Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Granulation procedure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of modified ultrahigh molecular weight polyethylene powder direct extruded tubing

InactiveCN1807062AImprove mechanical propertiesSimple processTubular articlesScrew extractorGranulation procedure

The invention relates pipes manufacturing method, specially one-step method manufacturing pipe technique. The method comprises the following steps: mixing the LCP, UHMW-PE and special adjuvant, sending them into single screw extractor with 42-45Deg helix angle, compressing the powdery material, melting, plastifying, direct squeezing pipes, using die to form cast, cooling with water chamber, drawing with draw machine, cutting with cutting machine, and realizing the production of UHMW-PE. Due to cancel the granulation procedure ad directly squeeze pipes, the mechanics property of UHMW-PE in improved, the technology is simplified and the space is saved.

Owner:江苏星鑫工程管道有限公司

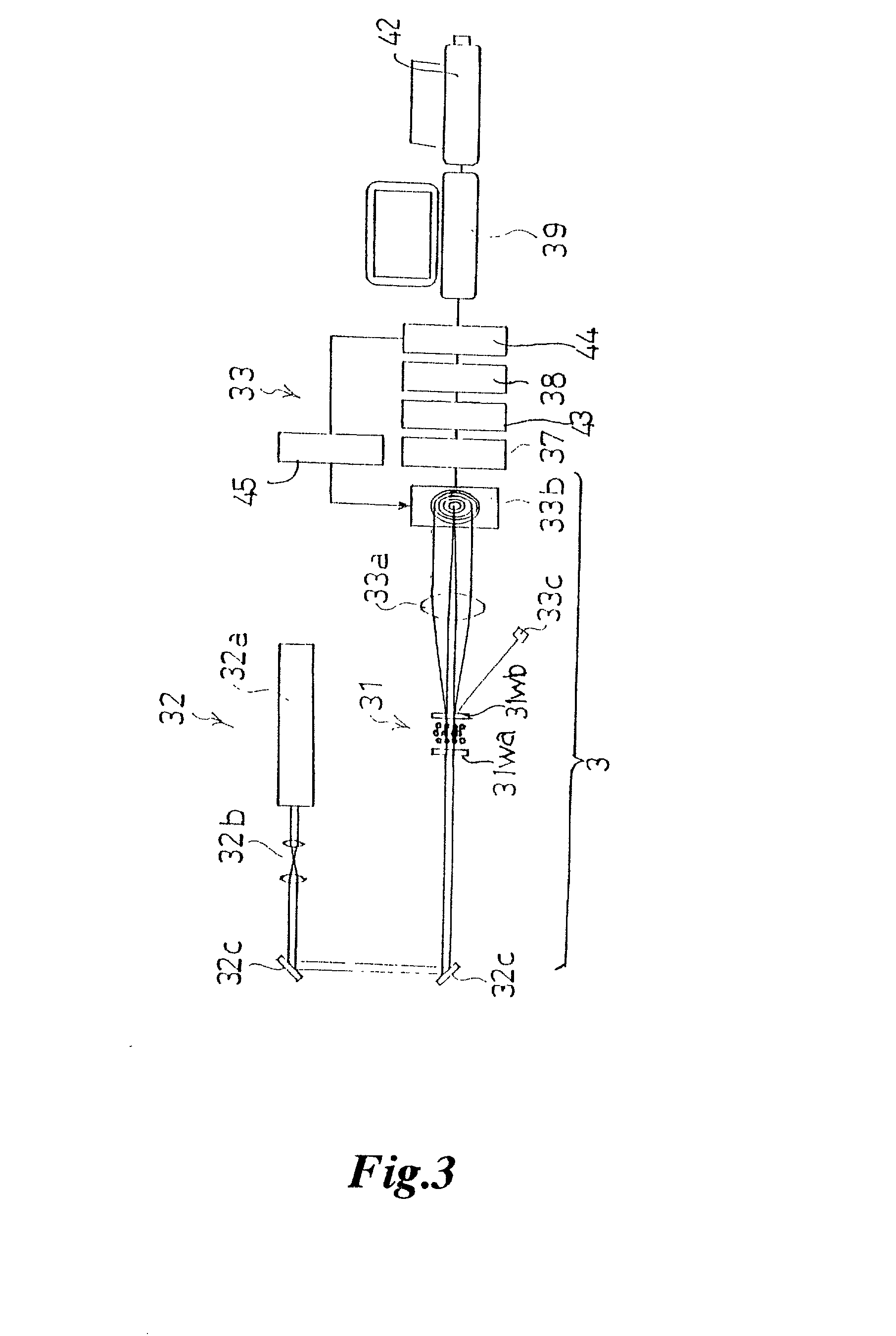

Production method for granulated materials by controlling particle size distribution using diffracted and scattered light from particles under granulation and system to execute the method

InactiveUS20010042287A1Efficient executionDrying solid materials with heatParticle size analysisChemical physicsMeasuring instrument

Production method for granulated materials with a desirable particle size distribution, comprises sampling step of sampling diffracted and / or scattered light data obtained by applying beam light on the growing particles under granulation as the measured data at fixed time intervals, analyzing step of analyzing particle size distribution data of the growing particles by performing a particular arithmetic operation on the measured data, and controlling step of controlling a particle growing factor so as to conform the analyzed particle size distribution data to the corresponding objective particle size distribution data which are previously prepared in time series order according to the granulation procedure to be executed each time of comparison of the particle size distribution data analyzed from the measured data with the corresponding objective particle size distribution data. The system comprises a fluid layer and a sampling measurement instrument which is detachably connected to the fluid layer via a conduit, where the growing particles are introduced and the diffracted and / or scattered light data from the growing particles are sampled at fixed time intervals.

Owner:KYOWA HAKKO KOGYO CO LTD +1

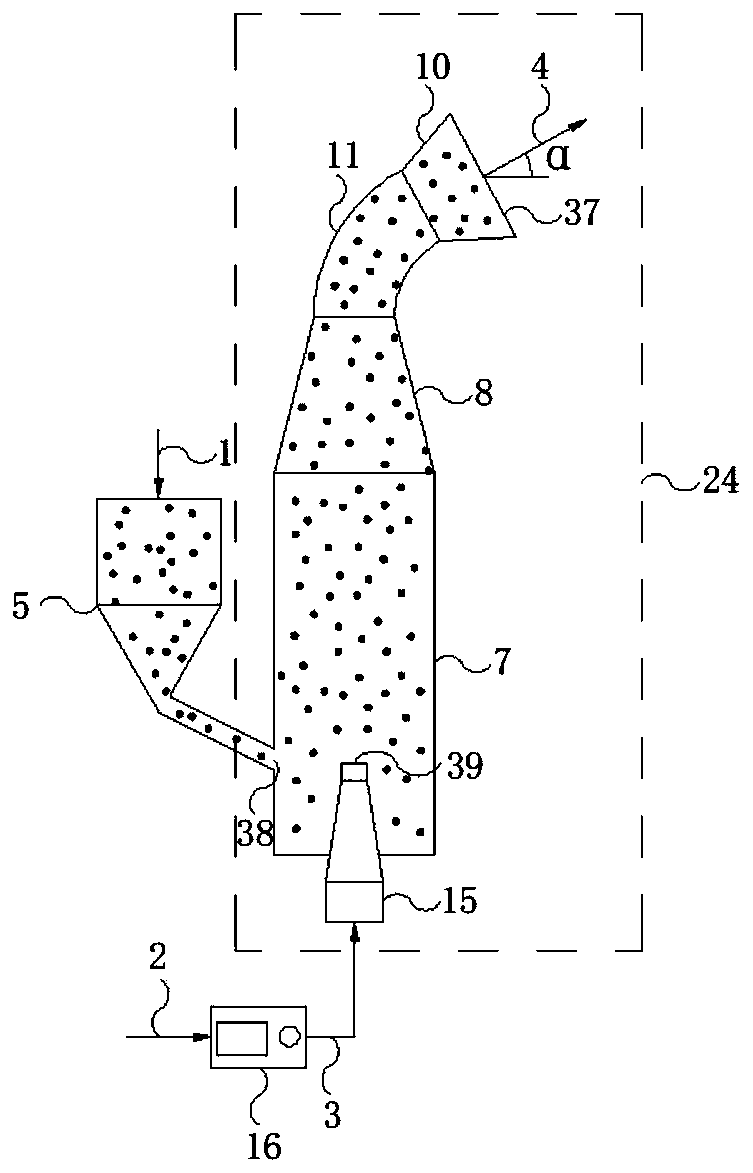

Method and device for producing semi-dry type ceramic powdery material

The invention relates to a semi-drying ceramic powder production method and a device thereof, which is characterized in that the method consists of crashing procedure, drying procedure, crushing procedure, iron-removing procedure, and granulation procedure. In the process of storing raw materials in a batching bin in the drying procedure, the dry hot air is pumped into the batching bin to reduce the water content of raw materials to be lower than 5 percent. And then, one or more dried raw materials are subject to the crushing procedure for being crushed into powder with a diameter of less than 0.125mm. Compared with the prior art, the semi-drying ceramic powder production method and device has the advantages of simple technique, small energy consumption, small investment, and low production cost.

Owner:何国昌

Production technology of amoxicillin capsule

InactiveCN107095857AHigh dissolution rateGuaranteed stabilityAntibacterial agentsPharmaceutical non-active ingredientsSide effectMagnesium stearate

The invention discloses a production technology of an amoxicillin capsule. The production technology comprises the steps of carrying out a soft material preparation procedure, namely firstly weighing1,000 parts of amoxicillin raw material powder and 8-12 parts of pregelatinized starch, adding the raw materials to an ultrafine grinder for grinding and mixing evenly to prepare a fine powder mixture of which the particle sizes are 900 meshes; adding 20-28 parts of purified water to the fine powder mixture, stirring and mixing evenly, then preparing amoxicillin particles in a wet granulator and drying by using a boiling dryer to obtain dried amoxicillin particles; carrying out a granulation procedure, namely crushing the dried amoxicillin particles, granulating through a 50mesh sieve and adding 18-23 parts of carboxymethyl starch sodium and 3-5 parts of magnesium stearate for mixing evenly; and finally carrying out a filling and polishing procedure and a packaging procedure to obtain a finished product amoxicillin capsule. The prescription and the technological process of the amoxicillin capsule are improved, the dissolution rate of the capsule is improved, oral absorption is complete, the curative effect is improved and the toxic and side effects are reduced.

Owner:SICHUAN PHARMA

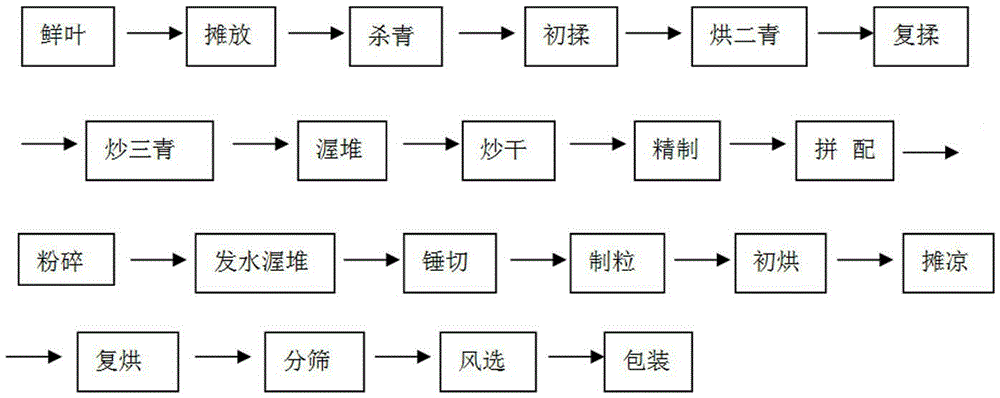

Manufacturing method for particle Tibetan tea

InactiveCN105325586AOvercoming the defect of variable turbidityEasy to brewPre-extraction tea treatmentScreening proceduresMedicine

The invention provides a manufacturing method for particle Tibetan tea in the field of tea leaf preparation. The particle Tibetan tea is manufactured through multiple procedures with fresh tea leaves or loose Tibetan tea as raw materials. The manufacturing procedures with fresh tea leaves as raw materials include the fresh tea leaf spreading procedure, the fixation procedure, the primary kneading procedure, the drying secondary fixation procedure, the secondary kneading procedure, the frying third-time fixation procedure, the pile fermentation procedure, the fry-drying procedure, the refining procedure, the blending procedure, the smashing procedure, the water evaporation and pile fermentation procedure, the hammer cutting procedure, the granulation procedure, the primary drying procedure, the spreading and airing procedure, the secondary drying procedure, the separated screening procedure, the winnowing procedure and the packaging procedure, and the finished Tibetan tea is obtained. The method overcomes the defects that exiting Tibetan tea is not convenient to brew and tea soup is prone to becoming turbid, and the particle Tibetan tea manufactured through the method is convenient to brew and clear, red and bright in tea soup.

Owner:SICHUAN JIXIANG TEA IND CO LTD

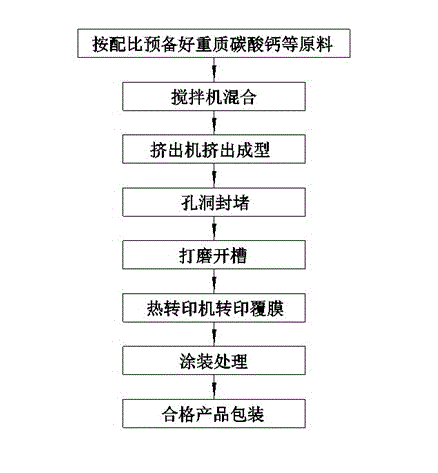

Novel stone floor and production process thereof

InactiveCN102875056AIncrease productivityImprove craftsmanshipPolyvinyl chlorideGranulation procedure

The invention discloses a novel stone floor and a production process thereof. The stone floor is prepared by raw materials of, by weight, 66-90 parts of ground calcium carbonate, 31-50 parts of polyvinyl chloride resins, 0.2-0.8 part of lead stearate, 0.2-2 parts of chlorinated polyethylene and 0.2-2 parts of dibutyl ester. According to the production process of the novel stone floor, a traditional granulation procedure is eliminated, and powdery base materials can be subjected to direct extrusion molding. The novel stone floor and the production process thereof have the advantages that the processing procedures are simplified, particularly the traditional granulation procedure is eliminated, the product production efficiency is improved, the production energy consumption is reduced, the production cost is saved, simultaneously, the raw material proportion is optimized, so that the cost is reduced and simultaneously the product processing property is improved, and the stone floor is really excellent in quality and reasonable in price.

Owner:云南德发绿源板业有限公司

Technology for functional fertilizer-saving synergistic fertilizers made of polysaccharide biological colloid of straw

InactiveCN107778078AImprove stress resistancePromote growthAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFermentationPlant growth

The invention discloses a technology for functional fertilizer-saving synergistic fertilizers made of polysaccharide biological colloid of straw. The technology includes extracting the polysaccharidebiological colloid from a raw material by the aid of enzymatic hydrolysis processes; treating extracted residues of the raw material by the aid of microbial fermentation processes to obtain microbialorganic matters; adding trace elements and fertilizers required in plant growth procedures into the microbial organic matters to obtain mixtures; adding the extracted polysaccharide biological colloidinto the mixtures in low-temperature granulation procedures to prepare products which are the functional fertilizer-saving synergistic fertilizers made of the polysaccharide biological colloid of thestraw. The raw material is the waste straw of crops. The technology has the advantages that growth and trace element absorption of the root systems of crops can be promoted by the functional fertilizer-saving synergistic fertilizers prepared by the aid of the technology, and fertilizer-saving synergistic effects further can be realized; the potential of hydrogen of soil can be regulated by the functional fertilizer-saving synergistic fertilizers, trace elements can be supplemented in the soil, and the stress resistance of the crops can be improved.

Owner:HEBEI ZHONGCANG FERTILIZER CO LTD

Production method of environment-friendly light-weight building ceramic

InactiveCN106747603AEasy to operateReduce charactersFeeding arrangmentsClay processing apparatusFoaming agentBrick

The invention relates to a production method of an environment-friendly light-weight building ceramic. The production method comprises the following steps: a. uniformly mixing polished brick waste residues generated by producing light-weight building ceramics, a reinforcer, an adhesive and a foaming agent by a dry process according to the proportion; b. loosely spreading the powder in a shuttle kiln with the thickness of 20-30mm, and shaving; and c. carrying out cold-working treatment on the prepared light-weight ceramic in the shuttle kiln by natural cooling so as to satisfy the production requirements. The spray tower granulation procedure is reduced to provide a light-weight building ceramic production method which has the advantages of energy saving, environment friendliness and higher production efficiency.

