Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Hull cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Hull cell is a type of test cell used to qualitatively check the condition of an electroplating bath. It allows for optimization for current density range, optimization of additive concentration, recognition of impurity effects and indication of macro-throwing power capability. The Hull cell replicates the plating bath on a lab scale.

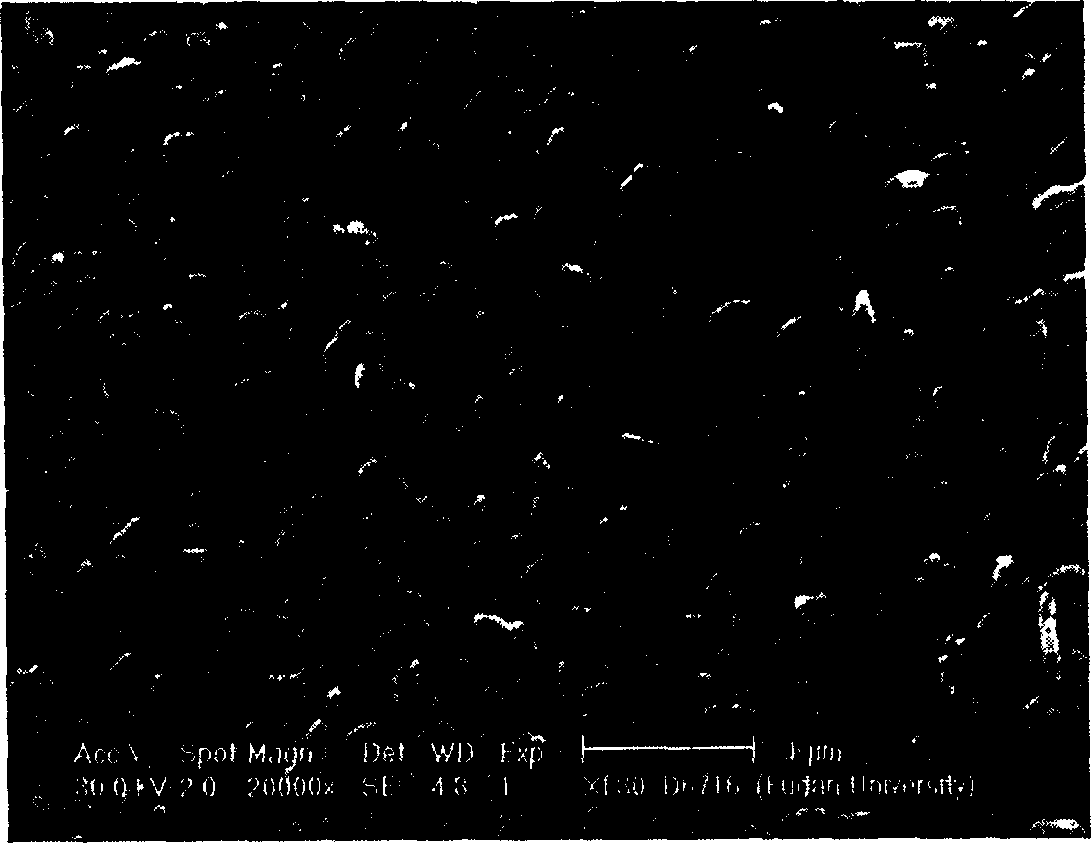

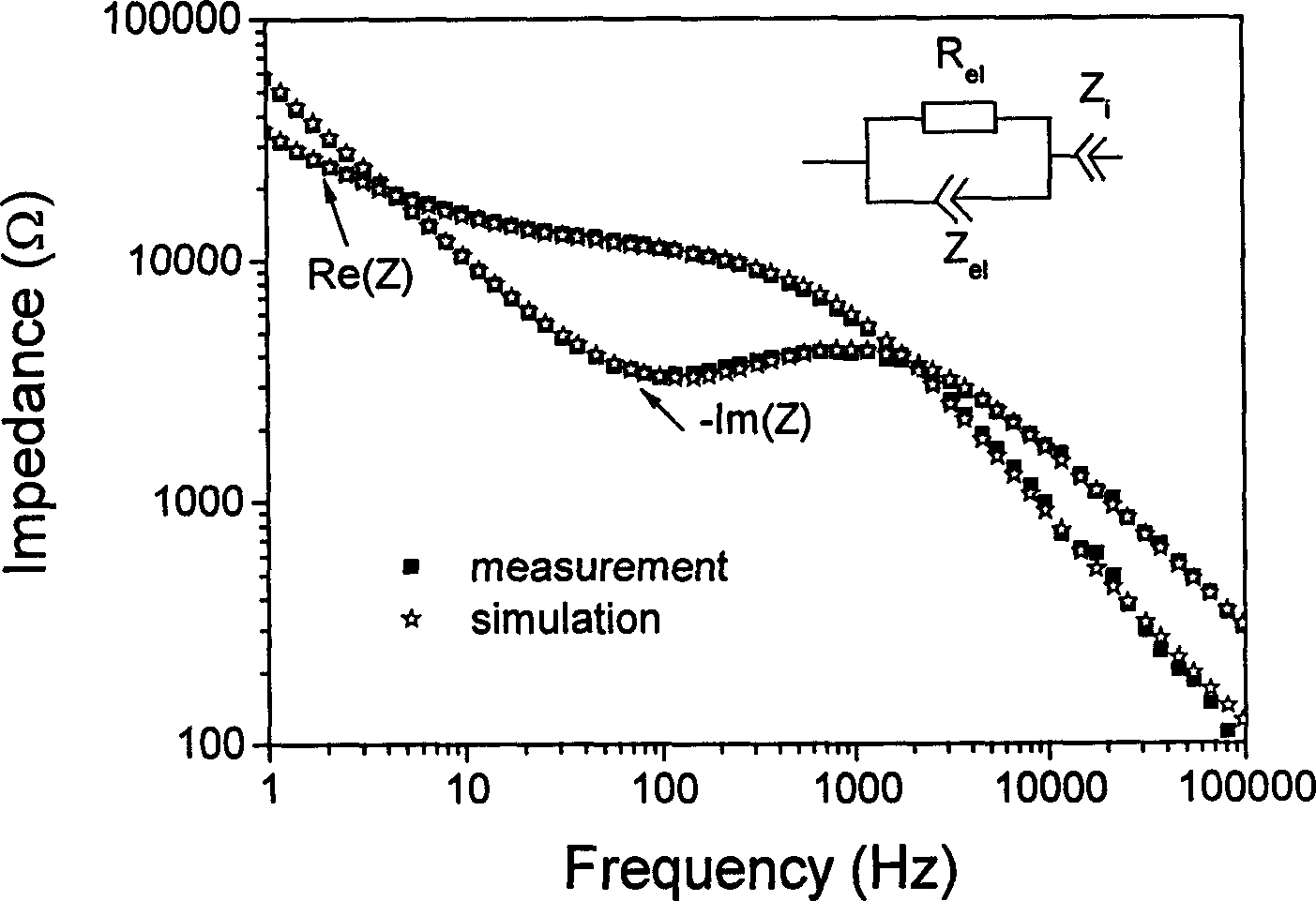

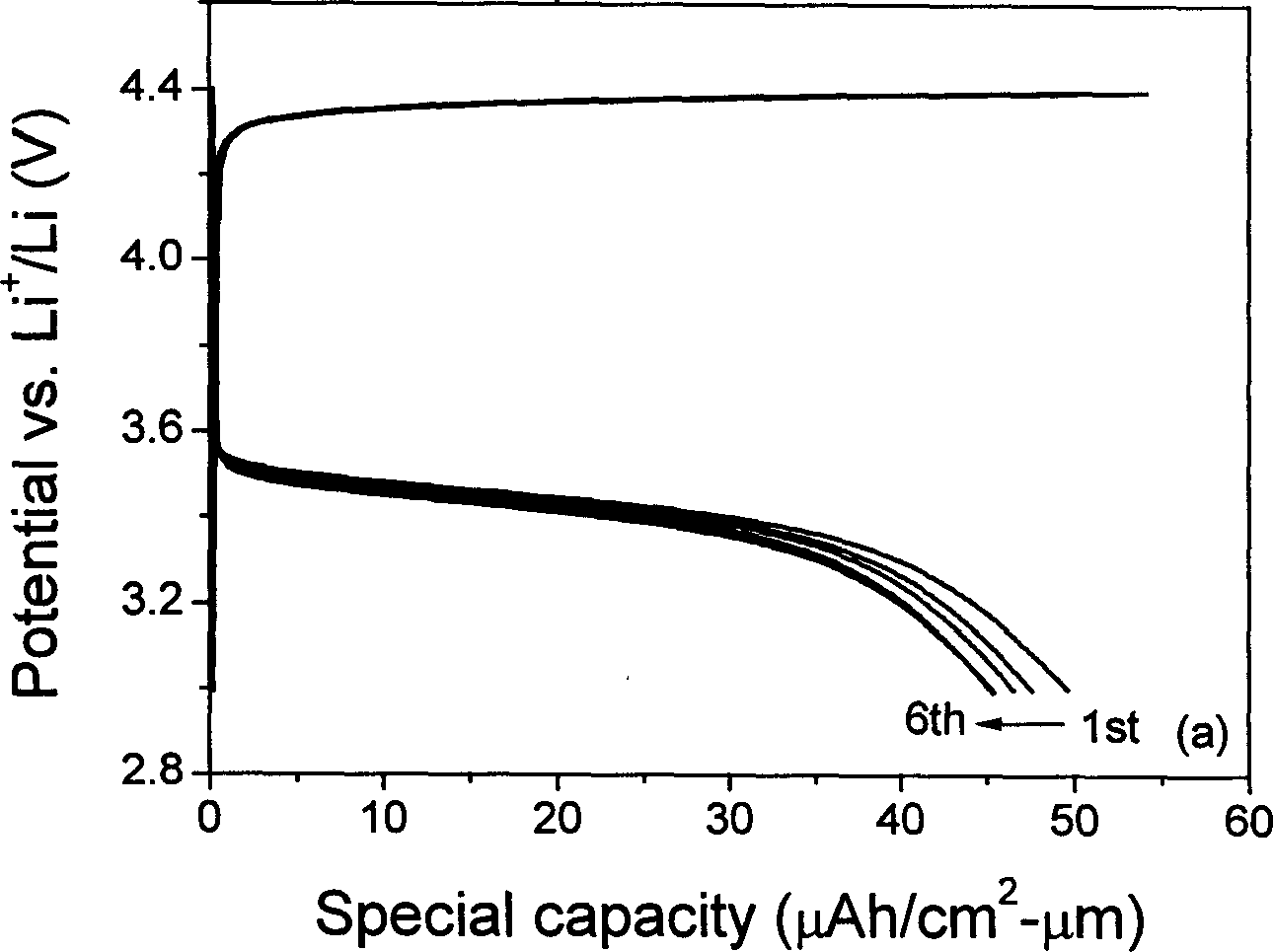

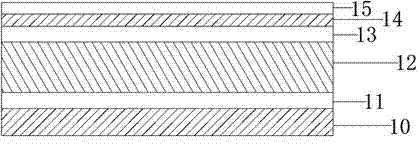

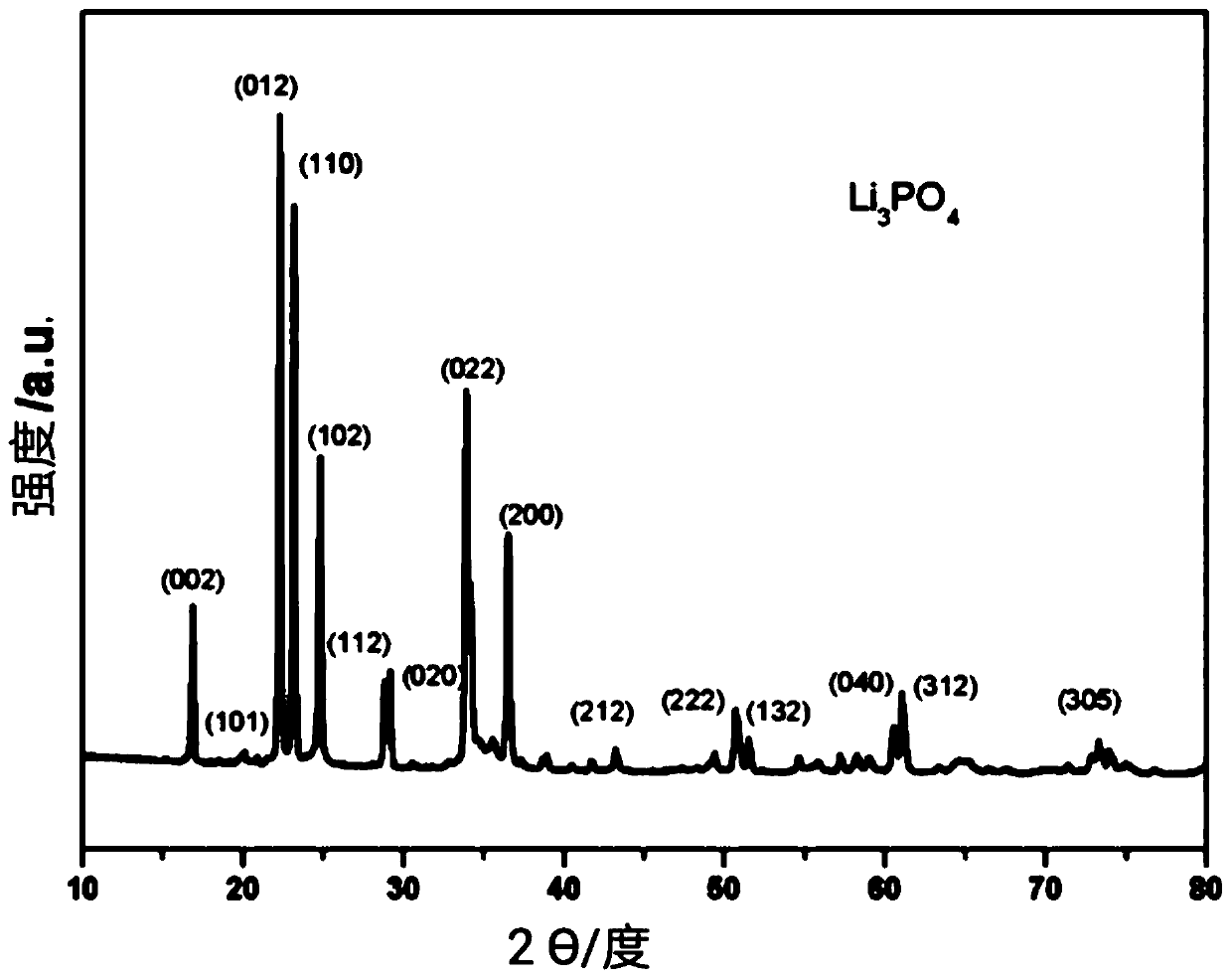

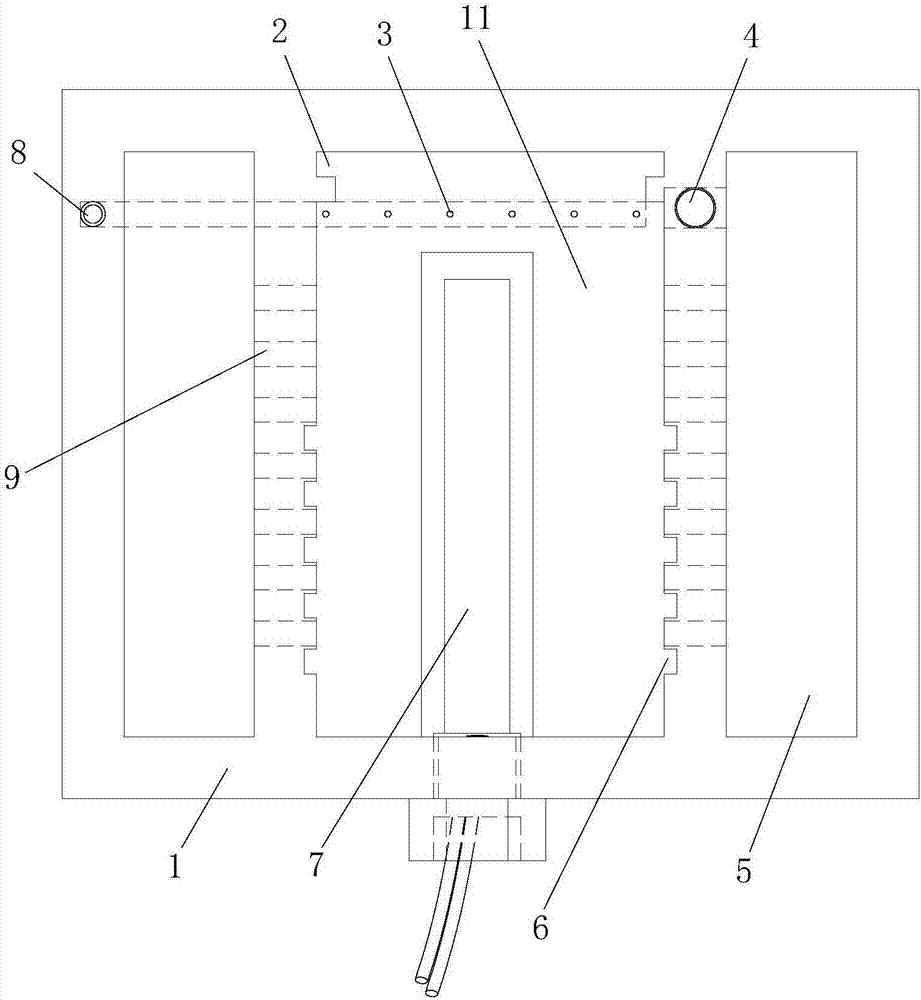

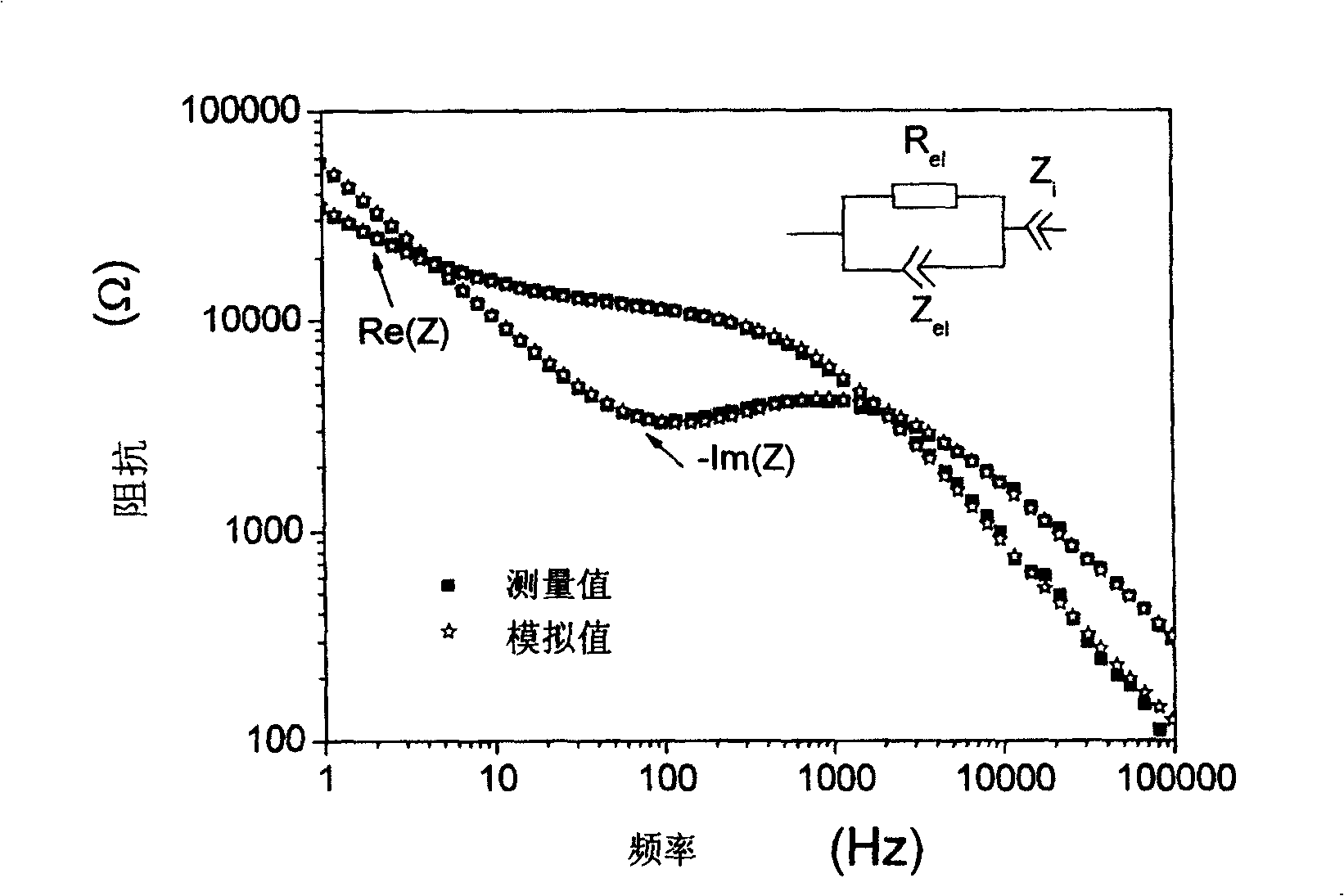

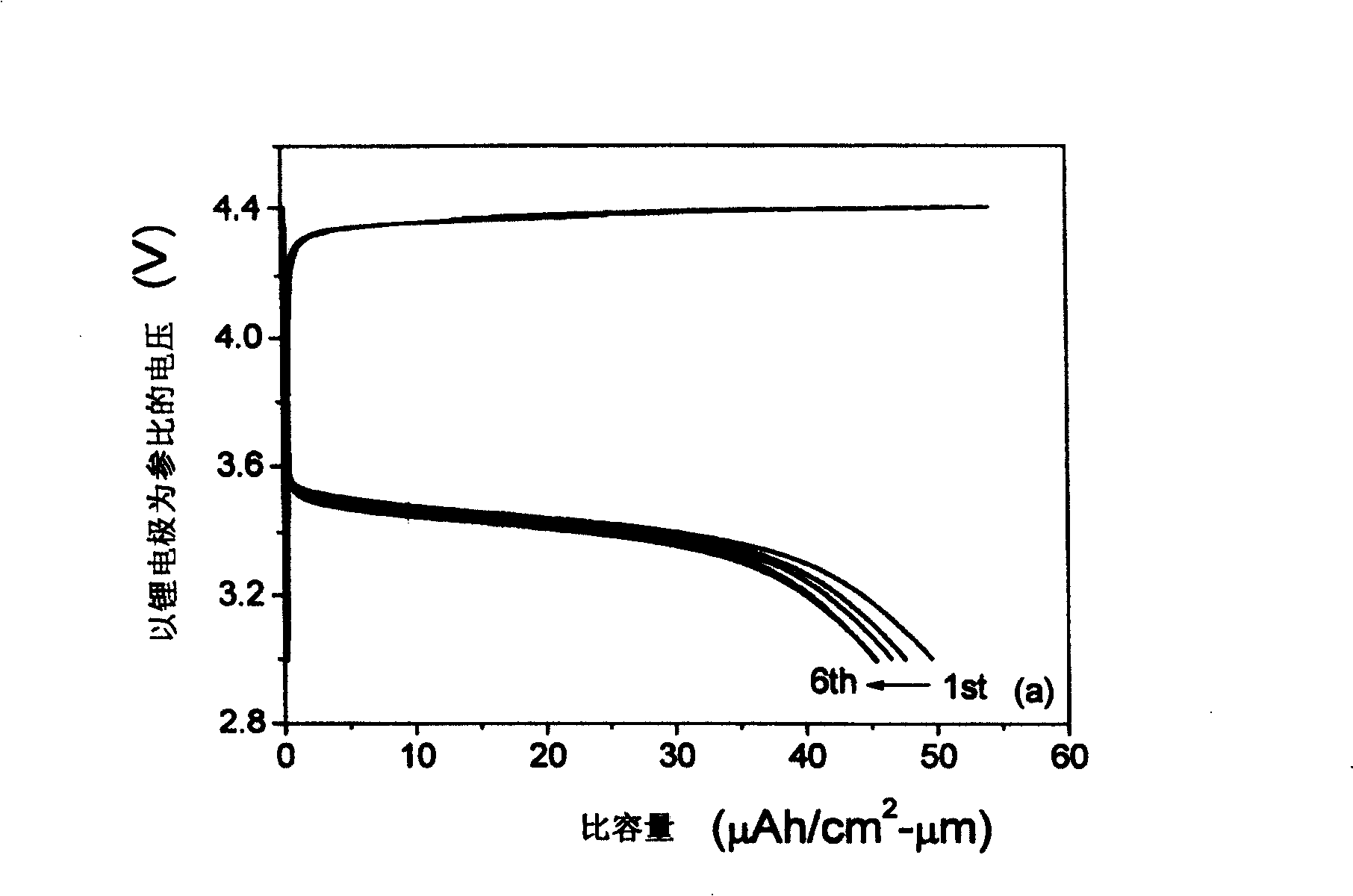

Method for preparing LLTO(lithium lanthanum titanate) film by electron beam heat evaporation

InactiveCN1789483AImprove charge and discharge performanceVacuum evaporation coatingSputtering coatingMetallic lithiumSolid state electrolyte

