MVF300 hole filling electroplating process

An electroplating process, an integrated technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., to achieve the effect of fine crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

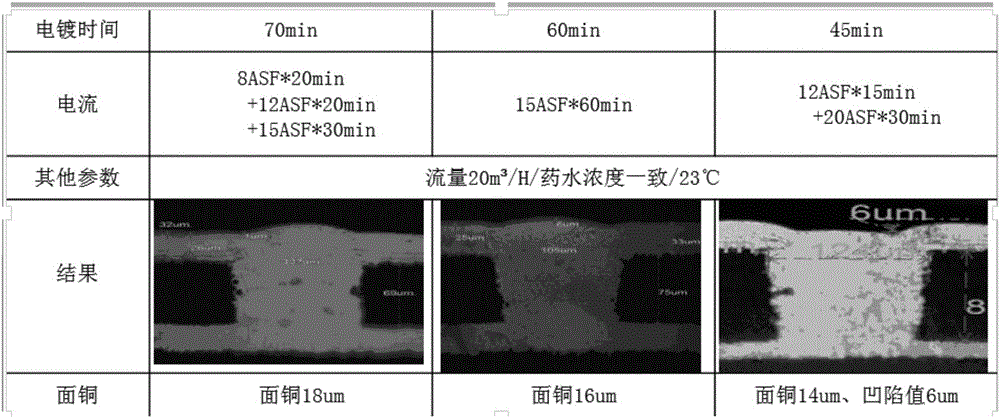

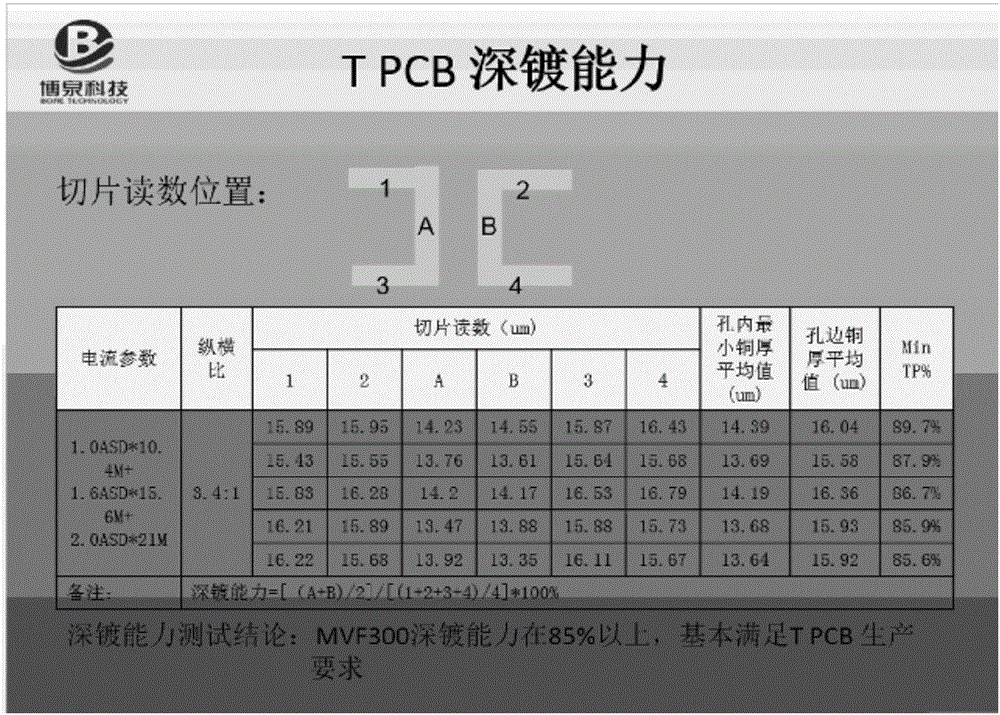

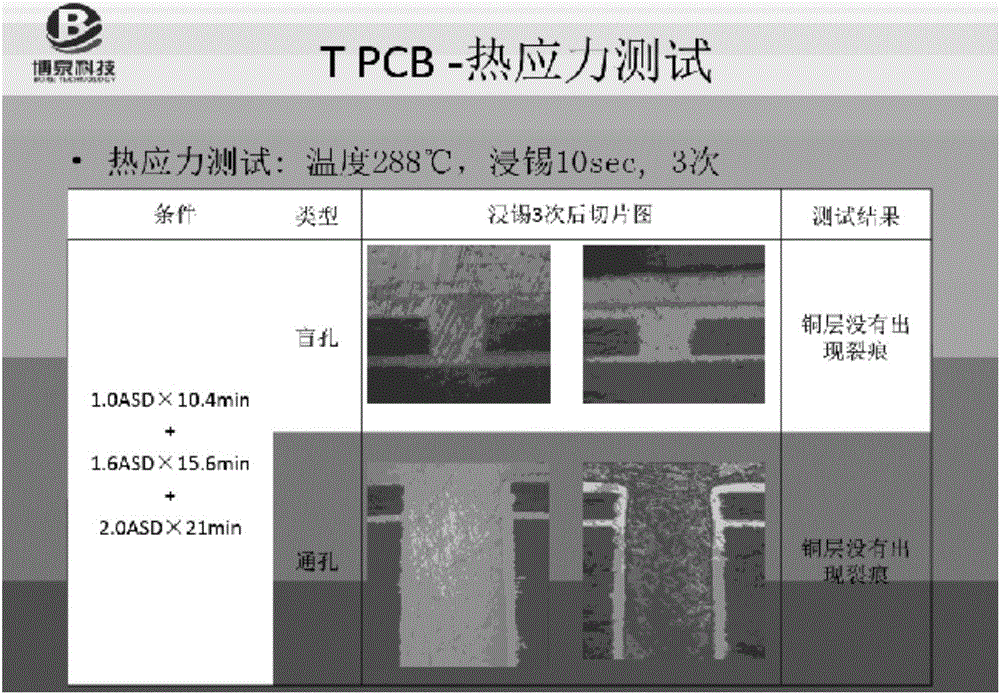

Embodiment 1

[0023] A MVF300 hole-filling electroplating process includes three processes: production and production of HDI boards, production and production of soft boards, and hole filling.

[0024] (1) The production process of HDI boards includes deglue removal, copper sinking, copper flash plating, hole filling, pretreatment, and inner layer circuit steps:

[0025] Each inner layer core board is made by inner layer pattern transfer and etching, and the inner layer core board and copper foil are pressed together through the prepreg to form a multi-layer inner layer board; then metallized slots are made on the multi-layer inner layer board, And the inner layer circuit is made on the upper and lower surfaces of the multilayer inner layer board. The multi-layer inner layer board, inner core board and copper foil are pressed together through the prepreg to form a multi-layer board, and the metallized slot holes become metallized buried holes; then metallized blind holes and metallized hole...

Embodiment 2

[0031] A MVF300 hole-filling electroplating process includes three processes: production and production of HDI boards, production and production of soft boards, and hole filling.

[0032] (1) The production process of HDI boards includes deglue removal, copper sinking, copper flash plating, hole filling, pretreatment, and inner layer circuit steps:

