPa)1 / 2 or more, each in an amount of 15% by weight or more.

Owner:NITTO DENKO CORP

Acrylic pressure sensitive adhesive composition and pressure sensitive adhesive tape

InactiveUS20050209380A1Improve adhesionExcellent pressure-sensitive adhesionInksAcid polymer adhesivesPolymer scienceMeth-

Provided is an acrylic pressure sensitive adhesive composition excellent in pressure sensitive adhesive characteristics and removability and a pressure sensitive adhesive tape using the acrylic pressure sensitive adhesive composition. An acrylic pressure sensitive adhesive composition containing an acrylic polymer obtained by at least copolymerizing a (meth)acrylic acid alkyl ester with an alkyl group having 2 to 14 carbon atoms and a carboxyl group containing unsaturated monomer copolymerizable with the (meth)acrylic acid alkyl ester, and tackifier resins, wherein the tackifier resins are respective resins each containing a natural product as a raw material, include at least 4 kinds of the resins-different in a molecular structure from one another and a content of each of the tackifier resins is in the range of 5 parts by weight or more and 20 parts by weight or less relative to 100 parts by weight of the acrylic polymer.

Owner:NITTO DENKO CORP

Reactive butyl rubber self-adhesive layer for waterproof roll and processing technology thereof

ActiveCN103102843ASelf-healingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof. The reactive butyl rubber self-adhesive layer comprises the following components in parts by weight: 20 parts of butyl rubber, 1.0-4.2 parts of ethylene vinyl acetate copolymer, 16.5-20.5 parts of tackifying resin, 18.4-24.0 parts of tackifier, 12-18 parts of carbon black, 9-14 parts of light calcium carbonate, 8.0 parts of functional aid, 1.8 parts of vulcanizing agent, 0.8 part of anti-aging agent and 0.5 part of coupling agent. The butyl rubber self-adhesive layer is prepared by mixing, kneading and extruding forming. Due to the mode, the invention provides a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof, the butyl rubber self-adhesive layer can be chemically reacted with cast-in-place concrete to form a whole, a permanent waterproof layer is formed and has the self-healing performance, the waterproof layer and various high polymer waterproof rolls can be compounded to form a functional waterproof material, and the reactive butyl rubber self-adhesive layer is suitable for various underground waterproof engineering.

Owner:常熟市三恒建材有限责任公司

Tire tread-use rubber composition

A tire tread-use rubber composition includes from 10 to 50 parts by weight of a tackifying resin having a softening point of from 100° C. to 150° C.; from 70 to 130 parts by weight of a carbon black having a nitrogen specific surface area of from 250 to 400 m2 / g; from 1 to 3 parts by weight of sulfur; from 0.5 to 4.0 parts by weight of a sulfenamide vulcanization accelerator; and from 1.5 to 5.0 parts by weight of a thiuram vulcanization accelerator per 100 parts by weight of a rubber component; wherein when A is a compounded amount in parts by weight of the sulfenamide vulcanization accelerator, T is a compounded amount in parts by weight of the thiuram vulcanization accelerator, and S is a compounded amount in parts by weight of the sulfur, a weight ratio (A+T) / S is from 2 to 4.

Owner:YOKOHAMA RUBBER CO LTD

Heat-conduction and electric-conduction hot melt glue and preparation method thereof

InactiveCN103540280AGood compatibilityReduce the amount addedNon-macromolecular adhesive additivesElectrically-conducting adhesivesThermoplasticPolymer science

The invention relates to a heat-conduction and electric-conduction hot melt glue and a preparation method thereof. The hot melt glue is high in heat-conduction and electric-conduction properties under a precondition that the elasticity and bonding strength of the original hot melt glue; the heat conduction coefficient reaches more than 2.0w / m.k. According to the hot melt glue, base materials comprise styrene thermoplastic elastomers (SEBS) and styrene-butadiene-styrene thermoplastic elastomers (ESBS) modified by epoxidation; a thickening agent comprises two of hydrogenated rosin, terpene resin and C9 petroleum resin; a filler is graphene solid powder with heat-conduction and electric-conduction functions; the addition amount of the base materials accounts for 30-40%; the addition amount of thickening resin accounts for 30-50%; the addition amount of the solid graphene powder accounts for 1.5-3.5%; the addition amount of the other accessory ingredient naphthenic oil accounts for 15-18%; the addition amount of an antioxidant accounts for 1-2%; the heat-conduction and electric-conduction hot melt glue is prepared from the components of the hot melt glue through a melt blending method.