The invention, belonging to lithium ion hull cell technical field, relates the method for preparation of LLTO used for solid state thin film lithium battery. The invention adopts the electron-beam vapor deposition method to prepare LLTO, comprising the following characteristics: large film deposit area, big deposition rate, and lithium ion ionic conductivity being 2í‡10-7S / cm. The LiCoO2 or LiMn2O4, LiPON and antiabrasion layer film, which are made with the method of radio-frequency magnetic control sputtering, and the metallic lithium anode film made with the method of vacuum heat evaporation are assembled to solid state thin film lithium battery. The specific capacity of cell is 45mAh / cm2-ª–m and 24mAh / cm2-ª–m, and the cycle index is up to 150 times. So the LLTO solid state electrolyte thin film made by the method of electron-beam evaporation can be used in solid state thin film lithium battery.

Owner:FUDAN UNIV

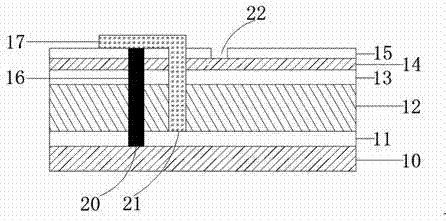

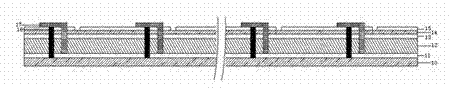

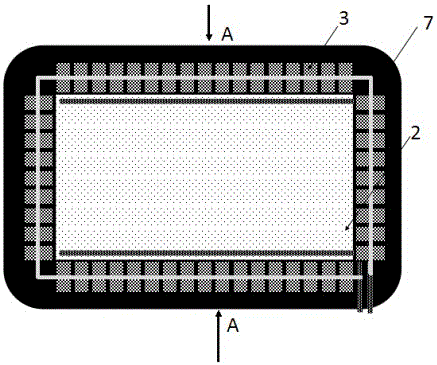

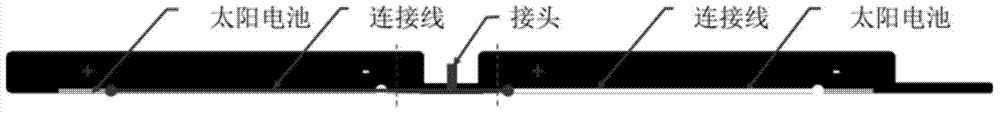

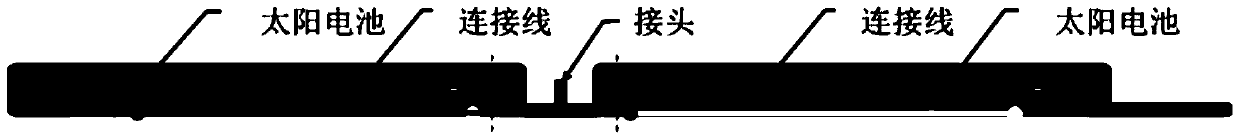

Method of etching single integrated assembly on flexible PI substrate CIGS hull cell through lasers

