Method for preparing LLTO(lithium lanthanum titanate) film by electron beam heat evaporation

A lithium lanthanum titanium oxide and electron beam technology is applied in the field of preparation of lithium lanthanum titanium oxide thin films, which can solve the problems of poor deposition efficiency and small deposition area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

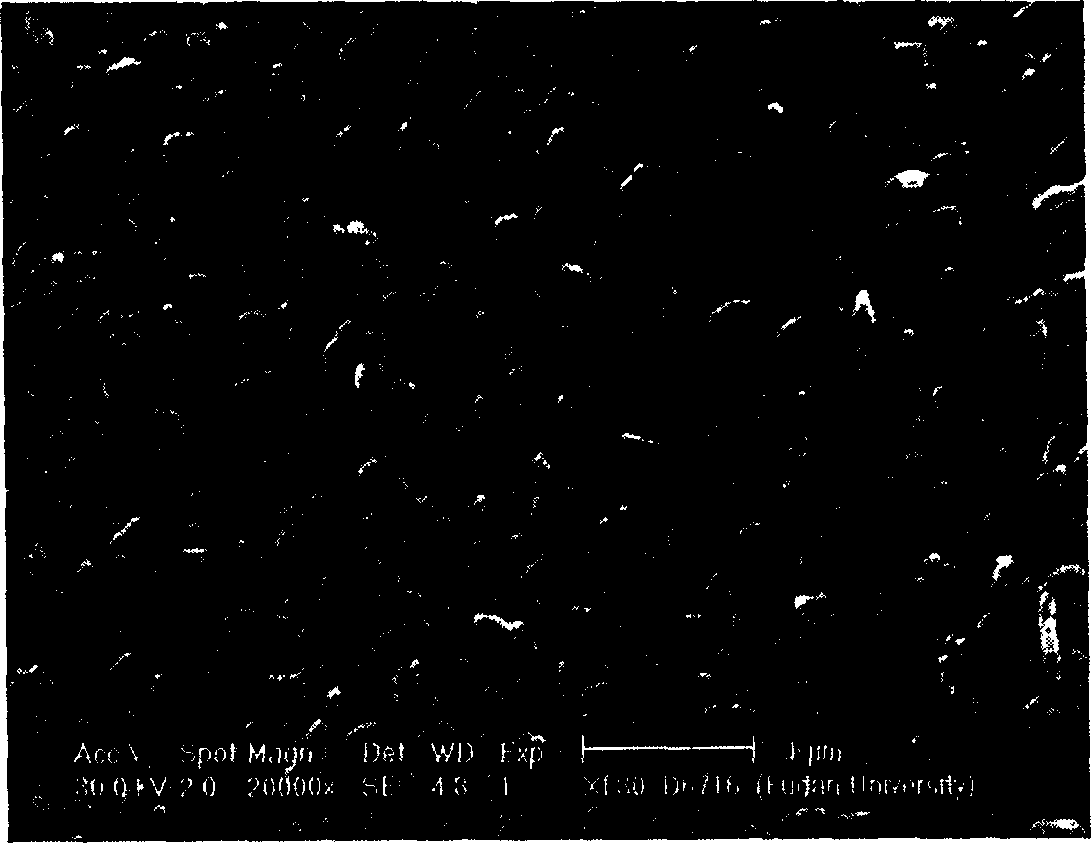

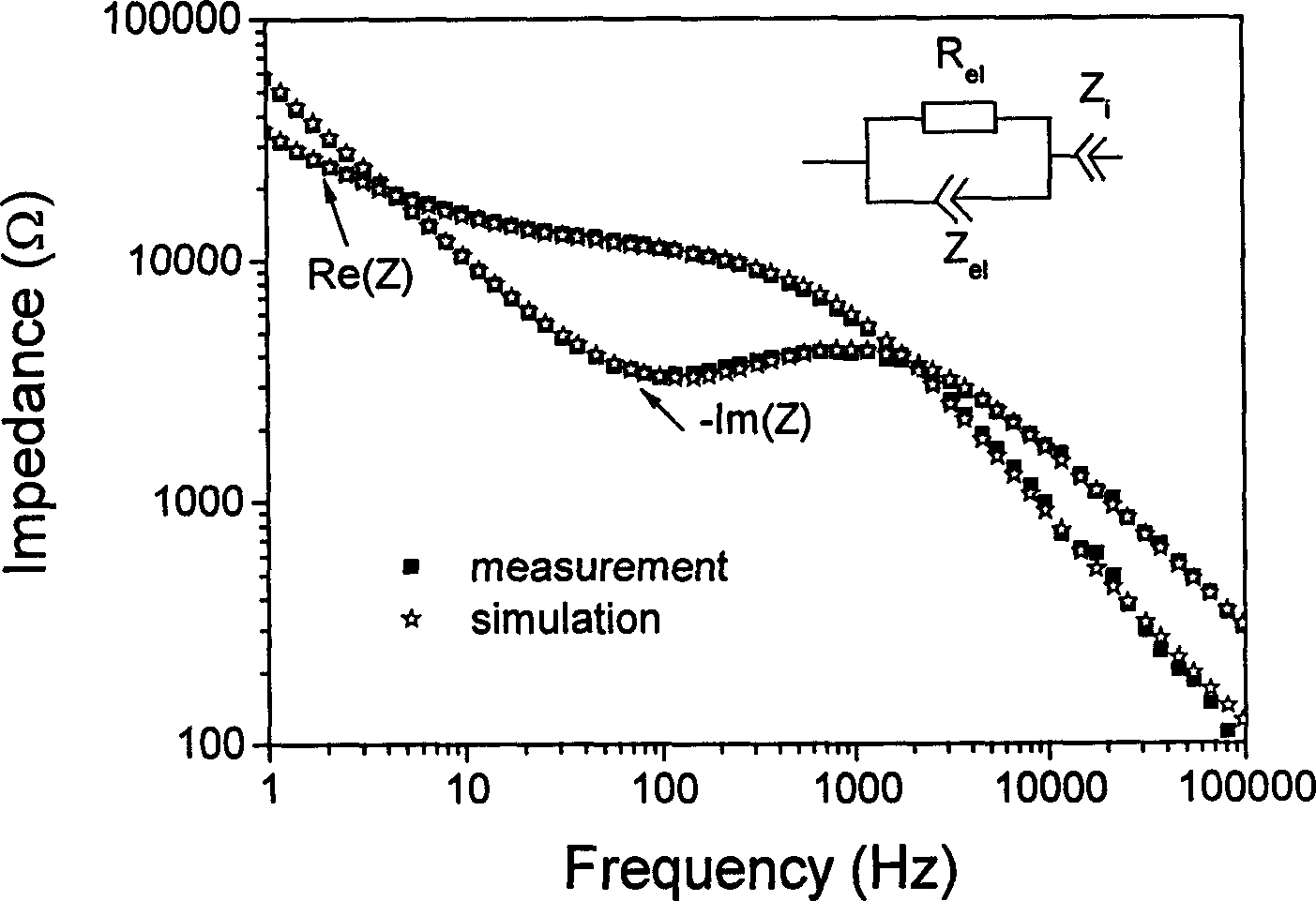

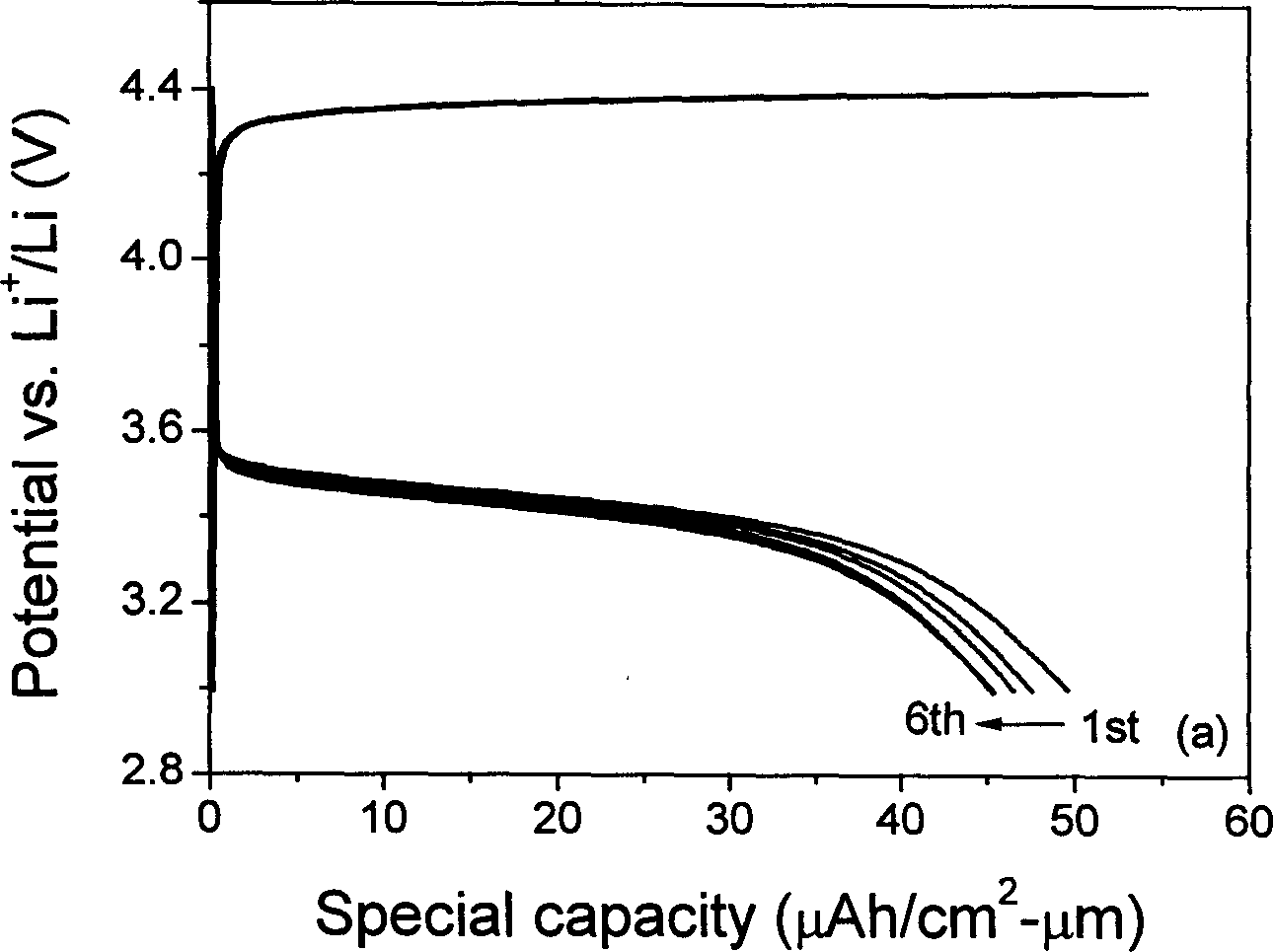

[0016] In the present invention, a lithium lanthanum titanium oxide (LLTO) solid electrolyte thin film is prepared by an electron beam thermal evaporation method. It is carried out in a vacuum system of electron beam thermal evaporation. First, use a molecular pump to pump the air pressure of the vacuum chamber to 1.0×10 -3 Pa, then the