Owner:SHENYANG JIANZHU UNIVERSITY

Preparation method of wet curing reaction-type polyurethane hot melt adhesive for textile

ActiveCN103497725AHigh initial bond strengthGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a wet curing reaction-type polyurethane hot melt adhesive for a textile. The preparation method mainly comprises the following steps: (1) stirring and mixing polyether polyol 4000E, polyether polyol 3000H and an antioxidant, heating and warming to about 120 DEG C, dewatering for 0.5 hour when the vacuum degree is smaller than 100Pa; (2) adding a tackifying resin, continuing to warm to 135-140 DEG C, dewatering for 1.5 hours when the vacuum degree is smaller than 100Pa; (3) cooling to 87 DEG C, adding 4,4'-diphenyl methane diisocyanate and a catalyst, stirring and reacting for 2 hours when the vacuum degree is smaller than 100Pa; (4) relieving a vacuum state, adding white carbon black, quickly stirring and evenly mixing, and continuing to stir for 10 minutes when the vacuum degree is smaller than 100Pa; and (5) keeping the discharge temperature at 85-100 DEG C, quickly discharging and encapsulating, and then curing for 4 hours under the condition of 80-85 DEG C, so as to obtain a target product. The product is applied to compounding of the textile, and has excellent peel strength, short opening time, good hydrolysis resistance and good storage stability.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