ActiveCN103618030ALow costImprove processing efficiencyFinal product manufactureSemiconductor devicesSilver pasteHigh resistance

The invention provides a method of etching a single integrated assembly on a flexible PI substrate CIGS hull cell through lasers. The method comprises the following steps: step 1, the lasers are used for etching the cell from a top electrode to the upper surface of a PI substrate to form a first channel; step 2, the first channel is coated and filed with insulating cement; step 3, the lasers are used for etching the cell from the top electrode to the upper surface of a back electrode to form a second channel; step 4, the second channel and the top electrode are coated with silver paste, and the silver paste spreads from the top of the second channel and goes beyond the top of the first channel; step 5, the lasers are used for etching the cell from the top electrode to the upper surface of a high resistance layer to form a third channel, and then intraconnection of the CIGS hull cell is completed. According to the method, intraconnection of the cell is conducted after the CIGS hull cell finishes growing, as a result, the situation that different layers of materials are required to be etched respectively after sedimentation in traditional separating type etching can be avoided, the processing efficiency of intraconnection of the cell is improved, and material cost is low.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Microvia-superfilling copper plating technology

InactiveCN104109886ASimplify device configurationReduce consumptionJewelleryCopper platingFilling rate

The invention discloses a microvia-superfilling copper plating technology. The microvia-superfilling copper plating technology comprises the following steps of a, carrying out activation treatment on a blind hole plate to be plated in a dilute sulphuric acid solution for 1-10min, carrying out water washing and drying, vertically fixing the blind hole plate to be plated to the middle of a Hull cell having the volume of 1500mL, and putting phosphor-containing copper plates as anodes having phosphor content of 0.04-0.065% at two ends of the cell, b, preparing a plating solution, c, switching on a power supply, carrying out electroplating at current density of 0.5-2ASD for 5-30min, increasing current density to 0.5-4ASD, carrying out electroplating for 10-20min, wherein the whole electroplating process is finished in a static state, then switching off the power supply, taking out the blind hole plate as a cathode, flushing the blind hole plate by distilled water, and blow-drying the blind hole plate by cold air to obtain a sample. Under the condition of absolutely no forced convection of the plating solution, the microvia-superfilling copper plating technology does not increase surface copper thickness and guarantees a high microvia-filling rate of the blind hole device.

Owner:SUR PRECISION METAL TECH

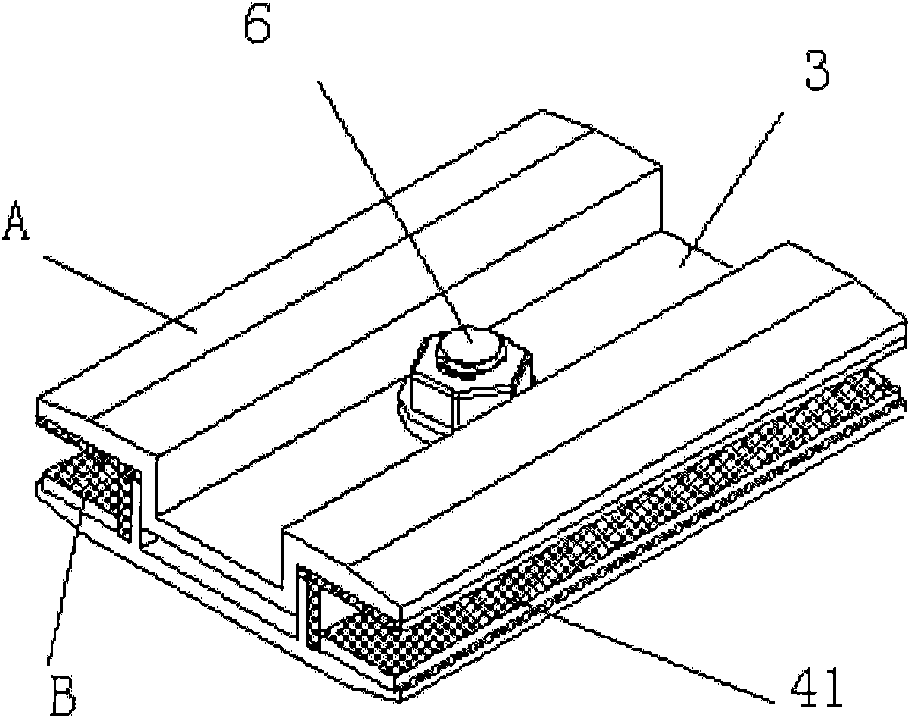

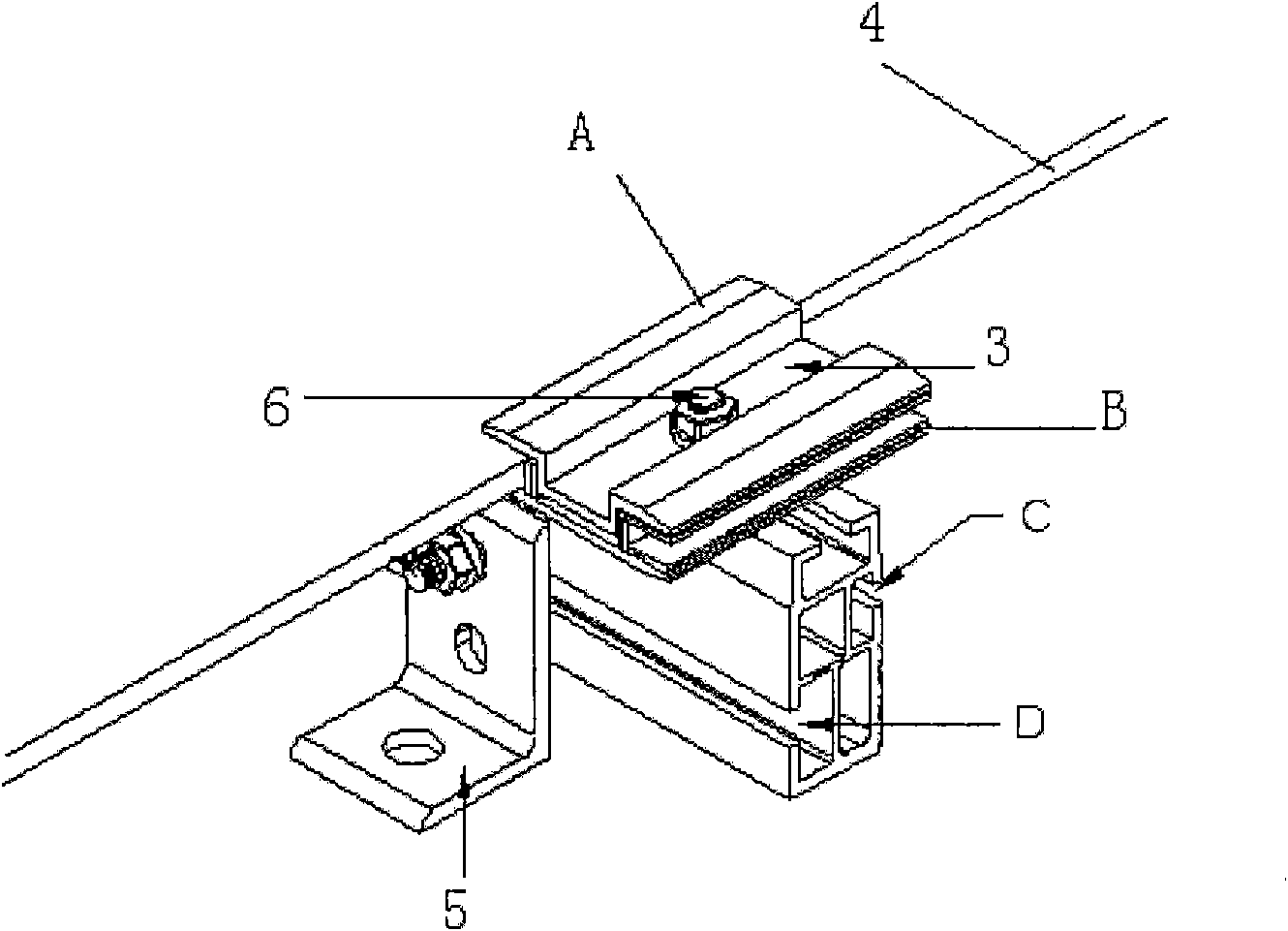

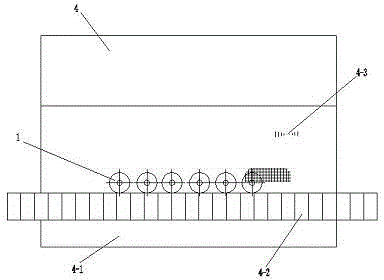

Hull cell module installing device and roof or ground connecting structure thereof

InactiveCN101826565AEasy to installNice appearancePhotovoltaic supportsSolar heating energyEngineeringSolar power

The invention relates to a hull cell module installing device and a roof or ground connecting structure thereof. The hull cell module installing device comprises an upper press block and a lower press block which are eudipleural, wherein a bolt fixing groove is arranged in the middle of the upper press block, and hull cells are respectively arranged between the upper press block and the lower press block which are eudipleural. The hull cell module installing device satisfies the structure bearing capacity, is functionally designed by combining the characteristics of practical products, reasonably and economically uses materials to ensure that a solar generation cell set can be conveniently installed, has attractive appearance, greatly improves the work efficiency and saves product and construction costs.

Owner:上海时瑞能源科技有限公司

Production process and production device for electroplating grade potassium pyrophosphate

The invention discloses a production process for electroplating grade potassium pyrophosphate. The production process comprises the following steps of taking 85 percent phosphoric acid and 48 percent potassium hydroxide as raw materials; performing a neutralization reaction in a neutralization reaction kettle, and controlling the pH value of slurry to be 8.5 to 9.5; filtering the slurry by a fine filter, then feeding the slurry into a slurry storage tank, and keeping the temperature of the slurry in the storage tank to be 70 to 90DEG C; feeding the slurry in the storage tank into an evaporation and concentration device for concentrating; then feeding a concentrated solution into a continuous crystallization device for performing continuous crystallization operation; after centrifugal treatment, returning filtrate to the evaporation and concentration device and enabling a potassium dihydrogen thophosphate crystal to enter vacuum drying equipment for performing vacuum drying treatment; conveying a dried material into an indirect heating dynamic polymerization furnace and polymerizing to form potassium pyrophosphate; cooling, breaking, screening and packaging to obtain a finished product. Compared with electroplating grade potassium pyrophosphate on the market, the electroplating grade potassium pyrophosphate obtained by the invention has the advantages of higher dissolution speed, higher purity, more excellent complexing power and better Hull cell test results.

Owner:湖北省兴发磷化工研究院有限公司

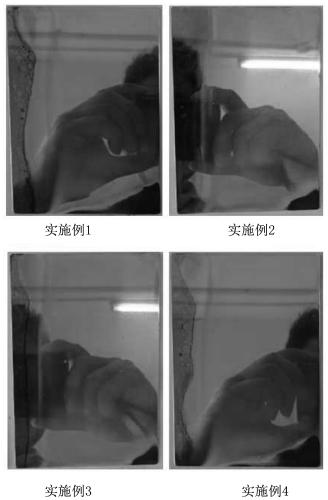

Preparation of general brightener for potassium salt zinc plating and sulfate zinc plating

The invention relates to preparation of a general brightener for potassium salt zinc plating and sulfate zinc plating. C6H5COONa, C10H10O, AESA, an NNO dispersing agent, an OP emulsifying agent, C6H5NO2 and other substances are dissolved, and mixed uniformly according to a certain ratio. The general brightener can be generally used for potassium salt zinc plating and sulfate zinc plating and brings great convenience to management and production. The brightener can obviously improve the brightness, the leveling property and density of a plating layer, and the requirement on total-area brightness of a test piece can be met in a 2A Hull cell test.

Owner:SHANDONG JIANZHU UNIV

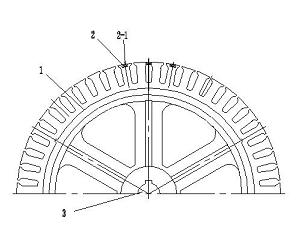

Insulation process of motor stator punching sheet for electric vehicle

ActiveCN102142746AReduce weightTo achieve the insulation effectElectric machinesApplying solid insulationSurface layerPunching

The invention provides an insulation process of a motor stator punching sheet for an electric vehicle, which comprises the steps of surface processing, protection, preheating and dip-coating curing of the motor stator punching sheet sequentially. The step of protection comprises the following sub steps that: a rotating shaft protection tool is connected at the position of a shaft hole of the motor stator punching sheet; and a hull cell protection tool is connected into a rebate of the hull cell. The hull cell protection tool comprises a protection block of a shape corresponding to that of the rebate of the hull cell and at least one pin. The step of dip-coating curing sequentially comprises the following steps of: firstly, placing the motor stator punching sheet in a fluidized bed; secondly, powdering; and finally, carrying out leveling processing. An insulating layer is formed on the surface layer of the motor stator punching sheet processed by the insulation process, the motor stator punching sheet can be direct subjected to subsequent processes such as wire insertion and the like and insulation paper and bamboo sticks in a stator punching sheet slot are reduced, and thus, the weight of a motor stator is reduced. The dip-coating of insulating powder is carried out in the fluidized bed, so the automation degree is improved, uniform dip-coating is ensured, the quality of the insulating layer is assured and the demand for batch production is met.

