Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Solder form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, more precisely in differential geometry, a soldering (or sometimes solder form) of a fiber bundle to a smooth manifold is a manner of attaching the fibers to the manifold in such a way that they can be regarded as tangent. Intuitively, soldering expresses in abstract terms the idea that a manifold may have a point of contact with a certain model Klein geometry at each point. In extrinsic differential geometry, the soldering is simply expressed by the tangency of the model space to the manifold. In intrinsic geometry, other techniques are needed to express it. Soldering was introduced in this general form by Charles Ehresmann in 1950.

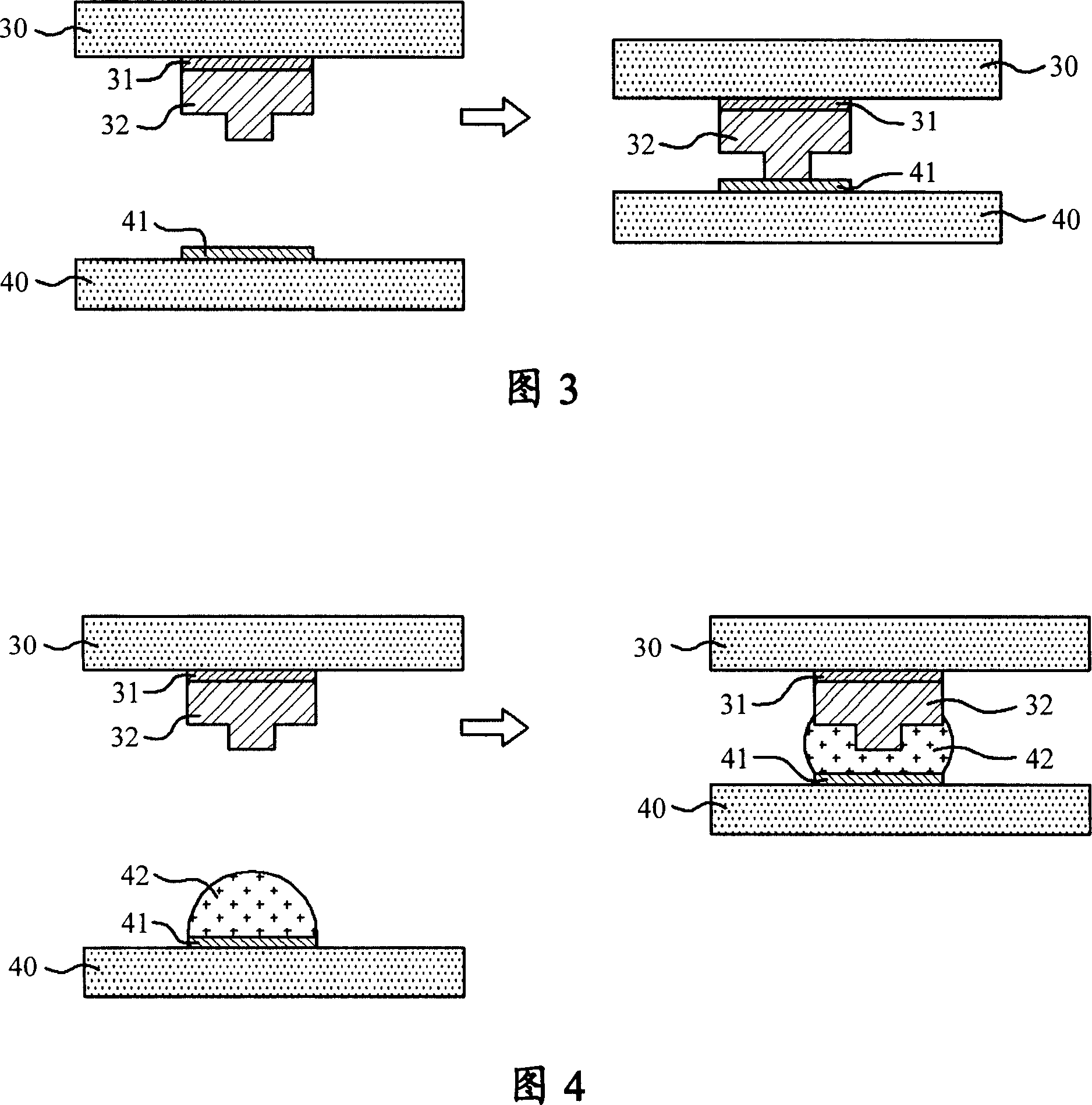

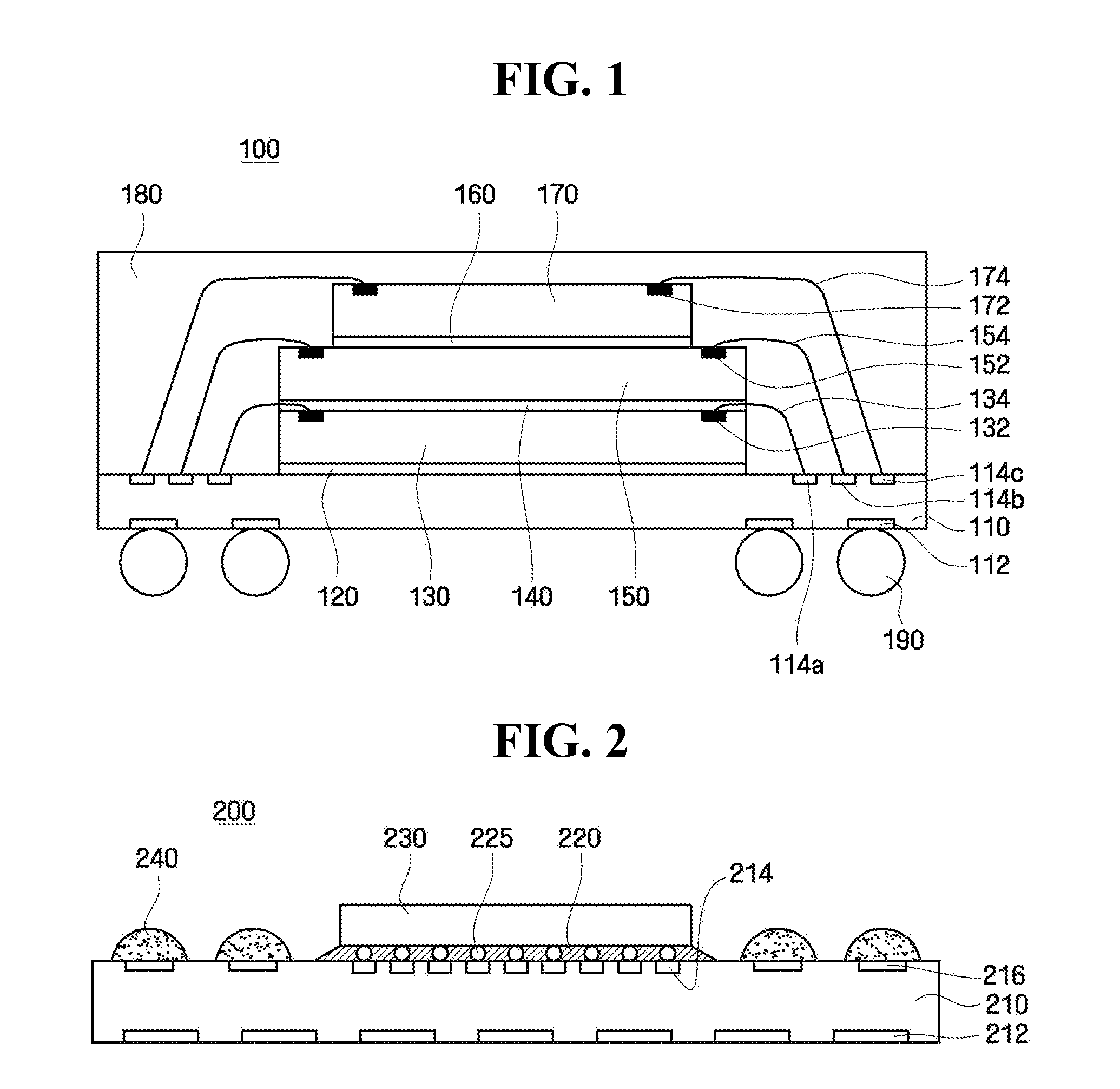

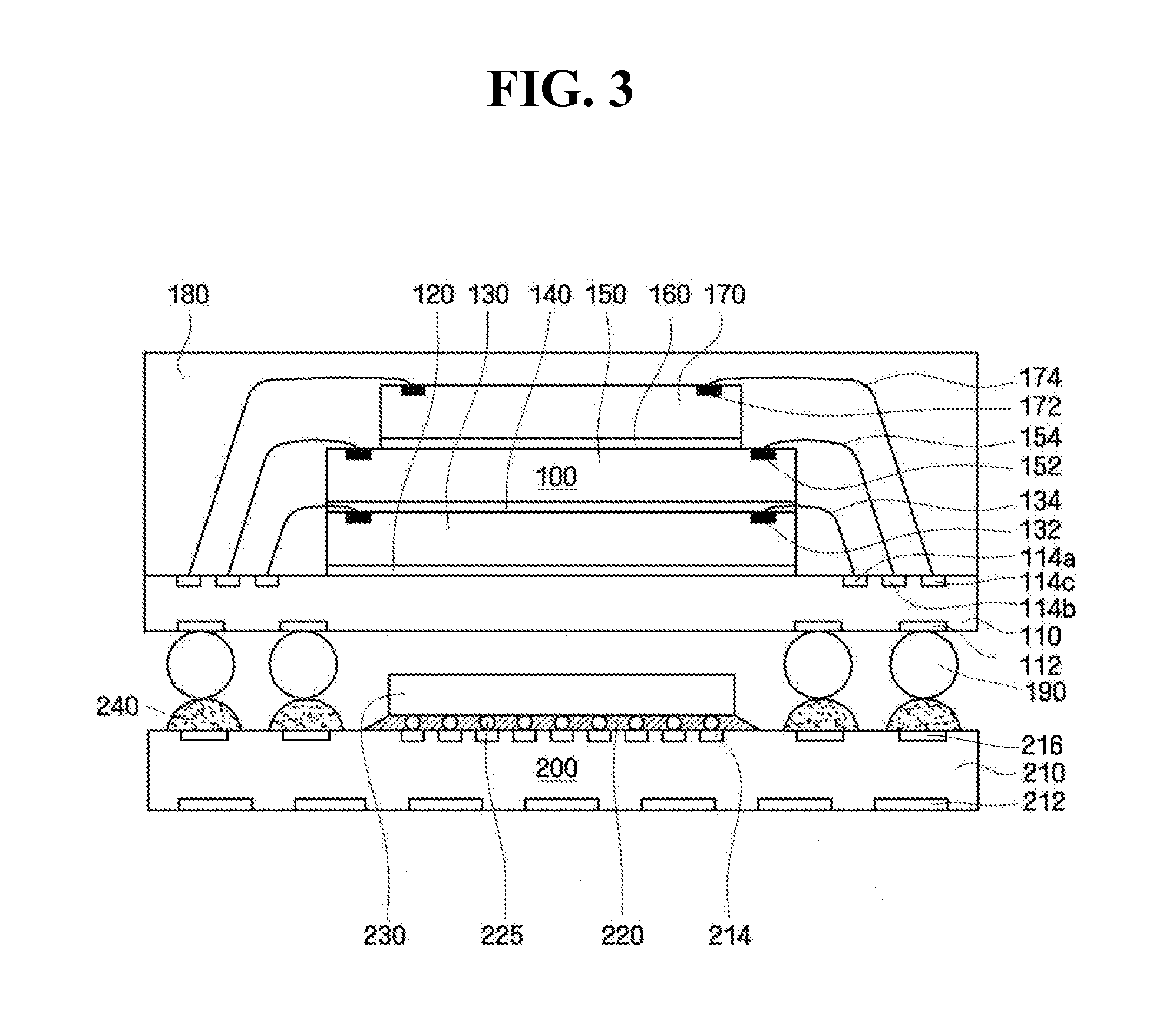

Post bump and method of forming the same

InactiveUS20110012261A1Prevent deviationAvoid flowSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringSolder form

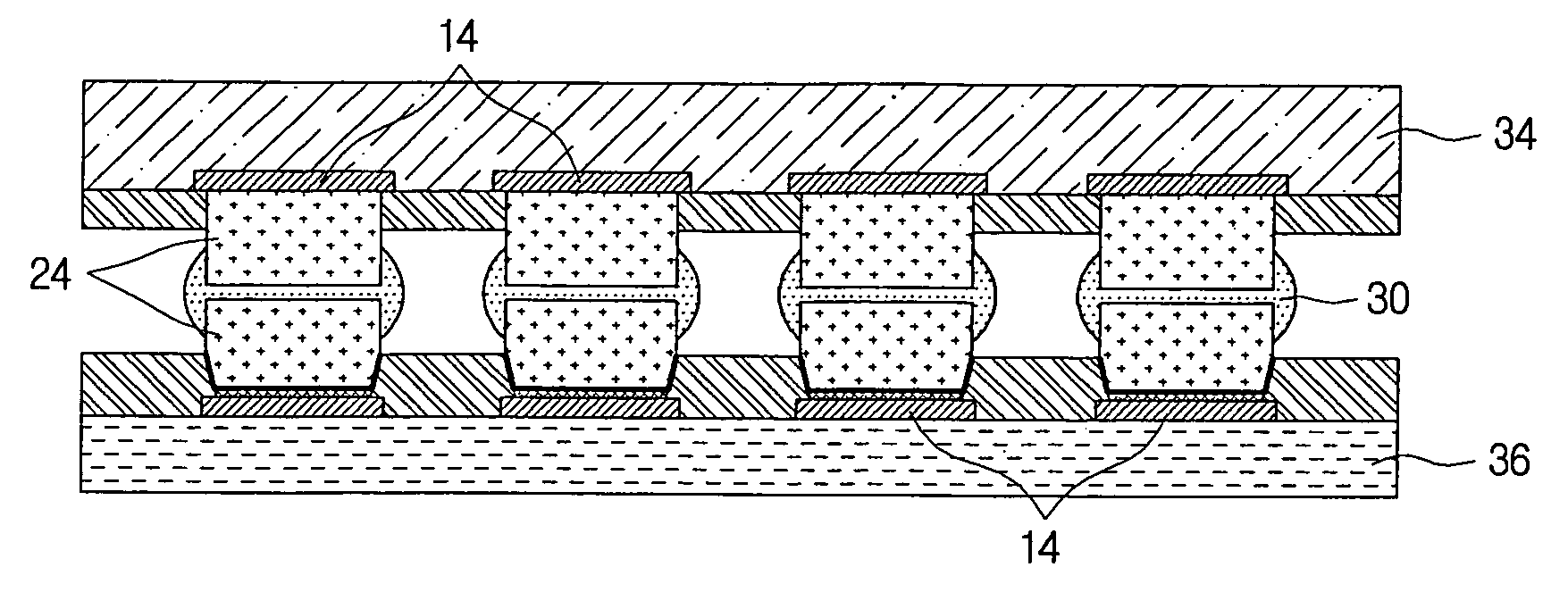

A post bump formed over an electrode pad of a substrate for electrically connecting to an external device, the post bump including a metal post formed over the electrode pad; and a solder formed over the metal post and shaped as a dome, the dome occupying a space defined by imaginary lines extending from a perimeter of the metal post along an axial direction of the metal post.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

