Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

316 results about "High fat diet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diet rich in fats, especially saturated (animal or tropical oils) fats. High-fat diets are ill-advised for those with arthritis, cancer, cardiovascular disease, diabetes, hypertension, obesity or stroke.

Bifidobacterium adolescentis and application thereof

InactiveCN107699517AImprove the level ofImprove oral glucose toleranceMilk preparationNervous disorderDiseaseIrritable bowel

The invention relates to the technical field of microorganisms, and discloses bifidobacterium adolescentis and an application thereof. The collection number of the bifidobacterium adolescentis CCFM8630 is CGMCC No.14395. The bifidobacterium adolescentis CCFM8630 has the advantages that the level of neurotransmitter 5-hydroxytryptamine in peripheral blood of rats can be remarkably upgraded by the bifidobacterium adolescentis CCFM8630; the increased level of hormones such as testosterone in the peripheral blood of the rats due to high-glucose and high-fat diet and anomaly of abundance of Blautiaand Turicibacter in intestinal floras of the rats can be recovered; simulated gastrointestinal fluid can be tolerated, the bifidobacterium adolescentis can be quickly colonized in intestinal tracts,accordingly, rat livers with metabolic syndromes, pathological injury of duodenums and increase of the contents of triglyceride and total cholesterol in serum due to the high-glucose and high-fat dietand oral glucose tolerance can be remarkably improved, and the bifidobacterium adolescentis can be used for preventing, relieving or treating metabolic disorder such as the metabolic syndromes, irritable bowel syndromes and psychological illnesses such as anxiety and depression which are related to the metabolic syndromes.

Owner:INFINITUS (CHINA) CO LTD

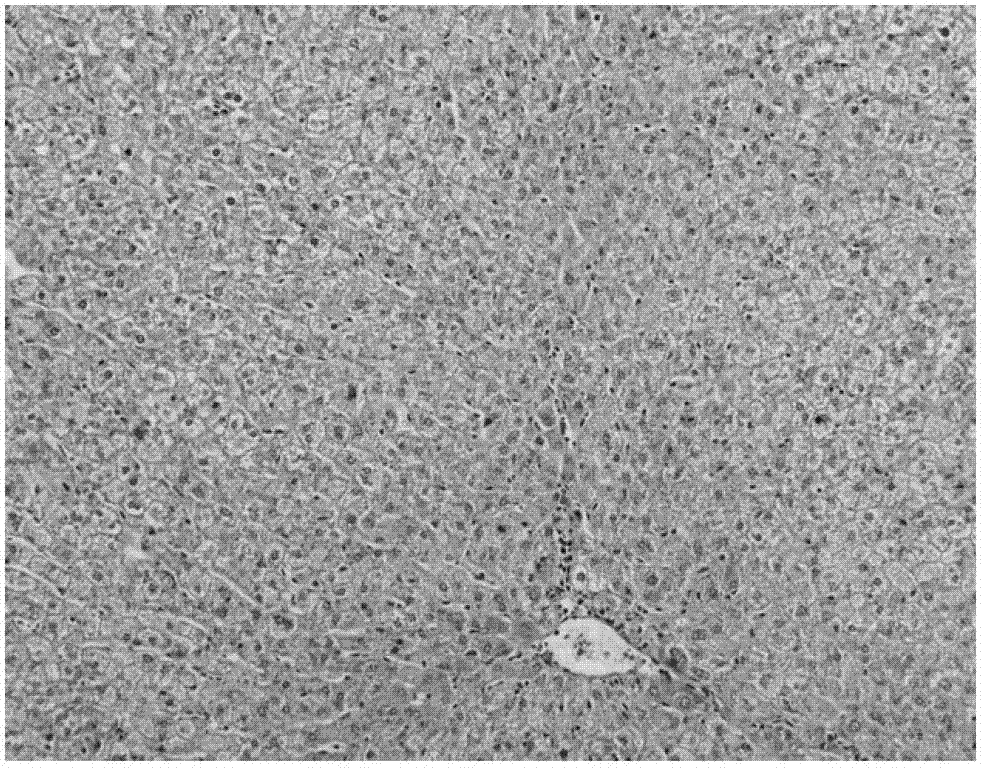

Application of composite high-fat forage to construct non-alcoholic fatty liver disease rat model

The invention belongs to the field of animal experiment models, and discloses application of a composite high-fat forage to construct a non-alcoholic fatty liver disease rat model. The high-fat forage is composed of the following raw materials in percent by mass: 77.5% of a rat basic forage, 10% of egg, 10% of coconut oil, 2% of cholesterol, 0.5% of bile salt, and 500mg / kg / d of sodium valproate calculated according to the rat weight. After 8 weeks, rats all have typical non-alcoholic fatty live symptoms, and liver has a lot of fat accumulation along with inflammatory cell infiltration. The model establishing time is short, the success rate is high, and the composite high-fat forage is applicable to pathogenesis research induced by high-fat-diet combined medicines with liver-toxicity side effect, screening of related control measures and efficacy evaluation of treatment medicines.

Owner:NANJING GENERAL HOSPITAL NANJING MILLITARY COMMAND P L A +1

Agent for Preventing Metabolic Syndrome

InactiveUS20070135521A1Blood pressure controlLower blood pressureBiocideMetabolism disorderHyperinsulinemiaActive component

Novel, safe, and highly effective agents for preventing insulin resistance and for preventing metabolic syndrome that contain astaxanthin and / or an ester thereof as an active component are provided. Even when a high-fat diet intake is continued, insulin resistance and subsequent hyperinsulinemia are suppressed by using the agent for preventing insulin resistance and the agent for preventing metabolic syndrome according to the present invention. Furthermore, suppression of fat degradation is thus inhibited and promotion of fat synthesis also is inhibited in adipose tissues, or glucose uptake into adipose tissues is inhibited, so that accumulation of fat within adipocytes is suppressed. Therefore, various diseases or symptoms having a relation to insulin resistance can be prevented or alleviated.

Owner:YAMAHA MOTOR CO LTD

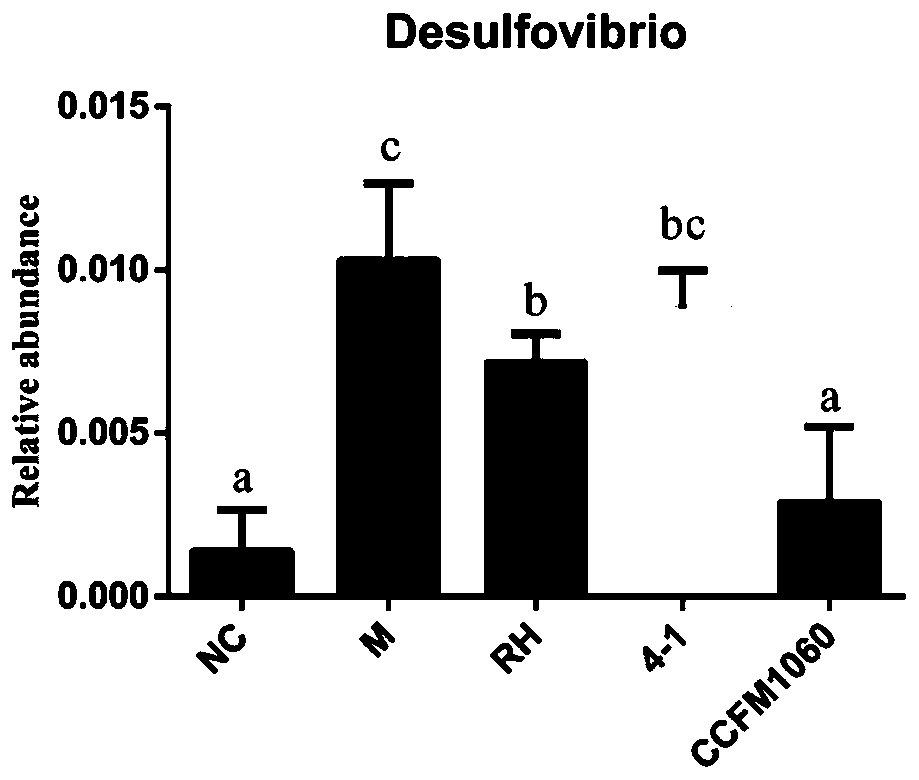

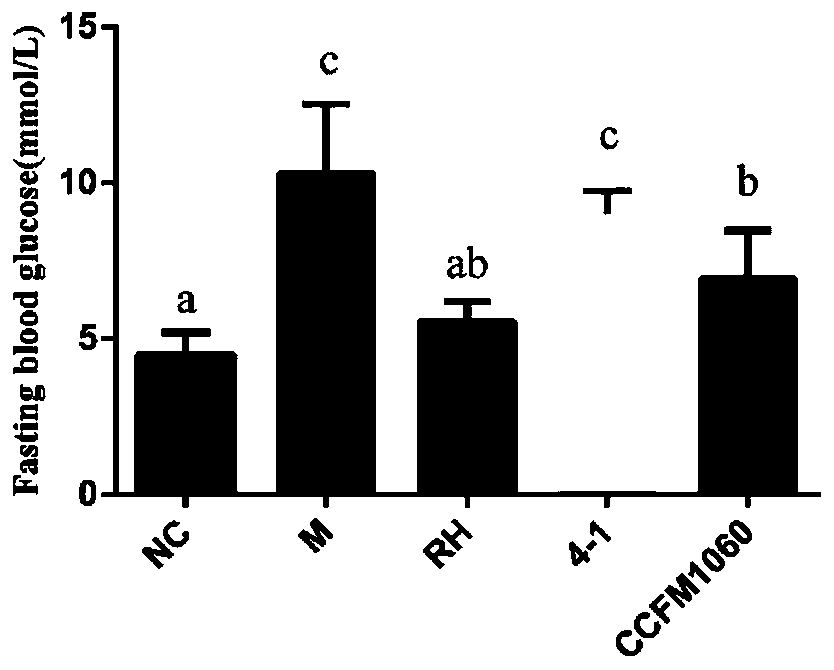

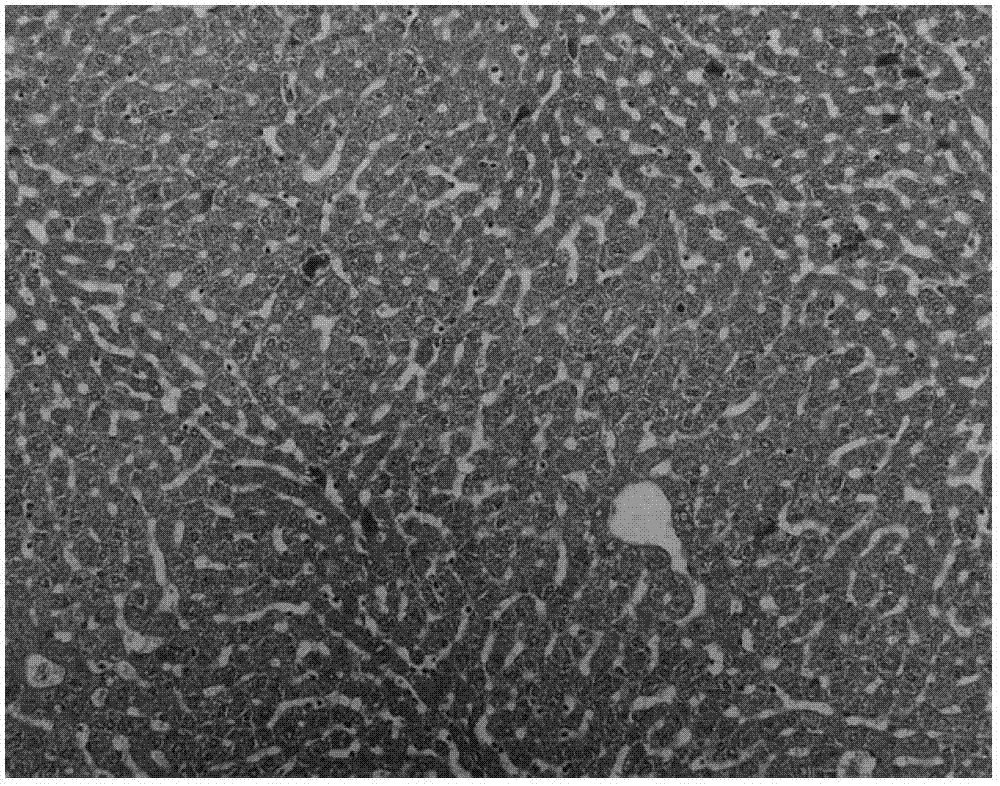

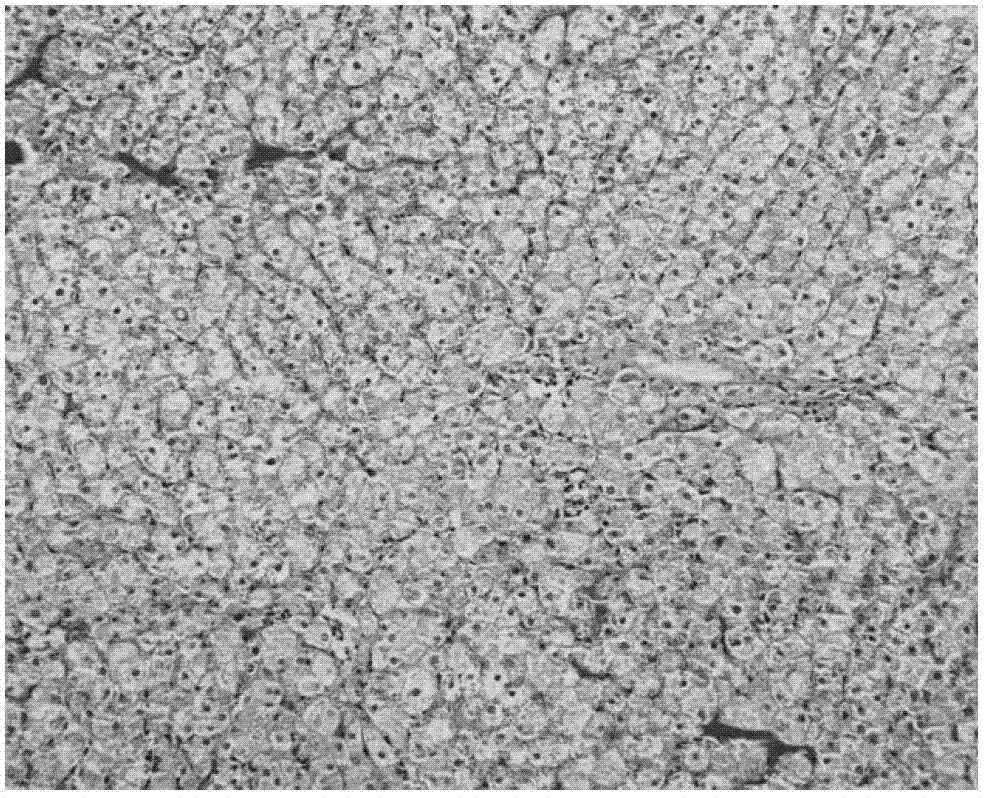

Application of lactobacillus rhamnosus CCFM1060 in preparation of functional microbial agents, foods and/or medicines

PendingCN110638843AImprove constipationIncrease abundanceMetabolism disorderDigestive systemBiotechnologyMicrobial agent

The invention discloses an application of lactobacillus rhamnosus CCFM1060 in preparation of functional microbial agents, foods and / or medicines. The lactobacillus rhamnosus CCFM1060 can tolerate thegastrointestinal environment of the human body, significantly improve fasting blood glucose rise and abnormal oral glucose tolerance of type 2 diabetics caused by high fat diet and STZ injection, reduce the area under the curve during glucose tolerance drug administration, and relieve insulin resistance; remarkably improve the increase of total cholesterol content and the increase of low-density lipoprotein cholesterol in serum of type 2 diabetics caused by high-fat diet and STZ injection; obviously relieve the inflammatory state of the liver; and significantly reduce pancreatic and liver pathological injuries caused by high-fat diet and STZ injection. The lactobacillus rhamnosus CCFM1060 has relatively strong adsorption capacity on perfluorooctanoic acid (PFOA), and has the capacity of relieving the toxicity of the PFOA.

Owner:JIANGNAN UNIV

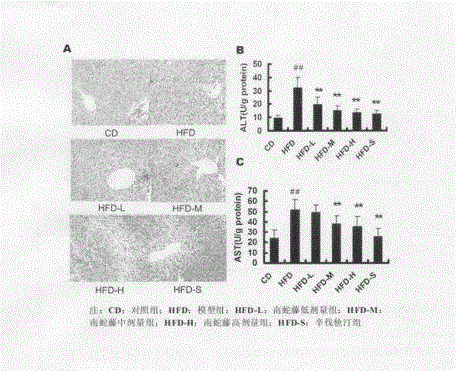

Application of geniposide in preparation of medicine for treating fatty liver disease

InactiveCN102961394AInhibition of increased AST activityReduce TG contentOrganic active ingredientsDigestive systemFatty liverSerum ige

The invention provides application of geniposide in preparation of a medicine for treating fatty liver disease, and relates to novel application of the geniposide. The geniposide can be used for preparing the medicine for treating fatty liver disease. The medicine can be prepared into commonly used clinical preparation according to conventional method, and the oral solid preparation is better, such as granule, tablet and capsule. The medicine contains 50 to 100mg / kg of geniposide by weight. The medicine is subjected to the test on high fat diet-induced golden hamster with fatty liver disease; and as the test shown, the medicine can obviously reduce the contents of serum TG (Triacylglycerol) and the content of liver tissue TG, and inhibit the raise of the activity of serum ALT (Glutamic-Pyruvic Transaminase) and AST (Glutamic Oxalacetic Transaminase), and has the effect of treating the fatty liver disease, so that the geniposide can be used for preparing the medicine for treating the fatty liver disease.

Owner:XIAMEN UNIV

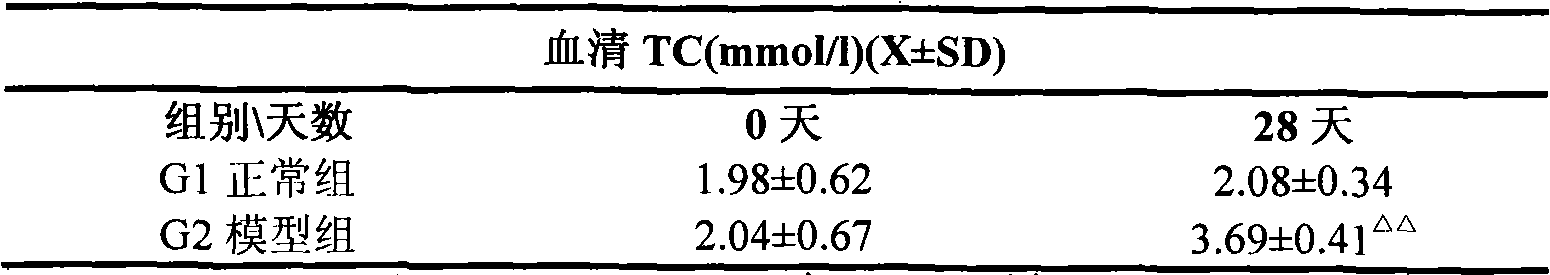

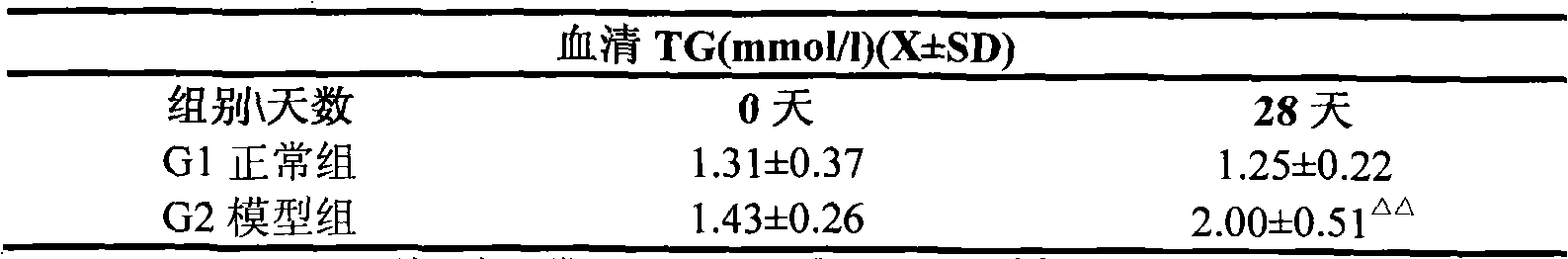

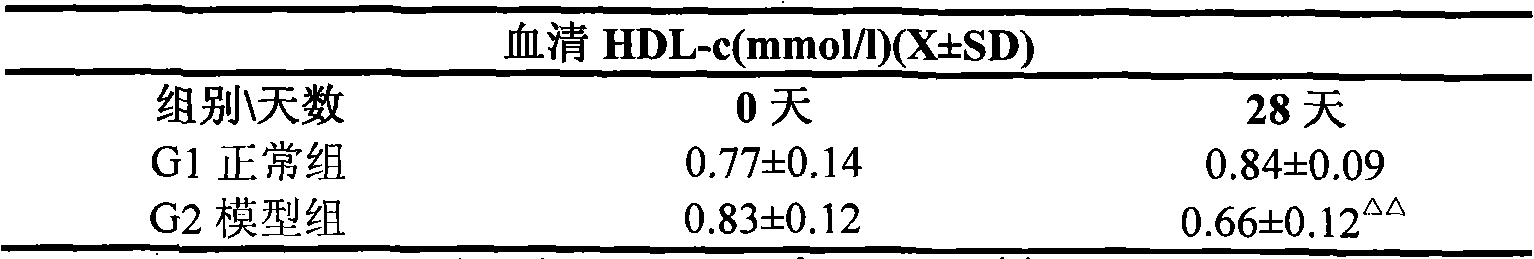

Preparation method of rat model with hypertension complicated by hyperlipidemia

The invention aims to establish a rat model concerning pharmacodynamic screening, pharmological study and efficacy evaluation of a traditional Chinese medicine for treating concomitant hyperlipidemia and hypertension. On the basis of a hypertension rat model, model set rats are fed with high fat diet each day continuously for 2-6 weeks so as to create a hypertension complicated by hyperlipidemia model. The characteristic indicators of the model are mainly that the total cholesterol and triglyceride as well as low density lipoprotein cholesterin can be increased, and high-density lipoprotein cholesterol can be decreased while the blood pressure is increased.

