Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Potassium ethyl xanthate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

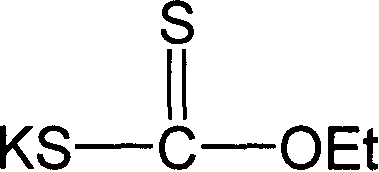

Potassium ethyl xanthate (KEX) is an organosulfur compound with the chemical formula CH₃CH₂OCS₂K. It is a pale yellow powder that is used in the mining industry for the separation of ores. Unlike the related sodium ethyl xanthate, the potassium salt exists as an anhydrous salt.

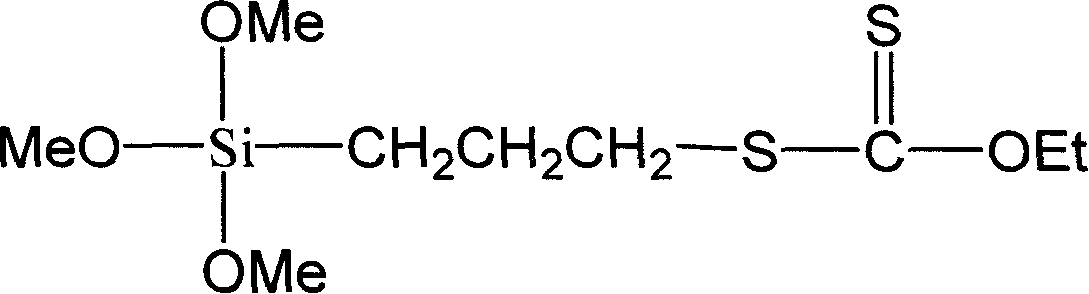

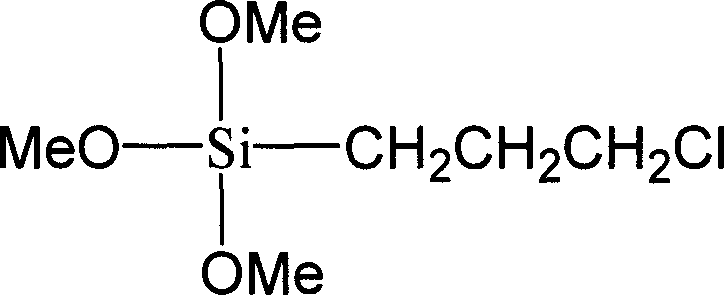

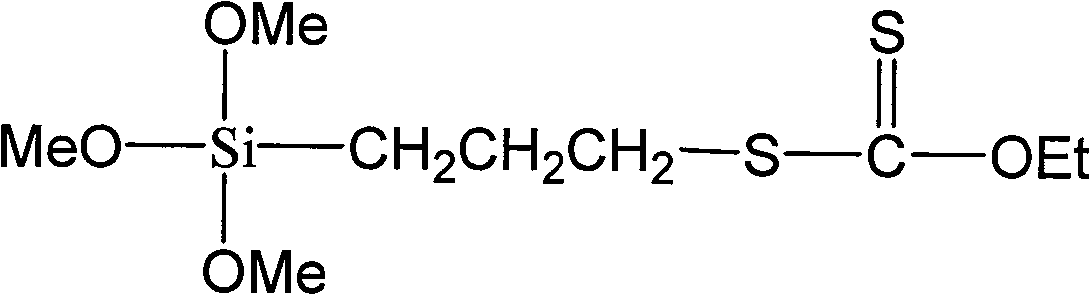

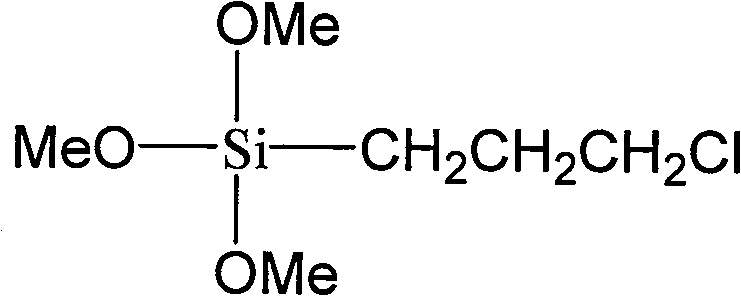

Sulfuric silane coupling agent and its synthesis process

InactiveCN1931862AGood dispersionImprove reinforcementGroup 4/14 element organic compoundsSilanesNitrogen

The present invention relates to one kind of sulfuric silane coupling agent and its synthesis process. In methanol as solvent, materials chloropropyl trimethoxyl silane and potassium ethyl xanthate react under the protection of pure nitrogen to produce xanthate propyl trimethoxyl silane as the target sulfuric silane coupling agent. Xanthate propyl trimethoxyl silane is used in treating inorganic filler, especially white carbon black rubber filler system, and can promote the dispersion of filler in the base material to make filler possess excellent reinforcing performance. It is suitable for high temperature mixing to lower the production cost and suitable for use for various inorganic powder fillers.

Owner:ZHEJIANG UNIV +3

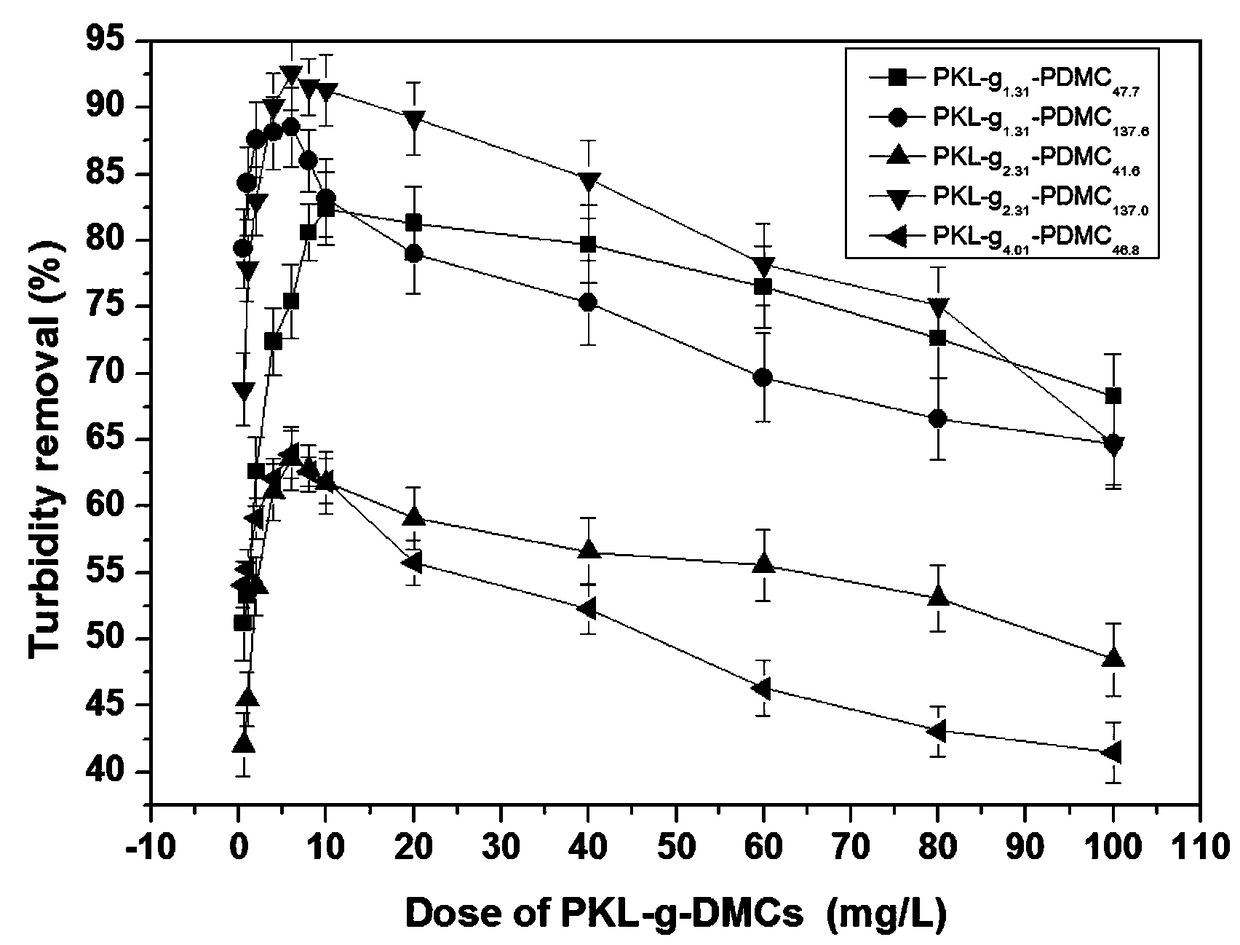

Lignin-based polyquatemary salt cation water treatment agent and preparation method thereof

