Printing solder detecting device

A technology of inspection device and soldering, which is applied in the direction of measuring device, assembling printed circuit with optical device and electrical components to achieve the effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

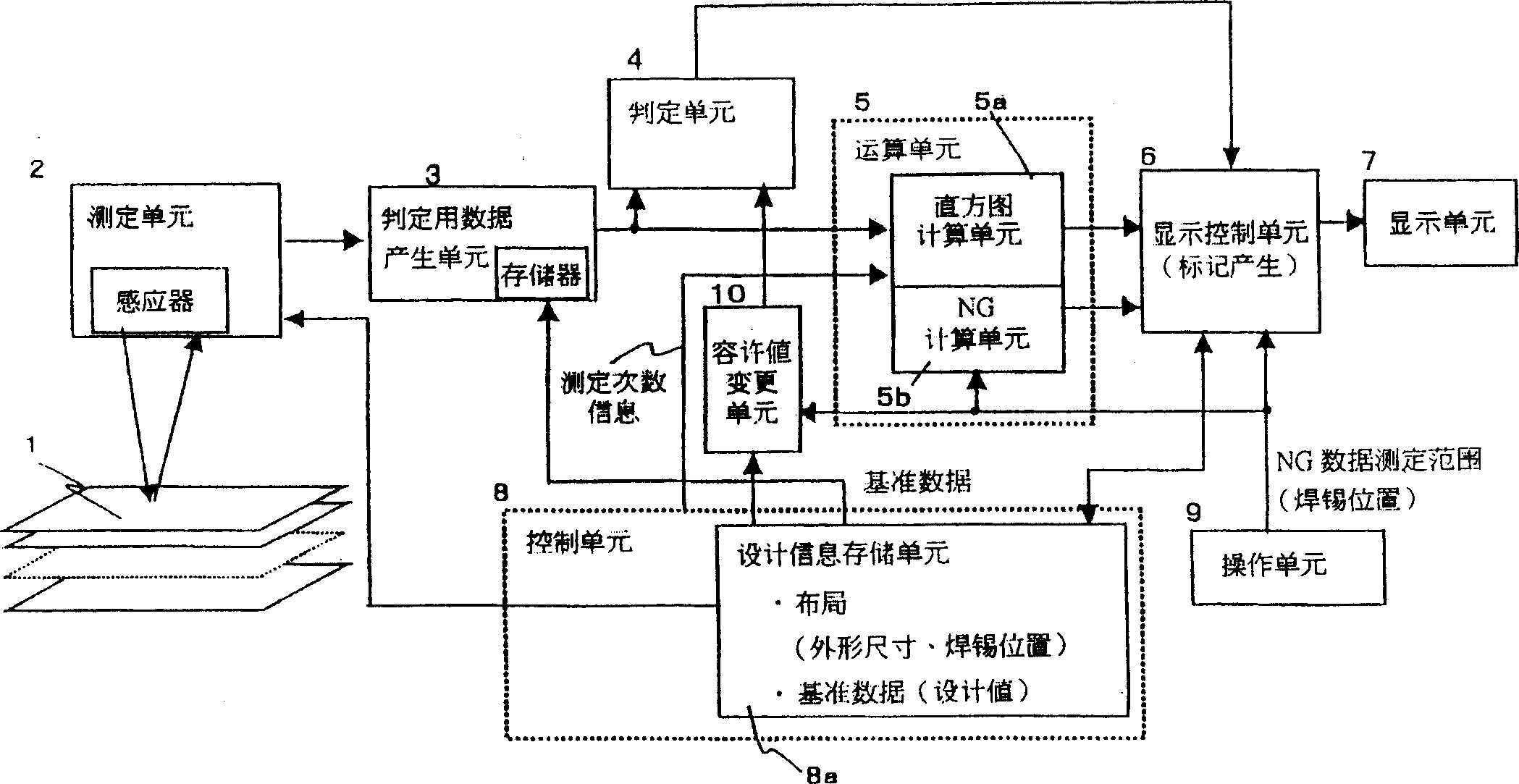

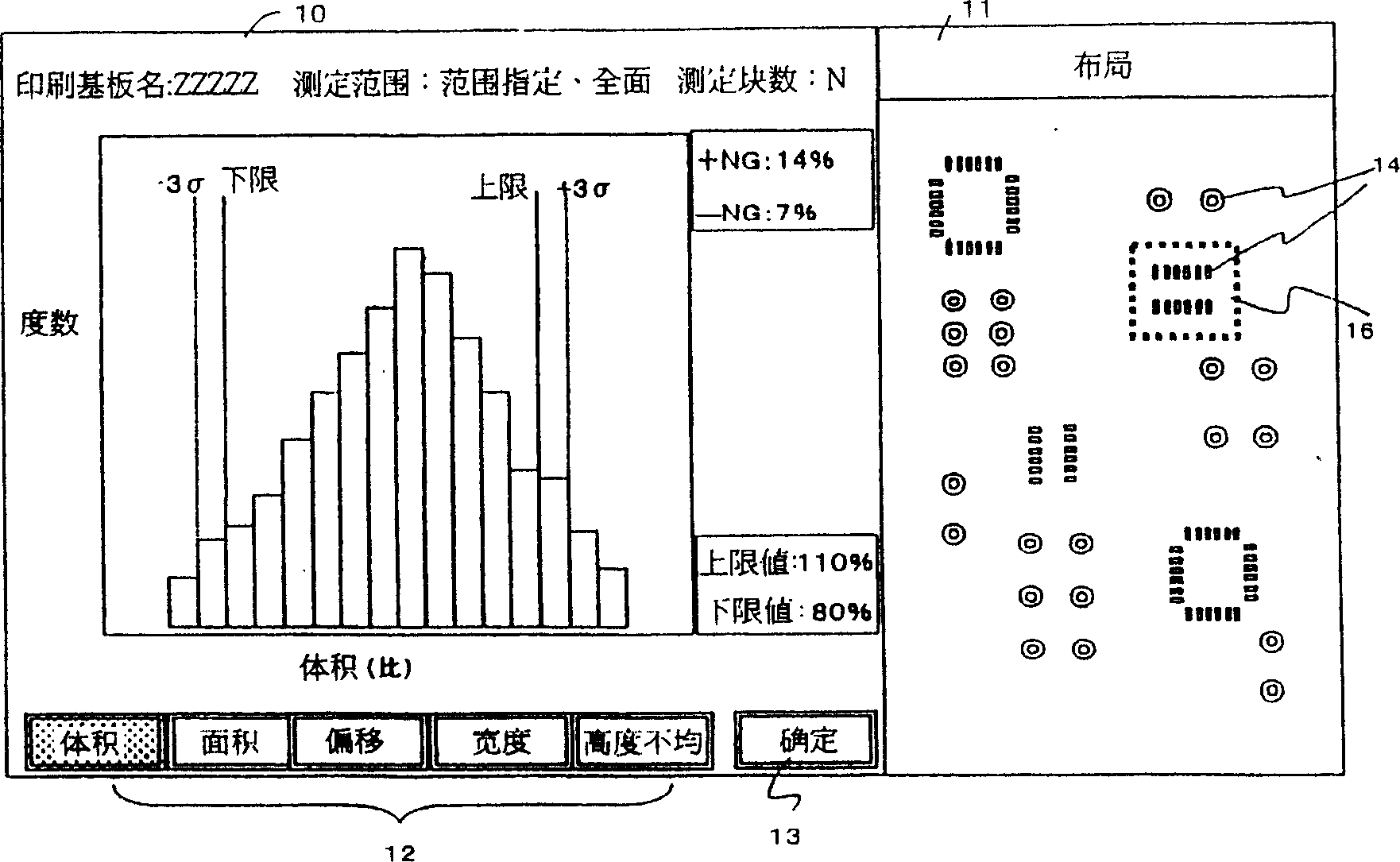

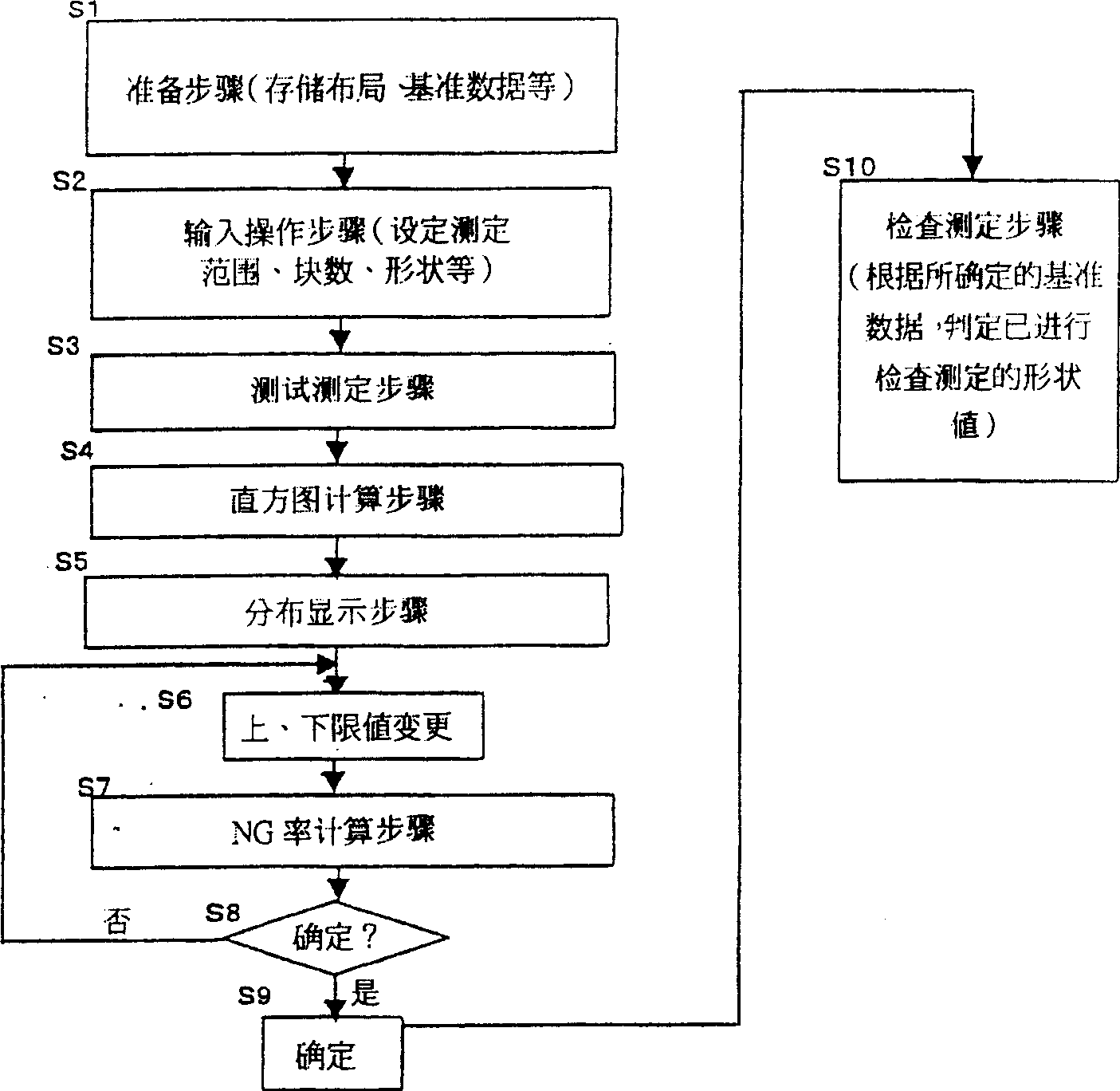

[0065] Embodiments of the present invention will be described using the drawings. figure 1 It is a functional block diagram showing the configuration of the embodiment of the present invention. figure 2 for figure 1 The display example of this embodiment is a display example of the NG rate and order distribution when the measurement range and shape are designated. image 3 to represent figure 1 The figure of the operation flow of this embodiment. Figure 4 for with image 3 A diagram of the different action flows of the usage operation. Figure 5 to express with figure 1 Functional block diagrams of the configurations of other embodiments corresponding to the embodiment of the present invention. Figure 6 to represent Figure 5 A diagram of an operation flow in another embodiment in . Figure 7 to represent Figure 5 Figures showing examples in other embodiments.

[0066] figure 1 In the measurement unit 2, there is a moving mechanism part (not shown), which receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com