Owner:ZHEJIANG CHINESE MEDICAL UNIVERSITY

Lactobacillus reuteri capable of intervening in metabolic syndrome and application

InactiveCN112322527AImproves resistance to oxidative stressHelp maintain structureMilk preparationBacteriaBiotechnologyPancreatic hormone

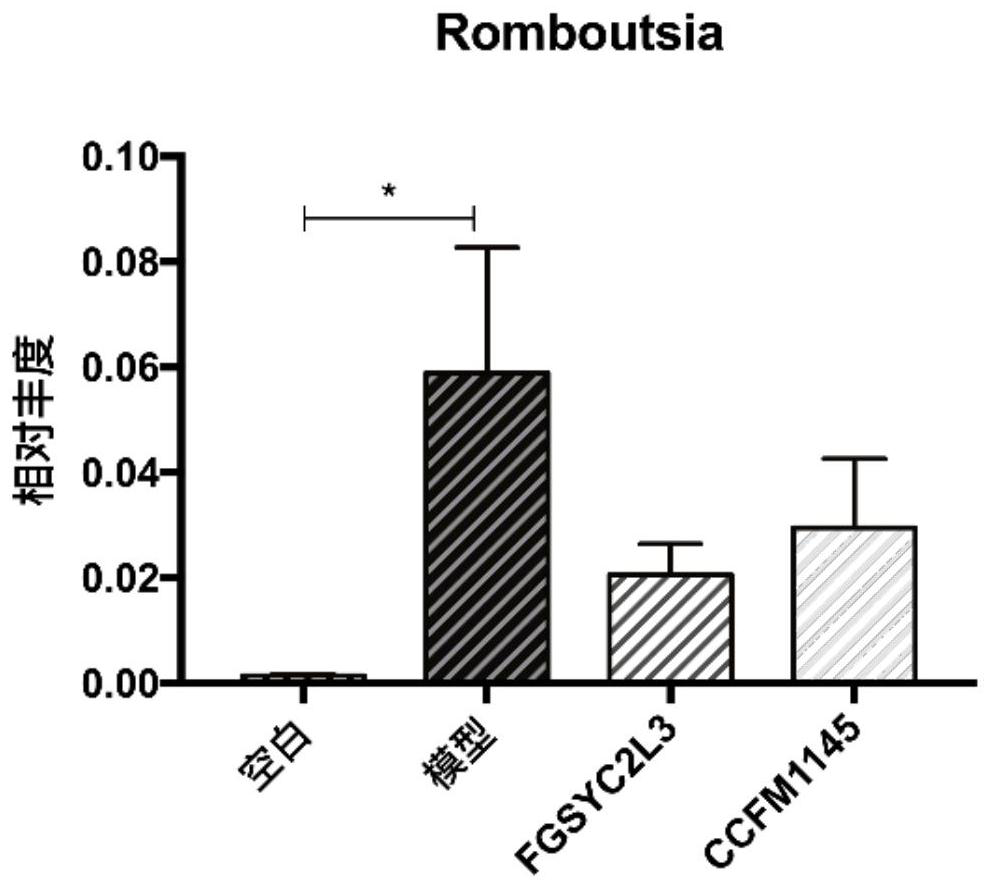

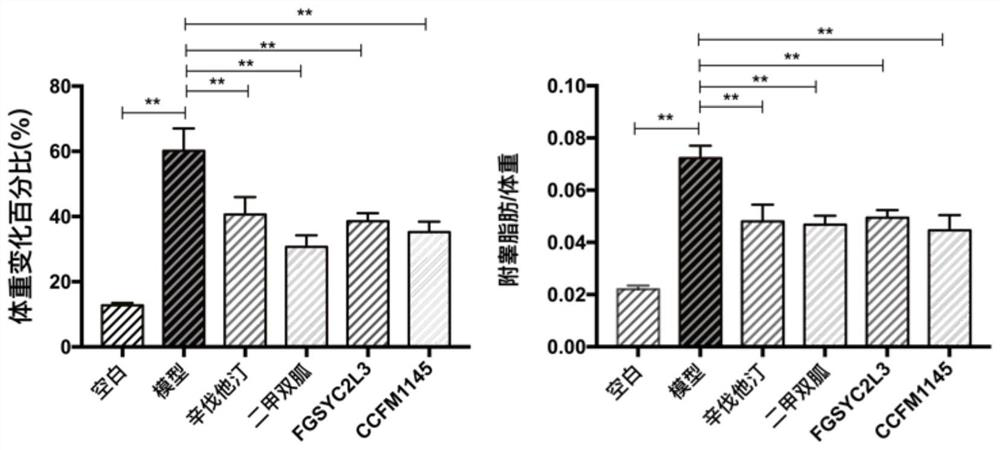

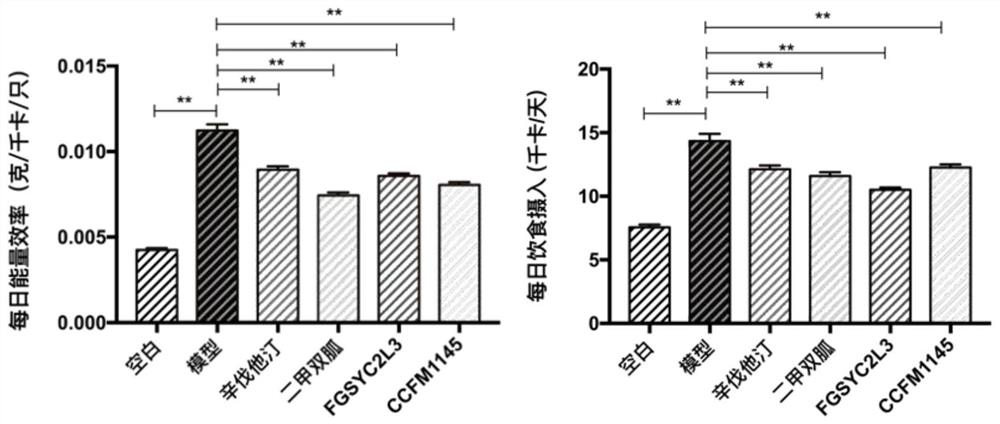

The invention discloses lactobacillus reuteri capable of intervening in metabolic syndrome and application, and belongs to the technical field of microorganisms. The lactobacillus reuteri CCFM1145 screened by the invention can significantly improve the increase of serum total cholesterol content of metabolic syndrome mice caused by high fat diet. The weight rise of metabolic syndrome individuals is relieved, and the daily diet intake and the energy efficiency are remarkably reduced. Fasting blood glucose and insulin resistance index levels of metabolic syndrome individuals are significantly improved. The rise of Romboutsia in the intestinal tract caused by high fat diet is obviously relieved. The levels of anti-oxidative stress CAT and SOD in the liver are remarkably improved, serum lipopolysaccharide endotoxin is inhibited, and a colon barrier structure is maintained. The lactobacillus reuteri CCFM1145 disclosed by the invention can be used for preparing pharmaceutical compositions and fermented foods for relieving diseases such as metabolic syndrome, non-alcoholic fatty liver disease and diabetes mellitus and the like, and has a very wide application prospect.

Owner:JIANGNAN UNIV

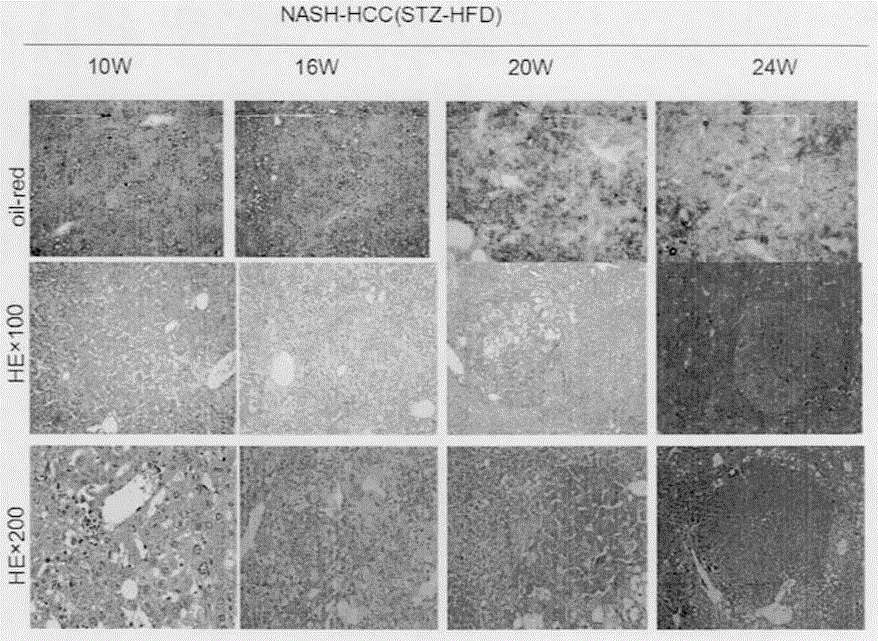

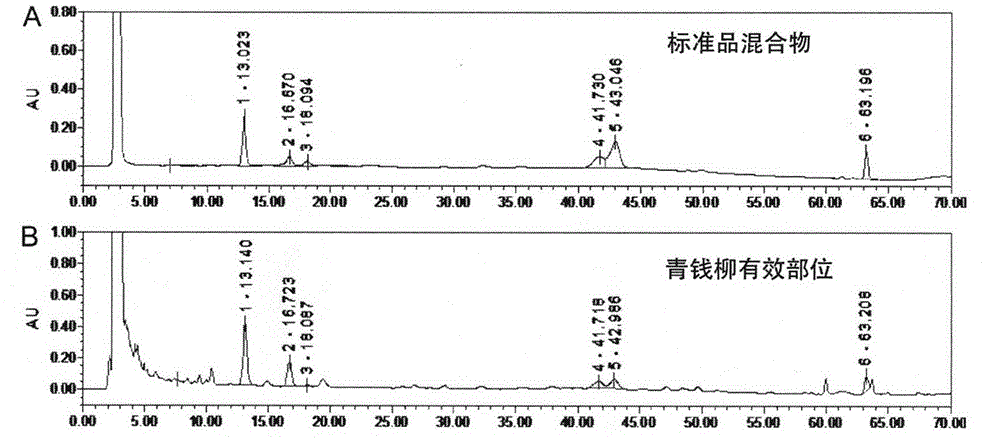

Fatty-liver-related liver cancer model building method based on knockout mice

ActiveCN105052830AIncrease incidenceMicrobiological testing/measurementAnimal husbandryKnockout animalGenotype

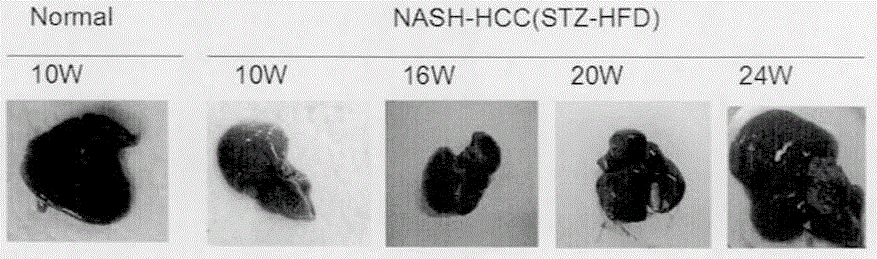

The invention relates to a fatty-liver-related liver cancer model building method based on knockout mice. The method is characterized in that APOE- / - and LDLR- / - knockout mice including female mice and male mice are selected, the female mice and the male mice are matched in number, and double knockout mice are obtained; a primer is designed, and the genotypes in mice are identified through a PCR (polymerase chain reaction) system; the PCR (polymerase chain reaction) system comprises an ApoE gene identification PCR conditions and LDLR gene identification PCR conditions; the double knockout mice are pregnant, and suckling mice are obtained; streptozotocin is injected to the suckling mice, the suckling mice begin a high-fat diet after ablactation, and finally the suckling mice surfer from liver cancer; it is identified that the suckling mice begin the high-fat diet after ablactation, fatty liver occurs six weeks later, NASH occurs 8-10 weeks later, dysplastic nodule occurs 13-16 weeks later, and the liver cancer occurs 18-24 weeks later. The occurrence rate of the liver cancer is about 100% 24 weeks later. The time when pure-gene APOE- / - and LDLR- / - knockout mice suffer from NASH and HCC due to the high-fat diet is advanced by 24-30 weeks, and the occurrence rate is high.

Owner:施军平

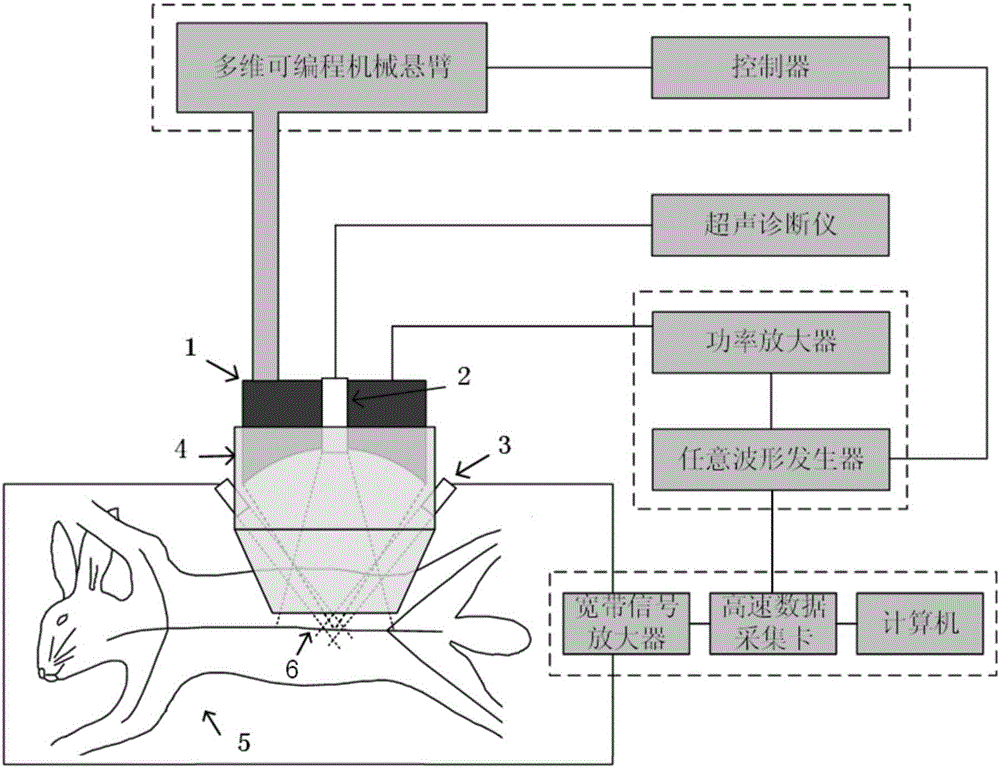

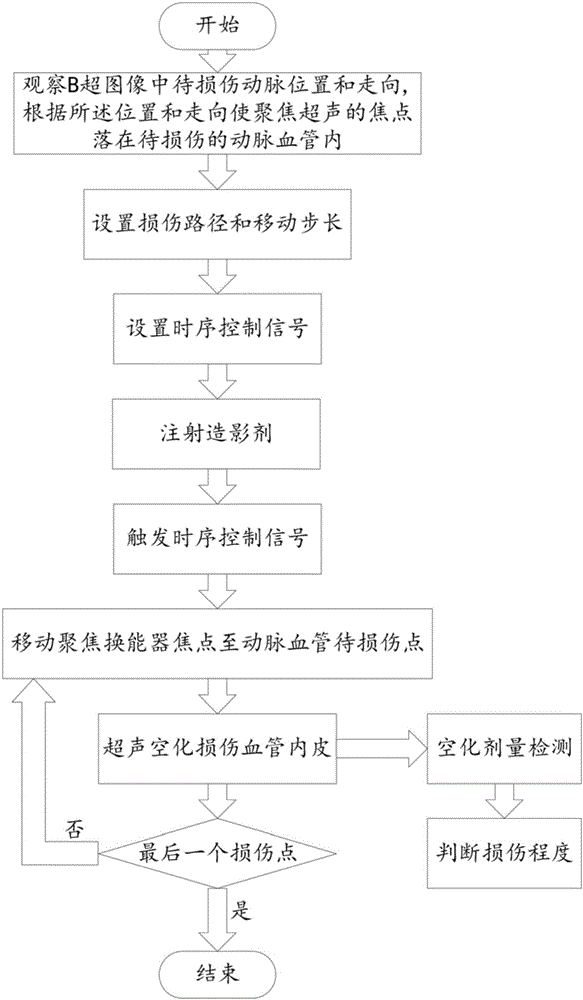

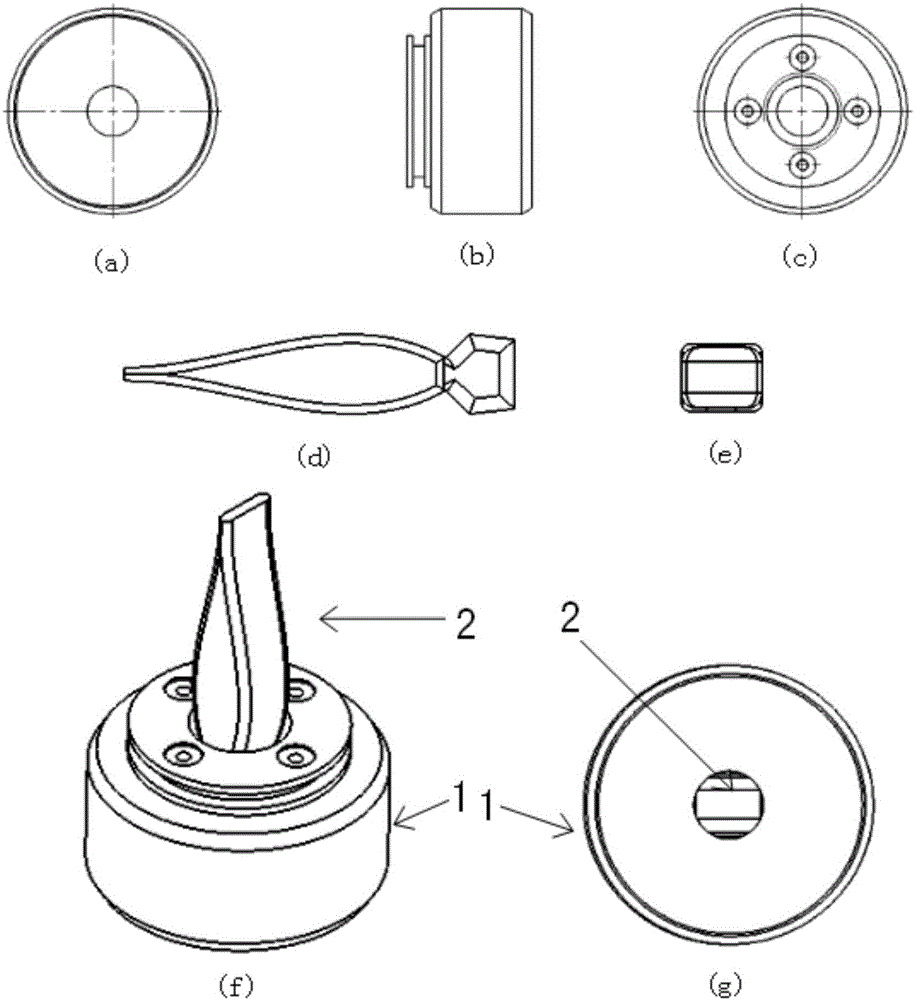

Ultrasonic-cavitation-injury-based method for establishing atherosclerotic-plaque animal model and blood vessel endothelial injury device

ActiveCN106039604ADamage site controlControl areaUltrasound therapyAccessory food factorsSurgical operationUltrasonic cavitation

The invention discloses an ultrasonic-cavitation-injury-based method for establishing an atherosclerotic-plaque animal model and a blood vessel endothelial injury device. The device comprises a composite probe, a B-mode image guiding module, a motion control module, a time sequence signal control and power drive module and a cavitation detection module. According to the invention, an endothelial ultrasonic-cavitation injury of a local artery blood vessel with controlled injury site, injured area, and injury degree can be realized; and then high-fat diet feeding is combined to form a method for establishing an atherosclerotic-plaque animal model with controllable and predictable plaque formation position and size. An atherosclerotic-plaque animal model for detecting imaging method sensitivity and effectiveness at different development stages can be established; no surgical operation is needed during the artery blood vessel endothelium injuring process; and the blood vessel endothelial injury difficulty and complexity are reduced.