Owner:GUANGDONG GELAISI CERAMICS +1

Method and device for environment-friendly recovery of precious metal in waste circuit board through combined smelting of waste circuit board, copper concentrate and desulfurized gypsum

PendingCN111826526AReduce governance costsTo achieve the purpose of recyclingEnergy inputSulfur-trioxide/sulfuric-acidCopper wireChemistry

The invention discloses a method and a device for environment-friendly recovery of precious metals in a waste circuit board through combined smelting of the waste circuit board, copper concentrate anddesulfurized gypsum. The method comprises the following steps of disassembling the waste circuit board, removing impurities such as tin, iron, aluminum and copper wires, crushing, mixing the crushedwaste circuit board with the copper concentrate, copper concentrate auxiliary materials and desulfurized gypsum, and granulating, adding in an Austenite furnace for smelting, wherein the desulfurizedgypsum reacts with other chemical components in the furnace in the smelting process to generate a dioxin inhibitor, thereby inhibiting the generation of dioxin; generating acid-contaminated desulfurized gypsum after the smelted flue gas is subjected to sulfuric acid absorption and acid-contaminated desulfurization and other procedures after waste heat recovery and electric precipitation, returningto a granulation procedure for cyclic granulation, thereby achieving the purpose of recycling the resource. According to the method disclosed by the invention, the dioxin inhibitor can be automatically generated, the problem that dioxin is generated when the waste circuit board and the copper concentrate are mixed and smelted is solved, and meanwhile, acid-contaminated desulfurized gypsum produced in the flue gas smelting and acid making process can be subjected to resource utilization, and the purposes of energy conservation and emission reduction are truly achieved.

Owner:DAYE NONFERROUS METALS

Method for producing granulated matter

InactiveCN101878041AAvoid contactAvoid interferencePowder deliveryOrganic active ingredientsGranulation procedureEnteric coating

It has been demanded to provide a method for producing a granulated matter capable of maintaining a stability of a chemically unstable substance in a neutral or acidic region for a long period of time with a simple and safe method in a preparation procedure, and a tablet produced by using the method. The invention provides a granulation method in which an unstable substance is successively subjected to aqueous stabilization treatment and granulation procedure. Further, it became possible to provide a tablet which is absorbed in the intestine without losing the potency in a gastric region by forming an intermediate layer on a surface of the thus obtained granule and subsequently subjecting the granule to enteric coating.

Owner:OHARA PHARMA

Heat treatment method of granulation ring mold

InactiveCN101760604AImprove wear resistanceLow priceFurnace typesHeat treatment furnacesHardnessGranulation procedure

The invention relates to a heat treatment method of a granulation ring mold, which has the characteristics that the granulation ring mold is made of 45 steel; the heat treatment method comprises preheat treatment and final heat treatment, wherein the preheat treatment and the final heat treatment both comprise a quenching step and a tempering step; carbon constructional quality steel is selected as the material of the ring mold, and is ordinary and cheap; an optimized subcritical quenching heat treatment process is adopted for enhancing abrasion resistant performance of the ring mold; treated metallurgical structure is a composite phase of tempered martensite and retained austenite; the optimal combination of hardness and toughness is found; and the abrasion resistant performance of the material reaches a optimal level. The ring mold has high comprehensive mechanical performance and high anti-abrasion capability of abrasive materials, and can replace expensive alloy steel and stainless steel materials for finishing granulation procedures.

Owner:GANSU AGRI UNIV

Process for manufacturing rubber soles

InactiveCN104924641AImprove the use range of production technologyLow priceDomestic footwearDomestic articlesRubber materialVulcanization

The invention discloses a process for manufacturing rubber soles. The technical scheme mainly includes that the process comprises winding strip-shaped rubber to obtain discs, arranging the strip-shaped rubber on a conveying device, supplying the strip-shaped rubber to an injection device, forwardly conveying the strip-shaped rubber in a barrel of the injection device, melting and storing the strip-shaped rubber, allowing the injection device to move forwardly, matching the injection device with forming molds, and injecting stored rubber materials into the forming molds; carrying out press-fit forming on the rubber materials by the aid of the molds to obtain rubber products after the rubber materials are injected into the forming molds. The process has the advantages that the rubber soles can be made of the strip-shaped rubber materials, accordingly, the service range of the process can be extended, the rubber materials only need to be melted to form a material in the shape of a disc strip, granulation procedures can be omitted, and the cost can be saved; the cold materials are arranged in the barrel, are melted via the barrel at appropriate temperatures and are injected into the forming molds, the vulcanization time required by the materials in the forming molds is shorter than the vulcanization time for manufacturing soles by the aid of the traditional process, and accordingly the production efficiency can be improved.