Owner:CHANGZHOU YUCHENG FUTONG MOTOR CO LTD

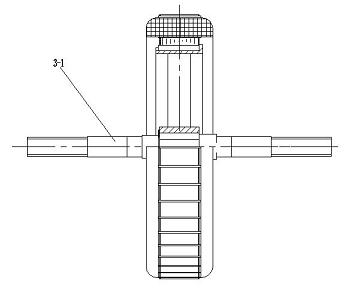

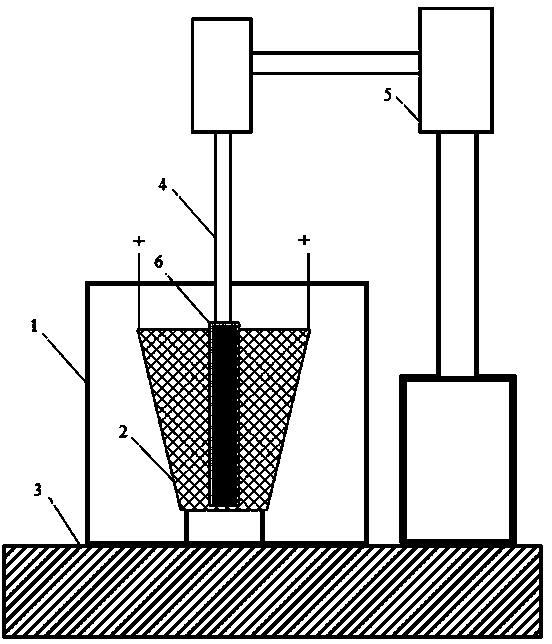

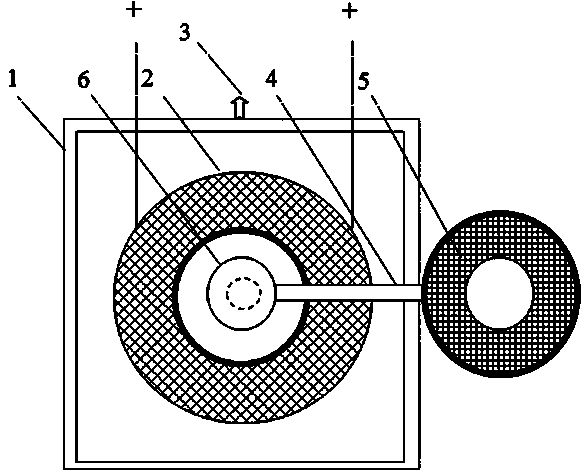

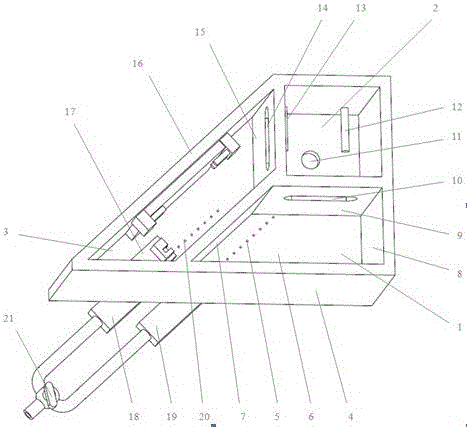

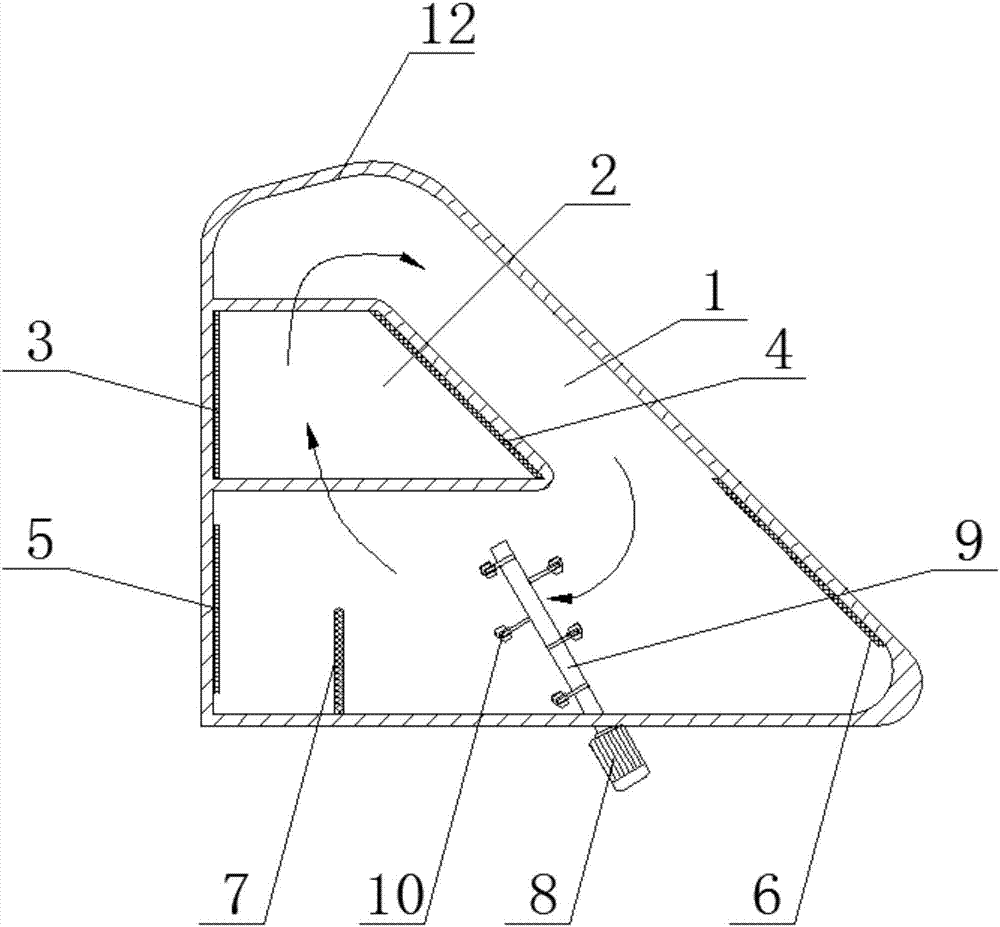

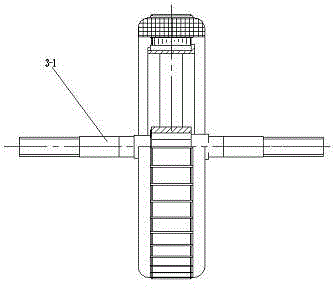

High-speed electroplating rotary hull cell

A high-speed electroplating rotary hull cell relates to a hull cell and aims to achieve the purpose of researching the performance of a high-speed electroplating solution in labs. The hull cell consists of an electroplating bath body, a bracket, a reticular anode and a rotary cathode, as well as a variable speed motor and a cantilever which drive the rotary cathode to rotate, wherein the electroplating bath body and the variable speed motor are fixed to the bracket; the reticular anode is fixed to the bottom of the electroplating bath body; the rotary cathode is inserted into the reticular anode and connected with the variable speed motor outside the electroplating bath body through the cantilever. The high-speed electroplating rotary hull cell can not only simply, conveniently and quickly analyze the properties of a plating solution and screen additives but also simulate the high-speed electroplating process to research the performance and the processing parameters of the high-speed electroplating solution so as to make up the shortcomings of labs in the prior art.

Owner:HARBIN INST OF TECH

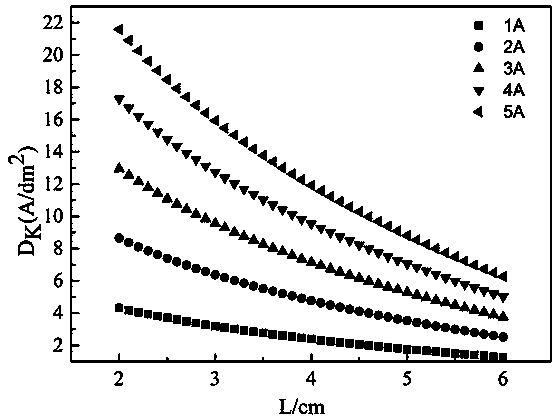

Method for processing chrome-containing tanned wastewater and recycling chrome metal

InactiveCN103695970AAchieve recyclingThe effluent Cr content is reducedWaste water treatment from animal processingWater/sewage treatmentIridiumLiquid waste

The invention discloses a method for processing chrome-containing tanned wastewater and recycling chrome metal. The method comprises the steps of simply preprocessing the tanned wastewater to remove solid impurities; putting a chrome-containing tanned waste liquor with the solid impurities removed in a hull cell, adding a small amount of carbamide, a proper amount of boric acid and methyl alcohol to adjust pH; taking an iridium-plated DSA (Dimensionally Stable Anode) polar plate as a positive pole, taking a plated part which is deoiled and polished before the plated is plated as a negative pole, and placing the positive pole and the negative pole in an electroplating bath; connecting a pulse power supply; adjusting the space between polar plates to be 7.5cm and adjusting voltage so that the potential of the negative pole electrode is kept between -0.96V and -1.1V, and the current density is 8-35A / dm<2>; and mechanically stirring and electrolyzing. Compared with the existing alkali precipitation technology, the method provided by the invention has the advantages that the content of Cr in produced water of the chrome-containing tanned wastewater processed by the method is obviously reduced; the content of chrome in the wastewater can be greatly reduced; the metal chrome can be recycled; and the problems of a large amount of chrome-containing sludge and high treatment cost in the existing tanned wastewater alkali precipitation technology can be solved.

Owner:SHAANXI UNIV OF SCI & TECH +1

Method for removing lithium from lithium-contained electrolyte in Hull cell

The invention relates to a separation process of a nonferrous metal, in particular to a method for removing lithium from a lithium-contained electrolyte in a Hull cell. The method is characterized inthat the electrolyte in the Hull cell is transferred to a delithium molten salt electrolyzer to be subjected to electrolysis, wherein the cathode of the delithium molten salt electrolyzer is a graphite cathode, so that lithium ions in an electrolyte melt are inlaid in the graphite cathode preferentially, and then removing of lithium in the electrolyte is conducted. According to the method, the lithium ions in the electrolyze melt can be selectively inlaid in the graphite cathode, when the content of the lithium in the cathode meets the requirement, the cathode which is subjected to lithium removing and full of the lithium serves as an electrolytic anode of magnesium chloride fused salt in an another magnesium chloride fused salt electrolyzer, the lithium in the graphite anode can enter themagnesium chloride fused salt and magnesium metal in the electrolysis process of the magnesium chloride fused salt, the lithium entering the magnesium electrolyzed fused salt can improve the electrical conductivity of the electrolyte, and the lithium-contained magnesium metal obtained through electrolysis can be used for preparing a magnesium lithium alloy. The method can reduce the lithium content of the lithium-contained electrolyte in the Hull cell, and provide conditions for effective utilization of the lithium.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

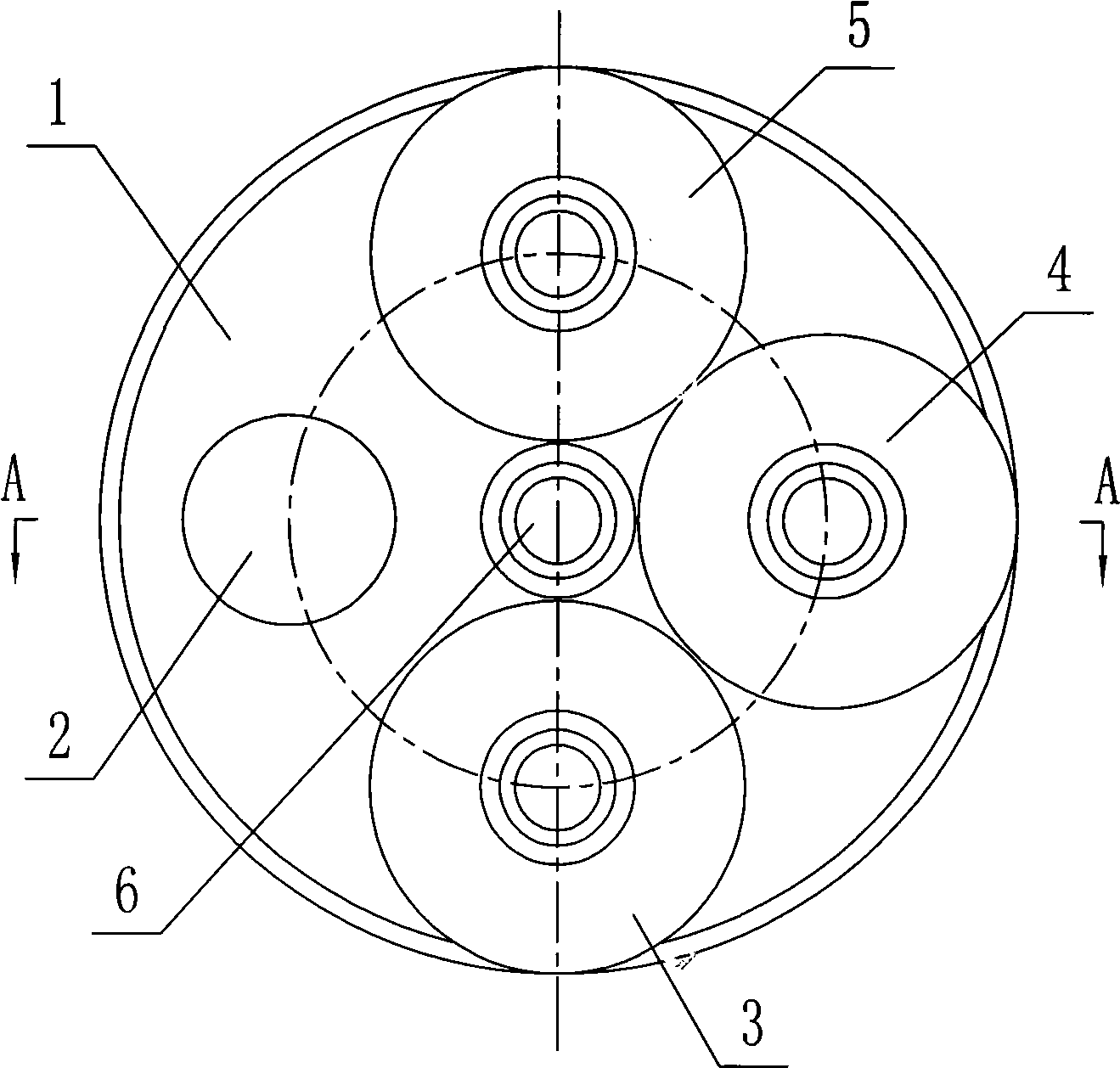

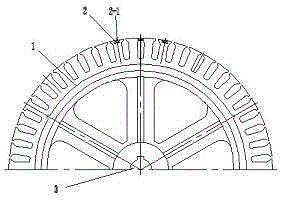

Continuous plasma reinforced chemical vapor deposition reaction chamber for preparing amorphous silicon film

InactiveCN101481795AMeet depositionSimple structureChemical vapor deposition coatingGas phaseAmorphous silicon

A continuous mode plasma enhanced chemical vapor deposition reaction chamber for preparing an amorphous silicon membrane comprises a support plate and a big cylindrical reaction chamber arranged on the support plate and formed by a reaction cover. The big reaction chamber is provided with a film entering chamber and three small round reaction rooms with the same structures. The axial leads of the three small round reaction rooms are parallel to the axial lead of the big reaction room. The distances between the centers of the circles of the three small round reaction chambers on the same horizontal cross-section and the film entering chamber and the center of the circle of the big reaction room are all equal. The centers of the circles of the three small round reaction chambers and the center of the circle of the film entering chamber are distributed on the same circumference. The reaction chamber can meet the deposition of P, I, N layers of hull cells, has simpler structure, is suitable for being used in the development of the hull cells and can meet the production of cell slices with the small size.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Hybrid solar skylight

InactiveCN105034770AGuaranteed light requirementsIncrease power generationSolid-state devicesPhotovoltaic energy generationHybrid typeElectrical battery

The invention relates to a solar skylight for an automotive roof. The solar skylight comprises a solar skylight body arranged in a mounting frame at the automotive roof. The edge of the solar skylight body is provided with a circle of black printing layer to be used for mounting a metal support and a skylight movement mechanism. A solar cell piece is arranged in the solar skylight body and composed of a semi-transparent hull cell and a light-proof cell distributed surrounding the hull cell. The light-proof cell is located on the outer side of the black printing layer. The light-proof cell is additionally arranged on the outer side of the original light-proof black printing layer, and the power generating power of the solar skylight is improved while the light transmitting area is not reduced.

