A kind of porous silicon-supported copper nanoparticle and its preparation method and application

A nanoparticle, porous silicon technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of pollution, high energy consumption, long cycle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a preparation method of porous silicon-supported copper nanoparticles, comprising the following steps:

[0038] Carrying out the first centrifugation of the porous silicon nanoparticle isopropanol suspension to obtain the first precipitate;

[0039] After ultrasonically mixing the first precipitate with the HF solution, a second centrifugation is performed to obtain a second precipitate;

[0040] The second precipitation, polyvinylpyrrolidone solution, CuSO 4 The solution is mixed with the hydrazine hydrate solution, and a reduction reaction is performed to obtain the porous silicon-supported copper nanoparticles.

[0041] In the present invention, the porous silicon nanoparticle isopropanol suspension is subjected to the first centrifugation to obtain the first precipitate.

[0042] In the present invention, the concentration of the porous silicon nanoparticles in the isopropanol suspension of the porous silicon nanoparticles is preferably 0.6×...

Embodiment 1

[0067] The 0.6 × 1 billion / mL suspension of porous silicon nanoparticles in isopropanol (IPA) was placed in a 1 mL EP tube, centrifuged at 12,000 rpm for 1 min, the IPA supernatant was removed, and 1 mL of 0.05% volume fraction was added to it. The HF solution was sonicated for 5 min, centrifuged at 13000 rpm for 1 min, removed the supernatant, washed twice with water and twice with isopropanol, removed the residual HF solution, and added 1 mL of 10% PVP solution, 60 μL CuSO 4 (10 mmol / L) solution and 1 μL of hydrazine hydrate solution (80% by mass), mixed quickly, ultrasonically reacted for 20 min, centrifuged at 13,000 rpm for 1 min, removed the supernatant, washed with water three times, and washed with isopropanol three times. Residual PVP solution was removed to obtain light gray-black precipitates (Si@Cu NPs) which were kept in isopropanol solution.