Owner:谢建华

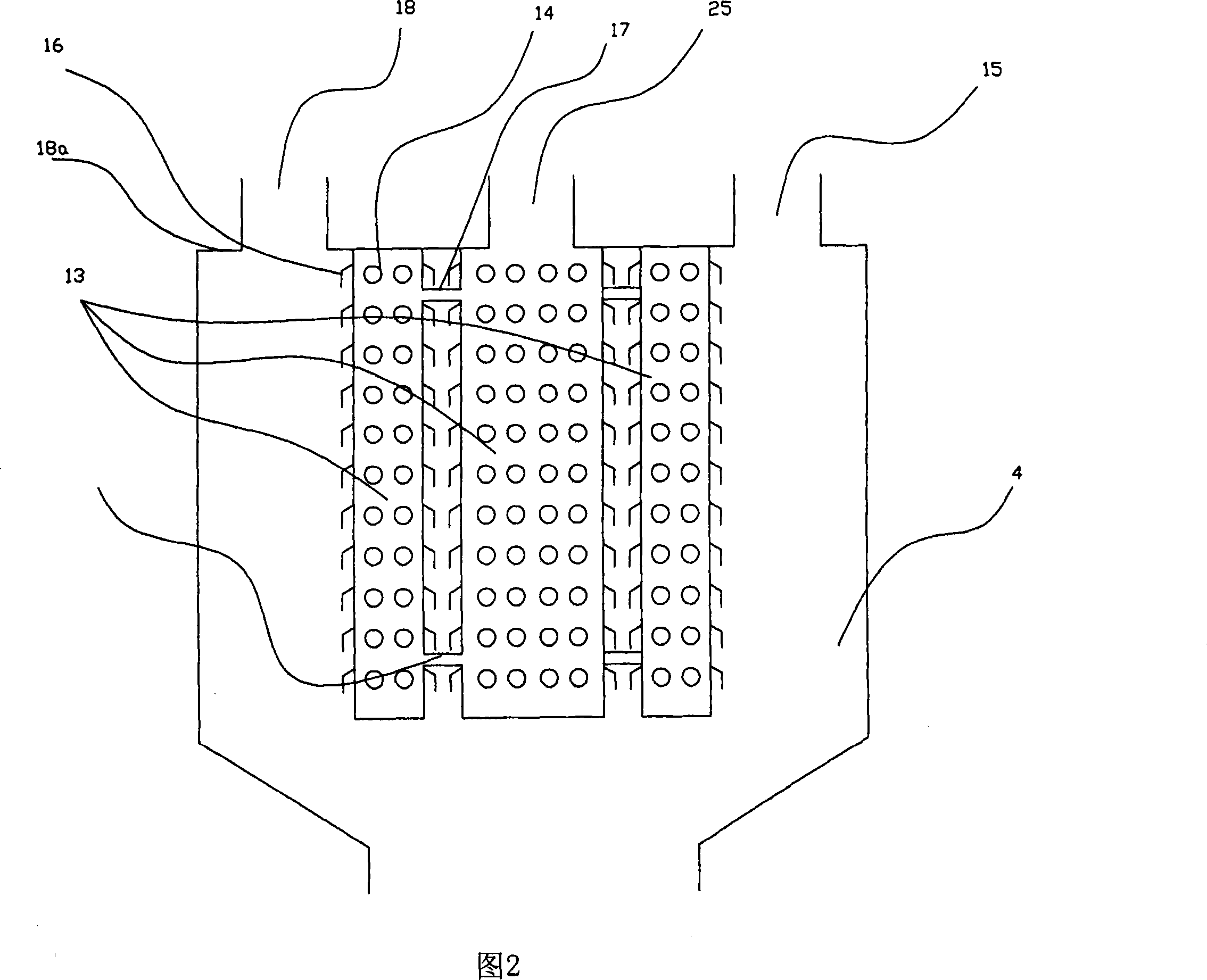

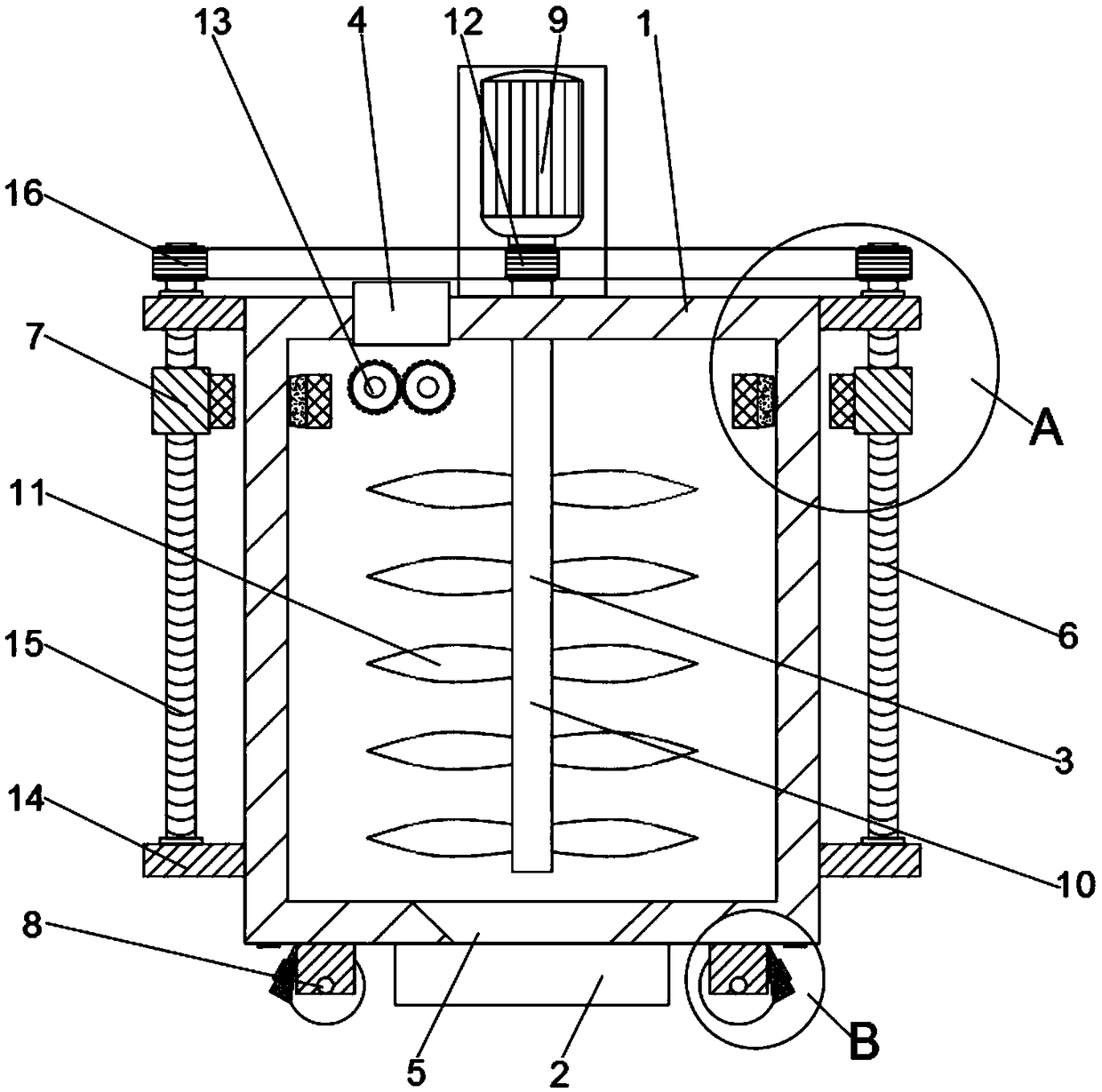

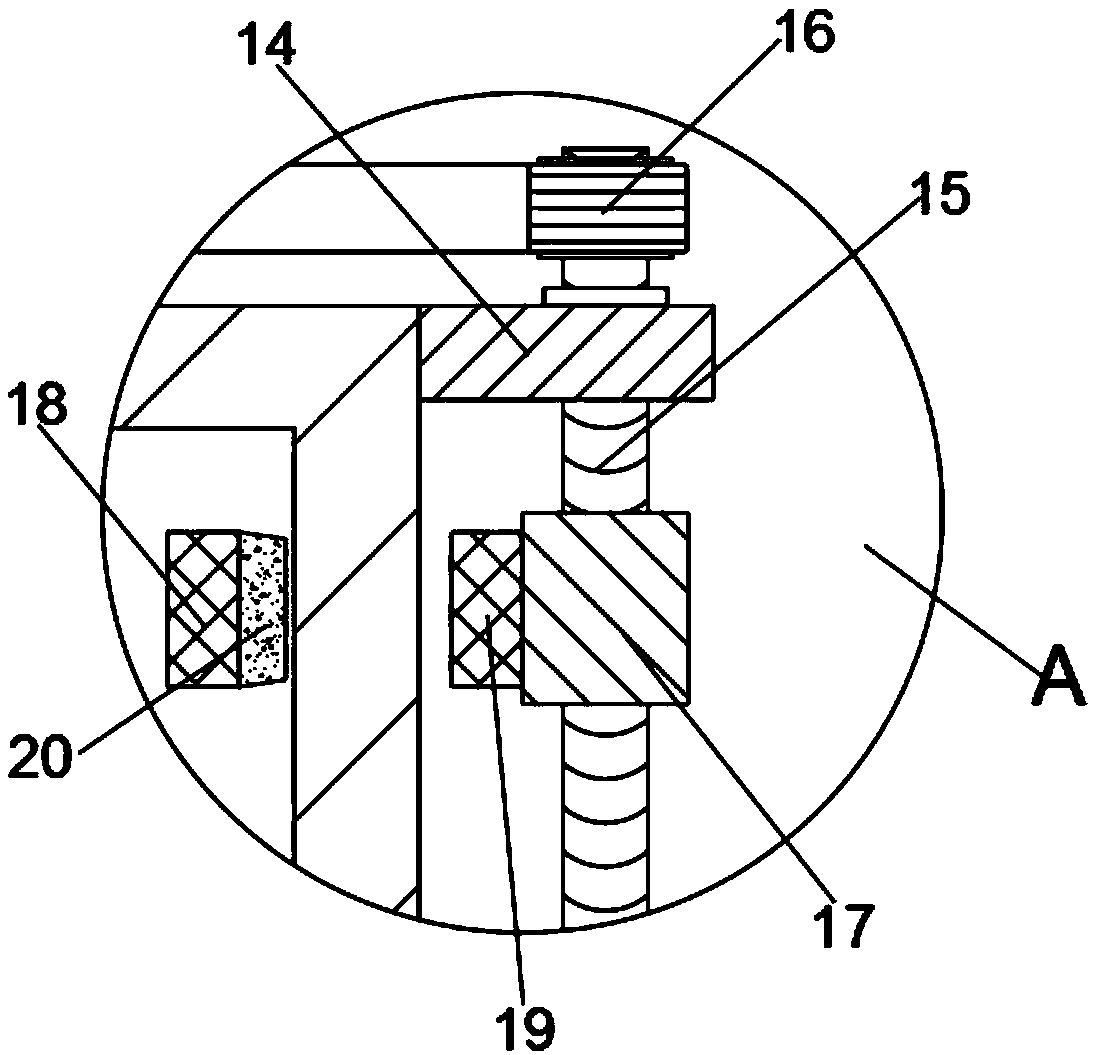

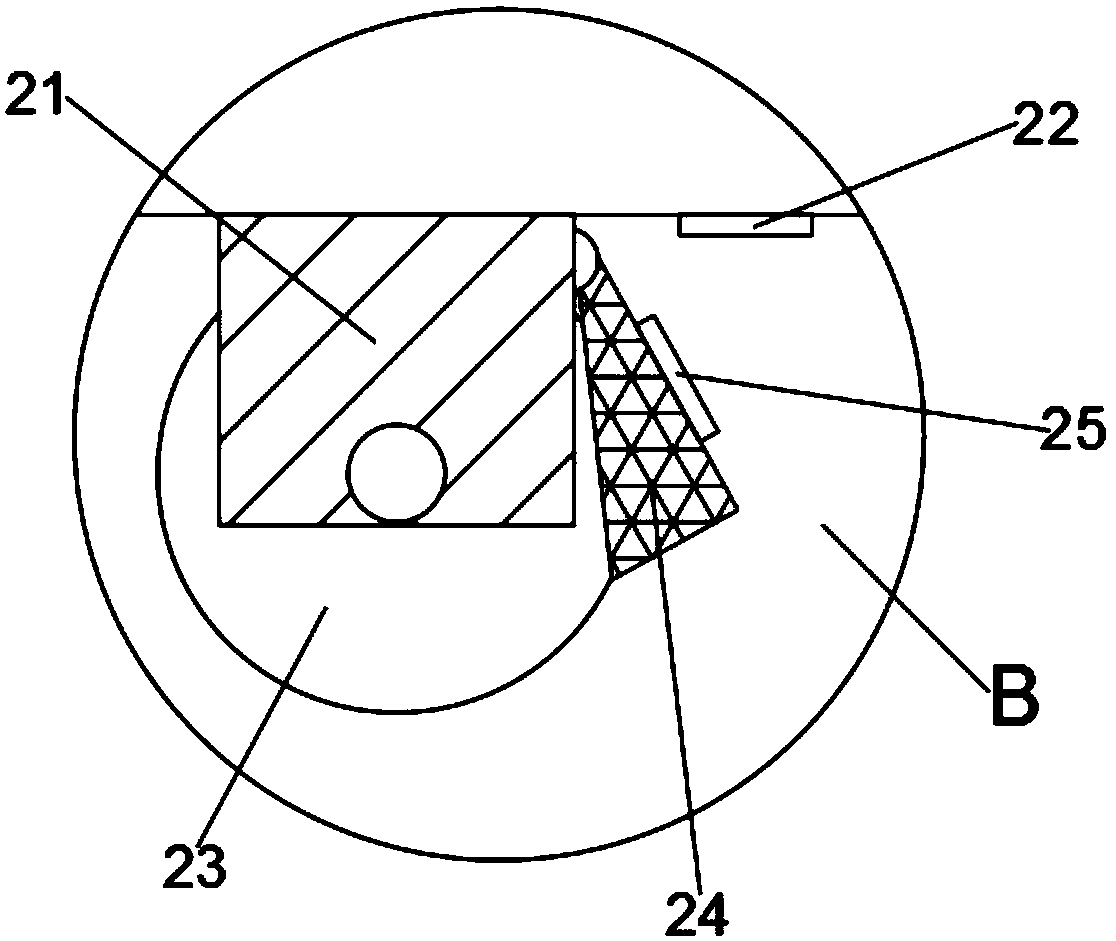

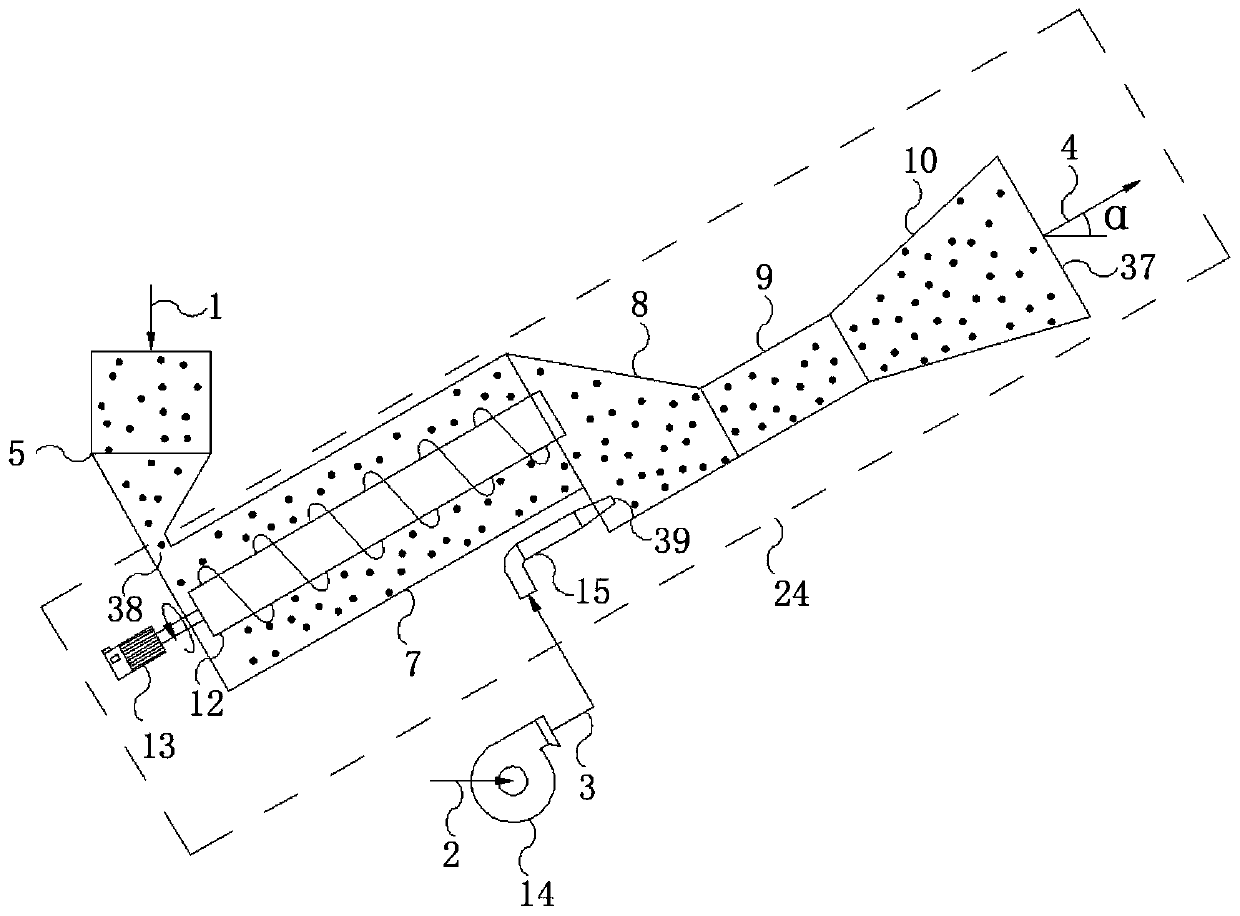

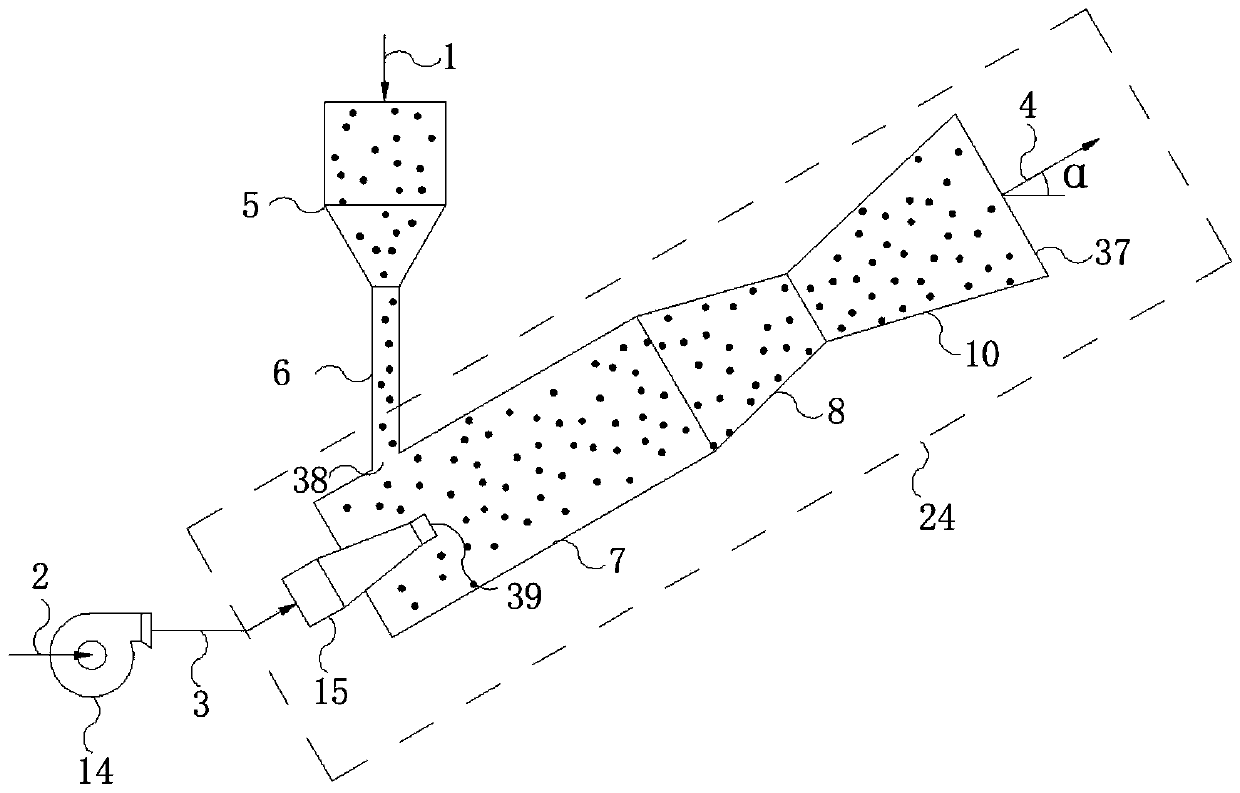

Furnace burden wet-process mixing granulator

PendingCN109395658AStable granulation processTransportation and packagingMixer accessoriesDrive motorEngineering

The invention discloses a furnace burden wet-process mixing granulator which comprises a furnace and a compression chamber. A stirring mechanism is fixedly connected with the upper end of the furnace,a stirring end of the stirring mechanism penetrates the top surface of the furnace and extends into the furnace, a feed inlet is formed in the upper end of the furnace, a discharge outlet is formed in the bottom of the furnace, the lower end of the discharge outlet is communicated with the compression chamber, lifting mechanisms are fixedly connected onto the side walls of the left end and the right end of the furnace and are in transmission connection with the stirring mechanism, and clearing mechanisms sleeve the lifting mechanisms in a threaded manner. The furnace burden wet-process mixinggranulator has the advantages that second annular magnets on the side walls of movable blocks can be driven by a driving motor to be lifted, accordingly, cleaning brushes on first annular magnets inthe furnace can be driven to be lifted, and the inner walls of the furnace can be cleaned; the furnace can be driven by movement mechanisms to move, the movement mechanisms are arranged at the lower end of the furnace, rollers can be restrained by limiting blocks when the furnace moves to reach corresponding locations, and accordingly granulation procedures are stable.

Owner:湖南省金润碲业有限公司

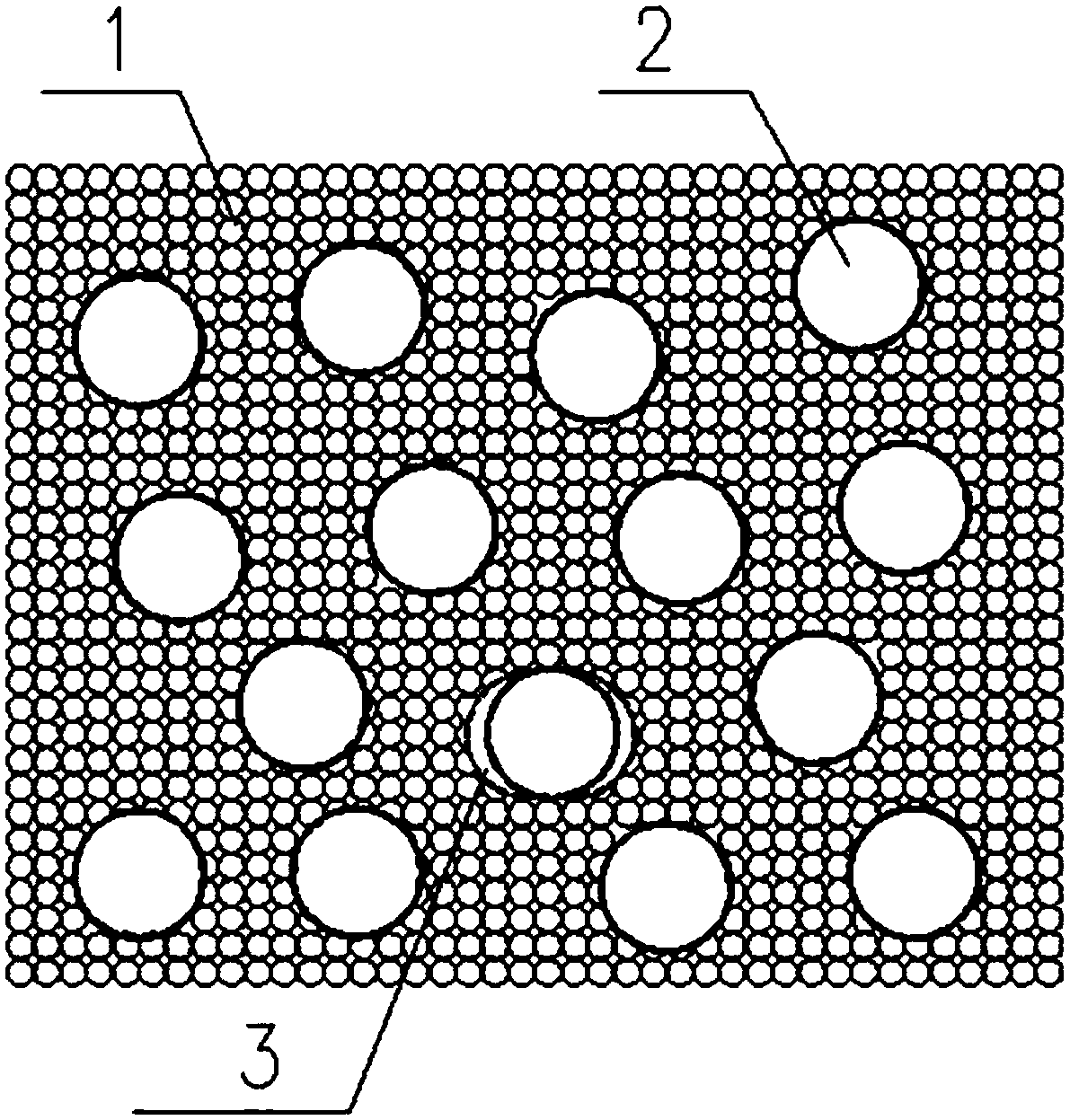

Globular rubber adjuvants and the method of preparating the same

ActiveUS20100314789A1Easy to shapeReduce heat transfer efficiencyGranulation by material expressionVulcanizationPolymer science

The present invention provides spherical rubber chemicals and the method for preparing the same. The spherical rubber chemicals of the present invention include spherical antioxidants, spherical vulcanization agents, spherical processing aids, spherical reinforcing agents, or spherical adhesive agents. With the spherical rubber chemicals of the present invention, the shortcomings of powdery or semi-spherical rubber chemicals are overcome, including eliminating the dust pollution during granulation procedure and avoiding the raw material loss and the environmental pollution, while solving the quality problem of lower melting point of product caused by the presence of fine powder crystal. Furthermore, the resultant rubber chemicals has an improved smoothness of surface, which is helpful to improve the flowing and mixing behaviors of the rubber chemicals in mixing or open milling process with rubbers.

Owner:SENNICS CO LTD

Method for preparing coated paddy rice fertilizers with reduced costs

InactiveCN108083887AImprove qualityIncrease productionCalcareous fertilisersClimate change adaptationPeatRapeseed

The invention discloses a method for preparing coated paddy rice fertilizers with reduced costs. The method includes steps of uniformly mixing ammonium nitrate, phosphorite powder, potassium nitrate,borax, coconut shell charcoal, lime powder, zeolite powder and dolomite powder with one another to obtain mixtures, sieving and granulating the mixtures and spraying sodium alginate compounds to coatthe mixtures in granulation procedures so as to obtain prefabricated materials; uniformly mixing thoroughly decomposed chicken manure, peanut hull powder, grass peat soil, sweet potato flour, wollastonite powder, zinc sulfate, manganese sulfate and brassinolide with one another to obtain first mixtures, adding the prefabricated materials into the first mixtures to obtain second mixtures, preheating and heating the second mixtures, spraying rapeseed meal on the second mixtures, adding mica powder into the second mixtures, continuing to stir the mica powder and the second mixtures and carrying out air drying to obtain the coated paddy rice fertilizers with the reduced costs. The method has the advantages that paddy rice can comprehensively absorb nutrients in a balanced manner by the aid ofthe coated paddy rice fertilizers, accordingly, the quality of the paddy rice can be improved, and the yield of the paddy rice can be increased; the physical and chemical properties of soil can be improved, the soil fertility can be fertilized, nutrient requirements of the paddy rice in integral growth periods can be met; furthermore, the method has the advantages of labor-saving, time-saving, high fertilizer utilization rate, and the like.