Owner:XI AN JIAOTONG UNIV

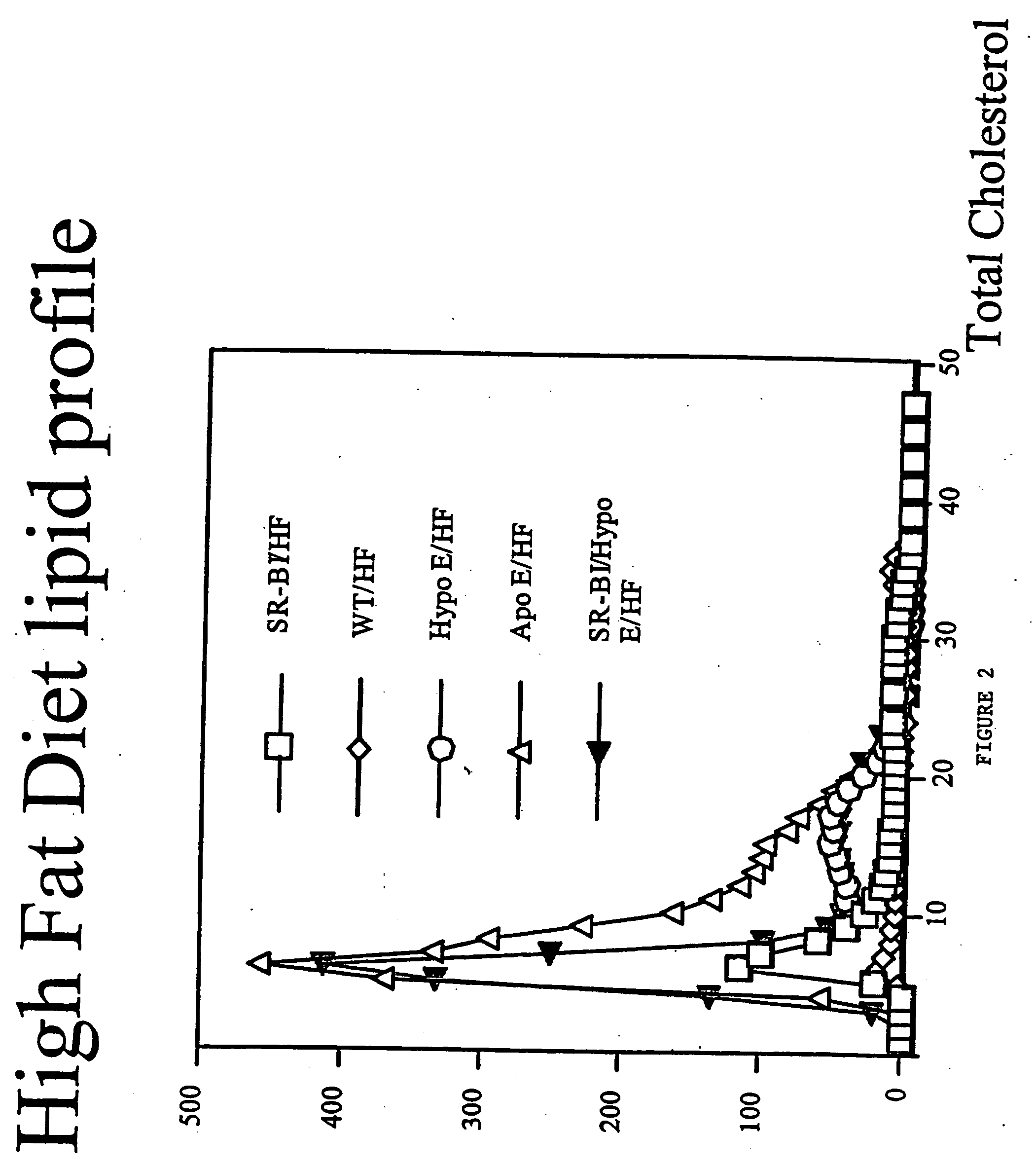

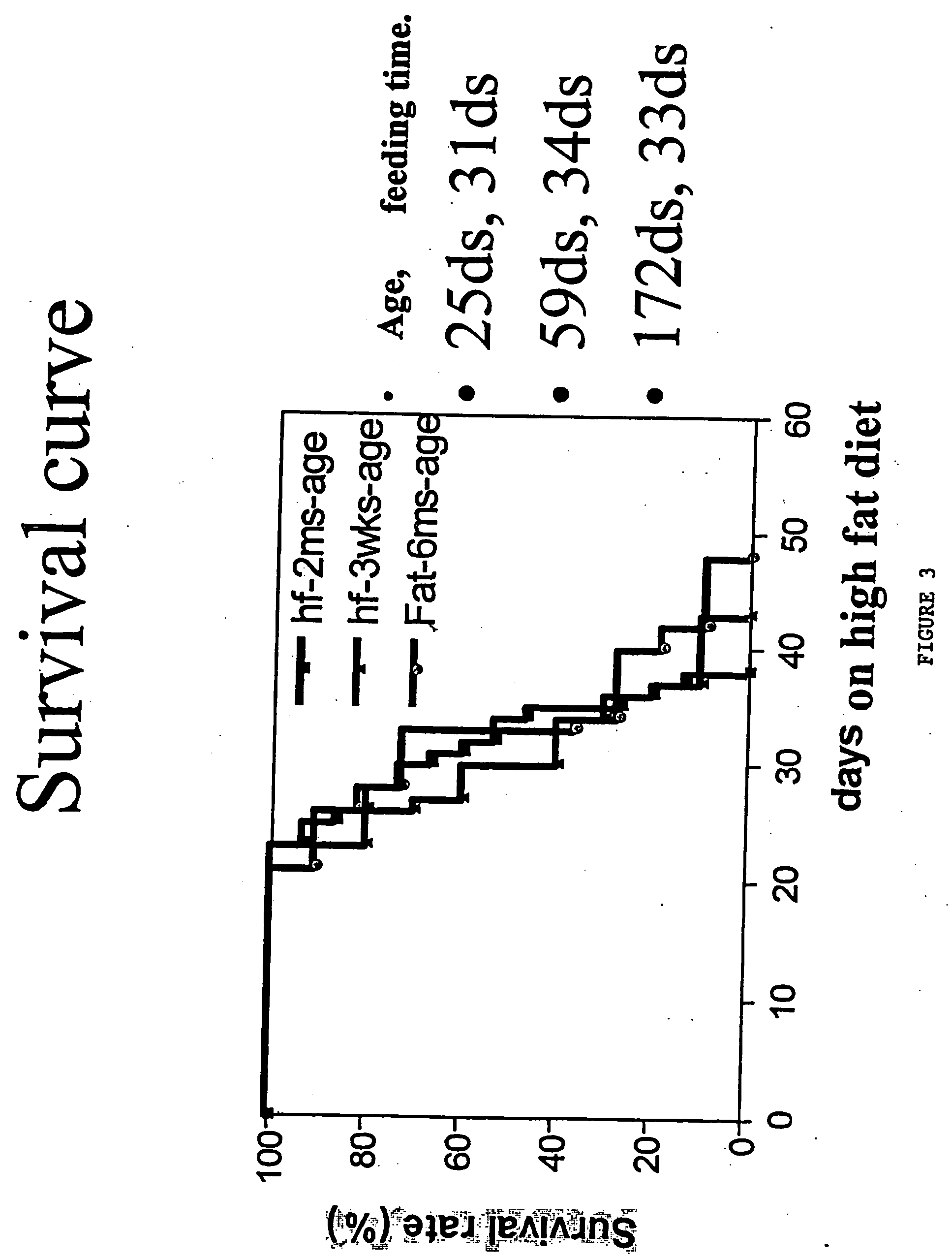

Inducible heart attack animal model

An animal model of coronary heart disease has been developed where myocardial infarct can be induced by altering the animal's diet. In all embodiments, this animal model is a result of reduced activity of scavenger receptor class BI (SR-BI) and apolipoprotein E (ApoE). In a preferred embodiment, the model is a result of crossbreeding two transgenic mouse lines: a knockout of SR-BI (SR-BI− / −) and an impaired ApoE expressor (hypoE). The impaired ApoE gene results in only 2-5% expression of ApoE and a reduction in cholesterol homeostasis. Resulting animals are predisposed to hypercholesterolemia but can live longer than a year on a normal low fat diet. Serum plasma levels can be significantly elevated by changing the animal's diet to one containing high levels of fat and cholesterol. Within a month on a high fat, high cholesterol diet, animals develop atherosclerosis and myocardial infarction occurs. Survival depends on the nature of the diet and the conditions of animal husbandry and can typically be around 20-30 days after administration of the modified diet depending on the specific conditions. Housing the animals alone or in groups significantly affects survival of these animals on a high fat diet. Analysis of B- and T-cell deficient SR-BI / ApoE / RAG2 triple knockout mice established that B- and T-lymphocytes do not play a key role in the pathophysiology of the SR-BI ApoE dKO model of human disease. These animal models can be used to study mechanisms and progression of CHD as a function of diet, treatment with drugs to be screened for efficacy or undesirable side effects, and social environmental effects.

Owner:MASSACHUSETTS INST OF TECH

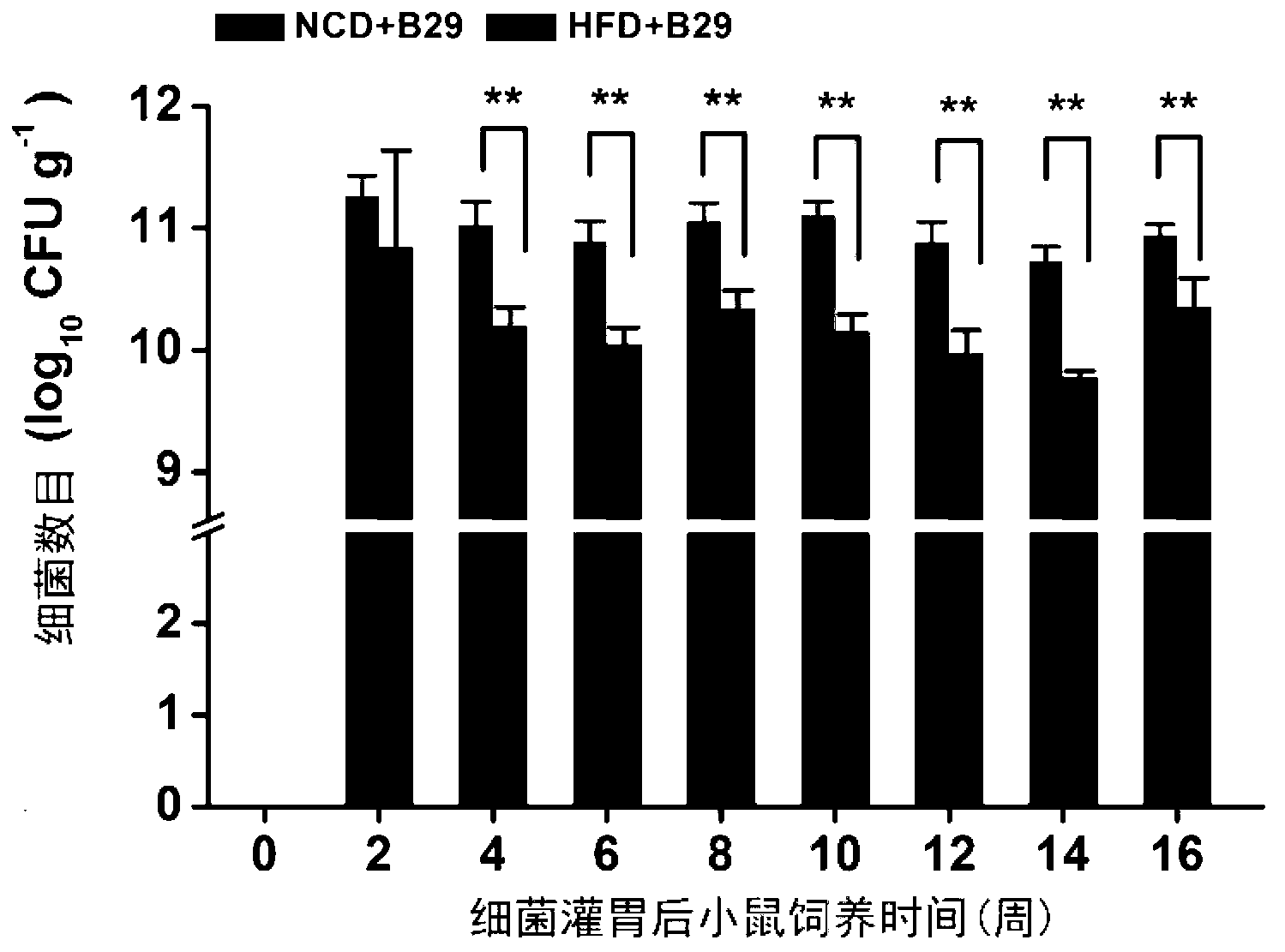

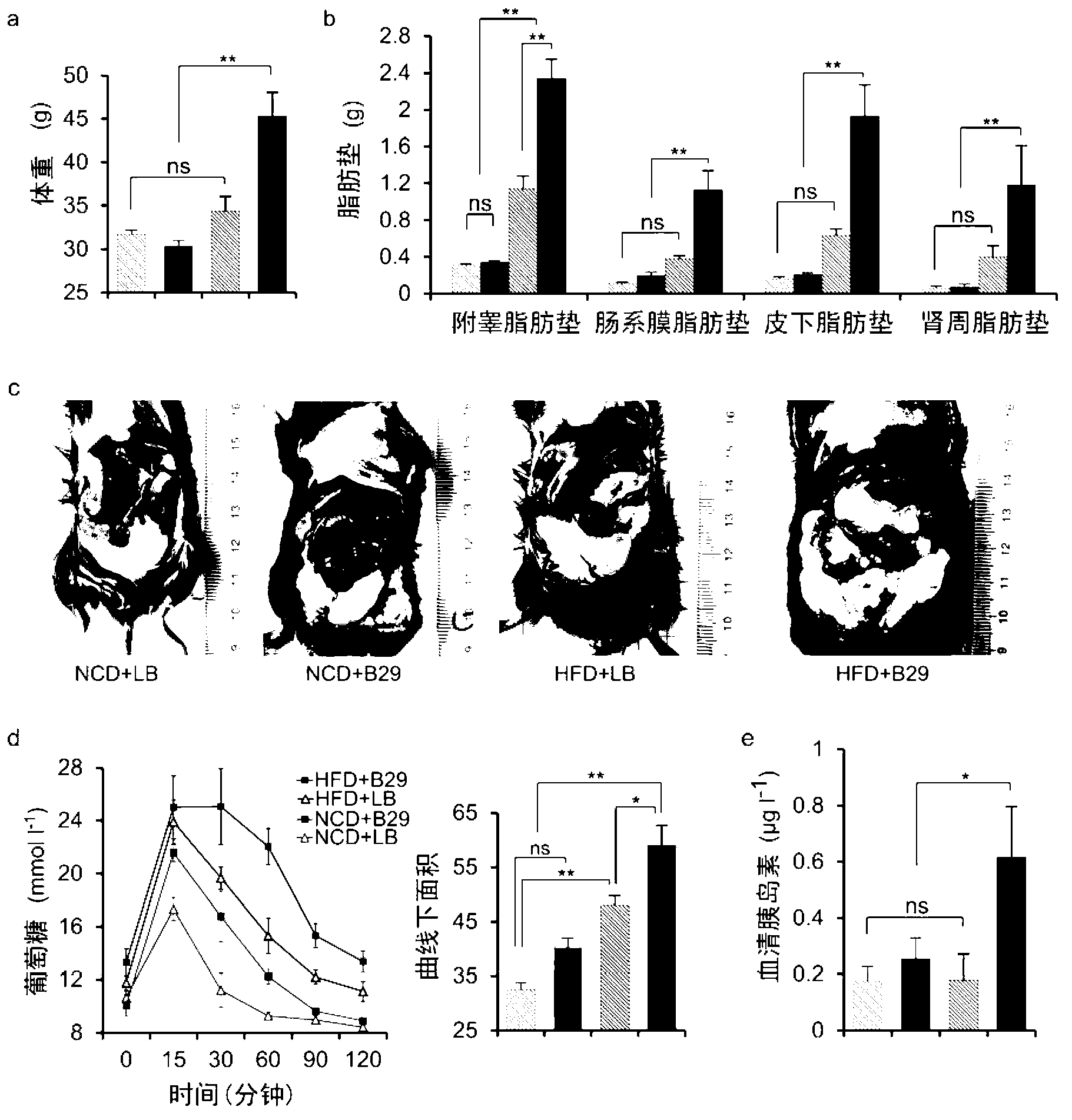

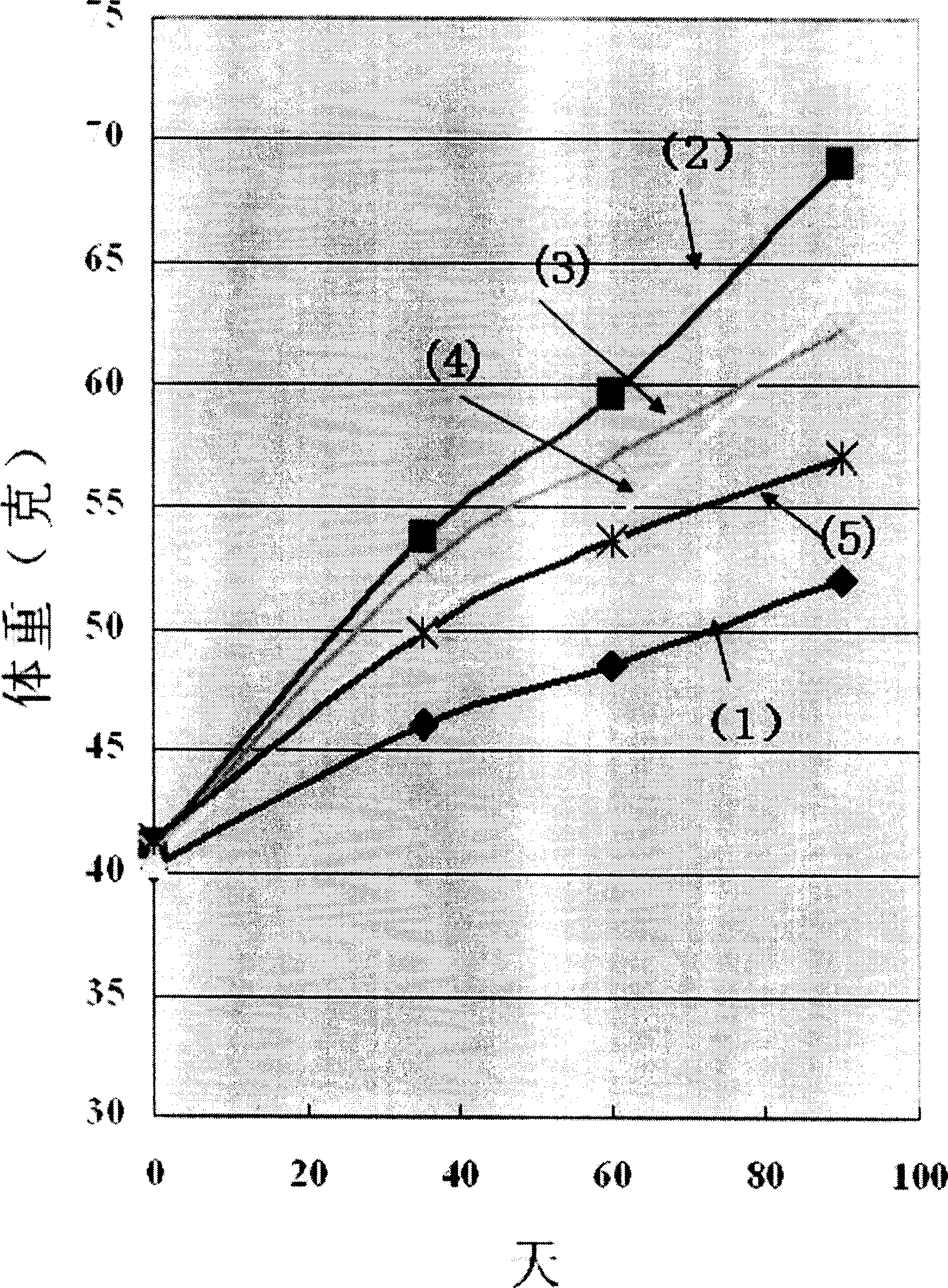

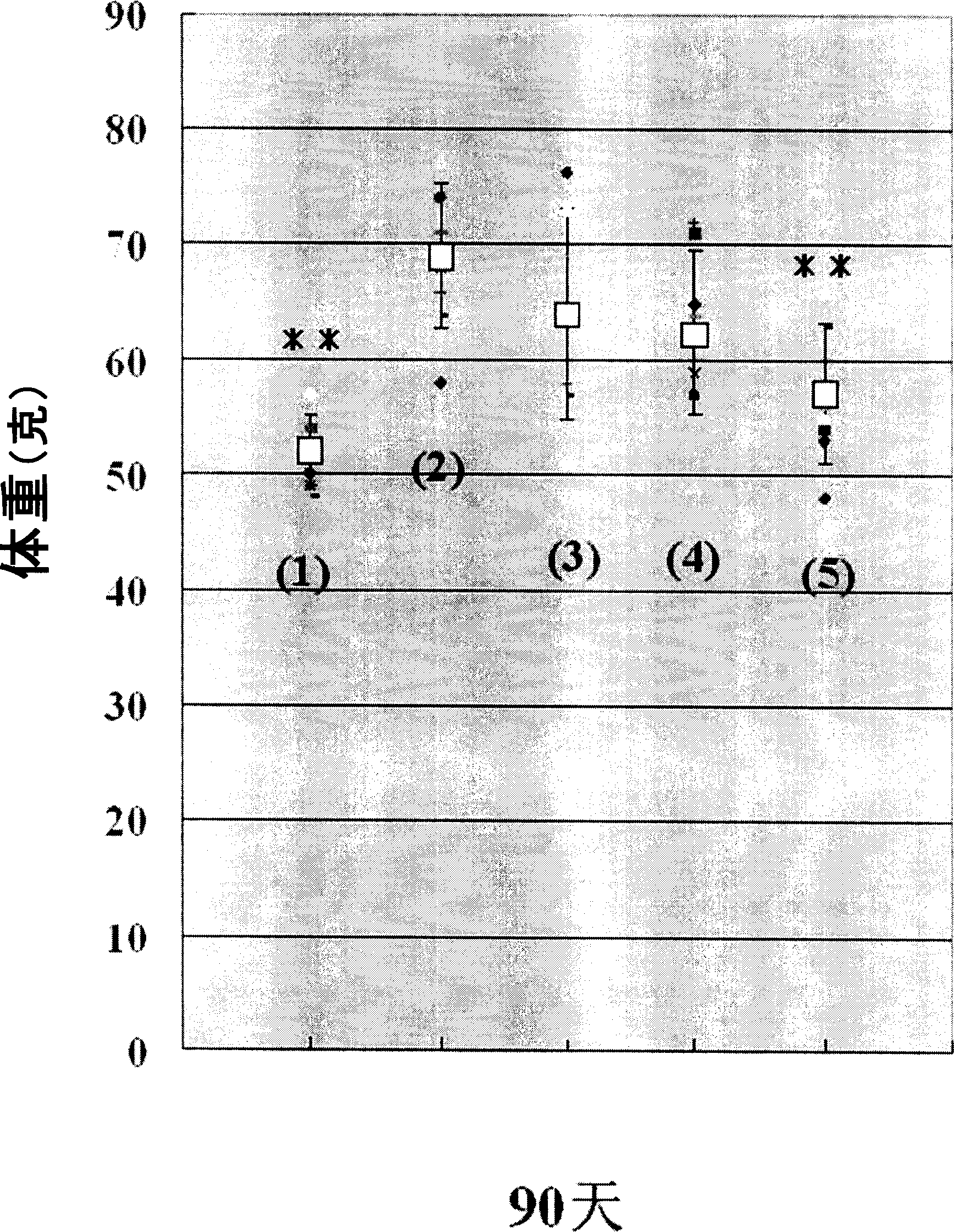

Method of establishing gnotobiotic animal obesity model and application of model

The invention provides a method of establishing a gnotobiotic animal obesity model and an application of the model. According to the method, a gnotobiotic animal obesity model is established by inoculating an LPS (lipopolysaccharides) producing strain under a high-fat diet condition. When a germfree animal is fed with high-fat diet, a microorganism such as LPS producing strain or a combination thereof is inoculated, then the microorganism can colonize in the intestinal tract of the germfree animal, and the animal shows symptoms of disorder of the systems of metabolism, immunity and the like such as obesity, insulin resistance and chronic inflammation at the same time. The invention also relates to a method for screening the microorganism involved in obesity and combination thereof and providing a drug target for treating obesity and a method for screening the microorganism with an effect of preventing and treating metabolic diseases such as obesity, and provides a new method for treating obesity; and the method provided by the invention can be applied to the screening and effect evaluation on foods (formula), medicines, nourishments, healthcare products, beverages and the like with an effect of preventing and treating metabolic diseases such as obesity.