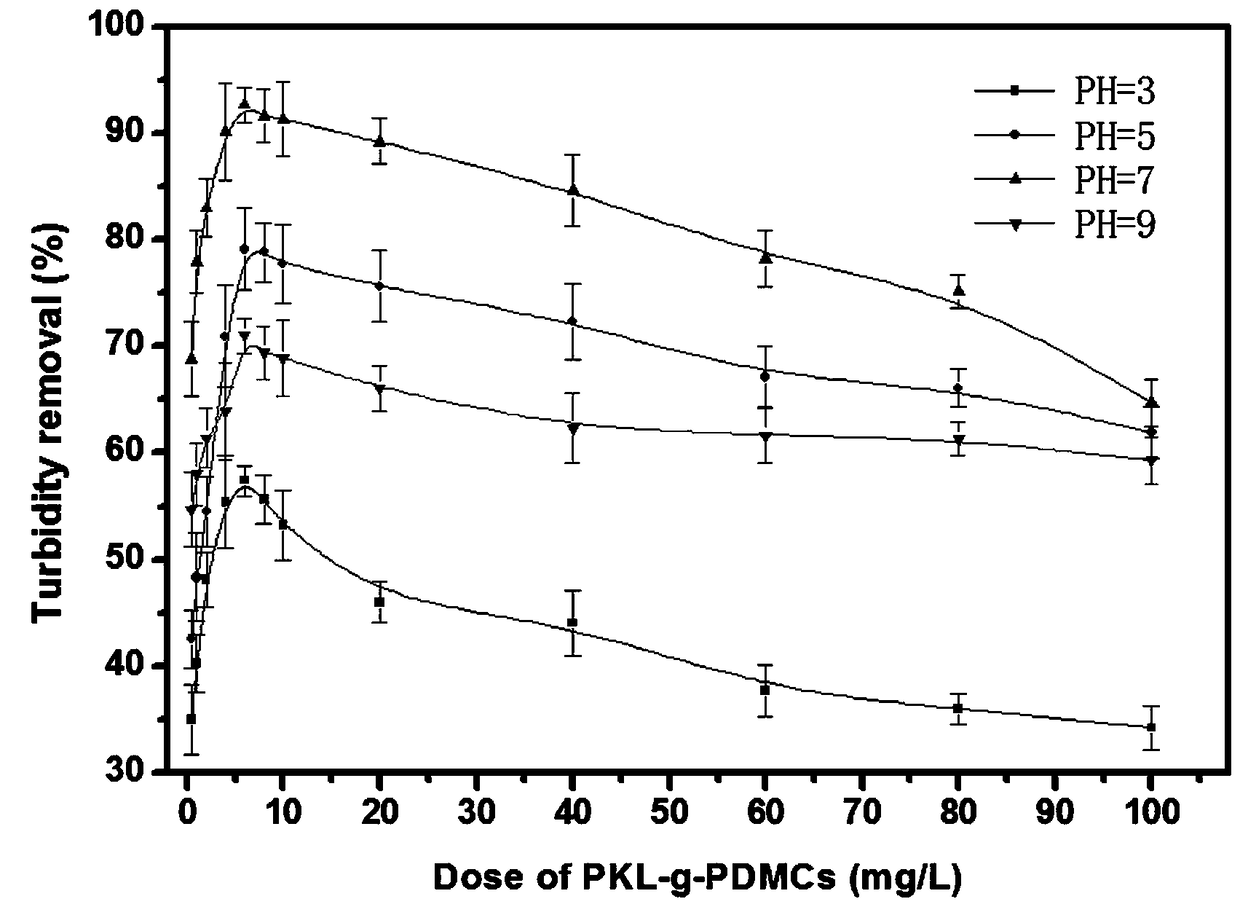

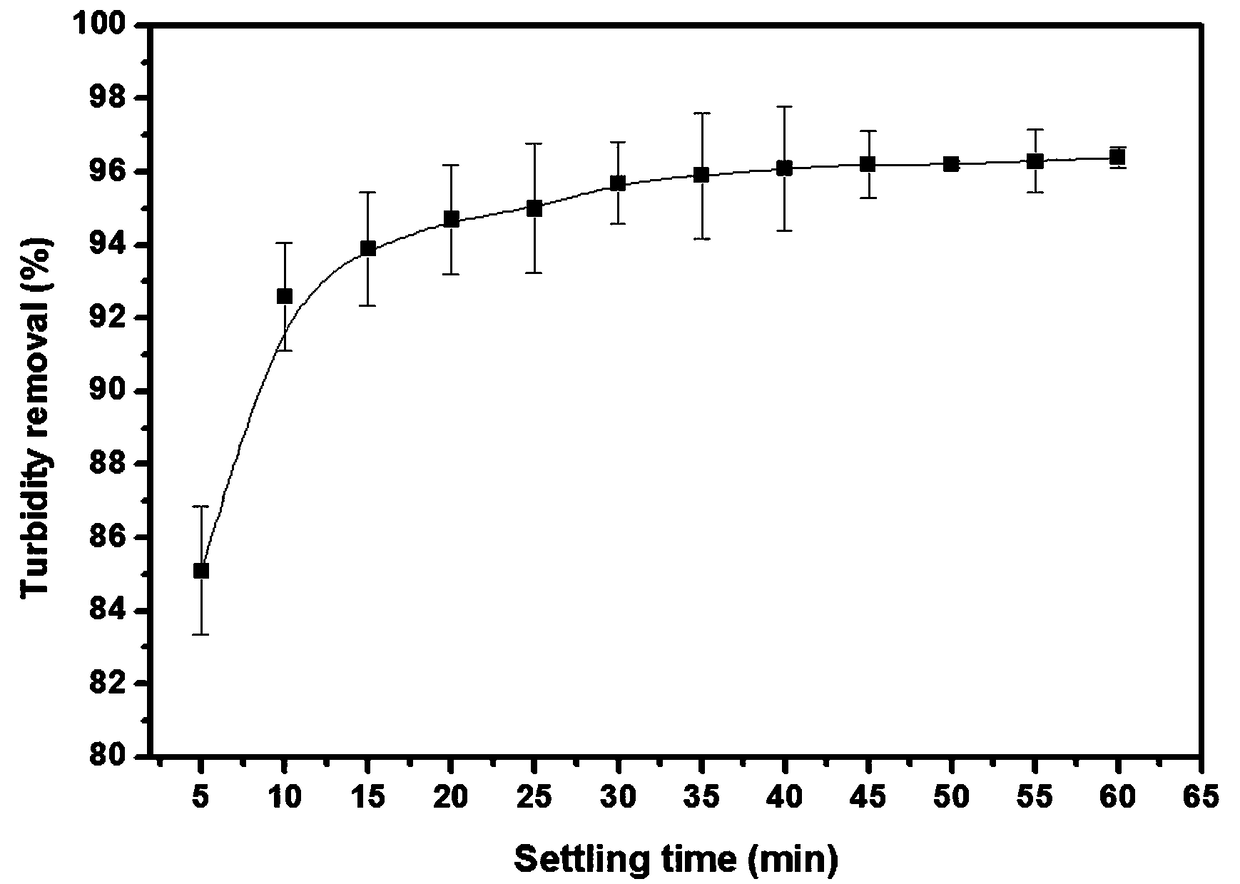

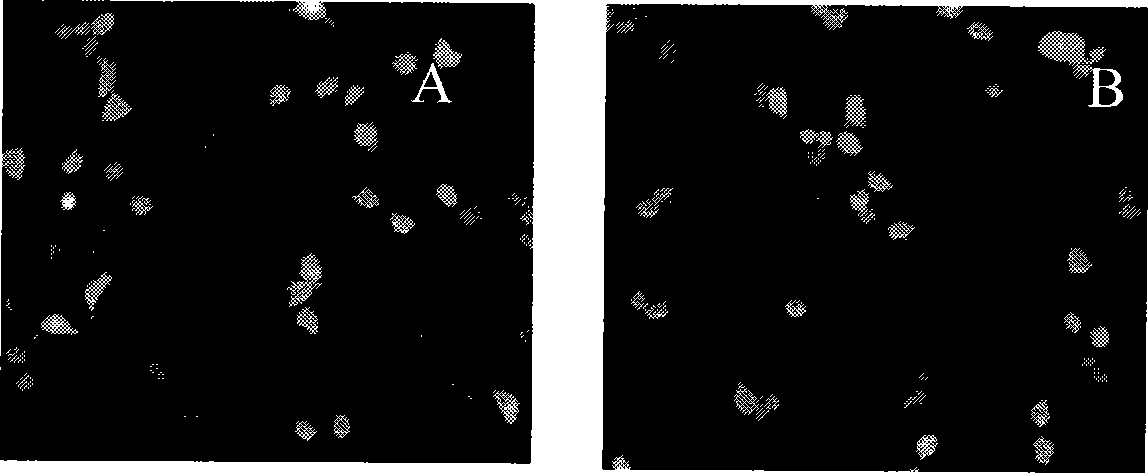

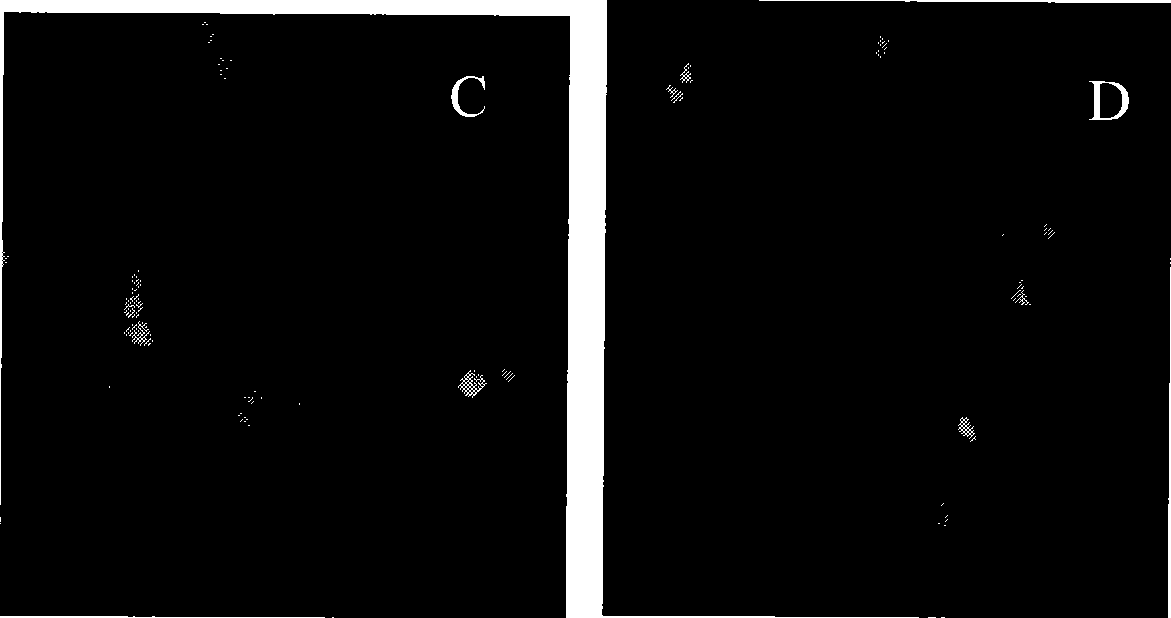

ActiveCN108751370AImprove settlement performanceImprove conversion rateWater/sewage treatment by flocculation/precipitation2-bromopropionic acidPotassium

The invention relates to the technical field of a sewage treatment material, in particular to a lignin-based polyquatemary salt cation water treatment agent and a preparation method thereof. The method is characterized in that potassium ethyl xanthogenate and 2-bromopropionic acid are used as raw materials for preparing 2-(ethoxythiomethyl) thiodipropionic acid; then, the 2-(ethoxythiomethyl) thiodipropionic acid and alkali lignin or lignin derivatives are synthetized into a lignin-based RAFT chain transfer agent through esterification reaction; finally, under the effects of a radical initiator and the lignin-based RAFT chain transfer agent, methacryloyloxyethyl trimethyl ammonium chloride is polymerized to obtain a star-shaped multi-arm lignin-based polyquatemary salt cation water treatment agent through free radical active polymerization. The method has the characteristics that the conversion rate is high; the molecular weight is great; the molecular weight distribution is narrow; the reaction conditions are mild; the target product structure can be designed, regulated and controlled according to the flocculating performance; the flocculating efficiency is high. The prepared water treatment agent can be widely applied to the removal of suspension solid particles difficult to settle in domestic sewage and industrial sewage.

Owner:GUANGXI UNIV FOR NATITIES

Polymethacrylate, preparation method and application thereof

InactiveCN101429260AAbility to promote endocytosisFacilitated releaseGenetic material ingredientsPharmaceutical non-active ingredientsAminolysisMethyl group

The invention relates to reductive cation polymethacrylate, a preparation method thereof, application of the polymethacrylate to establishment of gene nano-complexes and application of the polymethacrylate to gene therapy. The method comprises the following steps: 1, 3, 5-triisopropylphenyl is taken as a raw material and reacts with N- bromosuccinimide and potassium ethyl xanthate to obtain substituted 1, 3, 5- triisopropylphenyl potassium ethyl xanthate; and the substituted 1, 3, 5- triisopropylphenyl potassium ethyl xanthate is catalyzed by azo-bis-iso-butyrynitrile, and subjected to reversible addition-broken strand transfer polymerization, aminolysis and oxidation reaction with 2-(dimethylamino ethyl)metacrylic acid ester to obtain poly (1, 3, 5-three-terminal sulfhydryl (2-propyl phenyl -2-(dimethylamino)ethyl)) methacrylic acid ester) and disulfide bond crosslinking products of the poly (1, 3, 5-three-terminal sulfhydryl (2-propyl phenyl -2-(dimethylamino)ethyl)) methacrylic acid ester). The polymethacrylate can condense plasmid genes into nano complexes; the transfection efficiency of HEK293T cells and Hella cells is more than 30 percent; the toxicity is low; and the survival rate of the cells is more than 80 percent.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

