Method of etching single integrated assembly on flexible PI substrate CIGS hull cell through lasers

A thin-film battery, laser etching technology, applied in electrical components, semiconductor devices, circuits, etc., can solve the problems of reducing the processing efficiency of thin-film batteries, and achieve the effect of improving processing efficiency and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

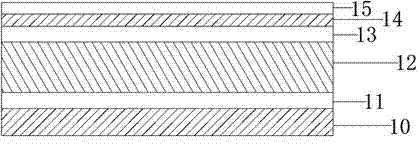

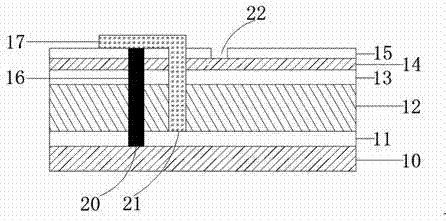

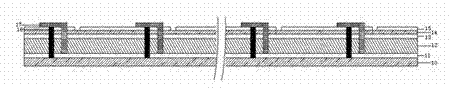

[0029] figure 1 It is a structural schematic diagram of the flexible PI substrate copper indium gallium selenium thin film battery described in the present invention; figure 2 The schematic diagram of the integrated assembly of the laser etching monomer of the flexible PI substrate copper indium gallium selenium thin film battery manufactured by the method of the present invention is provided, as figure 2 As shown, the battery includes a PI substrate 10, a back electrode 11, an absorber layer 12, a buffer layer 13, a ZnO high resistance layer 14, a top electrode 15, and an insulating adhesive layer 16 coated in the first trench 20 arranged in sequence. , the silver paste 17 filled in the second channel 21 and covering the surface of the top electrode on one side of the first channel; and the third channel 22 arranged parallel to the first channel 20 and the second channel 21 in sequence.

[0030] According to the present invention, the manufacturing method of the battery co...

Embodiment 2

[0041] For the first scribing in the above step 5, use a picosecond laser to fix the sample as in the above step 5. The laser wavelength is also 532nm green light scribing, the repetition frequency is preferably 1000kHz, and the processing speed is preferably 700mm / s. The power is preferably 3W, the width of the first channel 20 to be scribed for the first time is preferably 50-80 μm, and the laser is used to scribe the cell from the top electrode 15 (AZO layer) to the upper surface of the PI substrate 10, and the rest of the steps are the same as in the embodiment 1.

Embodiment 3

[0043] For the second scribing in the above step 7, use a picosecond laser to fix the sample as in the above step 5, and use the CCD camera of the laser to accurately align the first channel 20 of the first laser scribing for the second scribing , the laser wavelength is also scribed with 532nm green light, the repetition frequency is preferably 1000kHz, the processing speed is preferably 1000mm / s, the laser power is preferably 2.5W, and the width of the second channel 21 for the second scribe is preferably 50~70μm, The laser scribes the cell from the top electrode 15 (AZO layer) to the upper surface of the back electrode 11 (Mo film), and the rest of the steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com