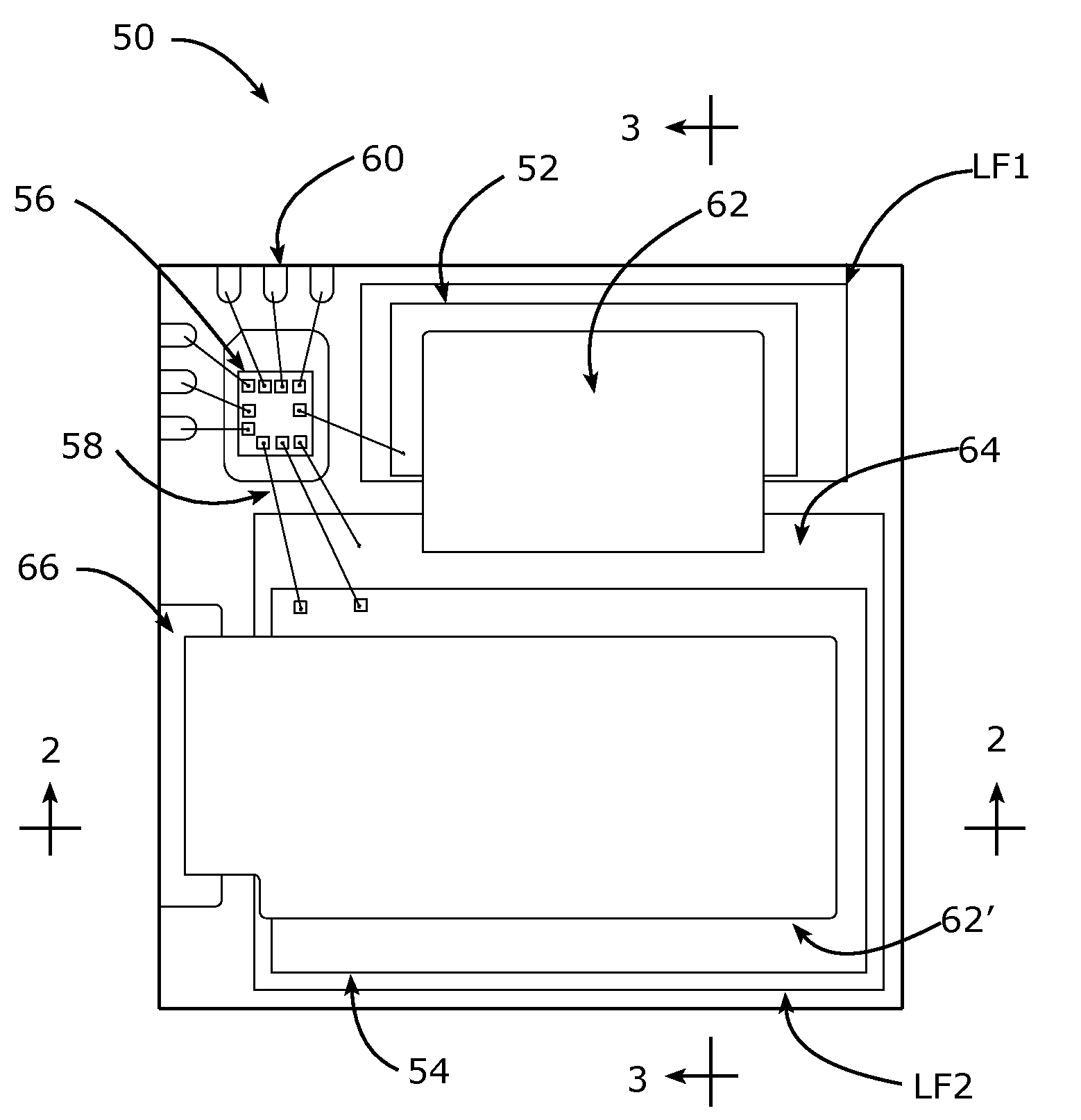

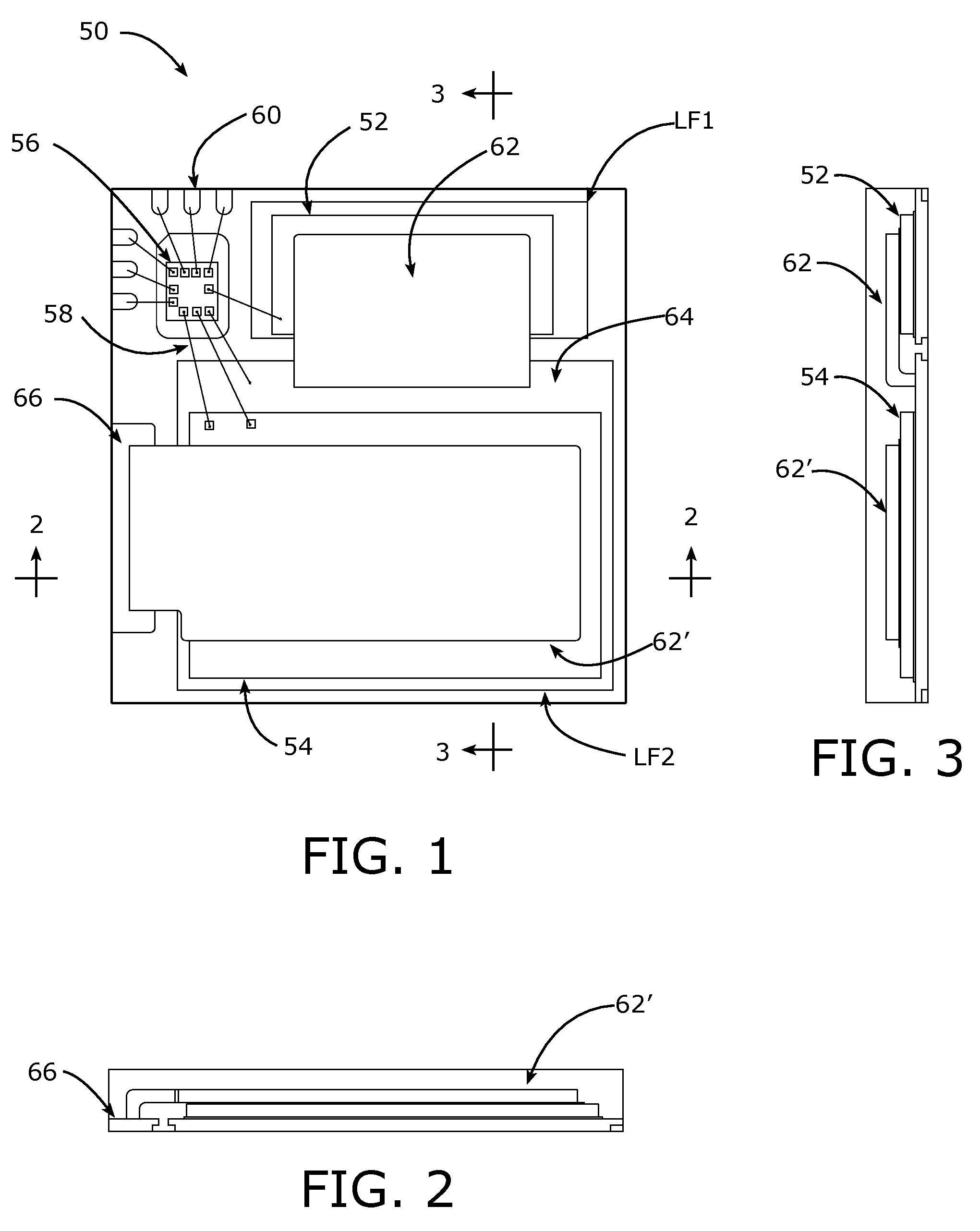

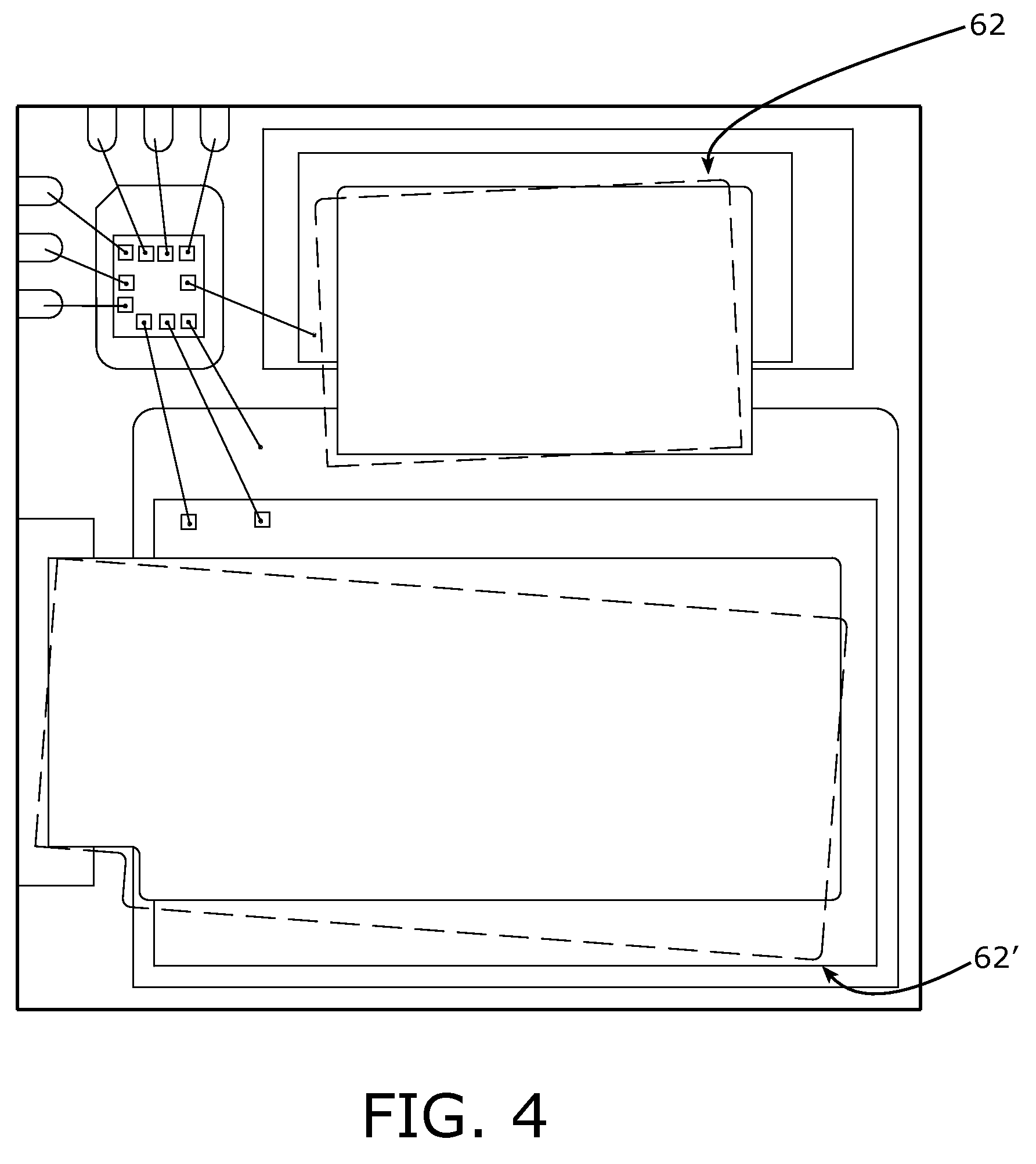

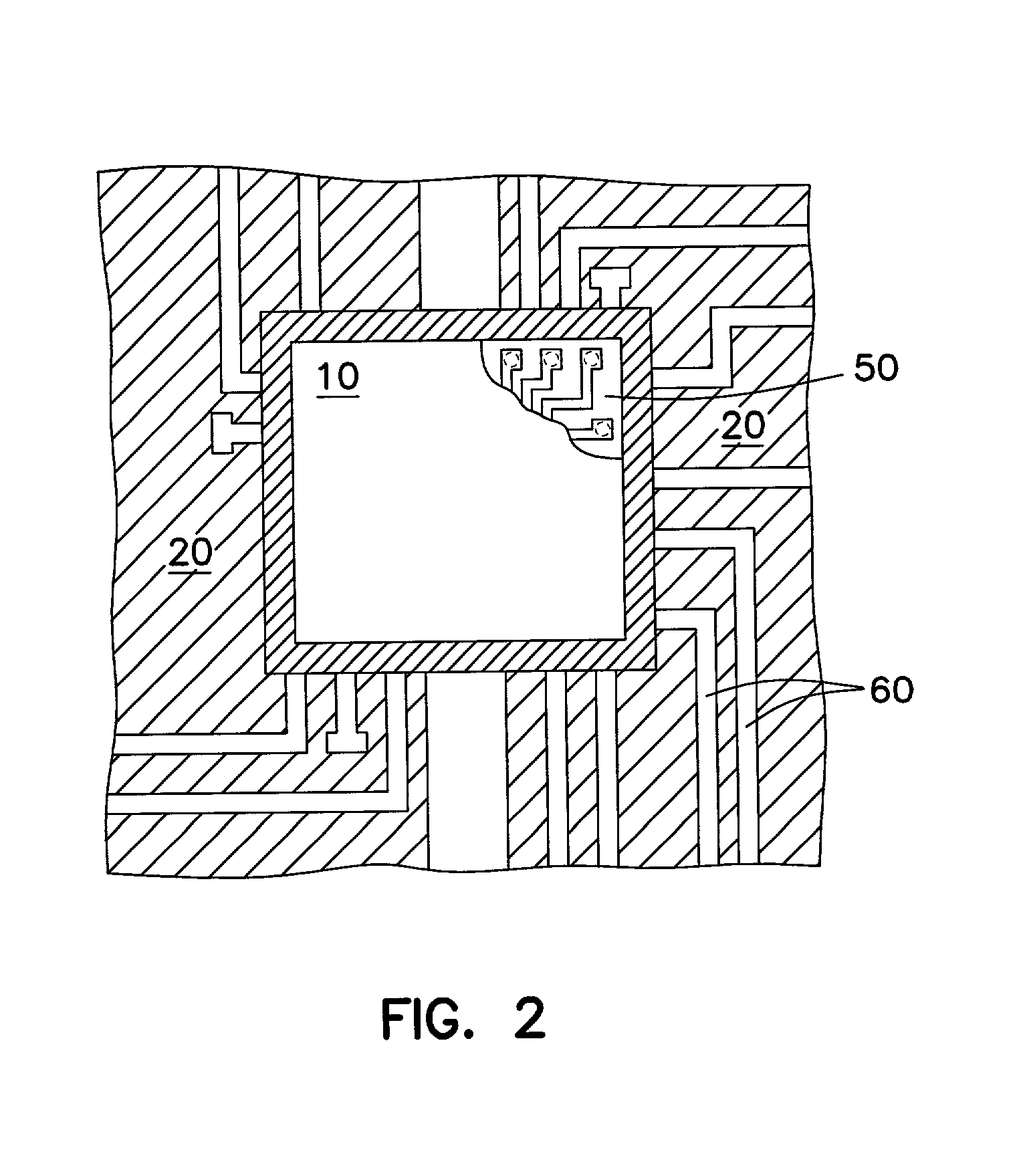

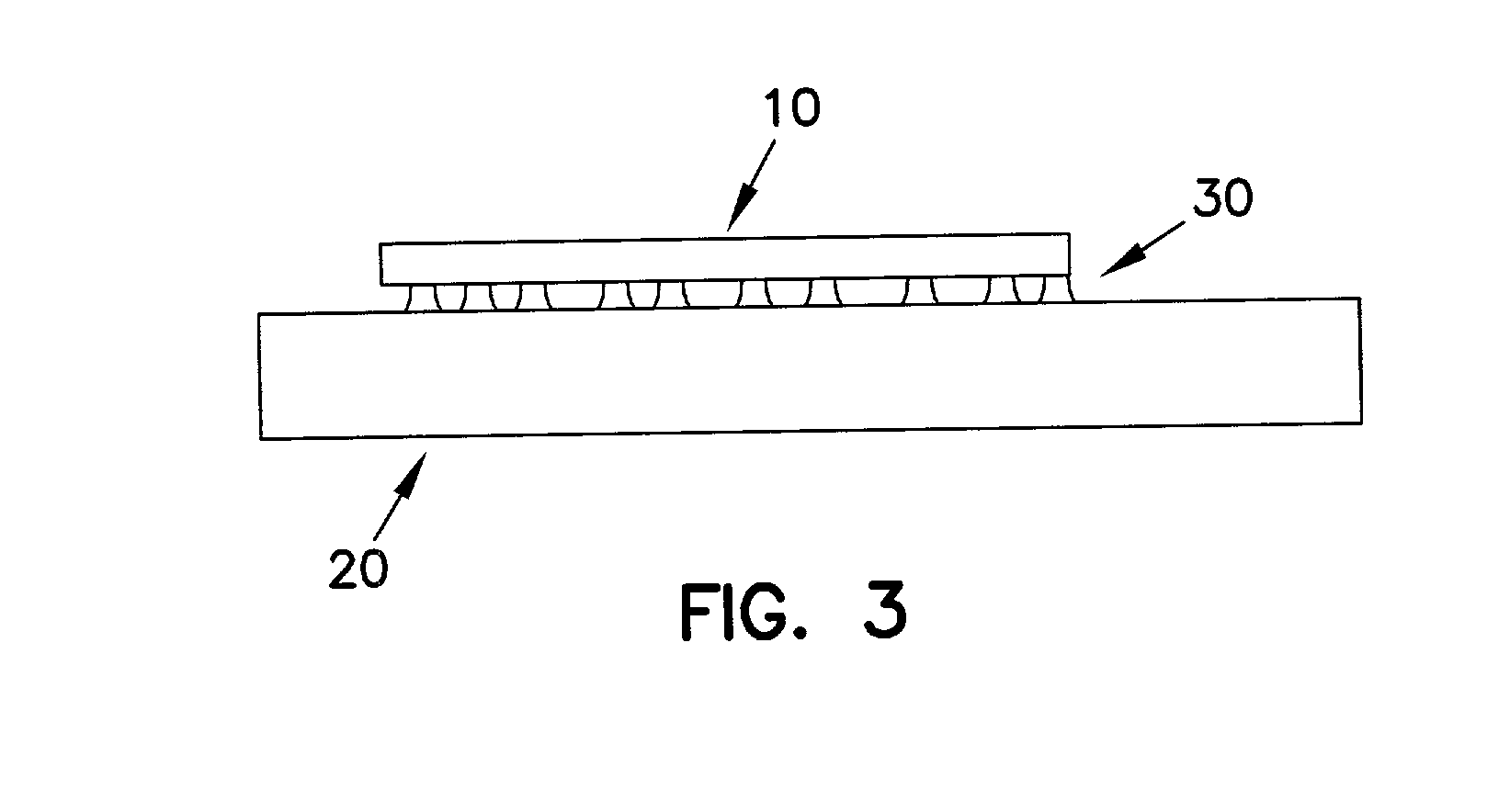

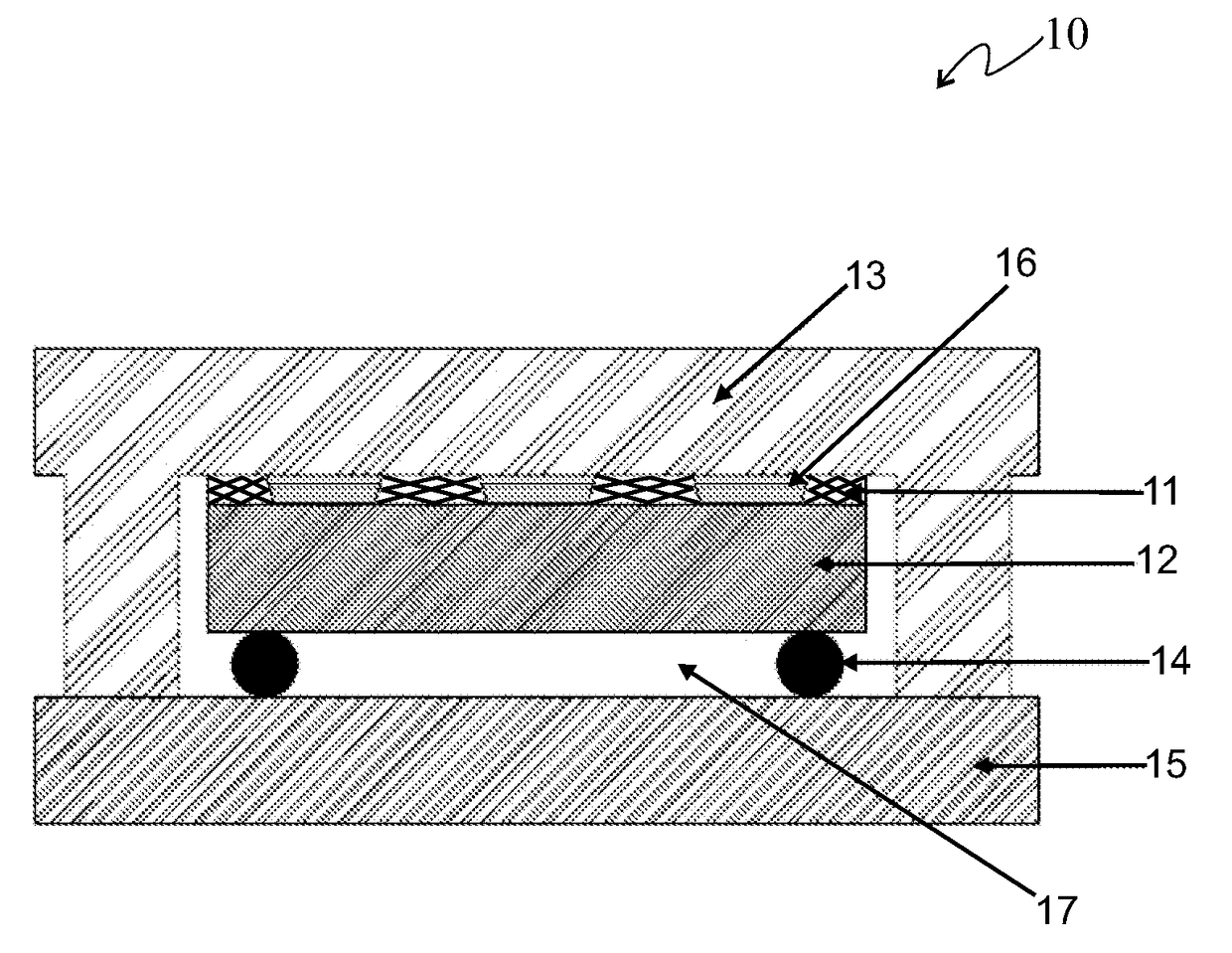

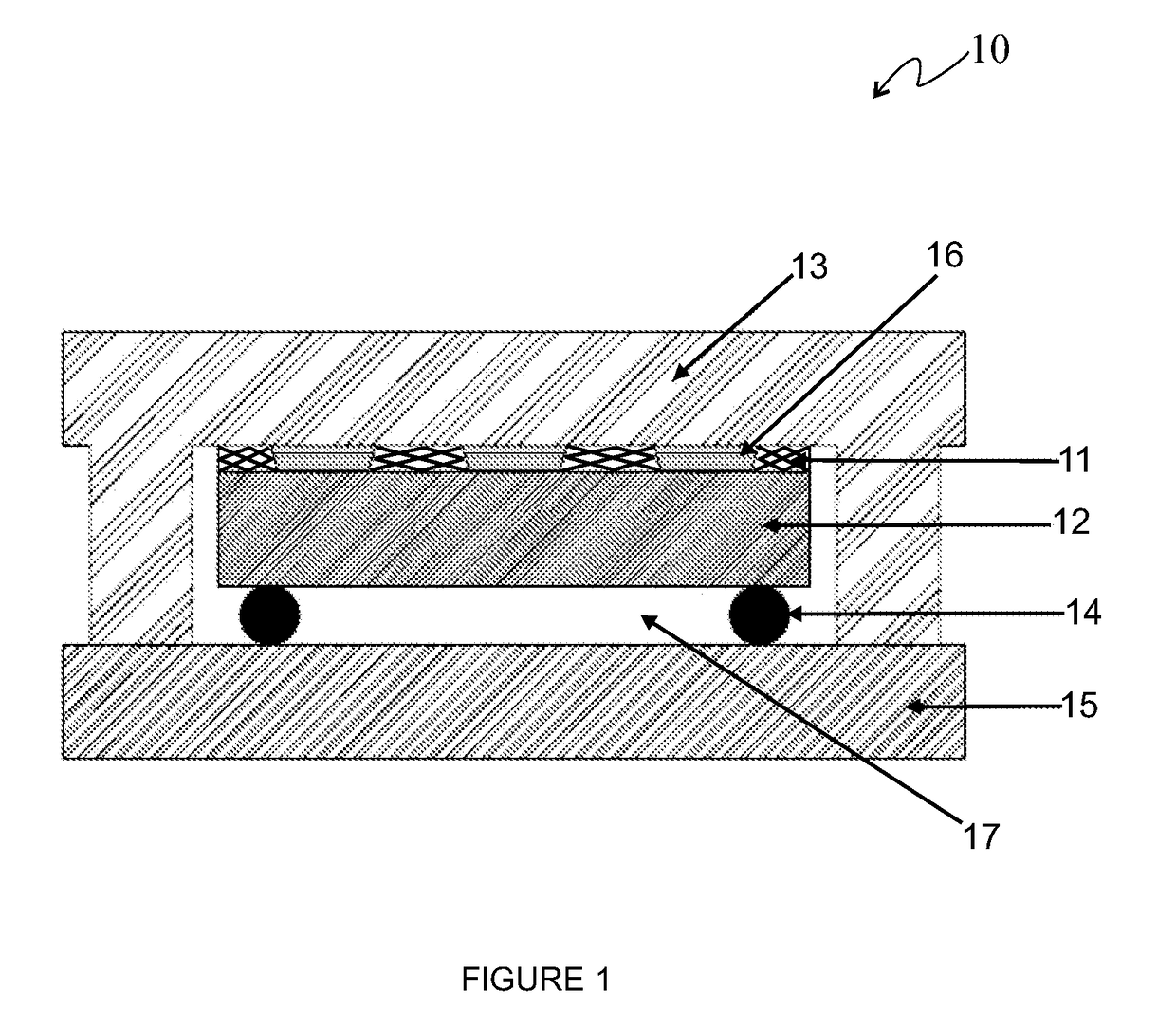

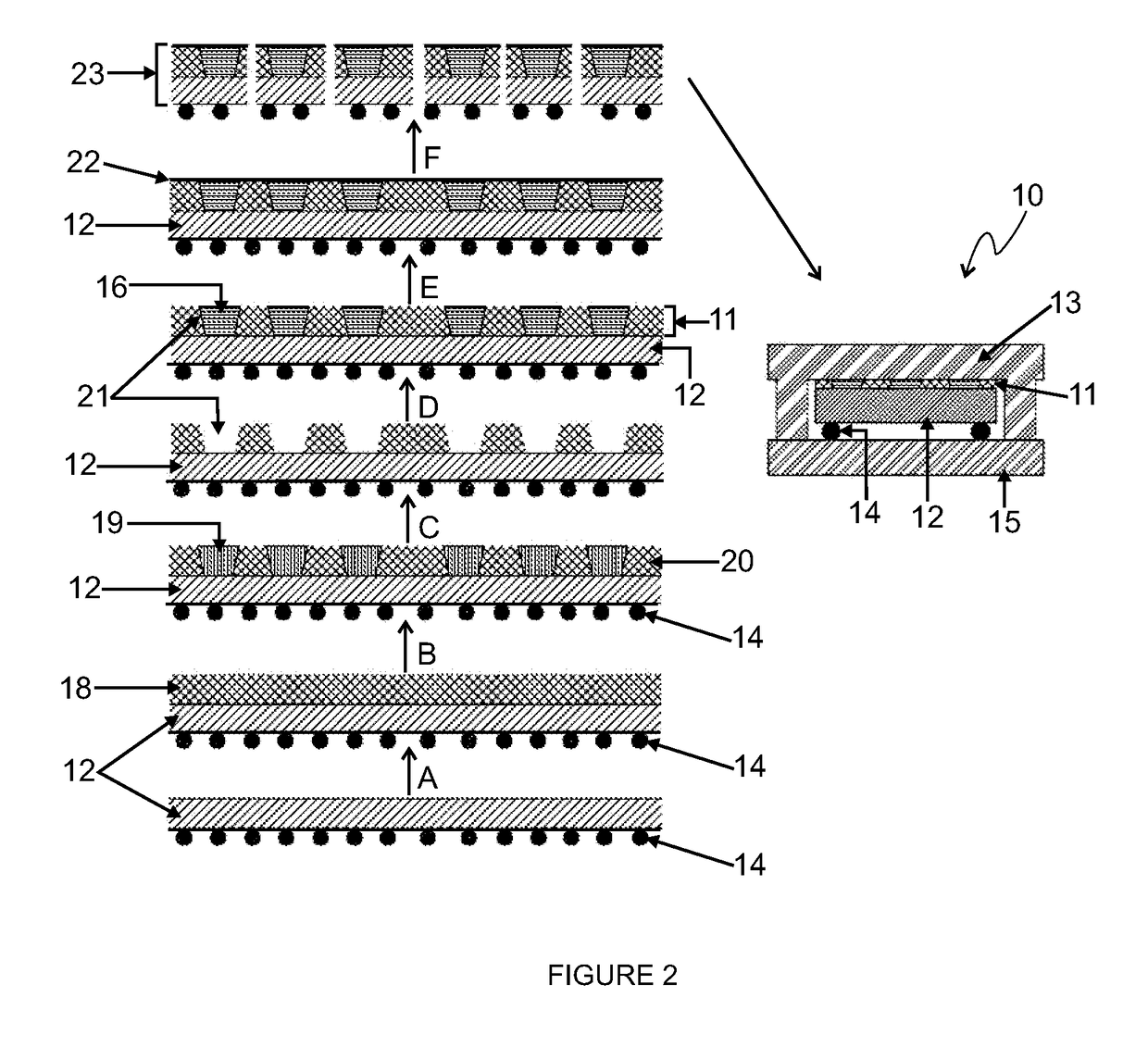

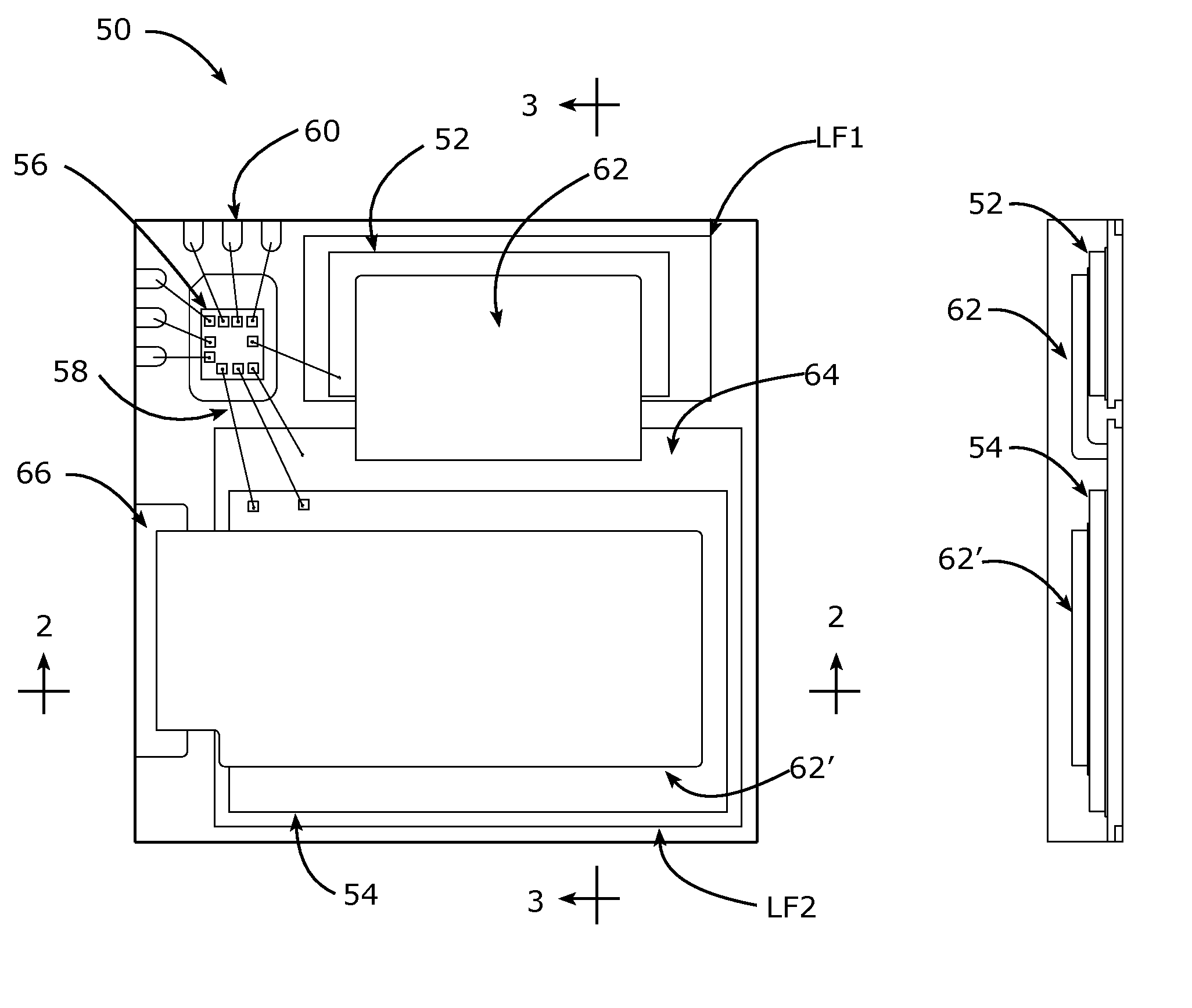

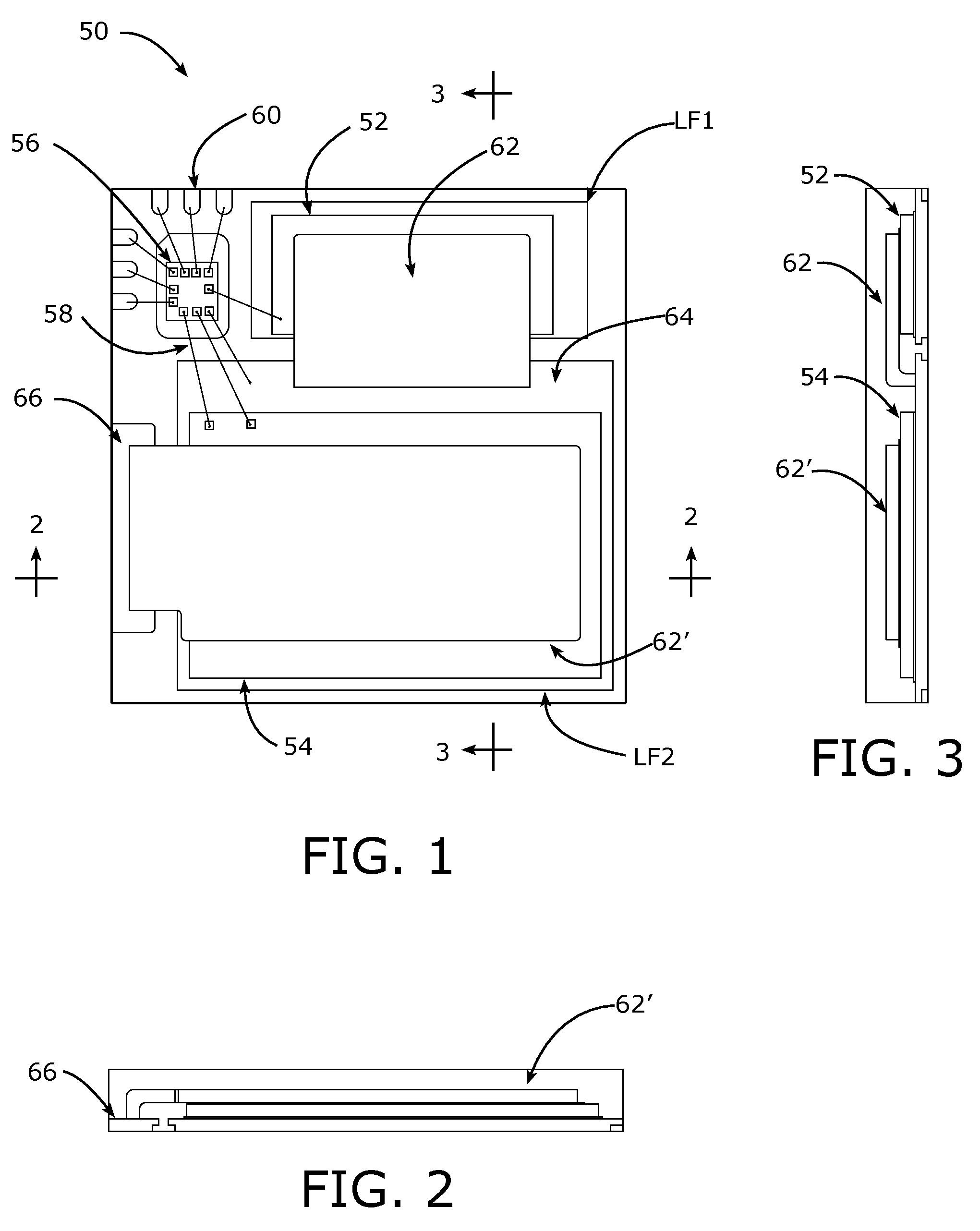

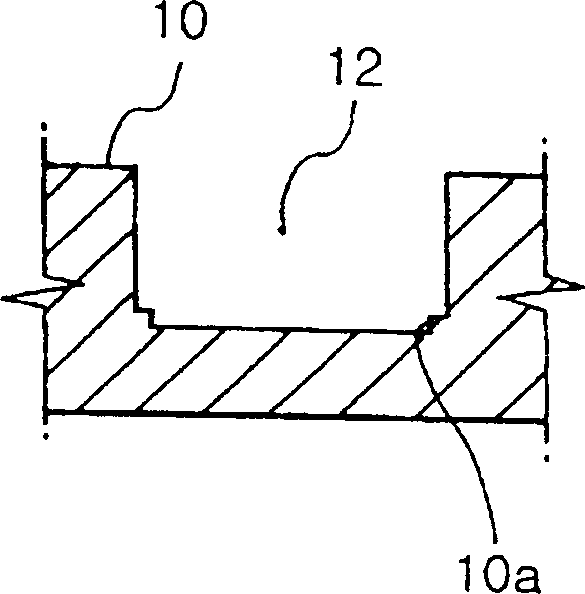

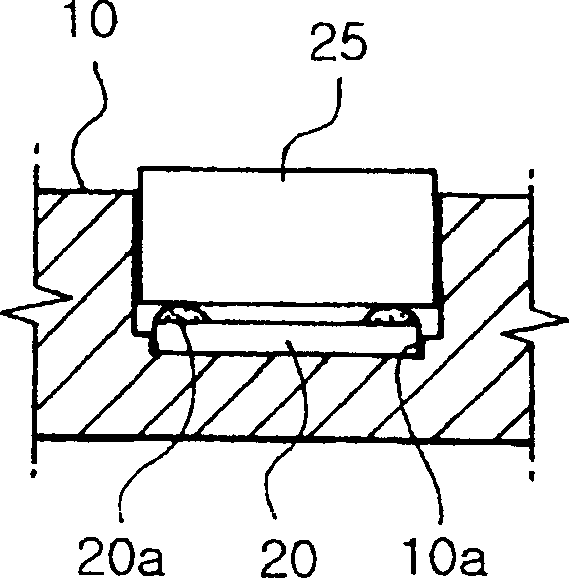

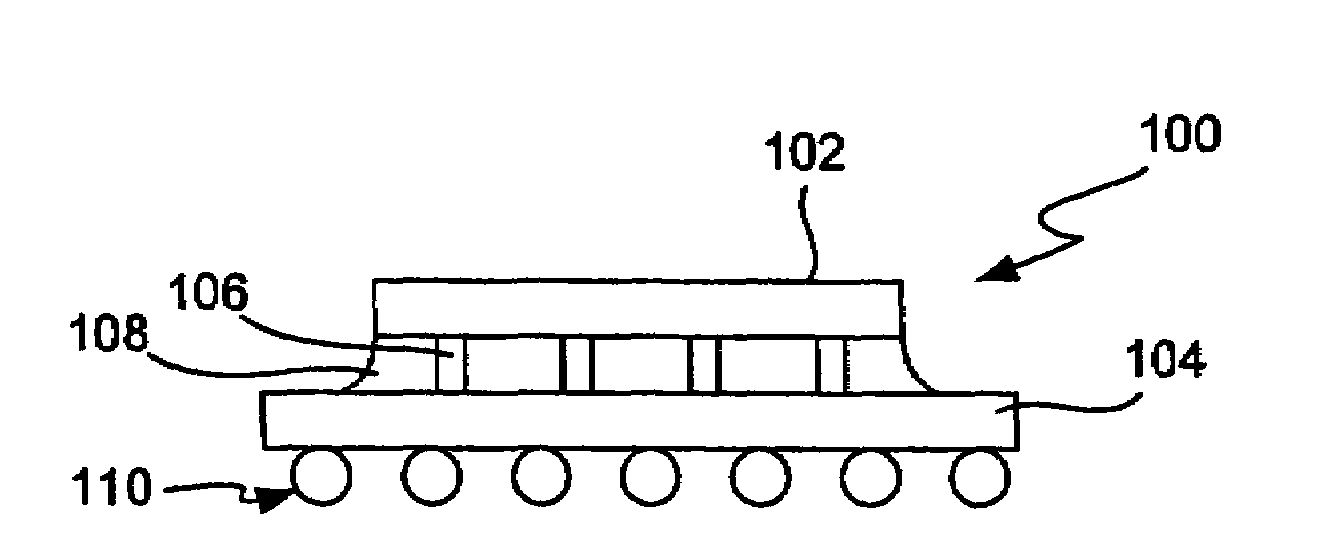

Self-Aligning Structures and Method For Integrated Circuits

ActiveUS20090121331A1Increase wettable surface areaMinimize overall surface areaSemiconductor/solid-state device detailsSolid-state devicesCurrent loadAdhesive

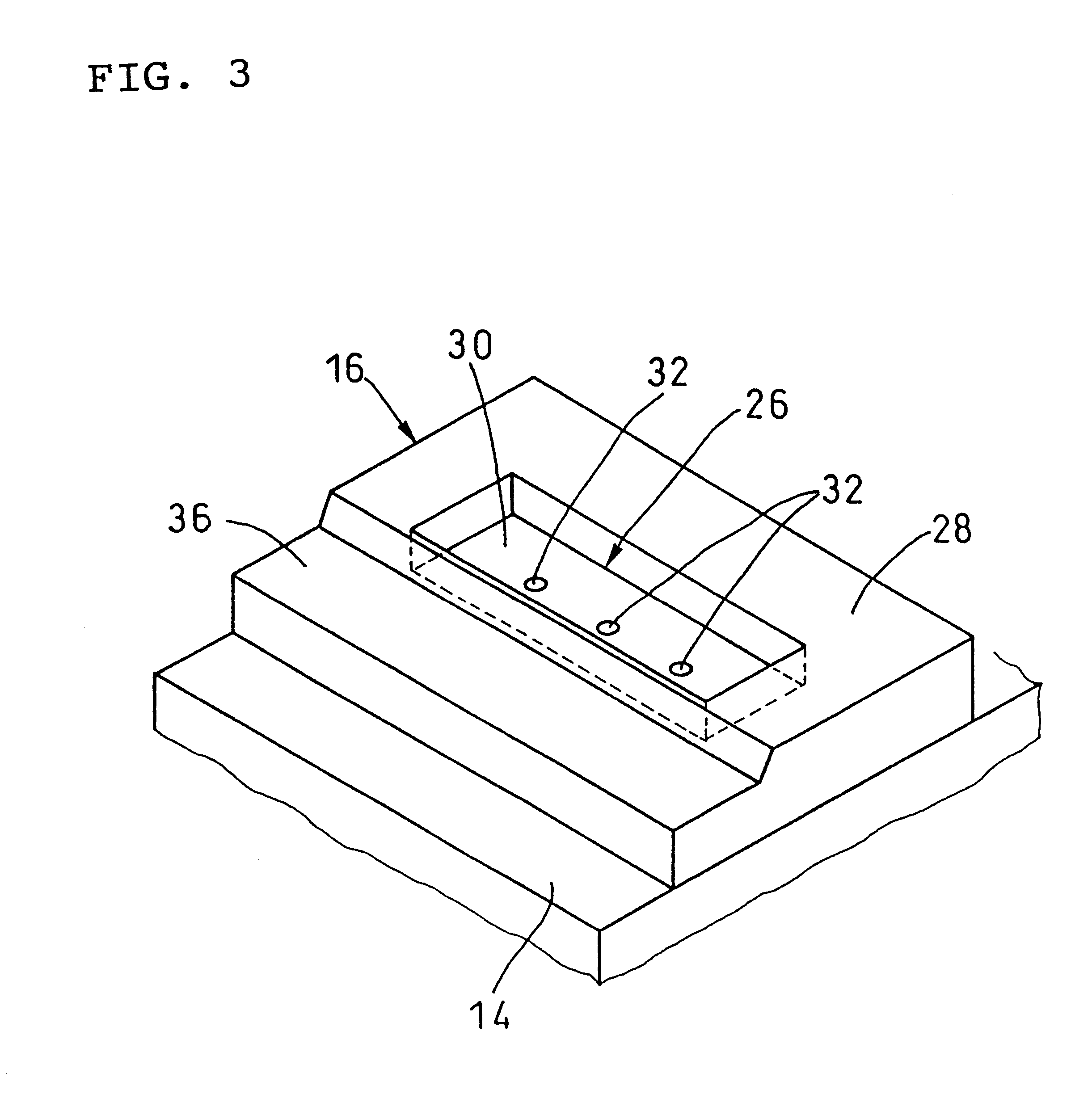

A lead frame having a die thereon connects a high current conductive area on the die to a lead frame contact using a copper clip that includes a structure portion that is received with a recess-like “tub” formed in the lead frame contact. In the preferred embodiment, a lead frame structure fabricated by etching includes at least one contact that is a half-etch recess or “tub” that receives one end of the clip structure and is retained in the tub by solder paste or an adhesive. The end of the clip that is received in the tub is held in place during subsequent handling until the clip and leadframe undergo solder reflow to effect an electrical connection sufficient to handle the current load and a also effect a reliable mechanical connection. One or more solder-holding pockets are formed a surface portion of the tub and / or the end of the clip that is received in the tub so that a volume of liquefied solder formed during the solder reflow step will effect alignment of any mis-aligned parts by “drawing” at least one of the parts against a “stop” surface.

