Surface fitting device package lead connecting method

A wire bonding and wire bonding technology, applied in the field of new wire bonding, can solve problems such as misalignment, complicated manufacturing process, easy damage or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

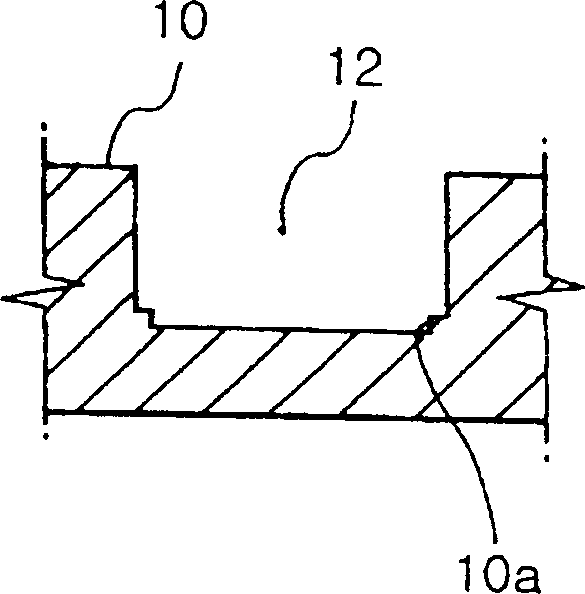

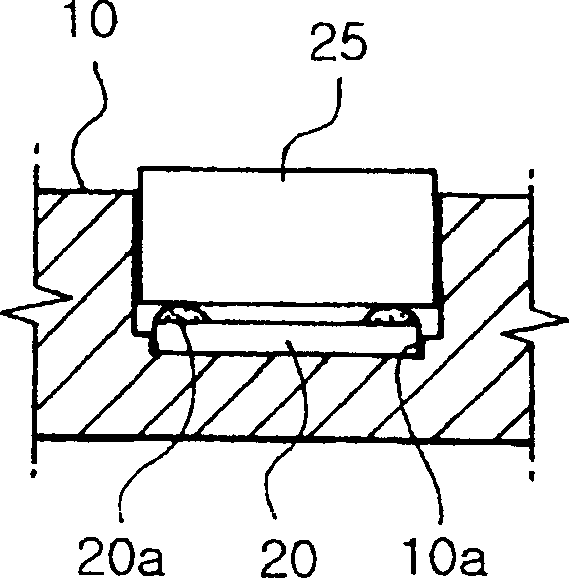

[0029] A wire bonding method for an SMD package according to the present invention will be described in detail below.

[0030] Figures 3a to 3d Schematic representation of the steps of a wire bonding method for an SMD package. First, if Figure 3a As shown in , the package 25 is arranged in the positioning groove of the support table 42 to allow the lead positioning surface of the package 25 on which the leads are positioned to face upward. The supporting platform 42 is made of common non-magnetic material or graphite material, and has a plurality of positioning grooves. Each positioning groove of the support platform 42 does not have to have the same size as the package or have a stepped structure like the positioning grooves of a conventional graphite jig. Therefore, the jig of the present invention can be easily manufactured and can prevent misalignment due to breakage of the stepped structure.

[0031] Such as Figure 3b As shown in , the leads 20 are positioned in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com