Continuous plasma reinforced chemical vapor deposition reaction chamber for preparing amorphous silicon film

A technology of amorphous silicon thin film and plasma, applied in the direction of gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of expensive, bulky, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

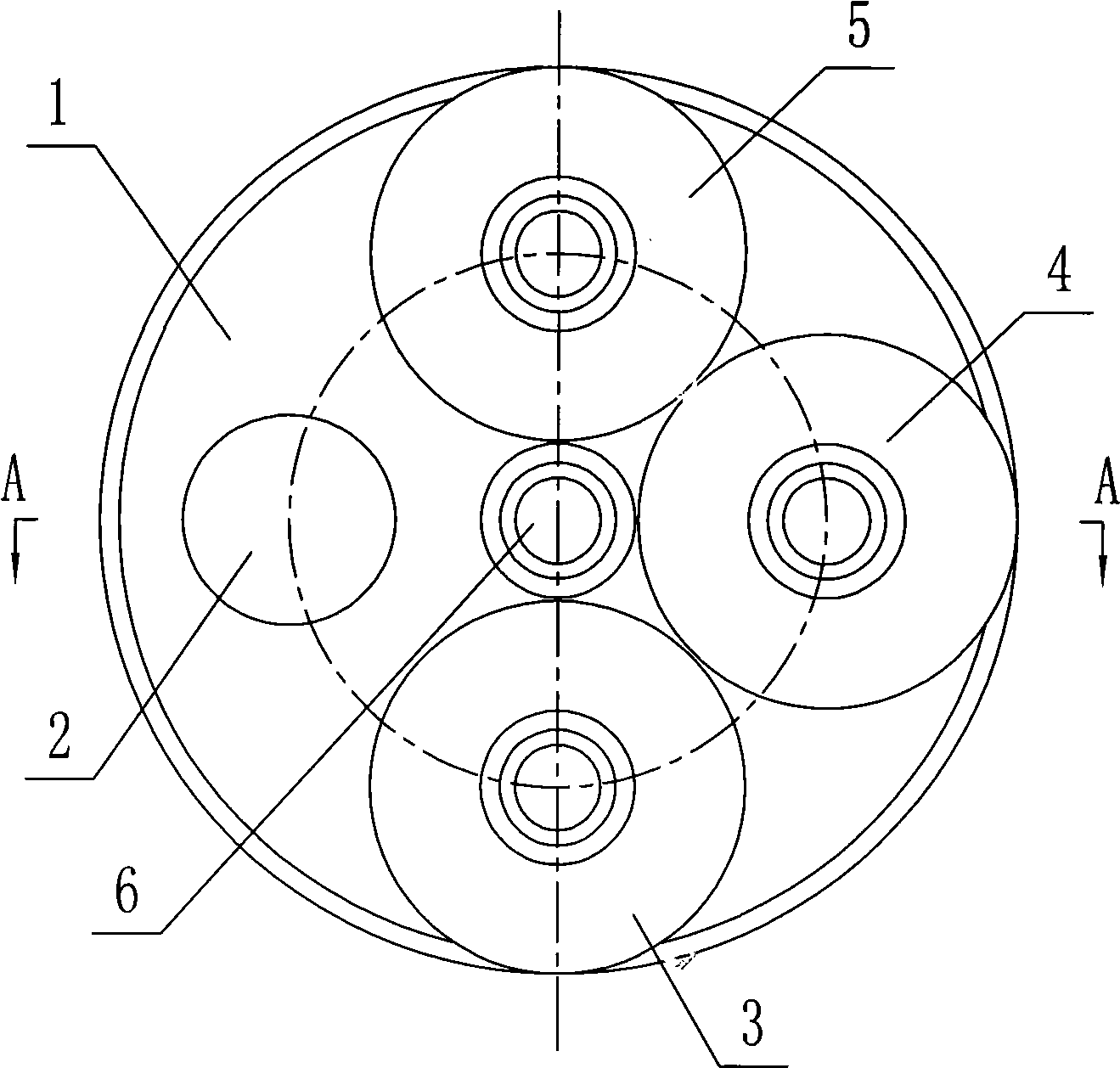

[0026] Such as figure 1 As shown, the continuous plasma-enhanced chemical vapor deposition reaction chamber for preparing an amorphous silicon thin film includes a large cylindrical reaction chamber 1 composed of a bottom plate 7 and a reaction cover 26 mounted on the bottom plate 7, and its structural characteristics Yes, the large reaction chamber 1 is provided with a piece-in chamber 2 and three circular small reaction chambers with the same structure, namely the first small reaction chamber 3, the second small reaction chamber 4, and the third small reaction chamber 5. The axis lines of the three small circular reaction chambers are all parallel to the axis line of the large reaction chamber 1, and on the same horizontal section, the center of the three small circular reaction chambers and the insertion chamber is from the center of the large reaction chamber. The distances are all equal, and the centers of the three small circular reaction chambers and the entry chamber are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com