Owner:INTERSIL INC

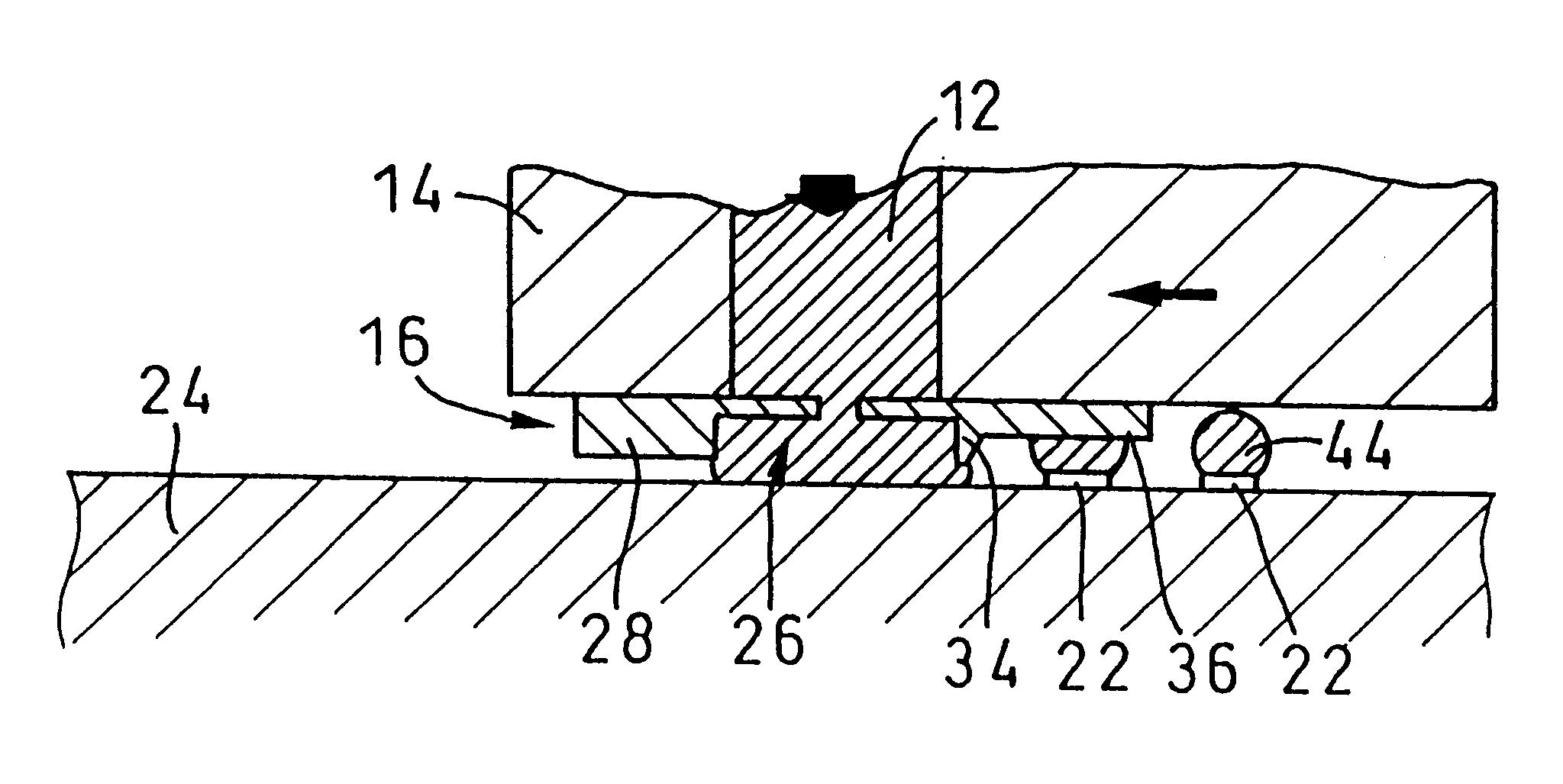

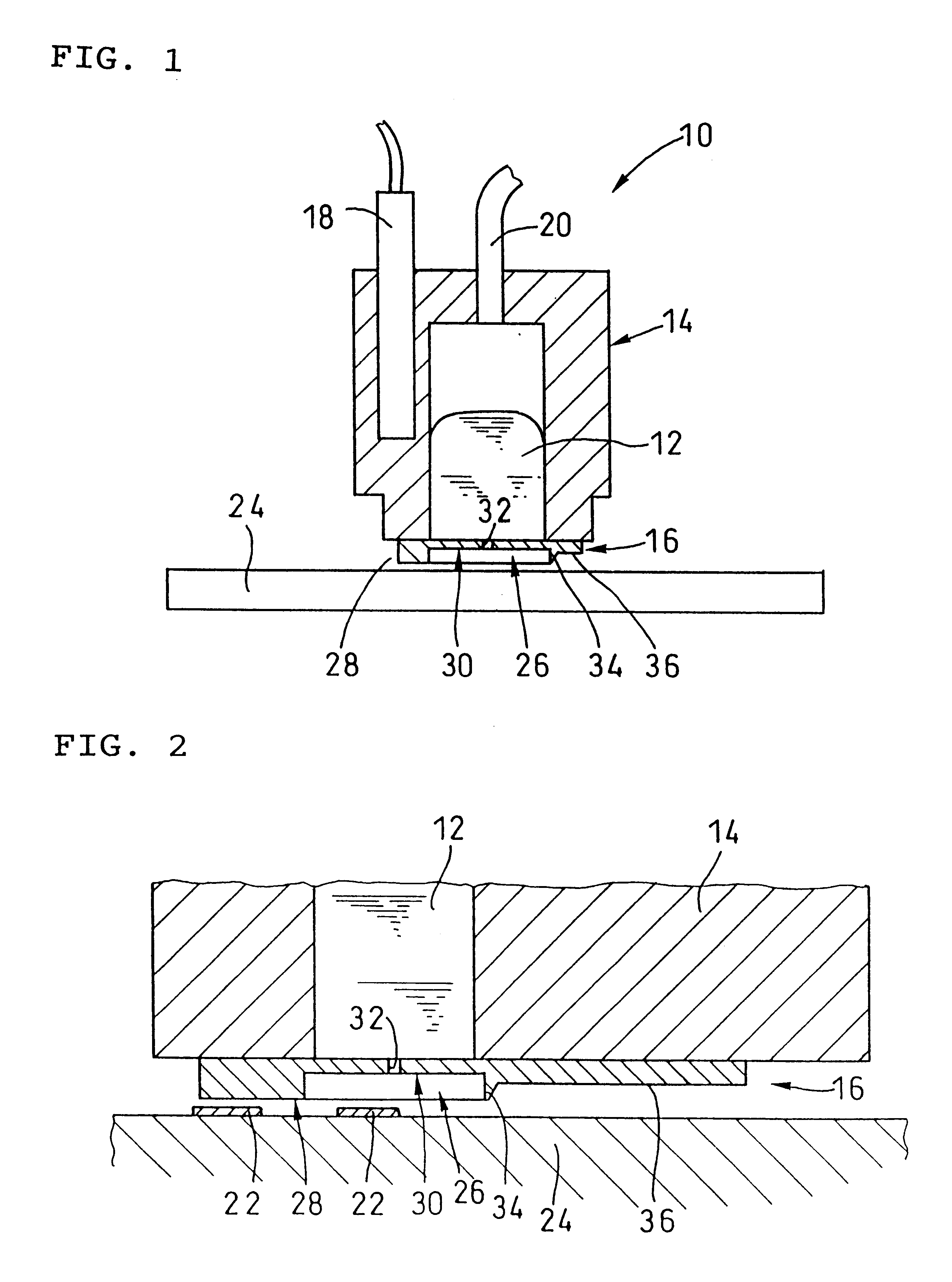

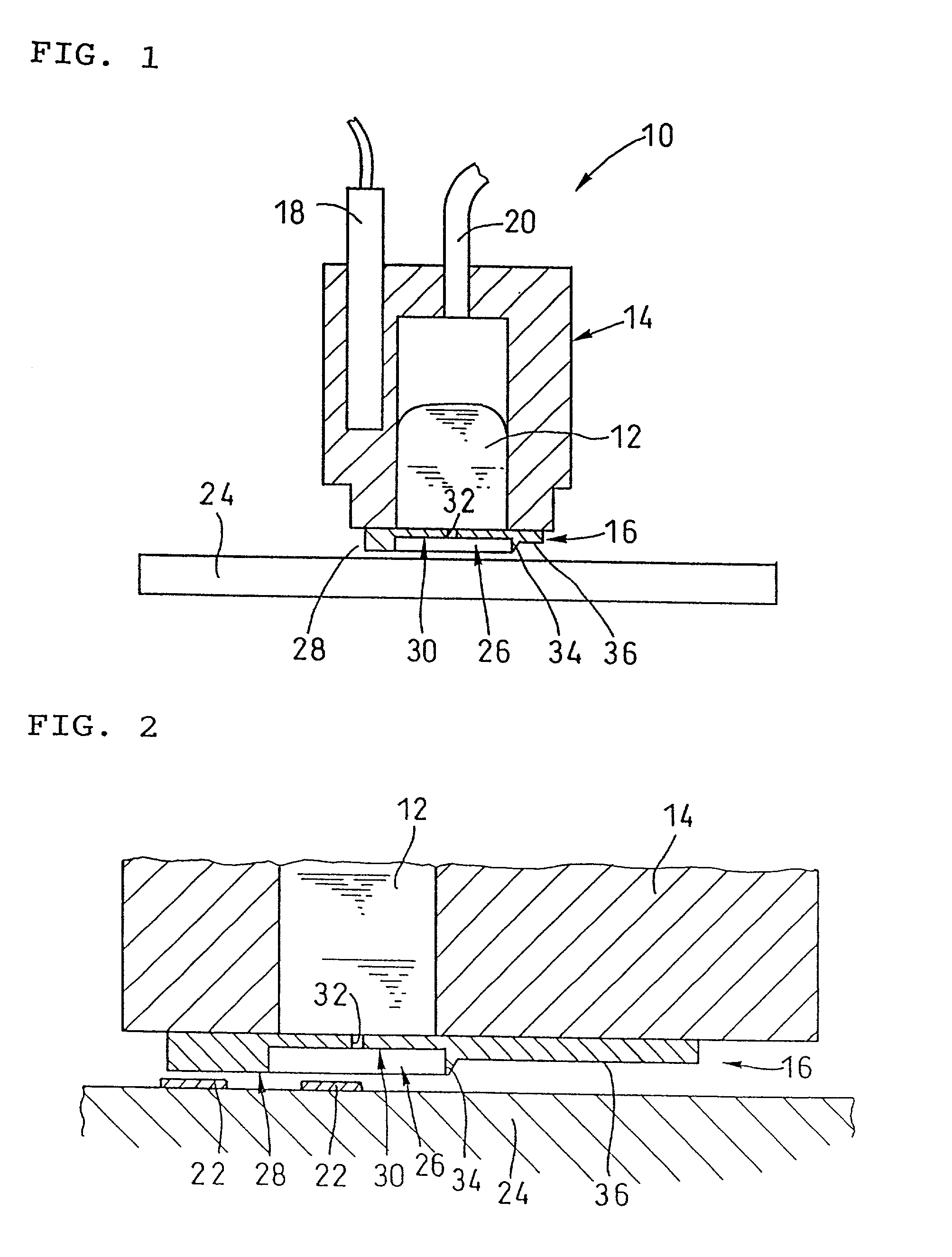

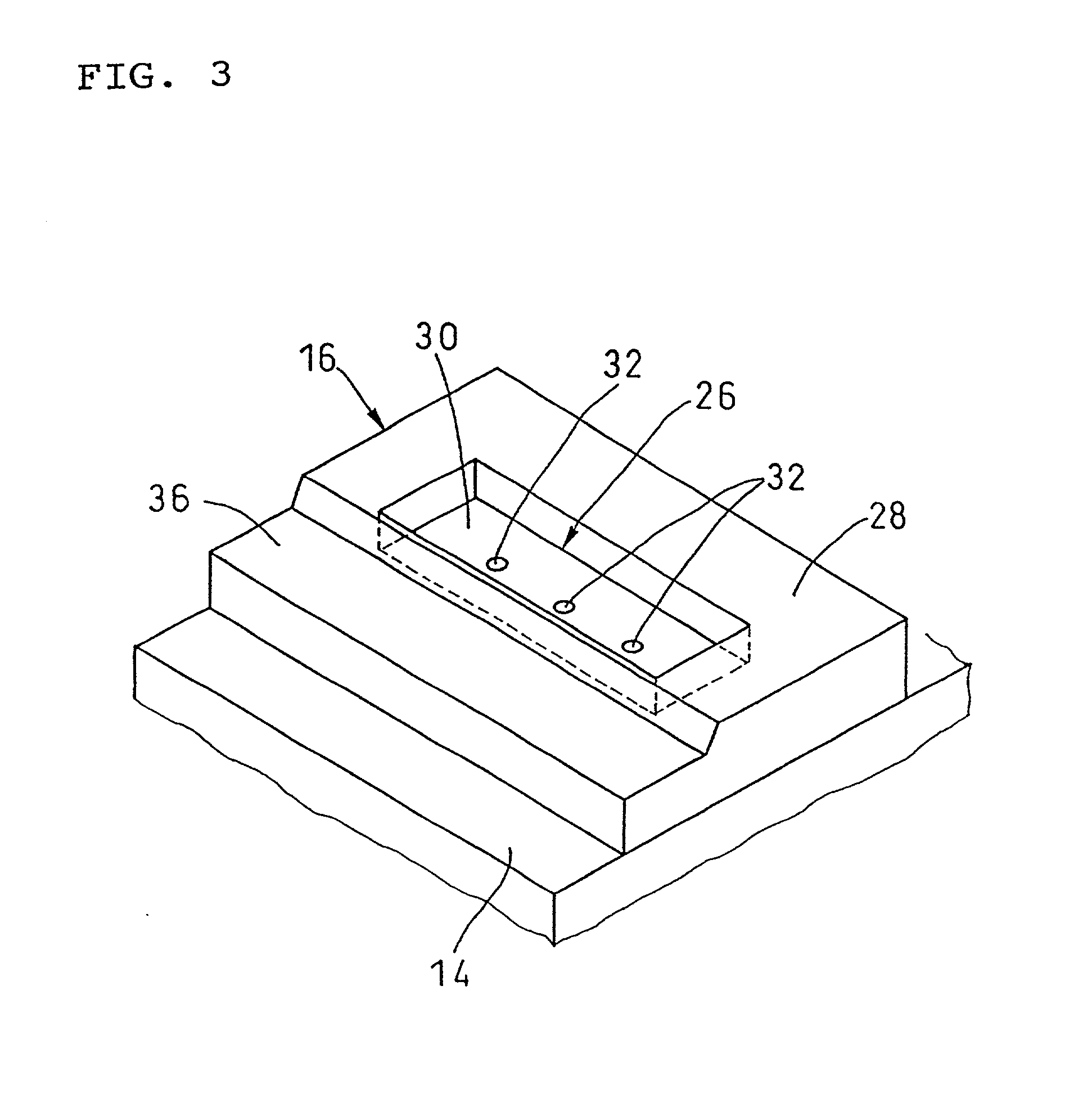

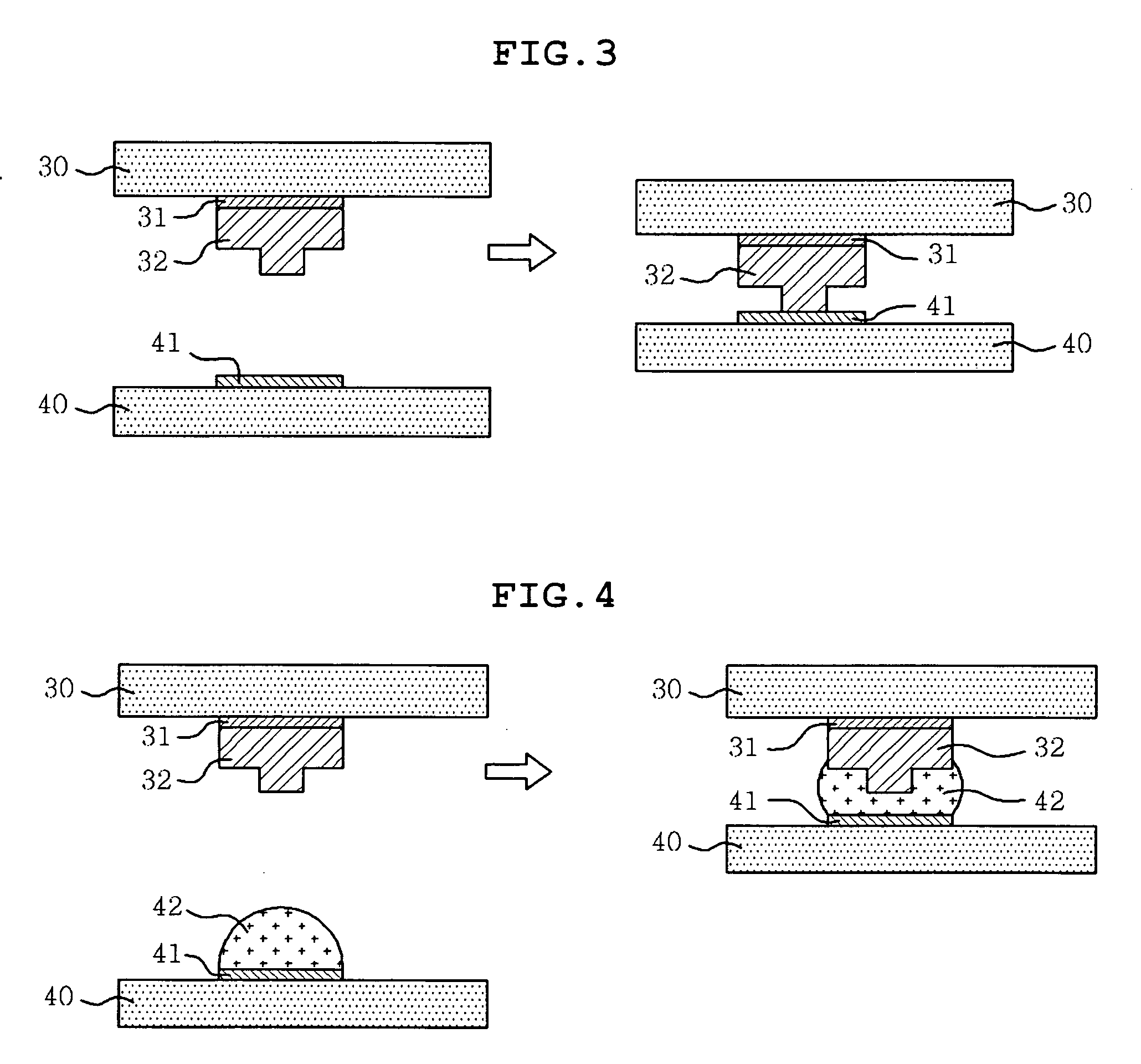

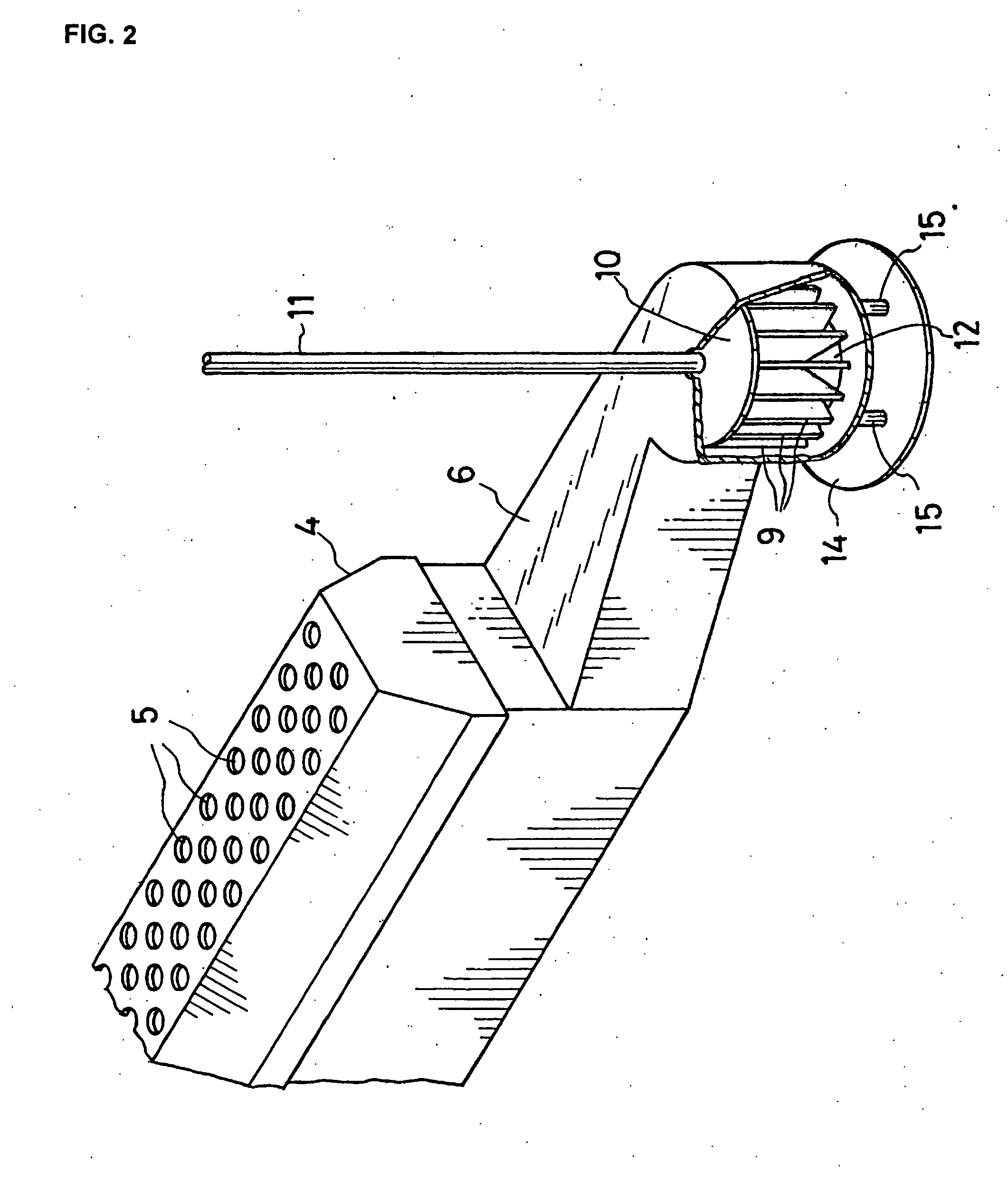

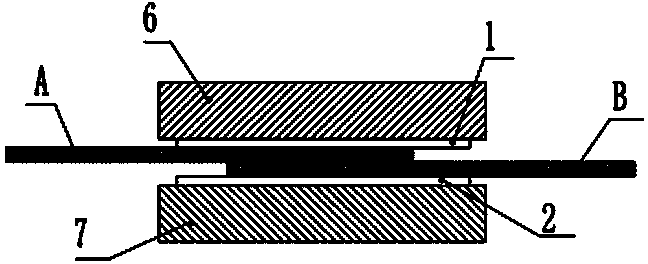

Solder bump forming method and apparatus

InactiveUS6273328B1Easy temperature controlPrinted circuit assemblingSemiconductor/solid-state device manufacturingInternal pressureEngineering

A bump forming apparatus comprises a container for retaining therein a solder melt, a solder forming member having a side wall portion and a ceiling portion which form, above a substrate's flat surface, a chamber for receiving therein the solder melt. The solder forming member also includes a height regulator portion provided on an exterior of the side wall portion and having a flat surface for restricting the height of the solder melt during formation. Heating means for heating the solder melt may also be provided. A hole in the solder forming portion allows solder melt to flow from the container to the chamber. Pressurizing means for pressurizing the solder melt in the container to thus expedite passage of solder melt into the chamber of the forming member may be used. Depressurization means for reducing the inside pressure of the container to cause the unused metal to return from the chamber into the container may also be used.

Owner:VEECO INSTR

High-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux

ActiveCN105127618AHigh activityStrong ability to remove filmWelding/cutting media/materialsSoldering mediaPotassium borohydridePotassium fluoride

The invention discloses a high-strength and high-toughness composite silver solder ring for in-situ synthesis of soldering flux. The high-strength and high-toughness composite silver solder ring comprises a silver solder ring body of a hollow structure. The silver solder ring body is formed by winding composite silver solder formed by a silver solder pipe and a flux core with which the silver solder pipe is filled. The flux core is prepared from boron micro-powder, sodium borohydride or potassium borohydride, potassium fluoborate, boric anhydride or boric acid, potassium fluoride or sodium fluoride or lithium fluoride, potassium bifluoride and potassium fluoroaluminate according to a certain proportion. The purpose of in-situ synthesis of the soldering flux through the boron micro-powder in the flux core and metal elements in the silver solder pipe is achieved, so that the content of the flux core is reduced, and when the content of the flux core is low, the solder still achieves good brazing manufacturability; meanwhile, due to the fact that the wall thickness of the solder pipe is increased, good toughness and high stiffness are achieved, the processing performance of the solder is greatly improved, the minimum diameter can be reduced to 0.8 mm, the solder can be easily wound into the solder ring with the intermediate diameter below 6 mm, and application and popularization of the automatic brazing process are facilitated.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

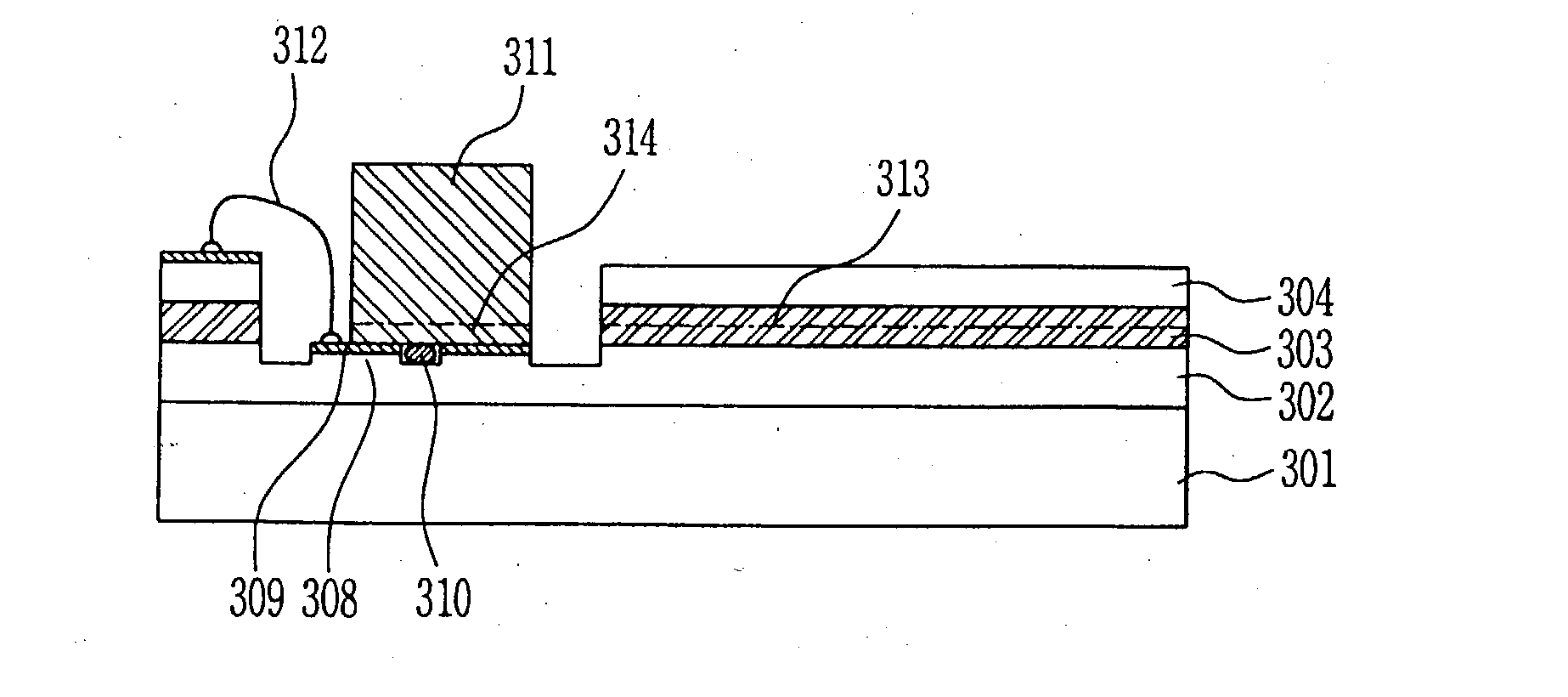

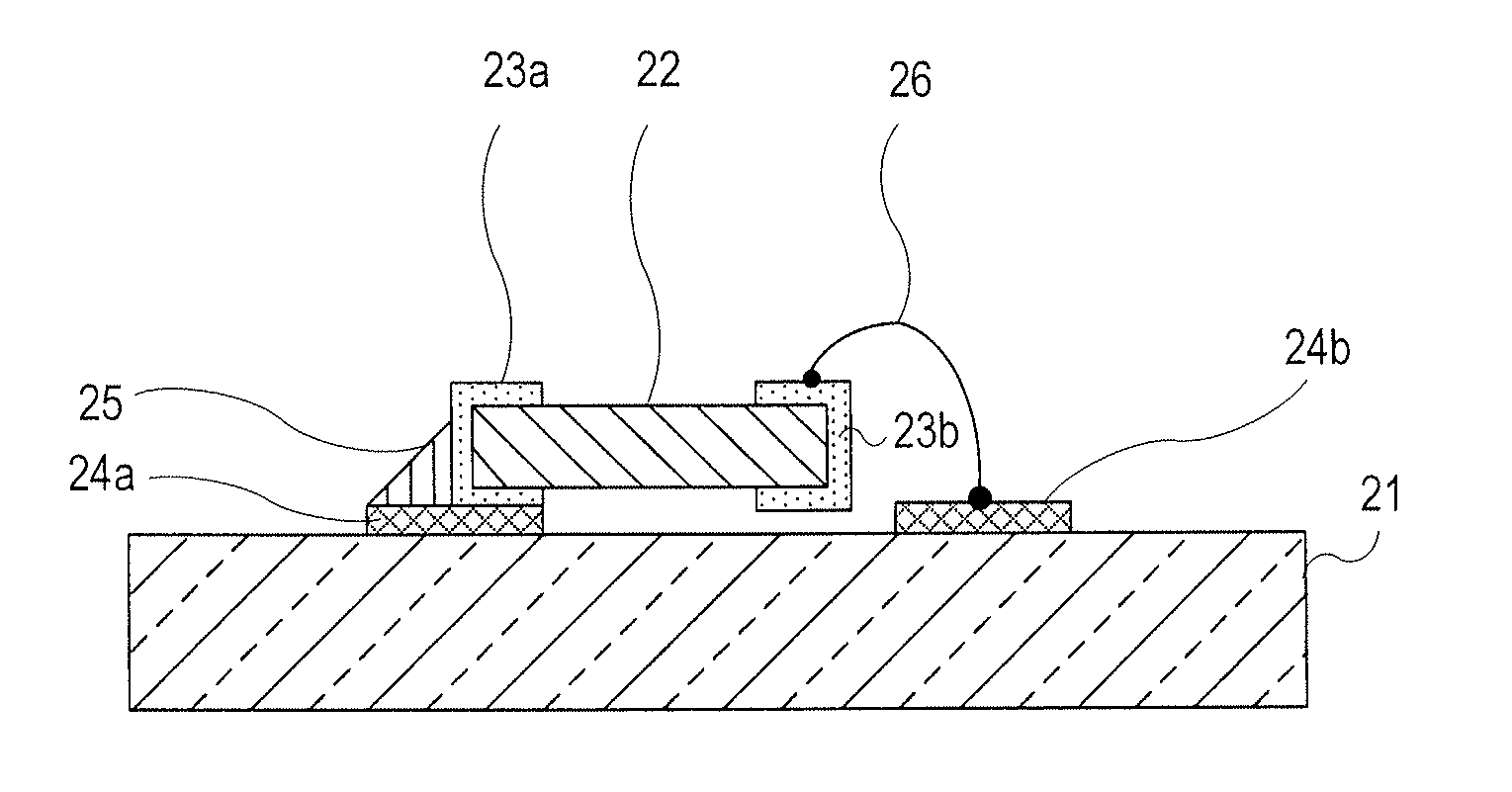

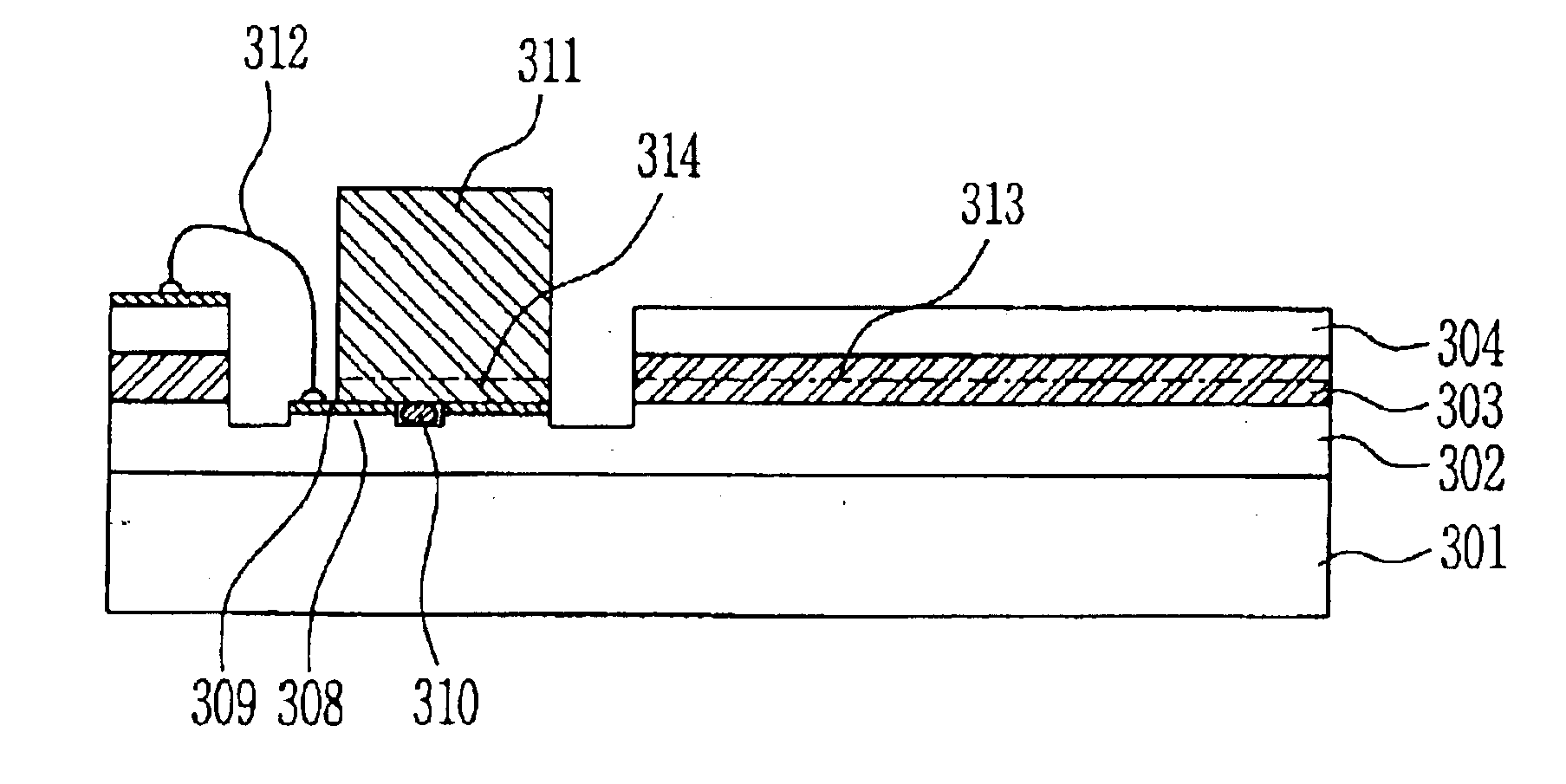

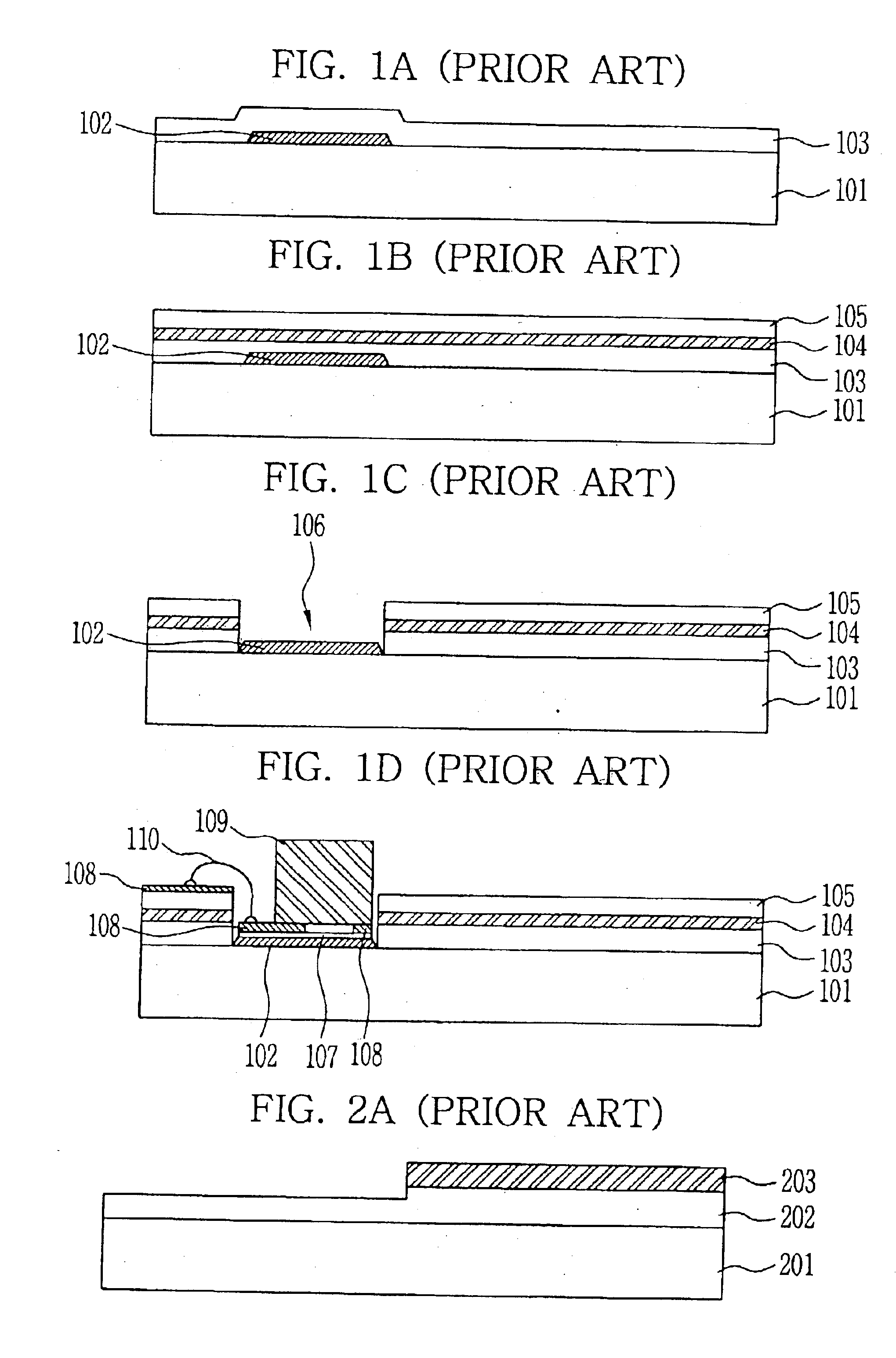

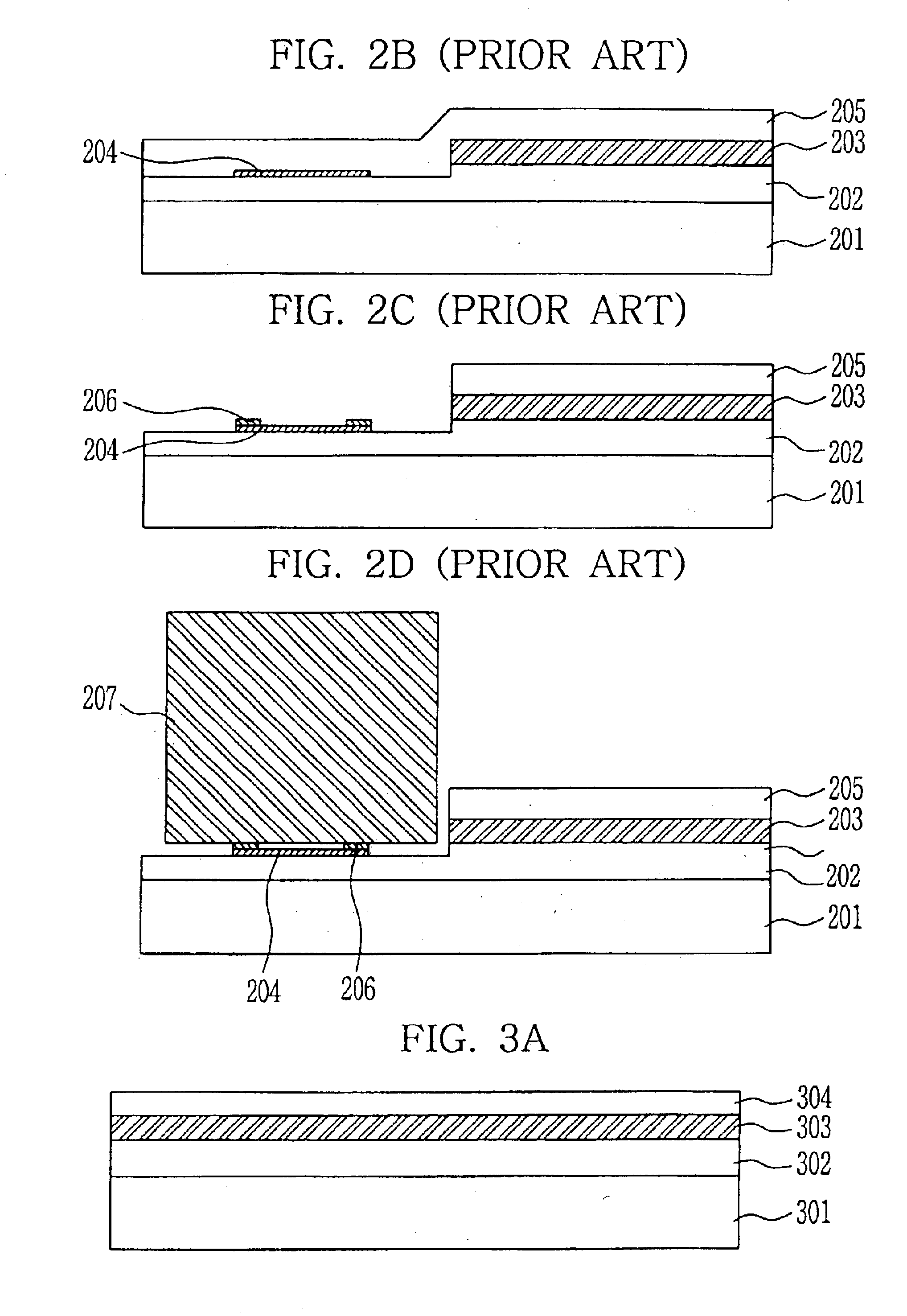

Optical waveguide platform and method of manufacturing the same

An optical waveguide platform and a method of manufacturing the same are disclosed. The optical waveguide platform comprises an optical waveguide having a lower clad layer, a patterned core layer and an upper clad layer which are laminated on one area of said substrate sequentially, a terrace formed by patterning said lower clad layer, on the other area of said substrate, a metal and a solder formed on said terrace and an optical device mounted on said terrace containing said metal and said solder. According to the present invention, the optical waveguide platform can be manufactured in a simple method without damaging the optical waveguide and the manufacturing cost thereof can be reduced.

Owner:ELECTRONICS & TELECOMM RES INST

Solder bump forming method and apparatus

InactiveUS20010010324A1Type is limitedEasy to separatePrinted circuit assemblingWelding/cutting auxillary devicesInternal pressureEngineering

A bump forming apparatus comprises a container for retaining therein a solder melt, a solder forming member having a side wall portion and a ceiling portion which form, above a substrate's flat surface, a chamber for receiving therein the solder melt. The solder forming member also includes a height regulator portion provided on an exterior of the side wall portion and having a flat surface for restricting the height of the solder melt during formation. Heating means for heating the solder melt may also be provided. A hole in the solder forming portion allows solder melt to flow from the container to the chamber. Pressurizing means for pressurizing the solder melt in the container to thus expedite passage of solder melt into the chamber of the forming member may be used. Depressurization means for reducing the inside pressure of the container to cause the unused metal to return from the chamber into the container may also be used.

Owner:VEECO INSTR

Selective deposition of solder ball contacts

InactiveUS20010014524A1Solid-state devicesSemiconductor/solid-state device manufacturingContact padSolder ball

Methods of forming solder ball contacts having dimensions of approximately 2.5 microns in diameter for use in C4-type connections. The methods form solder ball contacts using selective deposition of solder on metal contact pads of a device. The metal contact pads have exposed portions at the bottom of through holes. The through holes define the dimensions of the exposed portions of the metal contact pads, and serve to limit the dimensions of the resulting solder contact by limiting the area upon which deposition preferentially occurs. Subsequent reflow of the deposited solder forms a solder ball contact. Various devices, modules, systems and other apparatus utilizing such methods of forming solder ball contacts.