Owner:ANHUI SIERTE FERTILIZER IND

Returned mine sintering process and system

The invention discloses a returned mine sintering process. The process comprises the steps of sintered material preparing, embedded material obtaining and uniform mixing; sintered material preparing comprises a mixing procedure and a granulation procedure; in the mixing procedure, powdery fuel and a fluxing agent are added into iron ore powder, the iron ore powder, fuel and the fluxing agent are evenly mixed, and a mixing material is formed; in the granulation procedure, water is added into the mixing material, the steam is adopted to preheat the mixing material, the mixed material is preparedinto a particular sintered material, embedded material obtaining comprises a pellet material screening procedure and an embedded material storage procedure, the pellet material screening procedure comprises the steps that steel metallurgical pellets or pellets below a blast furnace melting tank are screened, and a returned mine material is screened out; in the embedded material storage procedure,the returned mine material is transported to a pellet returned mine bin to be stored; in the uniform mixing process, the sintered material and the returned mine material are conveyed to a uniform mixing device to be evenly mixed, the returned mine material serves as an embedded material to be evenly distributed in the sintered material, and a pellet returned mine embedded type sintered material is formed. According to the process, the ventilation performance of the sintered material can be improved.

Owner:SICHUAN DONGLIN MINE TRANSPORT MACHINERY

Spherical rubber chemicals and the method for preparing the same

The present invention provides spherical rubber chemicals and the method for preparing the same. The spherical rubber chemicals of the present invention include spherical antioxidants, spherical vulcanization agents, spherical processing aids, spherical reinforcing agents, or spherical adhesive agents. With the spherical rubber chemicals of the present invention, the shortcomings of powdery or semi-spherical rubber chemicals are overcome, including eliminating the dust pollution during granulation procedure and avoiding the raw material loss and the environmental pollution, while solving the quality problem of lower melting point of product caused by the presence of fine powder crystal. Furthermore, the resultant rubber chemicals has an improved smoothness of surface, which is helpful to improve the flowing and mixing behaviors of the rubber chemicals in mixing or open milling process with rubbers.

Owner:SENNICS CO LTD

Preparation method of special anti-bonding low-smoke halogen-free flame-retardant sheath material for GJFJZY type multi-core indoor optical cable

ActiveCN102952314AImprove liquidityGood dispersionFibre mechanical structuresPolypropyleneFire retardant

The invention discloses a preparation method of a special anti-bonding low-smoke halogen-free flame-retardant sheath material for a GJFJZY type multi-core indoor optical cable, which comprises the following steps: selecting the following components of the sheath material in parts by weight: 5-15 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyethylene, 5-10 parts of polypropylene, 55-65 parts of flame retardant, 5-10 parts of compatilizer, 2-3 parts of ultra-high molecular weight silicone, 0.5-1.5 parts of high-melting-point polyethylene wax and 0.3-0.8 part of antioxidant; mixing in a kneading machine for 8-12 minutes, and discharging when the mixing temperature is 135-150 DEG C; and feeding into a double-screw extruder, and sequentially performing double-screw plasticization and single-screw granulation, wherein the temperatures of all sections of the screws are as follows: the temperature of a charging section is 90-110 DEG C, the temperature of a conveying section is 120-130 DEG C, the temperature of a plasticization section is 130-140 DEG C, and the temperature of a machine head is 135-145 DEG C; and the granulation procedure adopts an air cooling and hot cutting process. Thus, the prepared sheath layer material is a new material and is greatly different from a core wire material in performance; and under the lubrication action of the ultra-high molecular weight silicone and the high-melting-point polyethylene wax in the sheath layer material, the sheath layer and the core wire can not be bonded, thereby ensuring the quality of a GJFJZY type multi-core indoor optical cable.

Owner:SUZHOU HENGLI COMM MATERIAL +1

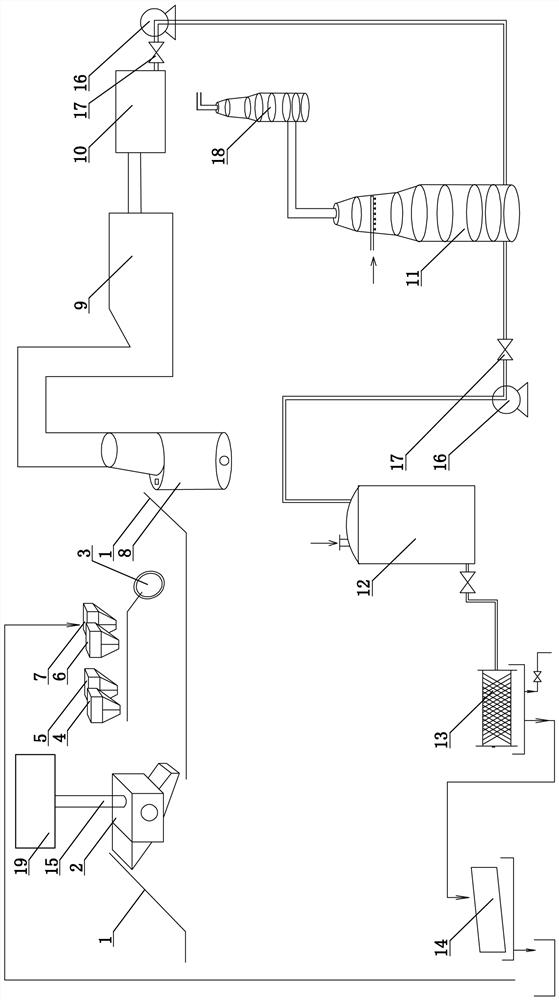

Granulating device and heat recovery method for melted slag

ActiveCN109207659AGuaranteed centrifugal effectImprove crushing effectRecycling and recovery technologiesRecovery methodSlag

The invention relates to a granulating device and heat recovery method for melted slag. The heat recovery method comprises the following procedures: an air-powder flow production procedure: mixing powder with compressed air; a melted slag granulation procedure: jetting the produced air-powder flow to a melted slag flow to convert the melted slag flow into high-temperature granulated slag; and a melted slag powder returning procedure: returning fine-grain powder produced in the melted slag granulation procedure as powder for the air-powder flow production procedure to the air-powder flow production procedure for cyclic usage. According to the invention, high-speed air-powder flow is used as a granulating medium for granulation of the melted slag into high-temperature melted particles; fineslag particles obtained after screening of cooled granulated slag are used as the powder for the air-powder flow for cyclic usage; and waste heat in high-temperature granulation air after granulationof the melted slag is utilized. During granulation and heat recovery of a melting furnace, the energy loss of the granulating medium is low; impact kinetic energy on the melted slag is large; and on the premise of ensuring the granulation effect of the melted slag, the energy consumption of an air source can be reduced and high-grade hot air can be obtained.

