Surface modified PD-SNO 2 Preparation method and application of microspheres

A surface modification, pd-sno2 technology, applied in the field of preparation of Pd-SnO2 microspheres, can solve the problems of limited application range and place of use, poor stability, poor selectivity, etc., and achieve simple use method and good crystallinity , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a surface modified Pd-SnO 2 Microspheres, its preparation method is specifically carried out according to the following steps:

[0033] (1) Mix 25mL deionized water and 25mL absolute ethanol as a solvent, weigh a certain amount of SnCl 4 ·5H 2 O is used as a raw material, and the raw material taken by weighing is added in the solvent and stirred to make it dissolve completely;

[0034] (2) Weigh a certain amount of PdCl 2 Add hydrochloric acid, ultrasonically dissolve, then add to the solution of step (1), and stir the obtained mixed solution at room temperature, wherein the molar ratio of tin tetrachloride to palladium in chloropalladium acid is 1:0.03;

[0035] (3) After the mixed solution in step 2 was stirred evenly, 0.1 mL of CTAB solution was added, and stirred vigorously at room temperature to obtain a precursor solution, wherein the molar ratio of tin tetrachloride to CTAB was 1:5;

[0036] (4) Transfer the precursor solution prepared ...

Embodiment 2

[0040] The invention provides a surface modified Pd-SnO2 Microspheres, its preparation method is specifically carried out according to the following steps:

[0041] (1) Mix 25mL deionized water and 25mL absolute ethanol as a solvent, weigh a certain amount of SnCl 4 ·5H 2 O is used as a raw material, and the raw material taken by weighing is added in the solvent and stirred to make it dissolve completely;

[0042] (2) Weigh a certain amount of PdCl 2 Add hydrochloric acid, sonicate and dissolve so that its palladium accounts for a mass percentage of 5%, then add in the solution of step (1), and the mixed solution obtained is stirred at room temperature; wherein, the mole of palladium in tin tetrachloride and chloropalladium acid The ratio is 1:0.05;

[0043] (3) After the mixed solution in step 2 was stirred evenly, 0.2mL of CTAB solution was added, and stirred vigorously at room temperature to obtain a precursor solution; wherein the molar ratio of tin tetrachloride to CTA...

experiment example 1

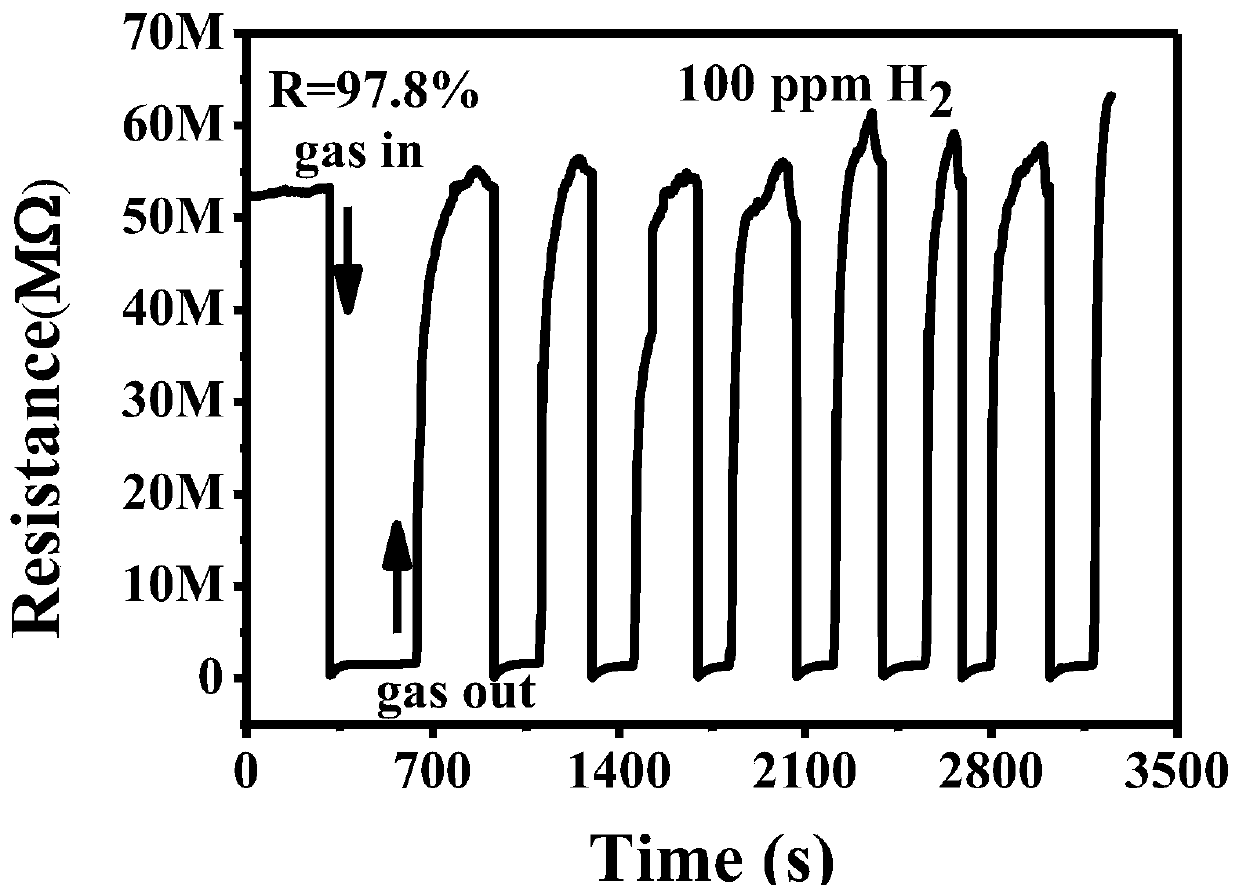

[0048] Surface-modified Pd-SnO in the above-mentioned embodiment 1 2 The application of microspheres is carried out as follows:

[0049] Surface-modified Pd-SnO 2 Microspheres are used as sensitive materials to prepare gas sensors. 2 to test;

[0050] The method for preparing the gas sensor is: the surface modified Pd-SnO 2 Put the microspheres in a mortar, add an appropriate amount of distilled water, and grind to obtain a uniform suspension, then spin-coat the suspension on the Au interdigitated electrode, and dry it in a blast drying oven at 80 °C for 4 h, that is, Get the gas sensor.