Owner:MICRON TECH INC

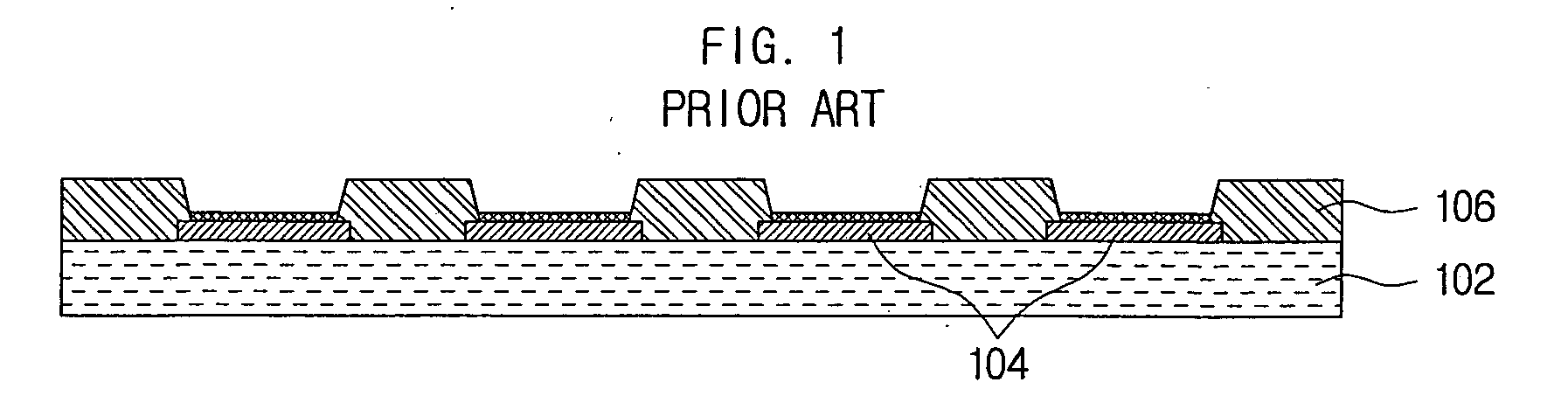

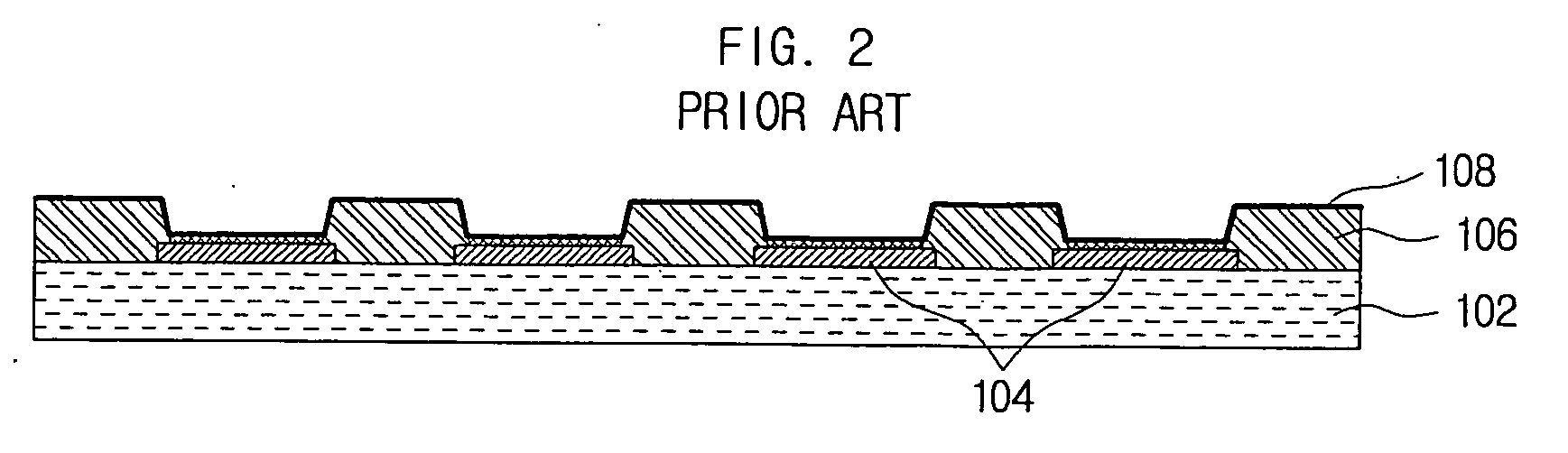

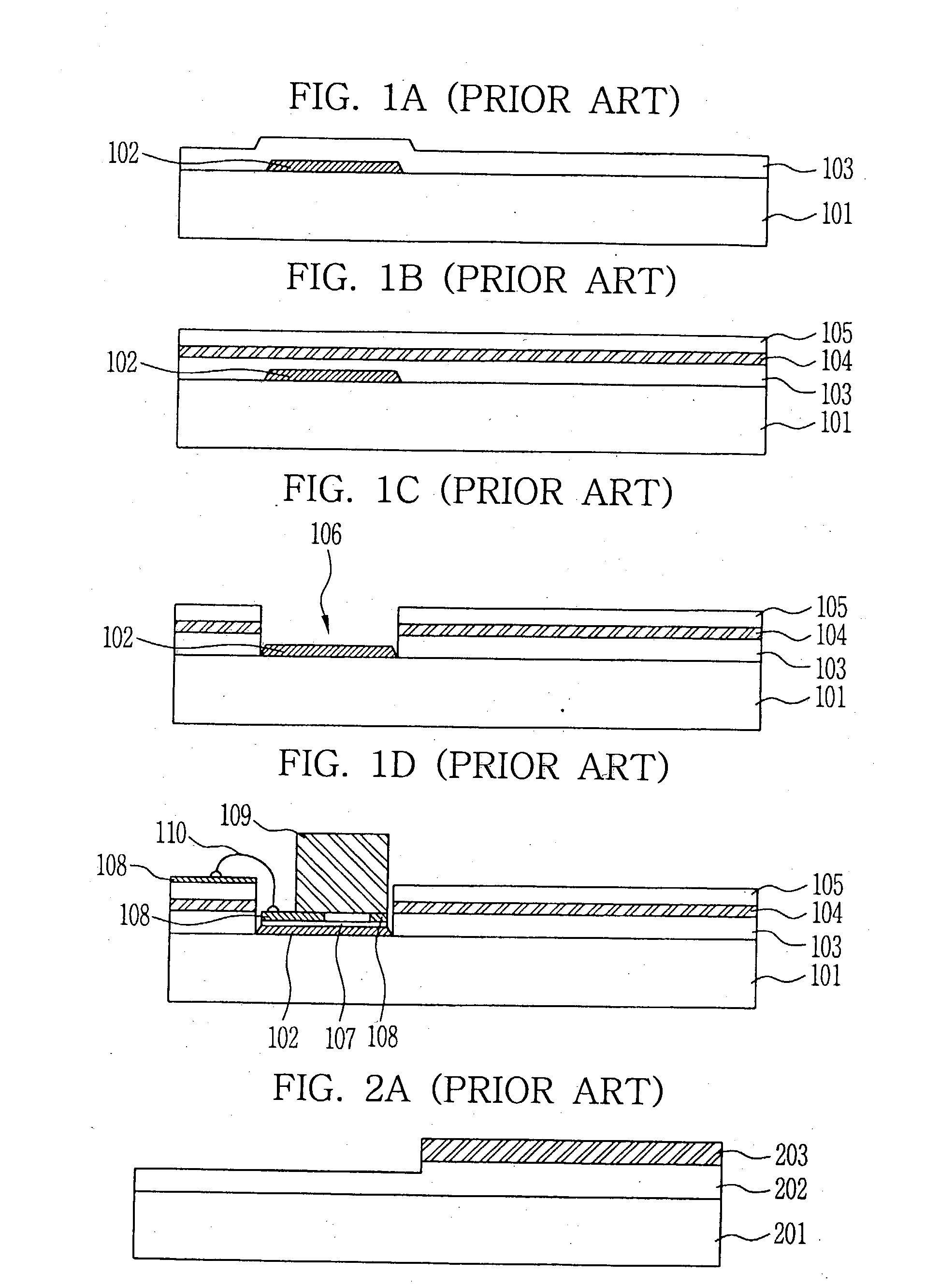

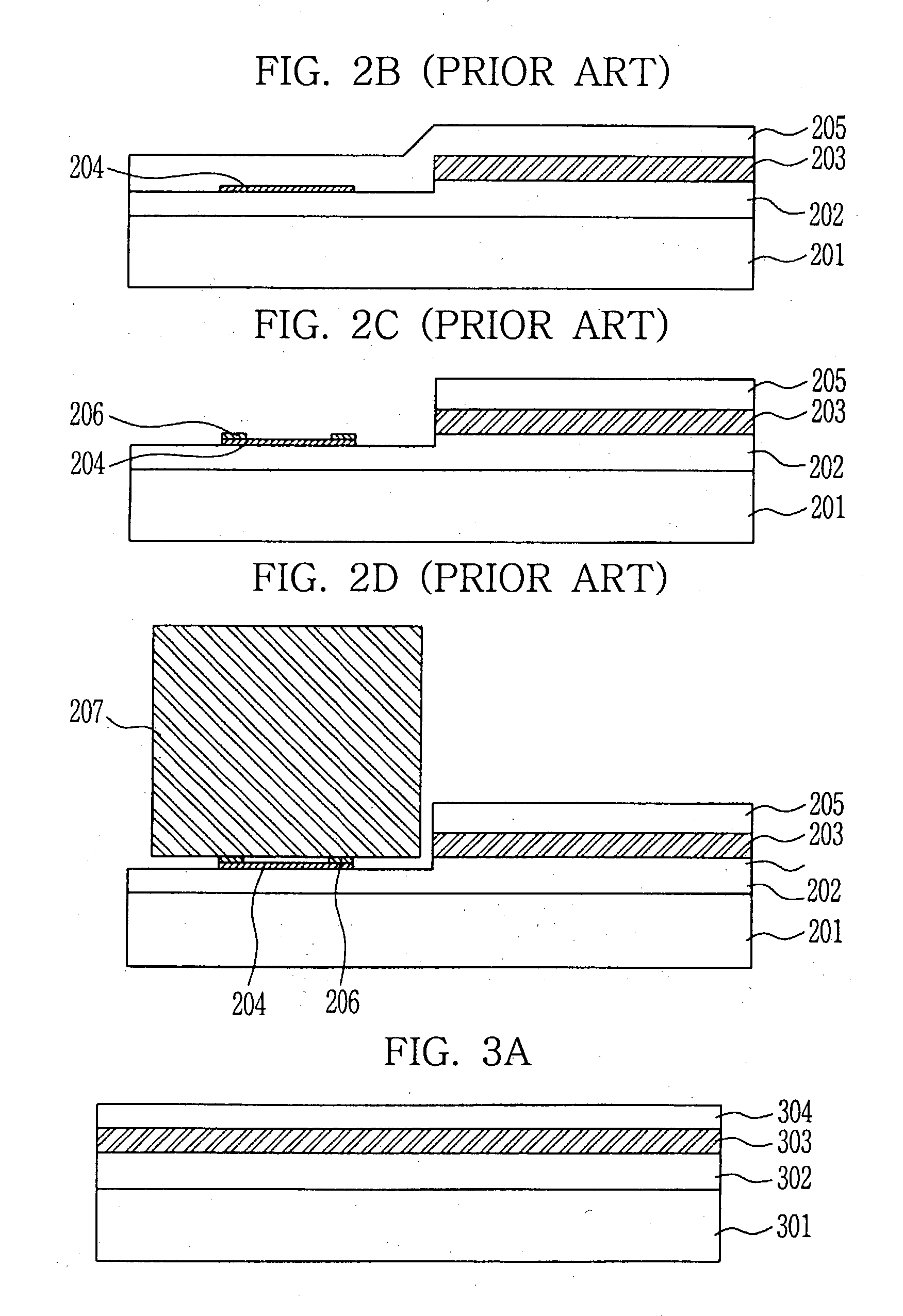

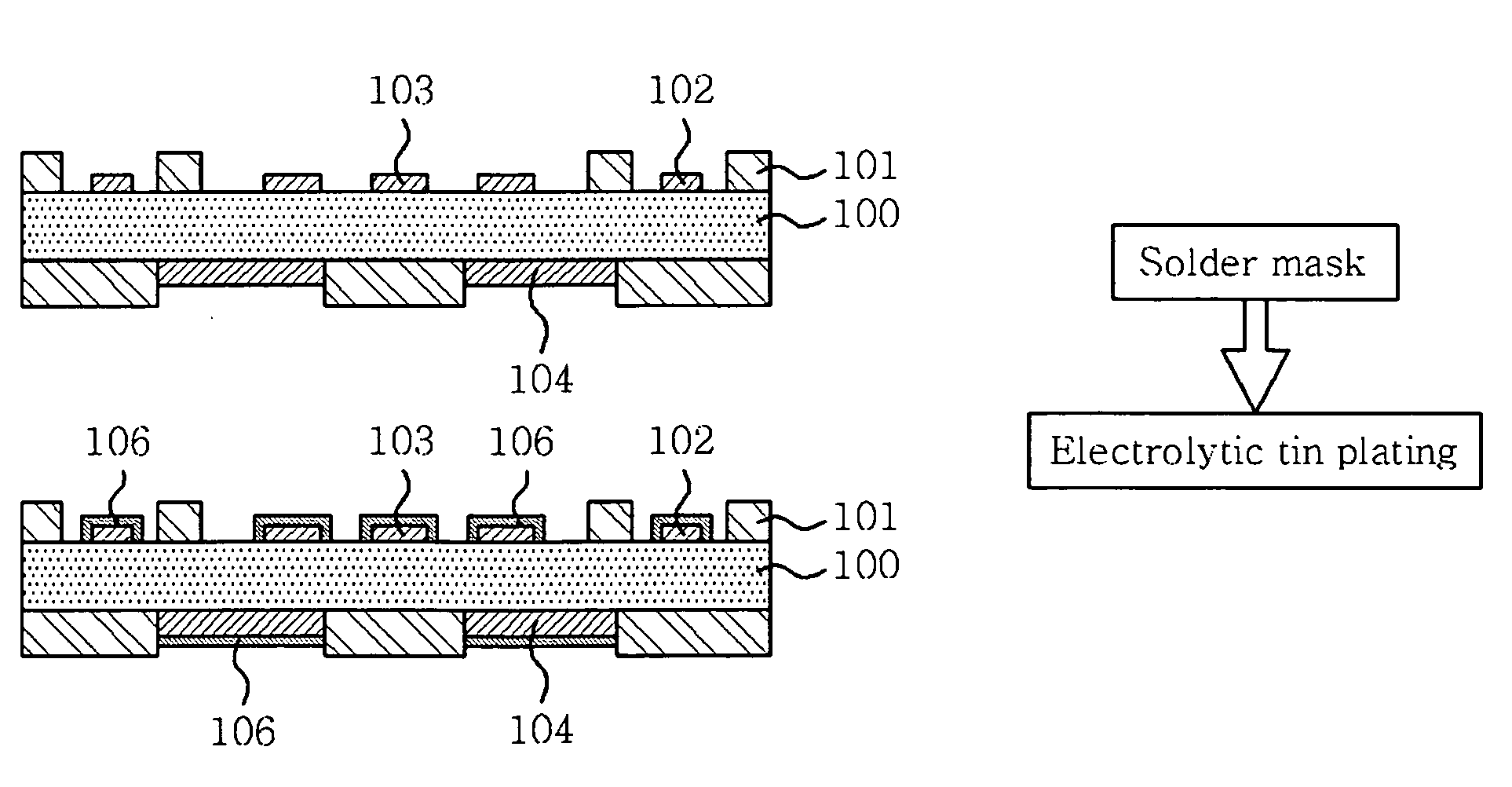

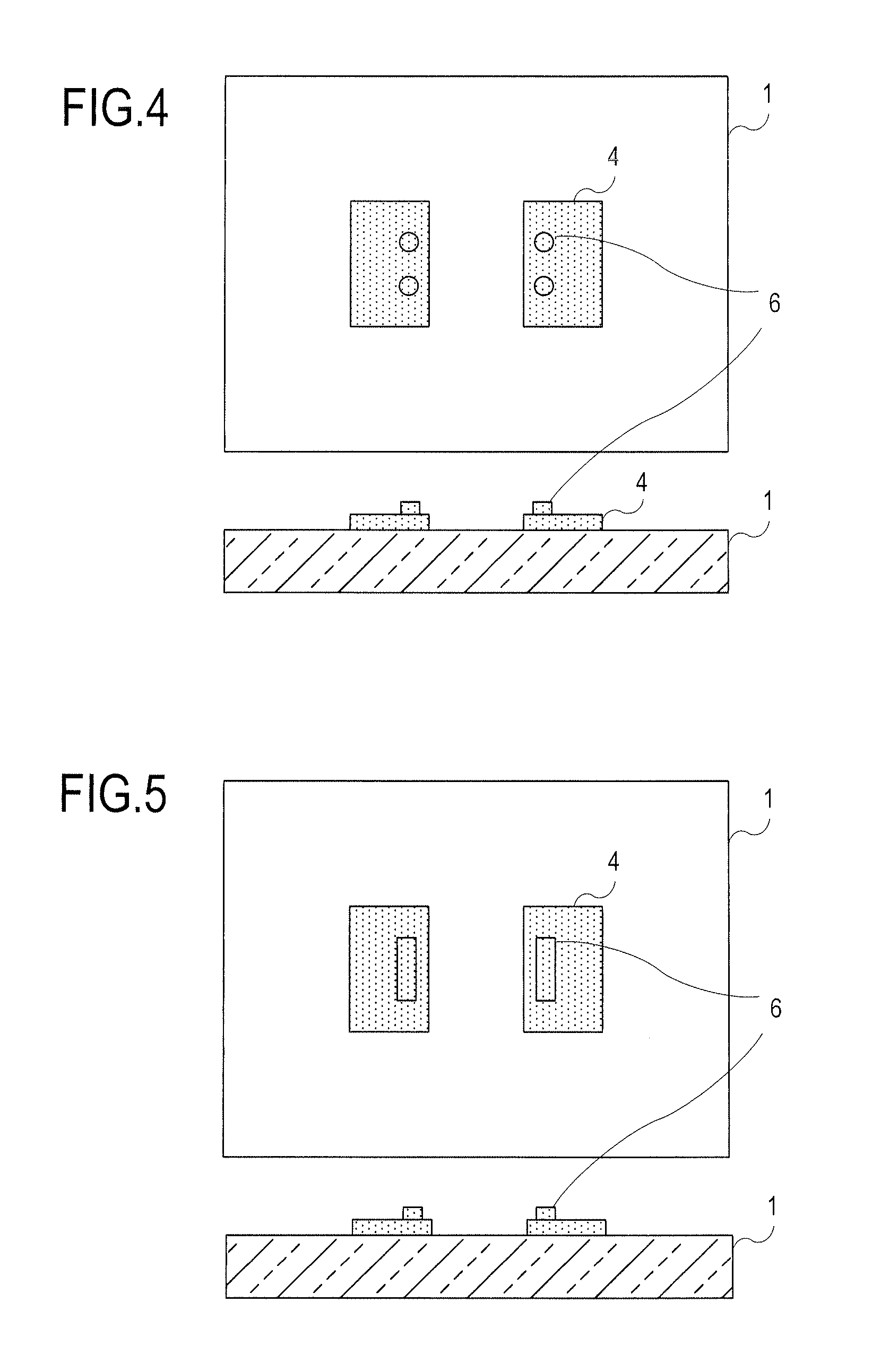

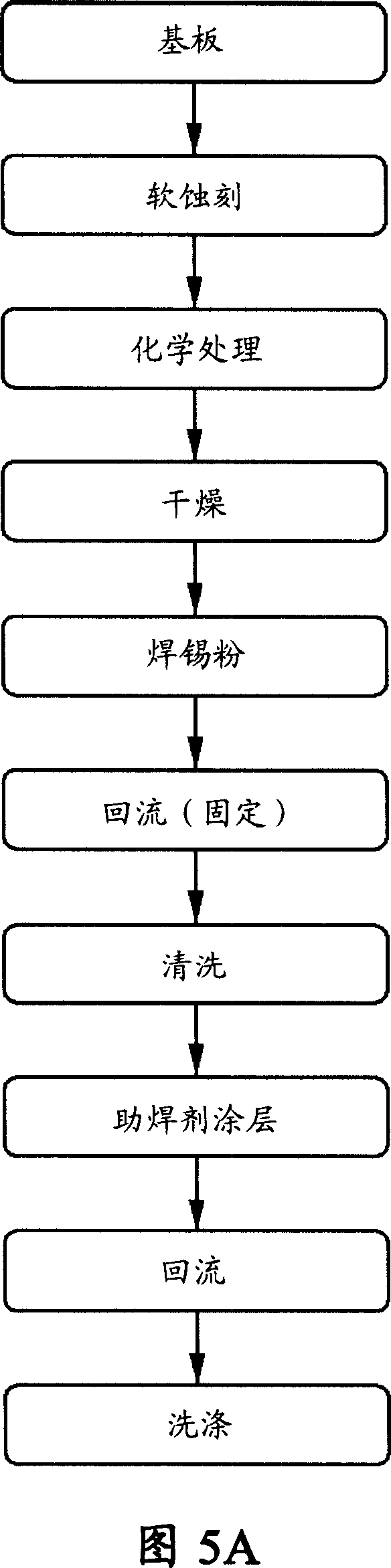

Printed circuit board for semiconductor package and method of manufacturing the same

InactiveUS20070170586A1Reduce manufacturing costFine pitchSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor packageAlloy

Disclosed are a printed circuit board for a semiconductor package and a method of manufacturing the same. Specifically, a printed circuit board for a semiconductor package includes predetermined circuit patterns, having a wire bonding portion and a bump portion for mounting a semiconductor and a soldering portion for connection to external parts, in which the bump portion has a pre-solder formed using a tin or tin alloy electroplating process. According to this invention, the pre-solder, which is formed by reflow using an electroplating process, permits easy increase of the height thereof to thus enhance bondability and underfilling capability, may be formed to a desired thickness by controlling a plating thickness, and furthermore, may be applied to a fine pitch through a masking process.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

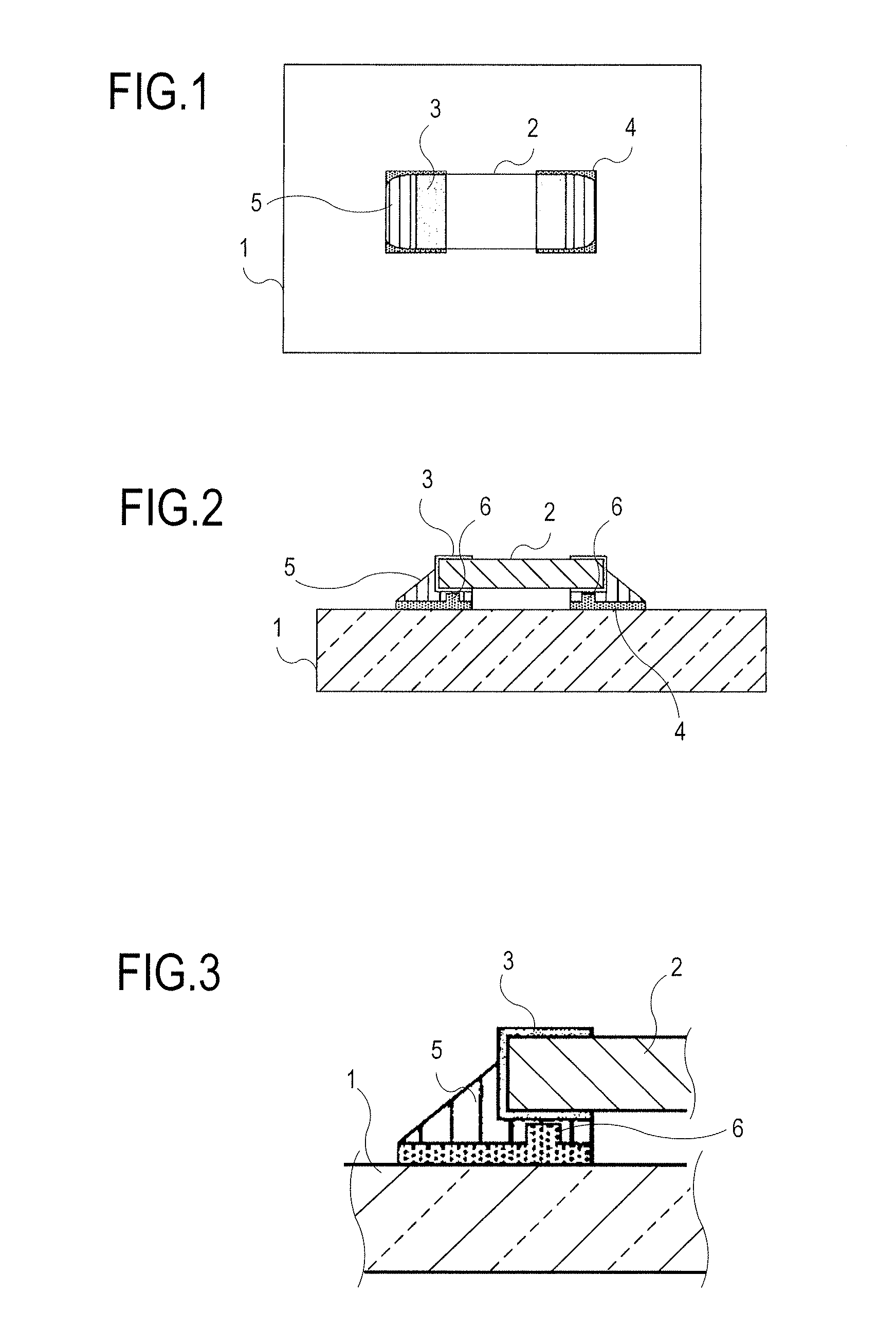

Oscillator

InactiveUS20120200366A1Suppression problemLow costPrinted circuit assemblingImpedence networksElectronic componentAdhesion strength

An oscillator that can suppress a solder crack caused by a temperature change by a simple structure at low cost and improve heat cycle resistance performance is provided. The oscillator includes an epoxy resin board and an electronic component mounted on the board. Two-terminal electrode patterns are formed on the board, and connected to terminal electrodes of the electronic component by solder. A projection is formed on each of the electrode patterns at a part connected to a corresponding terminal electrode to create a space between the terminal electrode and the electrode pattern, and the solder forms a fillet in the space. This contributes to enhanced adhesion strength of the solder.

Owner:NIHON DEMPA KOGYO CO LTD

Optical waveguide platform and method of manufacturing the same

InactiveUS6839497B2Increase speedSimple processCoupling light guidesOptical waveguide light guideWaveguideSolder form

An optical waveguide platform and a method of manufacturing the same are disclosed. The optical waveguide platform comprises an optical waveguide having a lower clad layer, a patterned core layer and an upper clad layer which are laminated on one area of said substrate sequentially, a terrace formed by patterning said lower clad layer, on the other area of said substrate, a metal and a solder formed on said terrace and an optical device mounted on said terrace containing said metal and said solder. According to the present invention, the optical waveguide platform can be manufactured in a simple method without damaging the optical waveguide and the manufacturing cost thereof can be reduced.

Owner:ELECTRONICS & TELECOMM RES INST

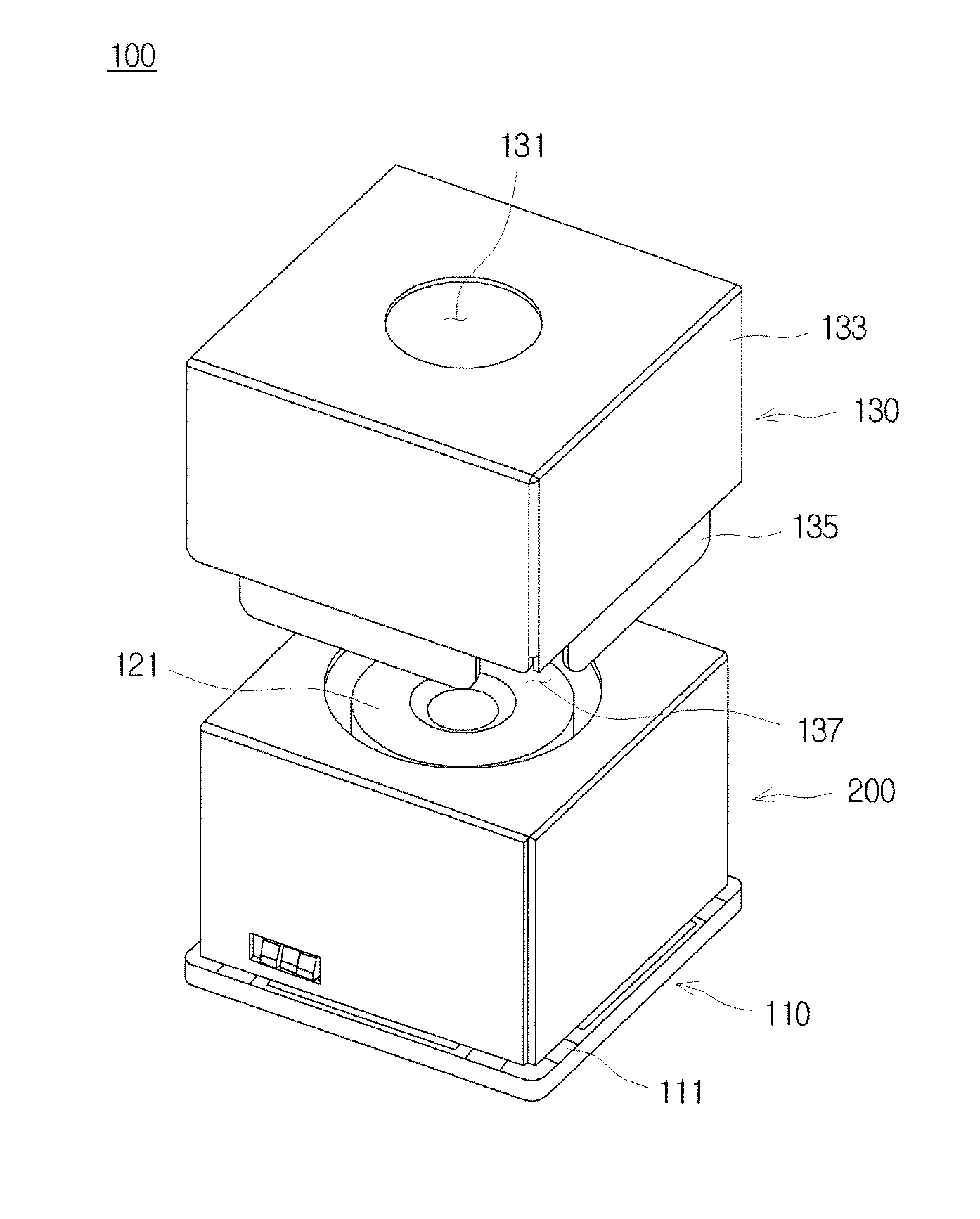

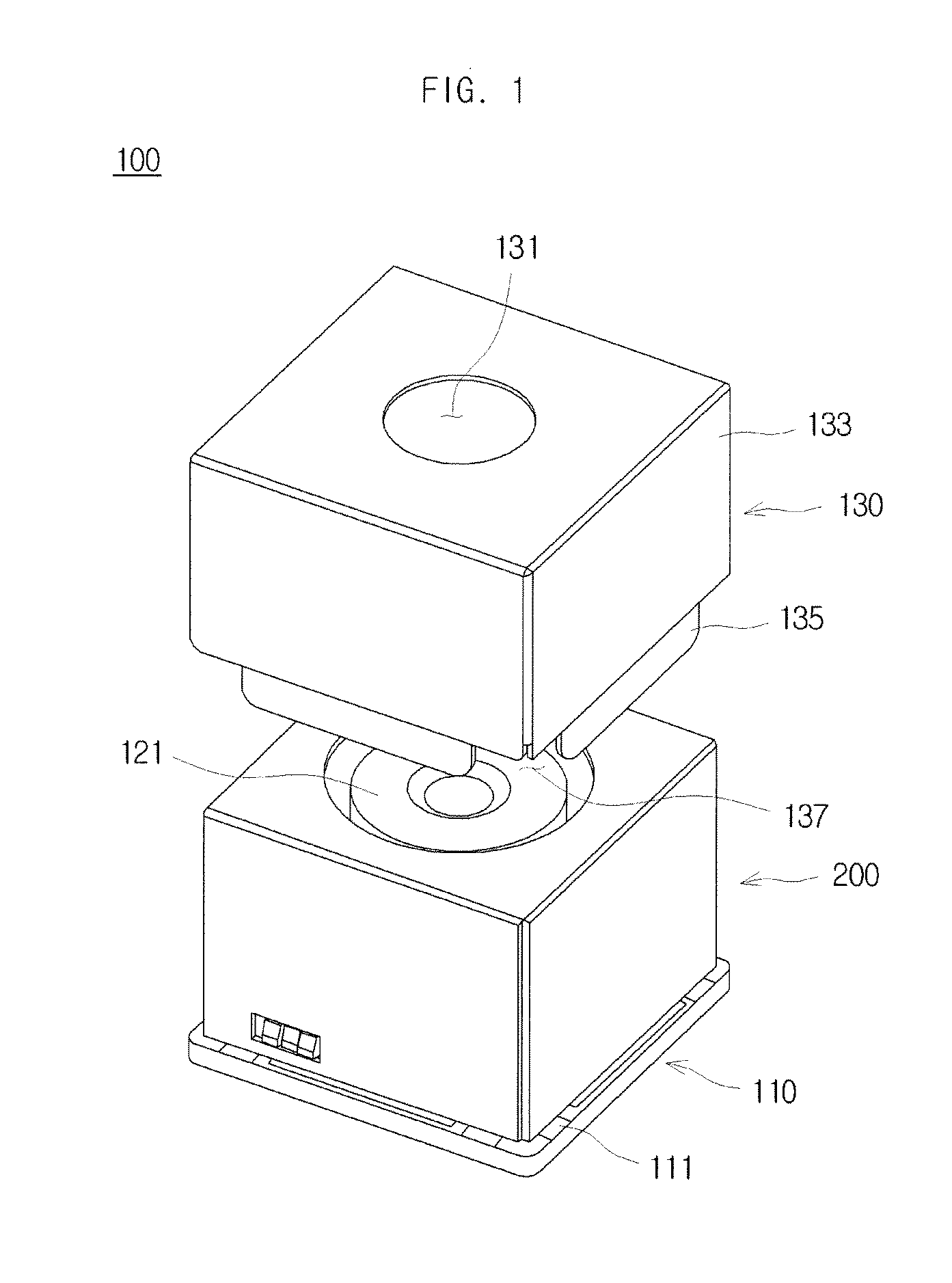

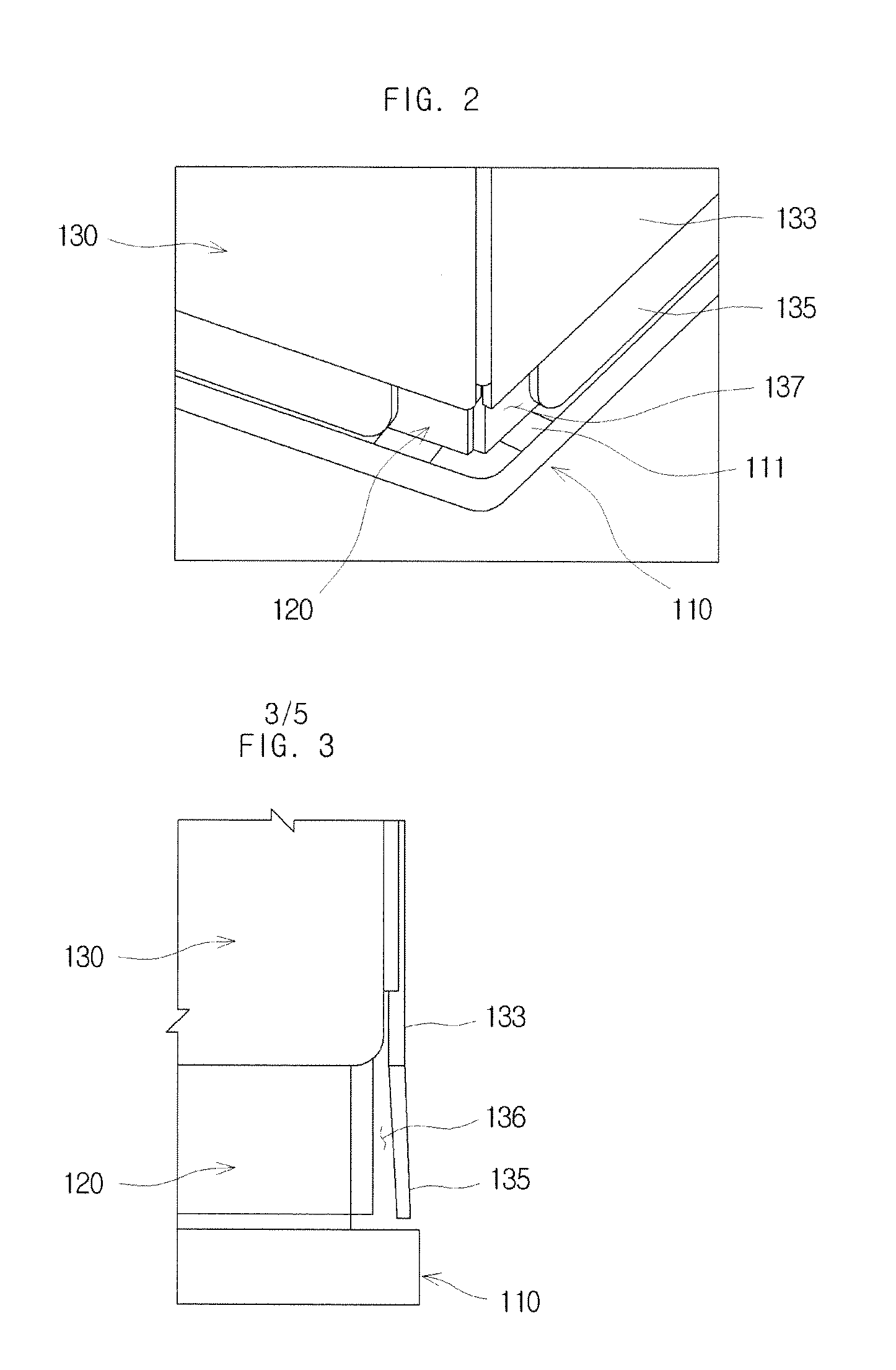

Camera module

ActiveUS20120039060A1Accurate supervisionSave spaceTelevision system detailsPrinted circuit groundingComputer moduleCamera module

A camera module is disclosed. The camera module in accordance with the present invention includes: a printed circuit board having a grounding pad formed on one surface thereof; a housing mounted on an upper side of the printed circuit board and including a lens inside thereof; a shield covering the housing in order to shield electromagnetic waves from an outside and having an opening cavity formed therein in correspondence with a location of the grounding pad; and a solder formed in the opening cavity and connecting the shield with the grounding pad.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