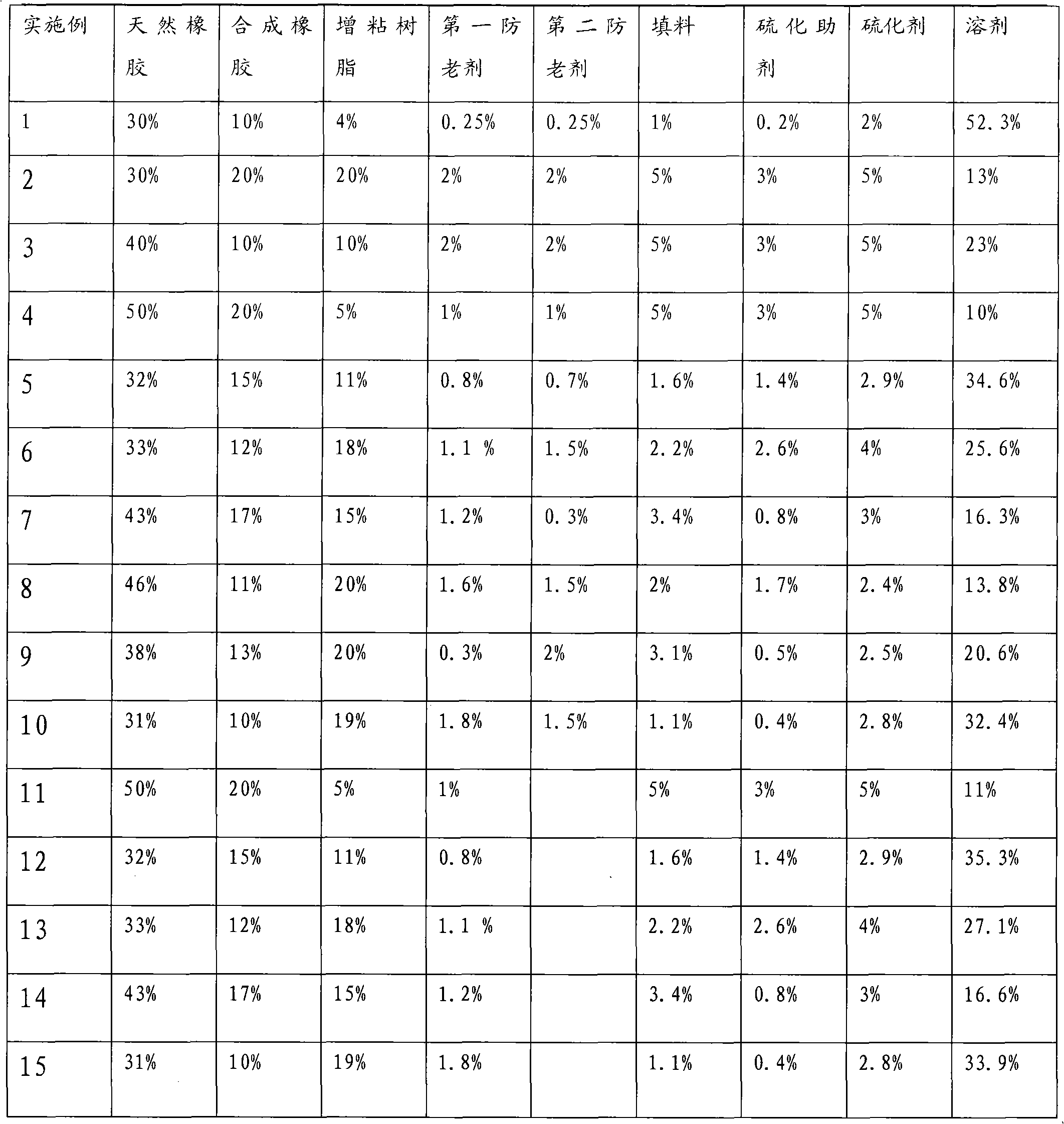

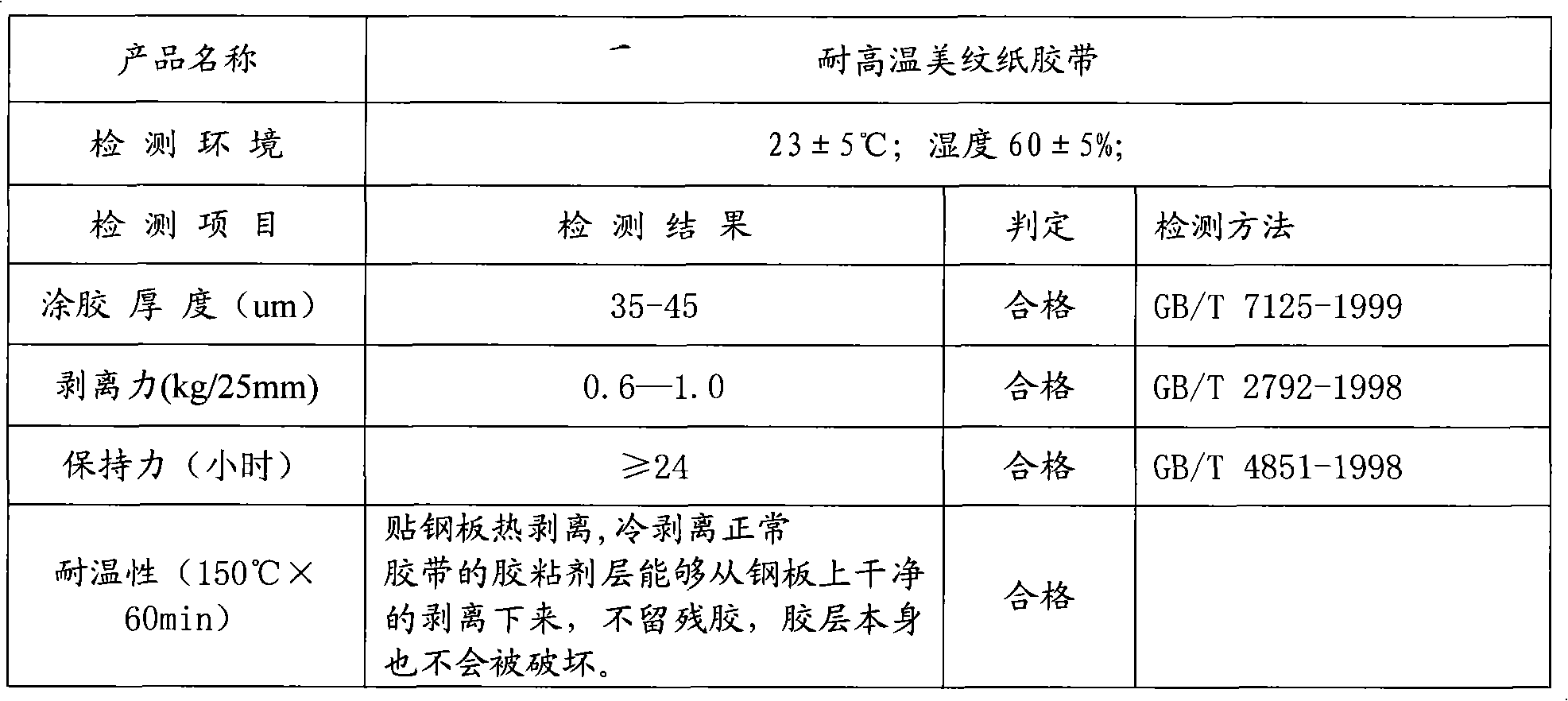

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Hot melt pressure sensitive adhesives for disposable articles