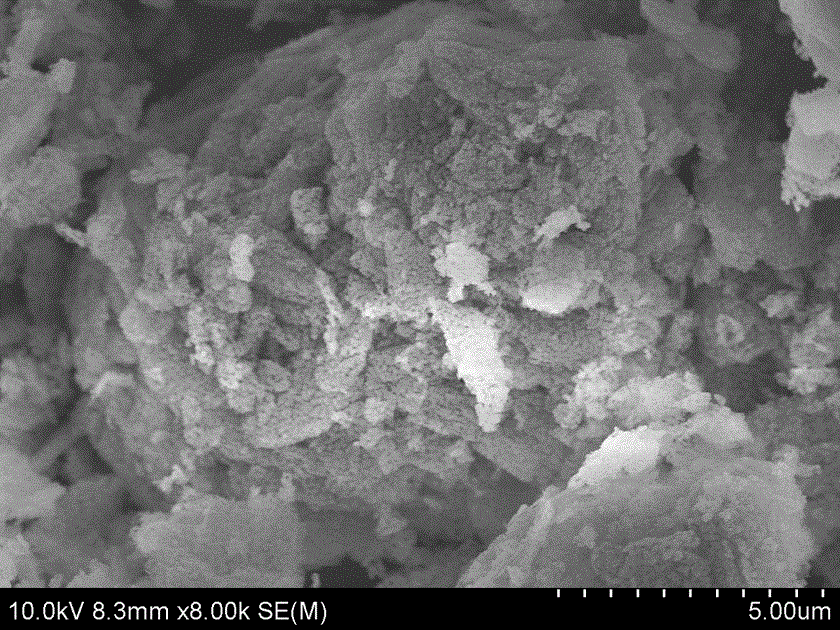

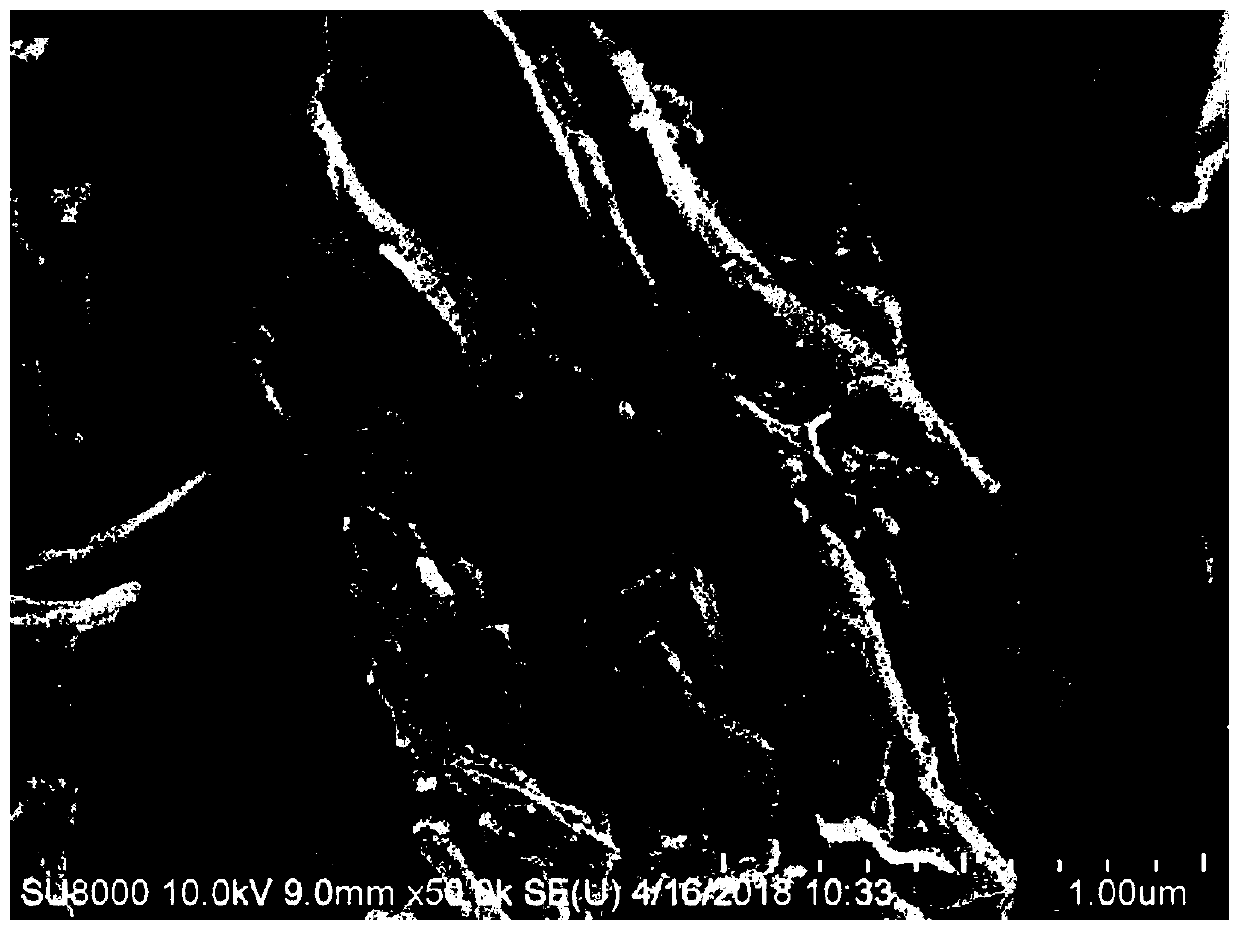

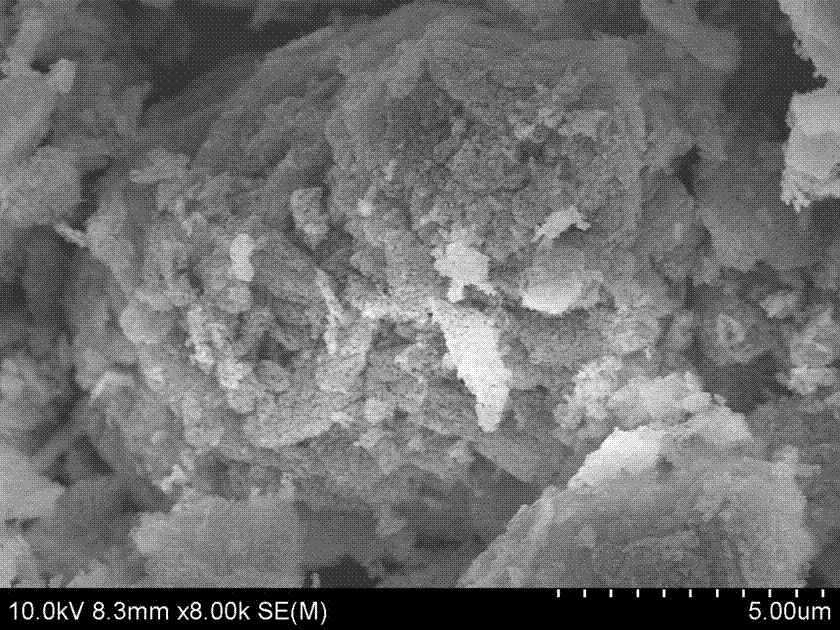

Preparation method of ZnO-CuO composite nano material

ActiveCN106542562AImprove gas-sensing propertiesSimple preparation processMaterial nanotechnologyZinc oxides/hydroxidesRoom temperatureZinc salts

The invention discloses a preparation method of a ZnO-CuO composite nano material. The preparation method comprises the following steps: stirring and dripping a potassium ethyl xanthate liquid into a zinc salt liquid; mixing obtained sediment with de-ionized water; drying to obtain zinc ethyl xanthate powder; stirring and dripping the potassium ethyl xanthate liquid into a copper salt liquid and drying to obtain copper ethyl xanthate powder; mixing copper ethyl xanthate and zinc ethyl xanthate to obtain powder A, and pre-mixing the powder A with the de-ionized water; adding an organic dispersant and an inorganic dispersant into a mixed liquid; drying and roasting, wherein the roasting temperature is 400 DEG C-500 DEG C, the temperature rising speed is 3 DEG C / min-10 DEG C / min and the roasting time is 2h-5h; and then cooling to room temperature to obtain the ZnO-CuO composite nano material. The method disclosed by the invention adopts a simple preparation process, is low in preparation cost, stable in performance and good in gas selectivity and has wide application prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

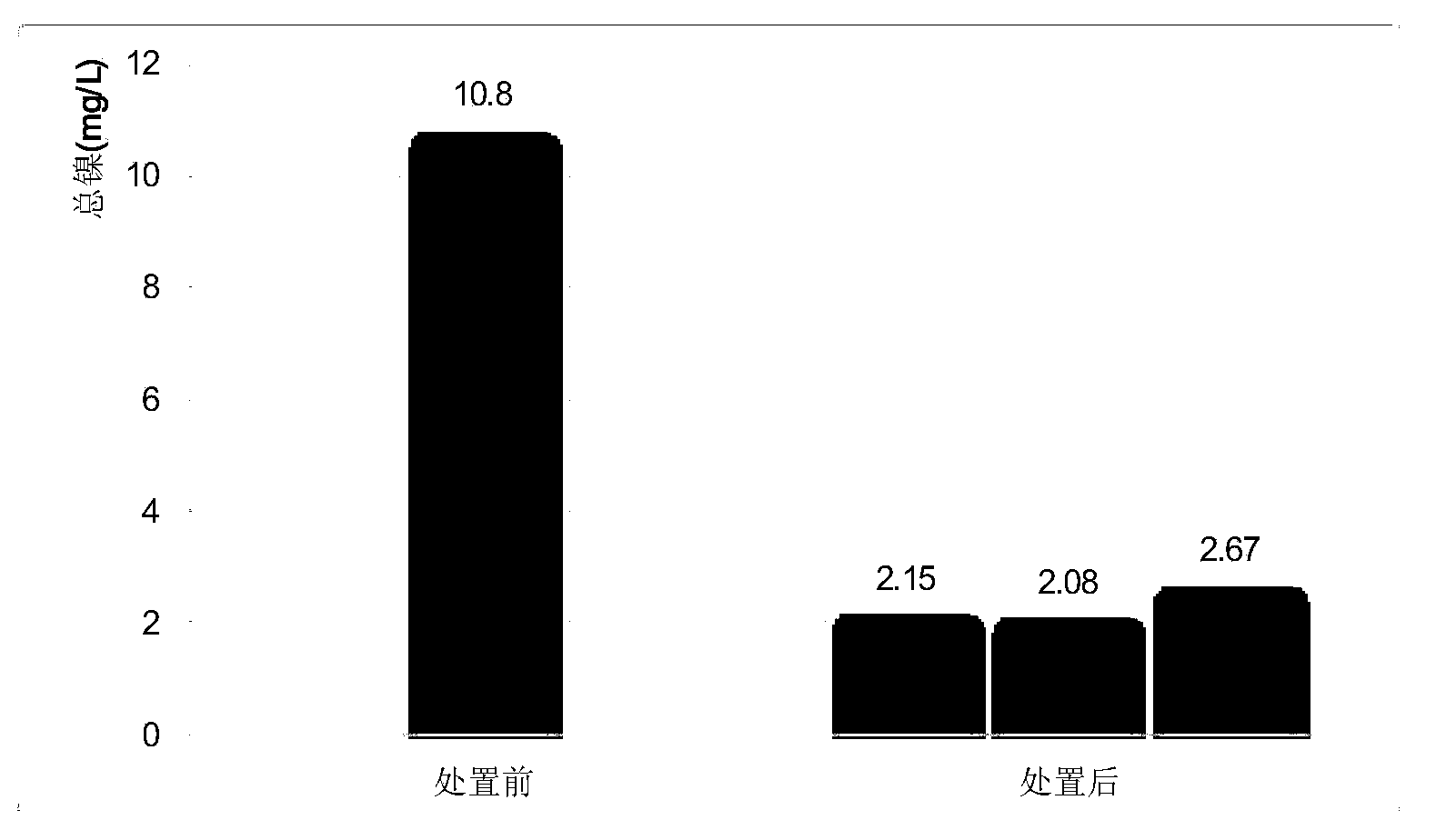

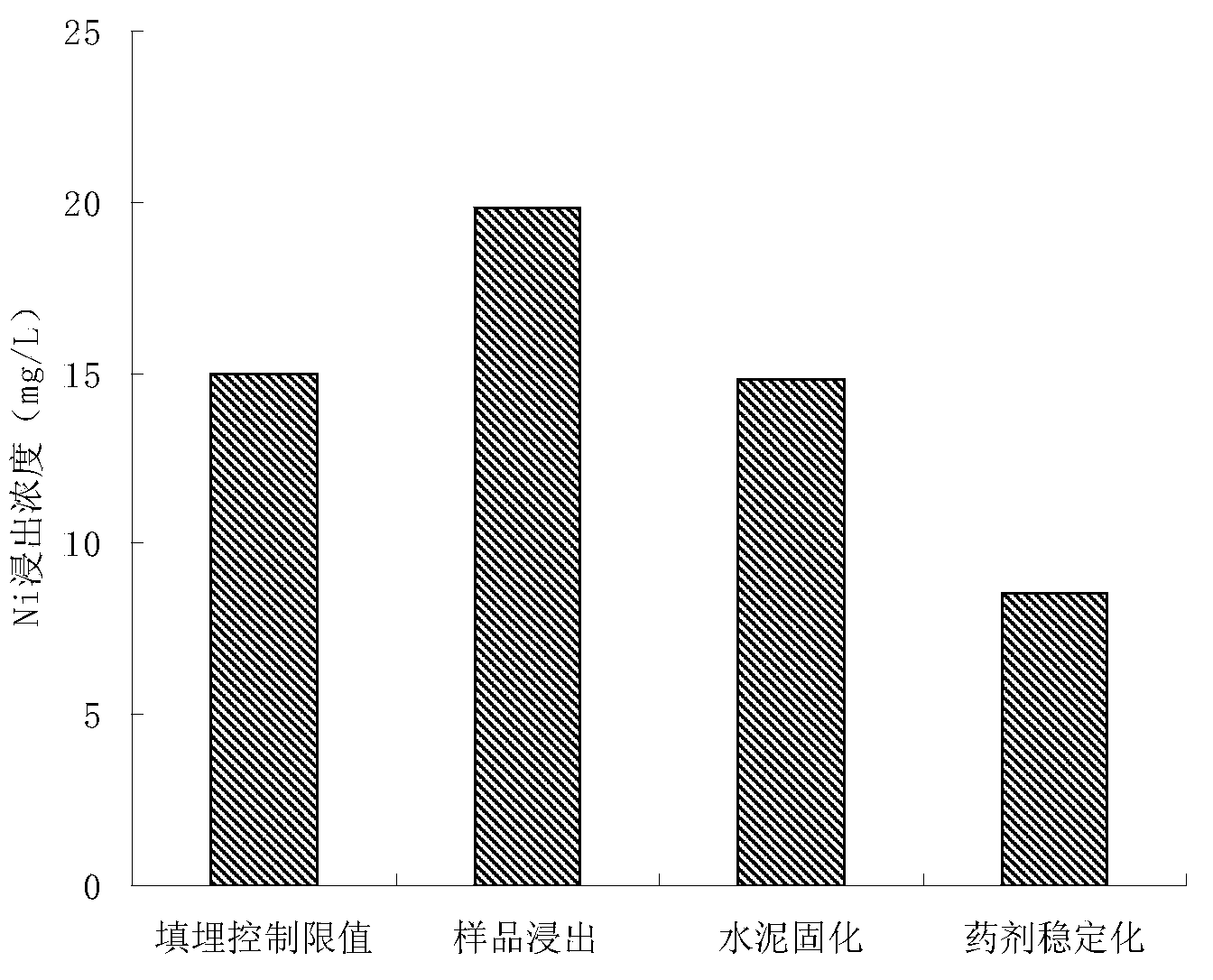

Stabilization chemical agent and processing method for processing nickel-containing dead catalyst

InactiveCN103861232AReduce leaching concentrationImprove stabilityChemical protectionMass ratioChemical agent

The invention relates to a stabilization chemical agent and a processing method for processing a nickel-containing dead catalyst. The chemical agent comprises artificial zeolite and potassium ethyl xanthate according to a mass ratio of (15-25): 1. The processing method comprises the following steps: weighing, conveying, performing stirring stabilization, and landfilling after discharging. According to the processing method, a conventional stabilization / solidification technology can be replaced and the enlargement ratio can be reduced to the maximum extent while the stabilization / solidification effect is guaranteed.