Owner:NINGBO SANDI SOLARTECH CO LTD

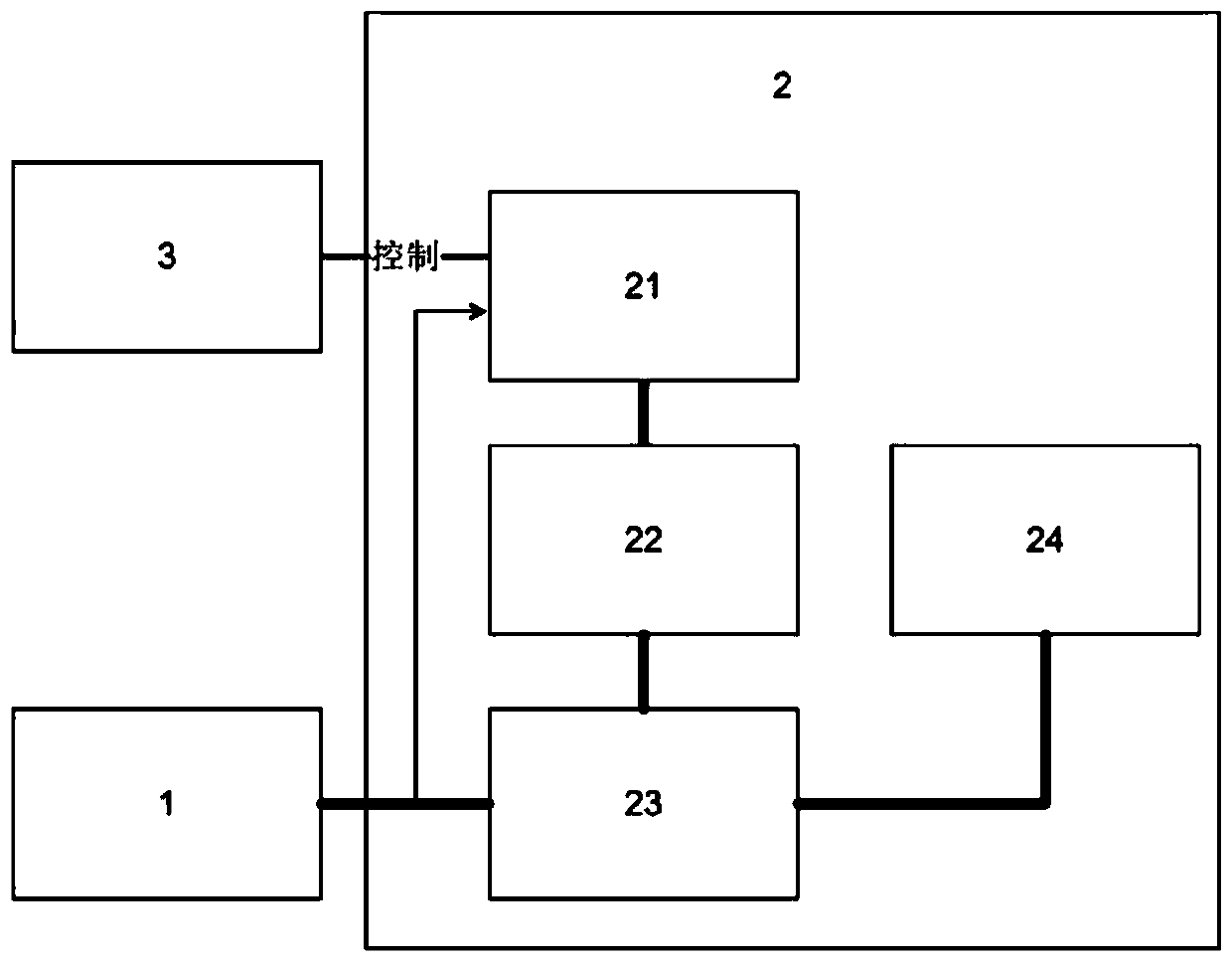

Power source compensation device and method based on solar cell

ActiveCN104716694ASimple structureEasy to carrySecondary cells charging/dischargingElectric powerElectrical batteryPower control system

The invention relates to a power source compensation device and method based on a solar cell. A charging device is connected with a control circuit or a power source control system integrated in an electric appliance and is the solar cell. The method includes the following steps: the charging device is connected to an electric appliance power connector, the electric appliance carries out voltage-current scanning on the output of the charging device through a microprocessor, when the absolute value of the difference between a detected open-circuit voltage value and a set voltage value is smaller than a threshold value, the microprocessor gives a control signal to a switch power source controller to enable the switch power source controller to control a switch power source to enable the output voltage of the charging device to be output to the switch power source at the set voltage, and the switch power source charges an electric appliance electricity-storage device at a fixed voltage value. By means of the power source compensation device, the hull cell is used as the power source; in addition, the stable voltage can be output to charge the electric appliance, and the power source compensation device and method can be widely used for different electric appliances.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

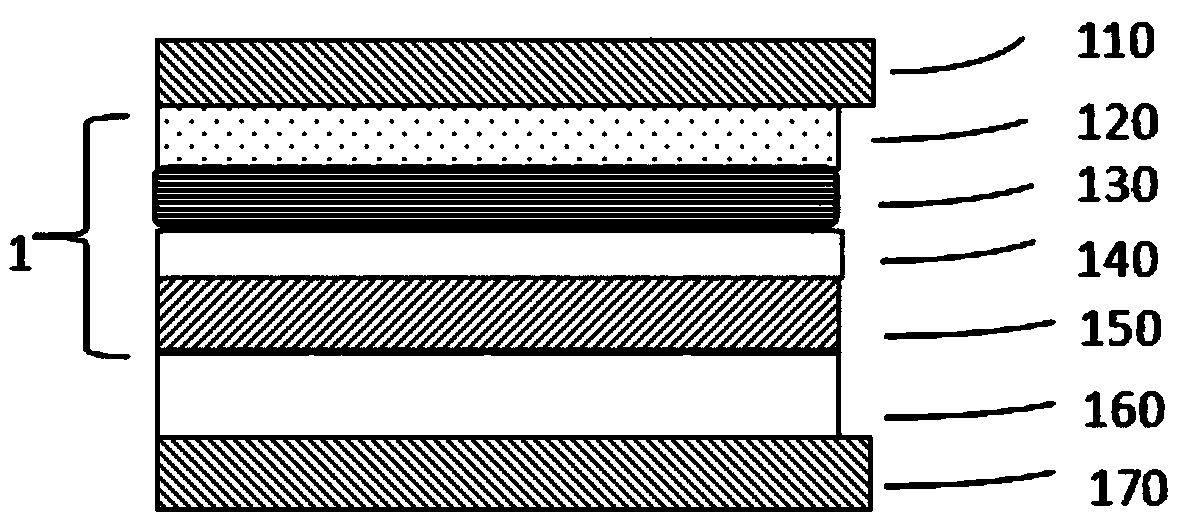

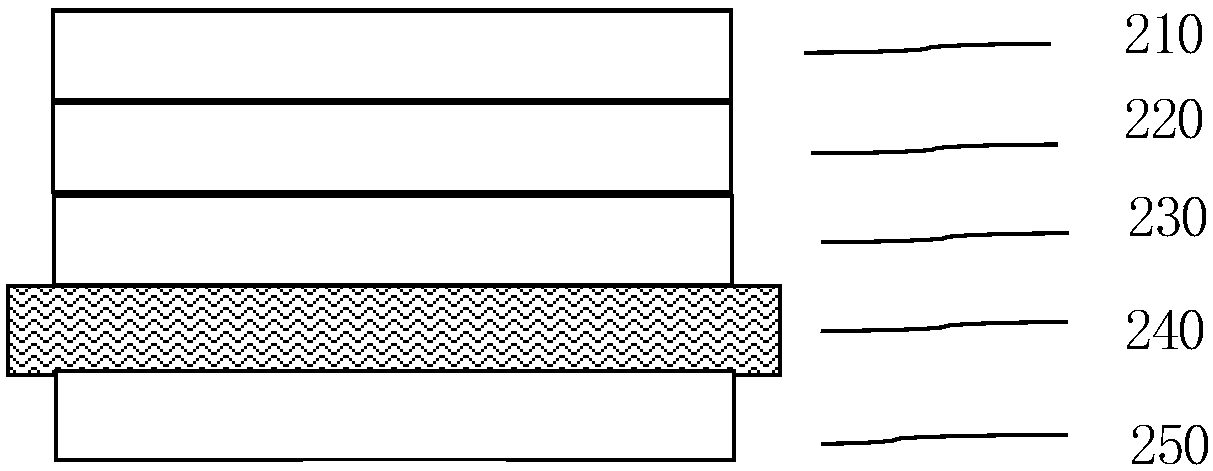

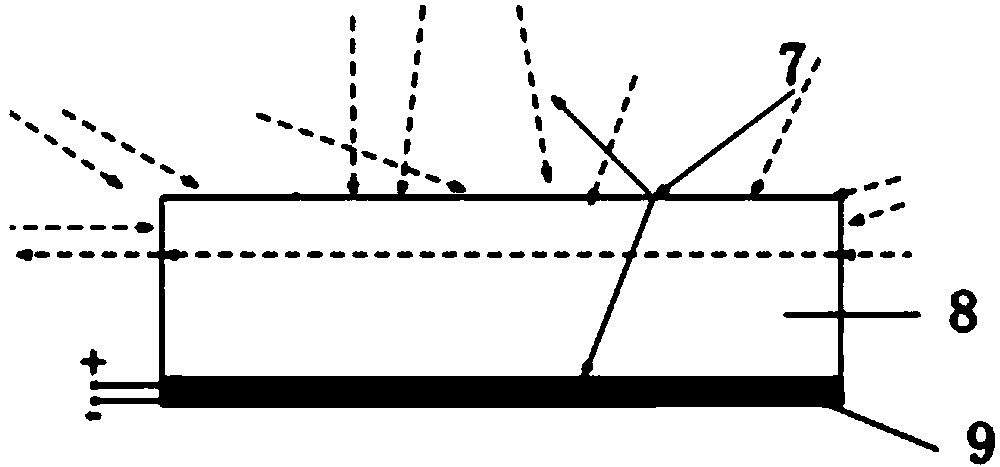

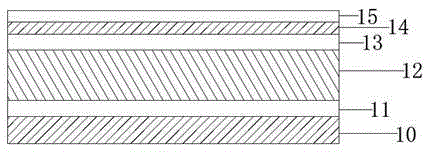

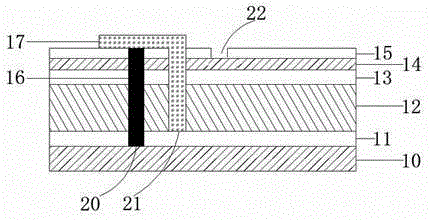

Cadmium telluride hull cell containing high-resistance layer and achieving self-cleaning function

InactiveCN107742651AAvoid contactImprove transmittanceFinal product manufacturePhotovoltaic energy generationOptoelectronicsHigh resistance

The invention discloses a cadmium telluride hull cell containing a high-resistance layer and achieving a self-cleaning function. The cell includes modified conductive glass (110), an electrode area (1) and backplate glass (170); the electrode area (1) is arranged between the conductive glass (110) and the backplate glass (170), and the modified conductive glass (110) includes a TiO2 membrane system (2), a TCO membrane (240) and the high-resistance layer (250) which are stacked in sequence. According to the hull cell, by modifying the upper and lower surfaces of the TCO membrane of the cadmiumtelluride hull cell, the purpose of achieving the self-cleaning function, a high conversion rate and low cost can be achieved.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

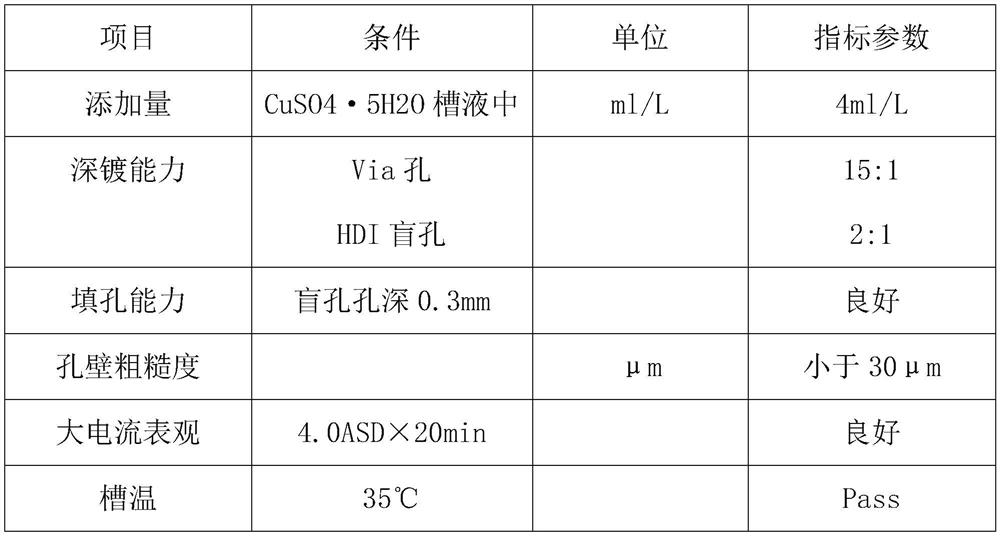

Copper plating additive production process

PendingCN113026065ASolve the defects of insufficient effectIncrease temperatureHigh current densityCopper plating

The invention discloses a copper plating additive production process, and relates to the technical field of electroplating production of circuit boards. The copper plating additive production process comprises the following steps: S1, blending a crystal grain refiner, a high-current density area additive and a low-current density area covering power enhancer according to proportions and quantifying the each reagent by using a weighing device, and mixing and stirring the raw materials to obtain initial solution A; S2, removing burrs of raw materials of the circular board by using a deburring machine, and separately drilling a via hole and an HDI blind hole on a point circuit board by using a data drilling machine; and S3, selecting a part of initial solution A to execute a hull cell experiment on the initial solution A; and detecting the large current representation and the addition amount of copper sulfate pentahydrate. According to the production process disclosed by the invention, by using the copper-plating additive, the cell liquid temperature, the hole conditioning capability, the copper plating time, the deep plating capability and the hole filling capability of the additive in electroplating working period can be improved, and the defect of the poor effect of existing copper-plating additives is overcome.