InactiveUS20050013996A1Increase stickinessImproved adhesion to polyolefinsAdhesive processesFilm/foil adhesivesPolymer scienceAntioxidant

A hot melt pressure sensitive adhesive (HMPSA) is obtained by combining a linear A-B-A block copolymer, wherein the B component is polyisoprene and the A component is polystyrene (S-I-S), at least one compatible tackifying resin, at least one plasticizer, antioxidant(s) and stabilizer(s) and optionally a wax, wherein the A-B-A block copolymer contains 0 to 10% by weight residual A-B diblock. The HMPSA is suitable as a positioning adhesive for disposable articles like plasters, bandages, sanitary napkins, e.g. feminine napkins, adult incontinent pads or diapers. The HMPSA has a viscosity from 3,500 mPas to 25,000 mPas at 140° C. and exhibits adhesion values from 1.0 to 3.0 N / cm at coat weights of 10 to 25 grams per square meter.

Owner:HATFIELD STEPHEN F

Composition for strechable film

ActiveUS20110318987A1Satisfactory formabilityEasy to peel offSynthetic resin layered productsLaminationPolymer scienceThin membrane

Provided is a composition for a stretchable film, which achieves a high-level balance between a high elastic modulus and a small permanent set, and can be formed into a stretchable film with satisfactory formability. A composition for a stretchable film comprises a block copolymer composition containing a block copolymer A represented by the following general formula (A) and a block copolymer B represented by the following general formula (B), and a tackifier resin:Ar1a-Da-Ar2a (A)(Arb-Db)n-X (B),in the general formulas (A) and (B), Ar1a and Arb each represent an aromatic vinyl polymer block having a weight average molecular weight of 6,000 to 20,000; Ar2a represents an aromatic vinyl polymer block having a weight average molecular weight of 40,000 to 400,000; Da and Db each represent a conjugated diene polymer block having a vinyl bond content of 1 mol % to 20 mol %; X represents a single bond or a residue of a coupling agent; and n represents an integer of 2 or greater.

Owner:ZEON CORP

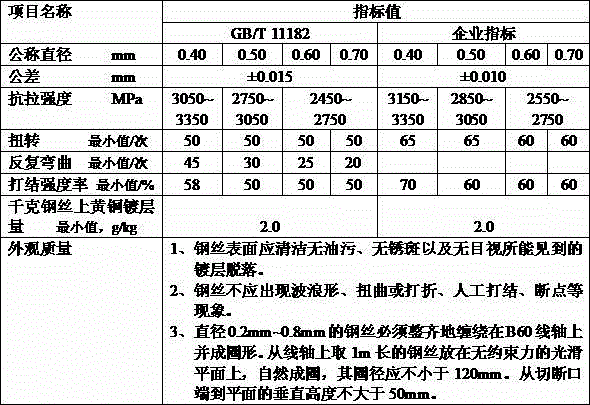

Ultra-high-pressure steel wire winding composite hose

ActiveCN104100783AImprove stress resistanceImprove pulse lifeFlexible pipesPolymer scienceMicrocrystalline wax

The invention discloses an ultra-high-pressure steel wire winding composite hose, which comprises an inner rubber pipe, a framework layer, a middle rubber layer and an outer rubber layer, wherein the framework layer is arranged outside the inner rubber pipe, the middle rubber layer and the framework layer are made into a whole, the outer rubber layer is arranged outside the middle rubber layer, inner rubber of the inner rubber pipe is prepared from the following ingredients including nitrile rubber, high styrene rubber, solution polymerized styrene-butadiene rubber, sulphur S, vulcanizing agents DTDM, vulcanization accelerators CZ, accelerators D, nanometer zinc oxides, stearic acid, scorch retarders CTP, flowing exhaust agents SC617, integral anti-aging agents 4020, anti-aging agents BLE, microcrystalline wax, carbon black, nanometer silicon dioxide, bonding agents RC, bonding agents RC-23, tackifying resin SP1068, dioctyl sebacate and polyolefin, and the middle rubber layer and the outer rubber layer are respectively made of different materials. The rubber pipe belongs to the ultra-high-pressure steel wire winding composite hose capable of bearing the pressure as high as 50 to 300 Mpa, and belongs to an ultra-high-pressure hydraulic rubber pipe meeting the requirements of engineering machinery and oil drilling.

