Cadmium telluride hull cell containing high-resistance layer and achieving self-cleaning function

A technology of thin-film cells and high-resistance layers, applied in the field of solar cells, can solve the problems of affecting cell efficiency, reducing conversion efficiency, affecting solar light transmittance, etc., so as to reduce costs, improve conversion rate, and increase visible light transmittance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

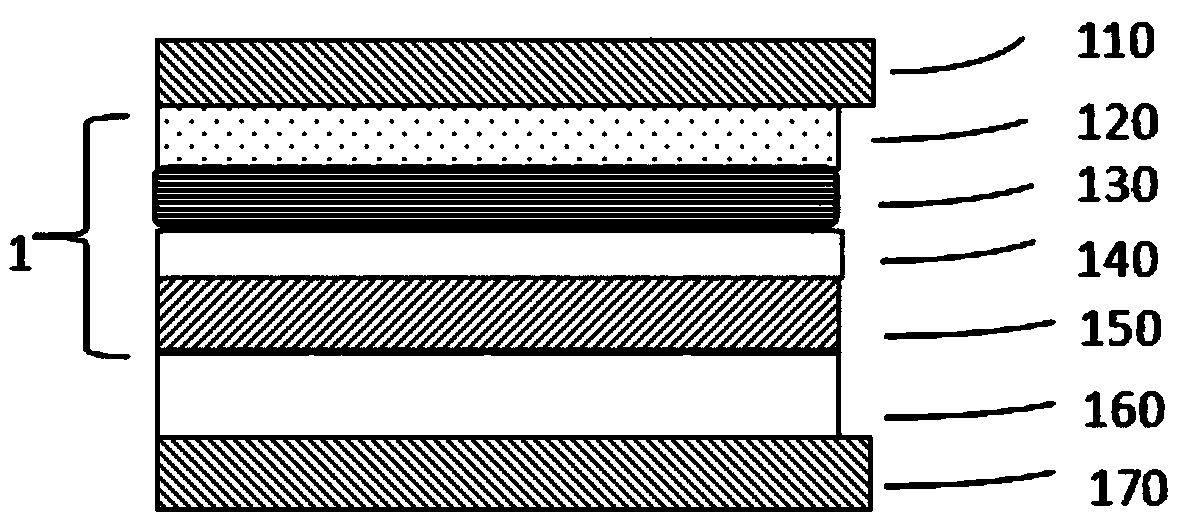

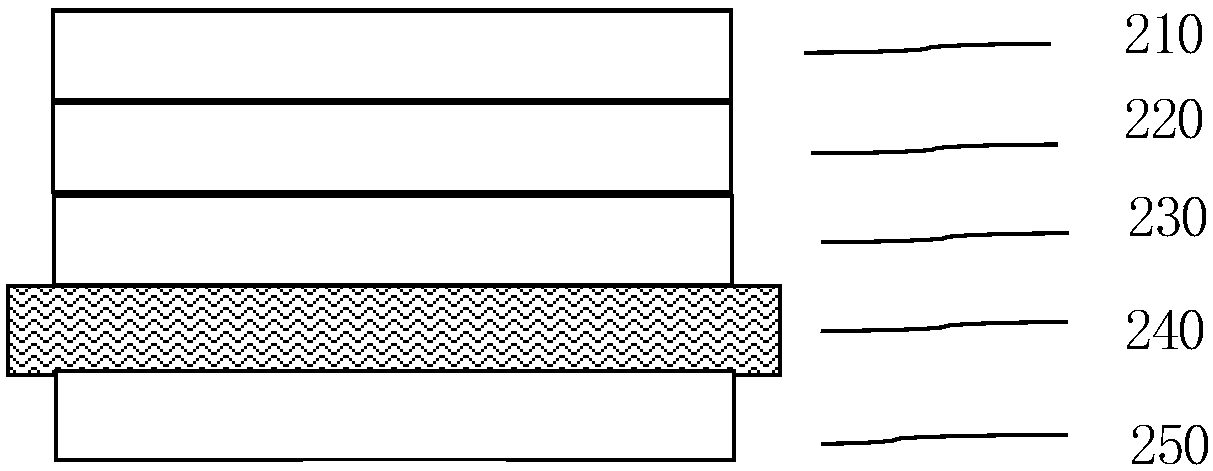

[0042] A method for preparing a cadmium telluride thin-film battery containing a high-resistance layer and having a self-cleaning effect described in the present invention comprises the following steps:

[0043] 1) TiO is sequentially deposited on the upper surface of the TCO film (240) 2 Film (210), MgF 2 Thin film (220) and TiO 2 A thin film (230) is obtained to obtain the TCO conductive glass to be processed; a layer of high resistance layer (250) is deposited on the lower surface of the TCO conductive glass to be processed to obtain the modified conductive glass (110).

[0044] 2) Deposit N-type layer (120), light absorbing layer (130), back contact transition layer (140) and back electrode layer (150) in sequence on the lower surface of the modified conductive glass (110) obtained in step 1). , and the back plate glass (170) is bonded to the lower surface of the back electrode layer (150), thereby obtaining a cadmium telluride thin film battery containing a high resista...

Embodiment 1

[0047] A cadmium telluride thin-film battery containing a high-resistance layer with self-cleaning effect, the preparation method of which comprises the following steps:

[0048] 1) TiO is sequentially deposited on the upper surface of the TCO film (240) 2 Film (210), MgF 2 Thin film (220) and TiO 2 Thin film (230), obtains the TCO conductive glass to be processed; Deposit a layer of intrinsic SnO on the lower surface of the TCO conductive glass to be processed 2 (250), promptly obtains modified conductive glass (110); Wherein, TiO 2 The film thickness of thin film (210) is 200-250nm, MgF 2 The film thickness of film (220) is 300-350nm, TiO 2 The film thickness of thin film (230) is 200-250nm, intrinsic SnO 2 The film thickness is 600-650nm.

[0049] 2) CdS film (120), CdTe film (130), ZnTe:Cu (140) and back electrode layer (150) are deposited successively on the lower surface of the modified conductive glass (110) obtained in step 1), and by adding EVA (160) combines t...

Embodiment 2

[0052] A cadmium telluride thin-film battery containing a high-resistance layer with self-cleaning effect, the preparation method of which comprises the following steps:

[0053] 1) TiO is sequentially deposited on the upper surface of the TCO film (240) 2 Film (210), MgF 2 Thin film (220) and TiO 2 Thin film (230), obtains the TCO conductive glass to be processed; Deposit a layer of intrinsic SnO on the lower surface of the TCO conductive glass to be processed 2 (250), promptly obtains modified conductive glass (110); Wherein, TiO 2 The film thickness of thin film (210) is 50-100nm, MgF 2 The film thickness of film (220) is 100-150nm, TiO 2 The film thickness of thin film (230) is 50-100nm, intrinsic SnO 2 The film thickness is 800-850nm.

[0054] 2) CdS film (120), CdTe film (130), ZnTe:Cu (140) and back electrode layer (150) are deposited successively on the lower surface of the modified conductive glass (110) obtained in step 1), and by adding EVA (160) combines the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com