Owner:SHANGHAI JIAO TONG UNIV +1

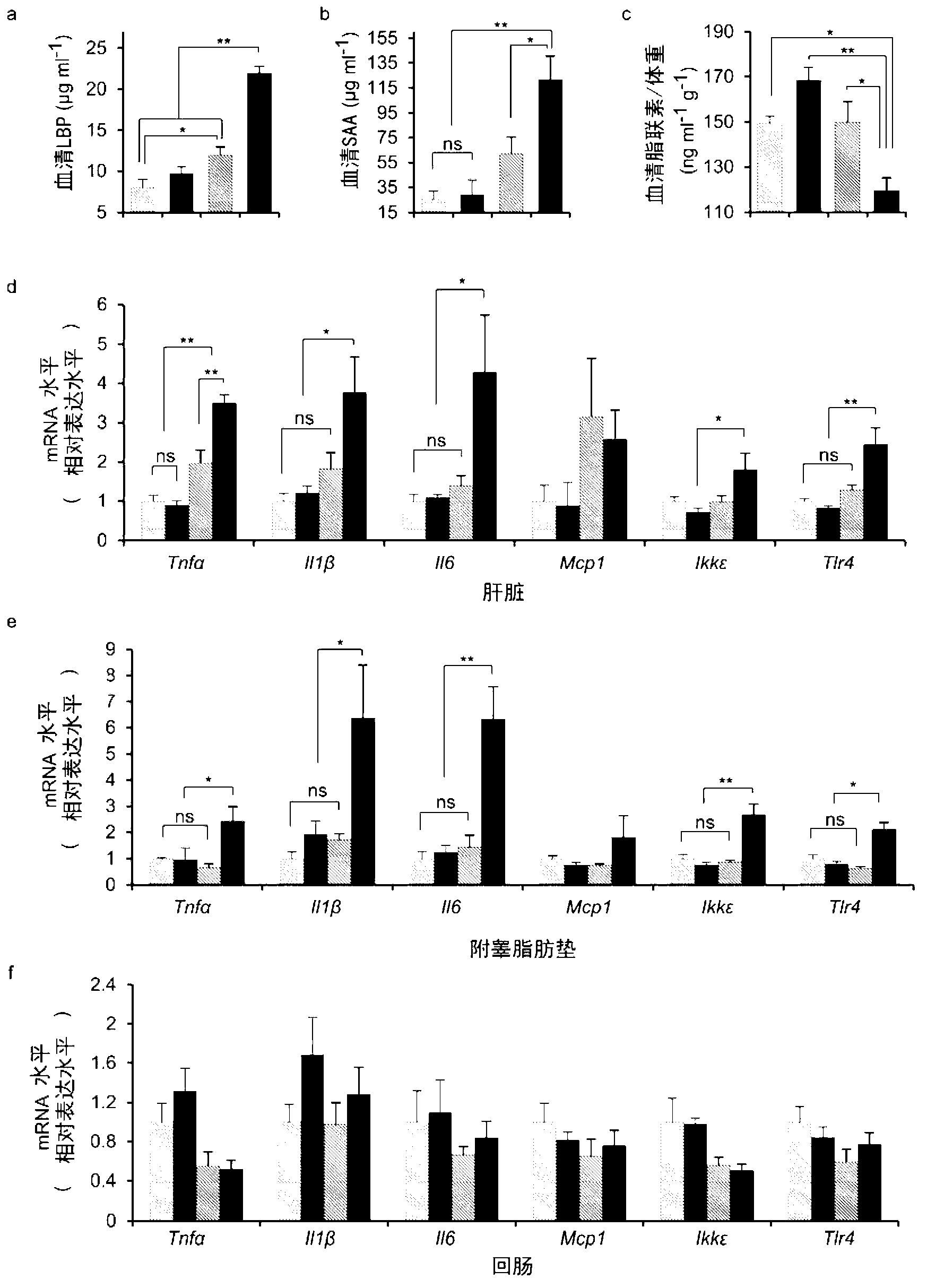

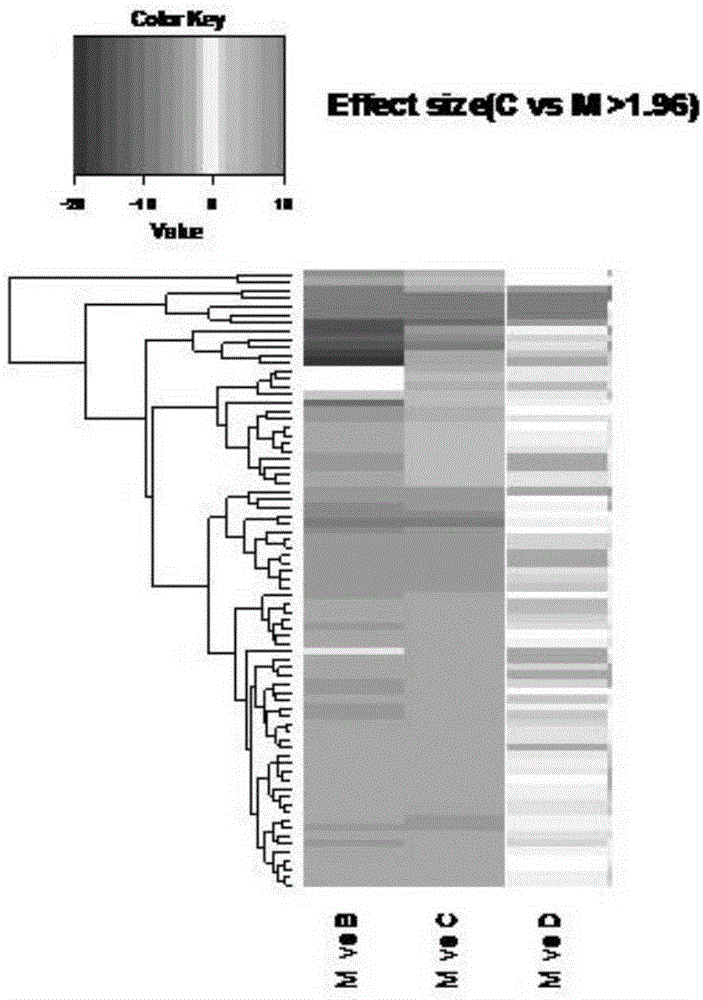

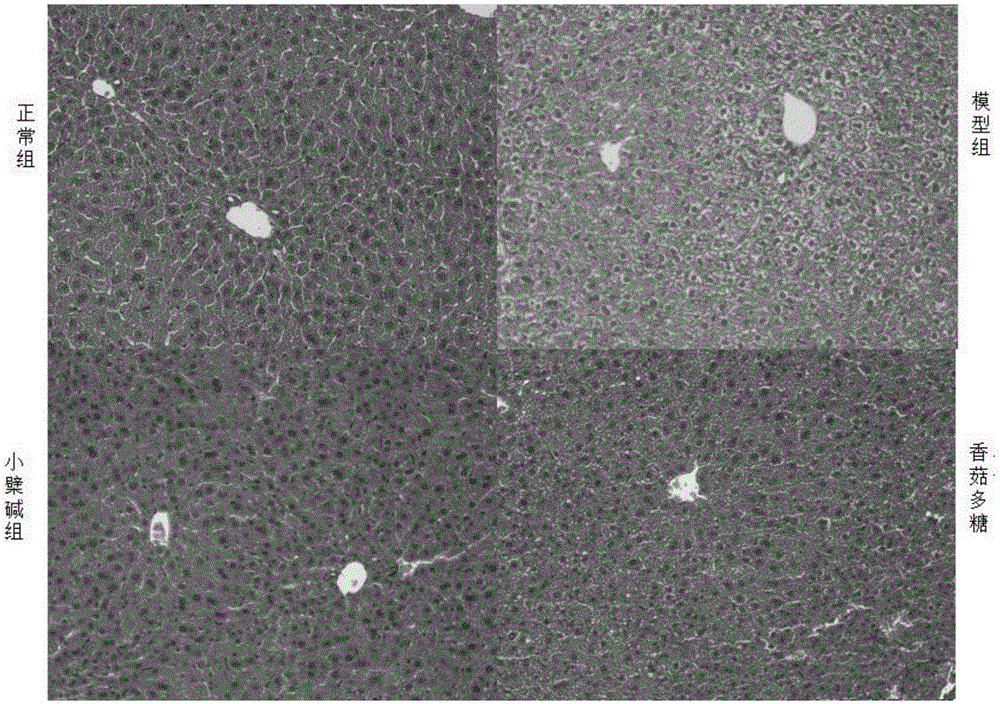

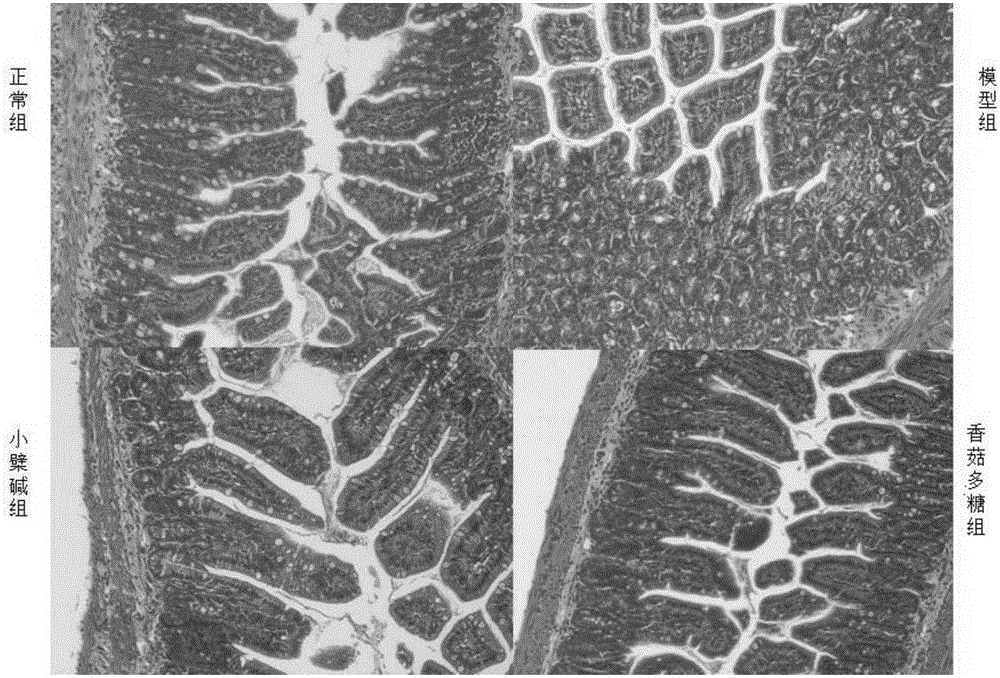

Application of lentinan in preparation of healthcare food with intestinal flora regulating function

InactiveCN106617080AIncrease abundanceReduce abundanceOrganic active ingredientsMetabolism disorderDiabetes modelTG - Triglyceride

The invention relates to the technical field of biology, in particular to application of polysaccharide. The invention provides the application of lentinan in preparation of healthcare food capable of improving the abundance of beneficial bacteria and reducing the abundance of harmful bacteria in intestinal florae. An applicant for the invention observes the influence of the lentinan on lipid metabolism in mice through the intestinal florae by inducing obesity type-2 diabetic models of the mice through high-fat diet; the lentinan provided by the invention can regulate intestinal flora disturbance caused by diet, and can obviously change the proportion of the harmful bacteria in the intestinal florae and make unbalanced intestinal florae in vivo to trend to be normal so as to regulate the blood fat and blood sugar indicators of obesity caused by the intestinal flora disturbance due to the diet; the content of triglyceride in blood plasma can be obviously reduced; the content of cholesterol, low-density lipoprotein and free fatty acid can be reduced.

Owner:INFINITUS (CHINA) CO LTD

Brick tea manufacturing technique

InactiveCN103181424ATea body tight knotFit for drinkingPre-extraction tea treatmentBrickHigh fat diet

The invention discloses a brick tea manufacturing technique which comprises the following steps: unpacking and removing impurities; chopping tea and performing bamboo basket screening; sieving; preparing water; boiling a tea glaze; weighing the tea; heating a pot heating and frying the tea; performing pouring sealing; beating the tea; holding a clapper; performing hole poking sealing; tying up; drying in the shade; breeding a fungus; and after drying tea seals in the shade until 70%-80% of each tea seal is dried, stacking the tea seals on a wooden house in sequence, covering the tea seals with palm sheets to allow automatic fungus breeding, opening the stacks again when vegetable seed flower yellow spots appear on the seal paper parcels, and drying separately for one to two months. The brick tea has the advantages of compact and tight tea body, black brown color, good bloom, flourished golden flowers, overflowing fungus fragrant, orange red and transparent tea soup, and mellow and long-lasting taste, is suitable for being drunk by people in high and cold areas and high fat diet areas, particularly for the people living in desolation areas such as deserts, gobi, plateaus and the like.

Owner:袁喜平

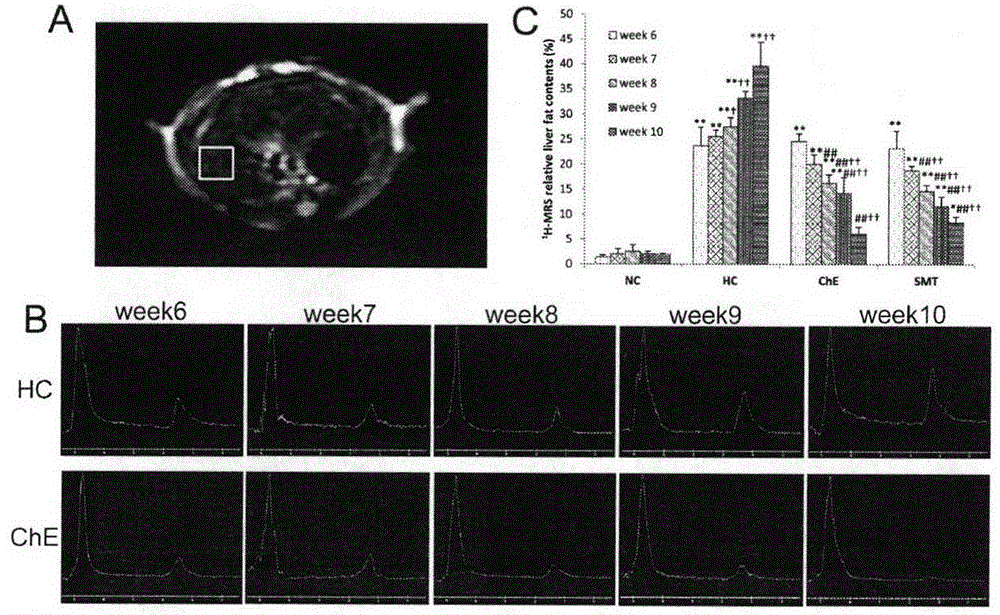

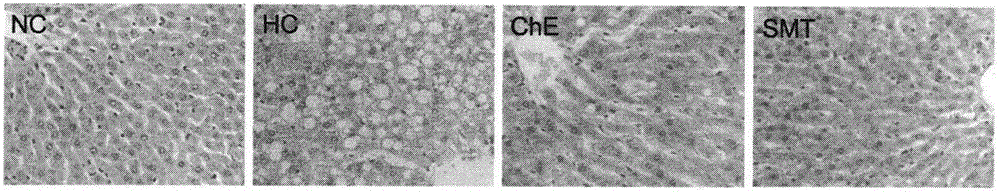

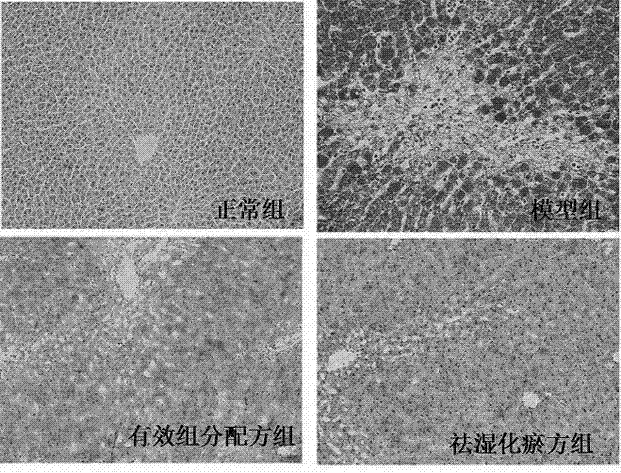

Application of cyclocarya paliurus effective part in preparation of medicine used for treating non-alcoholic fatty liver disease

The invention belongs to the field of pharmaceuticals and relates to application of a cyclocarya paliurus effective part in preparation of health products and medicines which are used for treating a non-alcoholic fatty liver disease. The cyclocarya paliurus effective part mainly contains natural triterpenoid and can be used for effectively reducing rat liver lipid accumulation degree and triglyceride level which are caused by high fat diet, improving the liver histology and liver functions and improving the liver oxidative stress and the organism inflammatory level, so that the cyclocarya paliurus effective part can be used for obviously alleviating non-alcoholic fatty liver disease and preparing health products and medicines which are used for treating the non-alcohol fatty liver disease. The application of the cyclocarya paliurus effective part has the advantage that application range of cyclocarya paliurus preparation in the medical field.

Owner:CHINA PHARM UNIV

Application of lactobacillus plantarum powder in regulating fat metabolism and intestinal flora of obese rats

PendingCN111467506AReduce contentReduce TG contentCompounds screening/testingPowder deliveryBacteroidesGut flora

The invention provides an application of lactobacillus plantarum powder in regulating fat metabolism and intestinal flora of fat rats. The lactobacillus plantarum powder can reduce the in-vivo fat content, increased under induction of high-fat diet, of rats and reduce the body fat rate; the FFA content, increased under induction of high-fat diet, in serum of rats can be remarkably reduced; meanwhile, the TG content in the serum of obese rats can be reduced, and the HDL-C content is increased; the lipid metabolism function of the livers of the obese rats can be improved, and activation of a fatty acid synthesis pathway of the obese rats is inhibited; the condition of intestinal flora disorder of the obese rats can be improved, and the flora richness, flora diversity, flora structure and composition of the obese rats can be maintained; increase of relative abundance of firmicutes is inhibited; the relative abundance of bacteroides is improved; the relative abundance ratio of the firmicutes to the bacteroides in intestinal tracts of rats under the condition of high fat diet is reduced; and the similarity of intestinal flora of the obese rats and healthy rats is increased.

Owner:HEBEI NORMAL UNIV +1

Lactobacillus plantarum with functions of losing weight and reducing lipid and application thereof

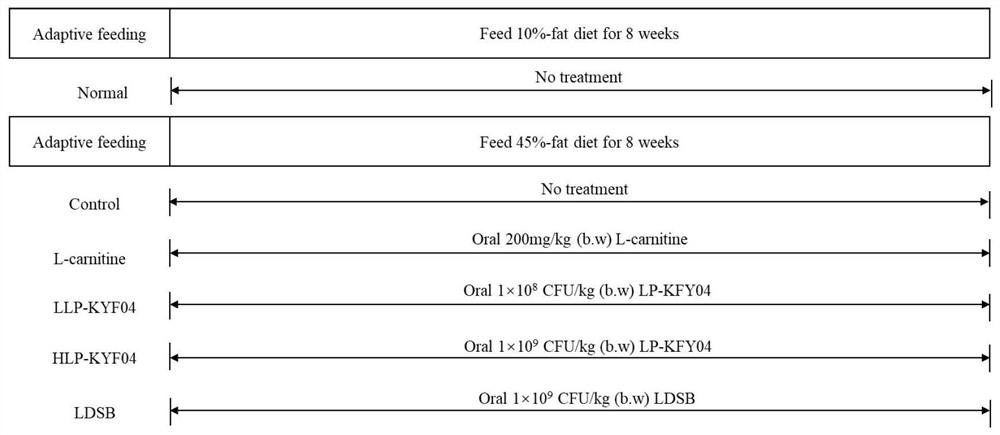

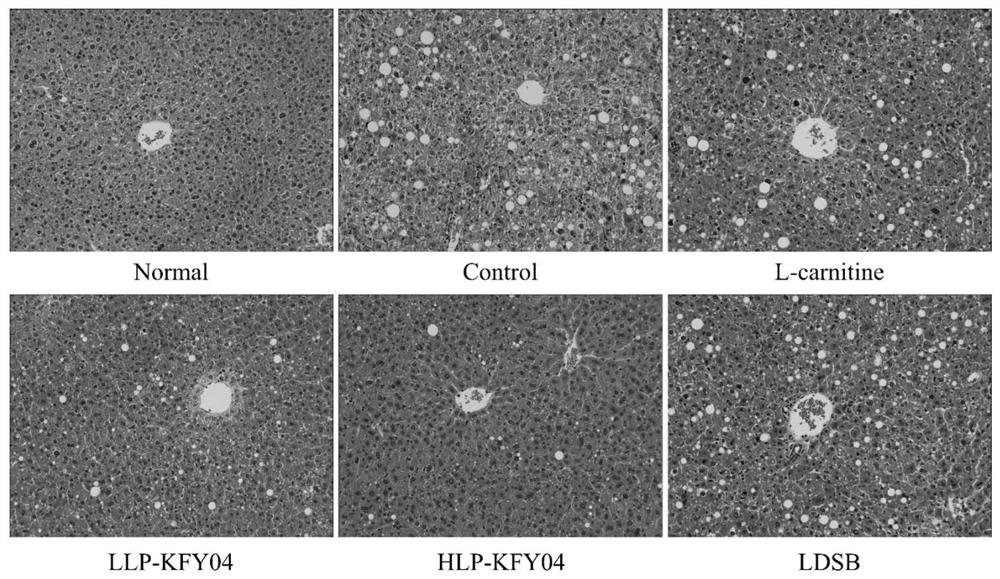

The invention discloses lactobacillus plantarum with functions of losing weight and reducing lipid and an application thereof, and belongs to the technical field of microorganisms; the lactobacillus plantarum LP-KFY04 is lactic acid bacteria (LAB), and the preservation number is CGMCC No. 15651; lactobacillus plantarum KFY04 is separated from yoghourt and is used for mice maintaining 45% fat diet;then liver and serum samples are obtained, and gene expression related to the TG level, oxidation, inflammation and PPAR pathway is detected to evaluate the influence of LP-KFY04 on obesity, oxidation and inflammation; and results show that the LP-KFY04 can be used for relieving obesity of mice induced by high fat diet, and the LP-KFY04 can effectively reduce liver injury and fat accumulation caused by obesity.