Owner:河南亿博科技股份有限公司

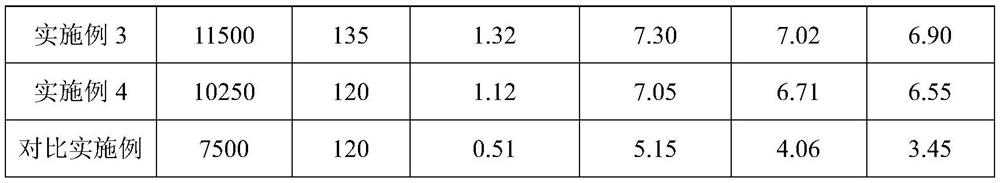

High-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and preparation method thereof

InactiveCN111849408AExtended opening hoursHigh initial bond strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a high-initial-adhesion-strength moisture-curable polyurethane hot melt adhesive and a preparation method thereof. The adhesive is prepared from the following raw materials inparts by weight: 20-50 parts of polyether polyol, 10-40 parts of crystalline polyester polyol, 5-30 parts of liquid polyester polyol, 10-20 parts of polyisocyanate, 10-35 parts of thermoplastic acrylic resin, 2-15 parts of tackifying resin, 0.1-0.5 parts of a catalyst and 0.1-1 part of an antioxidant. The moisture-curable polyurethane hot melt adhesive provided by the invention has the advantagesof long opening time, high initial adhesion strength, high curing speed, higher final adhesion strength, favorable damp-heat resistance and favorable high / low-temperature impact resistance, and can achieve the goals of no pressure maintaining and high-efficiency production of electronic products.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD +3

Disposable article hot melt adhesive

InactiveUS20100305528A1Liquid/solution decomposition chemical coatingBaby linensPolymer sciencePolyolefin

A hot melt adhesive comprises an ethylene α-olefin copolymer, an acid anhydride modified polyolefin and a hydrogenated tackifying resin. The hot melt adhesive has excellent viscoelastic properties and can be used in a variety of applications. In one application, attaching an elastic band to a flexible film, the adhesive has excellent viscosity and, in a finished absorbent article, a minimal creep characteristic. Also disclosed is a disposable article using the adhesive to adhere adjacent surfaces within the disposable article including an elastic band to a polyolefin backing film, for example, in a diaper, incontinent article or other such structure.

Owner:ADHERENT LAB

Adhesion-modified expandable polyolefin compositions and insulated vehicle parts containing expanded adhesion-modified polyolefin compositions

Polyolefin compositions that expand freely to form stable foams are disclosed. The compositions contain specified levels of adhesion-promoting resins. The compositions include at least one heat-activated expanding agent and typically include at least one heat-expanded crosslinker. The compositions are effective as sealers and noise / vibration insulation in automotive applications.

Owner:ONER DELIOMANLI DIDEM +4

Solvent-free UV (ultraviolet) curing glue for optical transparent adhesive tape and preparation method and application thereof

ActiveCN103725245ALow VOCGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceSolvent free

The invention belongs to the technical field of UV (ultraviolet) curing glue, and discloses solvent-free UV curing glue for an optical transparent adhesive tape and a preparation method and application thereof. The glue comprises the following components in parts by mass: 20-60 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 10-25 parts of acrylate monomer, 1-10 parts of thiol, 1-10 parts of tackifying resin, 0.1-1 part of leveling agent, 0.5-2 parts of antifoaming agent and 0.5-2 parts of photoinitiator. In the invention, the colloid crosslinking density and colloid strength are improved by preferentially adopting aliphatic polyurethane acrylate with low functionality degree and adding hyperbranched polyester acrylate; the acrylate monomer adjusts the viscosity and enhances the colloid strength; the caking property is improved by adding the thiol containing an ether structure; the prepared non-solvent UV curing glue for an optical transparent adhesive tape has high toughness, high light transmittance, low haze, high colloid strength, high viscosity, high thickness and low VOC (volatile organic compound) content.