Owner:TIANJIN UNIV

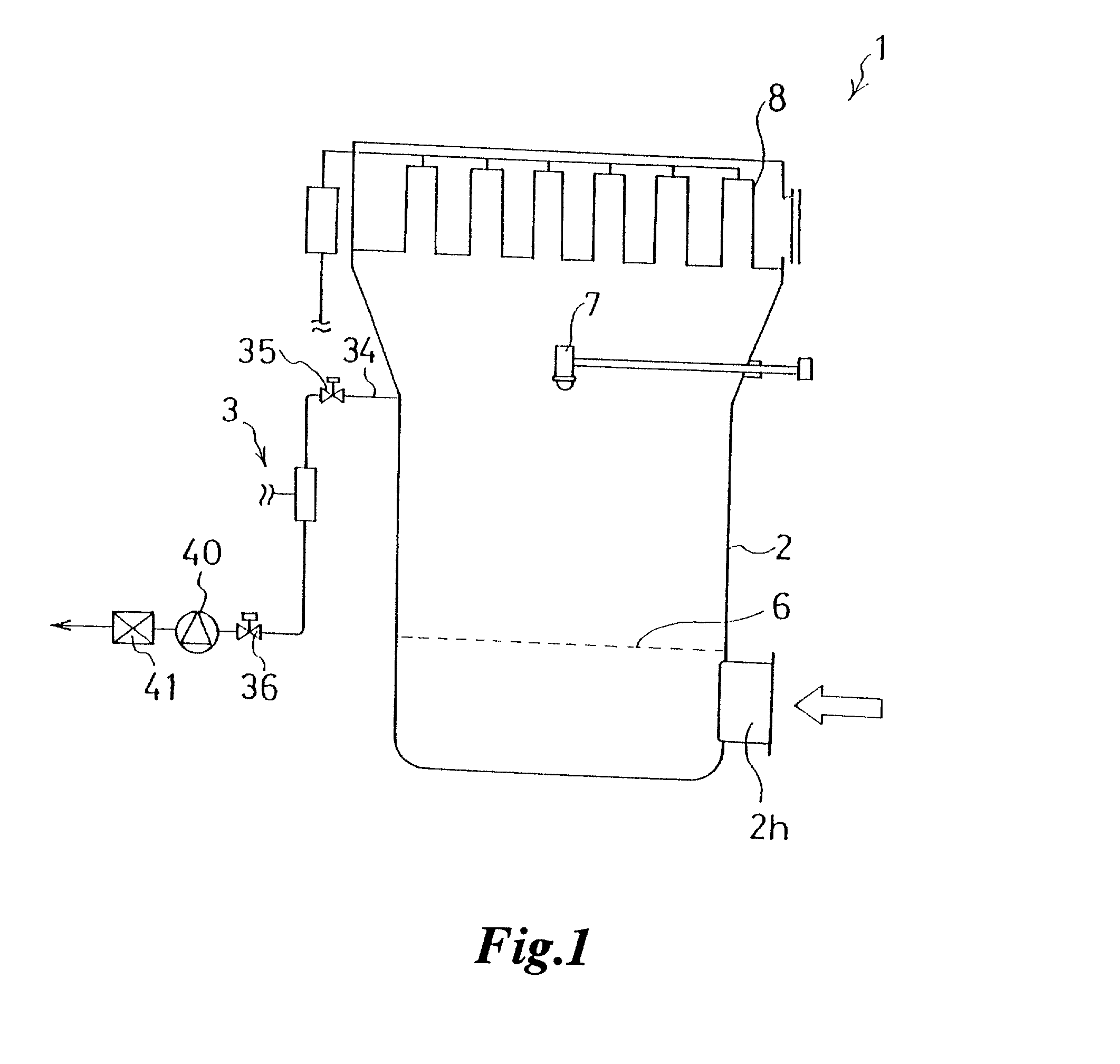

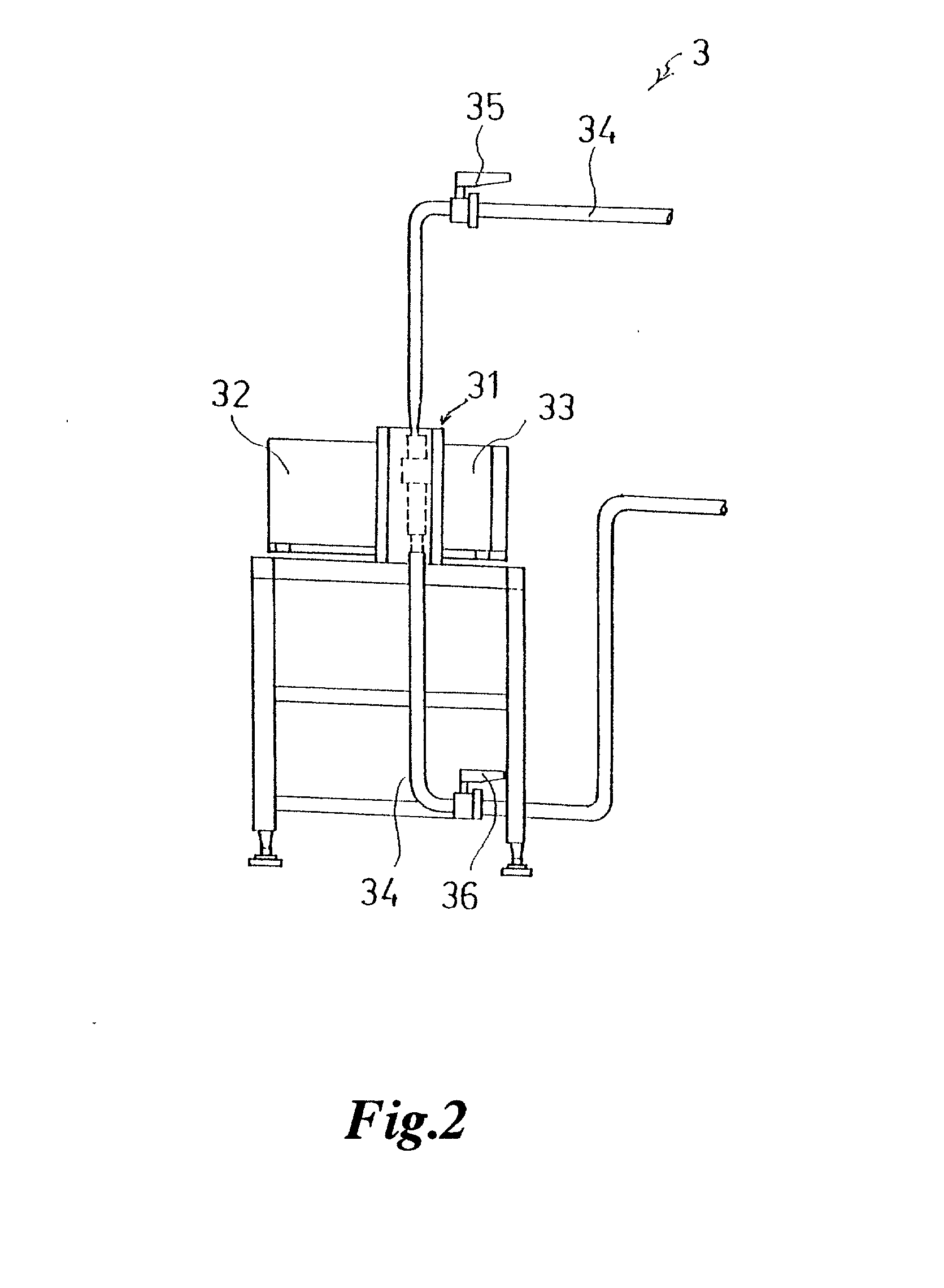

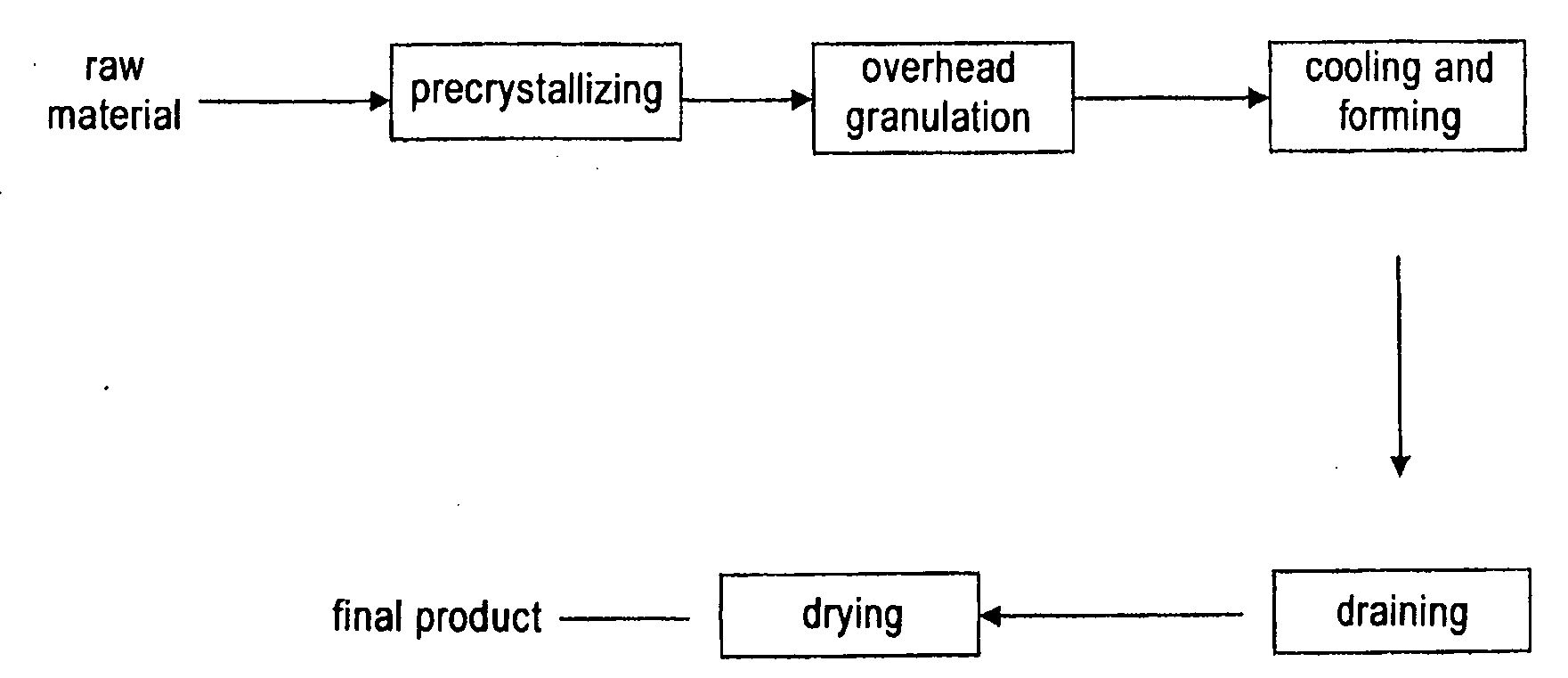

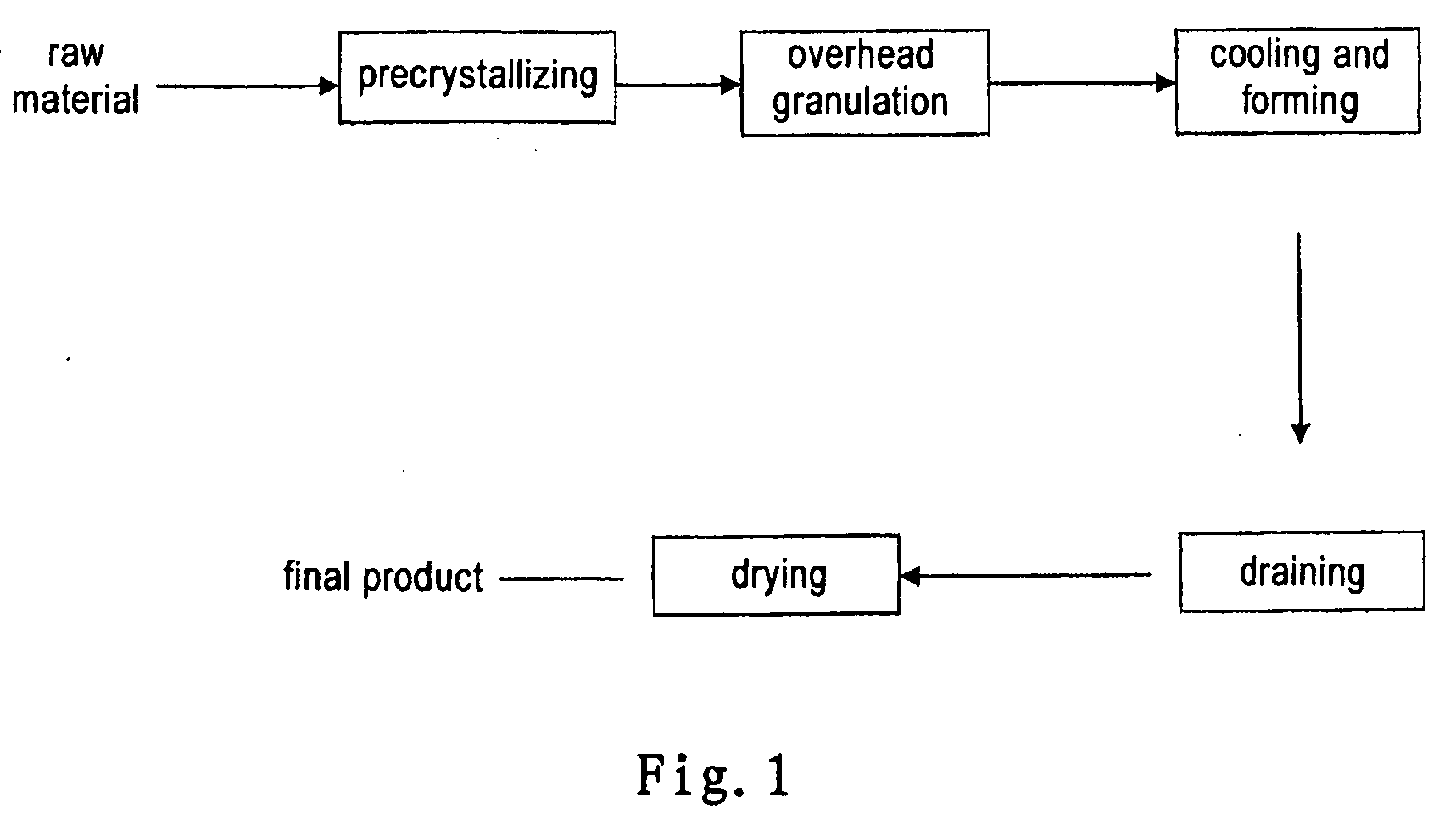

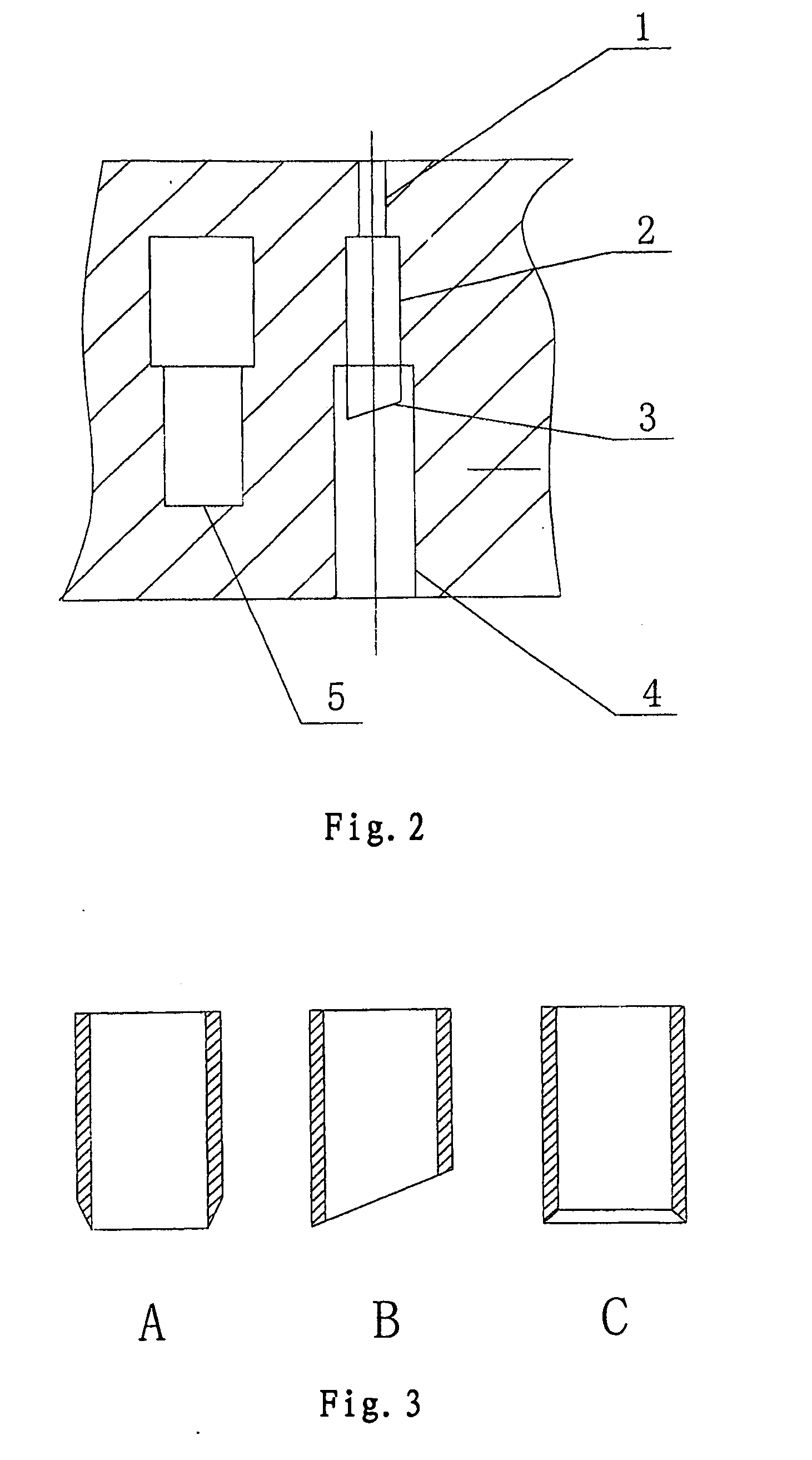

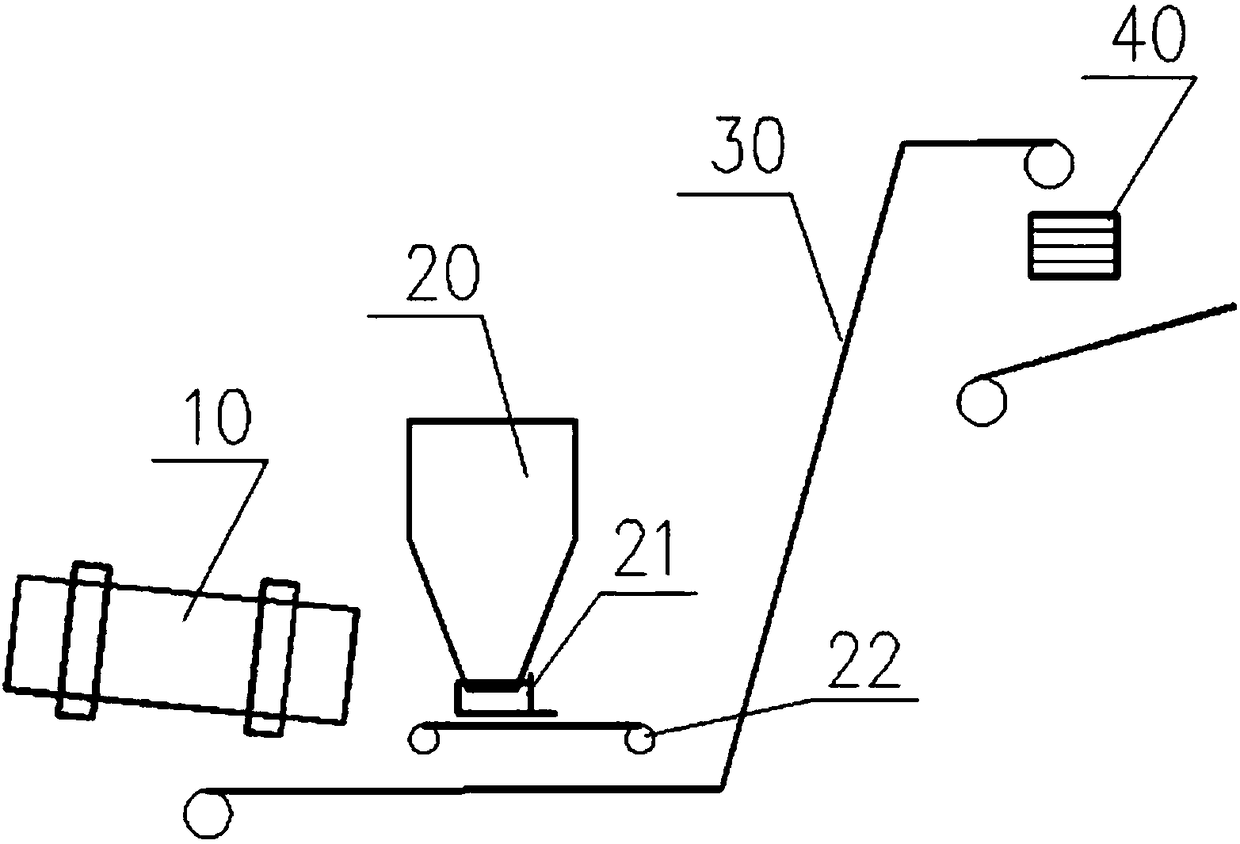

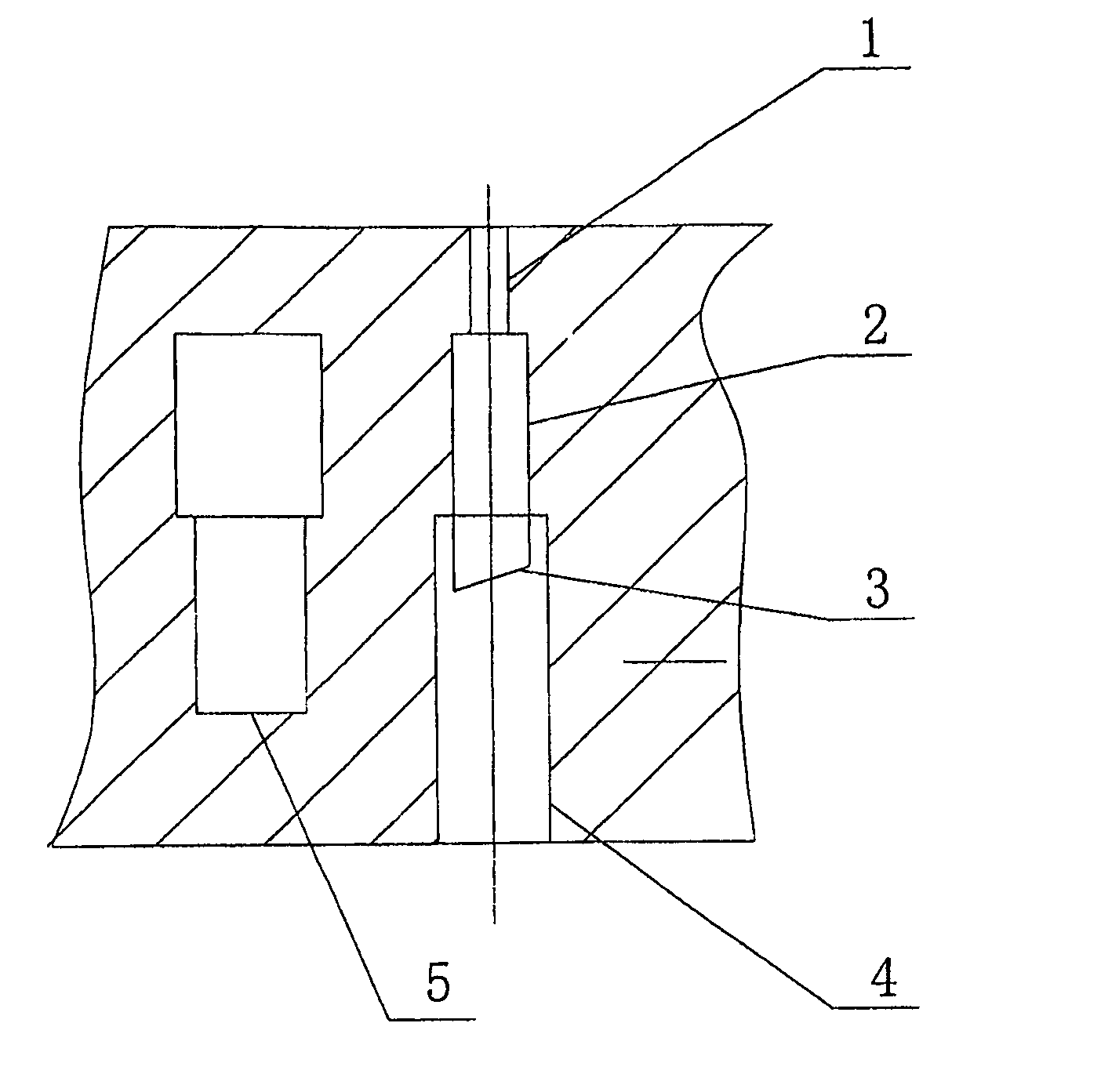

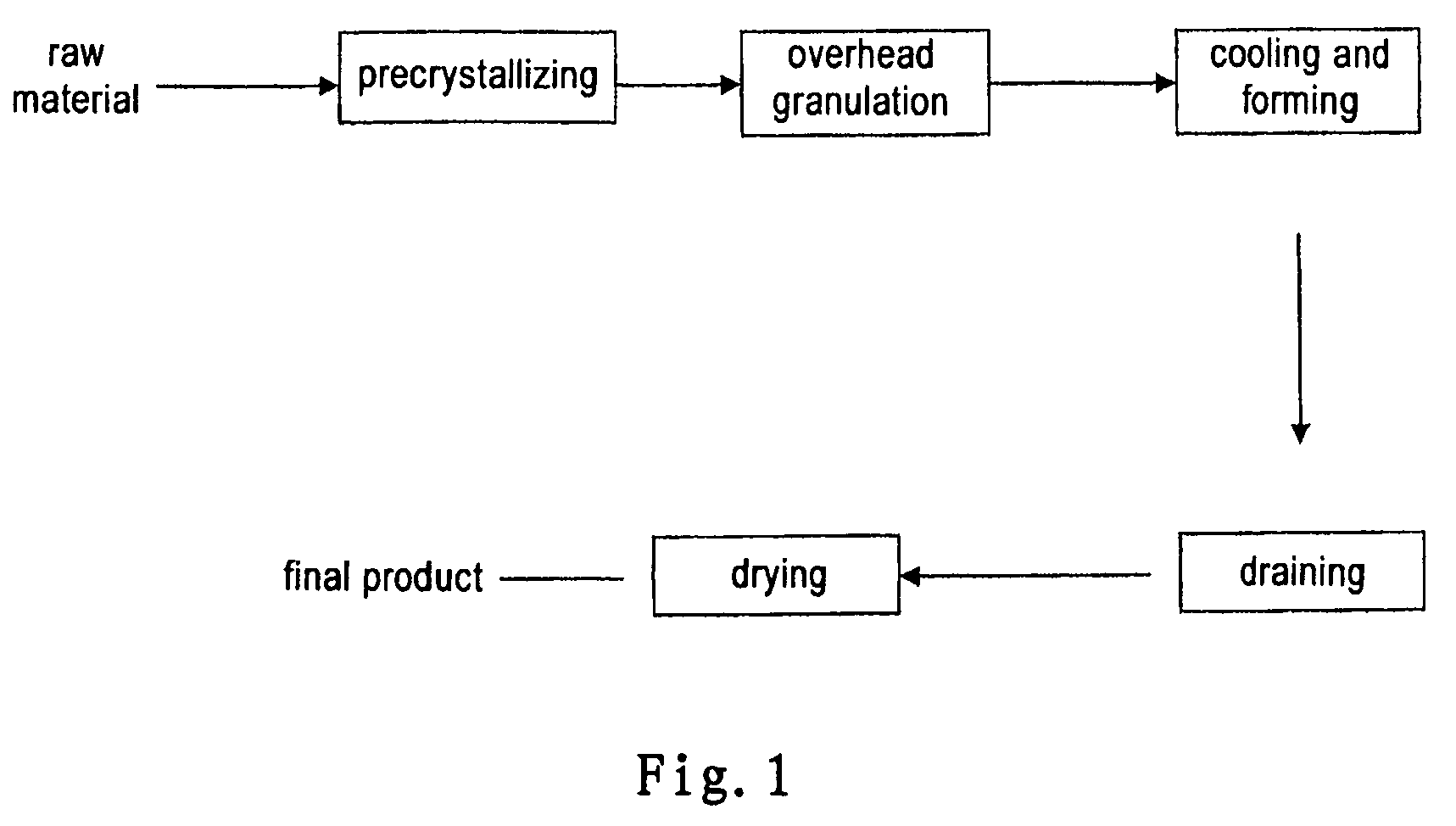

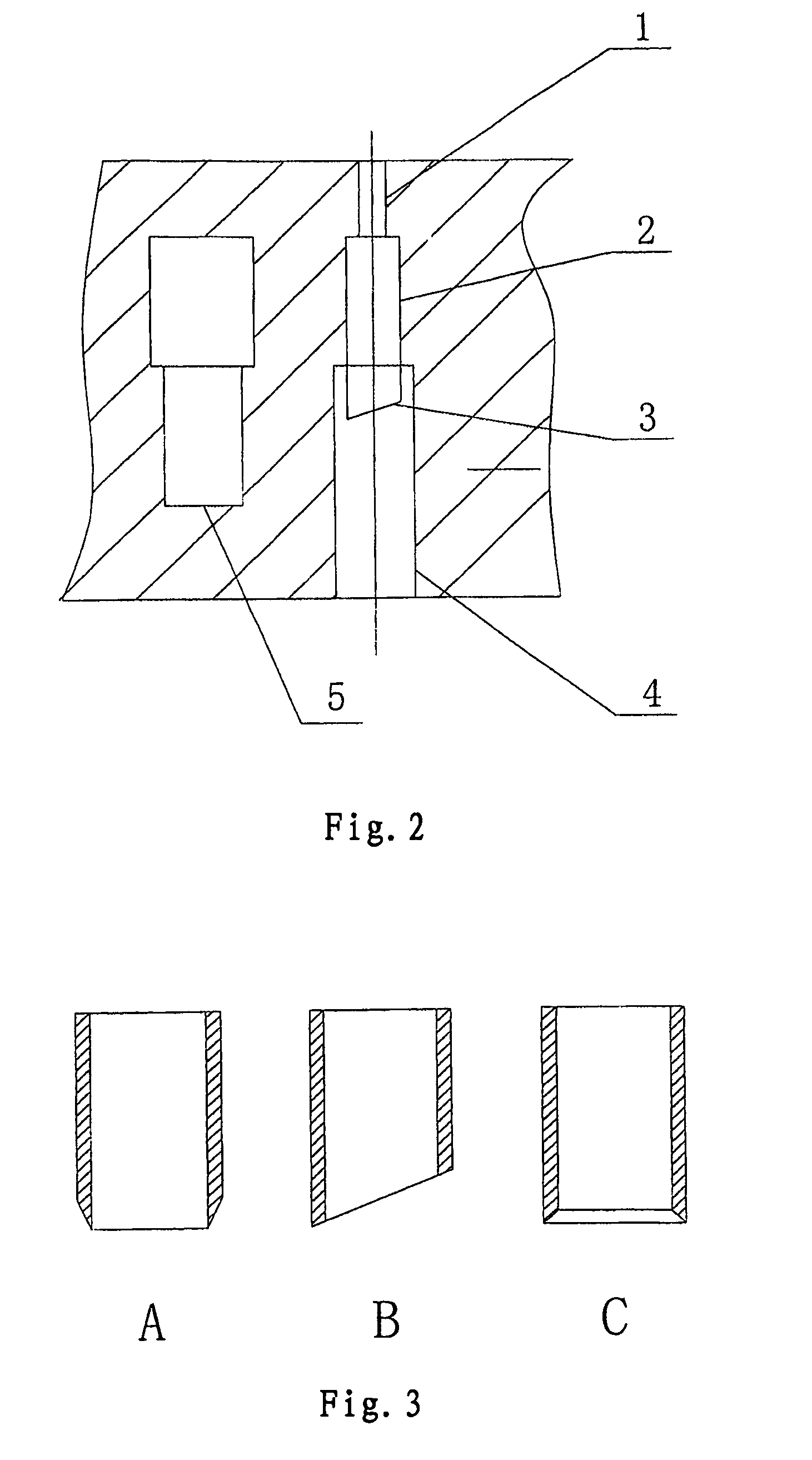

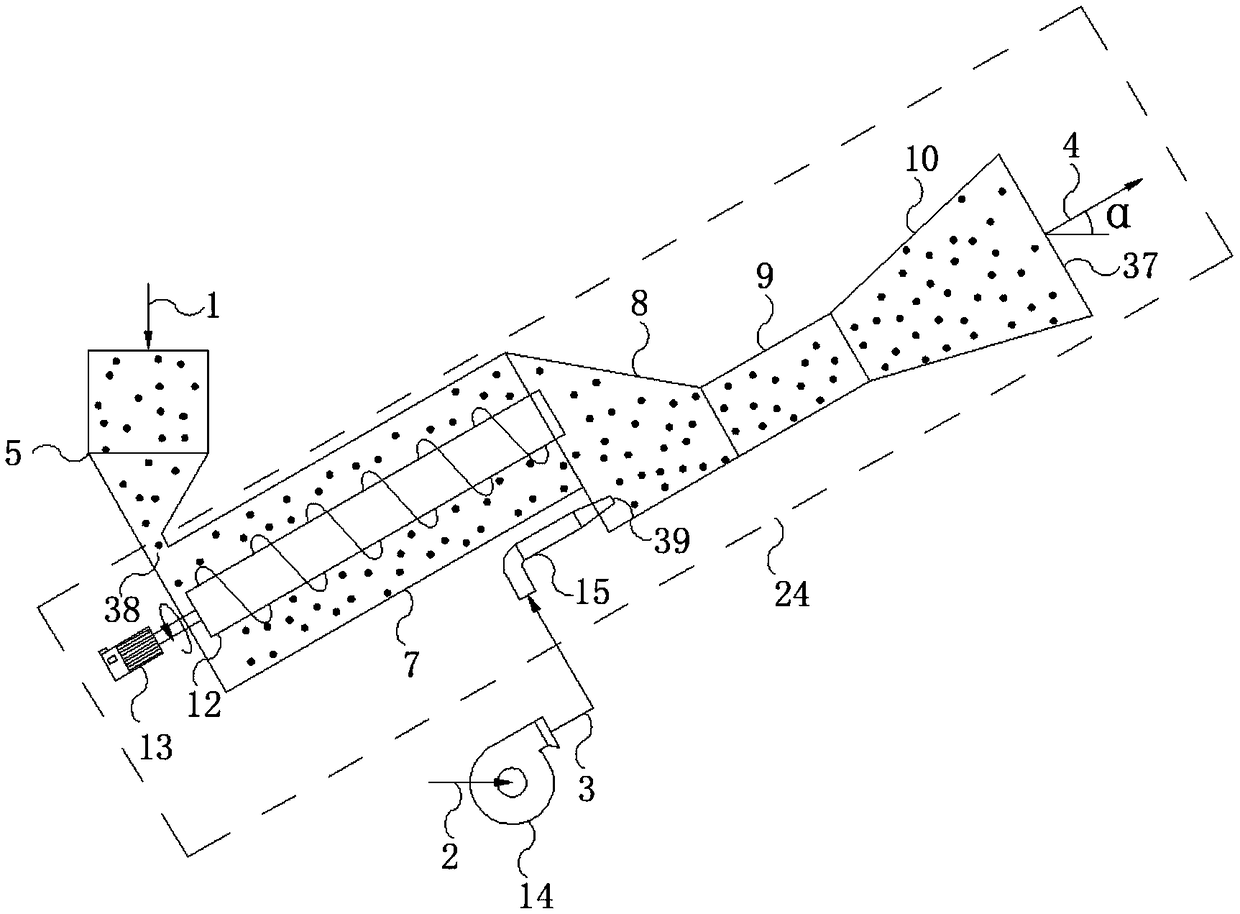

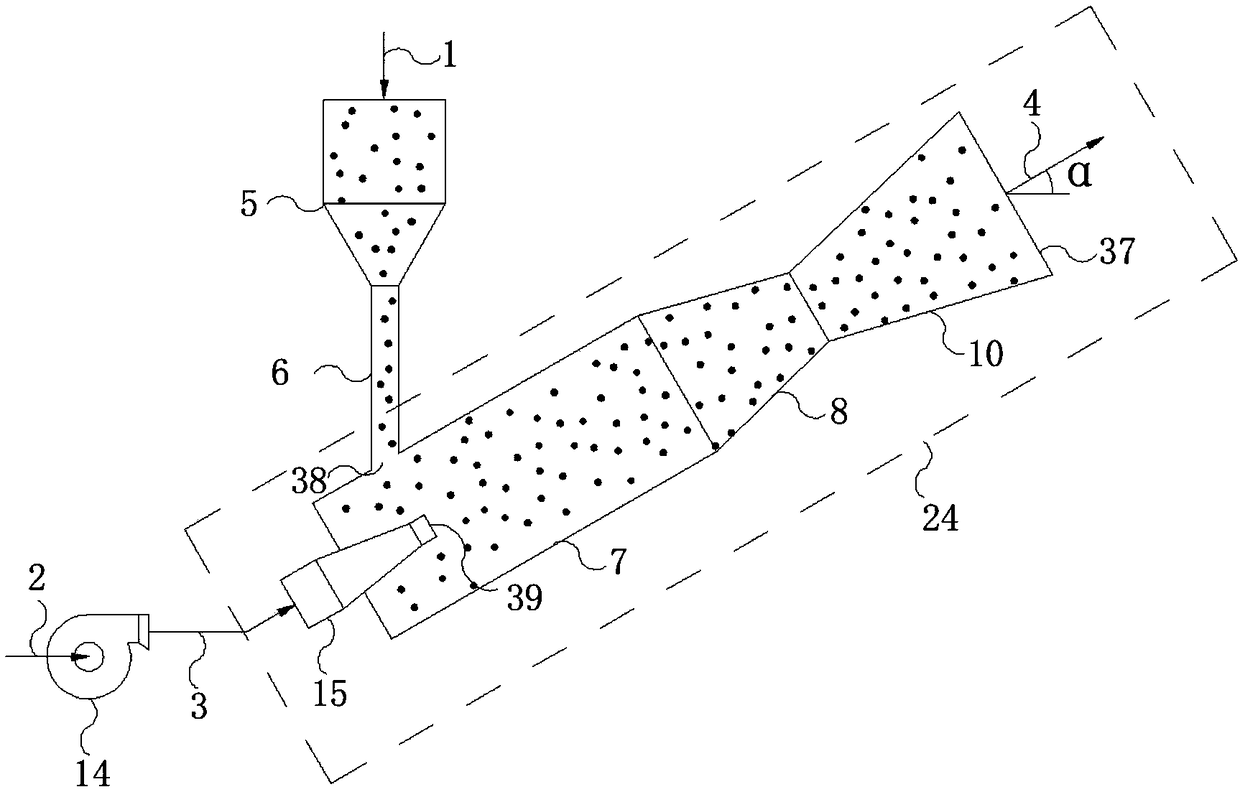

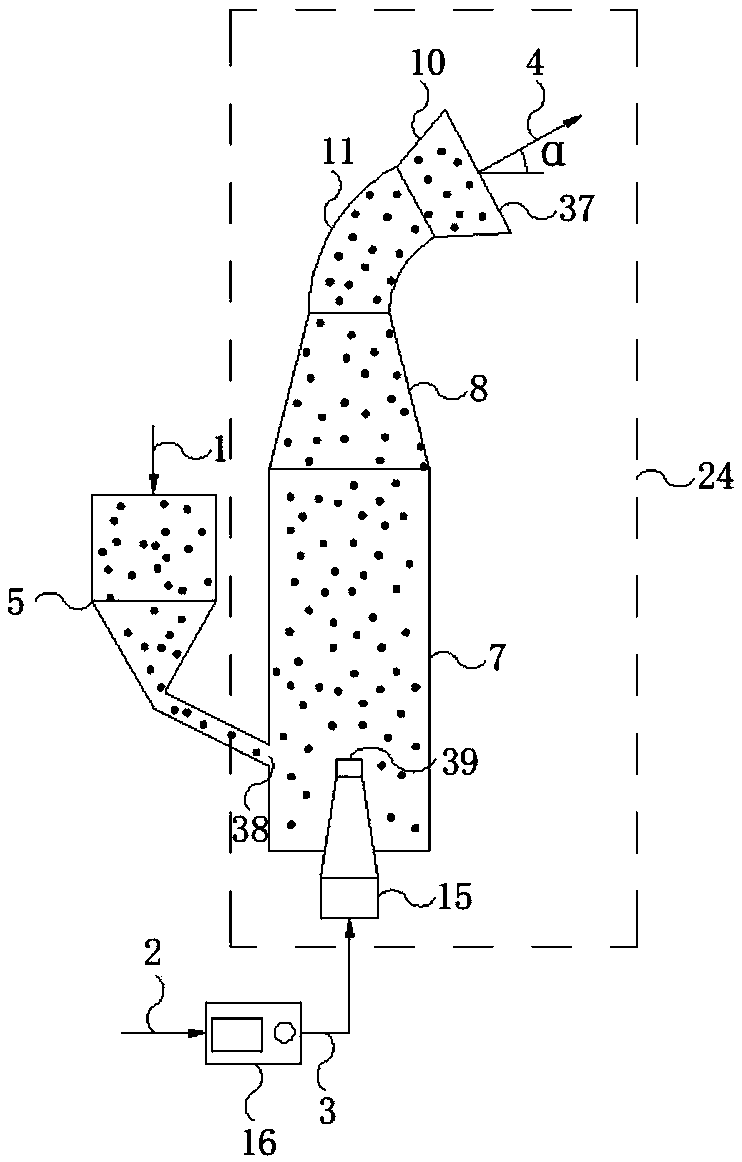

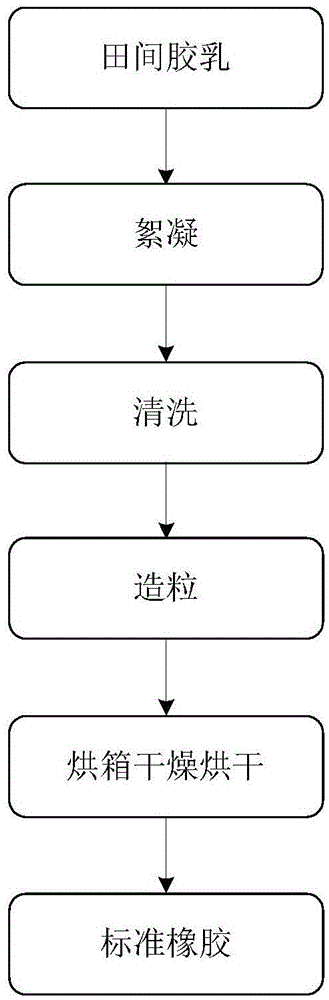

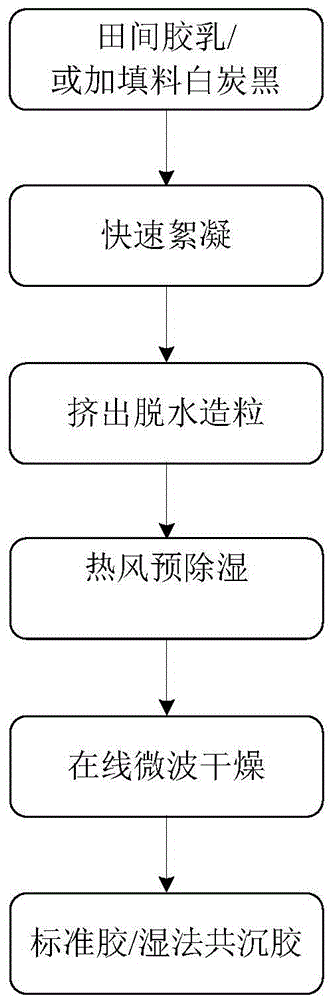

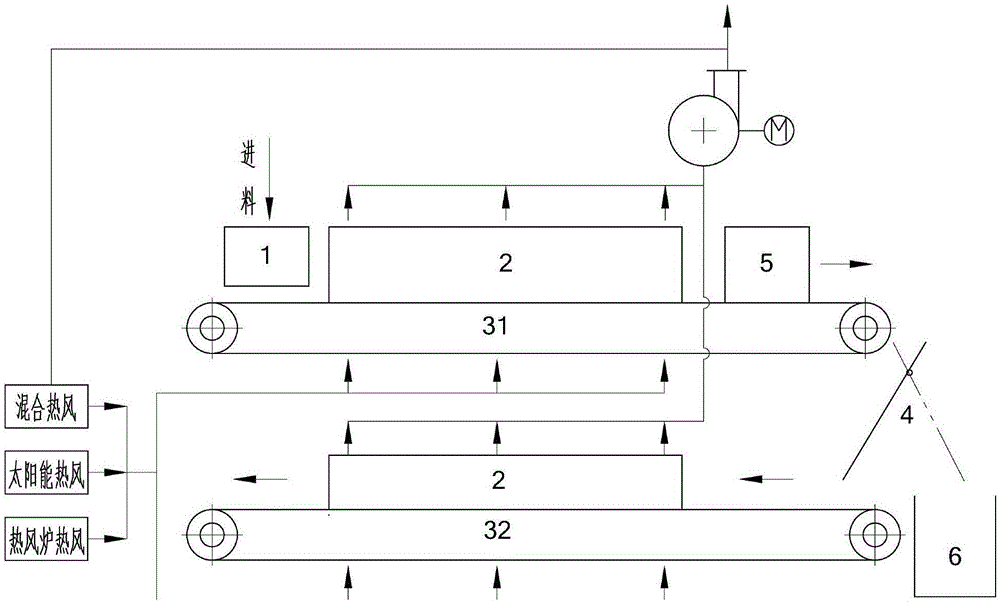

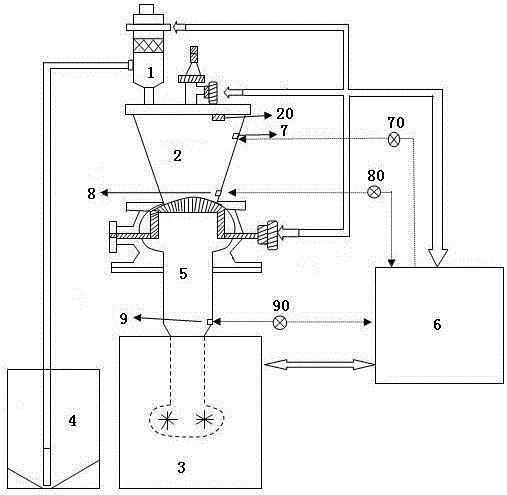

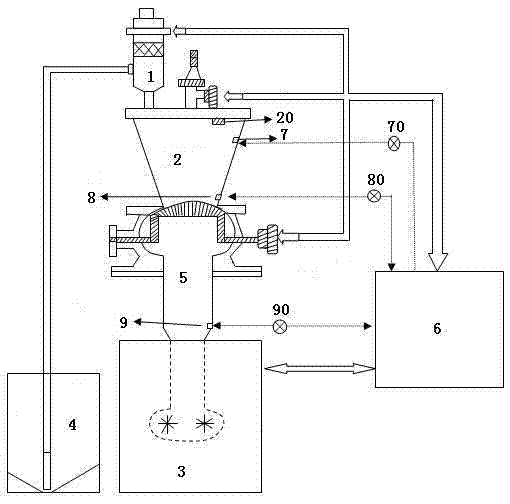

Natural rubber production process and natural rubber production equipment with solar hot-air pre-dehumidification function

The invention discloses a natural rubber production process and natural rubber production equipment with a solar hot-air pre-humidification function. The natural rubber production process and the natural rubber production equipment have the advantages that a pre-humidification procedure is additionally carried out between a granulation procedure and a drying procedure, air can be heated by the aid of solar energy, the surfaces of squeezed and dehydrated rubber materials can be dehumidified by the aid of the hot air, accordingly, moisture on the surfaces of natural rubber can be effectively removed and dried, follow-up microwave drying energy consumption can be greatly reduced, the drying efficiency can be greatly improved, the cost can be reduced in an energy-saving and efficient drying mode, and the competitiveness of products can be improved; energy can be saved by the aid of drying methods, the drying methods are environmentally friendly and are high in drying efficiency, and the natural rubber (or co-precipitation rubber with the natural rubber) can be continuously and automatically produced.