Owner:江苏新申奥生物科技有限公司

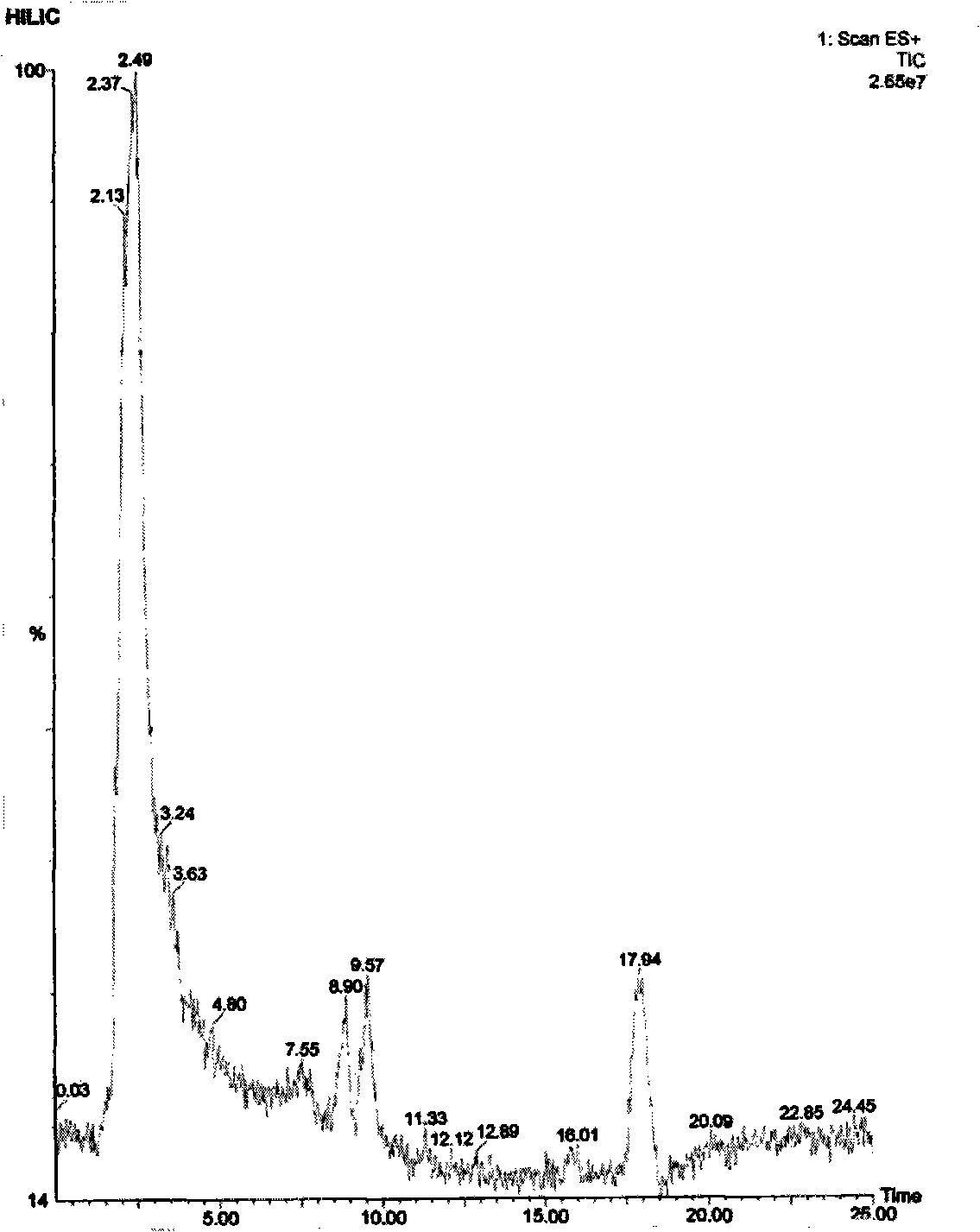

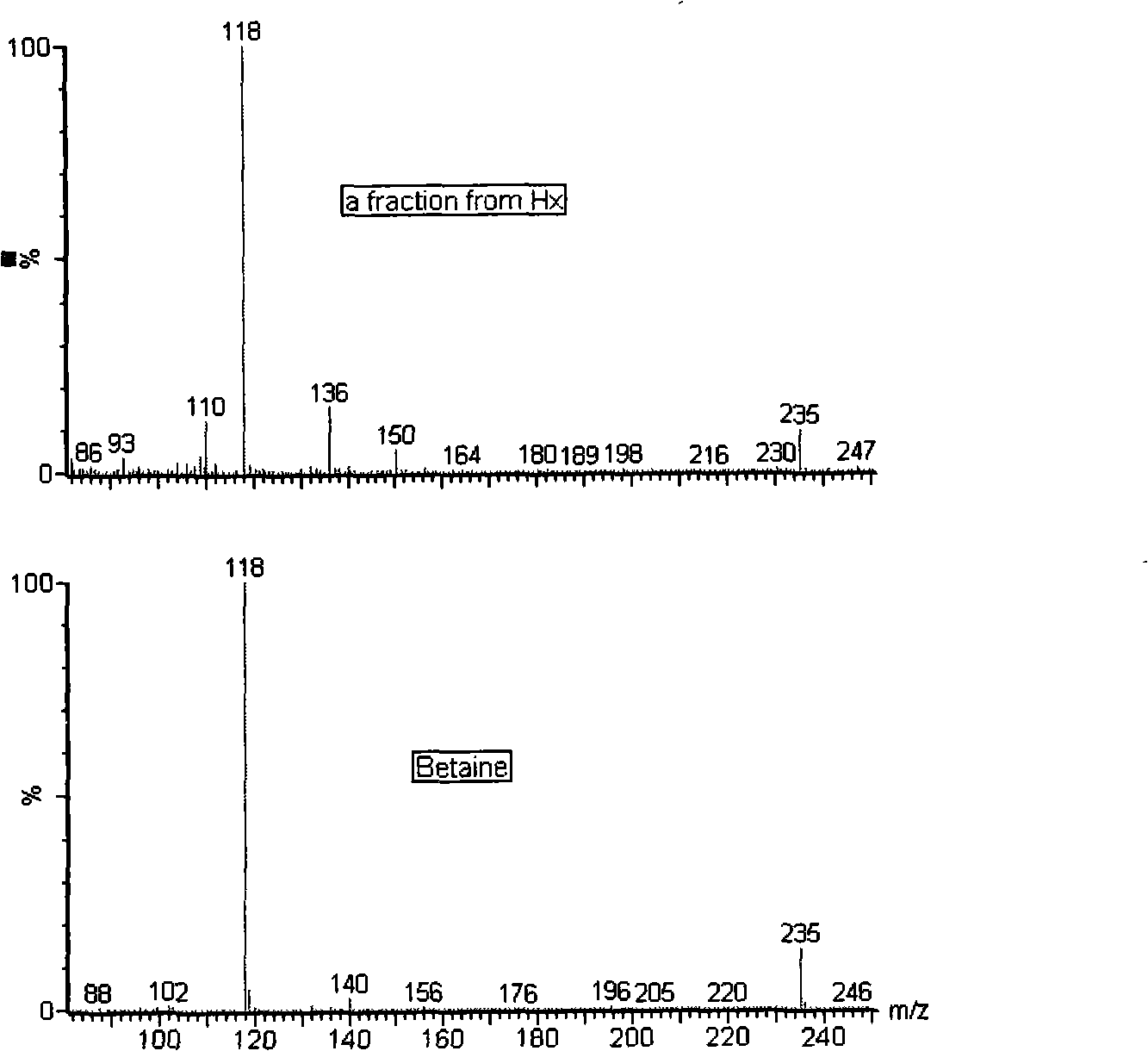

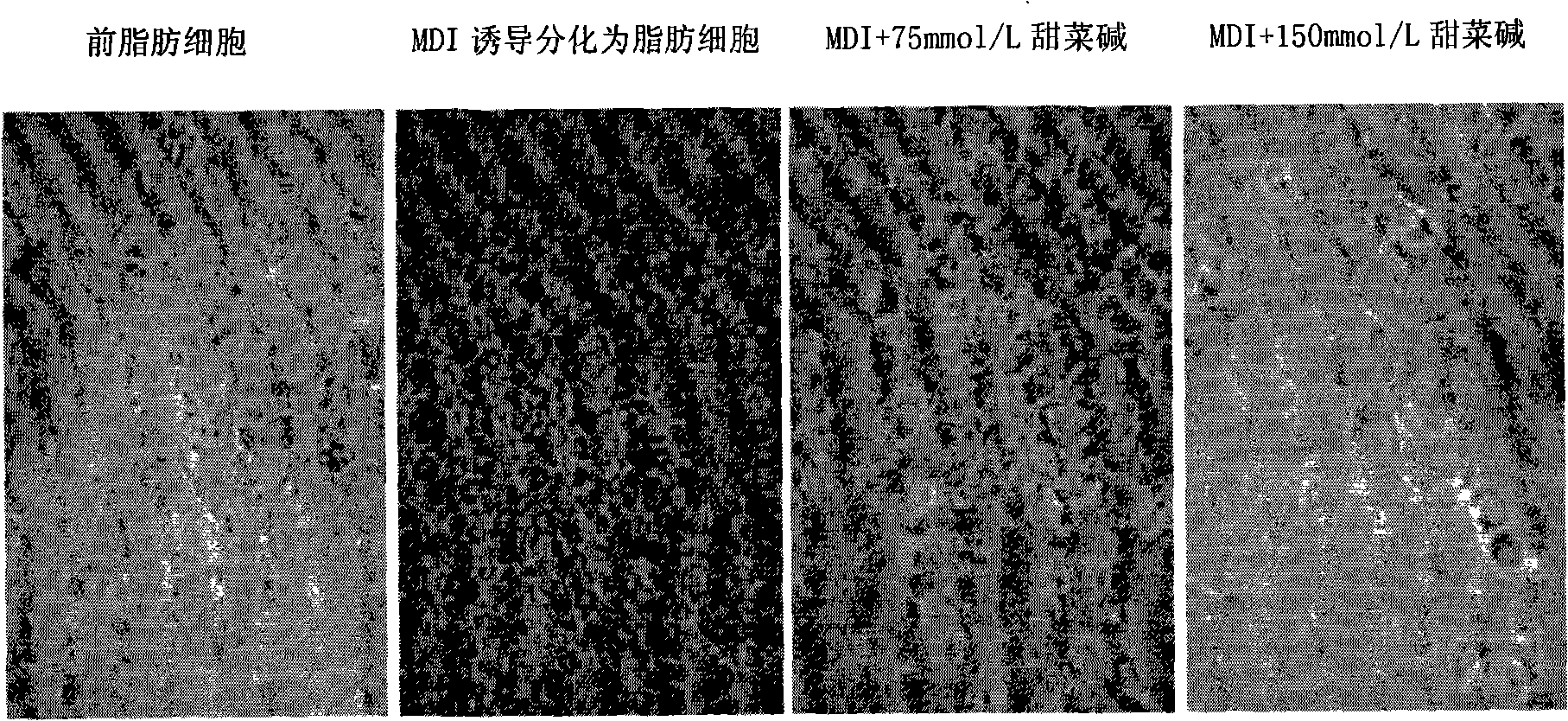

Applications of betaine in preparing medicament for preventing and treating alimentary obesity

InactiveCN101322698AInhibition of differentiationPrevent Dietary ObesityOrganic active ingredientsMetabolism disorderBetaineAdditive ingredient

The invention belongs to the technical field of the traditional Chinese medicines and relates to the new medicinal application of betaine, in particular to the application of betaine on the treatment and prevention of dietary obesity. The betaine described in the invention is one of the ingredients of radix rehmanniae extract. Proved by animal tests, the betaine can inhibit differentiation of fat cells and the expression of key transcription factors in the differentiation of fat cells; the proliferation of fat cells can be restrained when the differentiation of fat cells is inhibited; moreover, the betaine can prevent weight gain induced by high fat diet, raise high density lipoprotein level in plasma and reduce low density lipoprotein in plasma, thus the betaine can be used for preparing the drugs for preventing and treating dietary obesity.

Owner:FUDAN UNIV

Lactobacillus plantarum BUFX and application thereof in metabolic syndrome

ActiveCN113308421AIncrease consumptionInhibitory activityBacteriaMetabolism disorderBiotechnologyAmylase

The invention provides a lactobacillus plantarum BUFX (Lactobacillus plantarum) and application thereof in metabolic syndrome, which relate to the technical field of microorganisms and application of the microorganisms. The strain is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CGMCC No.22172. The lactobacillus plantarum is separated and screened from feces of adults, can promote glucose consumption of HepG2 hepatoma carcinoma cells, inhibits alpha-amylase activity, can remarkably reduce the weight and blood fat content of high-fat diet mice, improves glucose tolerance, and has important application significance for preventing or treating metabolic diseases such as diabetes, obesity and the like.

Owner:BEIJING QUANTIHEALTH TECH CO LTD

Traditional Chinese compound medicament for treating fatty liver disease

ActiveCN102670642AGood prevention effectOrganic active ingredientsDigestive systemChlorogenic acidChinese herbology

The invention belongs to the field of traditional Chinese medicines and relates to a traditional Chinese compound medicament. The traditional Chinese compound medicament disclosed by the invention is prepared from atractylodes macrocephalaon polysaccharide, jasminoidin and chlorogenic acid in weight ratio of (100-500):(10-150):(1-50). The traditional Chinese compound medicament is produced into oral solid preparations such as granules, tablets and capsules by using a conventional method. Through a high fat die-induced rat fatty liver model experiment, screening applying uniform design and repeated verification, the results show that the traditional Chinese compound medicament has the efficacies that the content of triglyceride of a rat liver tissue in the model can be remarkably reduced, the liver fatty degeneration degree and liver damage are alleviated and no remarkable effect is achieved by a single component; and the compound medicament can be used for preparing medicaments for preventing and controlling simple fatty liver and fatty hepatitis or can be used for preparing medicaments for preventing and controlling the fatty liver diseases.