[0068] (1) Characterization of Si@Cu NPs

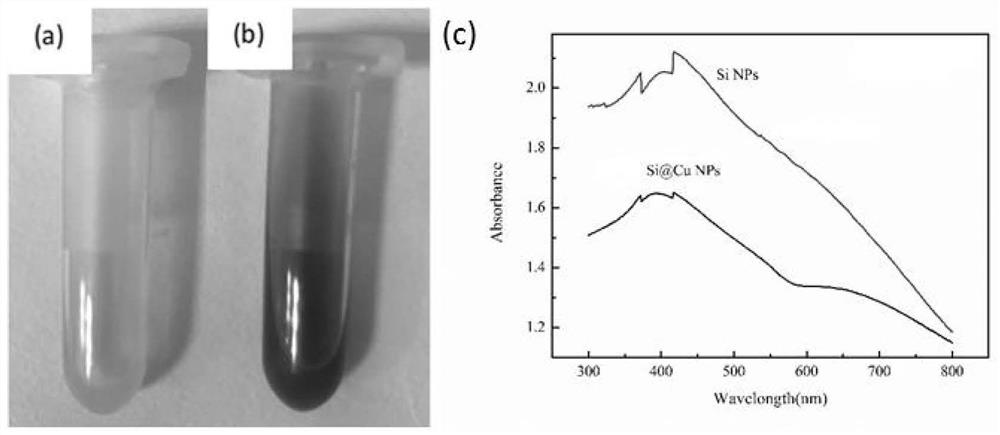

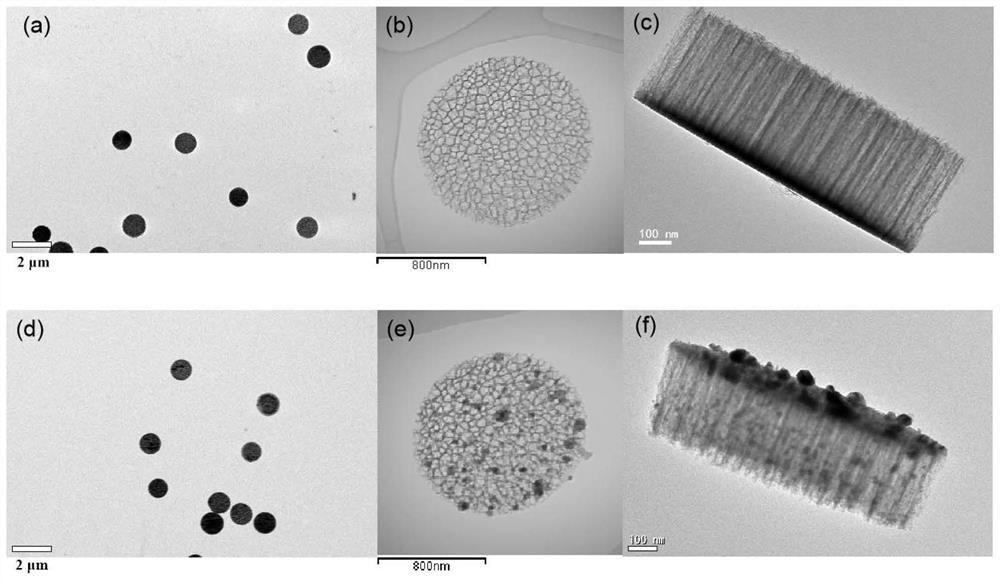

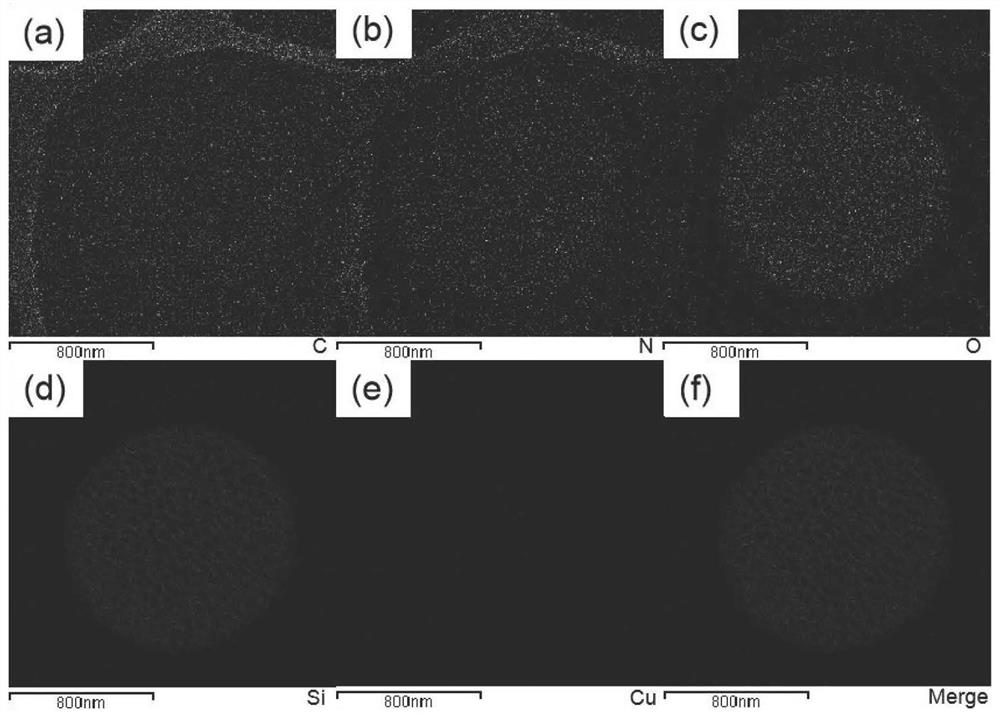

[0069] like figure 1 where (a) is the physical image of the Si NPs suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com