A kind of multi-functional Hall cell system

A Hall cell, multi-functional technology, applied in the direction of plating tanks, electrodes, cells, etc., can solve the problems of difficult to simulate the production site, no stirring device installed, uniform thickness distribution of electrodeposited layer and scientific evaluation of internal stress state, etc. problems, to achieve the effect of perfect function, low cost and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

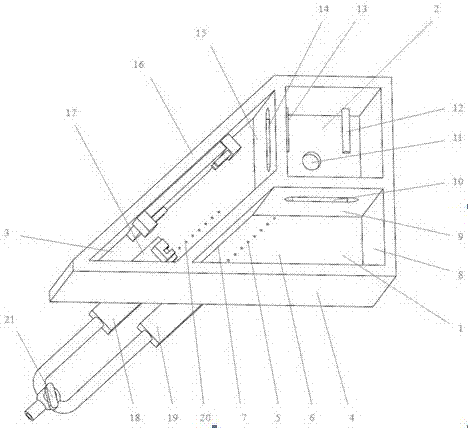

[0025] Combine below figure 1 and figure 2 The implementation of the invention is further described in detail: a multifunctional Hall cell system, which includes a Hall cell 1 , an adjustment cell 2 , and an electrodeposition cell 3 . The length of the anode wall 8 of the Hall cell is 85 mm, the length of the cathode wall is 127 mm, the length of the long side wall is 212 mm, the length of the short side wall is 120 mm, and the volume of the Hall cell is 1000 ml. The electrodeposition tank 3 is provided with a cathode clamping unit 17, and the cathode clamping unit 17 includes a clamping rod 17-2, a positioning plate 17-1 and a fixing member 17-3 provided with a straight groove 17-4; the straight groove 17-4 The axis is parallel to the cathode wall 7; the adjustment tank 2, the Hall tank 1 and the electrodeposition tank 3 share the bottom plate 6; the Hall tank 1 and the electrodeposition tank 3 share the cathode wall 7; the Hall tank 1 and the adjustment tank 2 share the sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com