Owner:SHUGUANG HOSPITAL AFFILIATED WITH SHANGHAI UNIV OF T C M

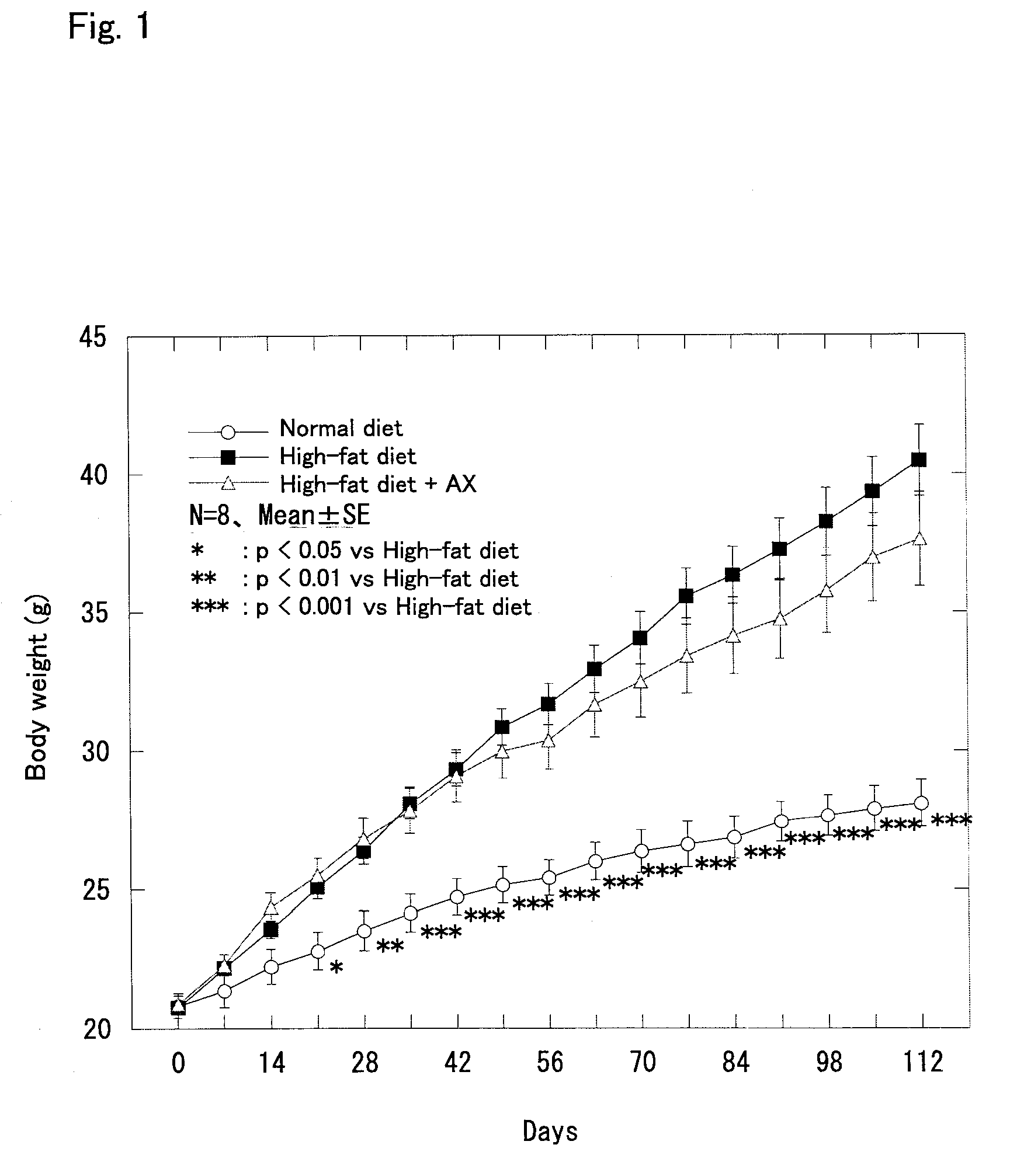

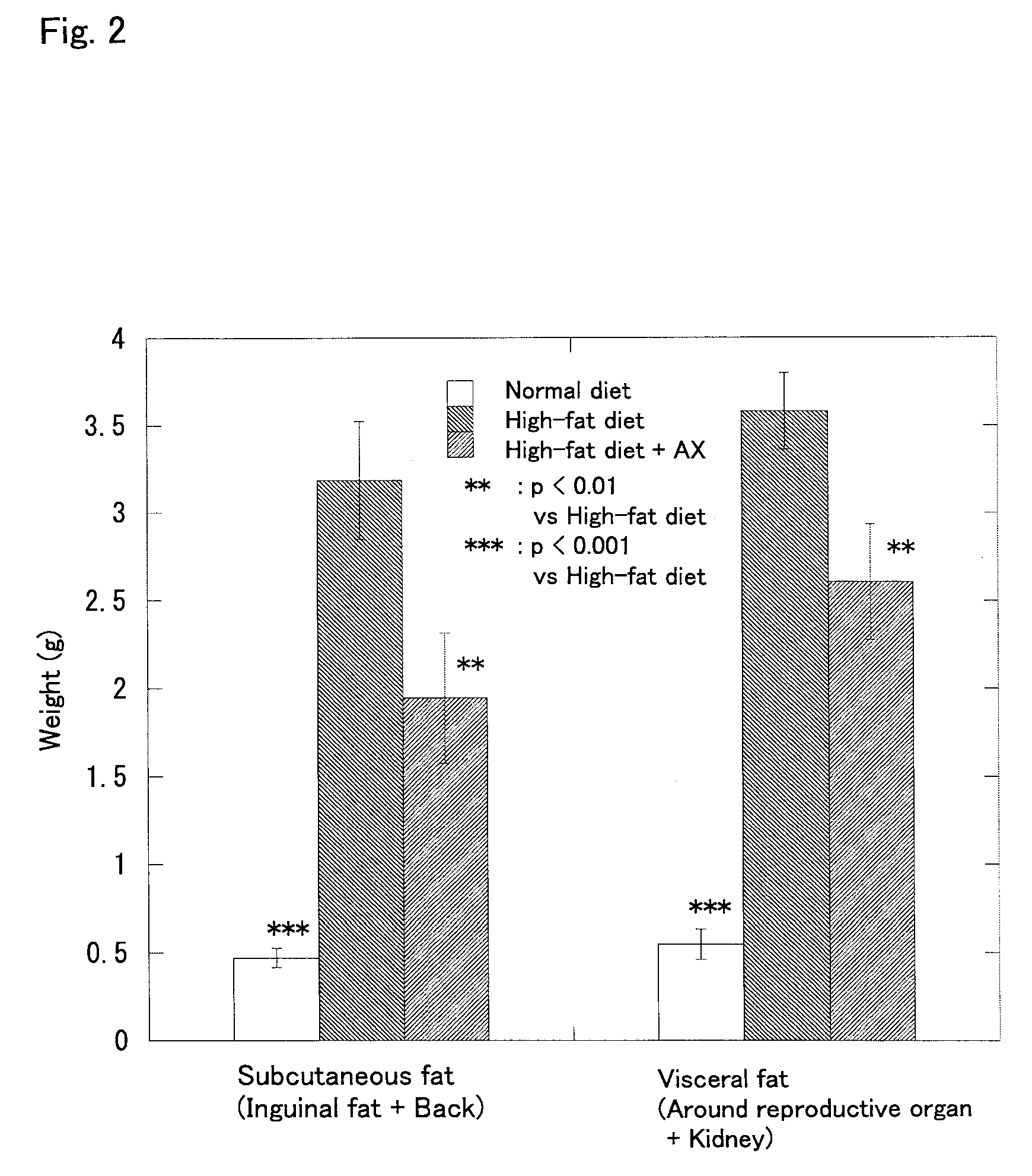

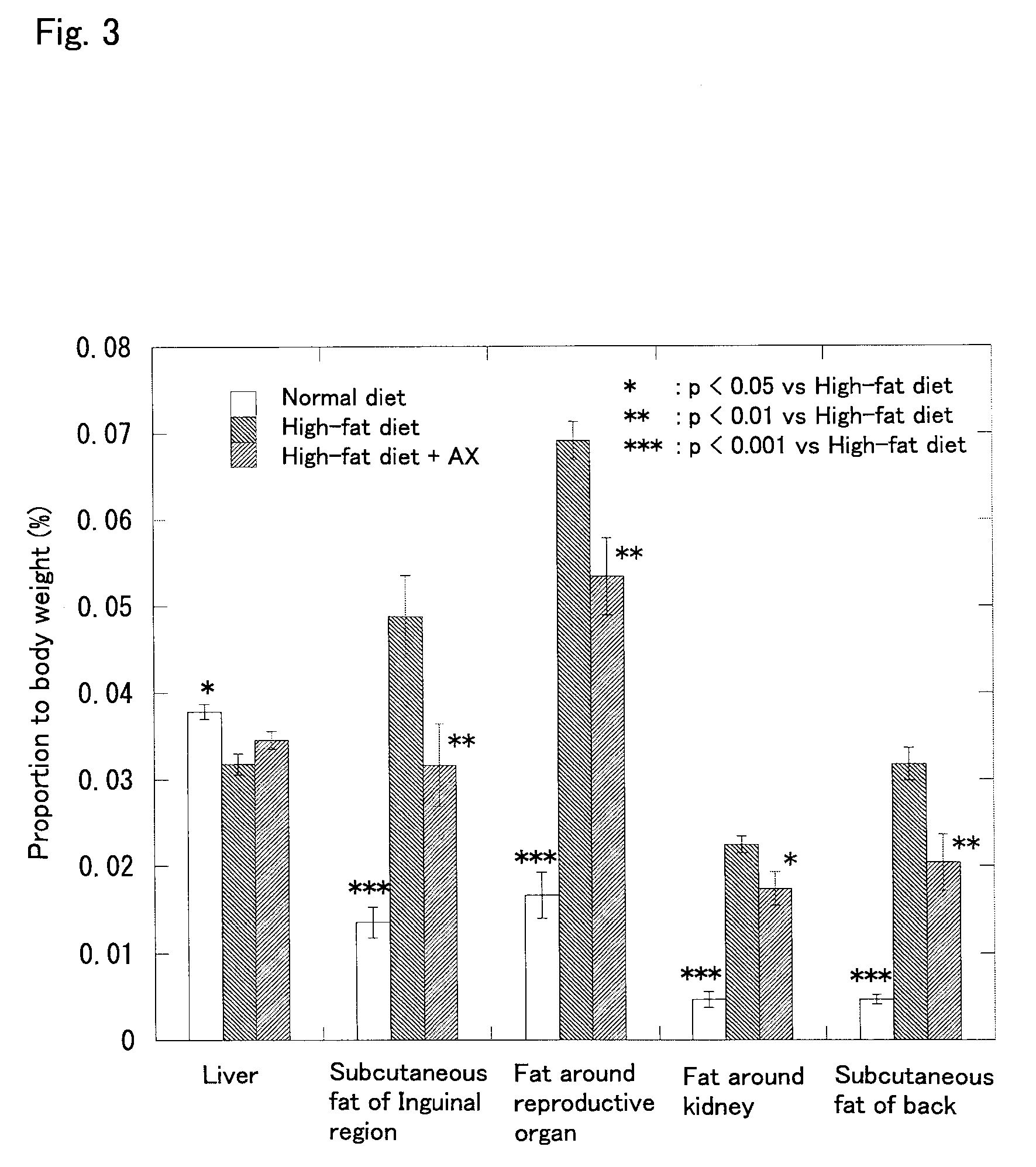

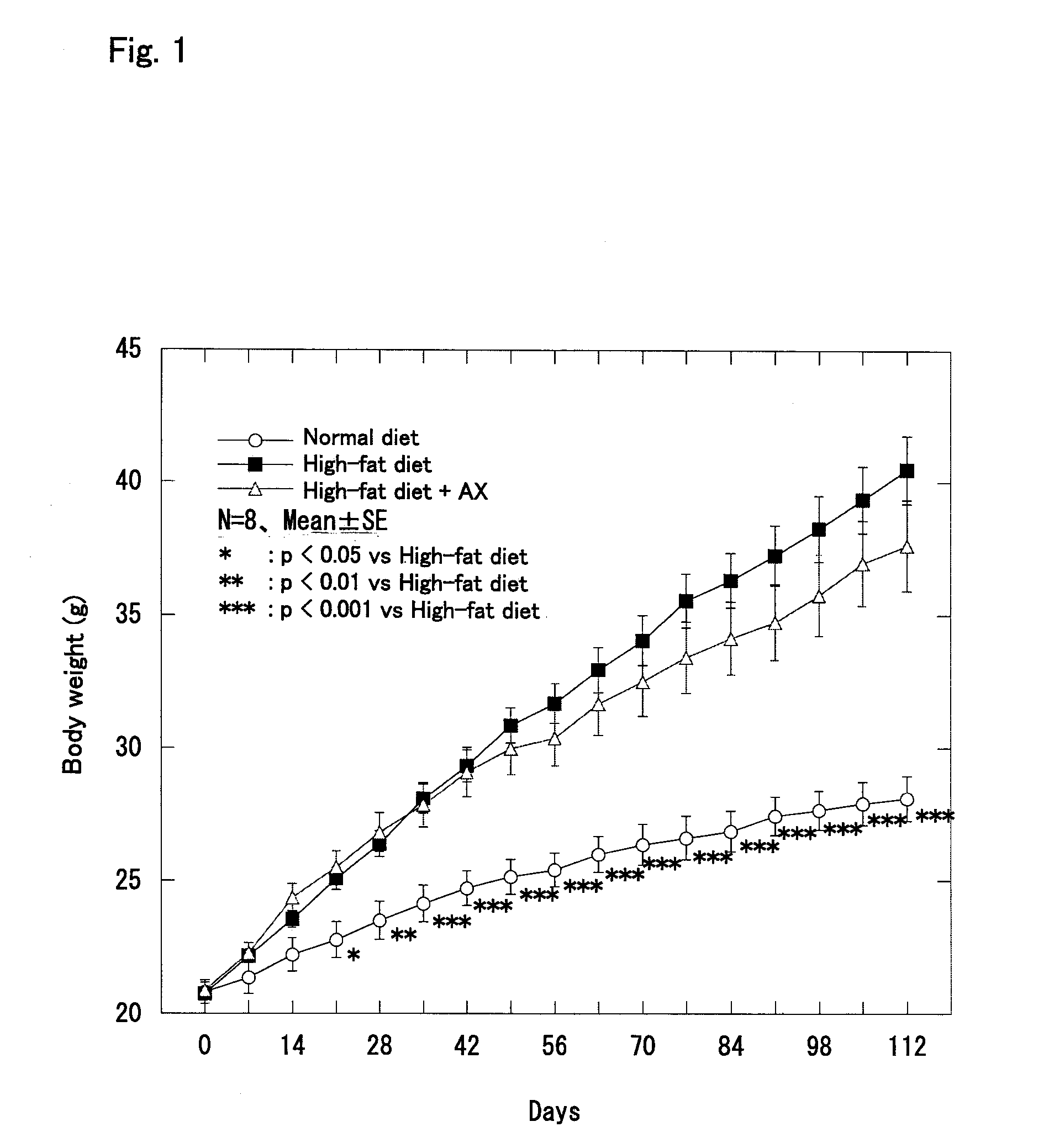

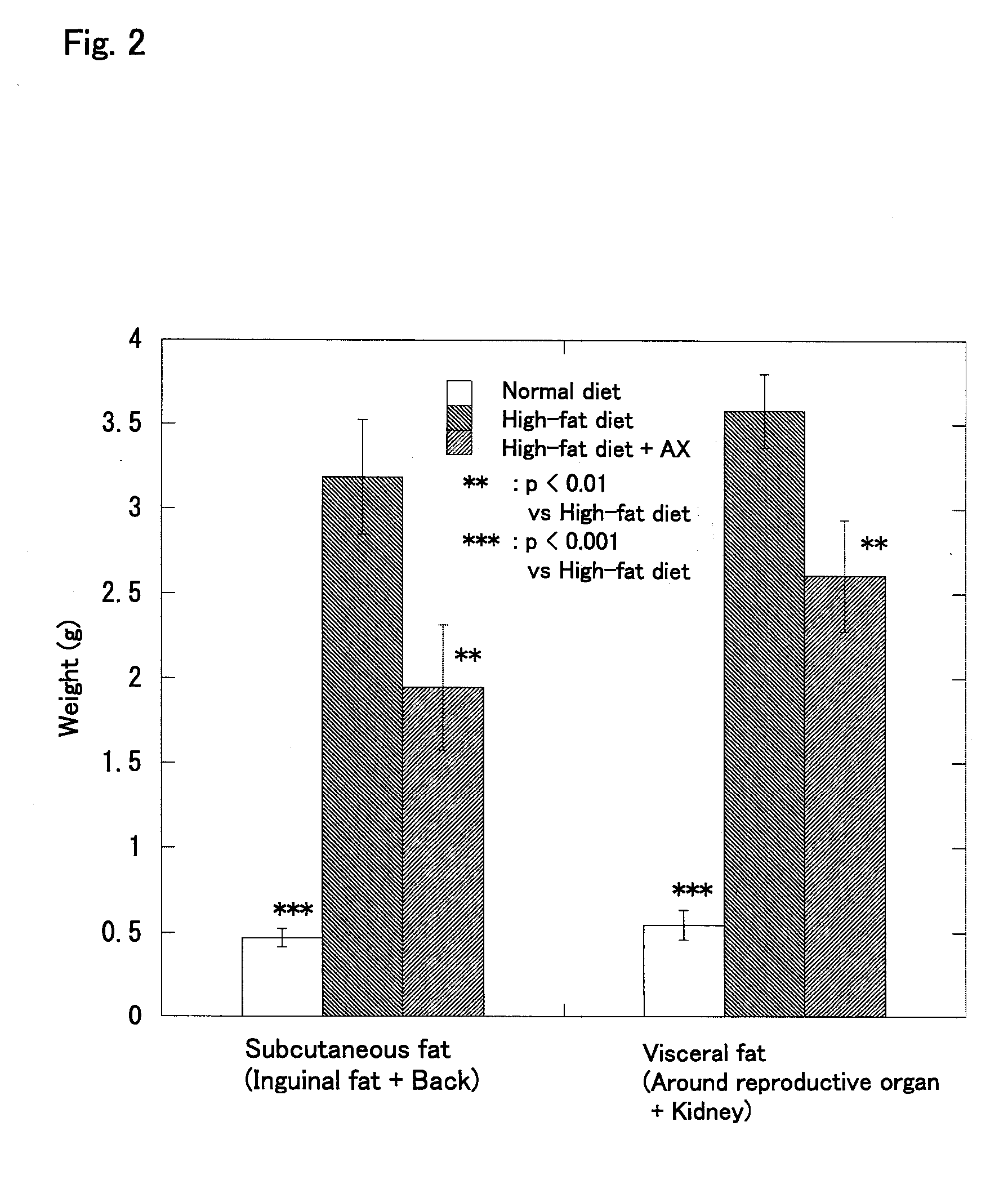

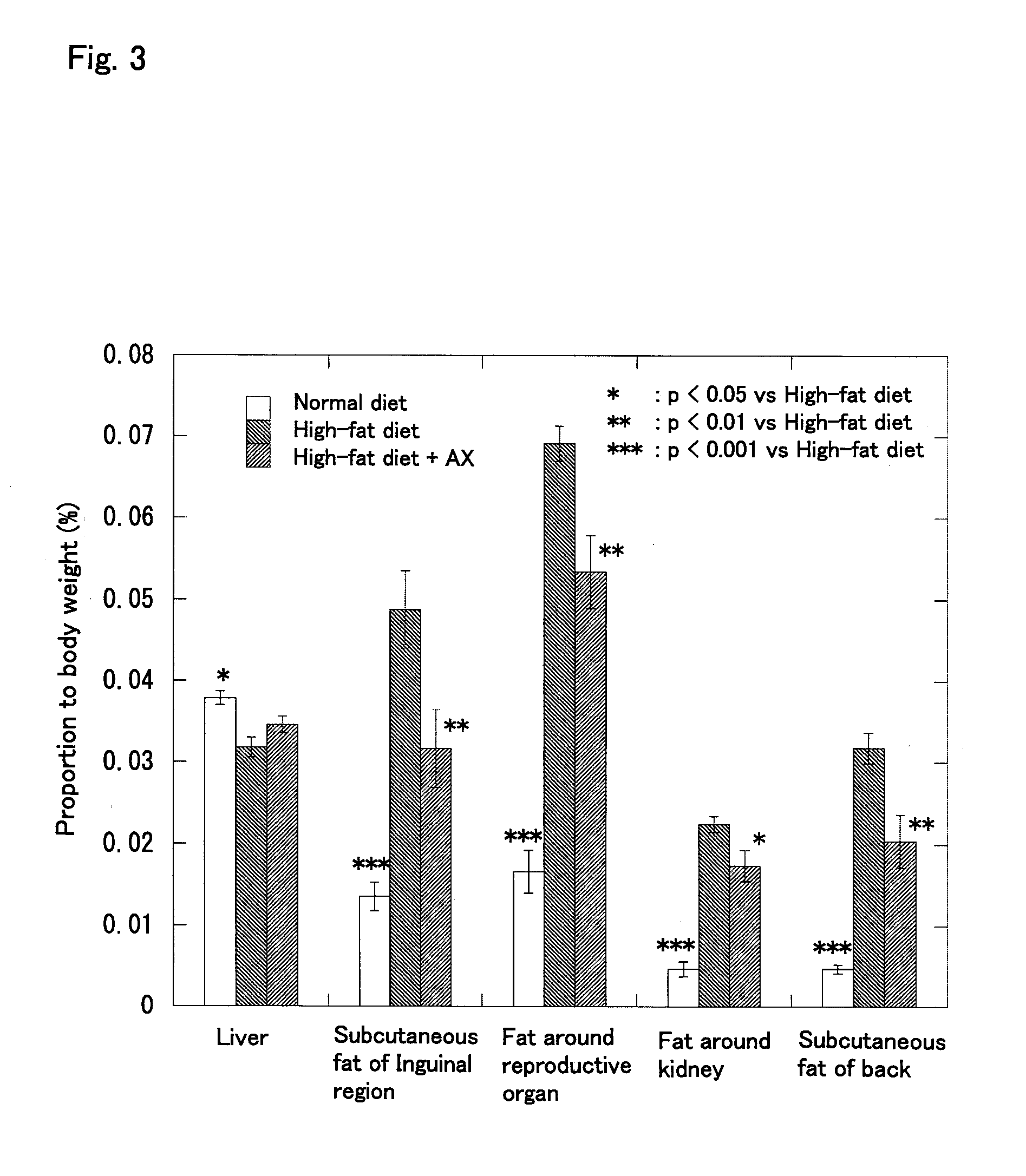

Agent for Suppressing Body Fat Accumulation

InactiveUS20070129436A1Inhibit fat accumulationLow toxicityBiocideMetabolism disorderAstaxanthinWeight gain

Novel and highly effective agents for suppressing fat accumulation and for suppressing body fat gain that contain astaxanthin and / or an ester thereof as an active component are provided. The agent for suppressing fat accumulation according to the present invention effectively suppresses accumulation of fat both in subcutaneous fat and in visceral fat. Even when high-fat diet intake is continued, body weight gain is suppressed by using the agent for suppressing body weight gain according to the present invention. Therefore, life-style related diseases, which are very likely to be caused by obesity, can be prevented, and the agents can be also used as an agent for preventing or alleviating a disease or a symptom having a relation to fat accumulation.

Owner:YAMAHA MOTOR CO LTD

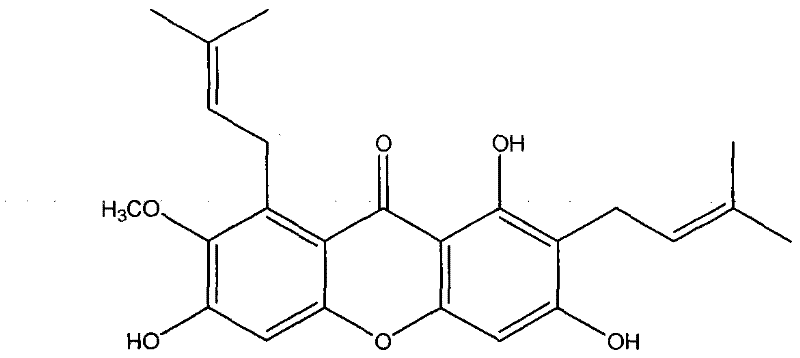

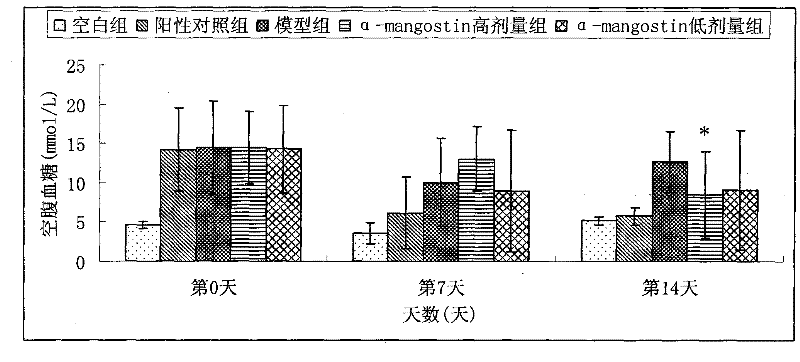

Application of alpha-mangostin for prevention and treatment of diabetes mellitus

InactiveCN102670581AImprove endurancePrevent or slow down diabetesOrganic active ingredientsMetabolism disorderAlpha mangostinHigh fat diet induced obesity

The invention provides an application of alpha-mangostin for prevention and treatment of diabetes mellitus. Alpha-mangostin can be used for decreasing blood glucose of diabetics, increasing glucose tolerance and improving symptoms of polydipsia, polyuria, polyphagia, emaciation and thirsty of the diabetics, can also be used for lowering high-fat-diet-induced obesity mouse total cholesterol content, has a cholesterol lowering effect, is capable of improving abnormality of the high-fat-diet-induced mouse glucose tolerance, and has functions of preventing and delaying obese patients from getting diabetes mellitus.