Owner:广州慧谷功能材料有限公司

Method of making multilayer structures using tapes on non-densifying substrates

ActiveUS7547369B2Tight dimensional controlRoof covering using sealantsMetallic material coating processesGreen tapeCeramic coating

A method of applying a ceramic coating to a substrate comprises laminating one or more layers of a green ceramic tape to a rigid substrate using a tackifying resin to adhere the tape to the substrate. Upon firing, the tackifying resin ensures near zero shrinkage of the tape in the XY plane without usage of elevated pressures or temperatures during lamination of green tape to the substrate. The thermal degradation completion temperature of the tackifying resin is lower than that of the resin binder used in the green tape.

Owner:FERRO CORP

Hot-Melt Adhesive

Hot-melt adhesives containing at least one aromatic modified polyethylene and / or polypropylene (co)polymer, a further ethylene or propylene / C4 to C20 alpha-olefin copolymer, and at least one tackifying resin are useful for the adhesive bonding of package and paperboard products.

Owner:HENKEL KGAA

Wind navigation room temperature vacuum seal rubber belt and producing method thereof

InactiveCN101402764AHigh elastic modulusHigh tensile strengthDomestic articlesHigh surfaceFilm material

The invention discloses an air navigation room temperature vacuum sealing adhesive tape and a manufacturing method thereof. The method comprises the steps: fillings, a vulcanizing agent, an activator, an accelerant and a tackifying resin are added into a butyl rubber; the fillings comprise light-weight calcium carbonate and heavy-weight calcium carbonate; the vulcanizing agent is 201 brominated methylol tert-octyl phenolic resin: the activator is halide and zinc oxide; and the accelerant is TMTD thiuram; and the tackifying resin is polyisobutylene resin. The sealing adhesive tape has the advantages that: the tape is applicable to heat-free curing in the application and joint production of vacuum bags. Under a vacuum condition and at room temperature, the adhesive tape can seal most of sealing thin films and curing tools and can clean the surface of tools at room temperature. The tape is mainly characterized by high elastic modulus, high tensile strength and high surface adhesive force, is easy for application, has quite high adhesive force to the sealing thin films and the curing tools, can be applied at room temperature, is applicable to most of composite materials and thin-film materials and the defoaming by multi-layer composite materials, thus being a low-cost adhesive tape for vacuum bags and being safe and reliable.

Owner:周玉铭

Elastomer-based hot-melt adhesive and preparation method thereof

InactiveCN103232825AImprove wettabilityReactive extrusion process is mature and stableMineral oil hydrocarbon copolymer adhesivesRosin adhesivesElastomerPolymer science

The invention relates to an elastomer-based hot-melt adhesive and a preparation method thereof. The hot-melt adhesive is characterized in comprising 5-40% of a grafted modified elastomer, 30-70% of an elastomer, 0-20% of polyolefin, 0-20% of tackifying resin, 0-2% of co-graft monomer, and 0-1% of an antioxidant. The grafted modified elastomer comprises 95-99% of an elastomer, 0.5-5.0% of a polar monomer, 0.1-1.5% of comonomer, and 0.1-2% of an initiator. The method has the advantages of mature and stable reactive extrusion process, good product toughness, high bonding strength, and good wettability upon substrate.

Owner:SHUNDE POLYTECHNIC

Acrylate resin quartzite floor coating and preparation method thereof

InactiveCN101665649ALow viscosityEnvironmentally friendly and non-toxicCoatingsHardnessSolid content

The invention relates to an acrylate resin quartzite floor coating and a preparation method thereof. The acrylate resin quartzite floor coating comprises the raw materials in portions by weight: 10-40 portions of acrylate monomers and / or ethane monomers, 0.1-2 portions of free radical polymerization initiator, 0.05-1 portion of reducing agent, 0.01-1 portion of accelerating agent, 0.05-5 portions of wetting agent, 0.05-5 portions of dispersing agent, 0.01-2 portions of defoaming agent and 20-80 portions of quartzite. Because a pre-polymerization technology is adopted, and the resin with high solid content and low viscosity is used as a film forming matter, the coating has no VOC emission and is environmental-friendly without toxicity. The acrylate monomers are used as the base material so that the obtained coating has high weather fastness, strong decoration, high adhesive force and large hardness; because the molecular weight of the resin with high solid content and low viscosity is low, the resin has good compatibility with other resins and can be modified by selecting other resins, and the comprehensive property of the floor is improved.