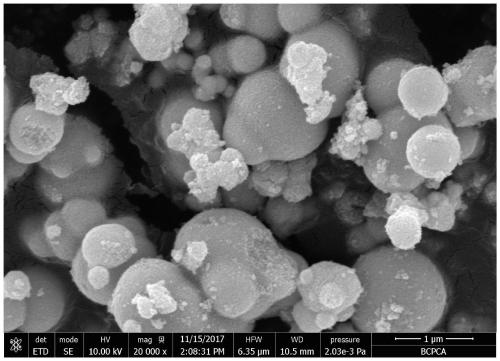

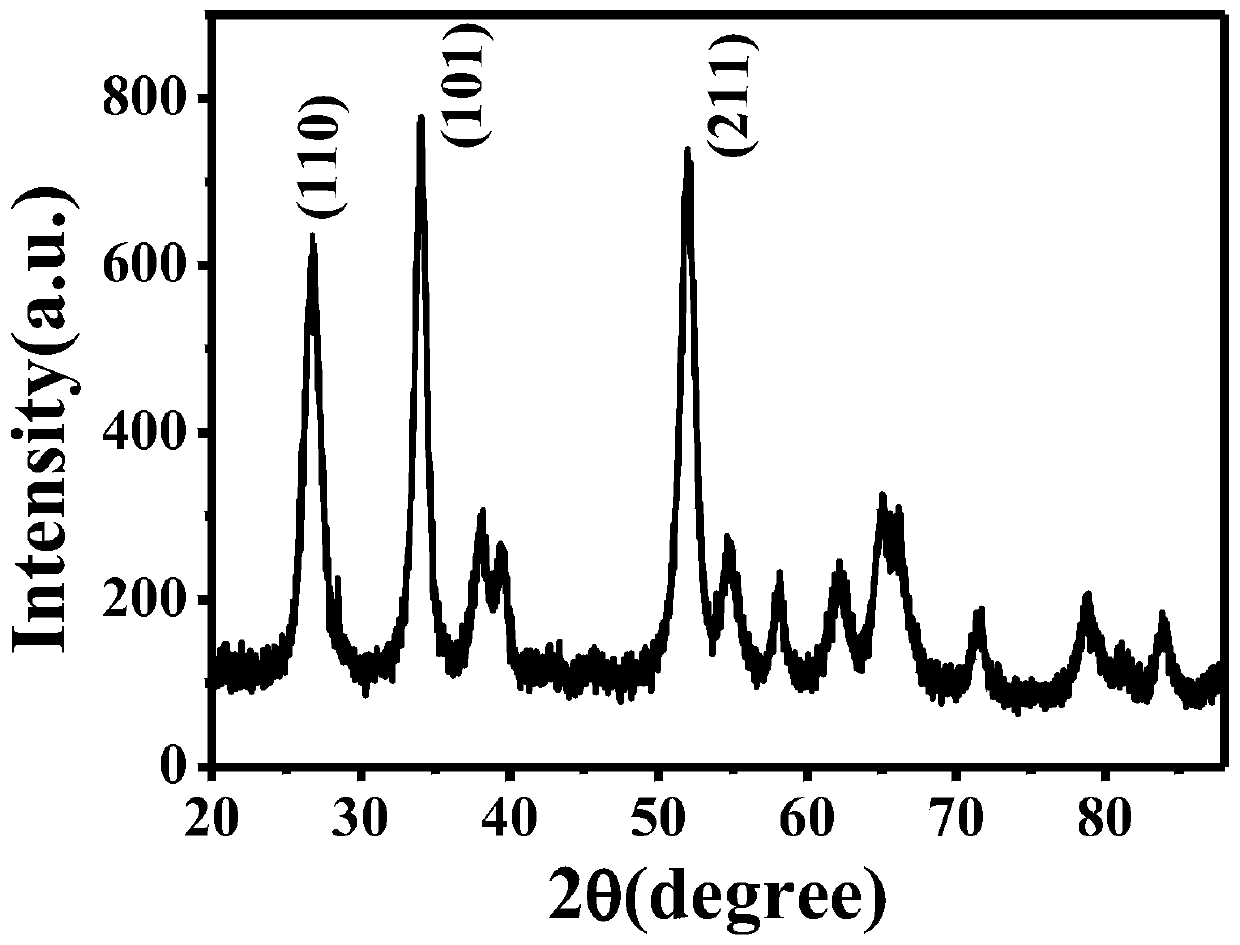

[0051] figure 1 It is the surface-modified Pd-SnO obtained in Example 1 2 The scanning electron microscope image of the microsphere shows that the material has a three-dimensional spherical morphology under the action of the surfactant CTAB, with an average diameter of about 1.2 μm. There are a large number of Pd nanoparticles on the surface of the sphere. These Pd nanoparticles Metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com