Owner:万向新元科技股份有限公司

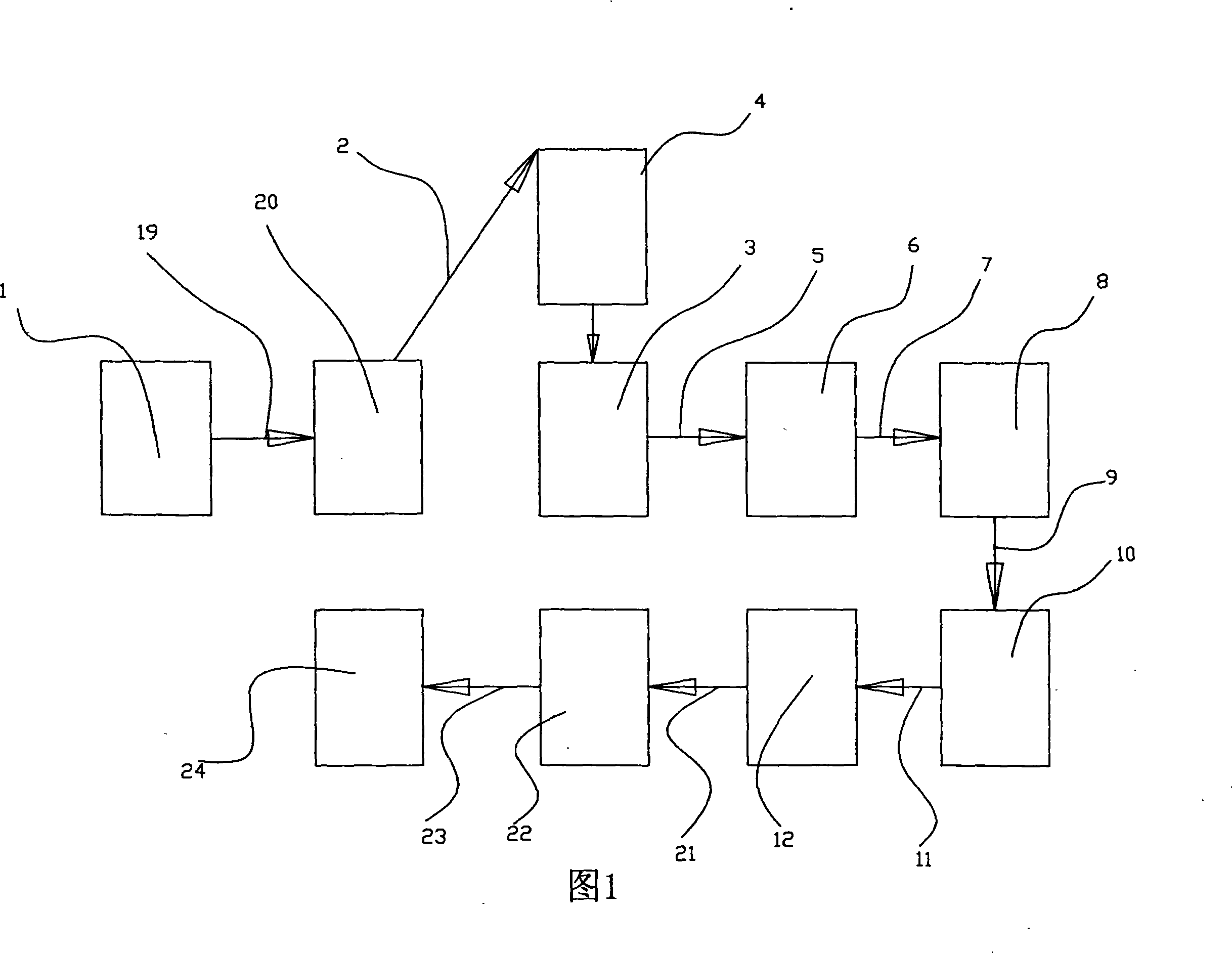

Drug granule mixing feeding tabletting all-in-one machine

InactiveCN103317747BUniform contentIncrease productivityShaping pressGranulation procedurePulp and paper industry

The invention relates to equipment for tabletting drug granules. In order to mix and tablet the drug granules and prepare finished drug products with uniform content, the invention provides the all-in-one machine for mixing, feeding and tabletting drug granules. According to the all-in-one machine, a mixing machine outputs a material to a tabletting machine, a feeding machine feeds the material to the mixing machine in batches, the mixing machine mixes the material in batches, a conveying mechanism for conveying the material after mixing of each batch is connected between the mixing machine and the tabletting machine, and the tabletting machine tablets the material in batches. The all-in-one machine automatically groups the drug granules in batches, and performs all-in-one processing on each batch of drug granules in time sequence; the all-in-one processing on each batch of drug granules includes feeding, mixing and tabletting operations carried out in sequence. As the tabletting capacity of each batch is less than that of the whole batch, the drug granules have low possibility of dissociation or separation during the tabletting operation, and the content of the finished drug products is uniform. The all-in-one machine for mixing, feeding and tabletting drug granules automatically accomplishes the mixing and tabletting process, and the wet granulation procedure is not required, so that the production efficiency is improved.

Owner:GUANGDONG MEDICAL UNIV +1

All-in-one machine for mixing, feeding and tabletting drug granules