Owner:ANSHAN TONGYI PHOTOELECTRIC TECH

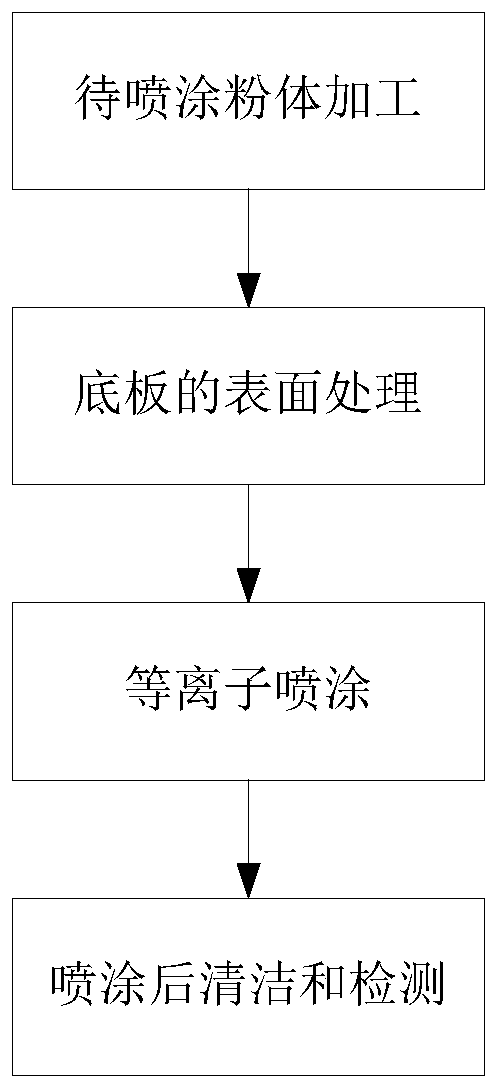

Sputtering target material preparation process based on plasma spraying technology

InactiveCN109881162AMeet preparation requirementsHigh densityMolten spray coatingElectric discharge tubesMaterials preparationSputtering

The invention discloses a sputtering target material preparation process based on a plasma spraying technology. The process comprises the steps that to-be-sprayed powder is processed to be within theparticle size range used for plasma spraying; the surface of a bottom board is subjected to surface treatment meeting the plasma spraying; the prepared to-be-sprayed powder is sprayed to the treated surface of the bottom board through a plasma spraying machine; and the sprayed bottom board is cleaned and detected. The sputtering target material preparation process uses the plasma spraying technology for preparing a target material, and the target material gas the high compactness (with the relative density of 93%) and high purity the same as primary powder materials; and compared with a hot pressing or sintering method, the preparation process not only can meet the preparation requirements of large-size target materials meeting the production demands of hull cells, but also can be used formanufacturing of target materials for electrode materials.

Owner:芮瑛 +1

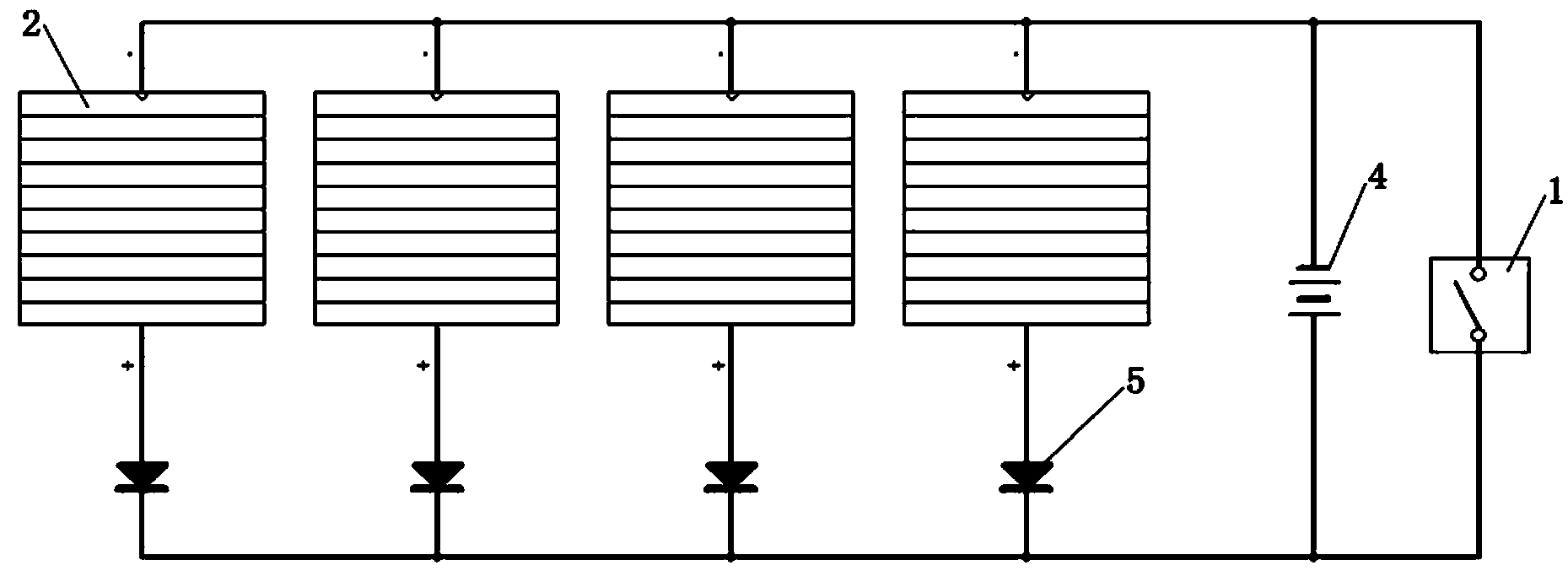

Micro-lens structure hull cell and wireless switch power supply system using scattered light rays to generate electricity

InactiveCN103368234APromote absorptionImprove conversion efficiencyBatteries circuit arrangementsElectric powerElectrical batteryEngineering

The invention discloses a micro-lens structure hull cell and wireless switch power supply system using scattered light rays to generate electricity. The micro-lens structure hull cell and wireless switch power supply system using the scattered light rays to generate the electricity comprises a hollow base body, wherein a control switch is placed on the upper surface of the base body, each side face of the base body is provided with N amorphous silicon hull cells, the N is larger than or equal to one, a storage battery and a diode are installed inside the base body, each amorphous silicon hull cell comprises a substrate and an amorphous silicon electricity generation layer plated on the bottom face of each substrate, and a micro-lens array structure is arranged on the top face of each substrate in a processed mode. The micro-lens structure hull cell and wireless switch power supply system using the scattered light rays to generate the electricity effectively improves the effect of absorption of the substrates of the hull cells to the scattered light rays in the space in the condition of dim light, an all-weather wireless switch which absorbs the dim light around to generate the electricity is manufactured on the basis, and the all-weather wireless switch does not need battery replacement, directly uses the indoor dim light to generate the electricity so as to achieve all-weather power supply, and is an environment-friendly switch free of energy consumption.

Owner:SOUTH CHINA UNIV OF TECH

Tinning operation process

InactiveCN105714365AThe operation process method is simple and clearFast operationCellsTinningElectrolysis

The invention discloses a tinning operation process. The tinning operation process is characterized by comprising the following steps: 1) ensuring that the water level and temperature of each cylinder are in normal states, wearing working boots and acid-and alkali-resistant gloves or fingerstalls according to production requirements and ensuring that a swing, a circulating pump, a direct current source and a pump are in normal states; 2) scrubbing a tinning bath; 3) injecting industrial pure water accounting for 1 / 4 of a standby bath into the standby bath, slowly adding metered sulfuric acid under stirring, adding metered copper sulphate in virtue of heat released in dissolving of sulfur acid in water and carrying out stirring until complete dissolving is realized, wherein temperature should not exceed 60 DEG C; 4) adding 1 to 2 ml of hydrogen peroxide into each L of a solution obtained in the previous step and carrying out violent air pumping and stirring for one to two hours; 5) phosphor copper treatment of a positive electrode; 6) taking out a soaked positive electrode bag, draining the positive electrode bag through dripping and sleeving the bag with titanium blue; and 7) carrying out sample and analysis, adjusting the components of a reagent solution to a controlled range, carrying out electrolytic treatment with an electrolysis plank at a rate of 2.0 A / dm<2> for 2 h, then carrying out electrolysis at a rate of 0.5 A / dm<2> for 3 to 4 h and adjusting the content of a luminescence agent to a normal range by using a Hull cell before trial plating. The tinning operation process is simple and clear and can improve operation speed and electroplating effect.

Owner:CHONGQING XUXINYUE NC MACHINERY CO LTD

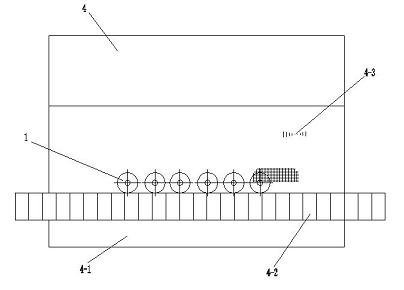

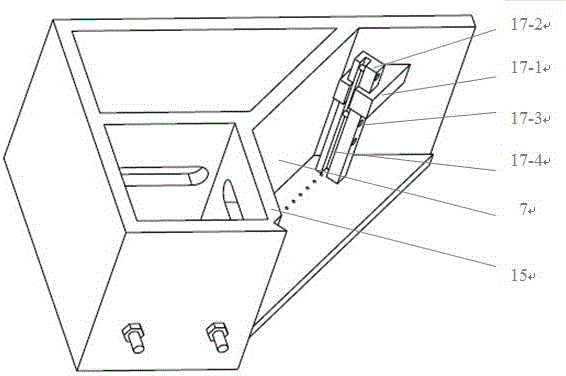

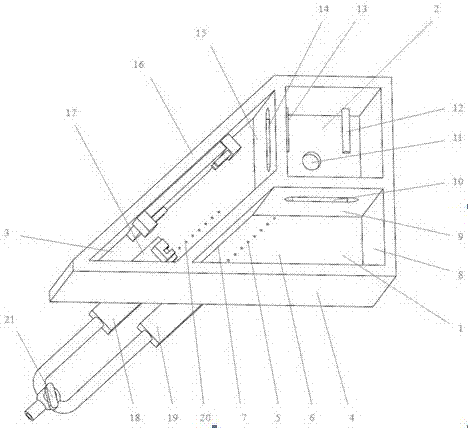

Multifunctional Hull cell system

The invention discloses a multifunctional Hull cell system. The system comprises a regulating cell, a Hull cell and an electrodeposition cell, wherein a cathode clamping unit is arranged in the electrodeposition cell and comprises a clamping bar, a locating plate and fixing parts; the clamping bar is provided with a straight channel; the axis of the straight channel is parallel to a cathode wall; the regulating cell, the Hull cell and the electrodeposition cell share a bottom plate; the Hull cell and the electrodeposition cell share the cathode wall; the Hull cell and the regulating cell share a short side wall; the electrodeposition cell and the regulating cell share a side wall; a row of liquid inlets is formed in bottom plates of the Hull cell and the electrodeposition cell respectively; a liquid outlet is formed in a bottom plate of the regulating cell; overflow ports are formed in the short side wall of the Hull cell and the side wall of the electrodeposition cell. The system has the advantages that the functions of the system are further perfected; not only does the system have all the functions of existing conventional Hull cells but also the system can evaluate the distribution characters of the indexes of electrodeposition layers, such as internal stress, hardness and thickness, under the process condition of being close to production; the system has a simple structure and is low in cost.

Owner:HENAN POLYTECHNIC UNIV

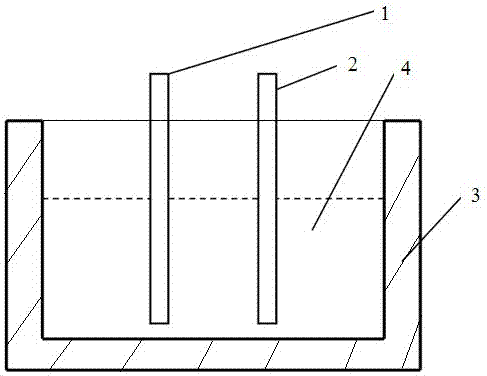

Method for testing electroplating current efficiency by using square Hull cell

InactiveCN107367438AEasy to upgrade toImprove accuracyWeighing by removing componentCellsThird partyEngineering

The invention discloses a method for testing the electroplating current efficiency by using a square Hull cell. The method comprises the following steps: taking a sample, polishing a test piece, placing the above sampled plating solution in the square Hull cell, heating the plating solution to a process temperature, cutting the test piece to form a required size, inserting an anode plate into an anode slot in the middle of the square Hull cell, connecting the positive electrode of a power supply to the anode plate, connecting the negative electrode of the power supply to the test piece, starting the power supply and an air pump, turning off the power supply when a predetermined time is reached, taking out and flushing the test piece, calculating the practical deposition mass of a plating layer and the mass of a plating layer deposited at a current efficiency of 100%, and calculating the current efficiency. The test method using the square Hull cell as a test device and designed according to the characteristics of the square Hull cell can be used to rapidly measure the practical current efficiency in order to accurately control the thickness of the plating layer, and the method also has the advantages of simplicity in operation, high efficiency, low cost, and realization of automatic implementation by electroplating manufacturers without a third party monitoring mechanism.