[0033] Each inner layer core board is made by inner layer pattern transfer and etching, and the inner layer core board and copper foil are pressed together through the prepreg to form a multi-layer inner layer board; then metallized slots are made on the multi-layer inner layer board, And the inner layer circuit is made on the upper and lower surfaces of the multilayer inner layer board. The multi-layer inner layer board, inner core board and copper foil are pressed together through the prepreg to form a multi-layer board, and the metallized slot holes become metallized buried holes; then metallized blind holes and metallized hole...

Embodiment 3

[0039] A MVF300 hole-filling electroplating process includes three processes: production and production of HDI boards, production and production of soft boards, and hole filling.

[0040] (1) The production process of HDI boards includes deglue removal, copper sinking, copper flash plating, hole filling, pretreatment, and inner layer circuit steps:

[0041] Each inner layer core board is made by inner layer pattern transfer and etching, and the inner layer core board and copper foil are pressed together through the prepreg to form a multi-layer inner layer board; then metallized slots are made on the multi-layer inner layer board, And the inner layer circuit is made on the upper and lower surfaces of the multilayer inner layer board. The multi-layer inner layer board, inner core board and copper foil are pressed together through the prepreg to form a multi-layer board, and the metallized slot holes become metallized buried holes; then metallized blind holes and metallized hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com