Method for removing lithium from lithium-contained electrolyte in Hull cell

A technology of electrolyte and Hall cell, applied in electrolysis process, electrolysis components, electrodes, etc., can solve the problems of high lithium fluoride concentration and lower electrolyte primary crystal temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

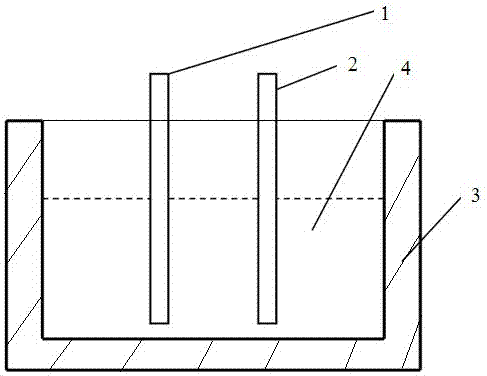

Image

Examples

Embodiment 1

[0021] The electrolyte in the Hall cell is 3% Al 2 o 3 , 3% CaF 2 , 1% MgF 2 , 3% KF, 7 %LiF, 45% NaF, 38% AlF 3 , transfer the electrolyte in the Hall cell to the delithiation molten salt electrolytic cell, and perform delithiation in the delithiation molten salt electrolytic cell. Ordinary carbon block is used as the anode, and graphite material is used as the cathode. The superheat of the electrolyte is 15°C during delithiation, the reduction potential is 1.75V, and Al is continuously added. 2 o 3 , keep the alumina concentration in the electrolyte at 2%-4%. After one delithiation, the LiF content in the electrolyte was reduced to 5.9%, and the lithium-containing graphite cathode obtained by delithiation was used as the anode for magnesium chloride electrolysis. When magnesium chloride is electrolyzed, the initial composition of the electrolyte (mass fraction) MgCl 2 10%~20%, CaCl 2 35%~40%, NaCl 40%~45%, KCl 5%~10%, electrolysis temperature 710℃, iron as cathode,...

Embodiment 2

[0023] The electrolyte in the Hall cell is 3% Al 2 o 3 , 3% KF, 5 %LiF, 49% NaF, 40% AlF 3 , transfer the electrolyte in the Hall cell to the delithiation molten salt electrolytic cell, and perform delithiation in the delithiation molten salt electrolytic cell. The inert cermet is used as the anode, and the graphite material is used as the cathode. During delithiation, the superheat of the electrolyte is 10°C, the reduction potential is 2.41V, and Al is continuously added 2 o 3 , keep the alumina concentration in the electrolyte at 2%-4%. After one delithiation, the LiF content in the electrolyte is reduced to 4%, and the lithium-containing graphite cathode obtained by delithiation is used as the anode for magnesium chloride electrolysis. When magnesium chloride is electrolyzed, the electrolyte composition (mass fraction) MgCl 2 3~7%, LiCl 8%~15%, KCl 80%~90%, electrolysis temperature 705℃, iron as cathode, cathode current density 0.6A / cm 2 , the lithium content in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com