High-speed electroplating rotary hull cell

A high-speed electroplating and Hull cell technology, applied in the field of Hull cell, can solve the problems of high debugging cost, single and complex plating solution information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

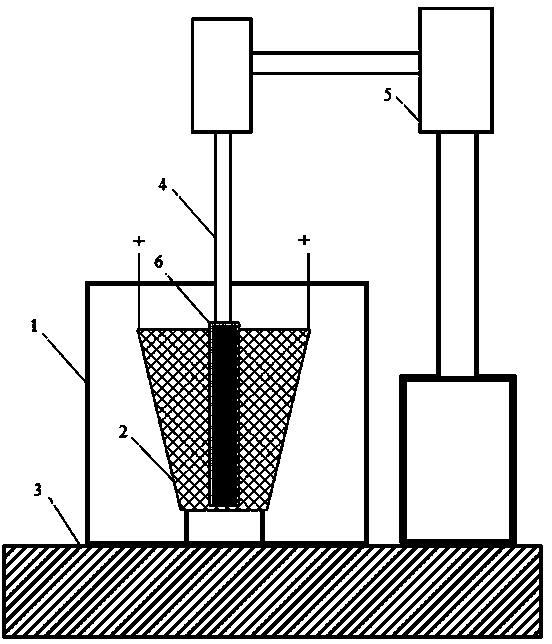

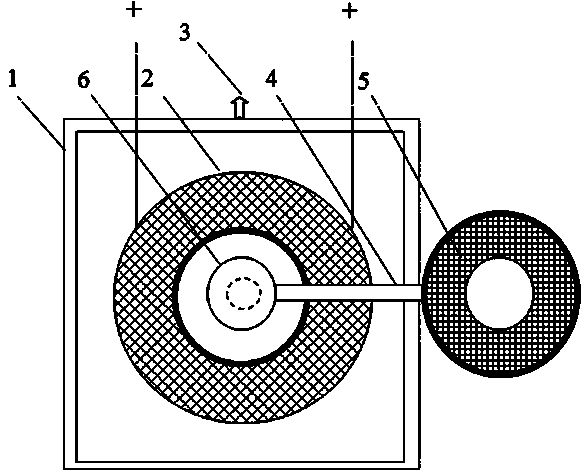

[0022] This embodiment provides a high-speed electroplating rotating Hull cell, which is composed of an electroplating cell body 1, a base 3, a mesh anode 2, a rotating cathode 6, a variable speed motor 5 and a cantilever 4 that drive the rotating electrode 6 to rotate. The bracket 1 is fixed on the bottom of the electroplating tank body 1, a mesh anode 2 is fixed on the electroplating tank body 1, and the rotating cathode 6 is inserted into the inside of the mesh anode 2. The rotating cathode 6 is connected with the swing arm 4, and the other end of the swing arm 4 is connected with a Variable speed motor 5, variable speed motor 5 is fixed outside electroplating tank body 1 with support 1.

[0023] Electroplating tank 1: the material is plexiglass, the shape is square, and the size is 140mm×140mm×60mm.

[0024] Mesh anode 2: the material is titanium-based iridium dioxide anode; diamond-shaped mesh, the overall shape is a circular truncated structure with a narrow lower end an...

Embodiment 2

[0064] The difference between this embodiment and the embodiment is: the material of the electroplating tank body 1 is PVC; the material of the mesh anode 2 is platinum with square mesh; the material of the rotating cathode 6 is copper pillar.

Embodiment 3

[0066] The difference between this embodiment and the embodiment is: the material of the electroplating tank body 1 is ceramics; the material of the mesh anode 2 is graphite with circular mesh; the material of the rotating cathode 6 is aluminum alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lower mouth diameter | aaaaa | aaaaa |

| Upper mouth diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com