Owner:南京市生态环境保护科学研究院

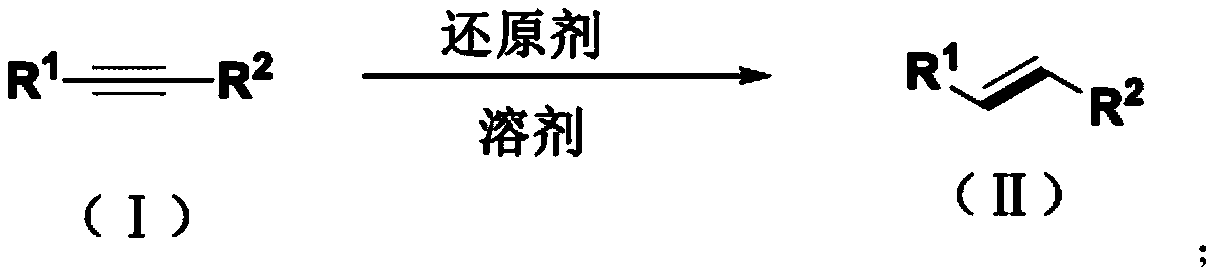

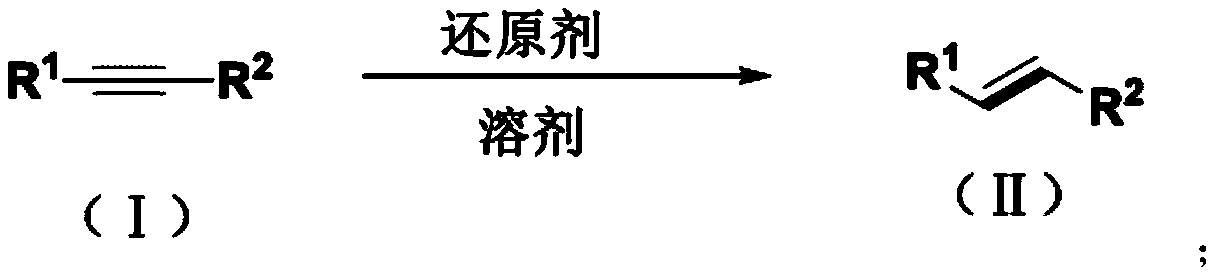

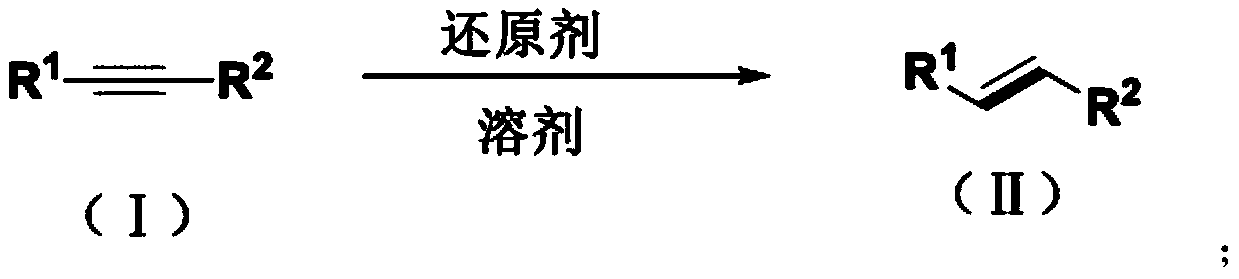

Method for synthesizing trans-olefin compound

InactiveCN111233610AReduce pollutionAtom economyOrganic reductionOrganic compound preparationThio-Ethyl group

The invention discloses a trans-olefin compound synthesis method, which comprises: carrying out a heating reaction on an alkyne compound represented by a general formula (I), a reducing agent and a solvent to obtain a trans-olefin compound represented by a general formula (II), wherein the synthesis route is as follows: R1 and R2 are independently selected from hydrogen, alkyl, cycloalkyl or aryl;wherein the reducing agent is a sulfur-containing compound and is selected from at least one of thioacetamide, N,N-dimethyl dithiocarbamate dimethyl ammonium salt, dimethyl amino sodium dithioformatedihydrate, potassium ethyl xanthate and potassium isopropyl xanthate. According to the method, a cheap, efficient and safe reducing agent is utilized to realize high-selectivity reduction of alkyne to prepare trans-olefin under the condition of no transition metal catalysis, so that the method is simple and easy to implement, wide in substrate application range and easy to realize industrialization.

Owner:WUYI UNIV

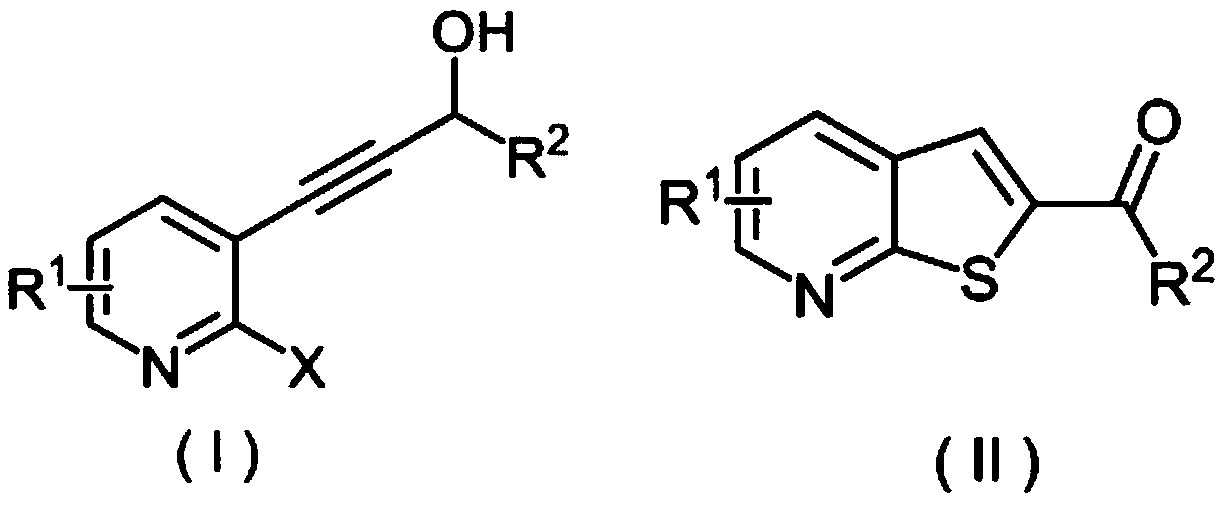

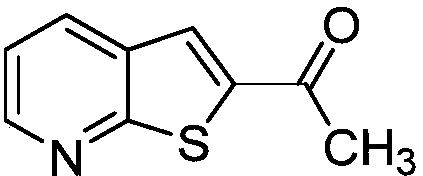

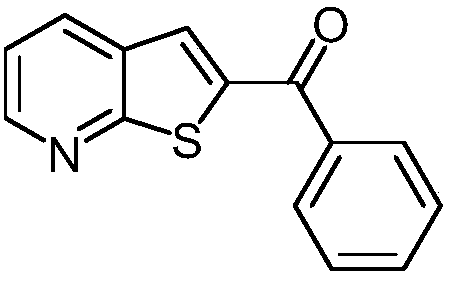

Method for synthesizing 2-carbonyl thienopyridine compound

The invention discloses a method for synthesizing 2-carbonyl thienopyridine compound. According to the method provided by the invention, 2-halo-3-alkynol pyridine as shown in formula (I) and sulfur sources are mixed; and with the aid of a catalyst, after reacting in a solvent for a while, 2-carbonyl thienopyridine compound as shown in formula (II) is prepared after purification treatment. The sulfur sources are selected from one or more of elemental sulphur, ammonium sulfide, thiourea, sodium sulfide, and ethyl potassium xanthate, and the catalyst is selected from one of copper acetate, cuprous iodide, cuprous bromide, cuprous chloride, copper chloride, cupric acetylacetonate, palladium chloride, and copper trifluoromethanesulfonate. The technical scheme of the invention has the advantagesof less reaction steps, simple operation method, wide source of reaction substrate, low costs and easy availability of the catalyst, high product yield and the like, and the technical scheme is verysuitable for industrial mass production. The formulas are shown in the description.

Owner:WUYI UNIV

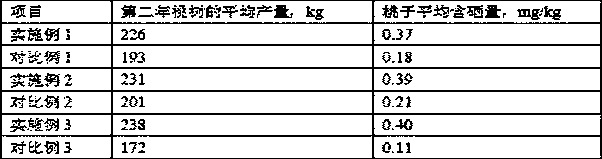

Planting method of high-yield selenium-rich peaches

InactiveCN108738996AAvoid churnPromote absorptionExcrement fertilisersFertilising methodsFecesPeach orchard

The invention discloses a planting method of high-yield selenium-rich peaches. The method comprises the following operation steps that firstly, sodium selenite, morpholine fatty acid salt fruit wax, L-Carnitine fumarate, potassium ethyl xanthate, ammonium oxalate and cerous chloride are evenly mixed to prepare a selenium additive; secondly, after fruits of peach trees are harvested, a peach orchard is subjected to tillage, the depth is 30-40 cm, and then selenium fertilizer is applied to the peach orchard, wherein the selenium fertilizer is prepared from decomposed animal manure and the selenium additive in the ratio of 200:1; thirdly, when the peach trees bloom, liquid selenium fertilizer is sprayed on the whole trees. The planting method of the high-yield selenium-rich peaches is environmentally friendly and low in cost, the yield of the peach trees is stable and high, and the content of selenium in the obtained peaches is not reduced.

Owner:全椒井府富硒生态牧业有限公司

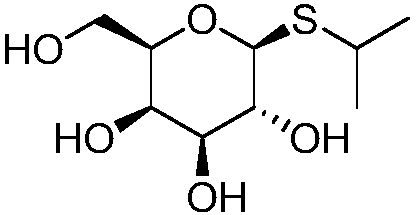

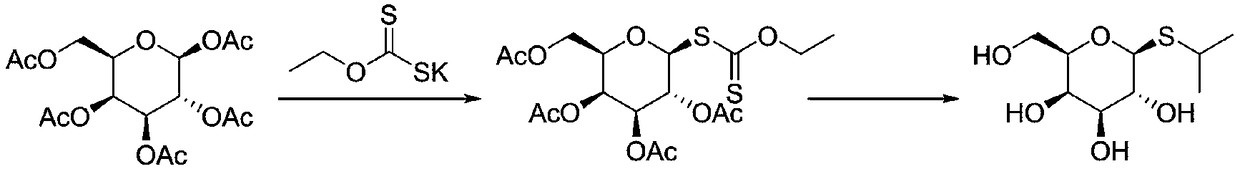

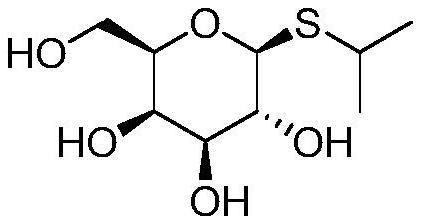

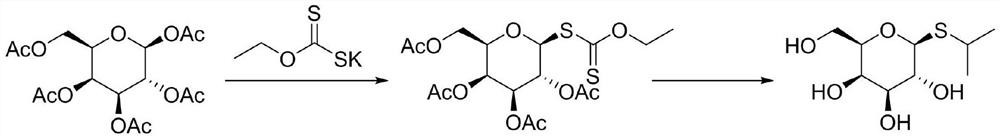

Method for synthesizing isopropyl-beta-D-thiogalactoside (IPTG)

ActiveCN108752399AAvoid harmShort synthetic routeSugar derivativesSugar derivatives preparationOrganic synthesisThiogalactosides

The invention provides a method for synthesizing isopropyl-beta-D-thiogalactoside (IPTG) and belongs to the technical field of organic synthesis. The method comprises the following steps: taking a compound beta-D-galactose pentaacetate as a raw material, and reacting with potassium ethyl xanthate in the presence of a catalyst so as to obtain tetraacetyl galactose ethyl xanthate; reacting with 2-bromopropane under an alkaline condition, so as to obtain the isopropyl-beta-D-thiogalactoside (IPTG). According to the synthetic method, the beta-D-galactose pentaacetate, potassium ethyl xanthate and2-bromopropane are taken as main raw materials, 2-mercaptopropane which is extremely unpleasant in smell, easy to diffuse and high in toxicity used in the original method is replaced, and the harm tothe environment is effectively avoided. The raw materials used in the method disclosed by the invention are readily available, the operating process is simple and convenient, the reaction condition ismild, and the method is safe, controllable and high in yield.

