Drug granule mixing feeding tabletting all-in-one machine

A technology of tablet press and mixer, applied in material forming presses, presses, manufacturing tools, etc., can solve the problems of adding soft materials for mixing, easy dissociation or segregation of drug particles, poor particle fluidity, etc. Improve production efficiency and the effect of uniform content of finished drug products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

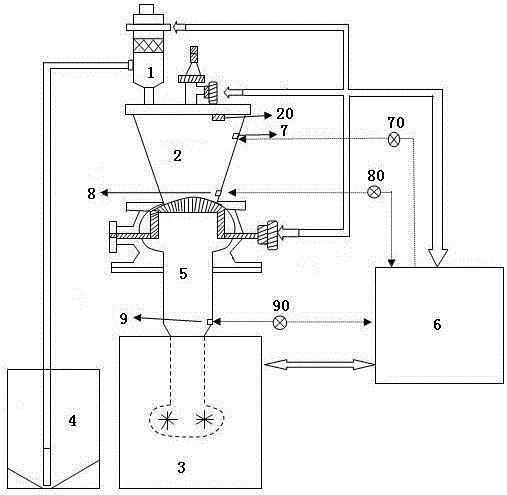

[0009] Medicine granule mixing, feeding and tablet pressing machine such as figure 1 , The feeding machine 1 is the mixer 2 for batch feeding, and the mixer 2 is for batch mixing. The feeding mechanism 5 is connected between the mixer 2 and the tablet press 3. After each batch is mixed, the valve is opened for feeding, so that the drug particles are output from the mixer 2 to the tablet press 3, and the tablet press 3 is pressed in batches sheet. In this embodiment, the mixer 2 is located above the tablet press 3, and the drug particles fall onto the tablet press 3 automatically by gravity. The linkage of each part of the medicine particle mixing, feeding and tablet pressing machine is uniformly controlled by the control unit 6. The medicine granule mixing, feeding and tablet pressing machine can have the following two working modes.

[0010] The first working mode is that the feeder 1 extracts some drug particles from the barrel 4 as the first batch and feeds them to the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com