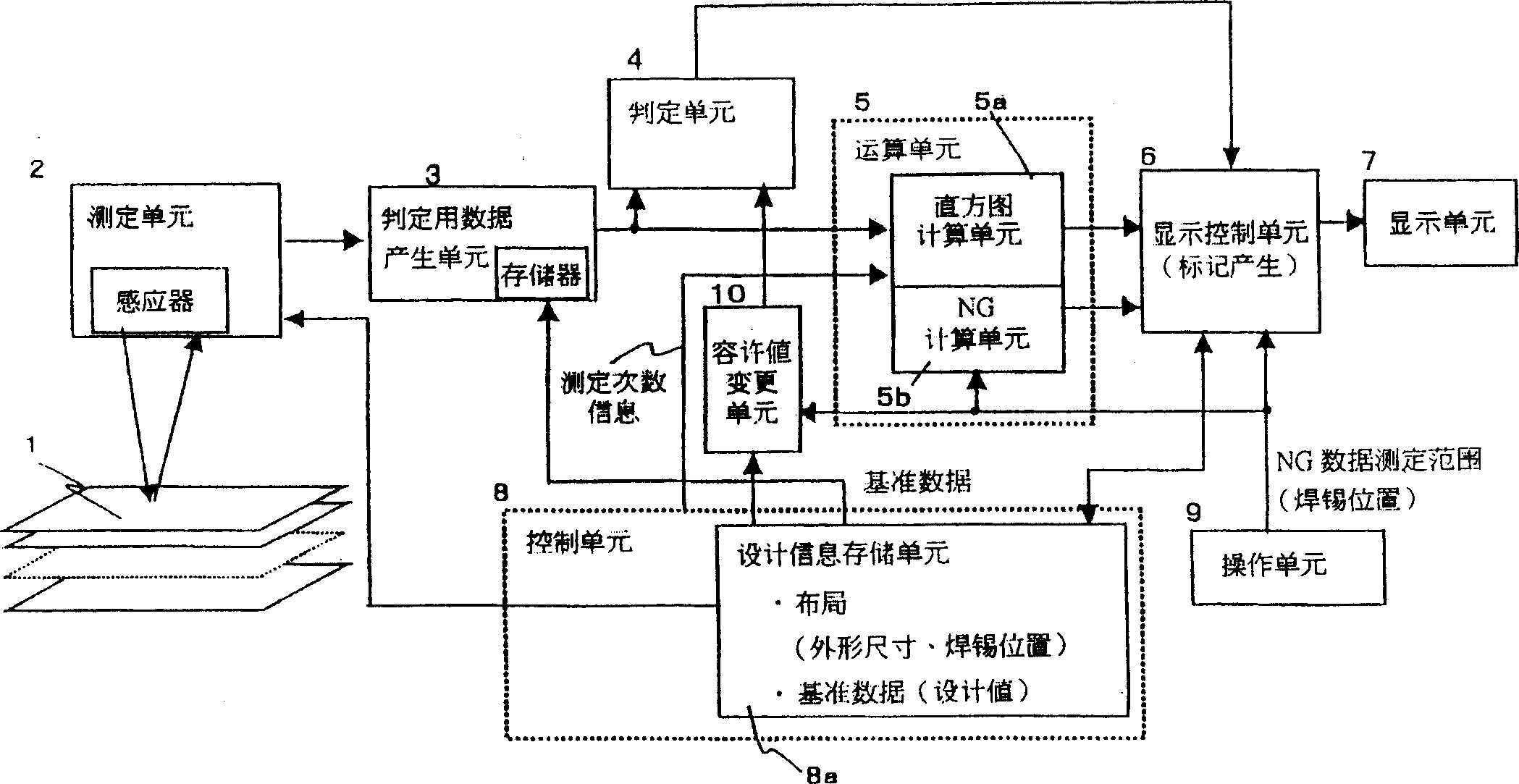

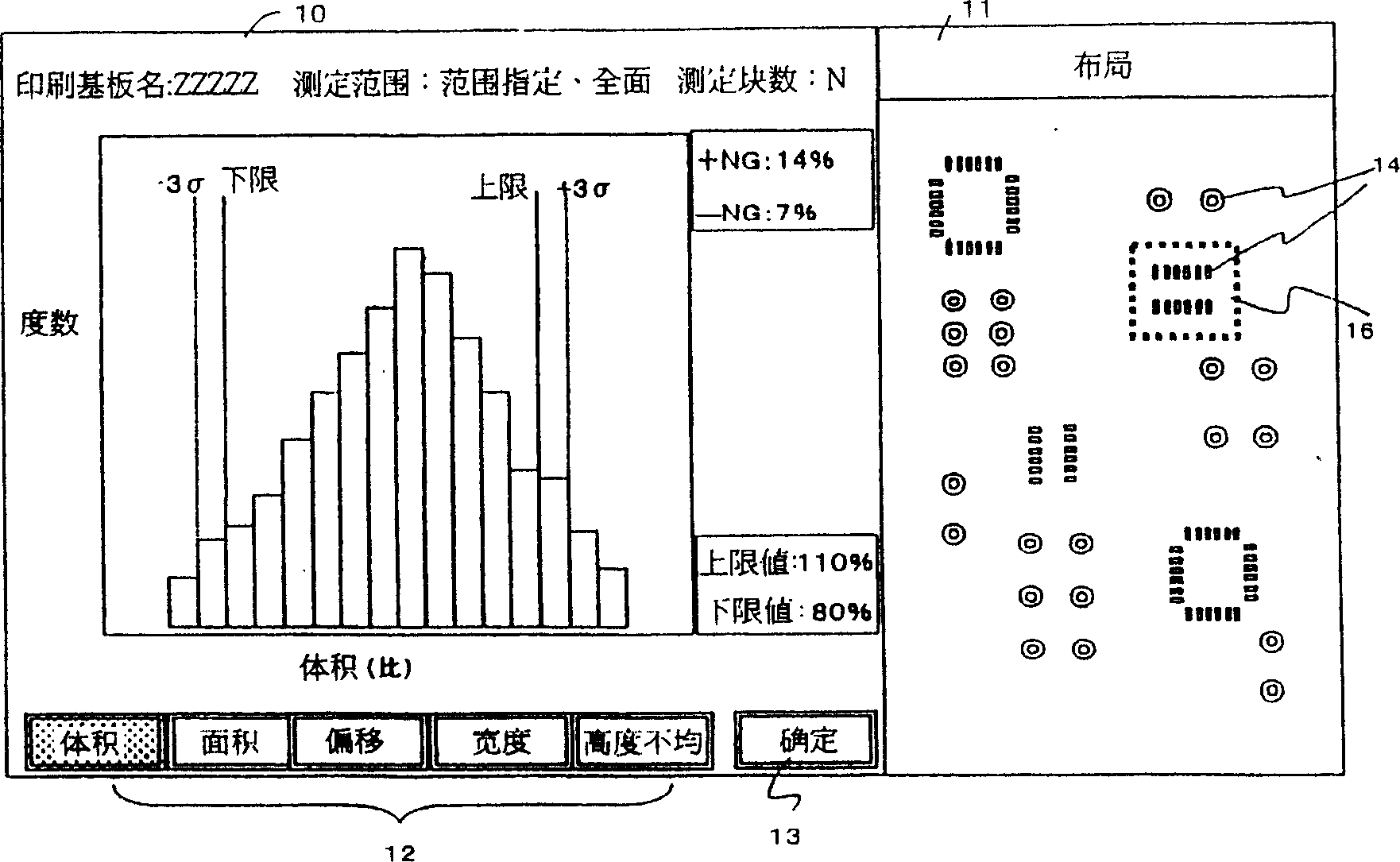

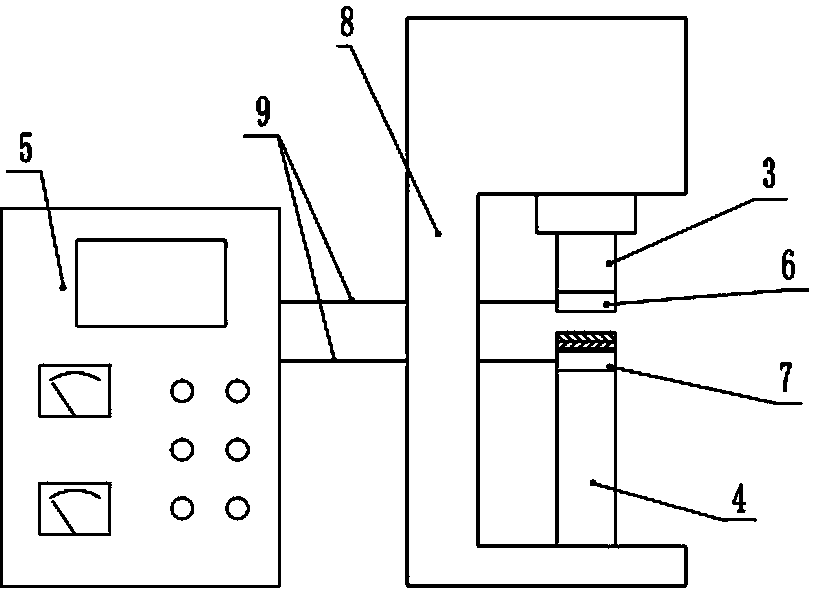

Printing solder detecting device

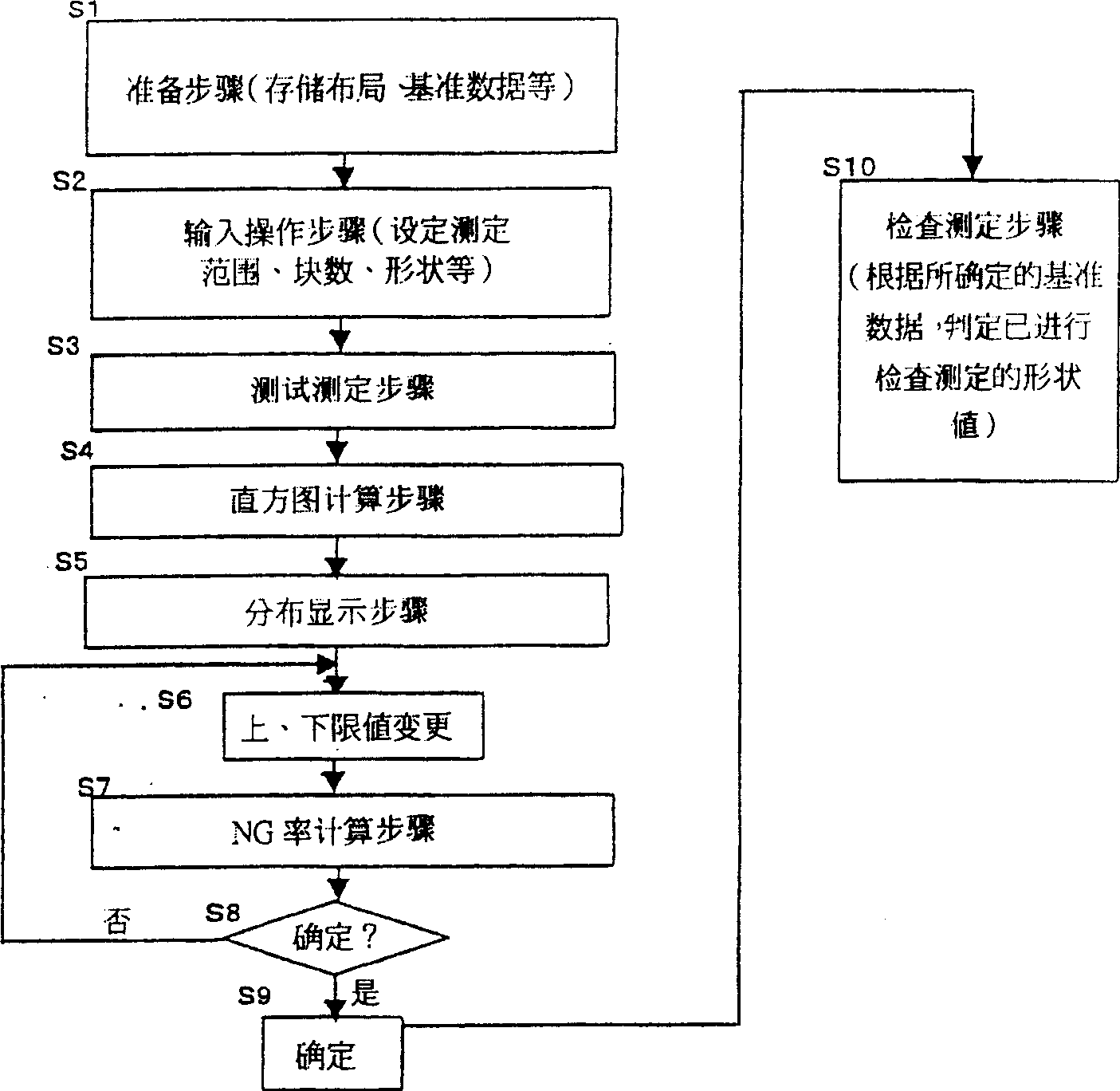

The invention provides the technology of judging quantity when displaying solder form distribution, easily designing reference value. The invention uses measuring unit (2) to measure soldering state, according the measured value, uses the histogram calculation unit (5a) to calculate frequency distribution of form value, uses display controlling unit (6) to display the frequency distribution on the display unit (7), and uses recognizable pattern to display variable input distribution range. The NG calculation unit (5b) calculates the fraction defective or percent of pass, and defines the expected distribution range.

Owner:ANRITSU CORP

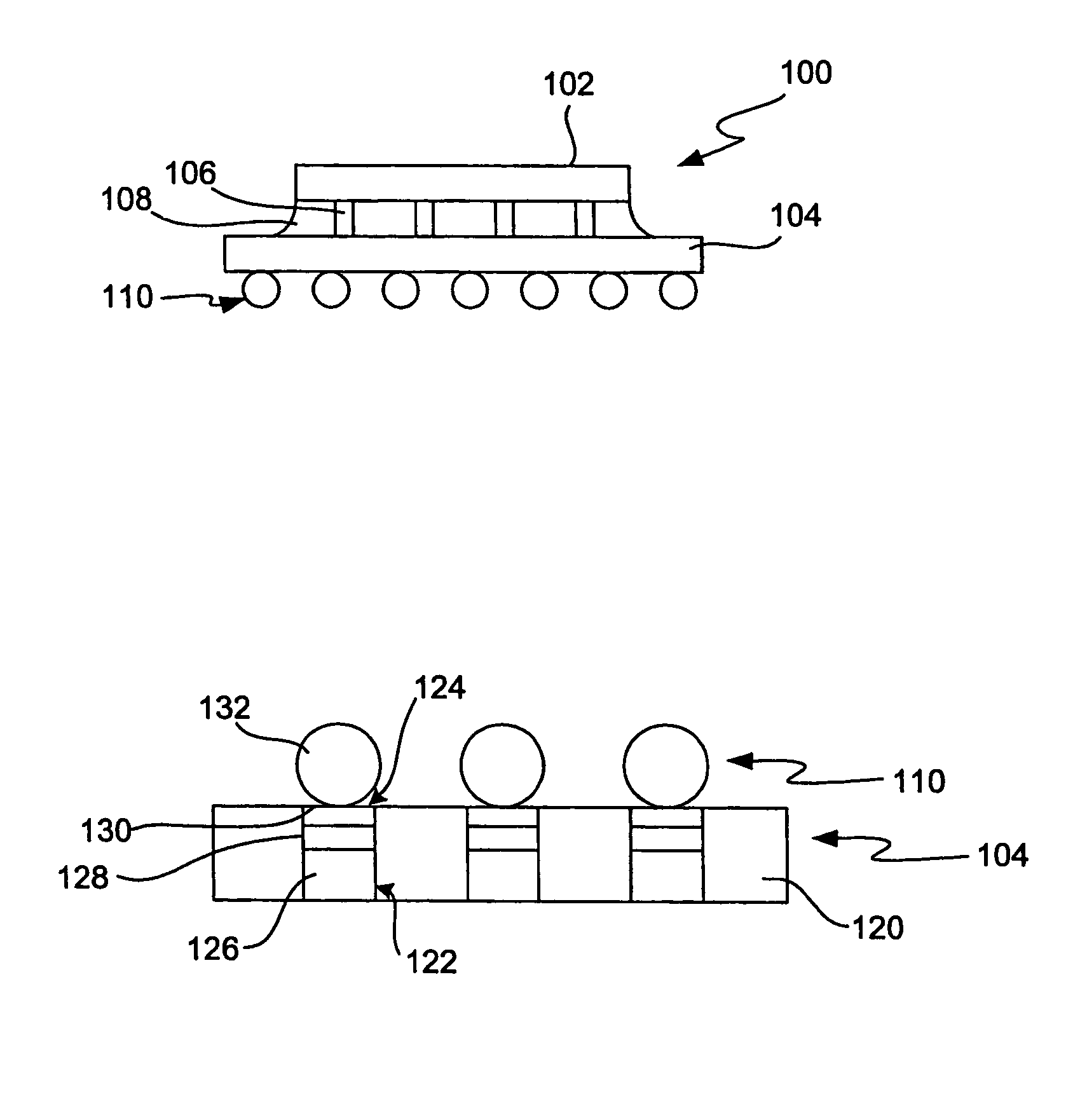

Photopatternable Silicones For Wafer Level Z-Axis Thermal Interposer

InactiveUS20170200667A1Increase working frequencyIncrease the challengeSemiconductor/solid-state device detailsSolid-state devicesInterposerSemiconductor package

Methods for fabrication of thermal interposers, using a low stress photopatternable silicone are provided, for use in production of electronic products that feed into packaging of LEDs, logic and memory devices and other such semiconductor products where thermal management is desired. A photopatternable silicone composition, thermally conductive material and a low melting point compliant solder form a complete semiconductor package module. The photopatternable silicone is applied on a surface of a wafer and selectively radiated to form openings which provided user defined bondline thickness control. The openings are then filled with high conductivity pastes to form high conductivity thermal links. A low melting point curable solder is then applied where the solder wets the silicone as well as the thermally conductive path that leads to low thermal contact resistance between the structured z-axis thermal interposer and the heat sink and / or substrate which can be a wafer or PCB.

Owner:DOW SILICONES CORP

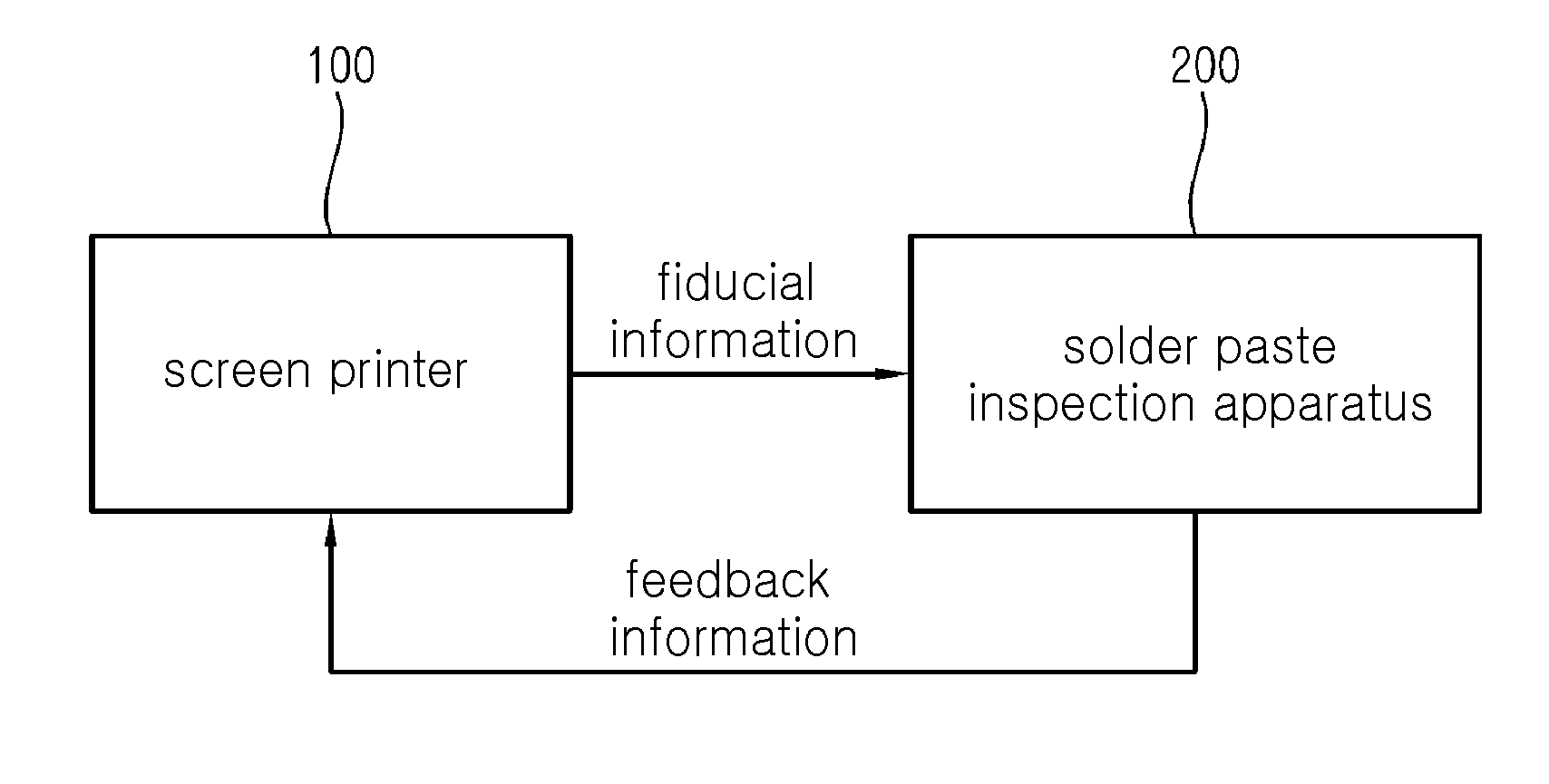

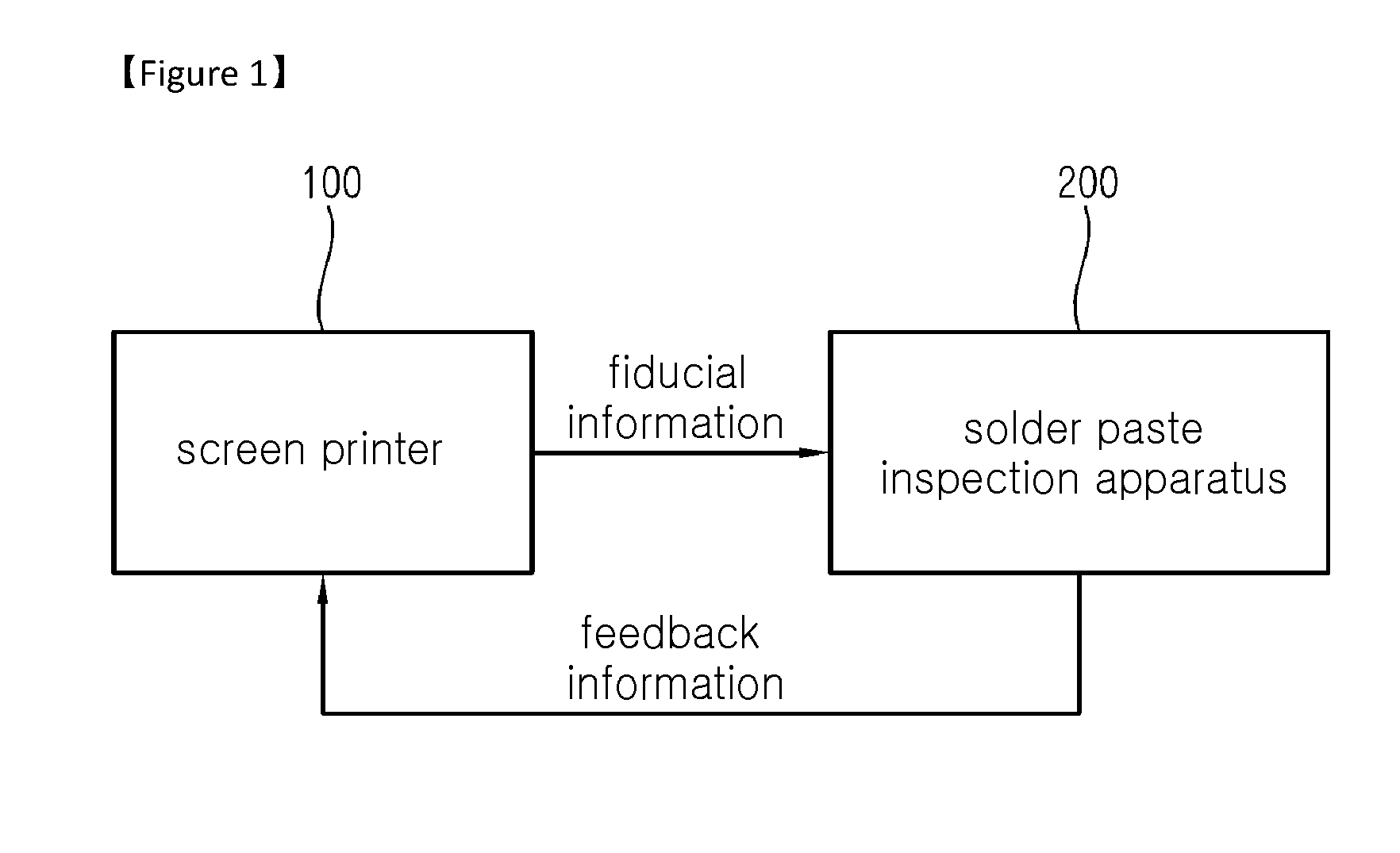

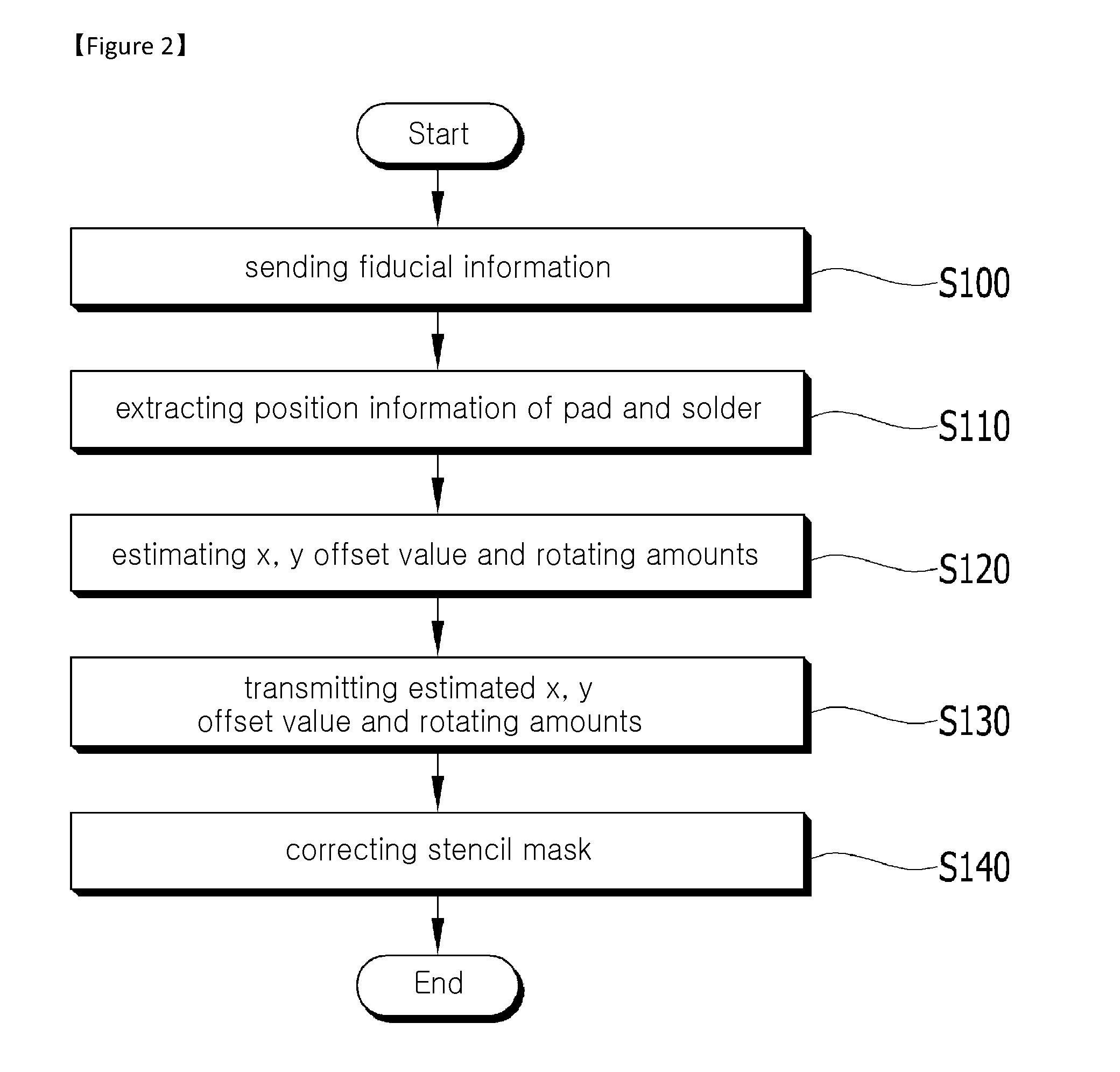

Method of correcting a screen printer and a board inspection system using the same

ActiveUS20150210064A1Improve welding reliabilityPrecise positioningPrinted circuit assemblingScreen printersEngineeringPrinting press

The present invention relates to a method of correcting a position of a stencil mask which comprises receiving fiducial information from a screen printer, extracting position information of a pad and position information of a solder formed on a board through measuring by a solder paste inspection apparatus, estimating an x, y offset value and a rotating amount of a stencil mask based on the fiducial information by using the position information of the pad and the solder, and transmitting the x,y offset value and the rotating amount of the stencil mask to the screen printer. Thus, a reliability of solder forming process may be increased by correcting a stencil mask position by transmitting a feedback of an x,y offset value and a rotating amount of the stencil mask from a solder paste inspection apparatus, in which the x,y offset value and the rotating amount are estimated based on fiducial information transmitted from the screen printer.

Owner:KOHYOUNG TECH +1

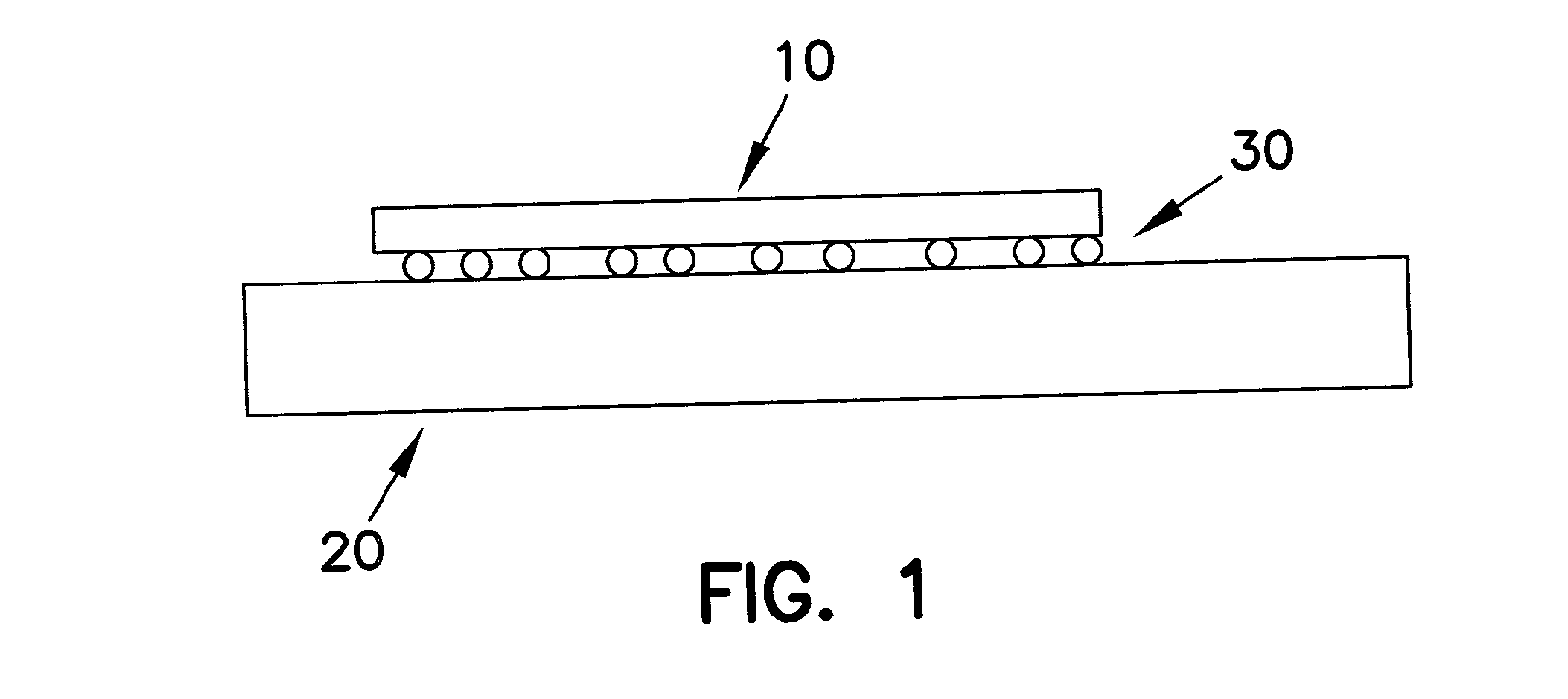

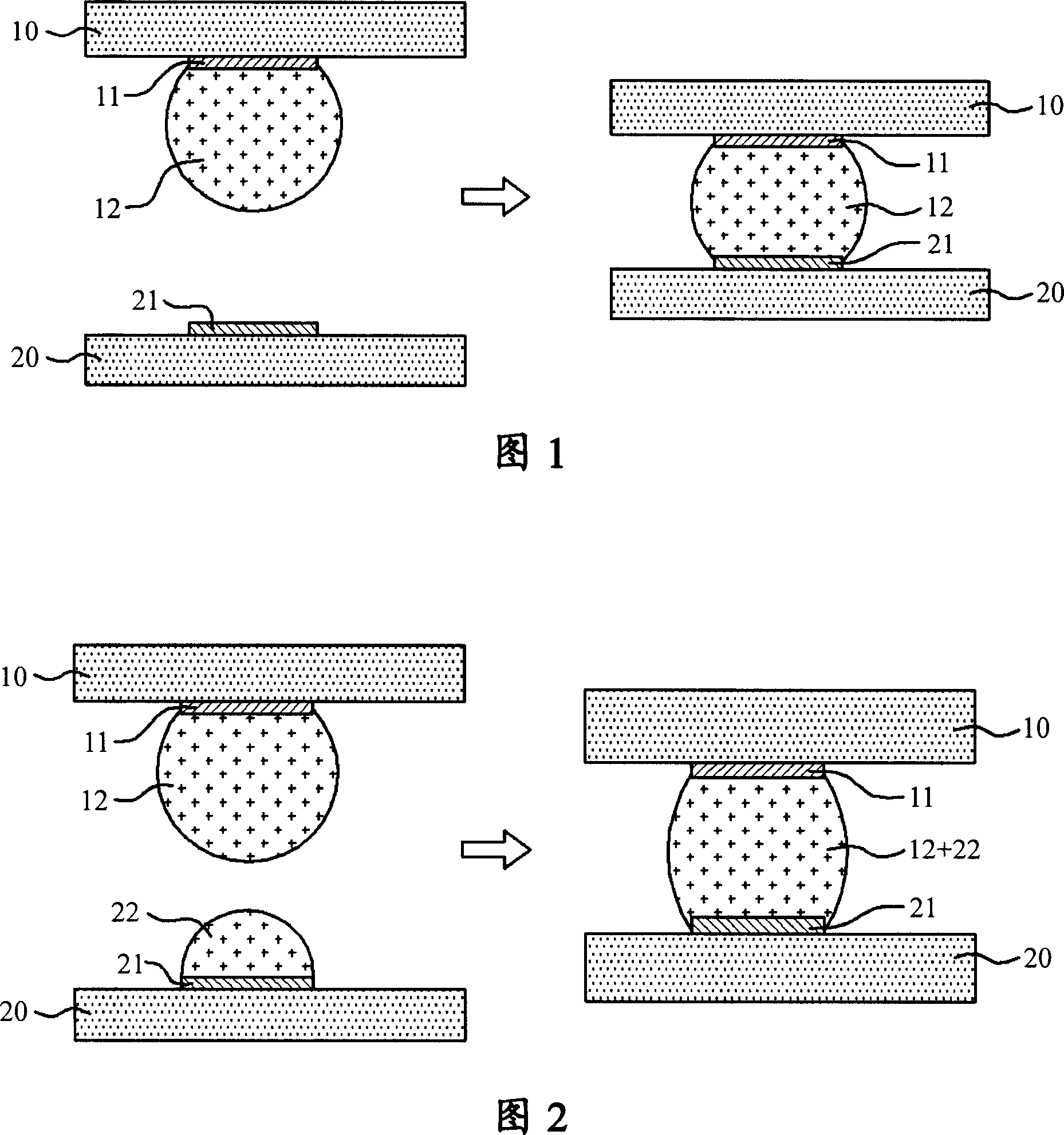

Self-aligning structures and method for integrated circuits

A lead frame having a die thereon connects a high current conductive area on the die to a lead frame contact using a copper clip that includes a structure portion that is received with a recess-like “tub” formed in the lead frame contact. In the preferred embodiment, a lead frame structure fabricated by etching includes at least one contact that is a half-etch recess or “tub” that receives one end of the clip structure and is retained in the tub by solder paste or an adhesive. The end of the clip that is received in the tub is held in place during subsequent handling until the clip and leadframe undergo solder reflow to effect an electrical connection sufficient to handle the current load and a also effect a reliable mechanical connection. One or more solder-holding pockets are formed a surface portion of the tub and / or the end of the clip that is received in the tub so that a volume of liquefied solder formed during the solder reflow step will effect alignment of any mis-aligned parts by “drawing” at least one of the parts against a “stop” surface.

