Soil saline-alkali prevention and control equipment and prevention and control method

A soil, saline-alkali technology, applied in chemical instruments and methods, restoration of polluted soil, mixers, etc., can solve problems such as easily missing the best planting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

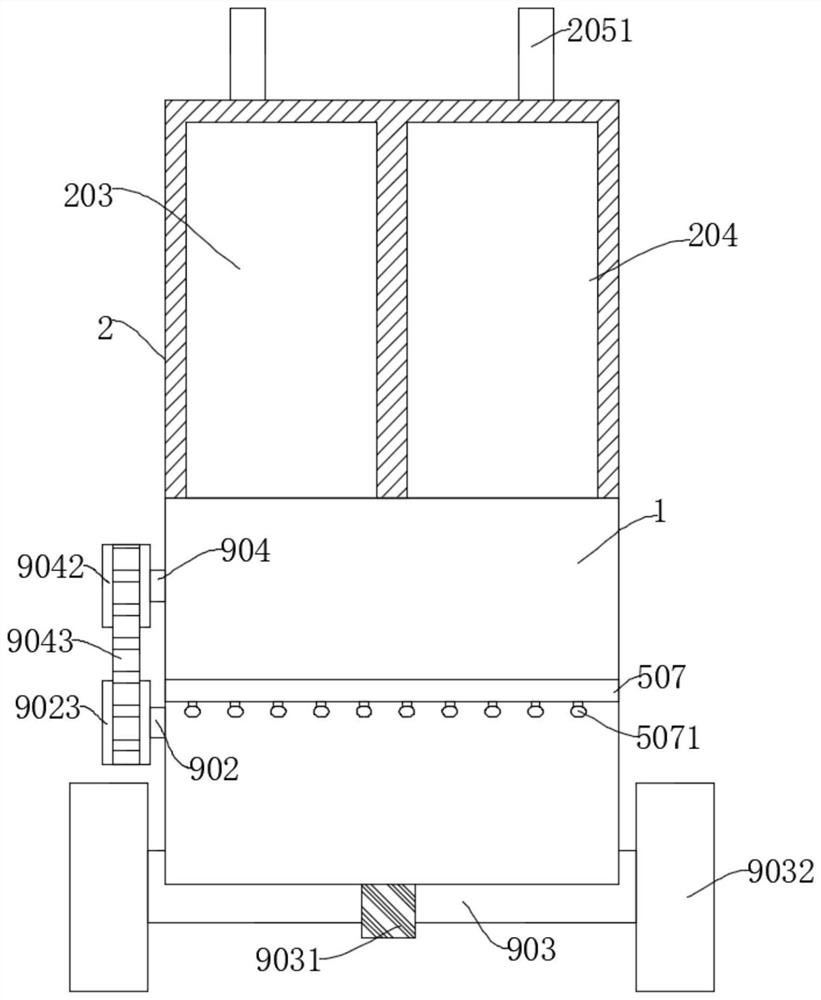

[0040] refer to figure 2 and Figure 4 , a soil salinity control equipment, including a base 1, a box body 2, a crushing mechanism, a stirring mechanism, a pH detector 508 and a second drive mechanism, the box body 2 is fixedly connected to the base 1, and the crushing mechanism is arranged on the bottom of the base 1 At the bottom, the pH detector 508 is arranged in the base 1, the base 1 is provided with a suction chamber 8, the suction chamber 8 is provided with a second fan 304, and the bottom of the suction chamber 8 is fixedly connected with the feed pipe 802 and the The discharge pipe 803, the second fan 304 cooperates with the feed pipe 802 and the discharge pipe 803, the feed pipe 802 cooperates with the crushing mechanism, the discharge pipe 803 cooperates with the pH detector 508, and there is a The third storage box 203 and the fourth storage box 204, the base 1 is provided with a mixing chamber 505, the stirring mechanism is arranged in the mixing chamber 505, a...