Owner:丹江口市御景生物医药有限公司

Application of silicon dioxide-supported perchloric acid-xanthate in removing chromium from industrial wastewater

ActiveCN107176664AGood dispersionAchieve removalWater contaminantsWater/sewage treatment by flocculation/precipitationRotary evaporatorPotassium

The invention relates to application of silicon dioxide-supported perchloric acid-xanthate in removing chromium from industrial wastewater. The silicon dioxide-supported perchloric acid-xanthate disclosed by the invention is characterized in that a preparation method for the silicon dioxide-supported perchloric acid-xanthate comprises the following steps: adding 300 to 400 meshes of silica gel, perchloric acid and xanthate into diethyl ether; stirring for 0.5 to 1h under room temperature; removing the diethyl ether by evaporation with a rotary evaporator; heating a remaining mixture to 100 to 105 DEG C under vacuum; and heating for 24 to 36h under the condition of keeping vacuum to obtain yellow powder, i.e., the silicon dioxide-supported perchloric acid-xanthate, wherein usage amount of the diethyl ether, the silica gel, the perchloric acid and the xanthate is that 1g of silica gel, 3mmol of perchloric acid and 3mmol of xanthate are added into every 5mL of diethyl ether; the xanthate is preferably selected from sodium ethyl-xanthate, potassium ethyl xanthate, sodium n-butyl-xanthate and potassium amyl xanthate.

Owner:YANGZHOU POLYTECHNIC INST

Silica-loaded sulfuric acid-xanthogenate sewage processing agent

InactiveCN107162152AGood dispersionAchieve removalWater contaminantsWater/sewage treatmentRotary evaporatorSodium ethylxanthate

The invention relates to a silica-loaded sulfuric acid-xanthogenate sewage processing agent. The preparation method comprises the following steps: adding 300-400 meshes silica gel in ether, concentrated sulfuric acid and xanthogenate, stirring the materials for 0.5-1 h at room temperature, steaming the material by a rotary evaporation instrument to remove ether, heating a residual mixture to the temperature of 100-105 DEG C under vacuum, and keeping vacuum heating for 24-36 h to obtain yellow powder which is the silica-loaded sulfuric acid-xanthogenate, wherein, the usage amount of ether, silica gel, concentrated sulfuric acid and xanthogenate is 1 g of silica gel, 3 mmol concentrated sulfuric acid and 3 mmol of xanthogenate added in every 5 mL of ether, and the xanthogenate preferably selects sodium ethyl-xanthonate, potassium ethyl xanthogenate, sodium n-butyl-xanthate and potassium amyl xanthate.

Owner:YANGZHOU POLYTECHNIC INST

Water-based lubricating oil and preparation method thereof

The invention discloses water-based lubricating oil. The water-based lubricating oil is prepared from the following substances in parts by weight: 60-80 parts of water, 7-10 parts of zinc diammonium ethylenediaminetetraacetate, 4-8 parts of N,N-diisopropylethanolamine, 10-15 parts of polyoxyethylene polyoxypropylene ether, 7-12 parts of histamine phosphate, 3-6 parts of chloroquine phosphate, 10-15 parts of 4-methylsalicylic acid, 12-15 parts of hexamethyl disiloxane, 10-18 parts of polyethylene glycol, 7-10 parts of 2-hydroxyl-4-dodecaoxydiphenylketone, 5-10 parts of nalidixate sodium, 2-6 parts of potassium ethyl xanthate, 3-8 parts of dimethylaminoborane and 3-7 parts of 1,3,5-trimethylpyrazole. The water-based lubricating oil takes water as a carrier and a plurality of chemical components are added, so that the lubricating performance of the water-based lubricating oil is improved.

Owner:苏州圣鑫莱新材料有限公司

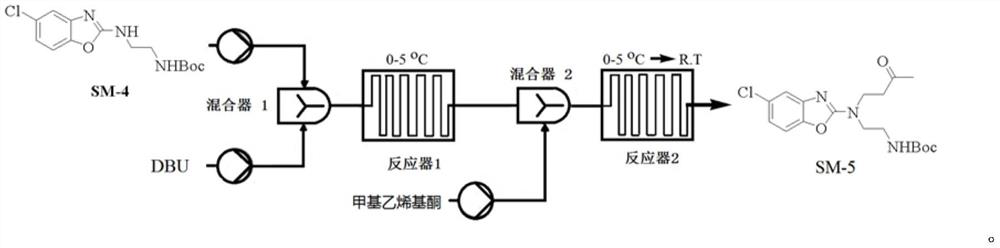

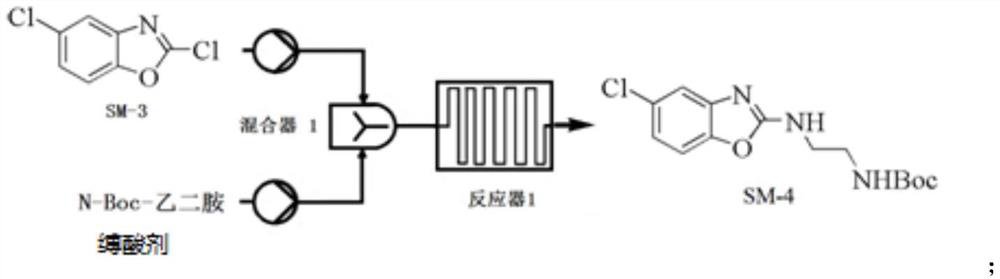

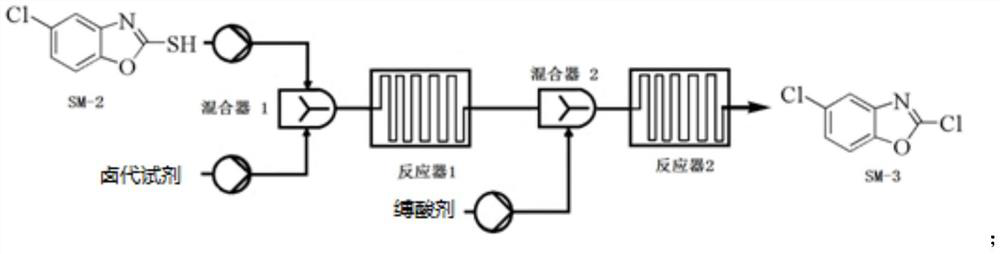

Continuous flow micro-reaction synthesis method of suvorexant intermediate

PendingCN113929673ASolve volatileAddresses highly toxic propertiesOrganic chemistryEthyl groupHalogenation

The invention relates to a continuous flow micro-reaction synthesis method of a suvorexant intermediate, and belongs to the technical field of medicine preparation. According to the preparation method, a key intermediate of a suvorexant bulk drug is technically optimized by adopting a continuous flow microreactor technology, and the suvorexant intermediate is synthesized by taking 2-amino-4-chlorophenol and potassium ethyl xanthate as initial raw materials through cyclization reaction, halogenation reaction, chiral resolution and other reactions. Meanwhile, influences of halogenating reagent types, acid-binding agent types and alkali equivalent factors involved in the technological process on the yield and purity of corresponding intermediates are investigated, and the optimal technological conditions are determined. The optimization process has the advantages of mild reaction conditions, simplicity and convenience in purification, environmental friendliness and the like, and is suitable for industrial large-scale production.

