Method and device for environment-friendly recovery of precious metal in waste circuit board through combined smelting of waste circuit board, copper concentrate and desulfurized gypsum

A technology for waste circuit boards and desulfurization gypsum is applied in the field of precious metals, which can solve the problems of not being able to completely suppress the production of dioxins, unable to be practically applied to industrial production, etc., so as to suppress the generation of dioxins in flue gas, save treatment costs, and be practical. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

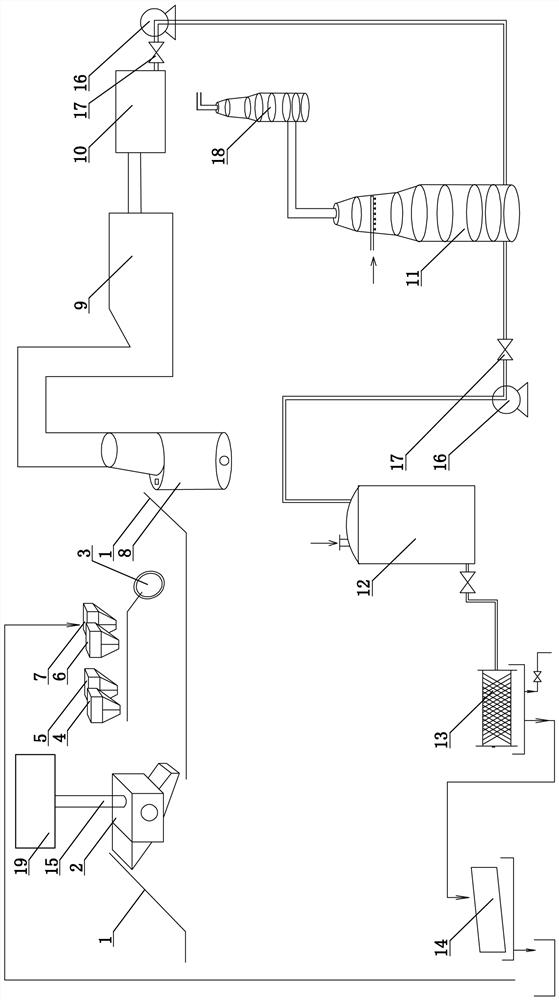

[0050] see figure 1 , the waste circuit board, copper concentrate and desulfurized gypsum joint smelting method for environmental protection and recovery of precious metals in the waste circuit board, comprising the following steps:

[0051] (1) Waste circuit board preparation: disassemble the waste circuit board, remove tin, iron, aluminum, copper wire and other impurities, and then crush it into copper-containing waste circuit boards with a size of 40 mm by the waste circuit board crusher 2;

[0052] (2) Mixing and granulation: Put copper-containing waste circuit boards together with copper concentrate, desulfurized gypsum, and copper concentrate auxiliary materials into the disc granulator 3 to make 10mm-sized pellets. The copper-containing waste circuit boards : copper concentrate: desulfurization gypsum: the mass ratio of copper concentrate auxiliary materials is 8:160:12:25;

[0053] (3) Austro furnace smelting: Put the above prepared pellets into Osmelt furnace 8 for s...

Embodiment 2

[0061] A method for environmentally friendly recycling of precious metals in waste circuit boards through joint smelting of waste circuit boards, copper concentrate and desulfurized gypsum, comprising the following steps:

[0062] (1) Waste circuit board preparation: Disassemble the waste circuit board, remove tin, iron, aluminum, copper wire and other impurities, and then crush it into copper-containing waste circuit boards with a size of 20 mm by a crusher;

[0063] (2) Mixing and granulation: Put copper-containing waste circuit boards together with copper concentrate, desulfurized gypsum, and copper concentrate auxiliary materials into the granulator to make 5mm-sized pellets. The copper-containing waste circuit boards: copper concentrate The mass ratio of ore: desulfurized gypsum: copper concentrate auxiliary materials is 5:150:10:30;

[0064] (3) Austro-furnace smelting: Put the above-mentioned prepared pellets into the Osmelt furnace for smelting. During the smelting pro...

Embodiment 3

[0070] A method for environmentally friendly recycling of precious metals in waste circuit boards through joint smelting of waste circuit boards, copper concentrate and desulfurized gypsum, comprising the following steps:

[0071] (1) Waste circuit board preparation: Disassemble the waste circuit board, remove tin, iron, aluminum, copper wire and other impurities, and then crush it into copper-containing waste circuit boards with a size of 30 mm by the waste circuit board crusher;

[0072] (2) Mixing and granulation: add copper-containing waste circuit boards together with copper concentrate, desulfurized gypsum, and copper concentrate auxiliary materials into the granulator to make 15mm-sized pellets. The copper-containing waste circuit board: copper concentrate The mass ratio of ore: desulfurized gypsum: copper concentrate auxiliary materials is 10:180:15:20;

[0073] (3) Austrian furnace smelting: Put the above-mentioned prepared pellets into the Osmelt furnace for smelting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com