InactiveCN103317747AUniform contentIncrease productivityShaping pressGranulation procedureEngineering

The invention relates to equipment for tabletting drug granules. In order to mix and tablet the drug granules and prepare finished drug products with uniform content, the invention provides the all-in-one machine for mixing, feeding and tabletting drug granules. According to the all-in-one machine, a mixing machine outputs a material to a tabletting machine, a feeding machine feeds the material to the mixing machine in batches, the mixing machine mixes the material in batches, a conveying mechanism for conveying the material after mixing of each batch is connected between the mixing machine and the tabletting machine, and the tabletting machine tablets the material in batches. The all-in-one machine automatically groups the drug granules in batches, and performs all-in-one processing on each batch of drug granules in time sequence; the all-in-one processing on each batch of drug granules includes feeding, mixing and tabletting operations carried out in sequence. As the tabletting capacity of each batch is less than that of the whole batch, the drug granules have low possibility of dissociation or separation during the tabletting operation, and the content of the finished drug products is uniform. The all-in-one machine for mixing, feeding and tabletting drug granules automatically accomplishes the mixing and tabletting process, and the wet granulation procedure is not required, so that the production efficiency is improved.

Owner:GUANGDONG MEDICAL UNIV +1

Method for treating sintering granules

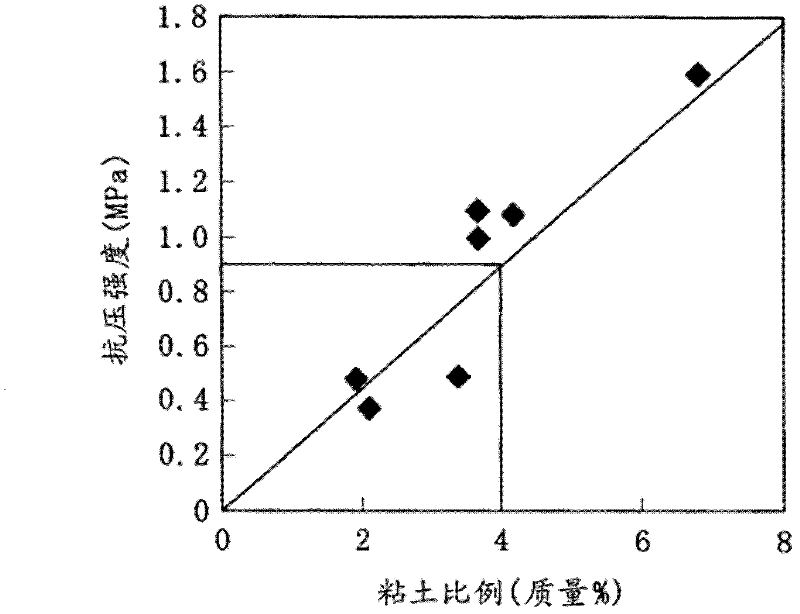

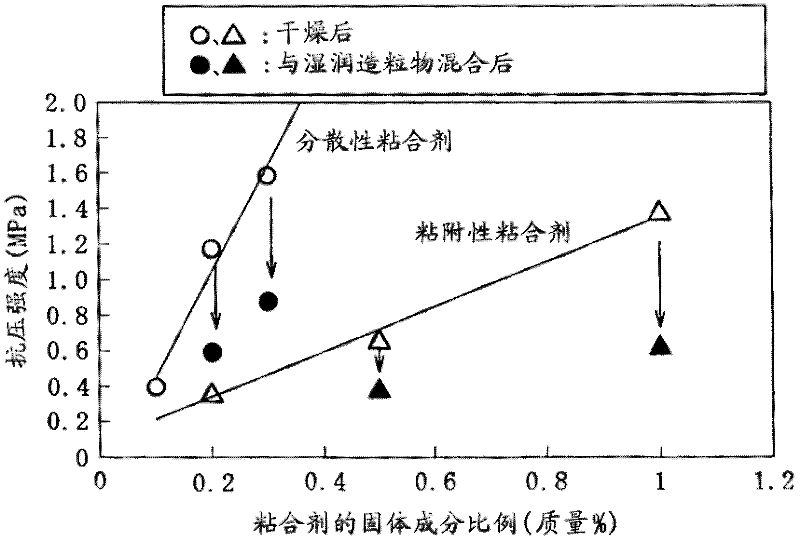

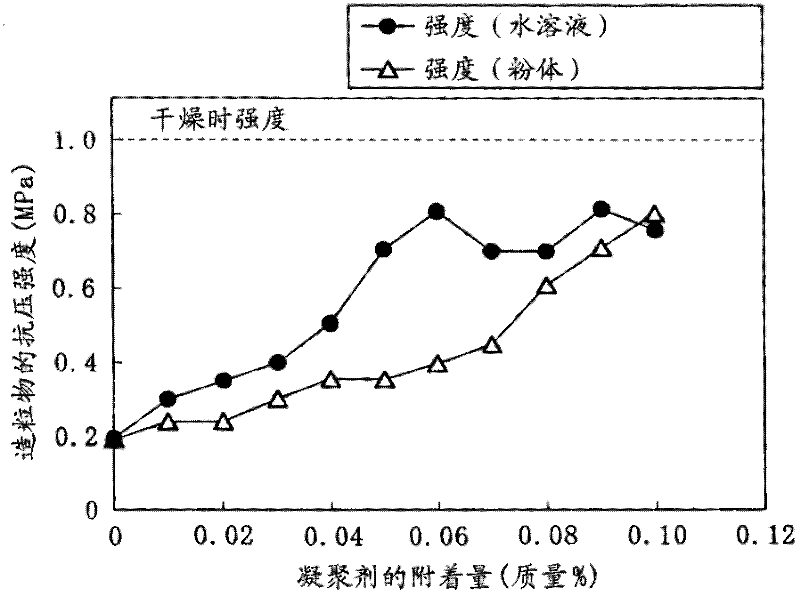

InactiveCN102333894ADecreased surface adhesion strengthReduce intensityGranulation procedureMoisture

