Hull cell module installing device and roof or ground connecting structure thereof

A thin-film battery and component installation technology, which is applied to the support structure of photovoltaic modules, electrical components, heating devices, etc., can solve the problems of heavy weight, high price, and small market penetration, and achieve beautiful appearance, convenient installation, and product saving and construction cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

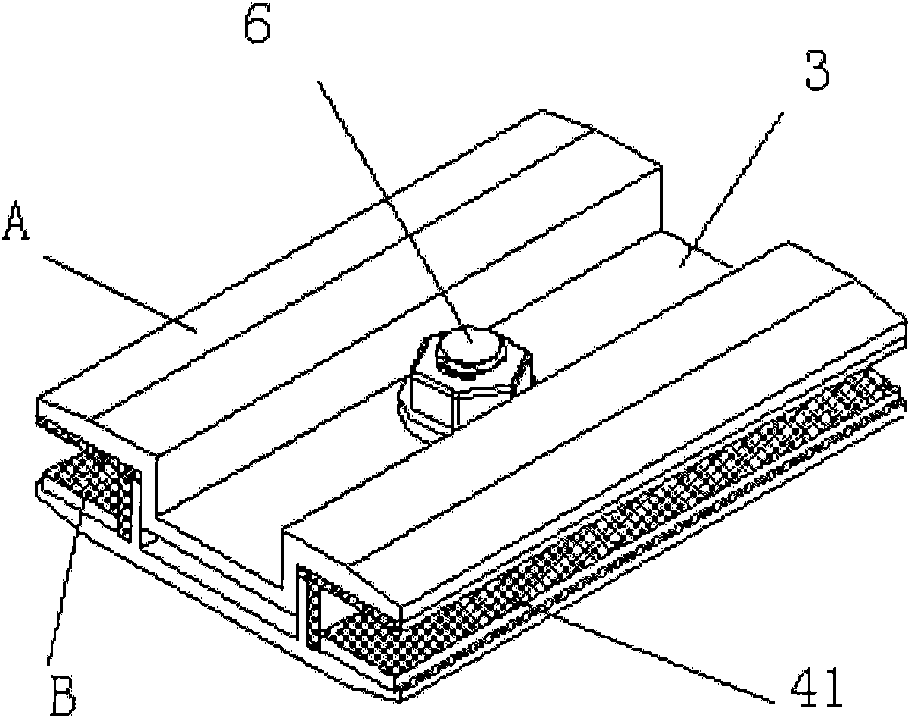

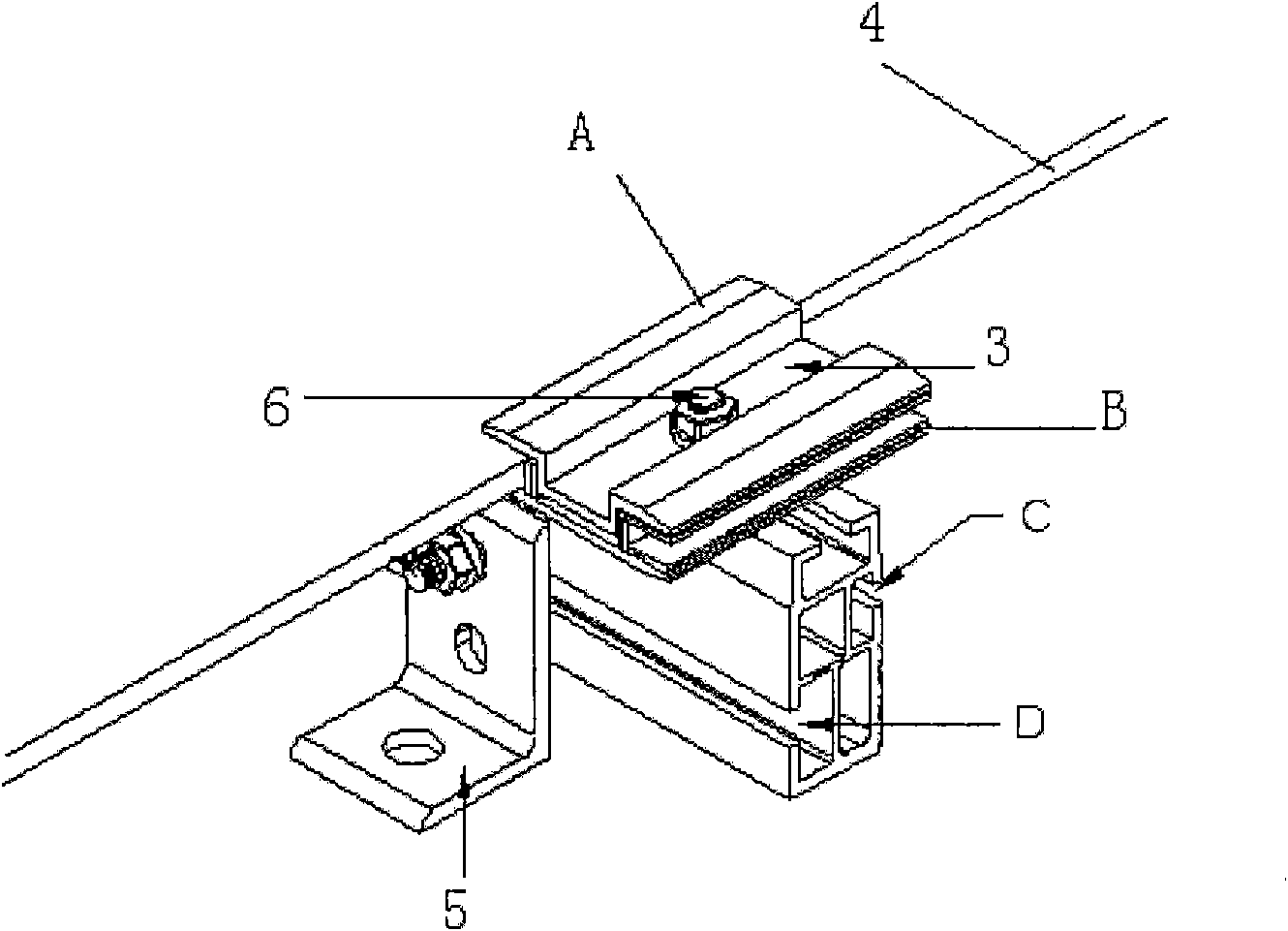

[0021] Depend on figure 1 , figure 2 , image 3 It can be seen that the thin-film battery module installation device of the present invention includes: a left-right symmetrical upper pressing block A and a lower cushion block B; there is a bolt fixing groove in the middle of the upper pressing block A; thin-film batteries 4 are placed on the left-right symmetrical upper pressing block Between A and the lower block B;

[0022] Rubber stickers 41 with anti-UV and anti-slip properties are attached to the middle and both sides of the upper pressing block A and the lower pad B where the thin-film battery 4 is placed.

[0023] Depend on figure 2 , image 3 , Figure 4 It can be seen that the structure that the installation device of the present invention is connected to the roof includes: at least one installation device; the installation devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com