Owner:东莞市同欣新材料有限公司

Method for preparing LLTO(lithium lanthanum titanate) film by electron beam heat evaporation

InactiveCN100422381CImprove charge and discharge performanceVacuum evaporation coatingSputtering coatingMetallic lithiumSolid state electrolyte

Owner:FUDAN UNIV

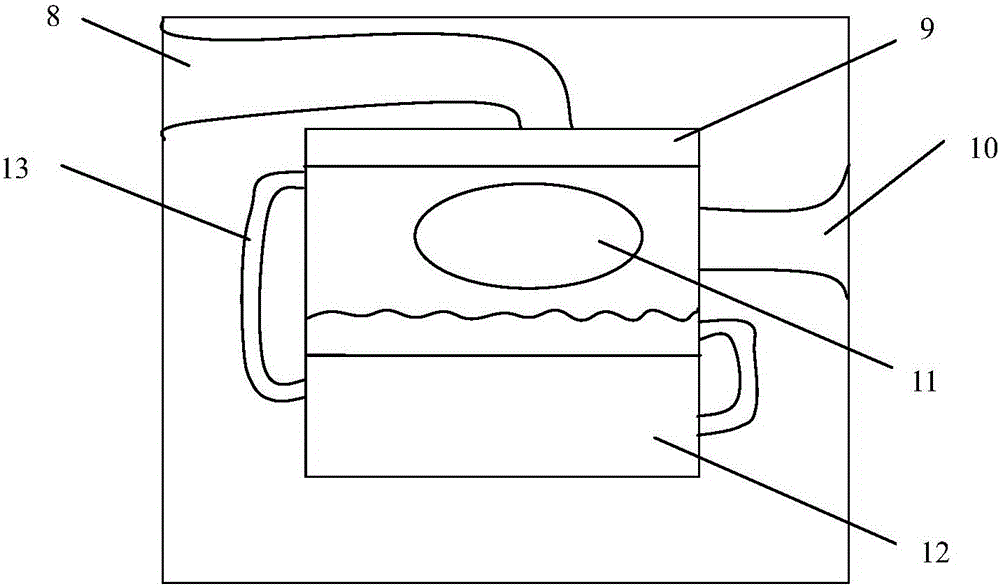

Hull cell structure for plating solution detection

The invention discloses a Hull cell structure used for plating solution detection, comprising an outer tank, an inner tank, a first anode, a first cathode, a second anode, a second cathode, a heating rod, a motor, a stirring shaft, and a through hole and the top edge; the outer tank is located outside the inner tank, two parallel side walls of the inner tank are provided with through holes, and the other two pairs of sides of the inner tank are respectively equipped with a first anode and a first cathode, so The outer tank and the inner tank are connected through through holes, the two opposite sides of the outer tank are respectively provided with a second anode and a second cathode, the outer tank is provided with a heating rod, and the stirring shaft is installed on Inside the outer tank. The invention has a large capacity of ferrying liquid, and under the action of stirring blades, the ferrying liquids of the inner tank and the outer tank are connected with each other, thereby avoiding the impact on the experimental results caused by the rapid change of the ferrying liquid. The invention has double-layered inner tanks and outer tanks, increases the capacity of the liquid during the experiment, and can test four test pieces at the same time, thus improving the test efficiency.

Owner:湖北协兴环保科技股份有限公司

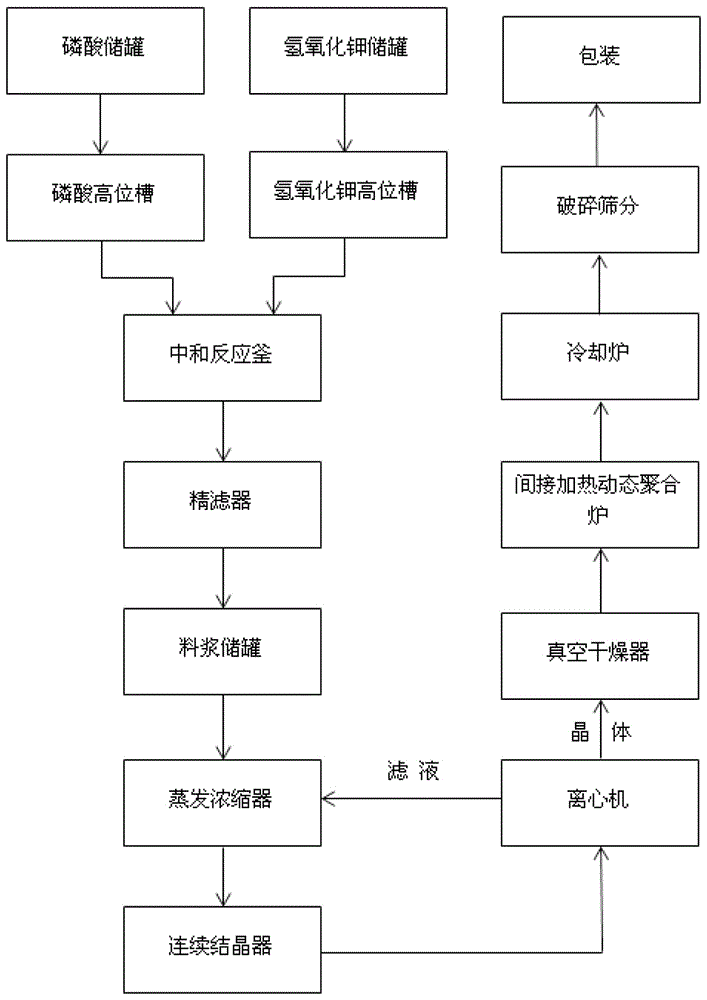

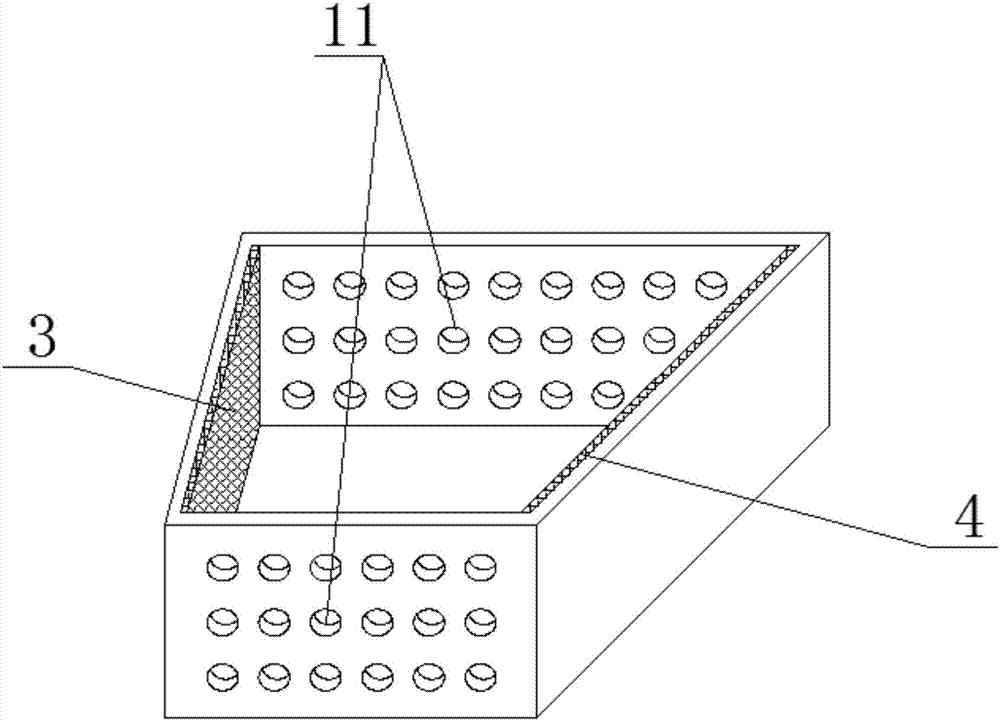

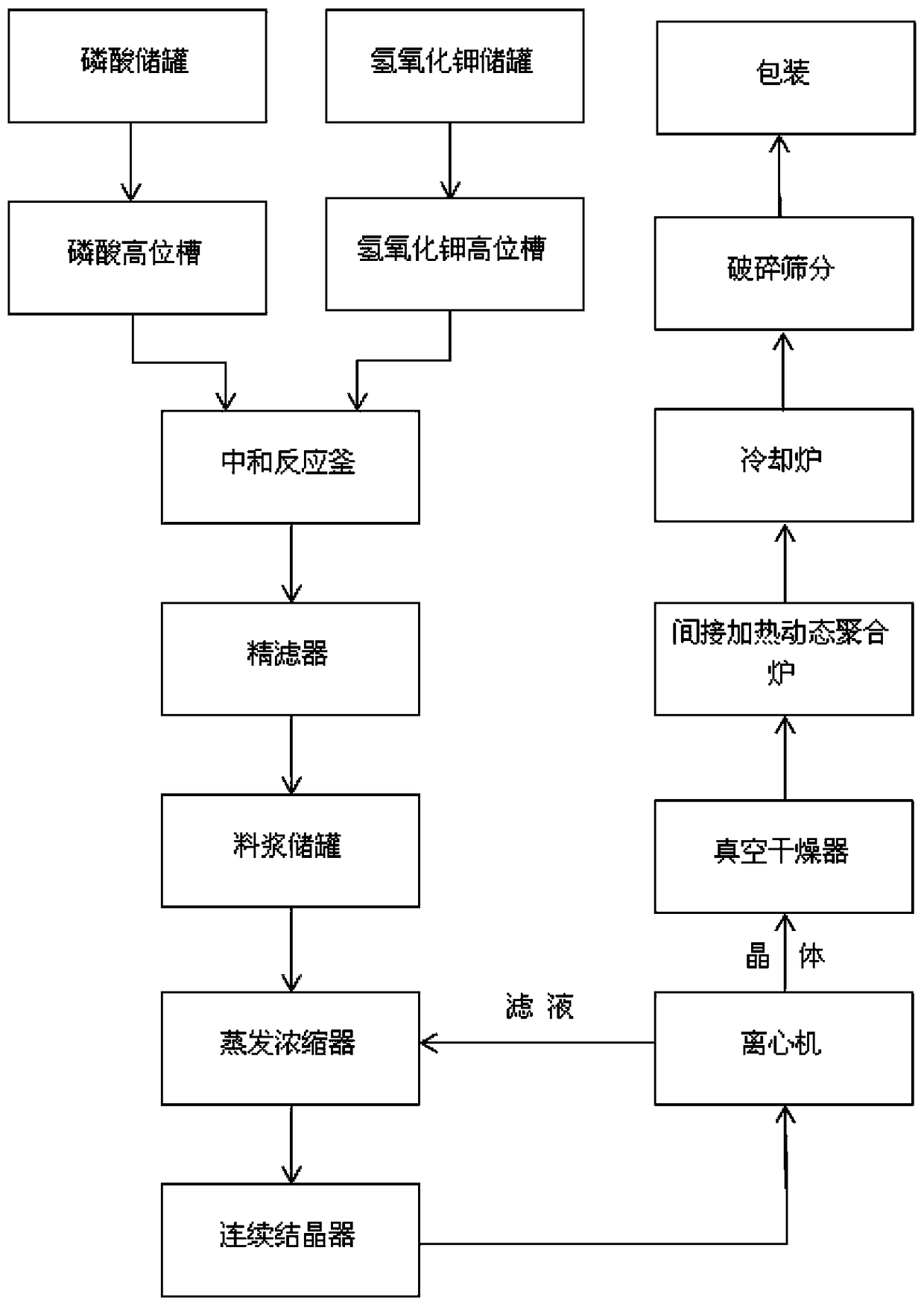

A kind of production process and device of electroplating grade potassium pyrophosphate

ActiveCN105967165BHigh purityIncrease brightnessPhosphorus compoundsPhosphoric acidPotassium hydroxide

The invention discloses a production process for electroplating grade potassium pyrophosphate. The production process comprises the following steps of taking 85 percent phosphoric acid and 48 percent potassium hydroxide as raw materials; performing a neutralization reaction in a neutralization reaction kettle, and controlling the pH value of slurry to be 8.5 to 9.5; filtering the slurry by a fine filter, then feeding the slurry into a slurry storage tank, and keeping the temperature of the slurry in the storage tank to be 70 to 90DEG C; feeding the slurry in the storage tank into an evaporation and concentration device for concentrating; then feeding a concentrated solution into a continuous crystallization device for performing continuous crystallization operation; after centrifugal treatment, returning filtrate to the evaporation and concentration device and enabling a potassium dihydrogen thophosphate crystal to enter vacuum drying equipment for performing vacuum drying treatment; conveying a dried material into an indirect heating dynamic polymerization furnace and polymerizing to form potassium pyrophosphate; cooling, breaking, screening and packaging to obtain a finished product. Compared with electroplating grade potassium pyrophosphate on the market, the electroplating grade potassium pyrophosphate obtained by the invention has the advantages of higher dissolution speed, higher purity, more excellent complexing power and better Hull cell test results.