Owner:湖南华腾医药有限公司

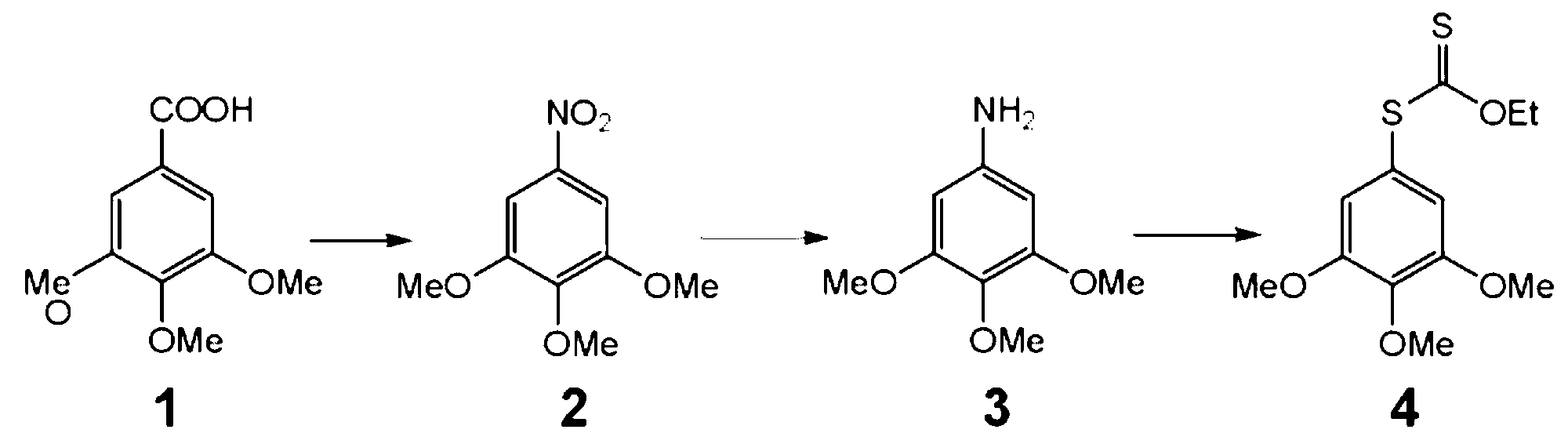

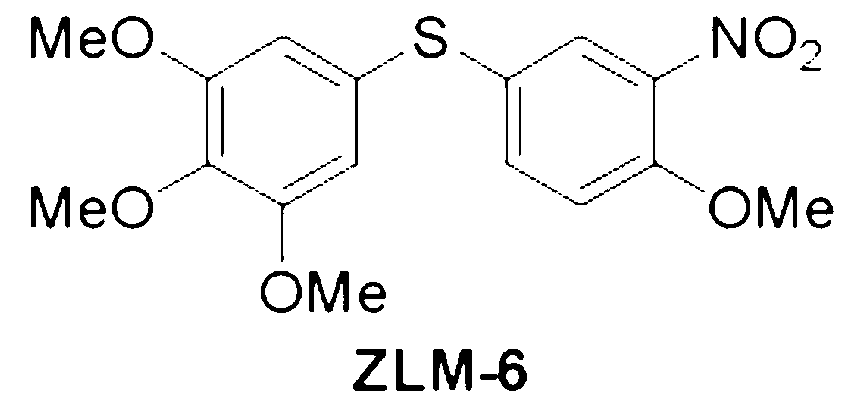

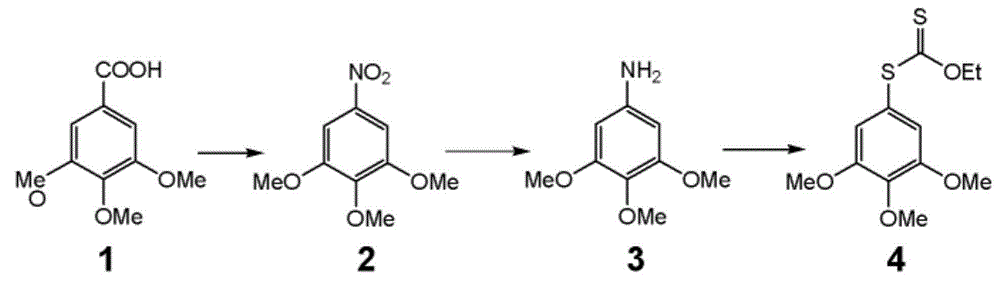

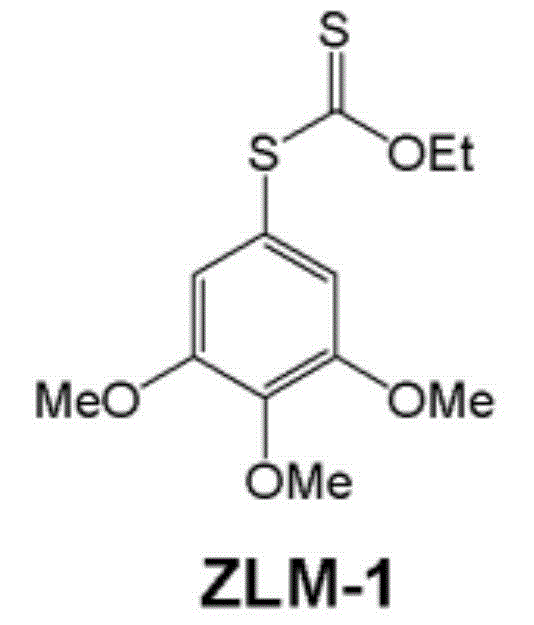

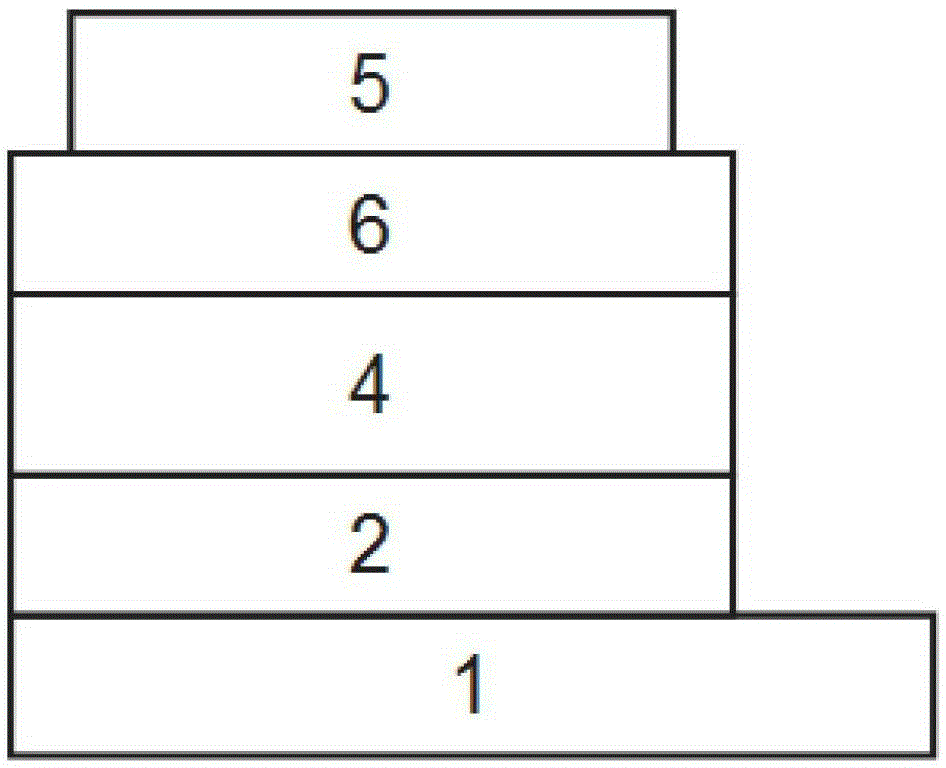

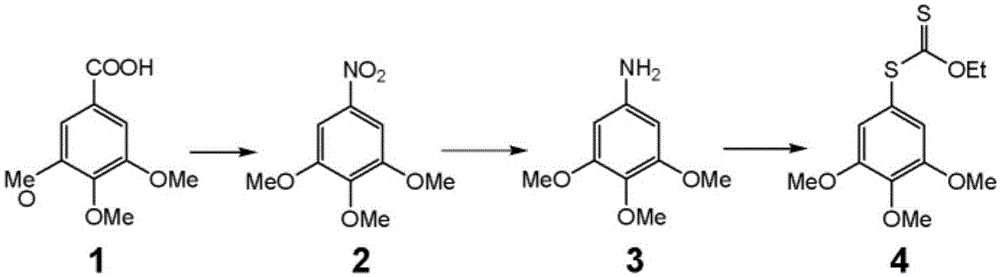

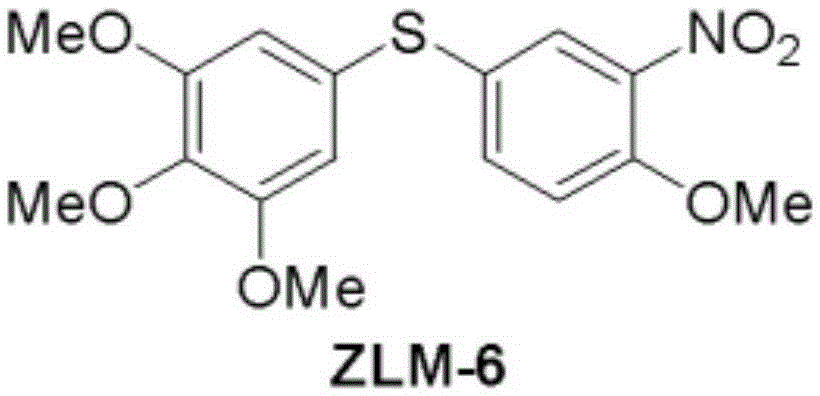

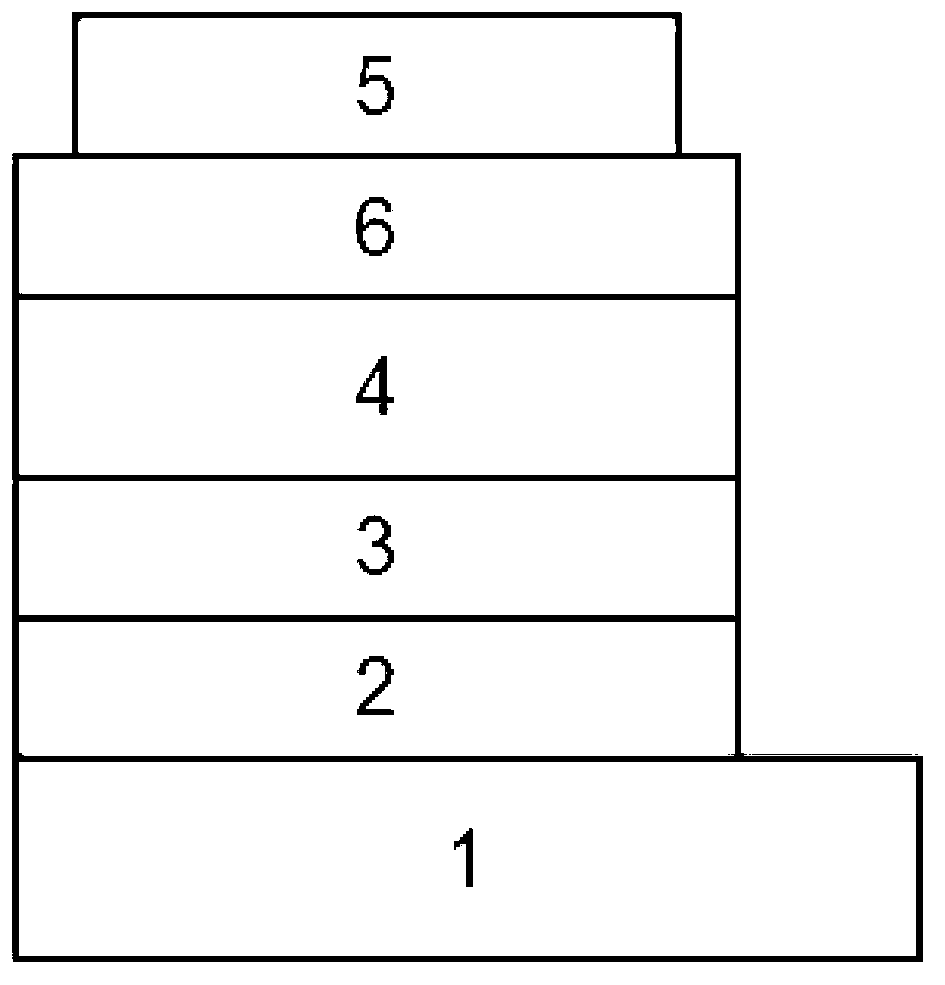

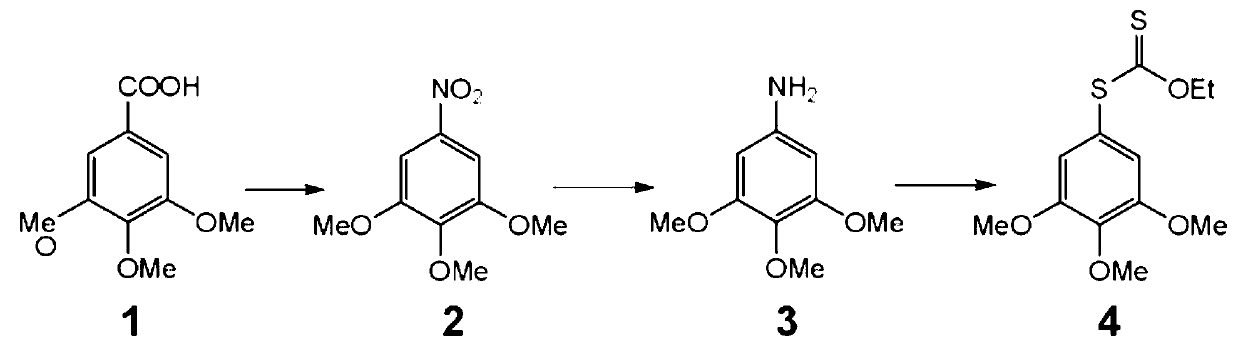

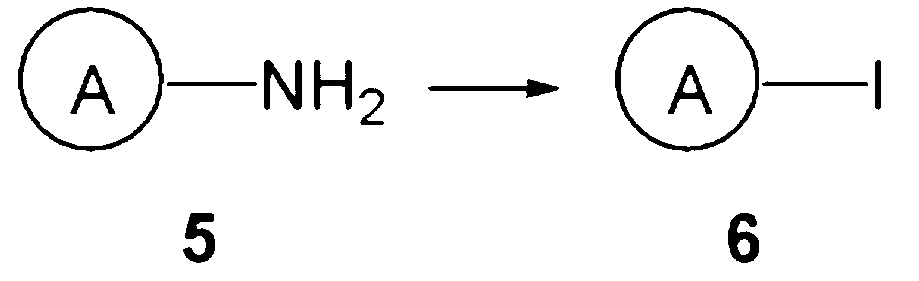

Manufacturing method of high-open-circuit-voltage photovoltaic cell

The invention discloses a manufacturing method of a high-open-circuit-voltage photovoltaic cell. The method comprises preparing a substrate, an anode, an active layer, an electronic transmission layer and a cathode successively, wherein the electronic transmission layer is a polymer with a structure of the general formula (I), and the polymerization degree n thereof is any integer between 1 and 300. The manufacturing method of the polymer comprises the following steps of: carrying out decarboxylative nitration on a compound 1 under the action of concentrated nitric acid and acetic acid to obtain a compound 2, and reducing the compound 2 to a compound 3 by using zinc powder / acetic acid or palladium carbon / hydrazine hydrate, then preparing a diazonium salt solution by using sodium nitrite and hydrochloric acid, and reacting with potassium ethyl xanthate to generate a compound 4; preparing a diazotate solution from aromatic amine 5 with sodium nitrite and hydrochloric acid, and reacting with sodium iodide to synthesize an aromatic iodide 6; (3) dissolving the compound 4 in tetrahydrofuran, and reducing the compound 4 to thiophenol 7 with lithium aluminum hydride; and (4) dissolving the aromatic iodide compound 6 and the thiophenol 7 in solvents of ethanediol and isopropanol or toluol and the like, and synthesizing a material with a structure of the general formula I under the action of potassium carbonate and cuprous iodide. The photovoltaic cell manufactured by using the material as the electronic transmission layer has a relatively high open circuit voltage and good device performance.

Owner:LIYANG CITY PRODIVITY PROMOTION CENT

Method for manufacturing solar cell comprising electron transport layer and hole transport layer

ActiveCN103000812BImprove performanceFinal product manufactureSolid-state devicesSodium iodideElectrical battery

Owner:LIYANG CITY PRODIVITY PROMOTION CENT

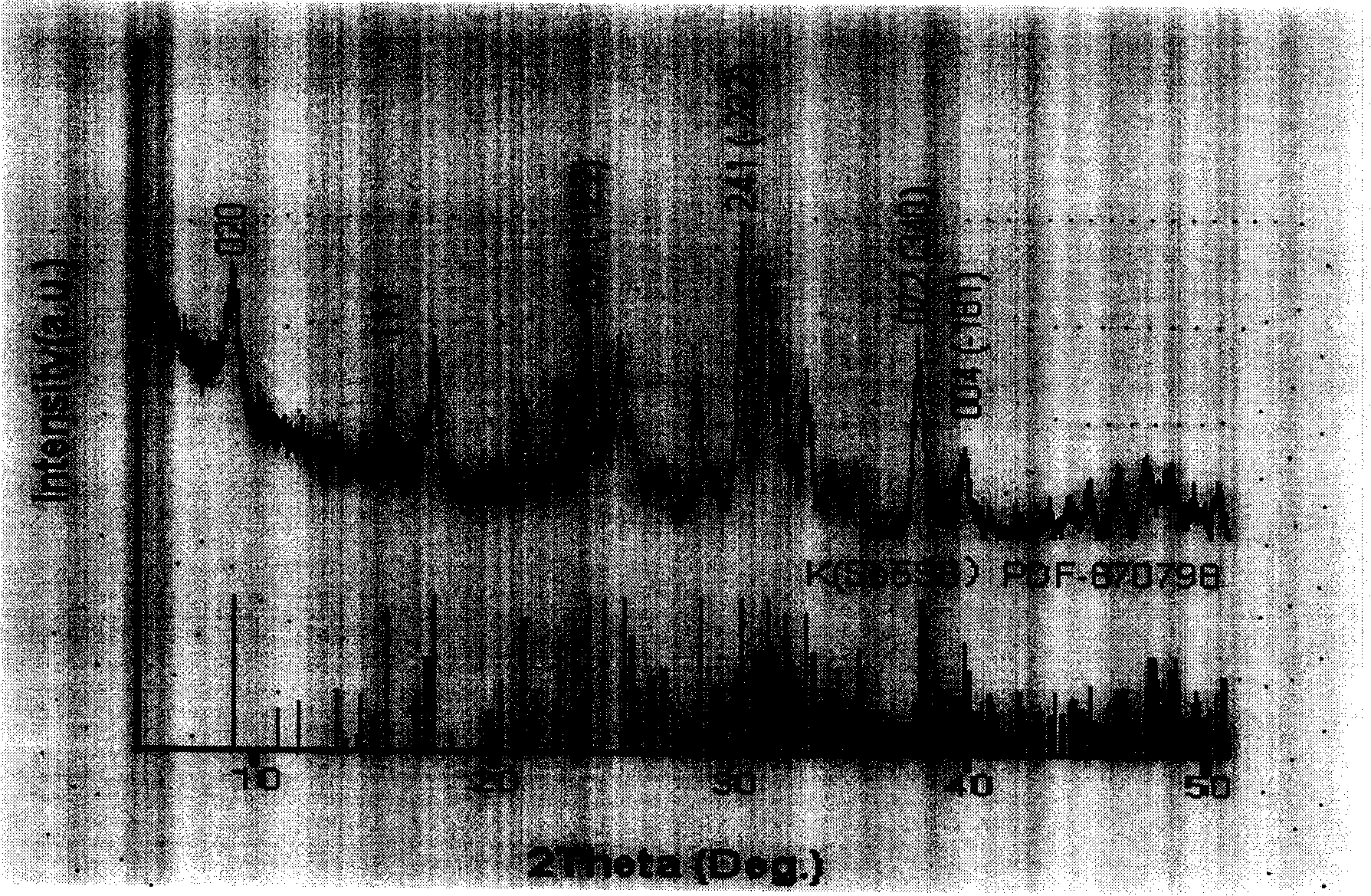

Super-high density information storage material antimony potassium sulfide and synthesis method thereof

