A kind of preparation method of zno-cuo composite nanomaterial

A composite nanomaterial, zno-cuo technology, applied in nanotechnology, analytical materials, nanotechnology, etc., can solve problems such as poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

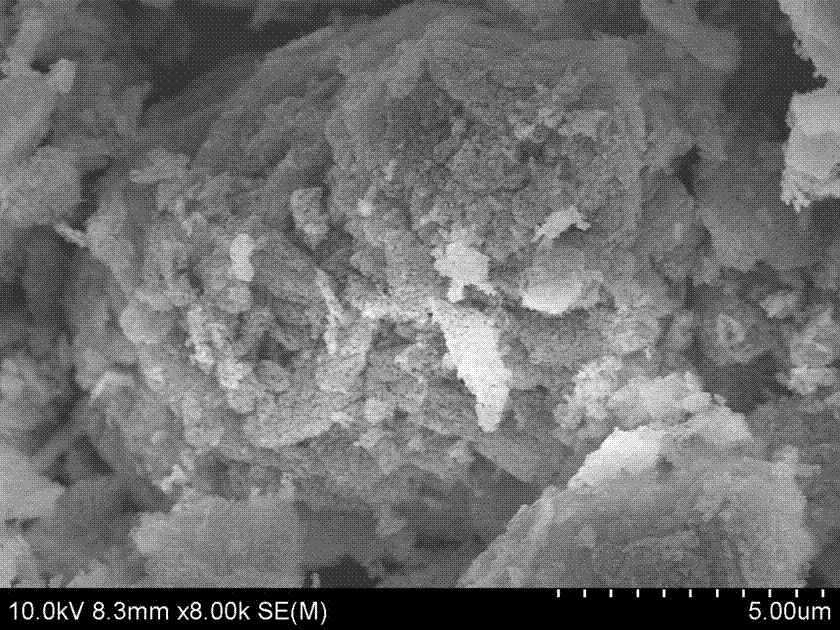

Image

Examples

Embodiment 1

[0016] Prepare the aqueous solutions of zinc chloride and potassium ethyl xanthate with a concentration of 0.1 at a molar ratio of 1:1.1, drop the potassium ethyl xanthate solution into the zinc chloride solution while stirring, and continue stirring for half an hour; filter with suction , mix the obtained precipitate with deionized water, stir for a while, filter with suction, repeat 3-5 times, and obtain zinc ethyl xanthate powder after drying; prepare copper chloride and ethyl xanthate powder with a concentration of 0.1M respectively in a molar ratio of 1:1.1 Add the aqueous solution of potassium ethyl xanthate, drop the potassium ethyl xanthate solution into the copper salt solution while stirring, continue to stir for half an hour; filter with suction, mix the resulting precipitate with deionized water, filter with suction, repeat 3-5 times, after drying, copper ethyl xanthate powder is obtained;

[0017] Mix copper ethyl xanthate and zinc ethyl xanthate at a molar ratio ...

Embodiment 2

[0022] Mix the aqueous solutions of zinc chloride and potassium ethyl xanthate with a concentration of 0.3 at a molar ratio of 1:1.5, drop the potassium ethyl xanthate solution into the zinc chloride solution while stirring, and continue stirring for half an hour; filter with suction , mix the obtained precipitate with deionized water, stir for a while, filter with suction, repeat 3-5 times, and obtain zinc ethyl xanthate powder after drying; prepare copper chloride and ethyl xanthate powder with a concentration of 0.3M in a molar ratio of 1:1.5, respectively. Add the aqueous solution of potassium ethyl xanthate, drop the potassium ethyl xanthate solution into the copper salt solution while stirring, continue to stir for half an hour; filter with suction, mix the resulting precipitate with deionized water, filter with suction, repeat 3-5 times, after drying, copper ethyl xanthate powder is obtained;

[0023] Mix copper ethyl xanthate and zinc ethyl xanthate at a molar ratio of...

Embodiment 3

[0028] Prepare the aqueous solutions of zinc chloride and potassium ethyl xanthate with a concentration of 0.2 at a molar ratio of 1:1.3, drop the potassium ethyl xanthate solution into the zinc chloride solution while stirring, and continue stirring for half an hour; filter with suction , mix the resulting precipitate with deionized water, stir for a while, filter with suction, repeat 3-5 times, and obtain zinc ethyl xanthate powder after drying; prepare copper chloride and ethyl xanthate powder with a concentration of 0.2M respectively in a molar ratio of 1:1.3 Add the aqueous solution of potassium ethyl xanthate, drop the potassium ethyl xanthate solution into the copper salt solution while stirring, continue to stir for half an hour; filter with suction, mix the resulting precipitate with deionized water, filter with suction, repeat 3-5 times, after drying, copper ethyl xanthate powder is obtained;

[0029] Mix copper ethyl xanthate and zinc ethyl xanthate at a molar ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com