Owner:北京红狮科技发展有限公司

Water-emulsion type paper-plastic composite adhesive and method for preparing same

InactiveCN101338175AGood adhesionImprove moisture resistanceRosin adhesivesMolded pulpDispersed media

The invention discloses a water emulsion paper plastic composite adhesive which comprises the compositions with the weight portions of 2-8 portions of SBS resin, 2-8 portions of EVA resin, 2-12 portions of mixed solvent, 15-25 portions of tackifying resin, 1-25 portions of polyvinyl alcohol, 1-3 portions of composite emulsifier and 20-30 portions of water. After the mutual solution of the SBS resin, the EVA resin, the mixed solvent and the tackifying resin in the compositions and the emulsification of water phase solution prepared from the composite emulsifier, water and the polyvinyl alcohol, the latex adhesive with the viscosity of 500-2500MPa.s and less than 0.6 percent of the water absorption rate is obtained. The adhesive takes water as dispersing medium and has the characteristics of environmental friendly performance of water emulsion laminating adhesive, transporting and storing safety, high adhering strength and good humidity resistance of solvent laminating adhesive, etc. The deficiencies of present solvent laminating adhesive and acrylic water emulsion laminating adhesive are solved.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Anti-fatigue and deflection-resistant tire sidewall rubber and production process thereof

InactiveCN101845156AReduce lossImprove process throughputSpecial tyresRolling resistance optimizationPolymer sciencePlasticizer

The invention relates to an anti-fatigue and deflection-resistant tire sidewall rubber and a production process thereof, in particular to an all-steel radial tire sidewall rubber and a production process thereof. The tire sidewall rubber is produced with the following raw materials in parts by weight: 40.0-50.0 of natural rubber of a raw rubber system, 50.0-60.0 of BR9000 butadiene rubber, 5.0-10.0 of reclaimed rubber, 45.0-50.0 of N375 carbon black, 3.50 of zinc oxide, 3.0-6.0 of aging resister, 4.0 of aromatic oil, 1.0 of plasticizer, 3.0 of tert-butyl phenolic tackifying resin, 1.5 of sulfur and 0.80 of promoter. The invention has the advantages of reducing the production cost and the production waste loss, improving the rubber process performance, and enhancing the fatigue resistance and deflection resistance of the side part of the finished tire.

Owner:八亿橡胶有限责任公司

Method Of Making Multilayer Structures Using Tapes On Non-Densifying Substrates

ActiveUS20080053592A1Tight dimensional controlExemption stepsRoof covering using sealantsMetallic material coating processesGreen tapeCeramic coating

A method of applying a ceramic coating to a substrate comprises laminating one or more layers of a green ceramic tape to a rigid substrate using a tackifying resin to adhere the tape to the substrate. Upon firing, the tackifying resin ensures near zero shrinkage of the tape in the XY plane without usage of elevated pressures or temperatures during lamination of green tape to the substrate. The thermal degradation completion temperature of the tackifying resin is lower than that of the resin binder used in the green tape.

Owner:FERRO CORP

Continuous two-stage preparation of solvent-free polyacrylate hotmelt PSAs

ActiveUS6881442B2High molecular weightHigh throughputFilm/foil adhesivesOrganic dyesSolvent freeAntioxidant

In a continuous two-stage process for preparing solvent-free polyacrylate hotmelt pressure sensitive adhesives which is gentle on the polymer and redeploys the solvent used in the process the following steps are carried out:polymerizing a self-adhesive pressure sensitive adhesive in solution, the solvent having a low vapor pressure;continuously mixing the polymer solution with antioxidants and preheating the mixture under superatmospheric pressure without boiling it;concentrating the polymer solution to a residual solvent content of less than 0.1% by weight in a concentrating extruder under the effect of reduced pressure and elevated temperatures;condensing, collecting, and re-using the solvent stripped off in the extruder;compounding the abovementioned solvent-freed hotmelt pressure sensitive adhesive with tackifying resins, fillers, stabilizers, crosslinkers or other additives in a second extruder at a moderate melt temperature;transferring the blended solvent-free self-adhesive pressure sensitive adhesive to a downstream coating unit.

Owner:TESA SE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com