InactiveCN101164892ARecord information storageAlkali metal sulfides/polysulfidesPotassium sulfideHigh density

This invention relates to super high density information storage material potassium stibium sulfide, and its synthetic method. This invention method overcomes the prior art shortcomings such as overcritical demands for synthesis of KSb5S8 and sensitiveness to the air. The production procedures are: polyethyl pyrrolidone is dissolved in ethandiol used as reaction medium; added, respectively, are stibium trichloride and potassium ethyl xanthate, agitating to obtain even solution, making them reacting thoroughly, and then proceeding the steps of cooling, washing and drying to obtain the inventive products with good crystallization, better shape and uniform aggregation state. Advantages are: simple process, high pureness of product, the shape of reactants can be controlled.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

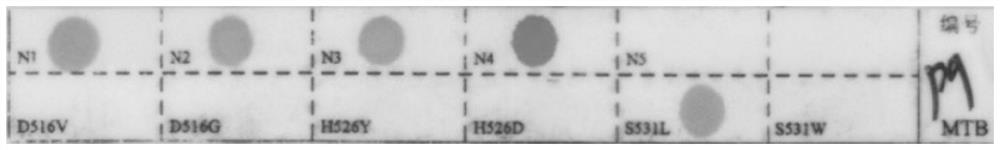

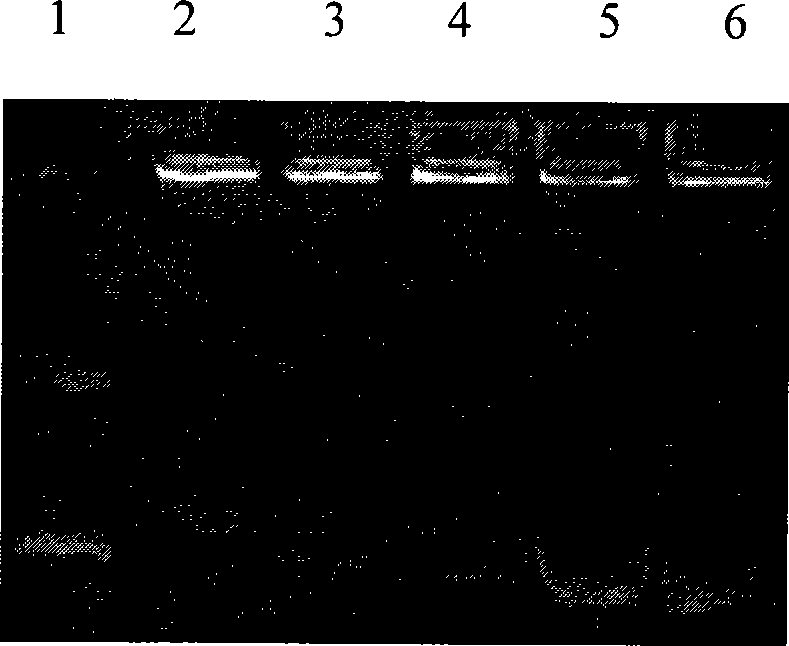

A method and kit for rapidly extracting Mycobacterium tuberculosis nucleic acid from sputum

The invention relates to the field of biomedical clinical diagnostic reagents, in particular to a kit for rapidly extracting Mycobacterium tuberculosis nucleic acid from sputum, comprising a lysate, a magnetic bead suspension, a cleaning solution and an eluent; the lysate includes 3-5mol / L potassium chloride, 3-5mol / L guanidine hydrochloride, 1% potassium ethyl xanthate and 0.2mol / L potassium phosphate buffer; the magnetic bead suspension is a nucleic acid composed of polyethyleneimine-modified magnetic beads Adsorption carrier; the cleaning solution is a hydrochloric acid solution; the eluent is a sodium hydroxide solution; a method for rapidly extracting Mycobacterium tuberculosis nucleic acid in sputum is further proposed, so as to finally realize high-quality and fast extraction of Mycobacterium tuberculosis nucleic acid in sputum Extraction and detection, reduce the cost of extraction, simplify the operation process, avoid the use of volatile organic solvents and high-concentration salt solutions, and reduce the hazards of kit reagents to the health of operators. At the same time, the kit is combined with existing automatic detection technology to achieve Potential for high-throughput, large-scale nucleic acid extraction and detection.

Owner:亚能生物技术(深圳)有限公司

Application of a silica-supported perchloric acid-xanthate in the removal of chromium from industrial wastewater

ActiveCN107176664BGood dispersionAchieve removalWater contaminantsWater/sewage treatment by flocculation/precipitationRotary evaporatorIndustrial waste water

The invention relates to application of silicon dioxide-supported perchloric acid-xanthate in removing chromium from industrial wastewater. The silicon dioxide-supported perchloric acid-xanthate disclosed by the invention is characterized in that a preparation method for the silicon dioxide-supported perchloric acid-xanthate comprises the following steps: adding 300 to 400 meshes of silica gel, perchloric acid and xanthate into diethyl ether; stirring for 0.5 to 1h under room temperature; removing the diethyl ether by evaporation with a rotary evaporator; heating a remaining mixture to 100 to 105 DEG C under vacuum; and heating for 24 to 36h under the condition of keeping vacuum to obtain yellow powder, i.e., the silicon dioxide-supported perchloric acid-xanthate, wherein usage amount of the diethyl ether, the silica gel, the perchloric acid and the xanthate is that 1g of silica gel, 3mmol of perchloric acid and 3mmol of xanthate are added into every 5mL of diethyl ether; the xanthate is preferably selected from sodium ethyl-xanthate, potassium ethyl xanthate, sodium n-butyl-xanthate and potassium amyl xanthate.

Owner:YANGZHOU POLYTECHNIC INST

A silica-loaded sulfuric acid-xanthate sewage treatment agent

InactiveCN107162152BGood dispersionAchieve removalWater contaminantsWater/sewage treatmentRotary evaporatorSodium ethylxanthate

The invention relates to a silica-loaded sulfuric acid-xanthogenate sewage processing agent. The preparation method comprises the following steps: adding 300-400 meshes silica gel in ether, concentrated sulfuric acid and xanthogenate, stirring the materials for 0.5-1 h at room temperature, steaming the material by a rotary evaporation instrument to remove ether, heating a residual mixture to the temperature of 100-105 DEG C under vacuum, and keeping vacuum heating for 24-36 h to obtain yellow powder which is the silica-loaded sulfuric acid-xanthogenate, wherein, the usage amount of ether, silica gel, concentrated sulfuric acid and xanthogenate is 1 g of silica gel, 3 mmol concentrated sulfuric acid and 3 mmol of xanthogenate added in every 5 mL of ether, and the xanthogenate preferably selects sodium ethyl-xanthonate, potassium ethyl xanthogenate, sodium n-butyl-xanthate and potassium amyl xanthate.

Owner:YANGZHOU POLYTECHNIC INST

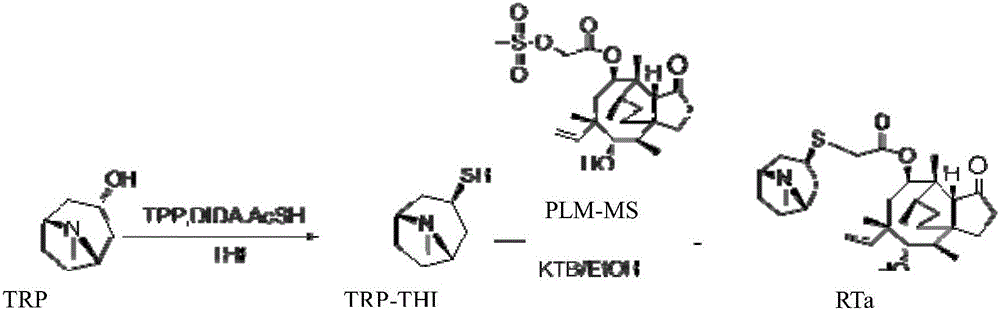

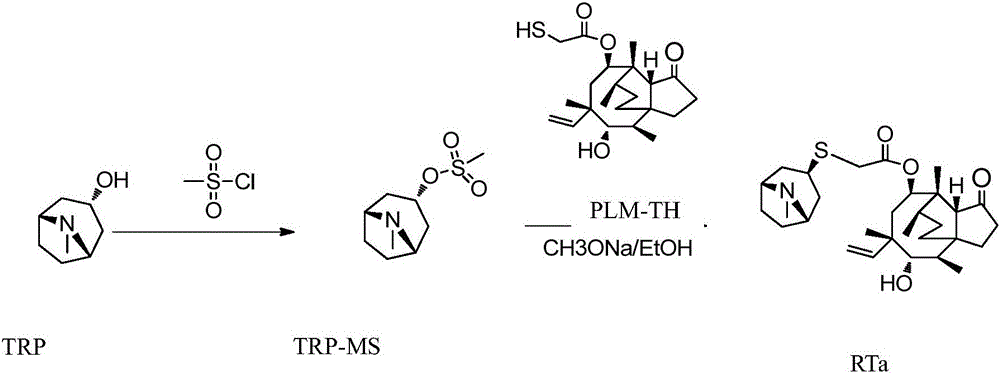

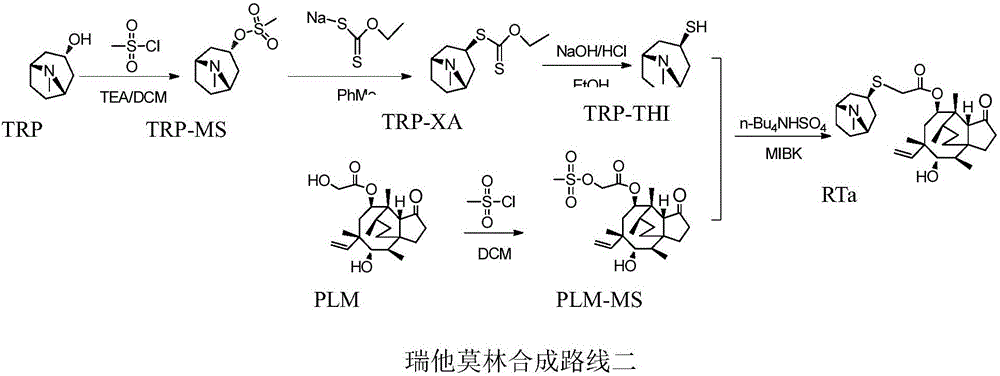

A kind of retapamulin synthetic method

The present invention provides a synthesis method for Retapamulin. The method comprises: using pleuromutilin as a starting material of one segment; obtaining PLM-TS by condensation reaction between the starting material and toluenesulfonyl chloride; using tropenol as a raw material of the other segment; obtaining TRP-MS by reaction between the raw material and toluenesulfonyl chloride; after performing substitution reaction between TRP-MS that uses water as a solvent and potassium ethyl xanthate, performing acidification between the substance and sulfuric acid to obtain an intermediate TRP-XAN; TRP-XAN undergoing hydrolysis in an ethanol NaOH solution; performing acidification between the substance and sulfuric acid to obtain an intermediate TRP-THI; the two segments TRP-THI and PLM-TS undergoing condensation reaction under alkaline conditions to obtain the final product, Retapamulin. The synthesis method for Retapamulin provided by the present invention is simple, environmentally friendly, easy in controlling the quality of intermediates of all steps, and suitable for the Retapamulin synthesis process in industrialized production.