Owner:INTERSIL INC

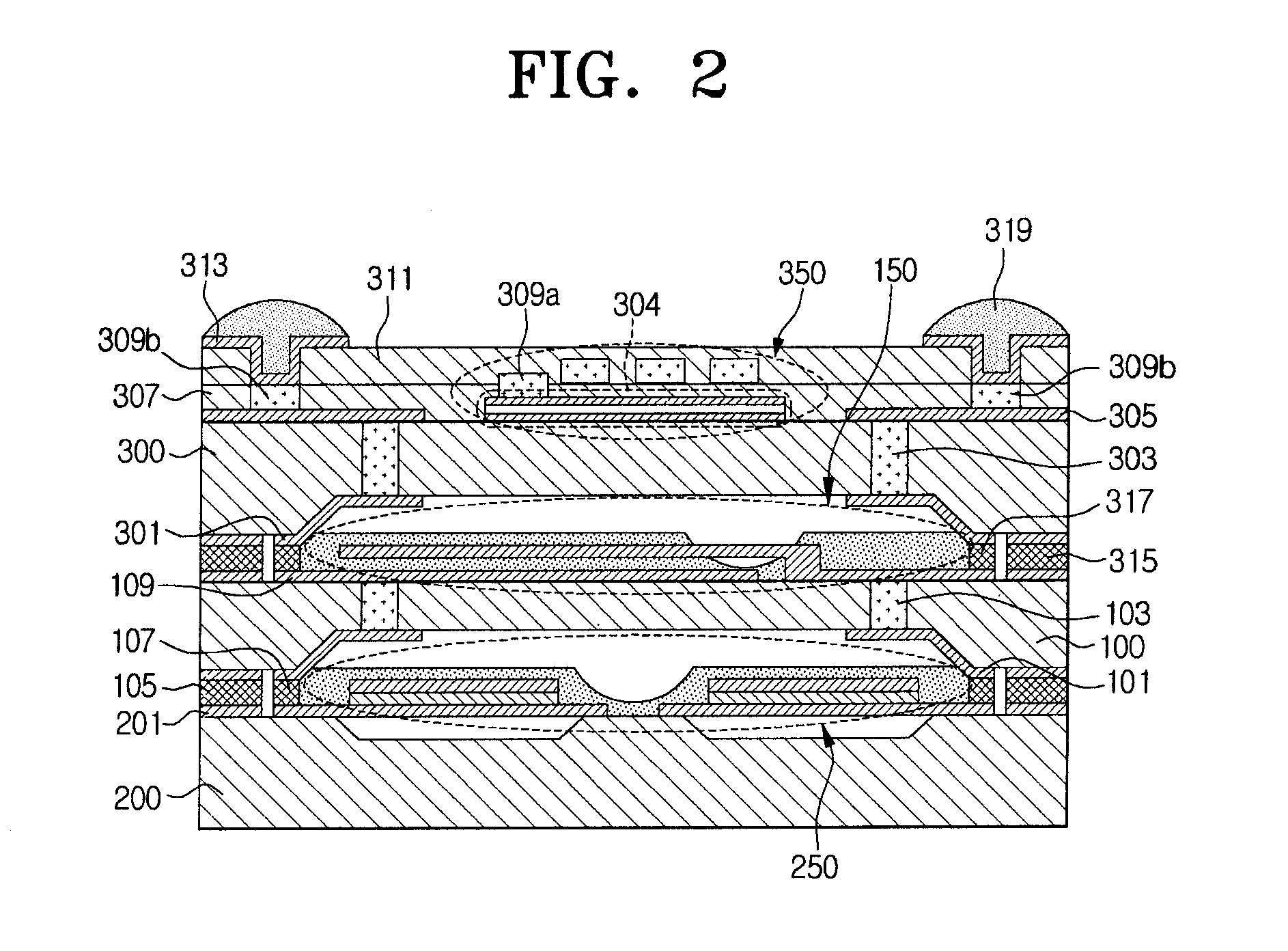

Multi stack packaging chip and method of manufacturing the same

A multi stack packaging chip and a method of manufacturing the chip are provided. The method includes forming at least one second circuit element on a first wafer; forming a second wafer having a cavity and a one third circuit element formed opposite to the cavity; forming a solder on the second wafer; and combining the second wafer with the first wafer so that the second circuit element and the cavity correspond. The chip includes a flip-chip packaged chip in which a first circuit element is packaged using a first wafer; a second circuit element formed on the first wafer; a second wafer having a cavity and combined with the first wafer so that the cavity and the second circuit element correspond; a third circuit element formed on the second wafer; and a solder formed on the second wafer, the solder electrically coupling the second wafer to a packaging substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

Printed circuit board for semiconductor package and method of manufacturing the same

InactiveCN101009263ASemiconductor/solid-state device detailsStacked resist layersSemiconductor packageEngineering

Disclosed are a printed circuit board for a semiconductor package and a method of manufacturing the same. Specifically, a printed circuit board for a semiconductor package includes predetermined circuit patterns, having a wire bonding portion and a bump portion for mounting a semiconductor and a soldering portion for connection to external parts, in which the bump portion has a pre-solder formed using a tin or tin alloy electroplating process. According to this invention, the pre-solder, which is formed by reflow using an electroplating process, permits easy increase of the height thereof to thus enhance bondability and underfilling capability, may be formed to a desired thickness by controlling a plating thickness, and furthermore, may be applied to a fine pitch through a masking process.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

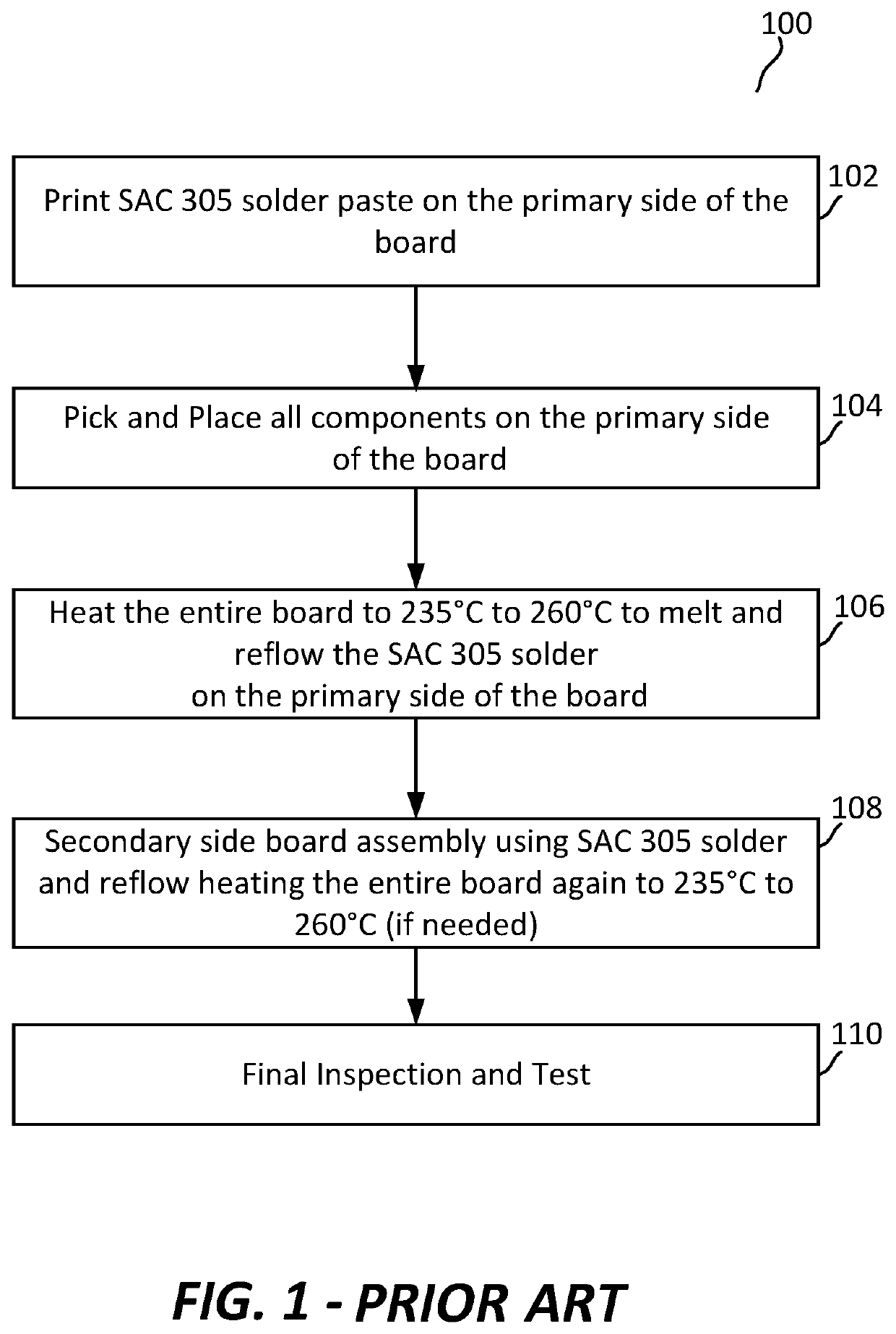

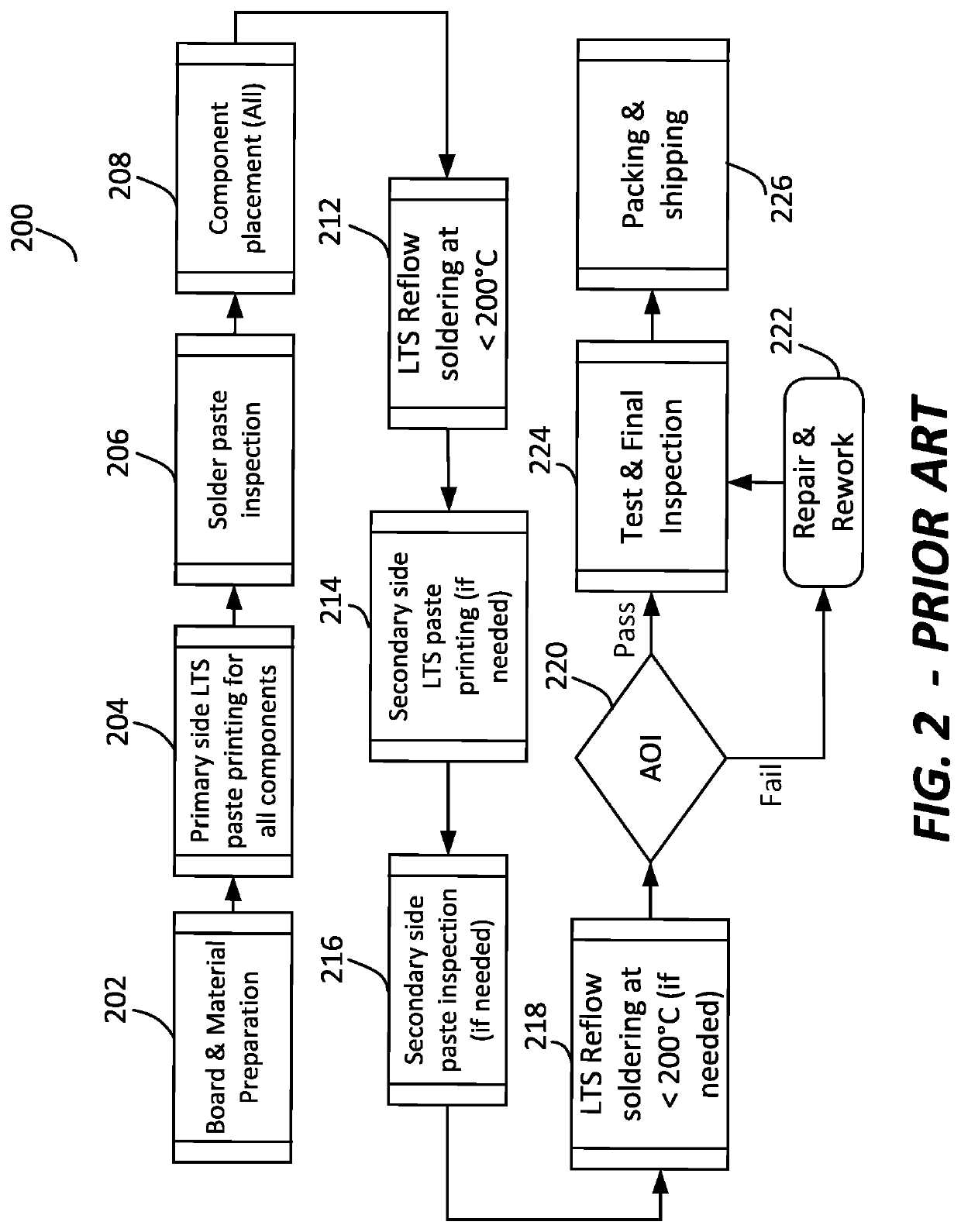

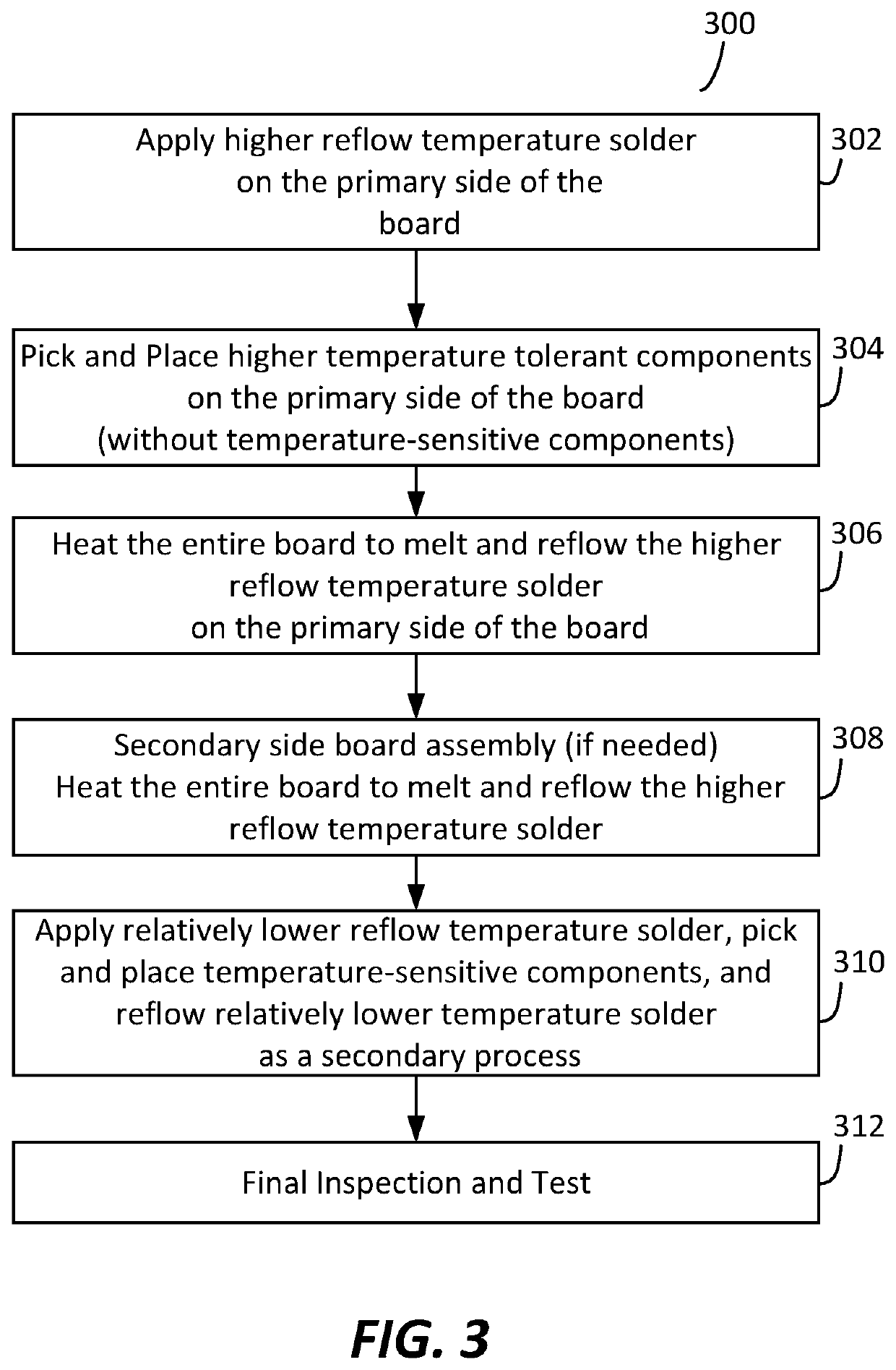

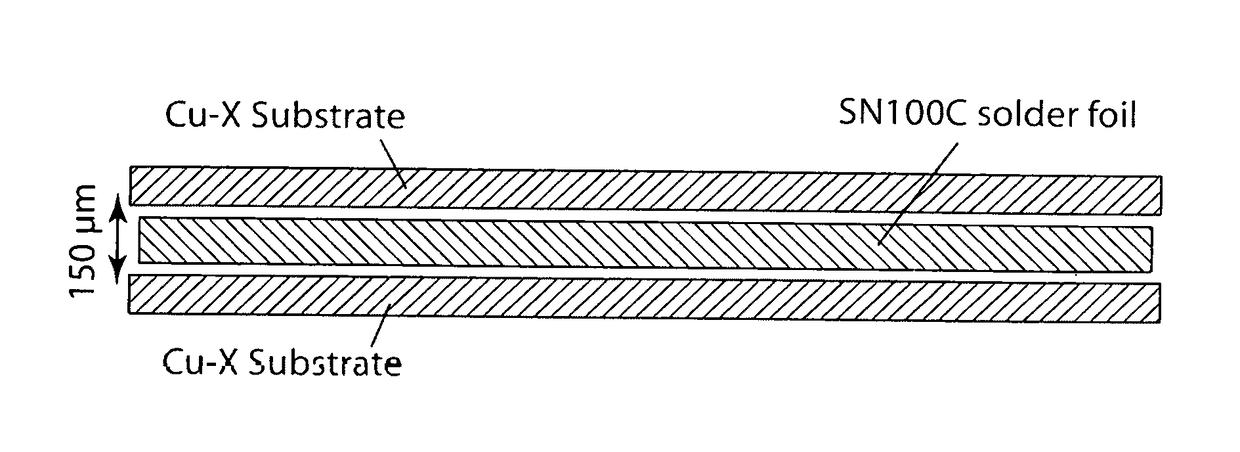

Printed Circuit Board Assembly Process Using Multiple Solders And Assembled Boards Made Using The Same

PendingUS20210315107A1Without sacrificing strengthImprove reliabilityPrinted circuit assemblingPrinted circuits repair/correctingEngineeringElectronic component

Board assembly processes are disclosed that may be implemented using multiple different electrically conductive solder types to assemble or attach different electronic components to a printed circuit board (PCB). For example, multiple different electronic components may be attached to a common PCB using a multiple-step assembly process that may be performed at different solder reflow temperatures and / or which may incorporate multiple different solder types having different respective minimum reflow temperatures (i.e., melting point temperatures). The disclosed processes may be implementing using a variety of different forms of solder, such as solder paste form, wire solder form, ingot solder form, etc.

Owner:DELL PROD LP

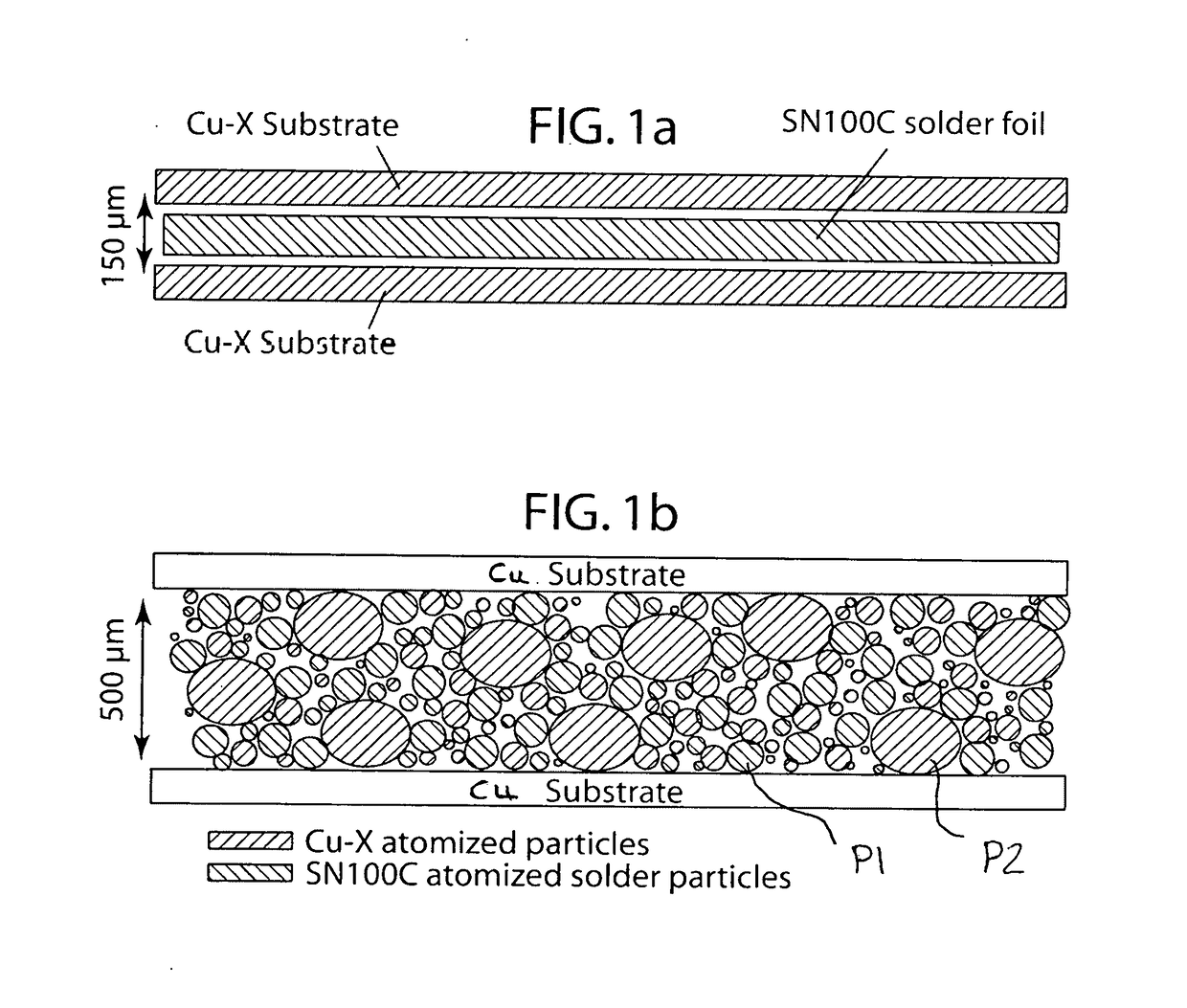

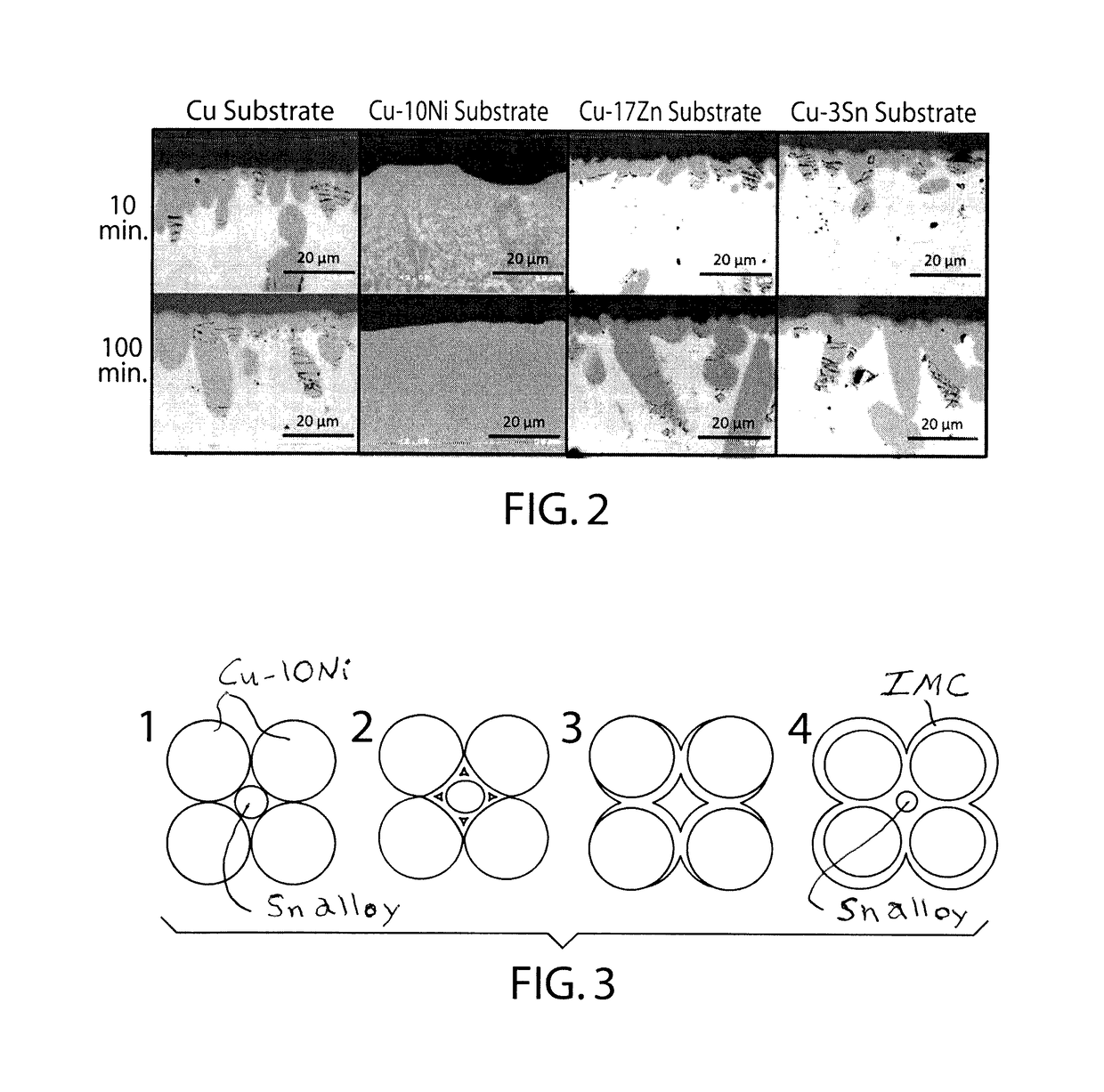

Lead-free composite solder

InactiveUS20170095891A1Improve conductivityReduce and eliminate porosityWelding/cutting media/materialsMetal/alloy conductorsComposite solderSolder paste

A composite solder material for mixing with flux to provide a composite solder paste. The solder material includes a mixture having a relatively low melting solder or solder-forming powder and a relatively high melting Ni-containing reinforcement powder. Use of the solder paste under solder reflow conditions produces a high melting point solder joint by liquid phase diffusion bonding wherein a Ni-stabilized high temperature hexagonal (Cu,Ni)6Sn5 phase is the solder joint matrix that bonds together the Ni-containing reinforcement powder particles. With each reflow cycle, more of the low melting solder or solder-forming powder is converted to the hexagonal (Cu,Ni)6Sn5 matrix phase, raising the final melting temperatures of the post-processed solder joint and giving the solder the ability to withstand higher Joule-heating, all while improving resistance to solder joint cracking.

Owner:IOWA STATE UNIV RES FOUND

Surface fitting device package lead connecting method

InactiveCN1389908AReduce gapSemiconductor/solid-state device detailsSolid-state devicesLead bondingSolder form

Disclosed herein is a lead bonding method for SMD packages. The lead bonding method includes the step of placing a package body with its lead-positioning surface facing upward. A lead with solder is arranged on the lead-positioning surface of the package body using vision system. The lead is spot-welded onto the package body to fix the lead to the package body. The package body spot-welded together with the lead is arranged in a positioning depression of a jig with the lead facing downward. The solder formed on the lead are melted to bond the lead to the package body.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

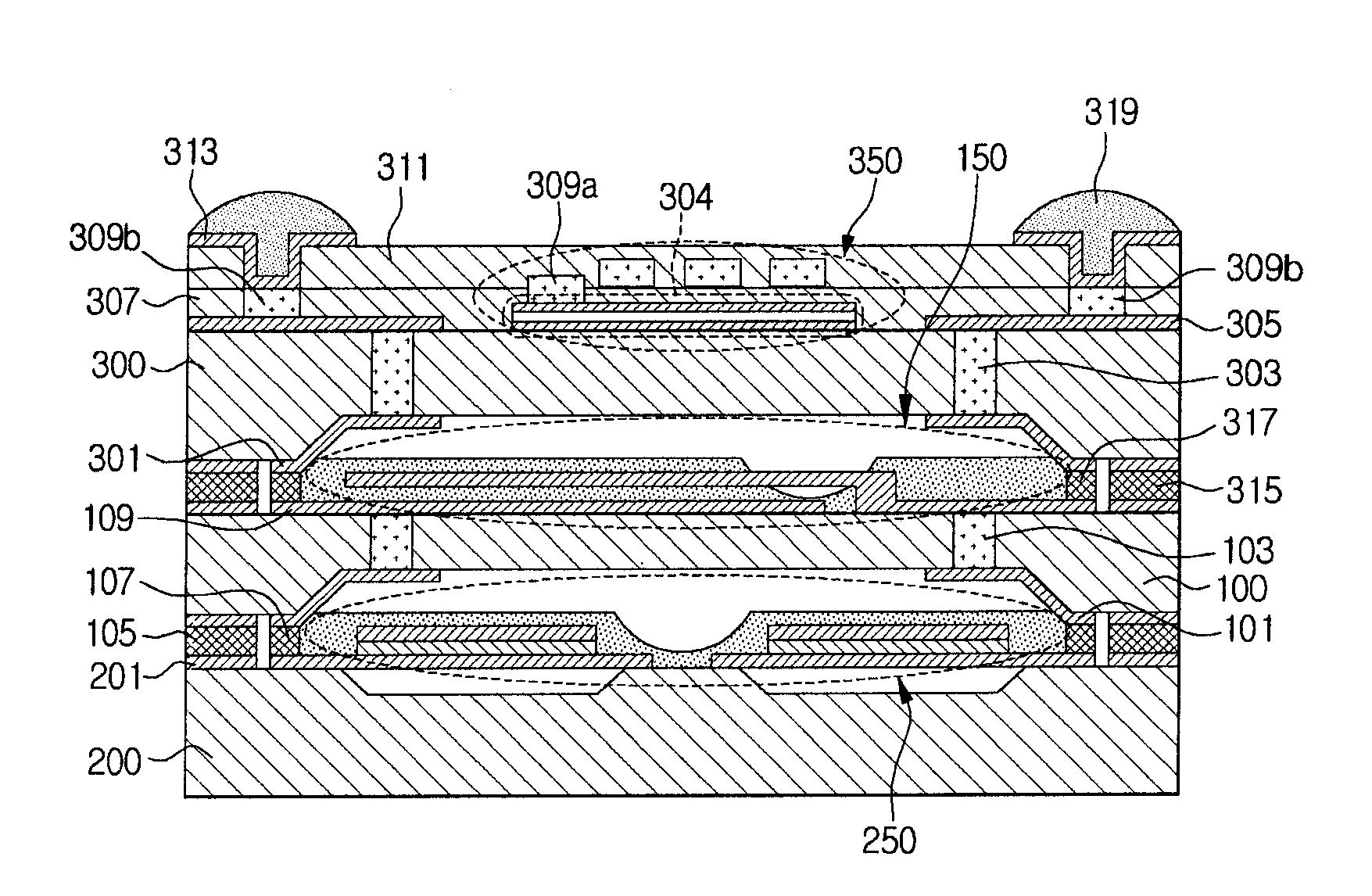

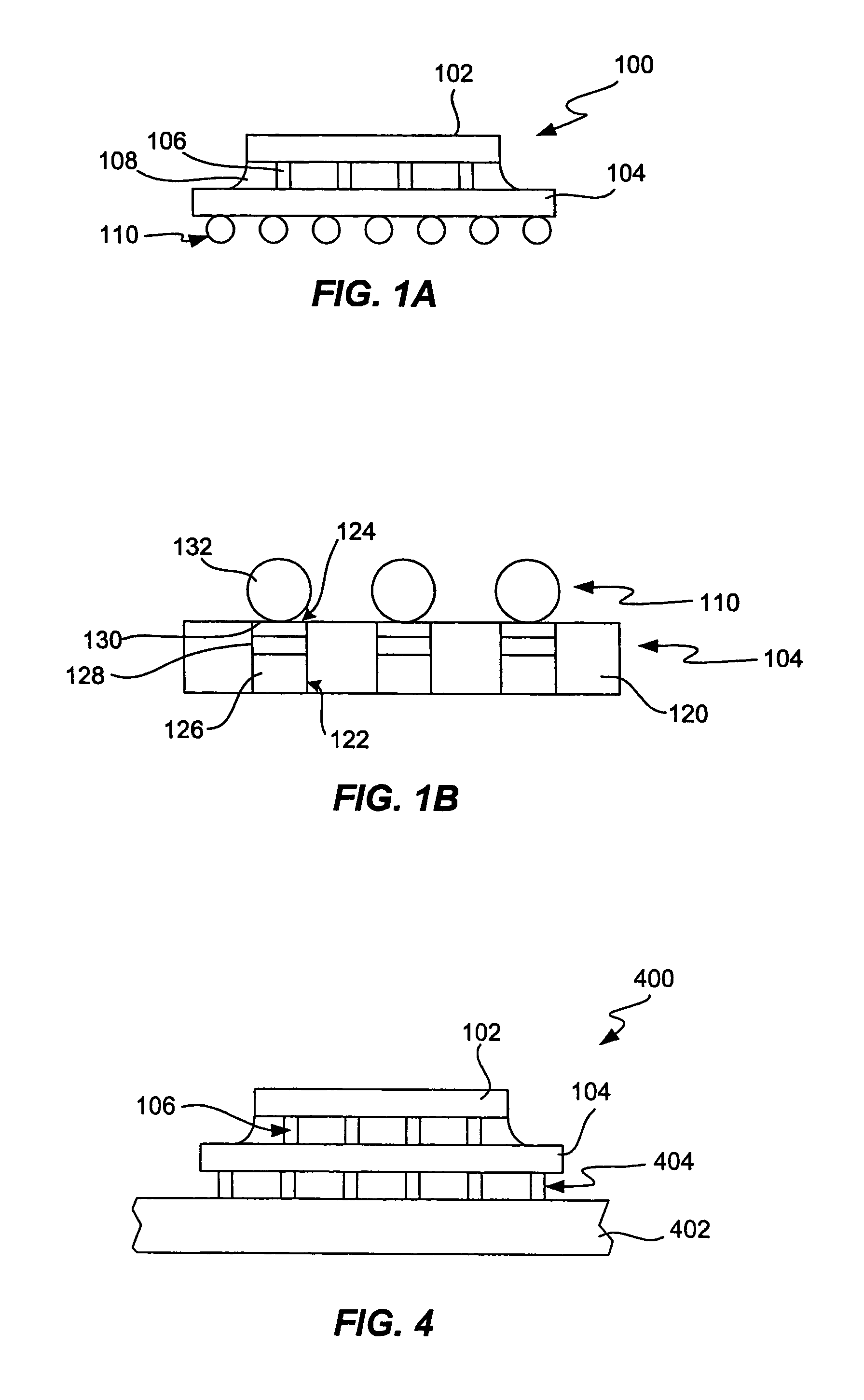

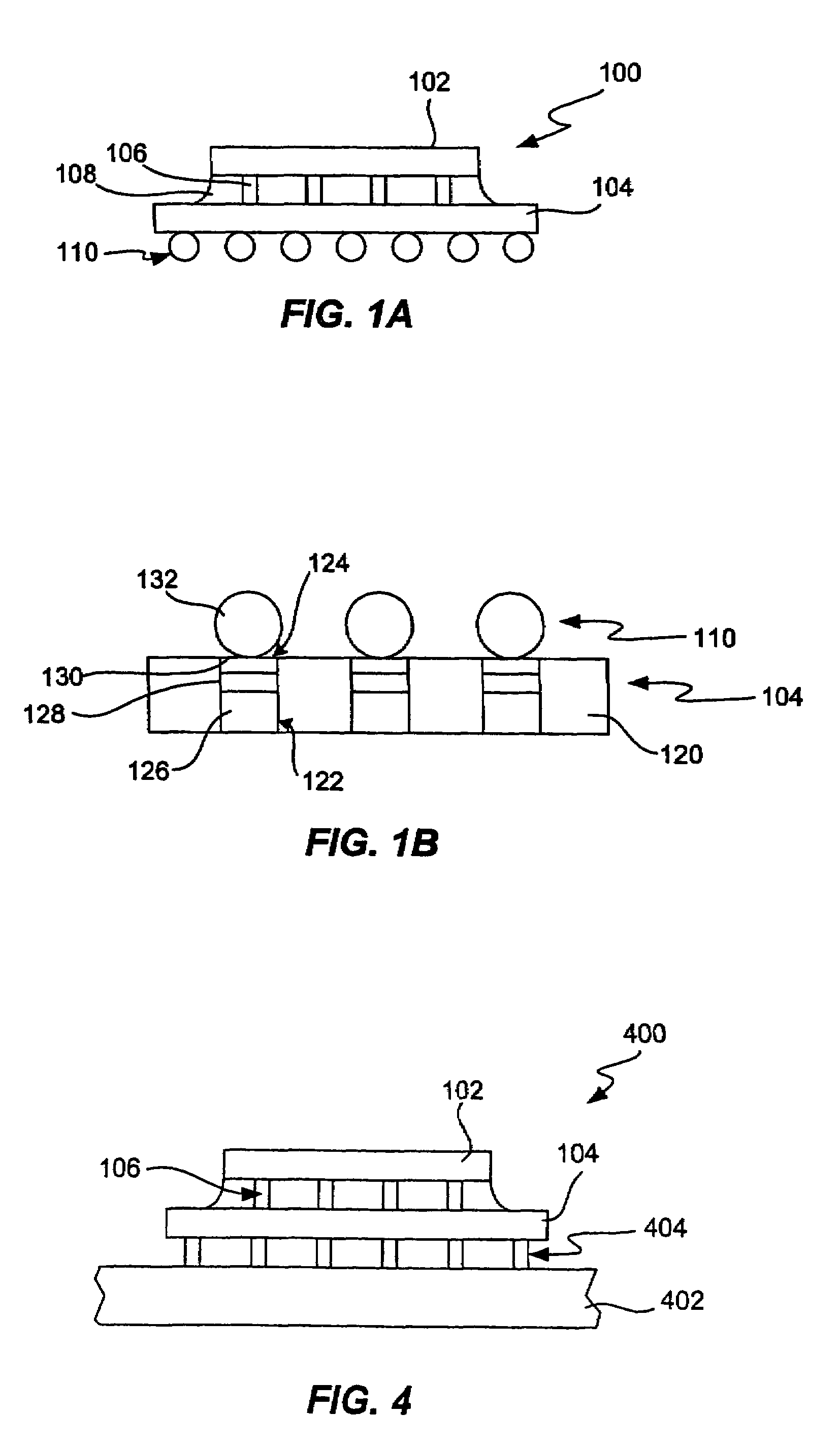

Electroless nickel immersion gold semiconductor flip chip package

InactiveUS6992397B1Few fractured solder bondImprove package reliabilitySemiconductor/solid-state device detailsSolid-state devicesDopantElectroless nickel immersion gold

A flip chip package, apparatus and technique in which a ball grid array composed of a doped eutectic Pb / Sn solder composition is used. The dopant in the Pb / Sn solder forms a compound or complex with the phosphorous residue from the electroless nickel plating process that is mixable with the Pb / Sn solder. The phosphorous containing compound or complex prevents degradation of the solder / under bump metallization bond associated with phosphorus residue. The interfacial solder / under bump metallization bond is thereby strengthened. This results in fewer fractured solder bonds and greater package reliability.