Disclosed is a method for treating sintering granules, which enables the maintenance of strength of granules even when the granules are exposed to excess moisture in a wet zone or when dry granules are mixed with wet granules and the dry granules reabsorb moisture, and which can achieve a continuous granulation treatment in a continuous treatment line. The method comprises supplying coated granules into a sintering machine, wherein the coated granules comprise: granule which are produced by subjecting a raw material containing an accessory raw material comprising a iron ore powder, a carbon material and caustic lime to a wet granulation procedure using a binder to produce granules; and at least one strength reduction-preventing agent selected from a coagulant, a hydrophobizing agent and a water repellent agent, which is adhered on the surfaces of the granules.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

Method for producing granulated preparation

InactiveUS20100247737A1Simple granulation operationEasy to operateOrganic active ingredientsDigestive systemGranulation procedureEnteric coating

It has been desired to provide a method for producing a granulated preparation capable of maintaining a stability of a chemically unstable substance in a neutral or acidic region for a long period of time with a simple and safe method in a preparation procedure, and a tablet produced by using the method.The invention provides a granulation method in which an unstable substance is successively subjected to aqueous stabilization treatment and granulation procedure. Further, it became possible to provide a tablet which is absorbed in the intestine without losing the potency in a gastric region by forming an intermediate layer on a surface of the thus obtained granule and subsequently subjecting the granule to enteric coating.

Owner:OHARA PHARMA

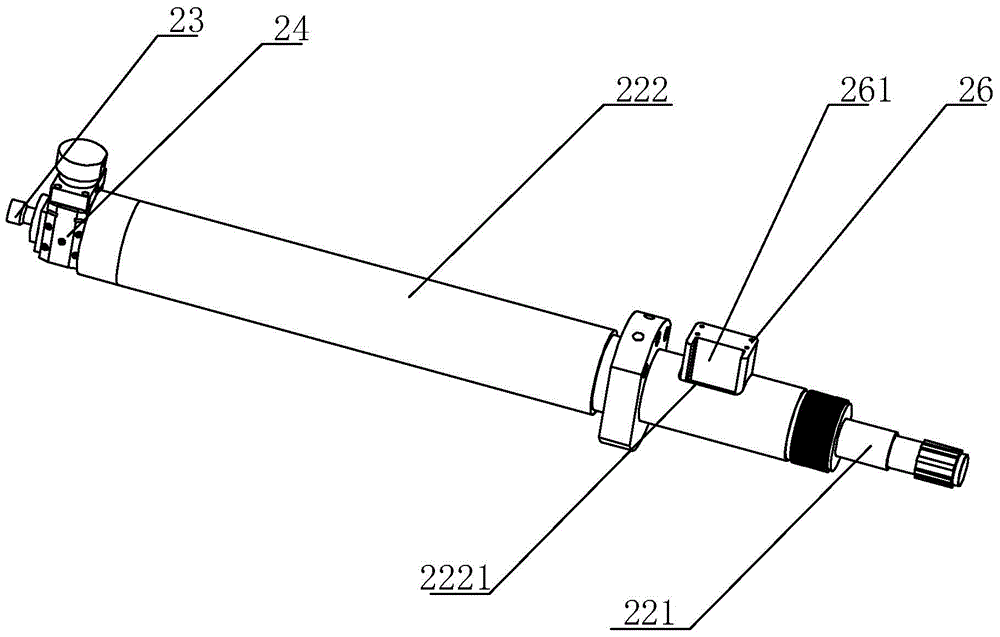

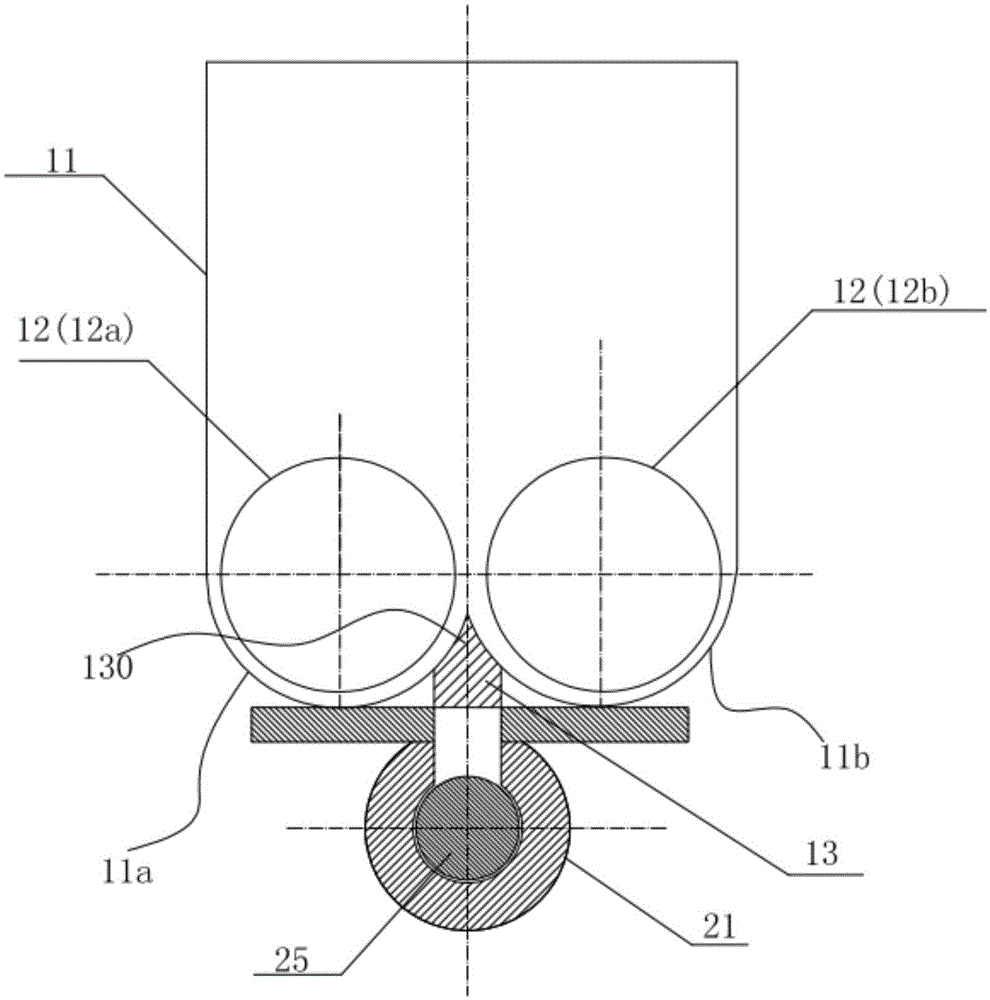

Powder injection molding feeding manufacturing equipment

ActiveCN104148638AAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

The invention discloses powder injection molding feeding manufacturing equipment which comprises a kneading device, an extruding device and a grain cutting device. A discharge outlet of the kneading device is communicated with a barrel inlet end of the extruding device, the grain cutting device is connected to a barrel outlet end of the extruding device, and powder materials are kneaded by the kneading device, then are directly fed into the extruding device, pass the extruding device and then are directly fed into the grain cutting device to be subjected to hot-cutting air-cooled granulation. The powder injection molding feeding manufacturing equipment for realizing powder injection molding feeding manufacturing effects has the advantages that large-scale continuous operation with high production efficiency can be carried out; the hot-state materials can be directly fed into follow-up machining links, accordingly, reheating temperature rise required by granulation procedures can be reduced, and energy consumption can be greatly decreased; labor can be saved, the efficacy of the equipment can be improved, the productivity can be enhanced, and the production cost can be reduced; crushing procedures which are carried out after intermediate cooling and solidifying can be reduced, dust can be prevented in material crushing procedures, and accordingly operation environments can be improved.

Owner:DONGGUAN HUAJING POWDER METALLURGY

A preparation equipment for powder injection molding feed

ActiveCN104148638BAvoid intercooling and solidificationAvoid it happening againHigh volume manufacturingEngineering

Owner:DONGGUAN HUAJING POWDER METALLURGY

Preparation method of traditional Chinese medicine granular preparation

PendingCN113712924AReduce usageReduce consumptionPharmaceutical non-active ingredientsGranular deliveryBiochemical engineeringProcess engineering

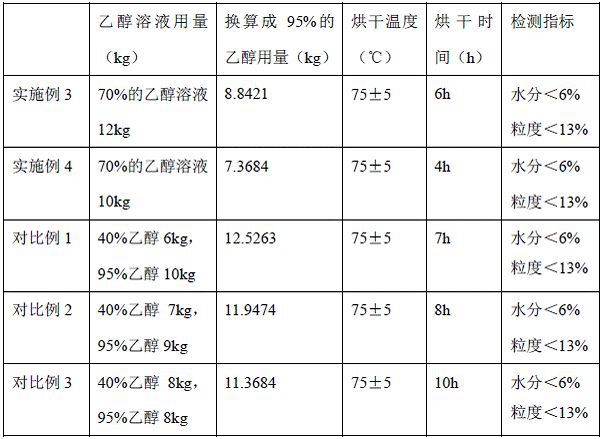

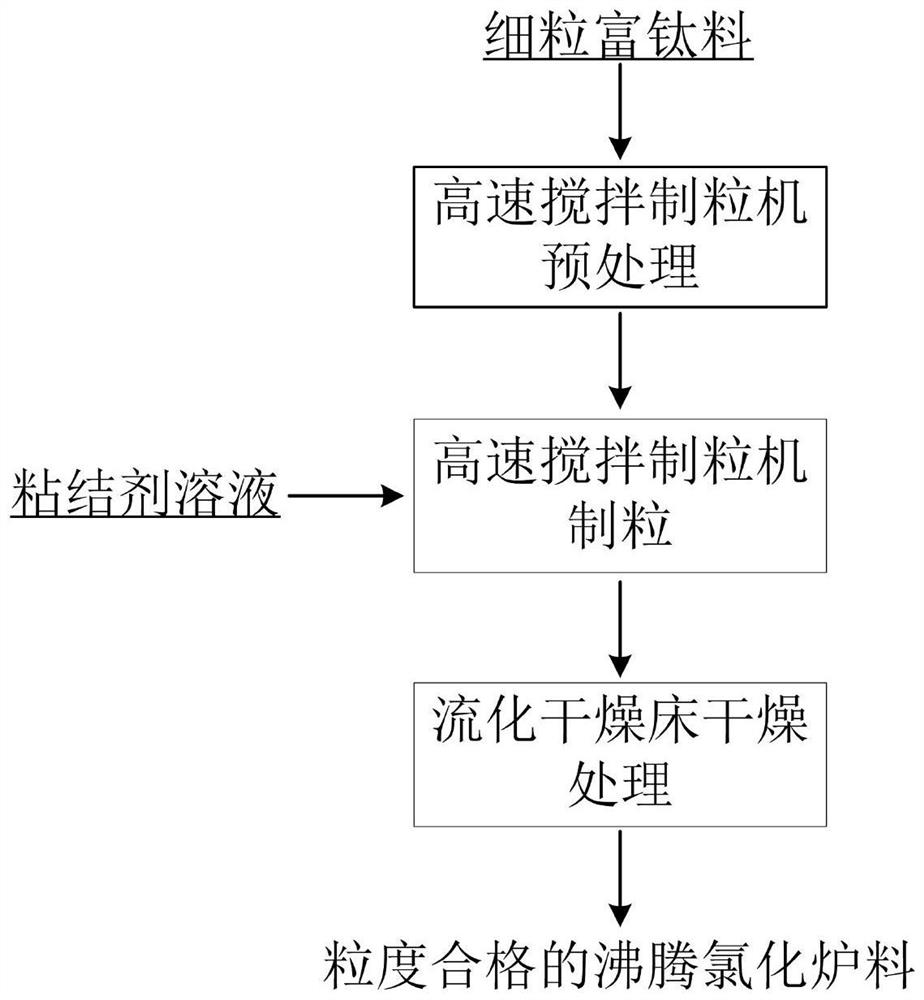

The invention discloses a preparation method of a traditional Chinese medicine granular preparation. The preparation method comprises the following steps: (1) preparing an ethanol solution; (2) pre-compressing treatment: extracting raw materials of the traditional Chinese medicine granular preparation to obtain extract, conducting drying and crushing, sieving with a 100 mesh sieve to obtain dry paste fine powder, putting the dry paste fine powder into a dry granulator for compressing into granules, sieving with a 12-60 mesh sieve to obtain pre-treated granules, and returning the remaining granules to the dry granulator; (3) mixing in a trough type mixer and drying: putting the pretreated granules into a trough type mixer, then adding the ethanol solution in the step (1), stirring for 10 minutes, and then drying at 75 + / -5 DEG C for 5 + / -1 hour; and (4) granulating: sieving the granules obtained in the step (3) with a 12 mesh sieve, and sealing and storing. The method provided by the invention reduces usage of ethanol, shortens drying time, reduces production energy consumption, shortens technological period of granulation procedure, and improves product yield.

Owner:陕西健民制药有限公司

Method for preparing fluidizing chlorination furnace charge by granulating fine-grained titanium-rich material

PendingCN114702063AGood particle qualityNo accumulationTitanium tetrachlorideGranulation procedureTitanium

Owner:CENT SOUTH UNIV

A granulation device and heat recovery method for molten slag

ActiveCN109207659BGuaranteed centrifugal effectImprove crushing effectRecycling and recovery technologiesGranulation procedureMolten slag

The invention relates to a granulating device and heat recovery method for melted slag. The heat recovery method comprises the following procedures: an air-powder flow production procedure: mixing powder with compressed air; a melted slag granulation procedure: jetting the produced air-powder flow to a melted slag flow to convert the melted slag flow into high-temperature granulated slag; and a melted slag powder returning procedure: returning fine-grain powder produced in the melted slag granulation procedure as powder for the air-powder flow production procedure to the air-powder flow production procedure for cyclic usage. According to the invention, high-speed air-powder flow is used as a granulating medium for granulation of the melted slag into high-temperature melted particles; fineslag particles obtained after screening of cooled granulated slag are used as the powder for the air-powder flow for cyclic usage; and waste heat in high-temperature granulation air after granulationof the melted slag is utilized. During granulation and heat recovery of a melting furnace, the energy loss of the granulating medium is low; impact kinetic energy on the melted slag is large; and on the premise of ensuring the granulation effect of the melted slag, the energy consumption of an air source can be reduced and high-grade hot air can be obtained.

Owner:TIANJIN UNIV

CPVC composition for granulation-free injection molding

The invention discloses a CPVC composition for granulation-free injection molding. The CPVC composition comprises the following components by weight: 100 parts of CPVC resin, 4-6 parts of a stabilizer, 0.5-1.5 parts of low-density non-oxidized polyethylene wax, 0.5-1.5 parts of high-density oxidized polyethylene wax, 5-10 parts of an impact modifier, 3-6 parts of a processing aid, 1-1.5 parts of an antioxidant and 2-5 parts of a filler. The CPVC composition for granulation-free injection molding in the invention does not need to undergo a granulation procedure and can be directly applied to injection molding to prepare a product with good physical properties and high smoothness.

Owner:上海泉恩塑胶有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com