Owner:JILIN AGRICULTURAL UNIV

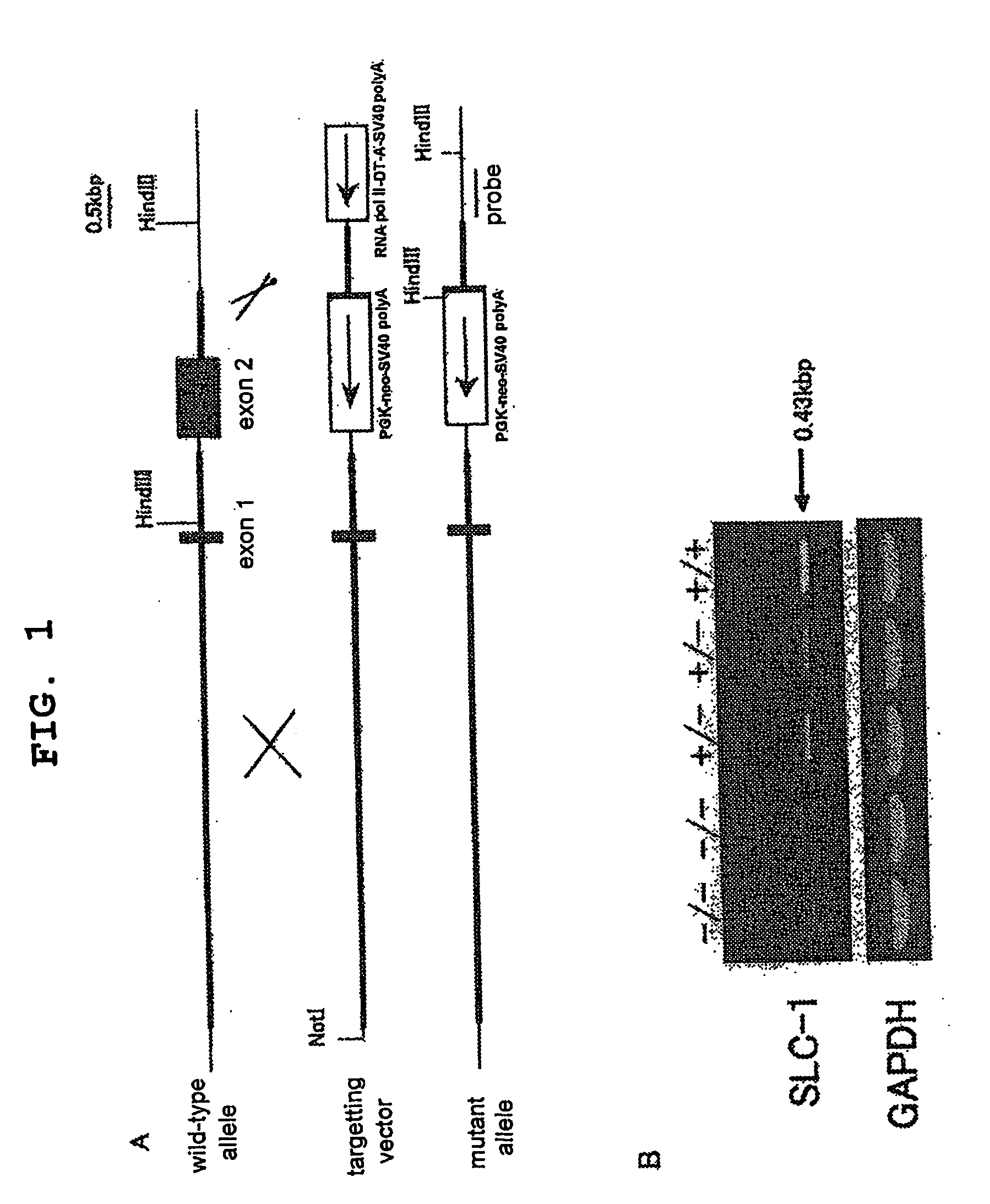

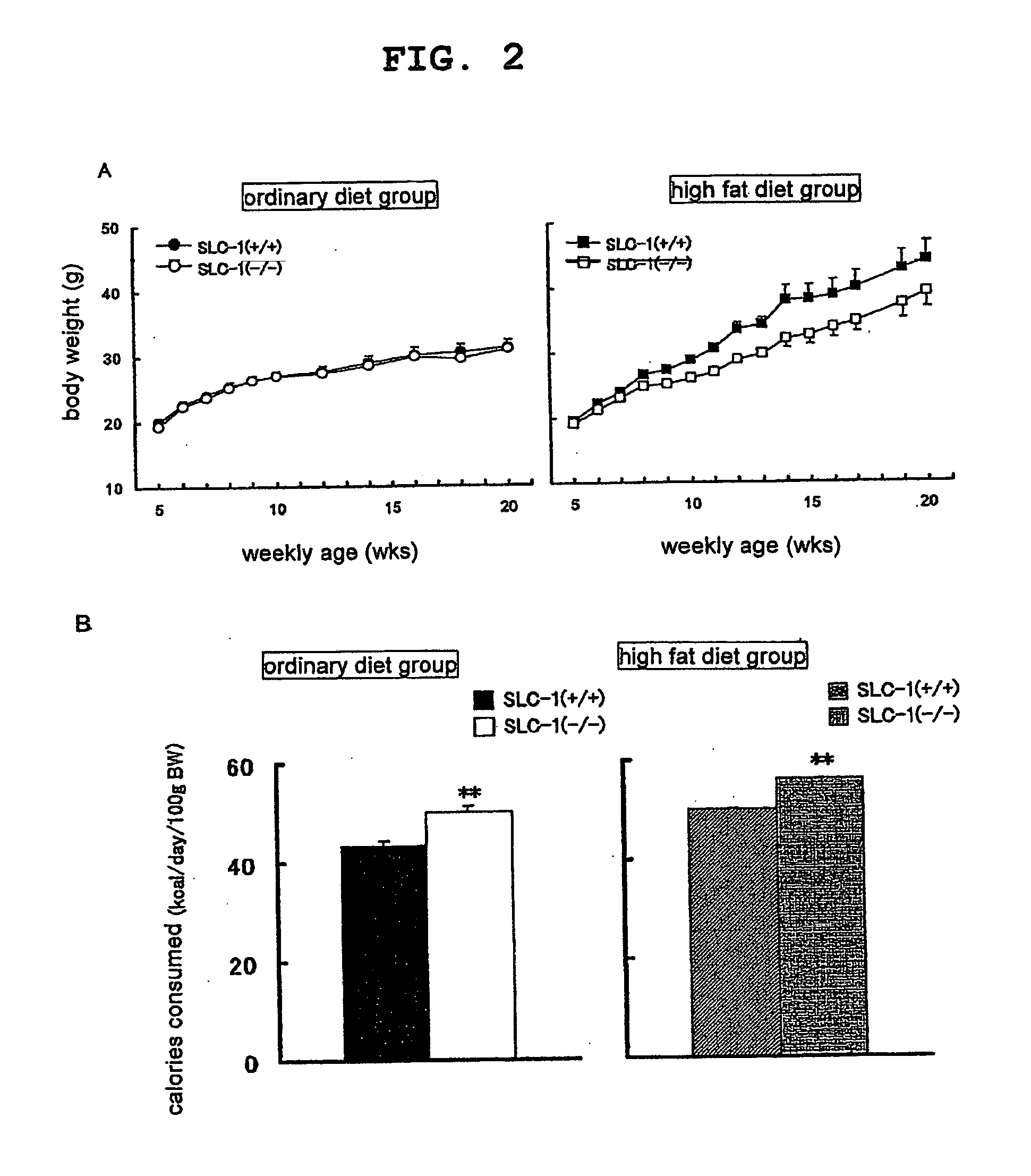

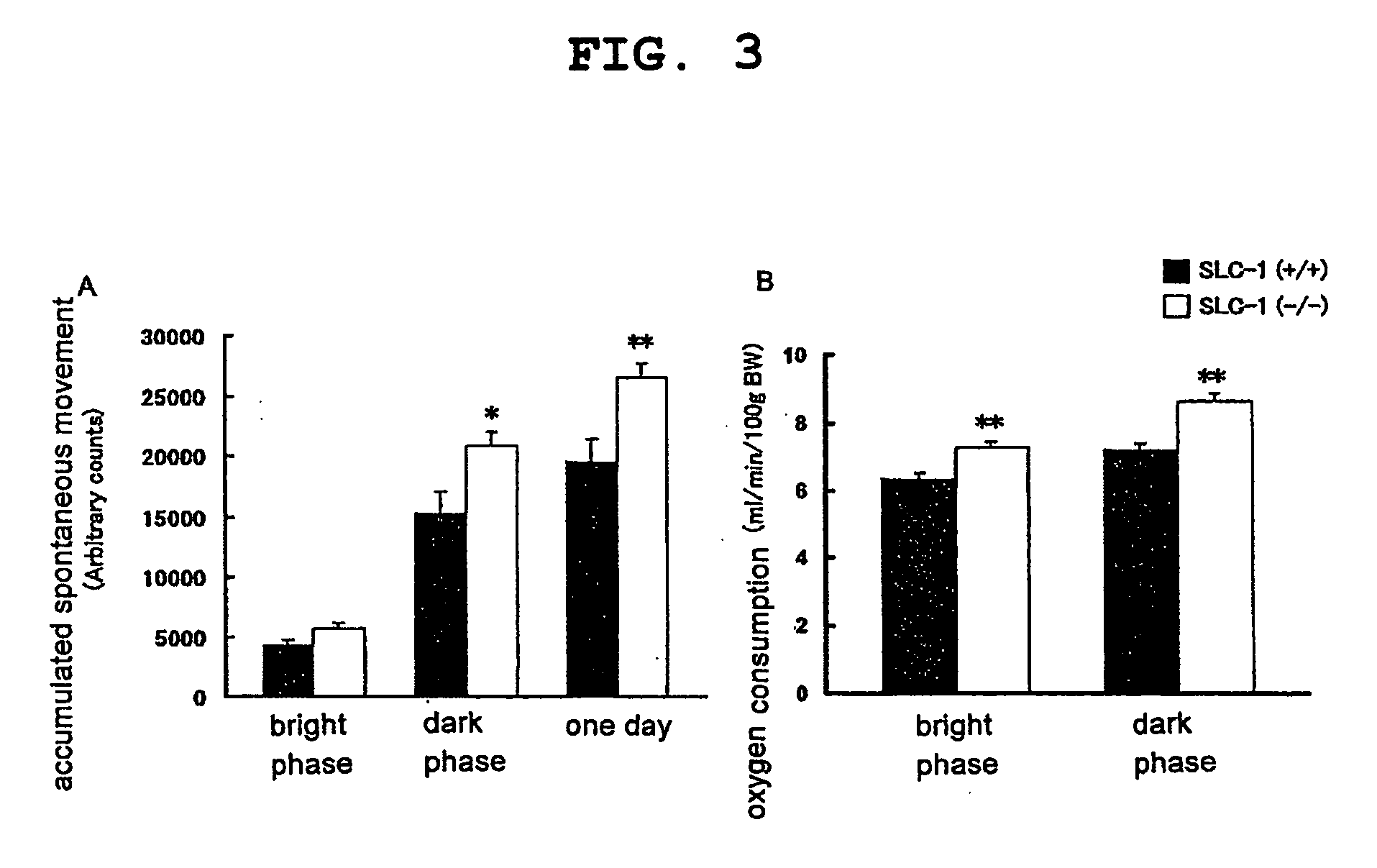

Genetically Modified Animal and Use Thereof

InactiveUS20090186946A1Small fat cell sizeIncrease insulin sensitivityBiocideOrganic active ingredientsHigh resistanceAcute hyperglycaemia

The present invention provides a non-human mammal deficient in the expression of the SLC-1 gene, having the characteristics of (1) a lower blood insulin level in glucose tolerance test, (2) increased insulin sensitivity, (3) higher resistance to obesity even on high fat diet, (4) a smaller white fat cell size, and (5) accentuated lipolysis, compared with the corresponding wild-type animal, or a portion of the body thereof. Also provided is an obesity and / or type II diabetes model non-human mammal that is deficient in the expression of the SLC-1 gene, having the characteristics of (1) elevated expression of adiponectin, (2) delayed onset of hyperglycemia, (3) a lower blood glycohemoglobin level, and (4) accentuated energy consumption, compared with the corresponding obesity and / or type II diabetes model non-human mammal wherein the expression of the gene is normal, or a portion of the body thereof.

Owner:TAKEDA PHARMACEUTICALS CO LTD

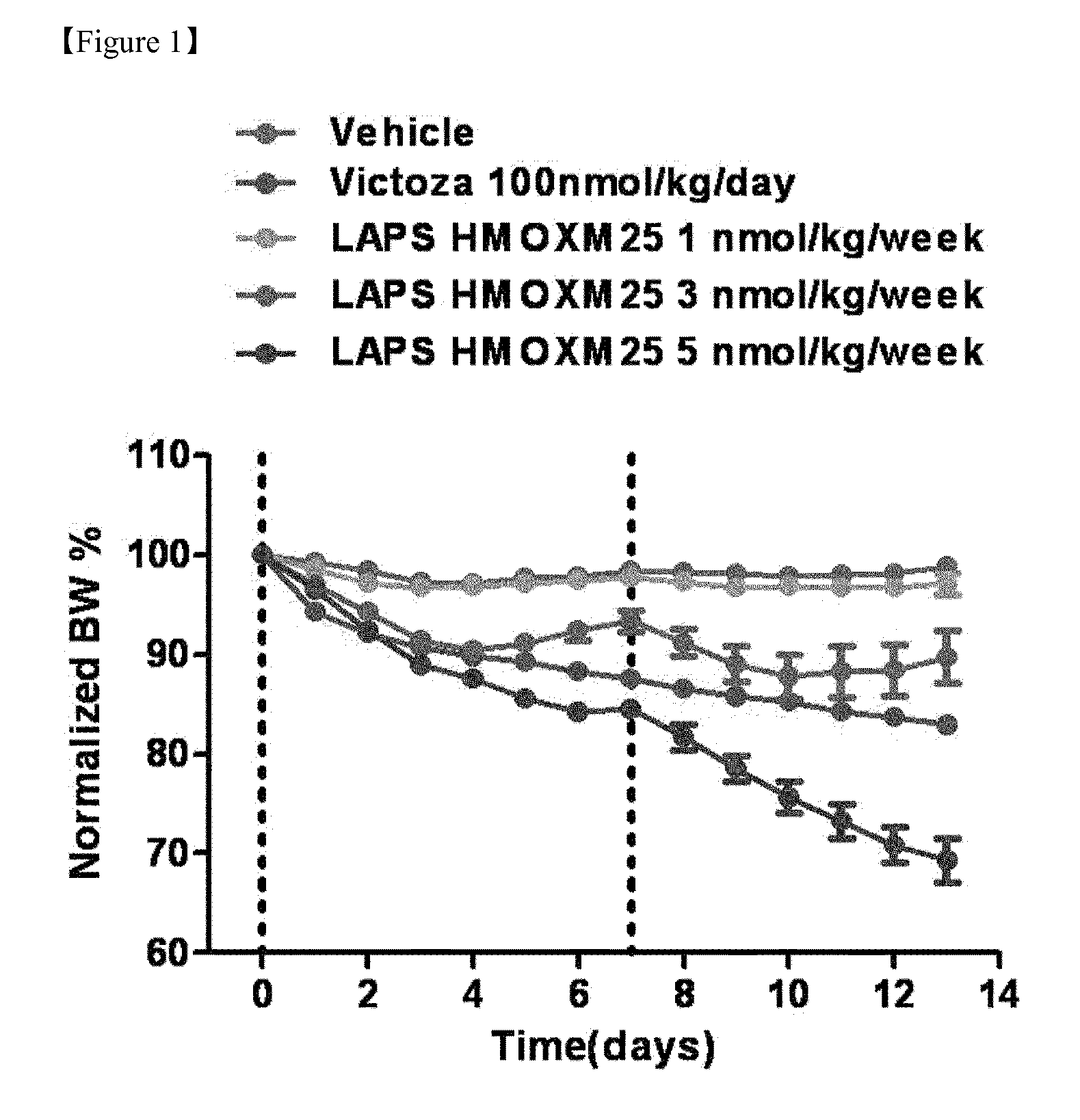

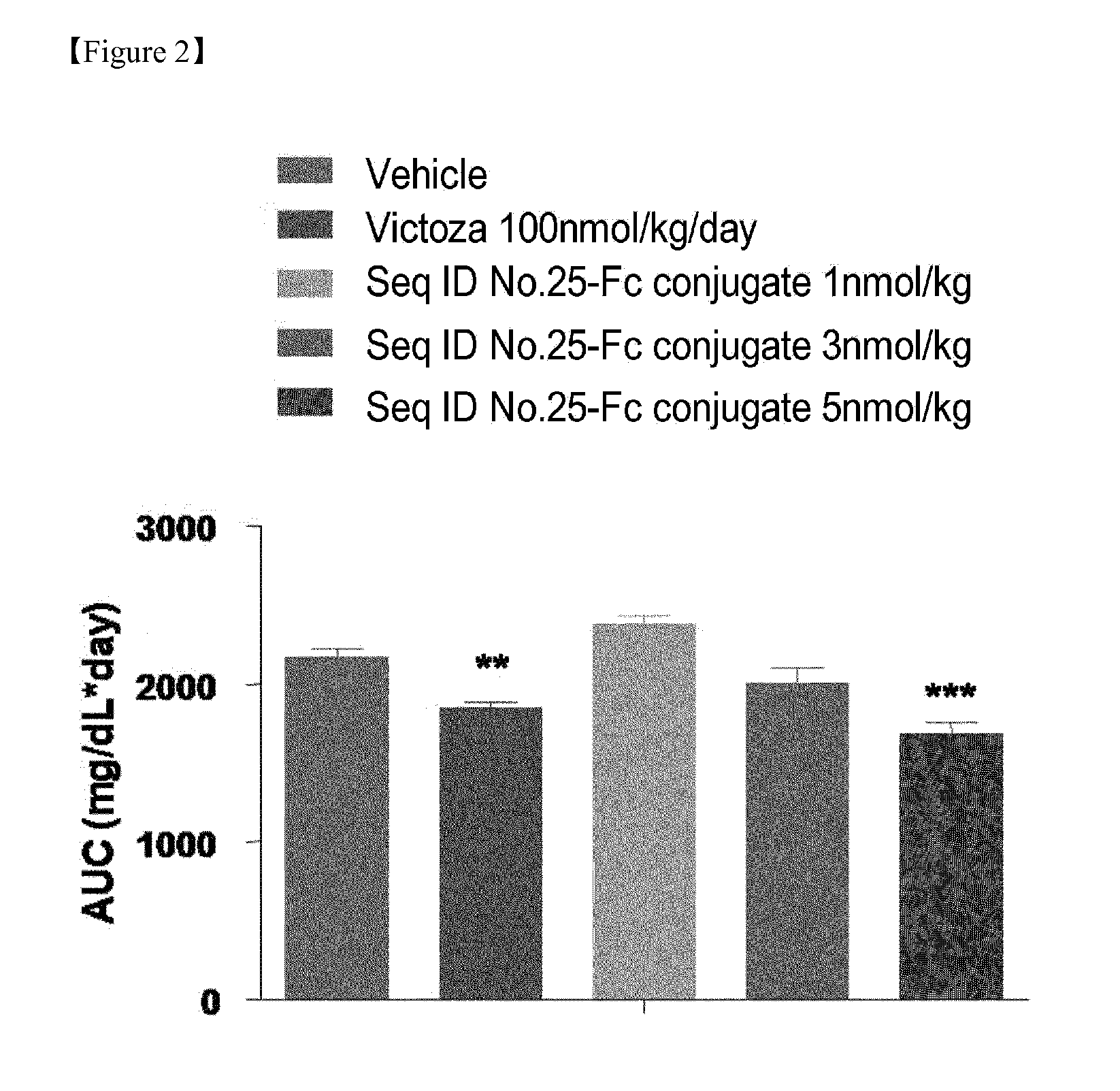

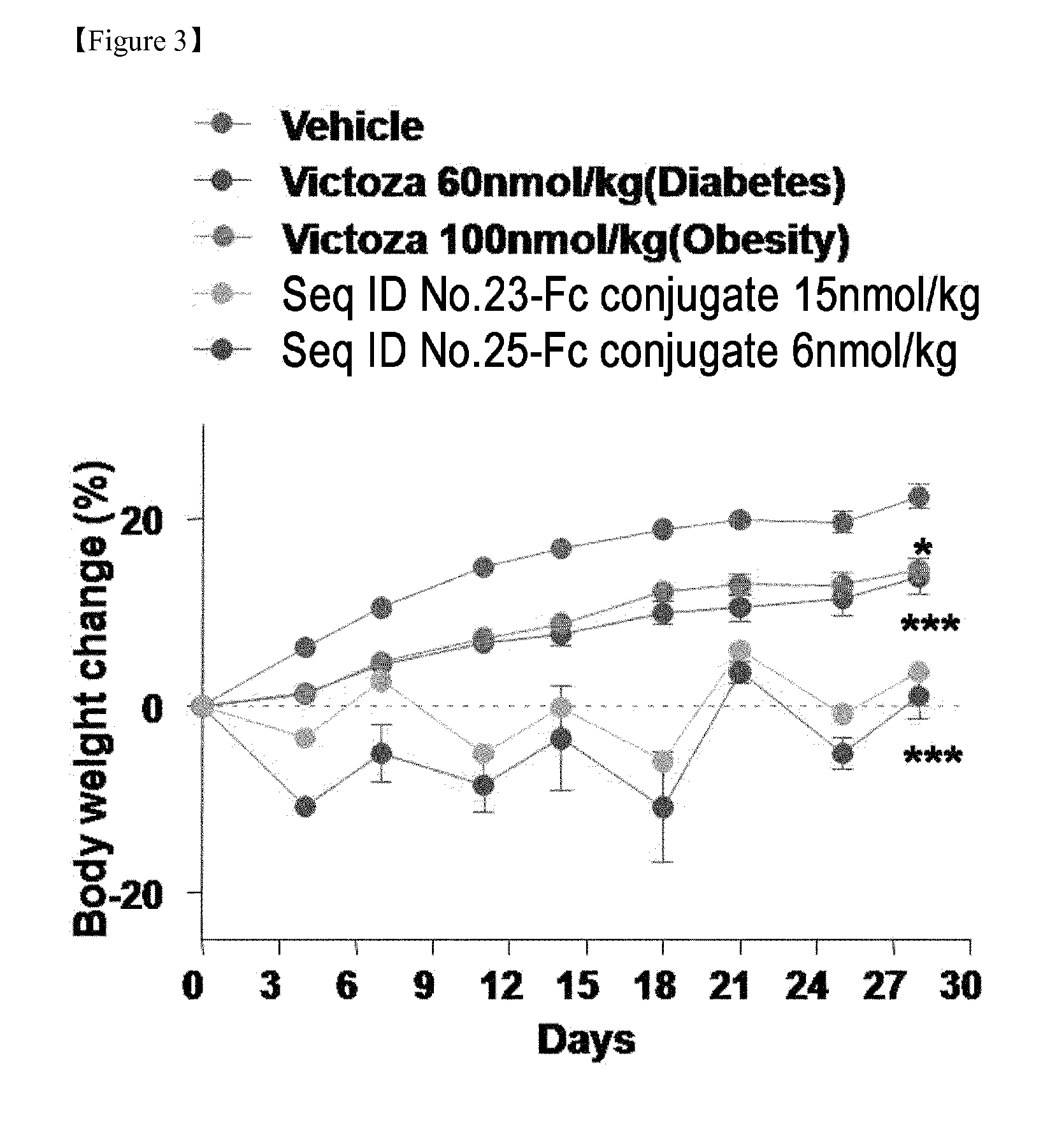

A composition for treating diabetes or diabesity comprising oxyntomodulin analog

InactiveUS20150299282A1High activityEasy to usePeptide/protein ingredientsMetabolism disorderNormal blood glucoseDiabetic complication

Disclosed are a composition for preventing or treating diabetes, diabesity or diabetic complications, containing an oxyntomodulin analog as an active ingredient and a method for treating diabetes, diabesity or diabetic complications, including administering a pharmaceutically effective amount of an oxyntomodulin analog to a subject. The oxyntomodulin analog shows a greater activity to activate a GLP-1 receptor and a glucagon receptor, than native oxyntomodulin. The oxyntomodulin analog induces an expansion of beta-cells and increases insulin secretion, thereby reducing blood glucose levels that were increased due to a high-calorie and high-fat diet. The oxyntomodulin analog induces decreases in a body weight and appetite to improve insulin sensitivity and is useful in maintaining normal blood glucose levels.