Embodiment 2

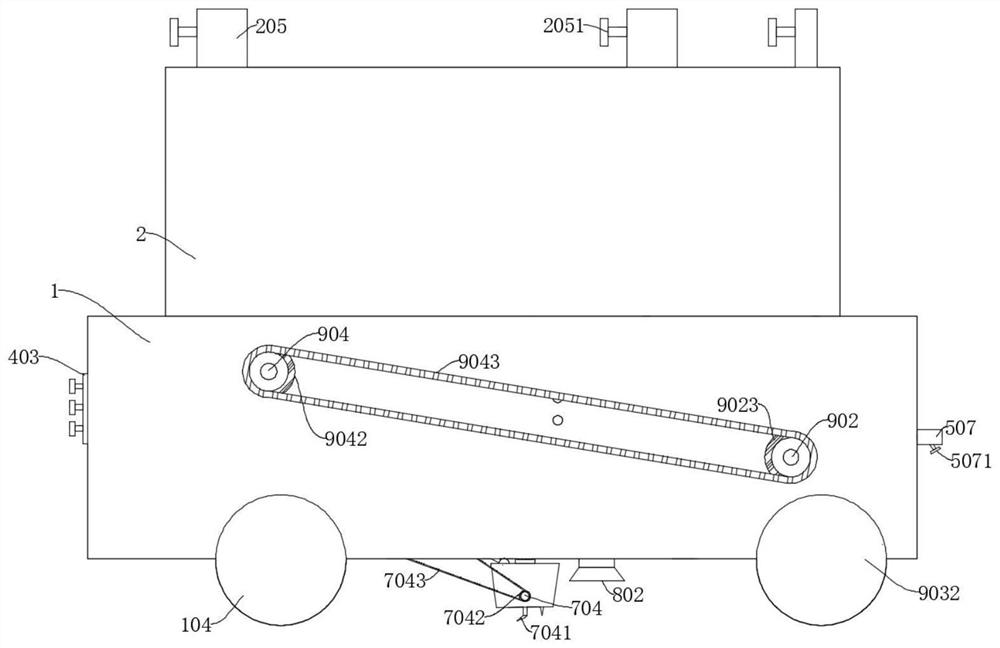

[0042] refer to figure 1 , figure 2 , image 3 , Figure 5 and Figure 7 , is basically the same as Embodiment 1, furthermore, the second drive part includes a second motor 9 and a seventh rotating shaft 903, the second motor 9 is fixedly connected in the base 1, and the output end of the second motor 9 is fixedly connected with a first The fifth rotating shaft 901, the fifth rotating shaft 901 is fixedly connected with the fifth gear 9011 and the sixth sprocket 9012, the two ends of the seventh rotating shaft 903 are provided with rear wheels 9032, the seventh rotating shaft 903 is fixedly connected with the seventh gear 9031, the The seventh gear 9031 is meshed with the fifth gear 9011. The base 1 is rotatably connected to a sixth shaft 902. The sixth shaft 902 is fixedly connected to a seventh sprocket 9022 and a sixth gear 9021. The seventh sprocket 9022 is connected to the sixth sprocket. 9012 is rotationally connected by the third chain 9013, the sixth rotating shaf...

Embodiment 3

[0044] refer to figure 2 ,and Figure 6 , is basically the same as in Embodiment 1, furthermore, the crushing mechanism includes a first motor 7 and crushing teeth 7041, the first motor 7 is fixedly connected in the base 1, the first motor 7 is located on the left side of the feed pipe 802, the first The output end of a motor 7 is fixedly connected with a threaded barrel 701, the threaded barrel 701 is internally threaded with a threaded rod 702, the bottom of the threaded rod 702 is rotatably connected with an installation box 703, and the inside of the installation box 703 is rotatably connected with a fourth rotating shaft 704, and the crushing teeth 7041 is fixedly connected to the fourth rotating shaft 704, the base 1 is provided with a mounting groove 705, the mounting groove 705 is rotatably connected with a directional rod 7051, and the directional rod 7051 is rotatably connected with the mounting box 703, and the base 1 is provided with a first mounting cavity 101 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com