flow ratio of the argon gas and oxygen gas that is passed into the vacuum chamber is controlled by two needle valves to be 2:1, the direction of the inlet is facing the deposition substrate, and the flow rate of the mixed gas is adjusted to keep the pressure of the vacuum chamber at 7×10 -2 Pa. When vaporized, the electron gun output power was 600 watts. Substrate and LiPO 3 The target distance is 30 cm. The deposition rate was 1.6 μm per hour. The substrate temperature was room temperature. Use stainless steel sheet or stainless steel sheet coated with electrode film, glass sheet or glass sheet coated with Au film as the substrate. LLTO...

Embodiment 2

[0021] First, use a molecular pump to pump the air pressure of the vacuum chamber to 1.0×10 -3 Pa, then the flow ratio of the argon gas and oxygen gas that is passed into the vacuum chamber is controlled by two needle valves to be 2:1, the direction of the inlet is facing the deposition substrate, and the flow rate of the mixed gas is adjusted so that the air pressure of the vacuum chamber is maintained at 5×10 -2 Pa. During evaporation, the electron gun output power was 300 watts. Substrate and LiPO 3 The target distance is 30 cm. The deposition rate was 1.0 μm per hour. The substrate temperature was room temperature. Use stainless steel sheet or stainless steel sheet coated with electrode film, glass sheet or glass sheet coated with Au film as the substrate. LLTO target by Li 2 CO 3 (98%), La 2 o 3 (99.95%) and TiO 2 (98%) powder was annealed at 900°C for 8 hours in air at a molar ratio of 1:1:4, and then pressed into discs.

[0022] The as-deposited film has an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com