Owner:ALTERA CORP

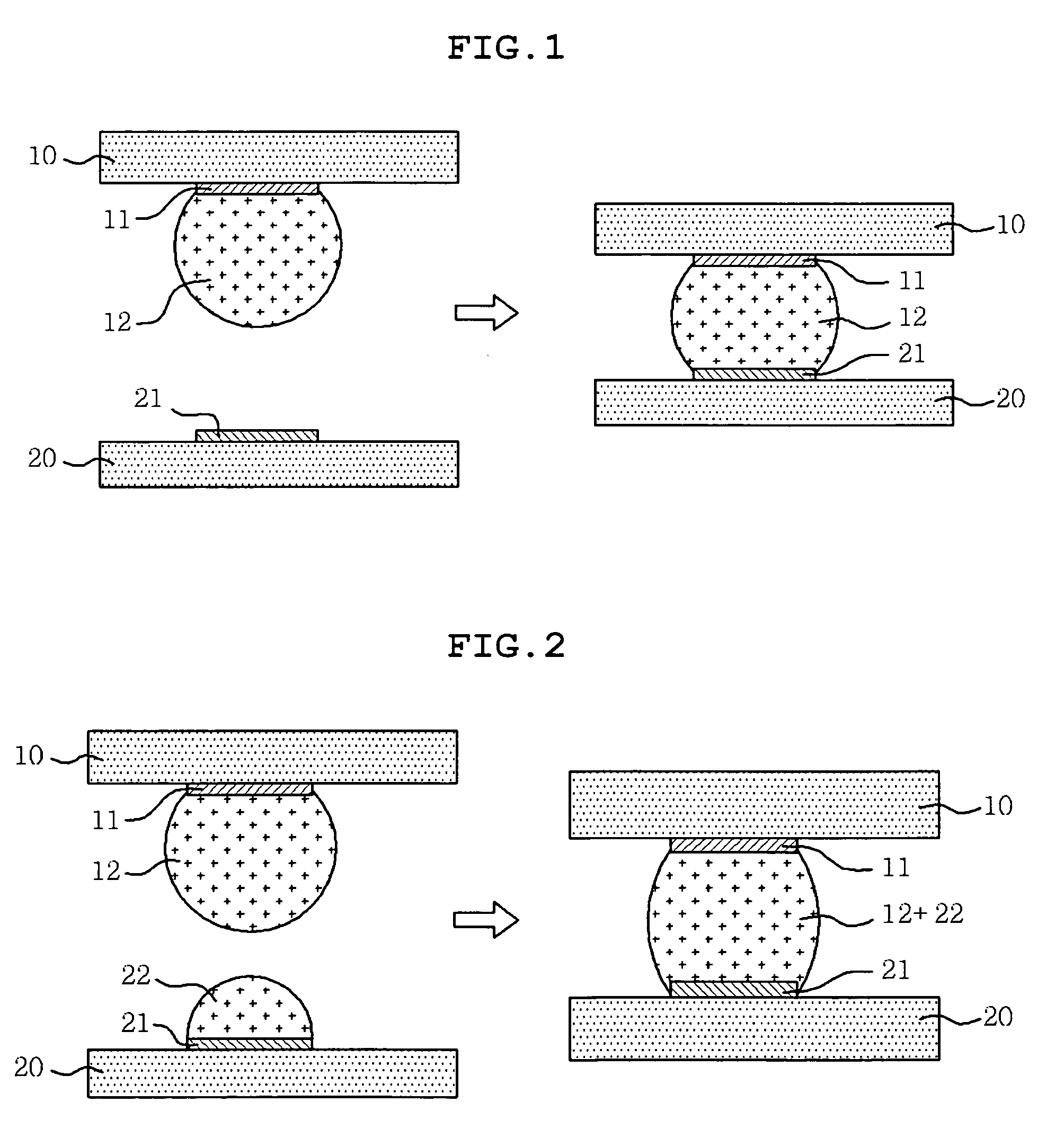

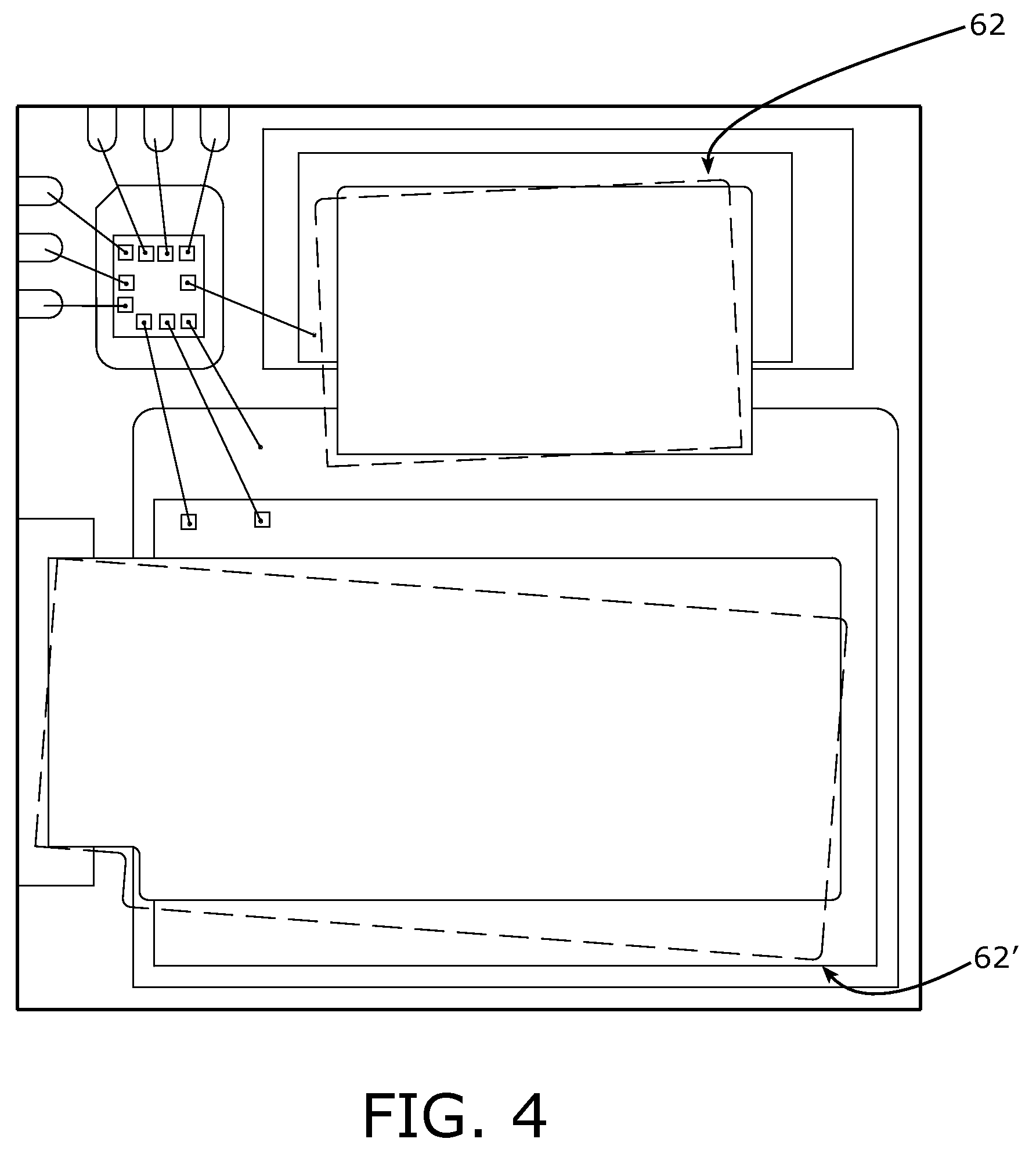

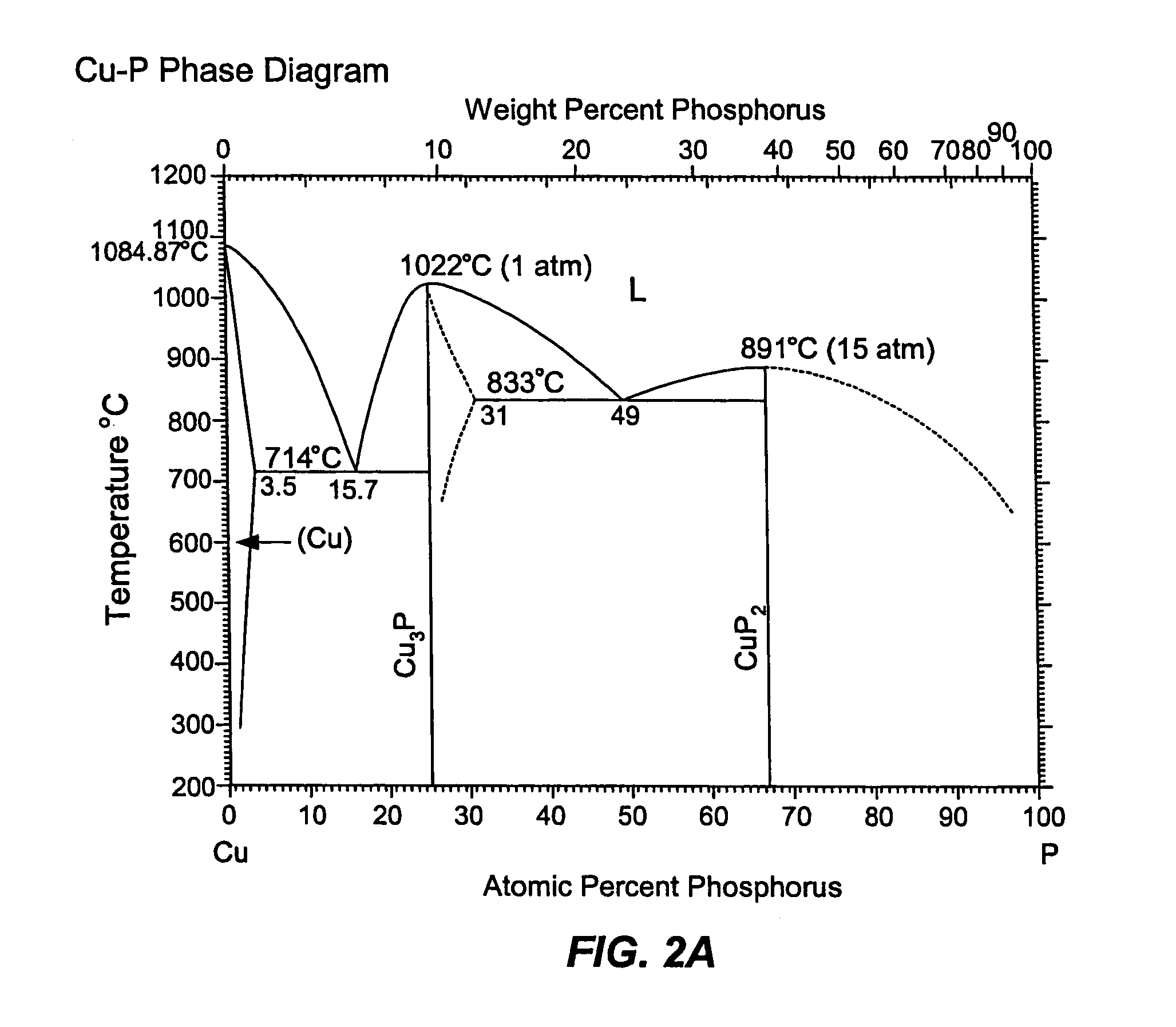

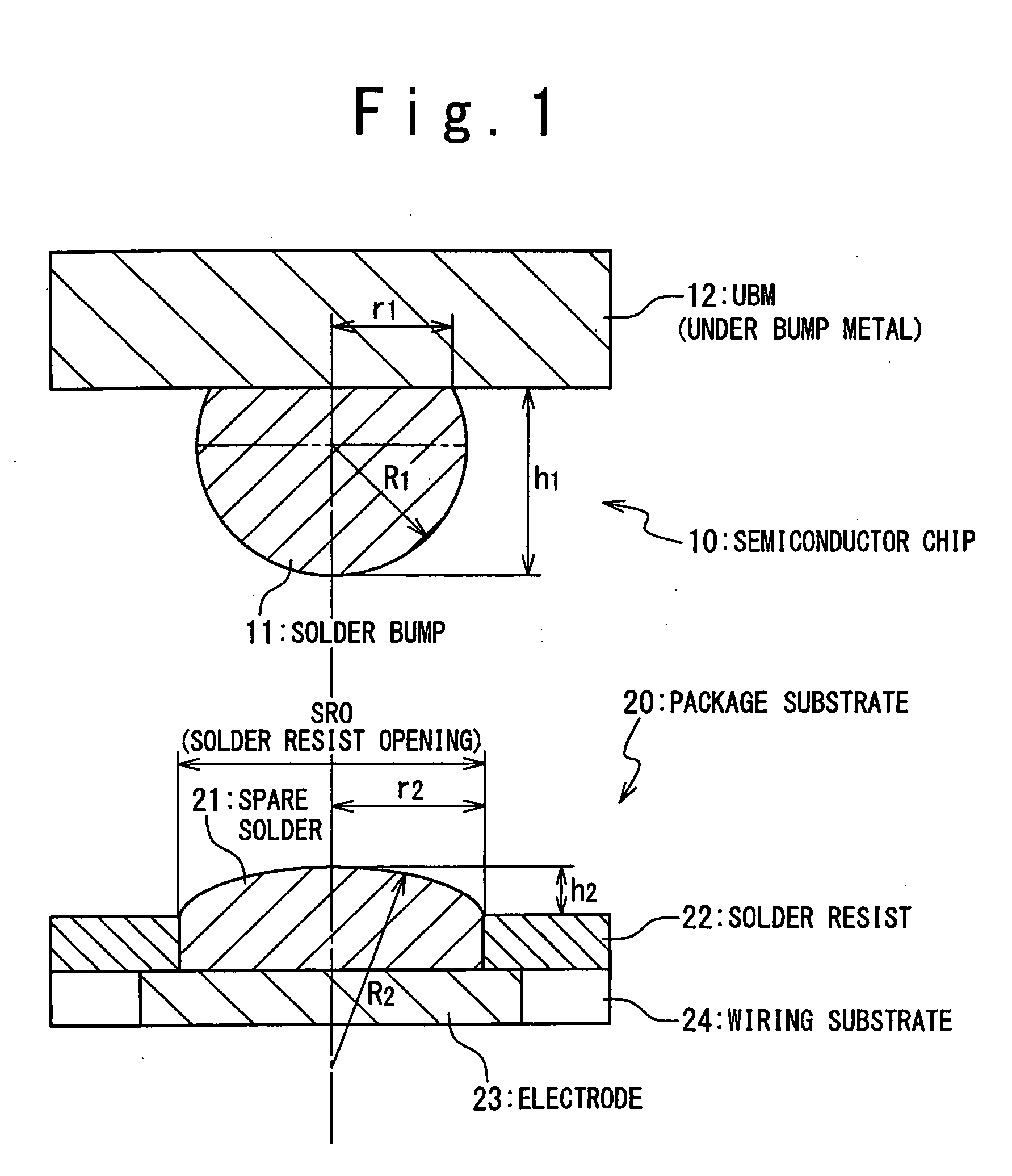

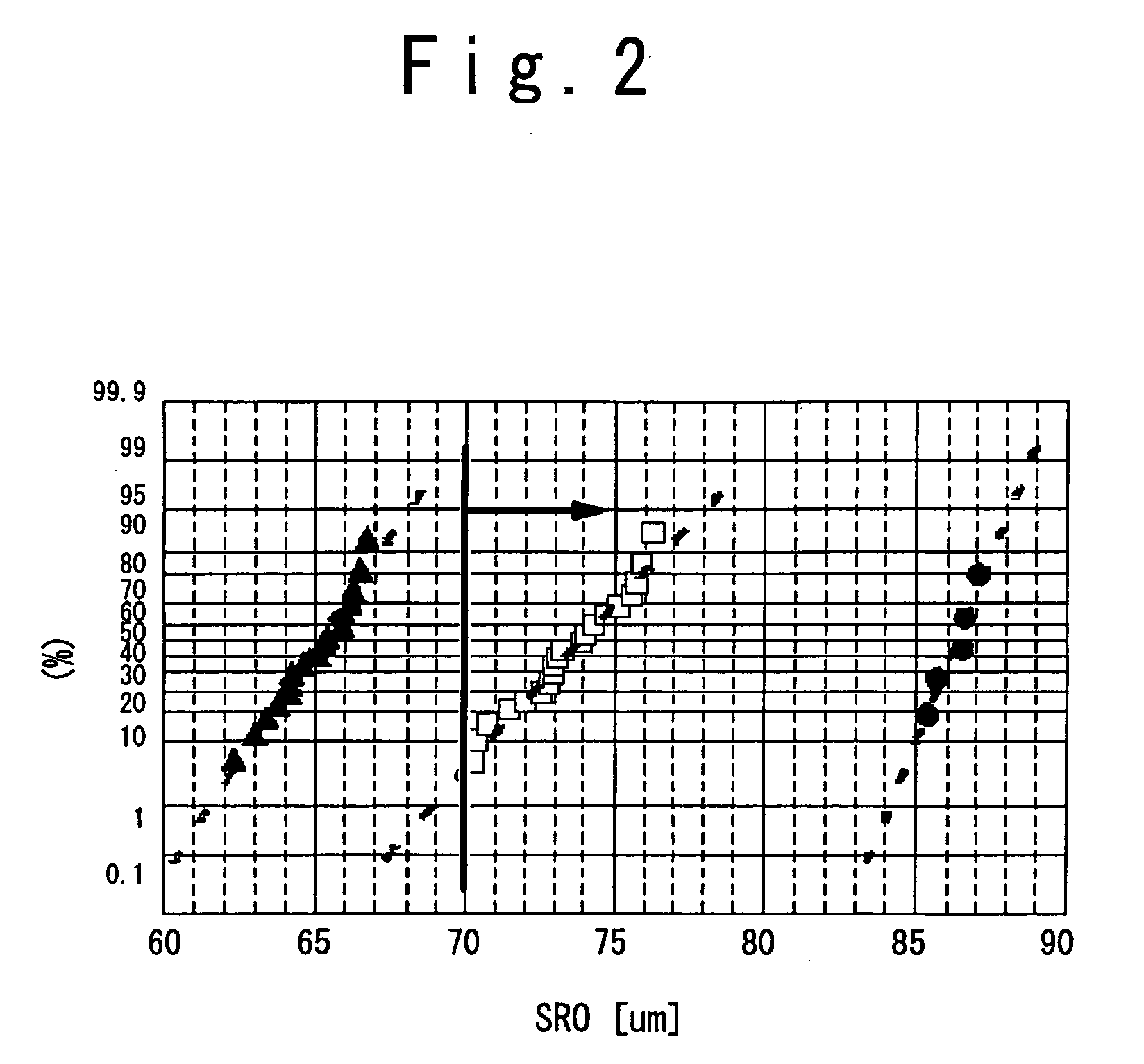

Manufacturing method of semiconductor device, and semiconductor device

InactiveUS20100140796A1Reliable electrical connectionDefective electrical connectionFinal product manufactureSemiconductor/solid-state device detailsResistSolder form

A manufacturing method of a semiconductor device includes a first to fourth steps. The first step includes a step of determining an UBM (Under Bump Metal) radius of an UBM of a chip. The second step includes a step of determining a first curvature radius of a solder bump formed on the UBM. The third step includes a step of determining a SRO (Solider Resist Opening) radius of a SRO of a substrate such that a ratio of the SRO radius to the UMB radius is in a range from 0.8 to 1.2. The fourth step includes a step of determining a second curvature radius of a spare solder formed on an electrode in the SRO such that the second curvature radius is equal to or more than the first curvature radius.

Owner:RENESAS ELECTRONICS CORP

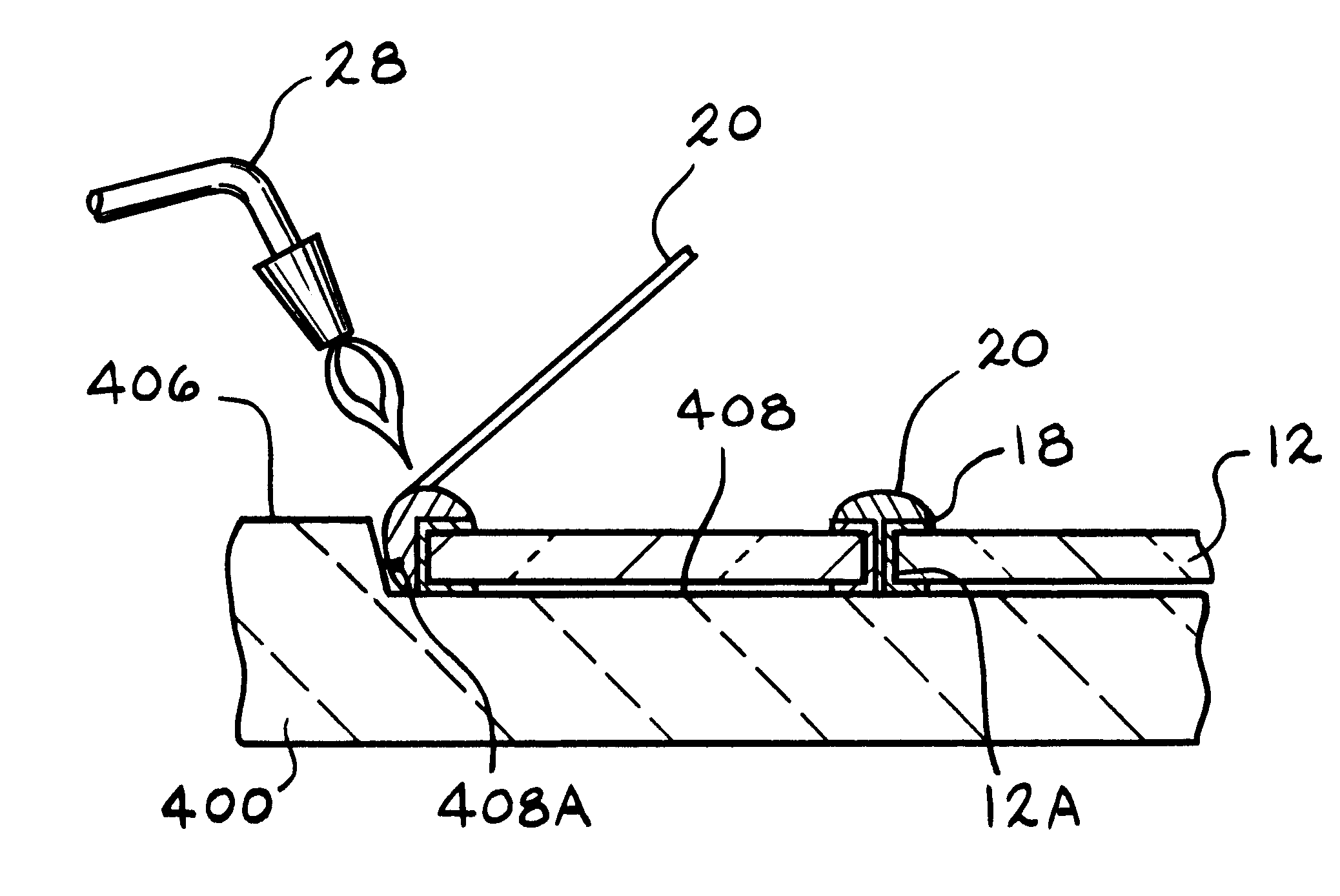

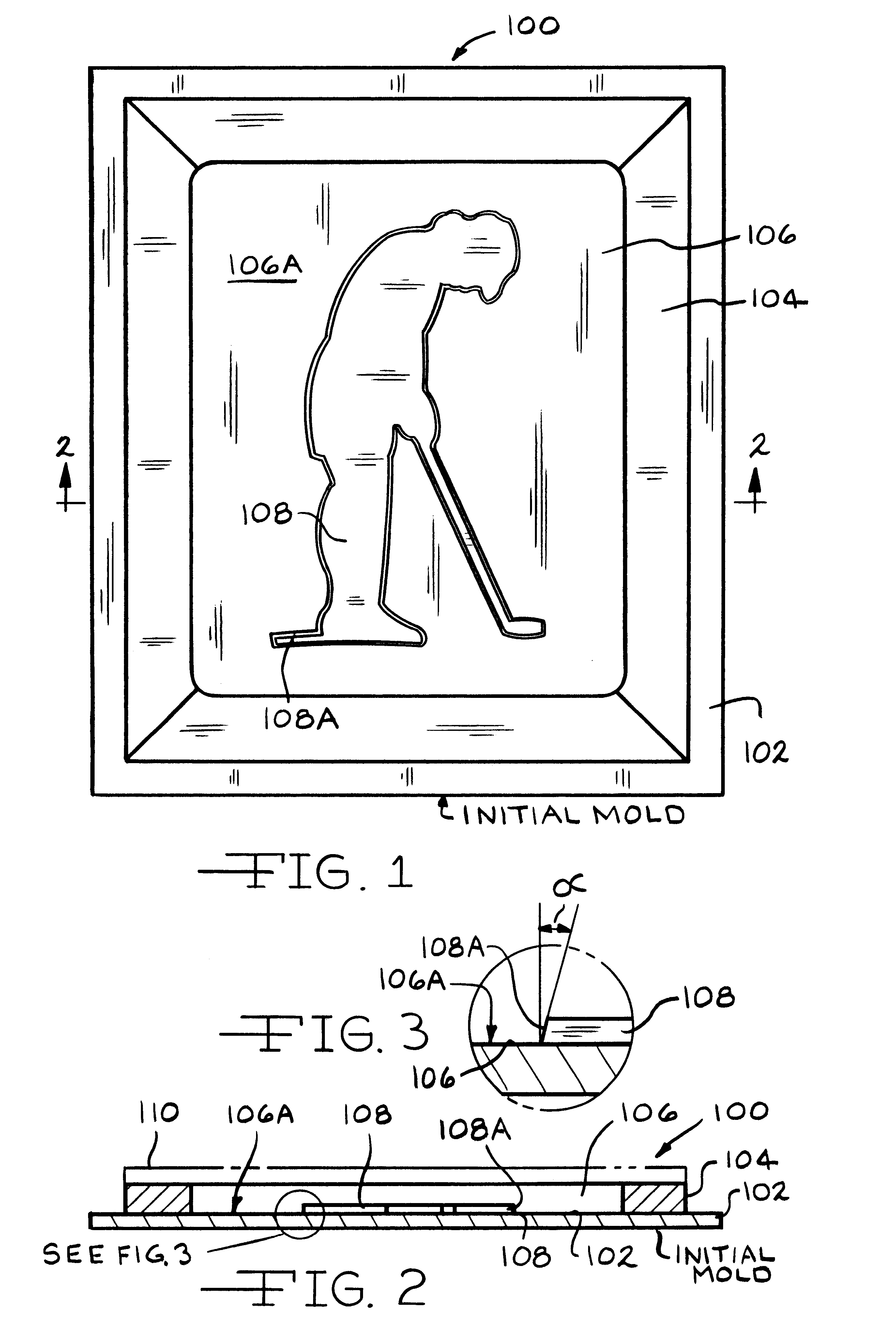

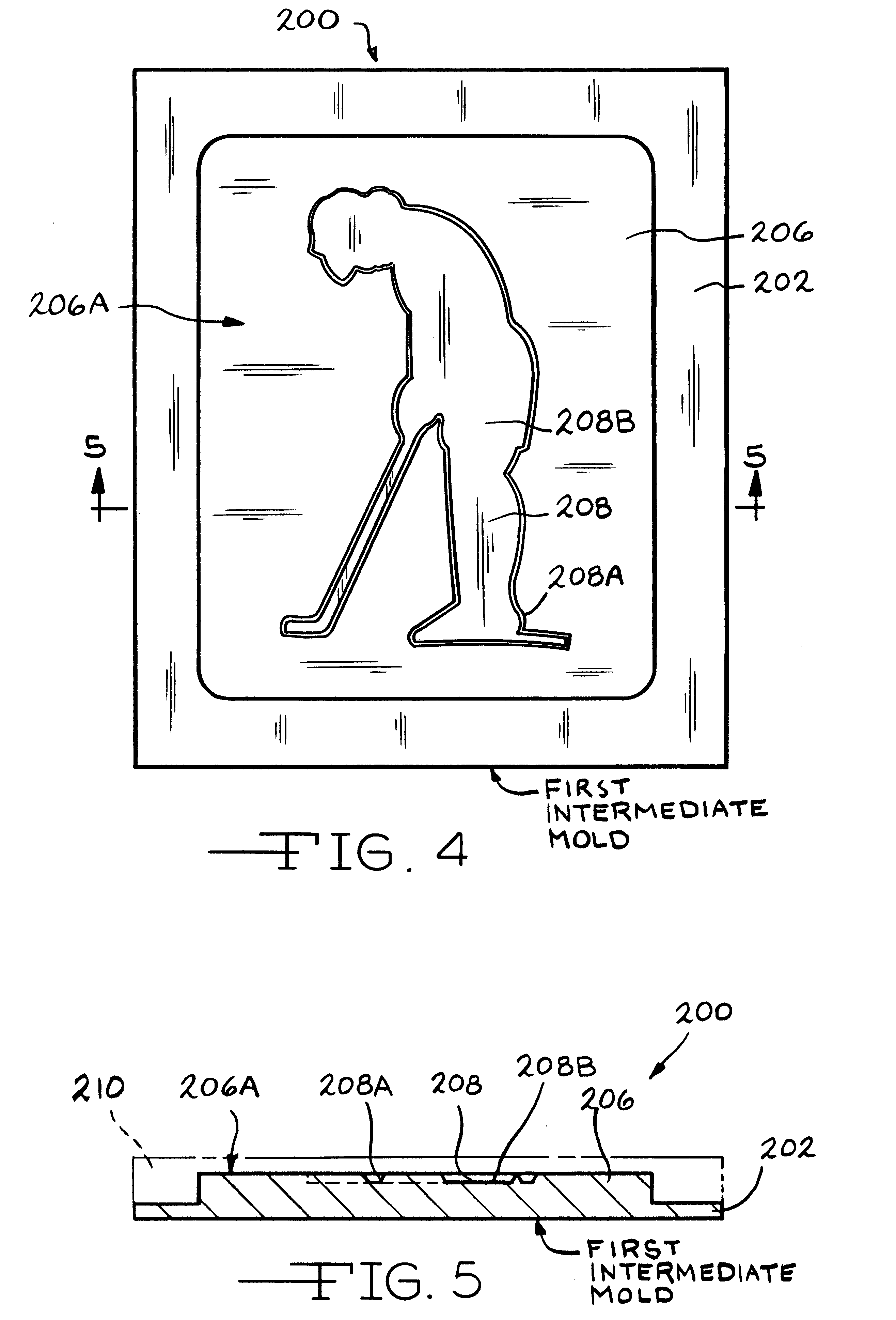

Method and apparatus for forming metal foil and solder assembled objects

A method and apparatus for constructing a metal foil and solder assembled object (10), is described. The apparatus includes a final mold (400) having a recessed final pattern (408). The sides (408A) of the final pattern form an obtuse angle with the floor (408B) of the final pattern. To create the object, material pieces (12), rods (14) and accessory pieces (16) are positioned in the final pattern. Prior to positioning the material pieces in the pattern, the edges (12A) of the material pieces are covered by foil (18). Once the material pieces, rods and accessory pieces are in place in the pattern, the pieces and rods are soldered together using conventional soldering techniques. The material pieces are positioned adjacent the sides of the pattern such that when the edges of the pieces are soldered, the solder (20) comes in contact with the sides of the pattern approximately half the distance up the edge of the material pieces. The contact with the sides causes the solder to form a radiused top portion above the point of contact with the sides such that the solder forms an aesthetically pleasing rounded bead around the edges of the material pieces.