Owner:湖北省兴发磷化工研究院有限公司

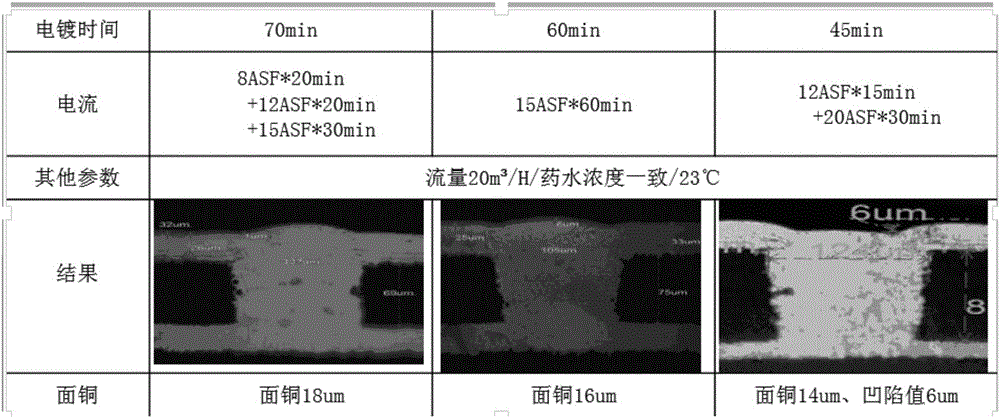

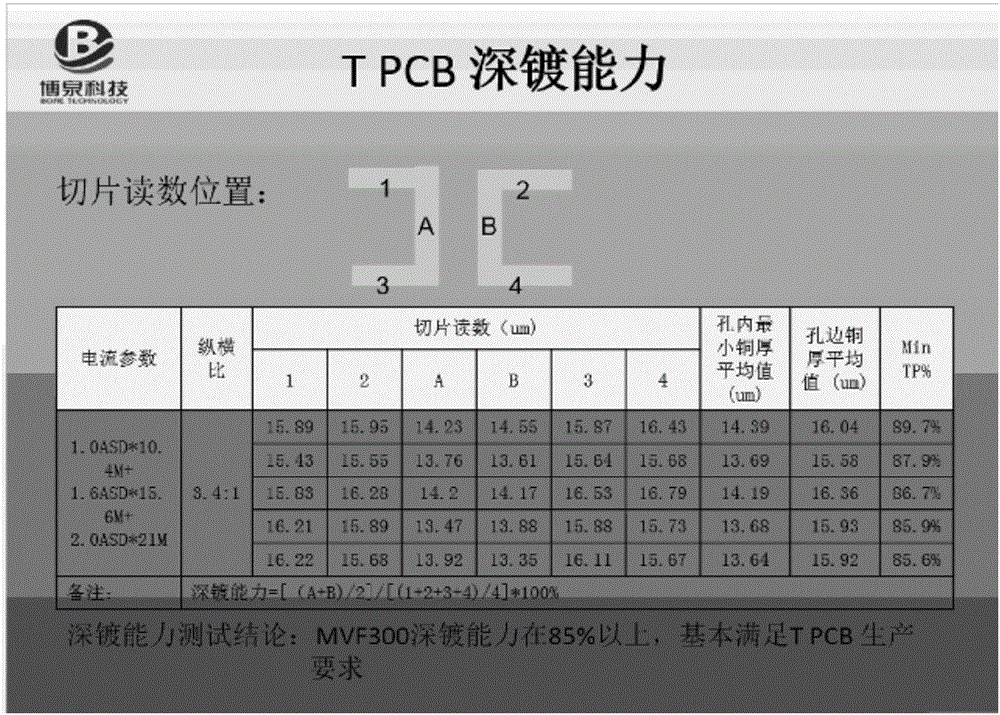

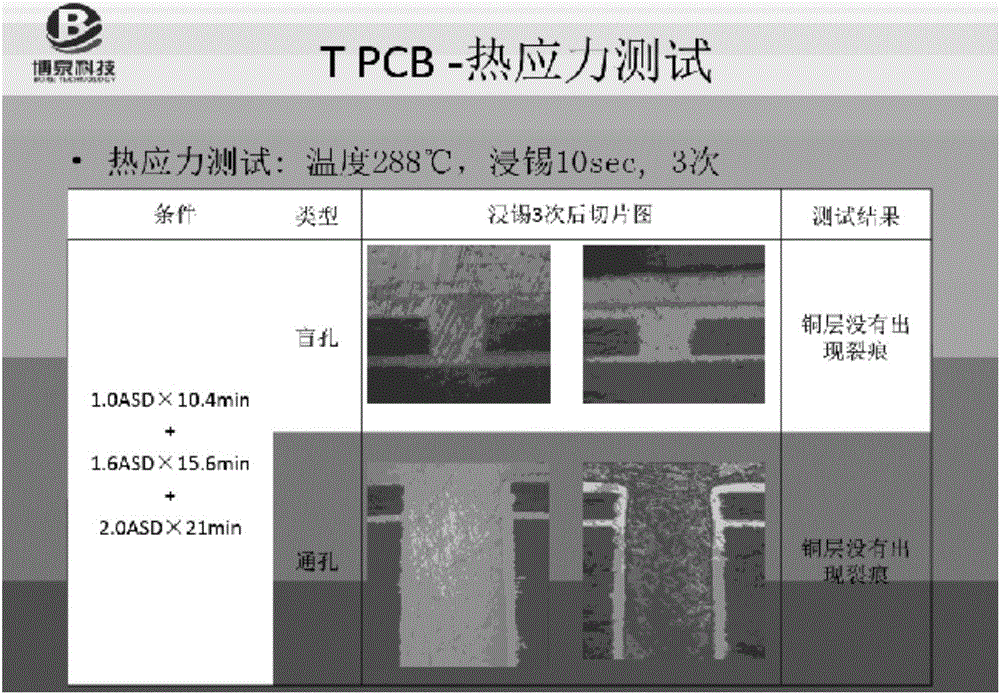

MVF300 hole filling electroplating process

InactiveCN106231818AImprove ductilityImprove uniformityPrinted element electric connection formationCopperCopper anode

The invention relates to an MVF300 hole filling electroplating process, and belongs to the technical field of electroplating. The process includes an HDI plate producing step, a soft plate producing step and a hole filling step. The electroplating liquid in the process shows stable and excellent hole filling effect and good deep electroplating force for conducting holes. Electroplating copper particles are bright and densely crystallized and have excellent ductility and uniformity. The diameter of a blind hole is 5mil, and the dielectric layer is 2.8mil, DC galvanography and copper anodes can be employed for Hull cells production and CVS analysis and control.

Owner:GUANGZHOU BORE ENVIRONMENTAL PROTECTION MATERIAL TECH

A kind of multi-functional Hall cell system

The invention discloses a multifunctional Hull cell system. The system comprises a regulating cell, a Hull cell and an electrodeposition cell, wherein a cathode clamping unit is arranged in the electrodeposition cell and comprises a clamping bar, a locating plate and fixing parts; the clamping bar is provided with a straight channel; the axis of the straight channel is parallel to a cathode wall; the regulating cell, the Hull cell and the electrodeposition cell share a bottom plate; the Hull cell and the electrodeposition cell share the cathode wall; the Hull cell and the regulating cell share a short side wall; the electrodeposition cell and the regulating cell share a side wall; a row of liquid inlets is formed in bottom plates of the Hull cell and the electrodeposition cell respectively; a liquid outlet is formed in a bottom plate of the regulating cell; overflow ports are formed in the short side wall of the Hull cell and the side wall of the electrodeposition cell. The system has the advantages that the functions of the system are further perfected; not only does the system have all the functions of existing conventional Hull cells but also the system can evaluate the distribution characters of the indexes of electrodeposition layers, such as internal stress, hardness and thickness, under the process condition of being close to production; the system has a simple structure and is low in cost.

Owner:HENAN POLYTECHNIC UNIV

Insulation process of motor stator punching sheet for electric vehicle

ActiveCN102142746BReduce weightTo achieve the insulation effectElectric machinesApplying solid insulationPunchingElectric machine

The invention provides an insulation process of a motor stator punching sheet for an electric vehicle, which comprises the steps of surface processing, protection, preheating and dip-coating curing of the motor stator punching sheet sequentially. The step of protection comprises the following sub steps that: a rotating shaft protection tool is connected at the position of a shaft hole of the motor stator punching sheet; and a hull cell protection tool is connected into a rebate of the hull cell. The hull cell protection tool comprises a protection block of a shape corresponding to that of therebate of the hull cell and at least one pin. The step of dip-coating curing sequentially comprises the following steps of: firstly, placing the motor stator punching sheet in a fluidized bed; secondly, powdering; and finally, carrying out leveling processing. An insulating layer is formed on the surface layer of the motor stator punching sheet processed by the insulation process, the motor stator punching sheet can be direct subjected to subsequent processes such as wire insertion and the like and insulation paper and bamboo sticks in a stator punching sheet slot are reduced, and thus, the weight of a motor stator is reduced. The dip-coating of insulating powder is carried out in the fluidized bed, so the automation degree is improved, uniform dip-coating is ensured, the quality of the insulating layer is assured and the demand for batch production is met.

Owner:CHANGZHOU YUCHENG FUTONG MOTOR CO LTD

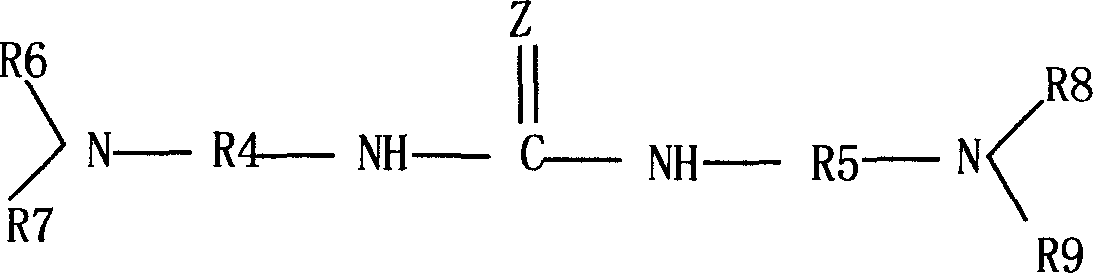

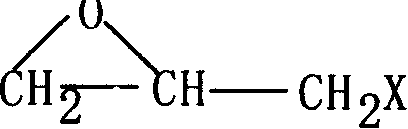

Polishing agent for alkaline non-cyanide zincate zinc plating and process for preparing polishing agent composition

The basic cyanide-free zincate galvanizing brightener and its composition brightener are copolymerized polymers produced by random copolymerization of compounds in the following molar ratios, the compounds and their molar ratios being: at least one nitrogen-containing Cyclic compound: at least one hydroxylamine: at least one di-tertiary amine containing acyl or sulfonyl group: epihalohydrin and / or glycerol halohydrin=0.5~5.0: 0.5~4.0: 0.5~5.0: 4.0~10.0; The preparation method is as follows: heating the nitrogen-containing heterocyclic compound, hydroxylamine, di-tertiary amine containing acyl group or sulfonyl group and an appropriate amount of water in the above formula, and adding epihalohydrin and / or glycerin halohydrin while stirring , the temperature is controlled below the reflux temperature, the time is 0.5-2 hours, then the temperature is raised to the reflux temperature, and the temperature is kept for 4-10 hours; the invention is easily soluble in water and alkaline solution, and is applied in the alkaline cyanide-free galvanizing process , The range of current density is wide, the total current of the Hull cell is 3A, the high current area does not burn, and the coating with excellent physical properties and bright mirror surface can be obtained, and the cost is low.

Owner:JIANGMEN DESHANG KEZUO TECHNOLOGY INDUSTRIAL CO LTD

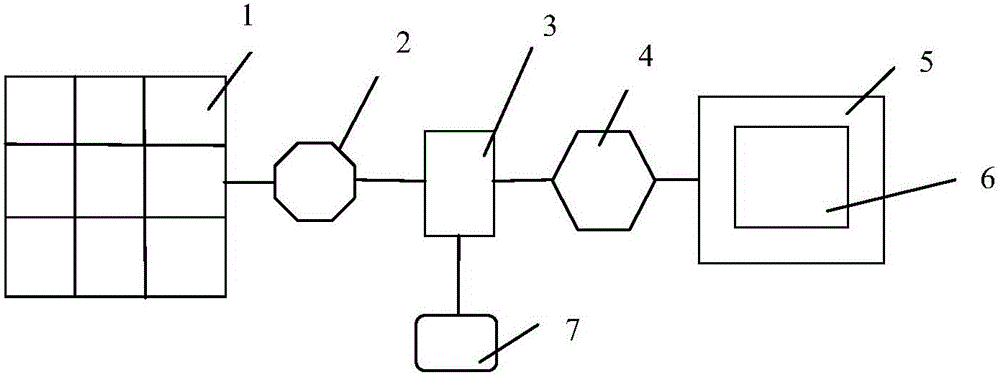

Solar film automobile energy-saving air purification system

InactiveCN106183724AReduction of EnaNo pollution in the processBatteries circuit arrangementsAir-treating devicesPower controllerElectrical battery

The invention discloses a solar film automobile energy-saving air purification system. The system comprises a power supply module and an air purification module. The power supply module comprises a solar hull cell, a photovoltaic controller, a storage battery and a power management controller. The air purification module comprises an air circulation device and an air treatment device. An automobile roof and an automobile body of an automobile are covered with the solar hull cell. The photovoltaic controller converts solar energy into electric energy to communicate with the storage battery. The storage battery can be connected with an external power source as well and can be used for standby charging under the condition that solar energy is not available. The power management controller controls the air purification system to work. By the adoption of the air purification system, the solar energy is mainly converted into the electric energy for supplying power, cleanliness and environment friendliness are achieved, water serves as a purifying medium in the air purification device and is low in price, easy to obtain and free of pollution, and therefore the air purification system is quite high in application and popularization value.

Owner:刘炳国

A solar battery-based power compensation device and method

ActiveCN104716694BSimple structureEasy to carrySecondary cells charging/dischargingElectric powerPower control systemControl signal

The invention relates to a power compensation device based on a solar battery. A charging device is connected with a control circuit or a power control system integrated in an electrical appliance; the charging device is a solar battery. The method includes the following steps: the charging device is connected to the power interface of the electrical appliance, and the electrical appliance performs voltage-current scanning on the output of the charging device through a microprocessor, and when the absolute value of the difference between the detected open circuit voltage value and the set voltage value is less than the threshold value , then the microprocessor gives the switching power supply controller a control signal, so that the switching power supply controller controls the switching power supply to output the output voltage of the charging device to the switching power supply at a set voltage, and the switching power supply uses a fixed voltage value to charge the electrical storage device. The device of the present invention uses a thin-film battery as a power source, and can output a stable voltage to charge electrical appliances, and is widely used in different electrical appliances.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for laser etching of monolithic integrated components for flexible pi substrate cigs thin film battery

ActiveCN103618030BLow costImprove processing efficiencyFinal product manufactureSemiconductor devicesHigh resistanceSilver paste

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com