Owner:汕头经济特区鮀滨制药厂

Polymethacrylate, preparation method and application thereof

InactiveCN101429260BImprove bindingAbility to promote endocytosisGenetic material ingredientsPharmaceutical non-active ingredientsDisulfide bondingEthyl group

The invention relates to reductive cation polymethacrylate, a preparation method thereof, application of the polymethacrylate to establishment of gene nano-complexes and application of the polymethacrylate to gene therapy. The method comprises the following steps: 1, 3, 5-triisopropylphenyl is taken as a raw material and reacts with N- bromosuccinimide and potassium ethyl xanthate to obtain substituted 1, 3, 5- triisopropylphenyl potassium ethyl xanthate; and the substituted 1, 3, 5- triisopropylphenyl potassium ethyl xanthate is catalyzed by azo-bis-iso-butyrynitrile, and subjected to reversible addition-broken strand transfer polymerization, aminolysis and oxidation reaction with 2-(dimethylamino ethyl)metacrylic acid ester to obtain poly (1, 3, 5-three-terminal sulfhydryl (2-propyl phenyl -2-(dimethylamino)ethyl)) methacrylic acid ester) and disulfide bond crosslinking products of the poly (1, 3, 5-three-terminal sulfhydryl (2-propyl phenyl -2-(dimethylamino)ethyl)) methacrylic acid ester). The polymethacrylate can condense plasmid genes into nano complexes; the transfection efficiency of HEK293T cells and Hella cells is more than 30 percent; the toxicity is low; and the survival rate of the cells is more than 80 percent.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

A kind of synthetic method of isopropyl-beta-d-thiogalactoside

ActiveCN108752399BAvoid harmShort synthetic routeSugar derivativesSugar derivatives preparationPtru catalystOrganic synthesis

The invention provides a method for synthesizing isopropyl-β-D-thiogalactoside (IPTG), which belongs to the technical field of organic synthesis. Using the compound β‑D‑galactose pentaacetate as raw material, react with potassium ethyl xanthate in the presence of a catalyst to obtain tetraacetyl galactose ethyl xanthate, and then react with 2‑bromo Propane reacts to give isopropyl‑β‑D‑thiogalactoside. The synthesis method uses β-D-galactose pentaacetate, potassium ethyl xanthate, and 2-bromopropane as the main raw materials, replacing the extremely bad smell, easy to diffuse and high toxicity used in the original method. 2-propanethiol, effectively avoiding the harm to the environment. The raw materials used in the invention are easy to obtain, the operation process is simple, the reaction conditions are mild, safe and controllable, and the yield is high.

Owner:丹江口市御景生物医药有限公司

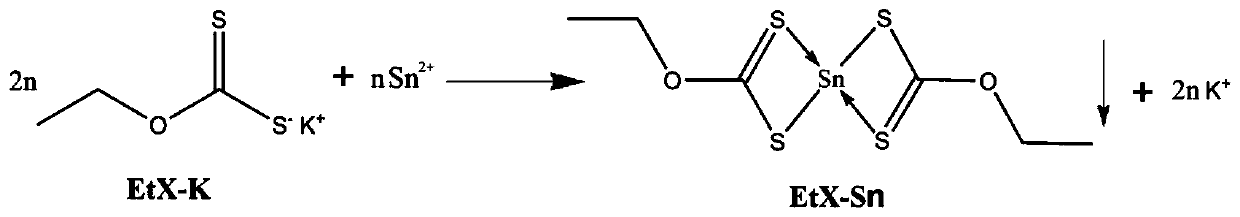

Method for preparing tin-based sulfide lithium ion battery negative active material under room temperature

PendingCN110061230AFully dispersedImprove conductivityCell electrodesSecondary cellsPotassiumVacuum drying

The invention provides a method for preparing a tin-based sulfide lithium ion battery negative active material under a room temperature, and relates to a preparation method of a lithium ion battery negative active material. The method aims to solve the problem of short cycle lifetime caused by large volume change of a tin-based negative electrode material. The method comprises the steps of firstly, preparing, in which a SnCl<2>.2H2O aqueous solution, an ethylxanthic acid potassium salt aqueous solution and a conductive carbon material dispersing liquid are prepared, and the SnCl<2>.2H2O aqueous solution is mixed with the conductive carbon material dispersing liquid; secondly, adding the ethylxanthic acid potassium salt aqueous solution to obtain a precipitation product; and finally, performing pumping, washing and vacuum drying. The ethylxanthic acid potassium salt is applied to the field of lithium ion battery preparation, the function of an organic framework is achieved, so that thetin-based material is fully dispersed, the volume effect is reduced, and the cycle lifetime is prolonged. The method is suitable for preparing the lithium ion battery negative active material.

Owner:HARBIN INST OF TECH +1

A kind of manufacturing method of the photovoltaic cell of high open circuit voltage

ActiveCN103022360BImprove performanceFinal product manufactureSolid-state devicesElectronic transmissionIodide

The invention discloses a manufacturing method of a high-open-circuit-voltage photovoltaic cell. The method comprises preparing a substrate, an anode, an active layer, an electronic transmission layer and a cathode successively, wherein the electronic transmission layer is a polymer with a structure of the general formula (I), and the polymerization degree n thereof is any integer between 1 and 300. The manufacturing method of the polymer comprises the following steps of: carrying out decarboxylative nitration on a compound 1 under the action of concentrated nitric acid and acetic acid to obtain a compound 2, and reducing the compound 2 to a compound 3 by using zinc powder / acetic acid or palladium carbon / hydrazine hydrate, then preparing a diazonium salt solution by using sodium nitrite and hydrochloric acid, and reacting with potassium ethyl xanthate to generate a compound 4; preparing a diazotate solution from aromatic amine 5 with sodium nitrite and hydrochloric acid, and reacting with sodium iodide to synthesize an aromatic iodide 6; (3) dissolving the compound 4 in tetrahydrofuran, and reducing the compound 4 to thiophenol 7 with lithium aluminum hydride; and (4) dissolving the aromatic iodide compound 6 and the thiophenol 7 in solvents of ethanediol and isopropanol or toluol and the like, and synthesizing a material with a structure of the general formula I under the action of potassium carbonate and cuprous iodide. The photovoltaic cell manufactured by using the material as the electronic transmission layer has a relatively high open circuit voltage and good device performance.

Owner:LIYANG CITY PRODIVITY PROMOTION CENT

Method for manufacturing polymer used as electron transfer layer of solar cell

The invention discloses a method for manufacturing polymer used as an electron transfer layer of a solar cell. The polymer is a polymer formed by polymerizing monomers which can be shown as a structural formula (I), wherein n in the polymer is one integral number ranging from 1 to 300. The method disclosed by the invention comprises the following steps of: firstly, decarboxylating and nitrifying a compound 1 to obtain a compound 2, then reducing the compound 2 into a compound 3, and then diazotizing and reacting with potassium ethyl xanthate to generate a compound 4; secondly, diazotizing aromatic amine 5, and then reacting with sodium iodide to synthesize an aromatic iodo product 6; and thirdly, firstly reducing the compound 4 to phenylthioalcohol 7, and reacting phenylthioalcohol 7 with an aromatic chloro compound 8 or the aromatic iodo compound 6 under the action of an alkaline catalyst to obtain a compound as shown in formula (1). The solar cell made by adopting the material as the electron transfer layer has a higher open circuit voltage and further has good device performance. The formula (I) is shown in the specification.

Owner:LIYANG CITY PRODIVITY PROMOTION CENT

Sulfuric silane coupling agent and its synthesis process

InactiveCN100516076CGood dispersionImprove reinforcementGroup 4/14 element organic compoundsSilanesCoupling

The invention relates to a sulfur-containing silane coupling agent and a synthesis method thereof. In the case of using methanol as a solvent, chloropropyltrimethoxysilane is used as raw material 1, potassium ethyl xanthate is used as raw material 2, and under the protection of high-purity nitrogen, the target product is finally produced by the reaction, and its chemical name is xanthate propyl Trimethoxysilane. Xanthate propyltrimethoxysilane can treat inorganic fillers, especially for white carbon black filled rubber systems, which can significantly promote the dispersion of fillers in the matrix, so that fillers have good reinforcing properties. The coupling agent can be used for high-temperature mixing, and it is not easy to cause scorching of the rubber. The use of this new type of sulfur-containing silane coupling agent can be mixed at a higher temperature, so the mixing time or mixing times can be reduced, thereby reducing the production cost. The development of silane coupling agents has expanded the application of inorganic fillers in rubber. This new type of sulfur-containing silane coupling agent can be applied to a large number of inorganic powder fillers.

Owner:ZHEJIANG UNIV +3

Method for manufacturing solar cell comprising electron transport layer and hole transport layer

ActiveCN103000812AImprove performanceSimple preparation processFinal product manufactureSolid-state devicesSodium iodideElectrical battery

The invention discloses a method for manufacturing a solar cell comprising an electron transport layer and a hole transport layer. The method comprises the steps of sequentially preparing a substrate, an anode, the hole transport layer, an active layer and a cathode, wherein the hole transport layer is PEDOT:PSS; and preparing the electron transport layer between the active layer and the cathode, wherein the electron transport layer is a polymer in the structure represented by general formula (I), the degree of polymerization of the polymer can be any integer within 1-300, and the manufacturing method of the polymer comprises the steps of firstly, obtaining a compound 2 through decarboxylation nitration of a compound 1, reducing into a compound 3, then diazotizing, and reacting with potassium ethyl xanthate to produce a compound 4; secondly, diazotizing aromatic amine 5, and reacting with sodium iodide to synthesize an aromatic iodo-product 6; and thirdly, reducing the compound 4 into thiophenol 7, and dissolving with aromatic chloride 8 or the aromatic iodo-product 6 under the effect of a basic catalyst to obtain the compound represented by general formula (I). The solar cell with the material serving as the electron transport layer is high in open-circuit voltage and good in device performance.

Owner:LIYANG CITY PRODIVITY PROMOTION CENT

A kind of preparation method of zno-cuo composite nanomaterial

ActiveCN106542562BImprove gas-sensing propertiesSimple preparation processMaterial nanotechnologyZinc oxides/hydroxidesRoom temperatureSediment

The invention discloses a method for preparing ZnO-CuO composite nanomaterials. The potassium ethylxanthate solution is dropped into a zinc salt solution while stirring, the resulting precipitate is mixed with deionized water, and the ethylxanthogen is obtained after drying. Zinc acid powder; drop the potassium ethylxanthate solution into the copper salt solution while stirring, and dry to obtain copper ethylxanthate powder; mix copper ethylxanthate and zinc ethylxanthate to obtain a powder A. Premix powder A with deionized water; add organic dispersant and inorganic dispersant into the mixed solution, dry and roast, the roasting temperature is 400~500°C, the heating rate is 3~10°C / minute, and the roasting time is 2~5 hours , and then cooled to room temperature to obtain Zn‑CuO composite nanomaterials. The advantages of this method include simple preparation process, low preparation cost, stable performance, good gas selectivity, and broad application prospects.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Super-high density information storage material antimony potassium sulfide and synthesis method thereof

InactiveCN101164892BRecord information storageAlkali metal sulfides/polysulfidesPotassium sulfideHigh density

This invention relates to super high density information storage material potassium stibium sulfide, and its synthetic method. This invention method overcomes the prior art shortcomings such as overcritical demands for synthesis of KSb5S8 and sensitiveness to the air. The production procedures are: polyethyl pyrrolidone is dissolved in ethandiol used as reaction medium; added, respectively, are stibium trichloride and potassium ethyl xanthate, agitating to obtain even solution, making them reacting thoroughly, and then proceeding the steps of cooling, washing and drying to obtain the inventive products with good crystallization, better shape and uniform aggregation state. Advantages are: simple process, high pureness of product, the shape of reactants can be controlled.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of thickening agent, thickening agent, fracturing fluid and application of fracturing fluid

InactiveCN111303322ANo toxicityEasy to flow backDrilling compositionBulk chemical productionEthyl acetateSolvent

The invention discloses a preparation method of a thickening agent, the thickening agent, a fracturing fluid and application of the fracturing fluid, and belongs to the technical field of fracturing.The preparation method of the thickening agent comprises the following steps: dissolving pentaerythritol and pyridine in trichloromethane in a protective gas atmosphere, stirring, slowly adding 2-bromopropionyl bromide, reacting, filtering, and drying to obtain a brominated precursor; dissolving the brominated precursor in trichloromethane, stirring, adding potassium ethyl xanthate, reacting, filtering, and drying to obtain a chain transfer agent; carrying out a polymerization reaction on the chain transfer agent, a polymer monomer and an initiator to obtain a reaction product; and dissolvingthe reaction product with ethyl acetate, precipitating with n-hexane, and then carrying out solvent volatilization and drying treatment to obtain the thickening agent. The thickening agent is non-toxic and environment-friendly, and the viscosity of a supercritical CO2 fracturing fluid can be greatly improved when the thickening agent and ethanol are used as a cosolvent.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com