Owner:HANLEY RICHARD E

Method of mounting an electroless nickel immersion gold flip chip package

InactiveUS7309647B1Few fractured solder bondImprove package reliabilitySemiconductor/solid-state device detailsPrinted circuit aspectsDopantElectroless nickel immersion gold

Owner:ALTERA CORP

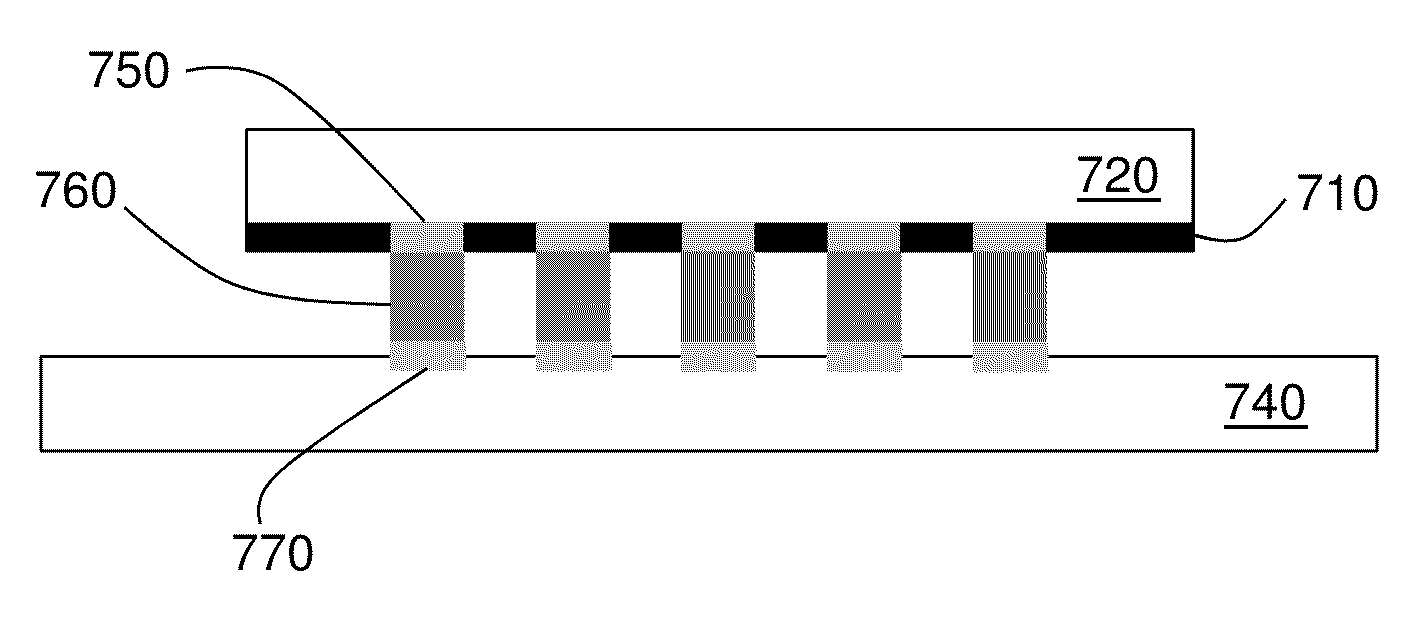

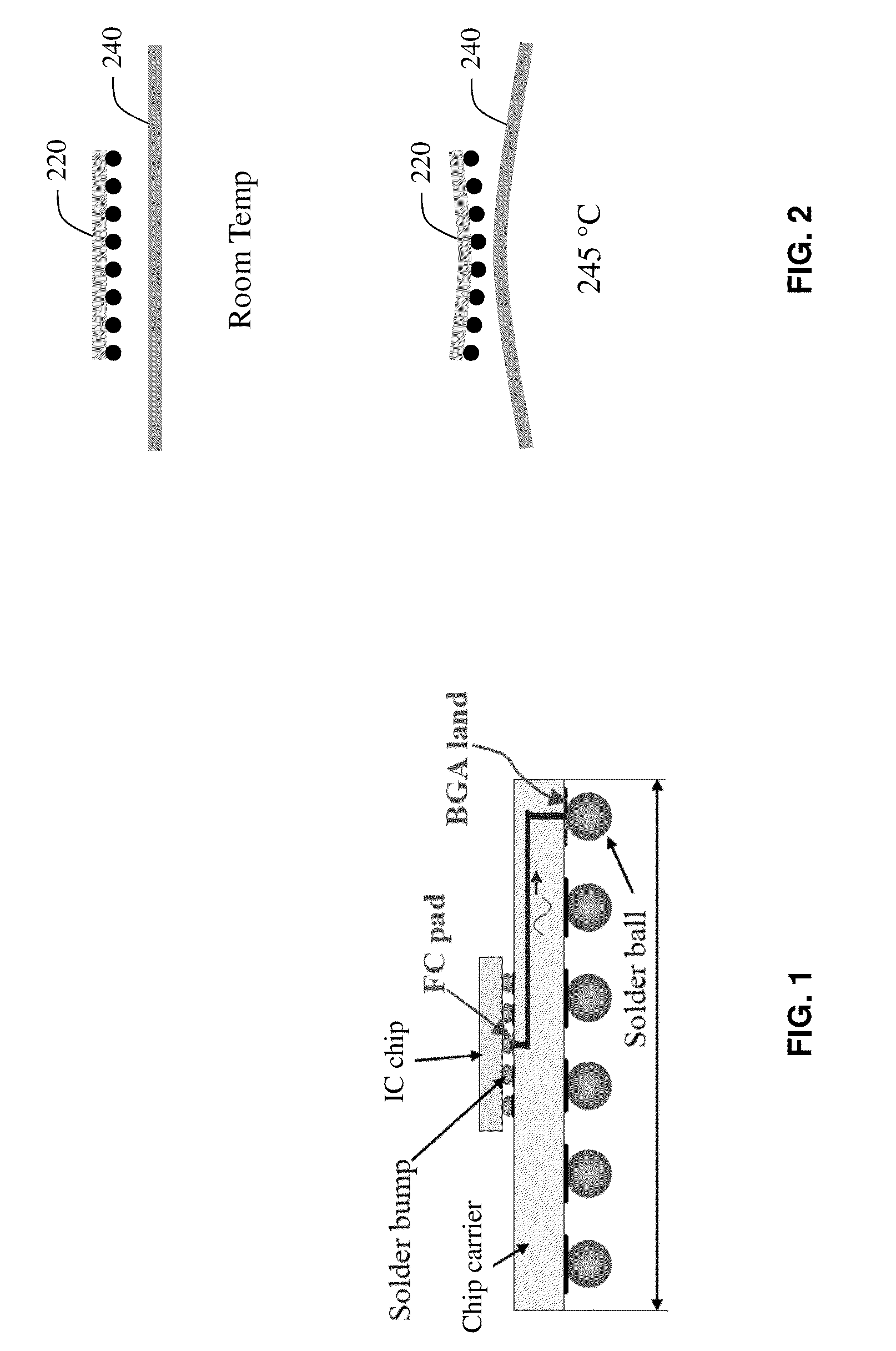

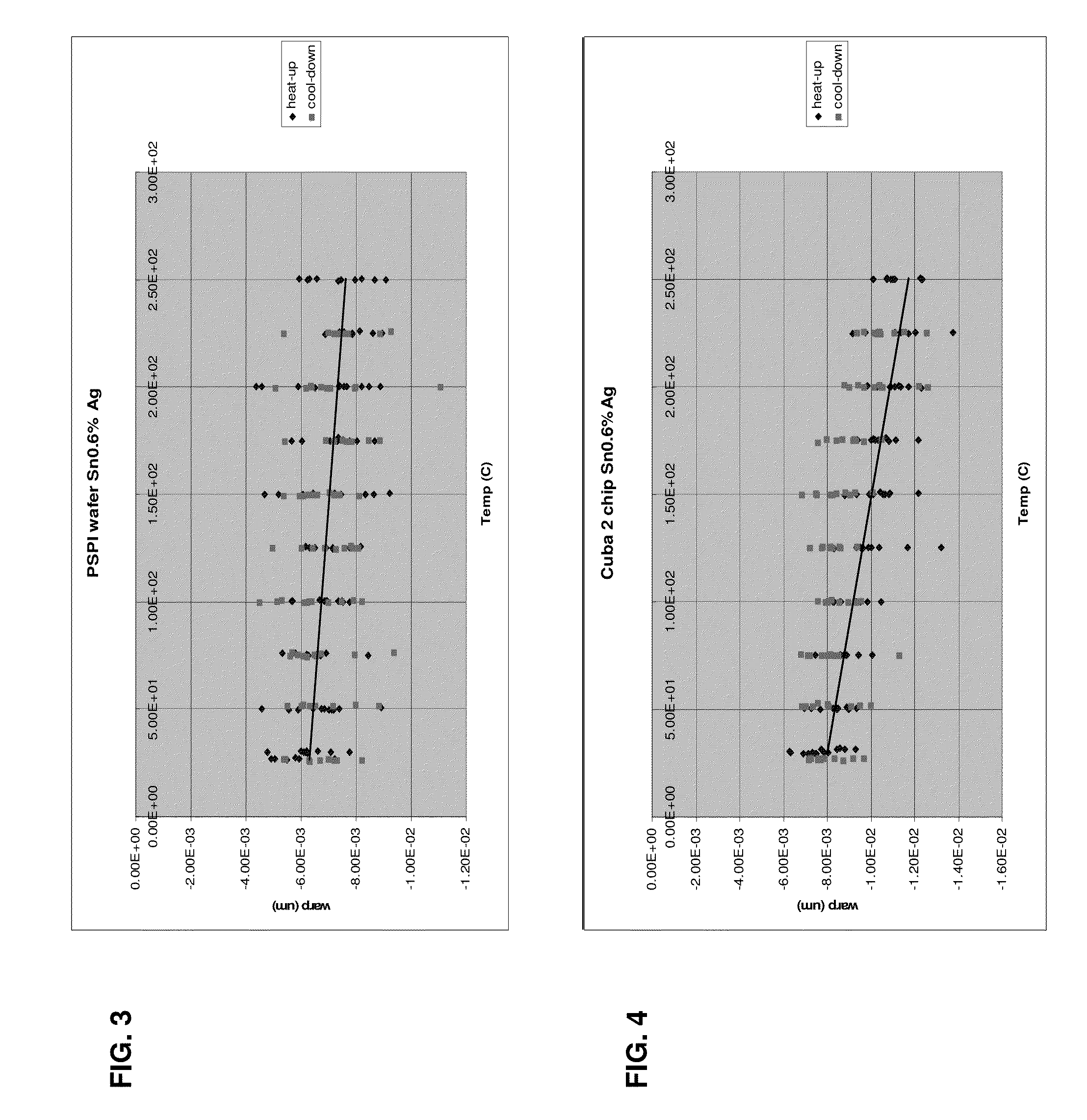

Overcoming chip warping to enhance wetting of solder bumps and flip chip attaches in a flip chip package

InactiveUS8927334B2Semiconductor/solid-state device detailsPrinted electric component incorporationElectrical connectionSolder form

Structures and methods for forming good electrical connections between an integrated circuit (IC) chip and a chip carrier of a flip chip package include forming one of: a tensile layer on a front side of the IC chip, which faces a tops surface of the chip carrier, and a compressive layer on the backside of the IC chip. Addition of one of: a tensile layer to the front side of the IC chip and a compressive layer the backside of the IC chip, may reduce or modulate warpage of the IC chip and enhance wetting of opposing solder surfaces of solder bumps on the IC chip and solder formed on flip chip (FC) attaches of a chip carrier during making of the flip chip package.

Owner:GLOBALFOUNDRIES U S INC

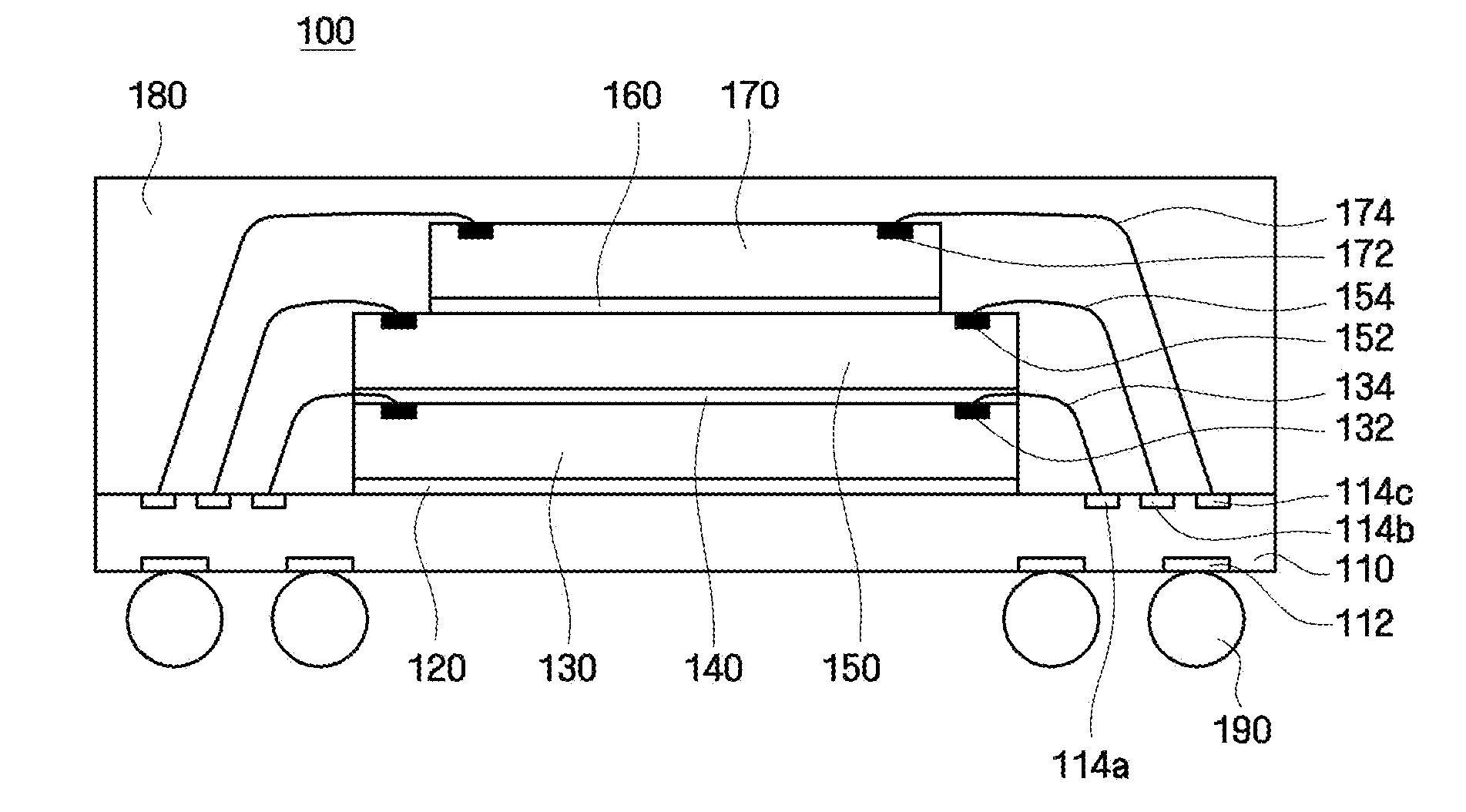

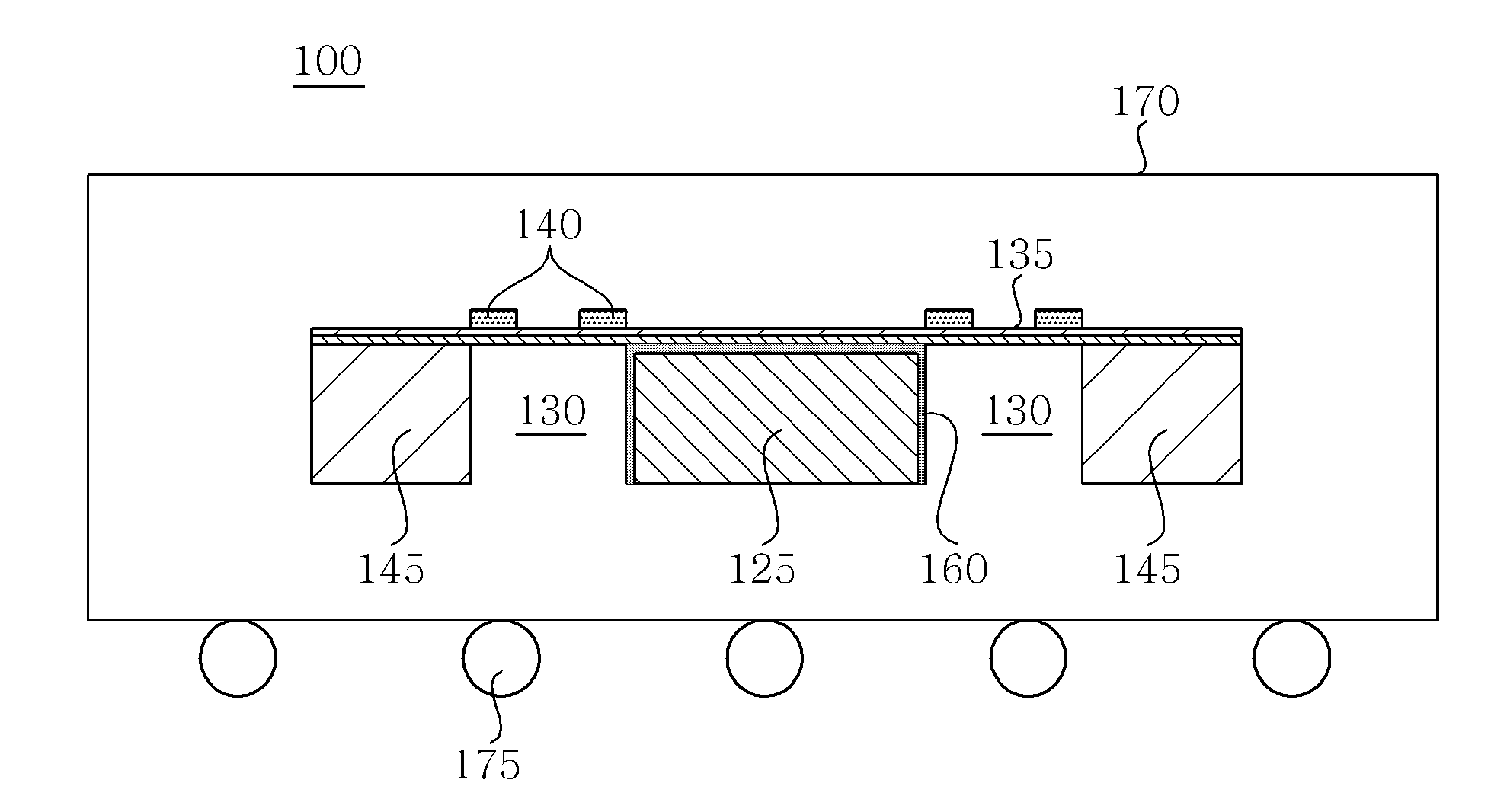

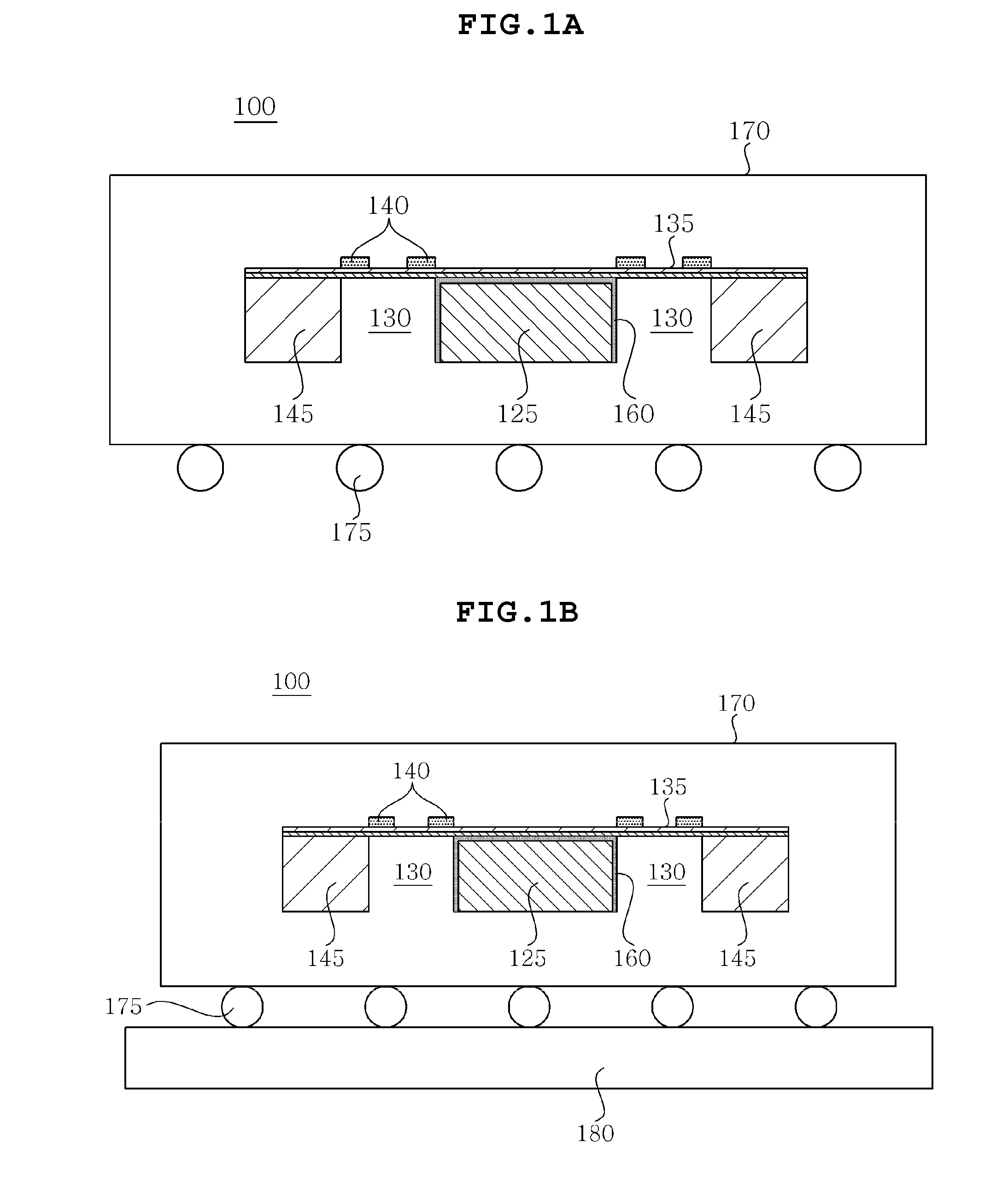

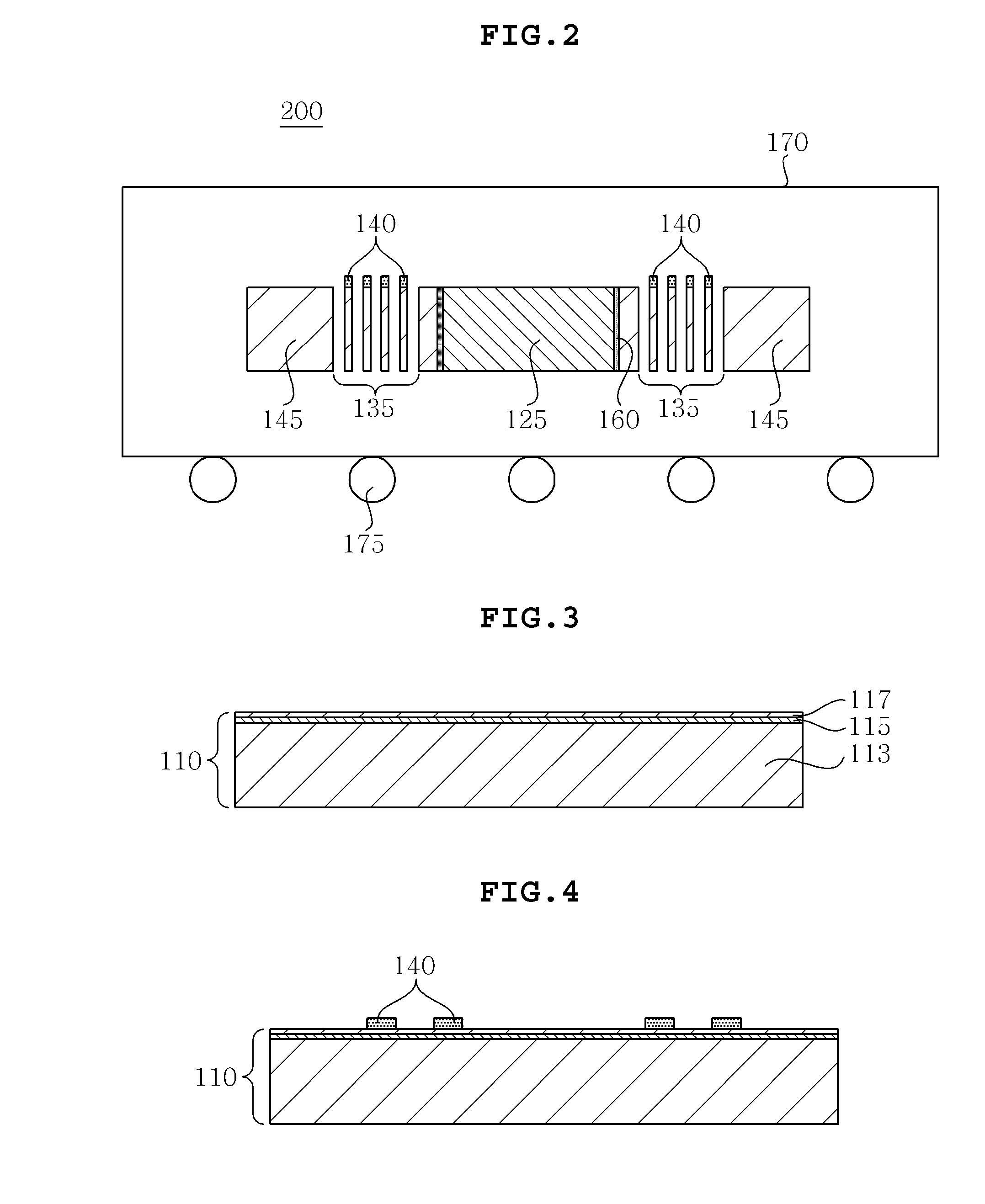

Stacked package, method of fabricating stacked package, and method of mounting stacked package fabricated by the method

ActiveUS20120252163A1Easy to makeMinimizing load appliedSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

Provided are a stacked package, method of fabricating a stacked package, and method of mounting a stacked package. A method includes providing an upper semiconductor package including an upper package substrate, upper semiconductor chips formed on a top surface of the upper package substrate, and first solders formed on a bottom surface of the upper package substrate and having a first melting temperature, providing a lower semiconductor package including a lower package substrate, lower semiconductor chips formed on a top surface of the lower package substrate, and solder paste nodes formed on the top surface of the lower package substrate and having a second melting temperature lower than the first melting temperature, and forming inter-package bonding units by attaching respective first solders and solder paste nodes to each other by performing annealing at a temperature higher than the second melting temperature and lower than the first melting temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

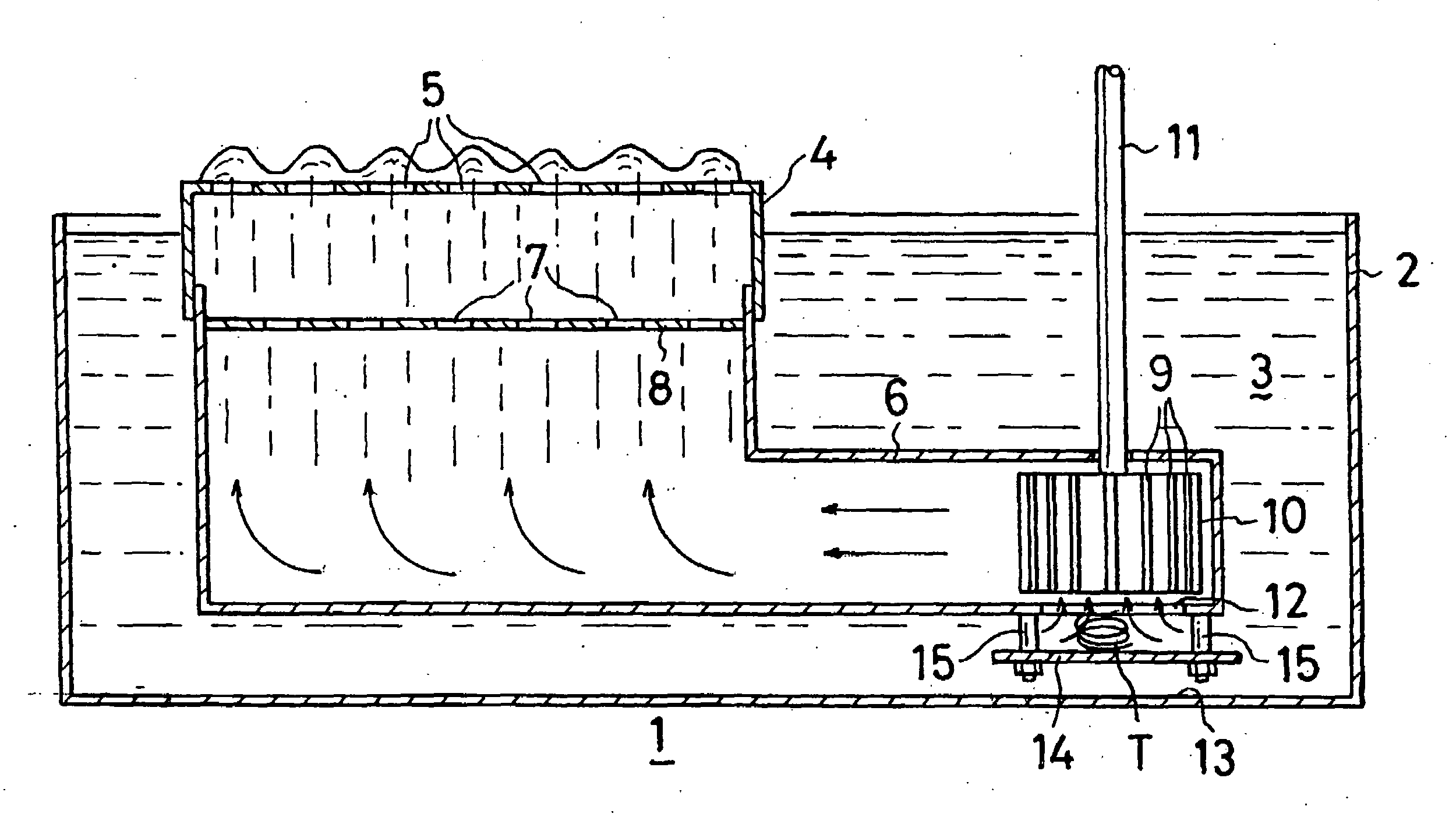

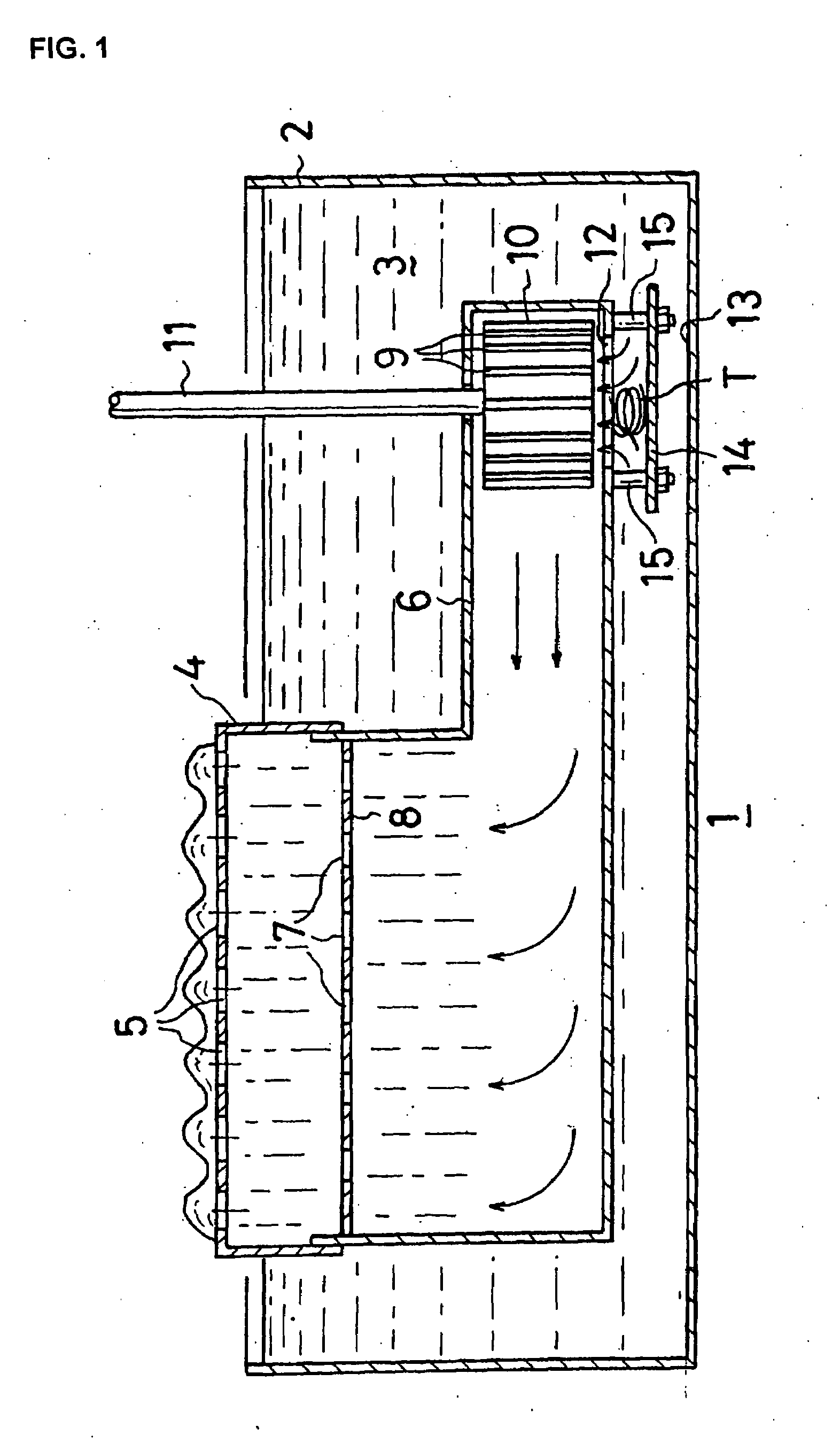

Wave Soldering Bath

ActiveUS20090050674A1Keep for a long timeGood effectWelding/cutting media/materialsSoldering mediaImpellerSolder form

In a conventional wave soldering bath, the bottom surface of a bath body in a position which is below the inlet of a duct underwent erosion by molten solder and had a hole formed therein, causing molten solder to be spilled out from the hole. The cause of erosion of the bottom surface of the bath body is a vortex (T) of molten solder formed below the duct inlet accompanying rotation of an impeller pump (10), and the vortex rubs the bottom surface of the bath body.In the present invention, a shielding member (14) is installed between the duct inlet (12) and the bottom surface (13) of the bath body such that the vortex is prevented from affecting the bottom surface.

Owner:SENJU METAL IND CO LTD

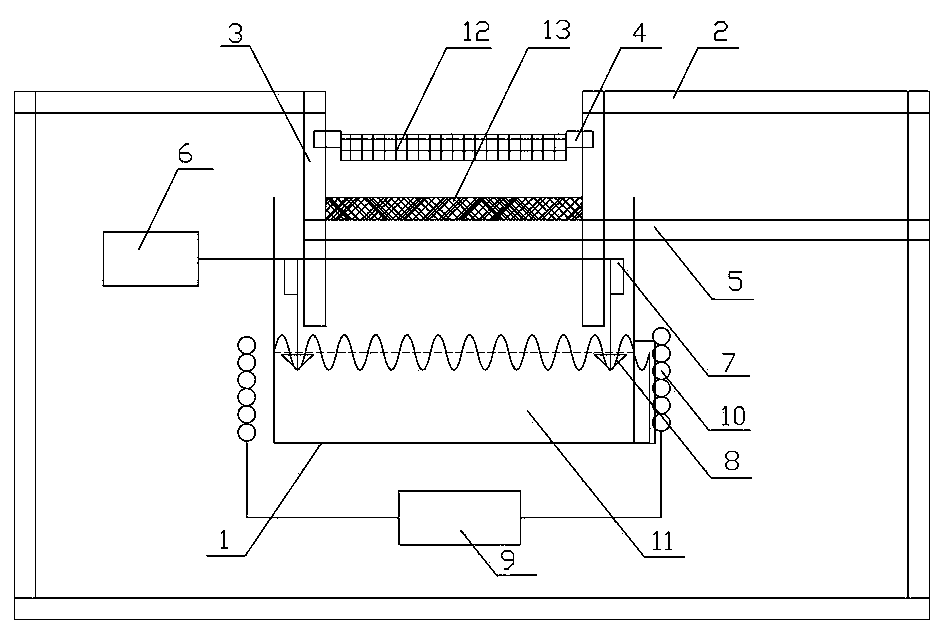

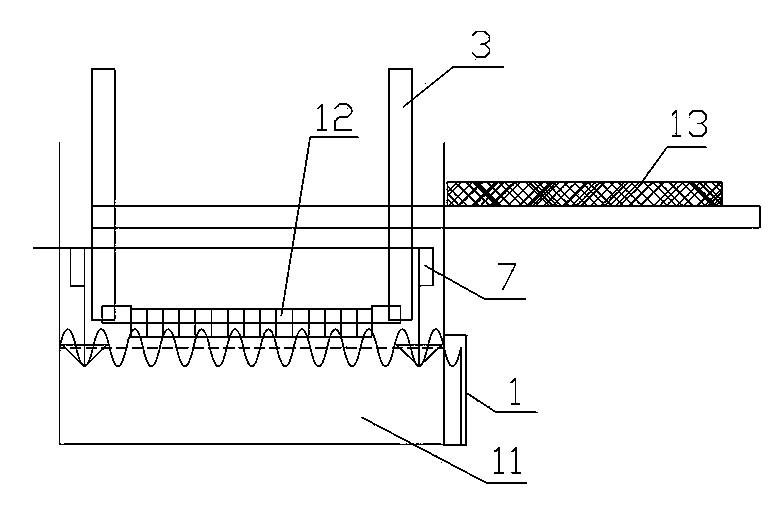

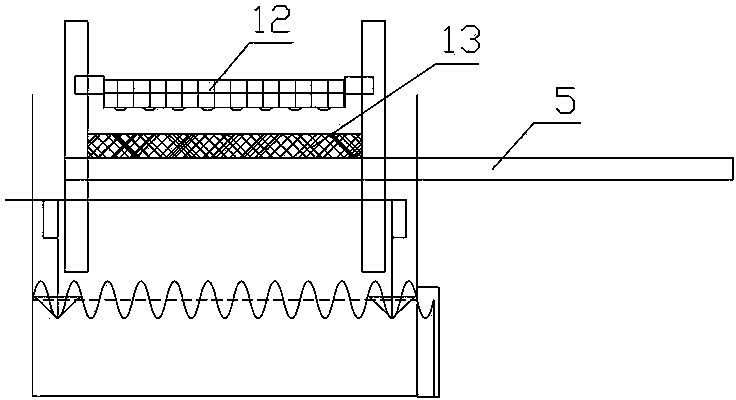

Stationary wave restrained large-area hard alloy soldering method and special equipment

ActiveCN103464855AEliminates the risk of braze crackingImprove slaggingSoldering apparatusRegular distributionCrucible

The invention discloses a stationary wave restrained large-area hard alloy soldering method, which is characterized in that special soldering equipment with a stationary wave generating device is used, first, after a solder is placed in a crucible for being fused, stationary waves are formed on the surface of the fused solder by the stationary wave generating device, after a to-be-soldered hard alloy piece is contacted with the wave crest on the surface of the fused solder, and the solder forms regular dotted or strip distribution on the to-be-soldered surface of the hard alloy, and then is connected with a metallic matrix to form discontinuous solder joints or strip soldering seams in regular distribution on a soldering interface between the hard alloy piece and the metallic matrix. The invention also discloses the special soldering equipment used in the method. The soldering method has the beneficial effects that a stress line accumulated on the soldering interface of the hard alloy is cut off, the stress of the soldering joint of the hard alloy is released, the cracking risk of a hard alloy tool during soldering is eliminated, and a new method is provided for solving the problem of overlarge stress due to soldering two large-area metals with different coefficients of thermal expansion.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Inertial sensor and method of manufacturing the sme

InactiveUS20130118258A1High sensitivityAvoid damagePiezoelectric/electrostrictive device manufacture/assemblyAcceleration measurement using interia forcesElectricitySurface mounting

Disclosed herein are an inertial sensor and a method of manufacturing the same. The inertial sensor includes: a flexible part; a mass body movably supported by the flexible part and including a metal; a post supporting the flexible part; piezoelectric elements driving the mass body or sensing displacement of the mass body; and a package enclosing the flexible part, the mass body, and the post, wherein the metal has a melting point lower than the Curie temperature of the piezoelectric elements and higher than that of a solder forming connection parts for a surface mounting technology (SMT) provided on the package.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Connection method of silver, copper and zinc belt-shaped solder and special connection device used in connection method

ActiveCN104191112AUniform materialReduce volatilityWelding/cutting media/materialsSoldering mediaSolder ballZinc

The invention discloses a connection method of silver, copper and zinc belt-shaped solder and a special connection device used in the connection method. According to the connection method, firstly, oxides on connection faces, to be connected, of two solder belts are removed; the connection portions of the solder belts are placed between an upper copper plate and a lower copper plate after being clamped and overlapped through the upper copper plate and the lower copper plate, and the contact faces of the solder belts are coated with silver solder flux and are placed between an upper pressure column and a lower supporting column; the upper pressure column falls downwards so as to tightly press the connection portions and keeps certain pressure; the upper copper plate and the lower copper plate are heated through an upper conductive electrode and a lower conductive electrode, so that the connection portions of the overlapped solder belts are heated and melted, the surfaces of the upper and lower copper plates are wetted through the melted solder, the surfaces of the copper plates are uniformly laid, the connection portions become thinner under pressure of the upper copper plate and the lower copper plate, redundant solder forms flash, the flash is cut off, the upper copper plate and the lower copper plate are worn off, and then connection is achieved. Materials of connectors of the solder belts are uniform, strength of the materials of the connectors of the solder belts is the same as that of base metal, and connection requirements in the rolling process of the silver, copper and zinc belt-shaped solder can be met. Meanwhile, the special connection device for the method is simple in structure and convenient to operate.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com