Owner:HANMI PHARMA

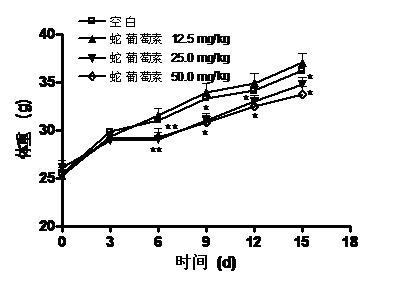

Application of ampelopsin in preparing medicines for treating obesity

InactiveCN102078315AImprove general conditionReduce fatOrganic active ingredientsMetabolism disorderFat mouseOral solutions

The invention discloses application of ampelopsin in preparing medicines for treating obesity, and relates to preparation and application of flavonoids compounds. The ampelopsin is used for preparing medicines or health products for treating the obesity, including oral tablets, capsules, granules, oral solution, sustained-release agents, pills and injection solution for treating the obesity, and pharmaceutically acceptable conventional formulations. The ampelopsin has obvious weight-losing effect on obese mice and overweight mice induced by high-fat diet; after the ampelopsin is poured into stomachs of the obese mice in a dose of 25.0mg / kg for 2 weeks, the abdominal fat is obviously reduced, shoulder fat cells are obviously shrunk, the weight is reduced to be normal, and the mice are generally good in conditions, freely acts and have smooth hairs. The maximum tolerance does of the mice through stomach perfusion can reach 18g / kg.

Owner:KUNMING MEDICAL UNIVERSITY

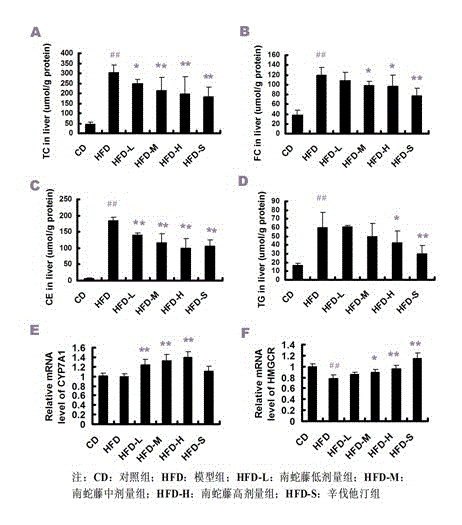

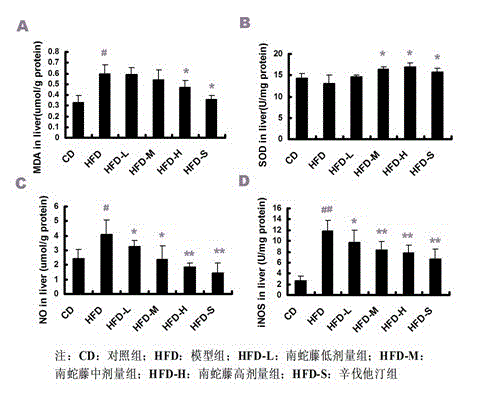

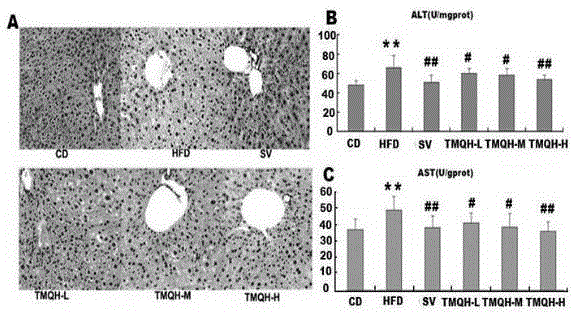

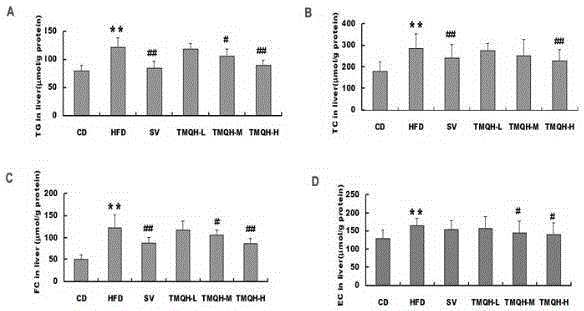

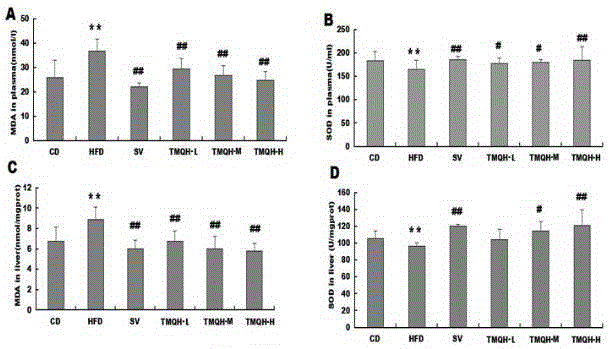

Application of celastrus orbiculatus alcohol extract in preparing medicine for treating non-alcoholic fatty liver disease (NAFLD)

InactiveCN103142679AHas antioxidant activityReduce sensitivityDigestive systemPlant ingredientsCelastrus orbiculatusPositive control

The invention discloses an application of a celastrus orbiculatus alcohol extract in preparing a medicine for treating non-alcoholic fatty liver disease (NAFLD). By adopting a high-fat diet induced guinea pig NAFLD model and taking simvastatin as a positive control medicine, the celastrus orbiculatus alcohol extract is orally taken for 8 weeks, then influence of the celastrus orbiculatus alcohol extract on NAFLD is observed, and a corresponding mechanism is explored; and the result indicates that the celastrus orbiculatus alcohol extract can be used for obviously improving the high-fat induced pathological alteration of liver tissue, easing the damage of liver cells, reducing the lipid accumulation in liver and suppressing oxidative stress reaction in liver. According to the invention, a new application of the celastrus orbiculatus alcohol extract is developed, and a new means of treating NAFLD is provided.

Owner:TAISHAN MEDICAL UNIV

Prevention of hyperinsulinemia in subjects undergoing growth hormone (GH) treatment

InactiveUS7141548B2Lower blood lipid levelsMore componentsOrganic active ingredientsPeptide/protein ingredientsLipid formationHyperinsulinemia

The present invention provides methods and compositions for preventing hyperinsulinemia that can result from therapeutic administration of growth hormone. The methods are carried out by imposing a restricted high-fat diet and / or by administering one or more drugs that lower serum lipids.

Owner:NOVO NORDISK HEALTH CARE AG

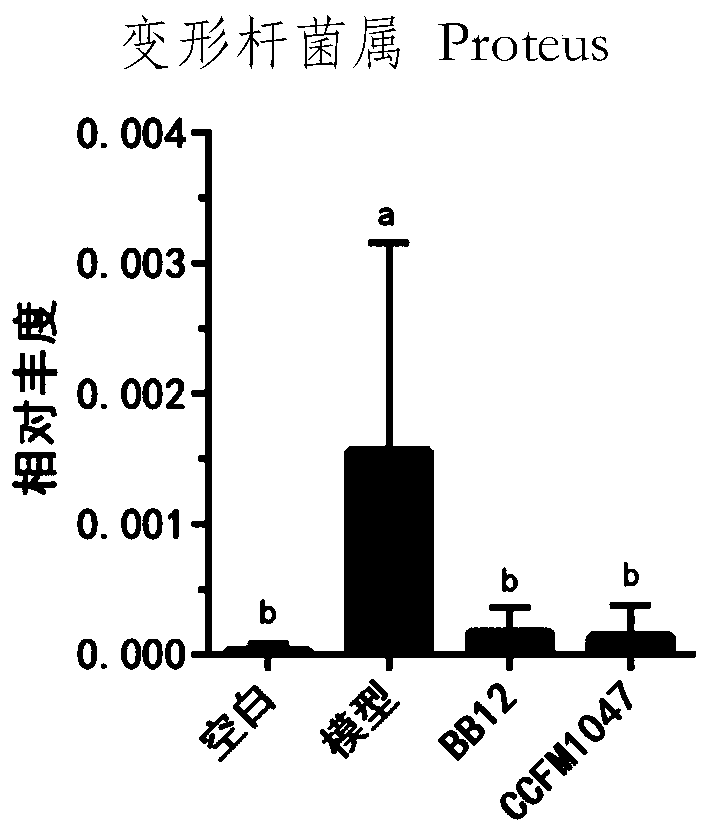

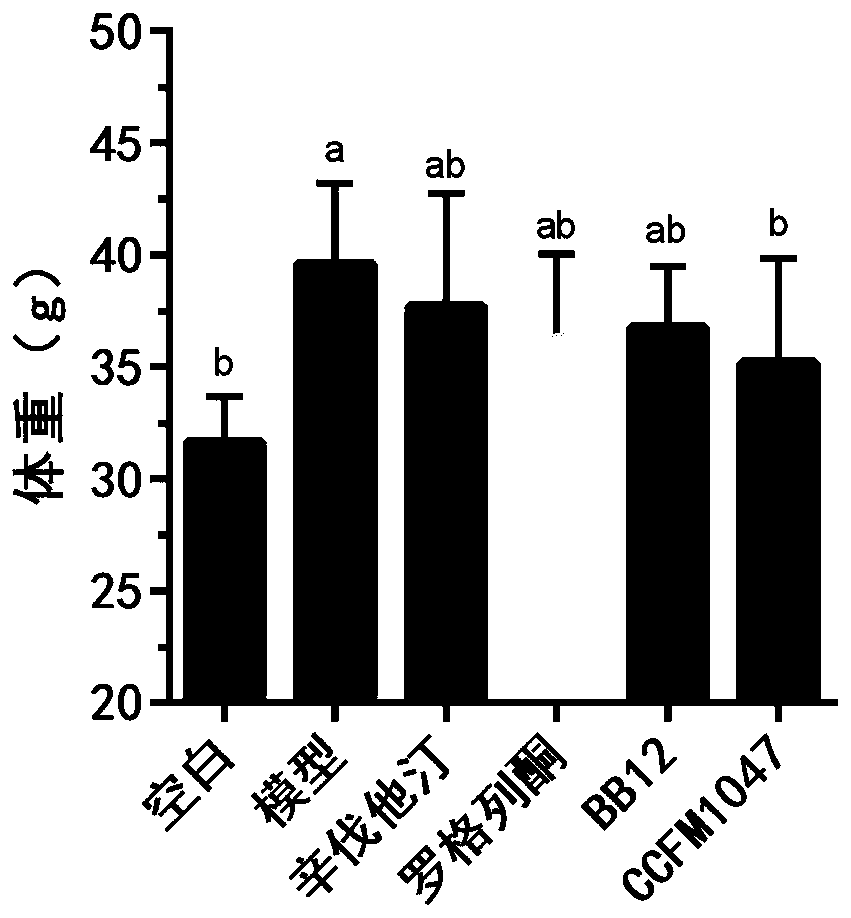

Bifidobacterium pseudocatenulatum CCFM1047, composition, fermented food, application and bacterial agent of bifidobacterium pseudocatenulatum CCFM1047 and preparation method of bacterial agent of bifidobacterium pseudocatenulatum CCFM1047

ActiveCN110106103ALower levelElevated reliefMilk preparationNervous disorderDiseaseLow density lipoprotein cholesterol

The invention discloses bifidobacterium pseudocatenulatum CCFM1047, a composition, fermented food, application and bacterial agent of the bifidobacterium pseudocatenulatum CCFM1047 and a preparation method of the bacterial agent of the bifidobacterium pseudocatenulatum CCFM1047. The bifidobacterium pseudocatenulatum CCFM1047 can tolerate the gastrointestinal environment of the human body, significantly improve abnormal fasting blood glucose and abnormal oral glucose tolerance of a mouse with the metabolic syndrome, reduce the area under the drug-time curve of glucose tolerance, reduce the serum insulin level, significantly relieve the weight rise of the mouse, significantly relieve the rise, caused by the high fat diet, of content of low density lipoprotein cholesterol in serum and triglyceride in the liver of the mouse with the metabolic syndrome and significantly relieve the rise, caused by the high fat diet, of Proteus in the intestinal tract; the bifidobacterium pseudocatenulatum CCFM1047 is used for preparing the medicine composition and the fermented food which relieve the metabolic syndrome and reduce the occurrence of diseases such as the Parkinson disease, intestinal infection and urinary tract and kidney infection and has a quite wide application prospect.

Owner:JIANGNAN UNIV

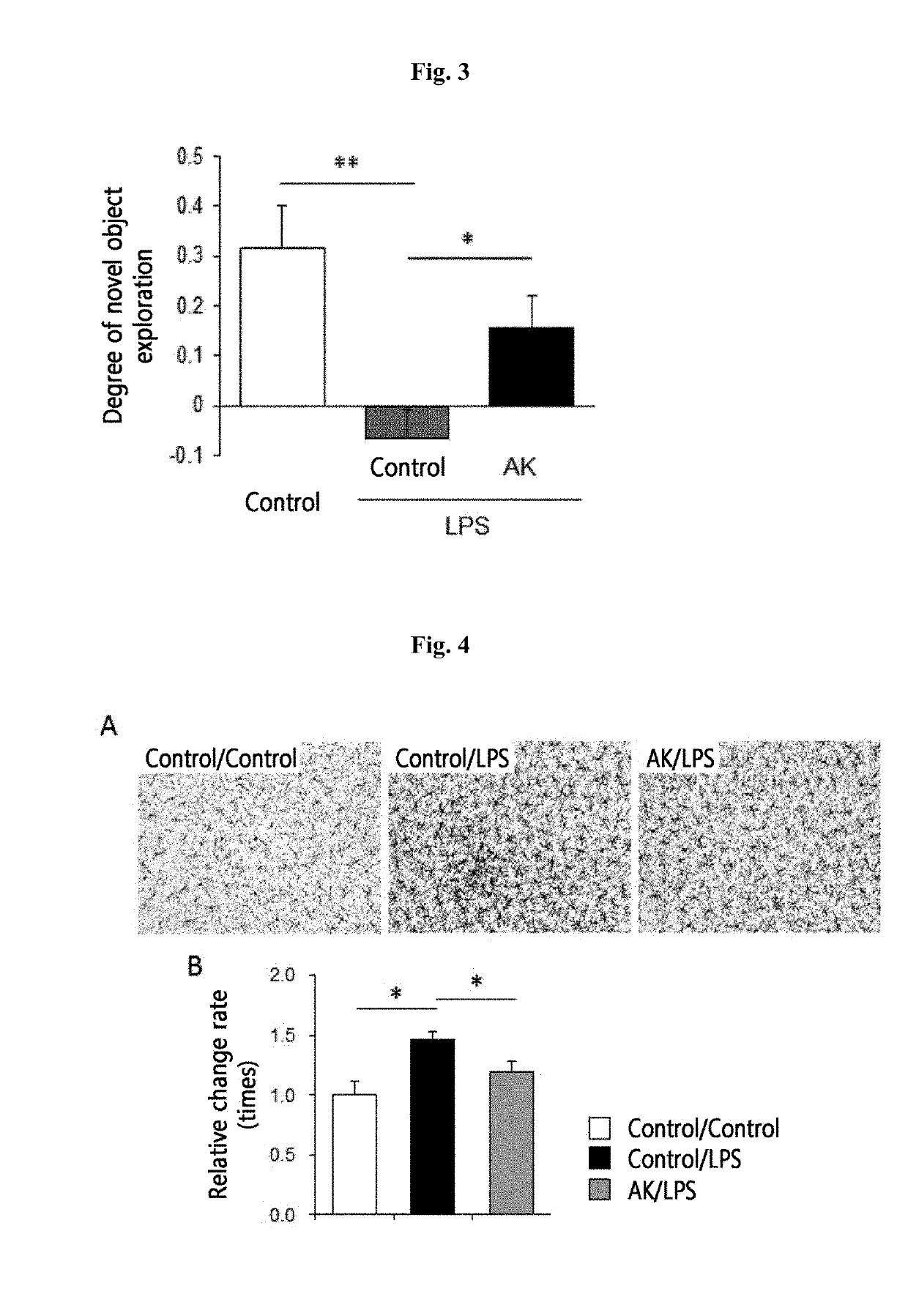

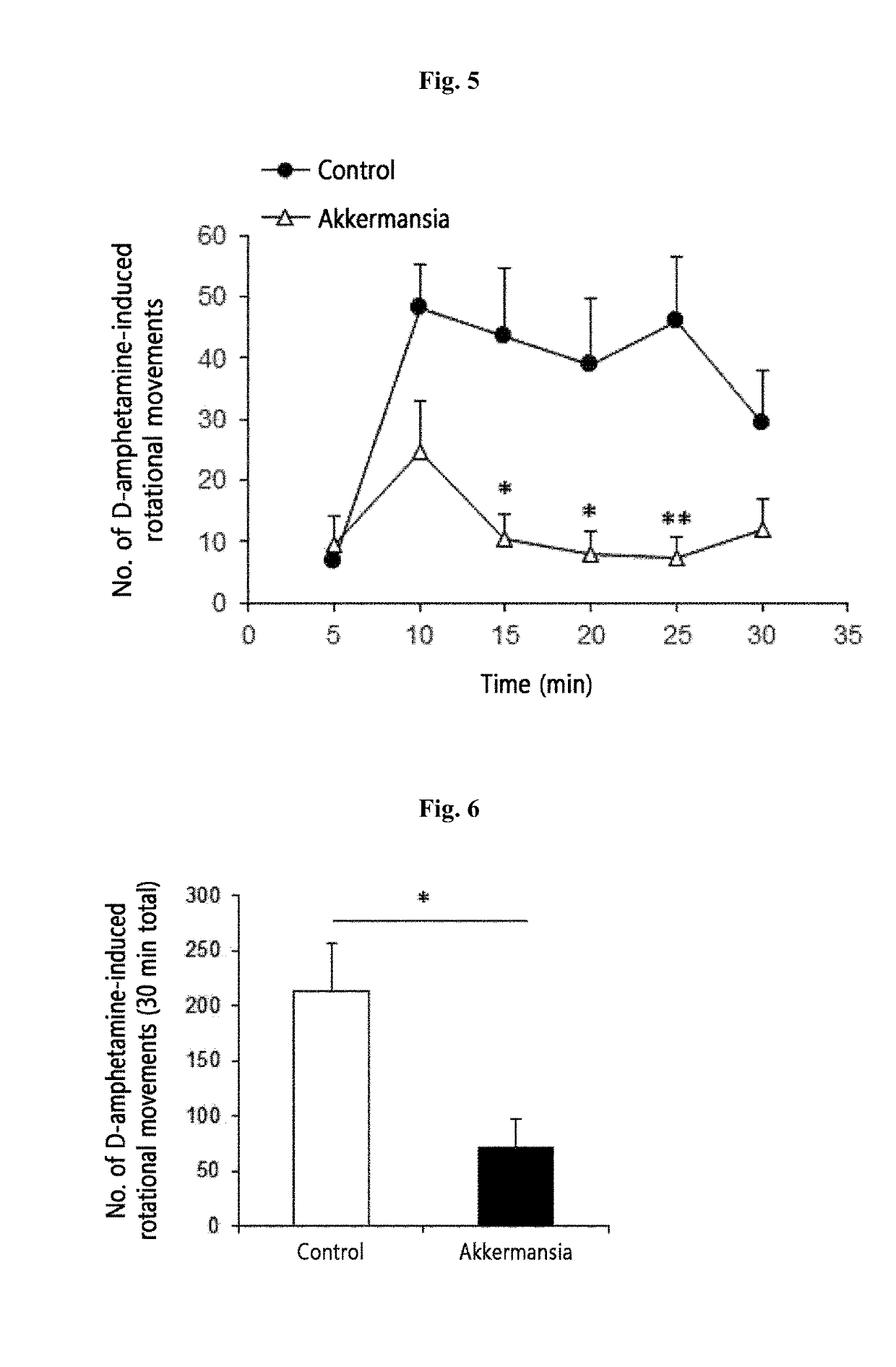

Akkermansia muciniphila strain having a prophylactic or therapeutic effect on a degenerative brain disease or metabolic disease and use thereof

PendingUS20190314425A1Avoid problemsImprove obesityNervous disorderBacteriaIntestinal microorganismsTherapeutic effect

The present disclosure relates to an Akkermansia muciniphila strain having a prophylactic or therapeutic effect on a degenerative brain disease and uses thereof. Since the Akkermansia muciniphila strain, the intestinal microorganism of the present disclosure, shows an effect of improving movement control and cognitive abilities as well as memory in an animal model having a degenerative brain disease such as Parkinson's disease and Alzheimer's disease, it can be useful in the prevention or treatment of brain diseases including Alzheimer's disease, Parkinson's disease, mild cognitive impairment, etc. In addition, it was confirmed in the present disclosure that compared to the Akkermansia muciniphila strain cultured in a mucin-containing medium, that cultured in a mucin-free medium showed a remarkable effect of improving hyperlipidemia, fatty liver, obesity, and hyperglycemia induced in a mouse model by high-fat diet when administered orally (in vivo). Accordingly, the present disclosure is expected to be very useful in relevant industries as a particular composition of culture medium and an optimized obligatory anaerobic culture method have been developed through the present disclosure.

Owner:HEALTHBIOME

Application of olecranone bean extraction in preparation of food for preventing and treating obesity and type II diabetes

An application of the chickpea's extract in preparing the food for decreasing triglyceride, cholesterol, low-density lipoprotein cholesterol and insulin sensitivity and treating and preventing obesity and diabetes B is disclosed.

Owner:骏神生物医学(上海)有限公司 +1

Application of Viburnum sargentii alcohol extract in preparation of NAFLD (non-alcoholic fatty liver disease) treatment drug

The invention relates to an application of a Viburnum sargentii alcohol extract in preparation of an NAFLD (non-alcoholic fatty liver disease) treatment drug. According to the application, a high fat diet induced apoE<- / ->NAFLD model is adopted, simvastatin is taken as a positive control drug, after the Viburnum sargentii alcohol extract is taken orally for 8 weeks, the influence of the Viburnum sargentii alcohol extract on the NAFLD is observed and corresponding mechanism is explored; results show that the Viburnum sargentii alcohol extract improves high fat induced hepatic tissue pathological changes obviously, reduces damage of hepatocytes, reduces lipid accumulation in a liver and inhibits oxidative stress reaction in the liver. The novel application of the Viburnum sargentii alcohol extract is developed, and one novel way is provided for NAFLD treatment.

Owner:TAISHAN MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com