Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104 results about "Electron beam deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

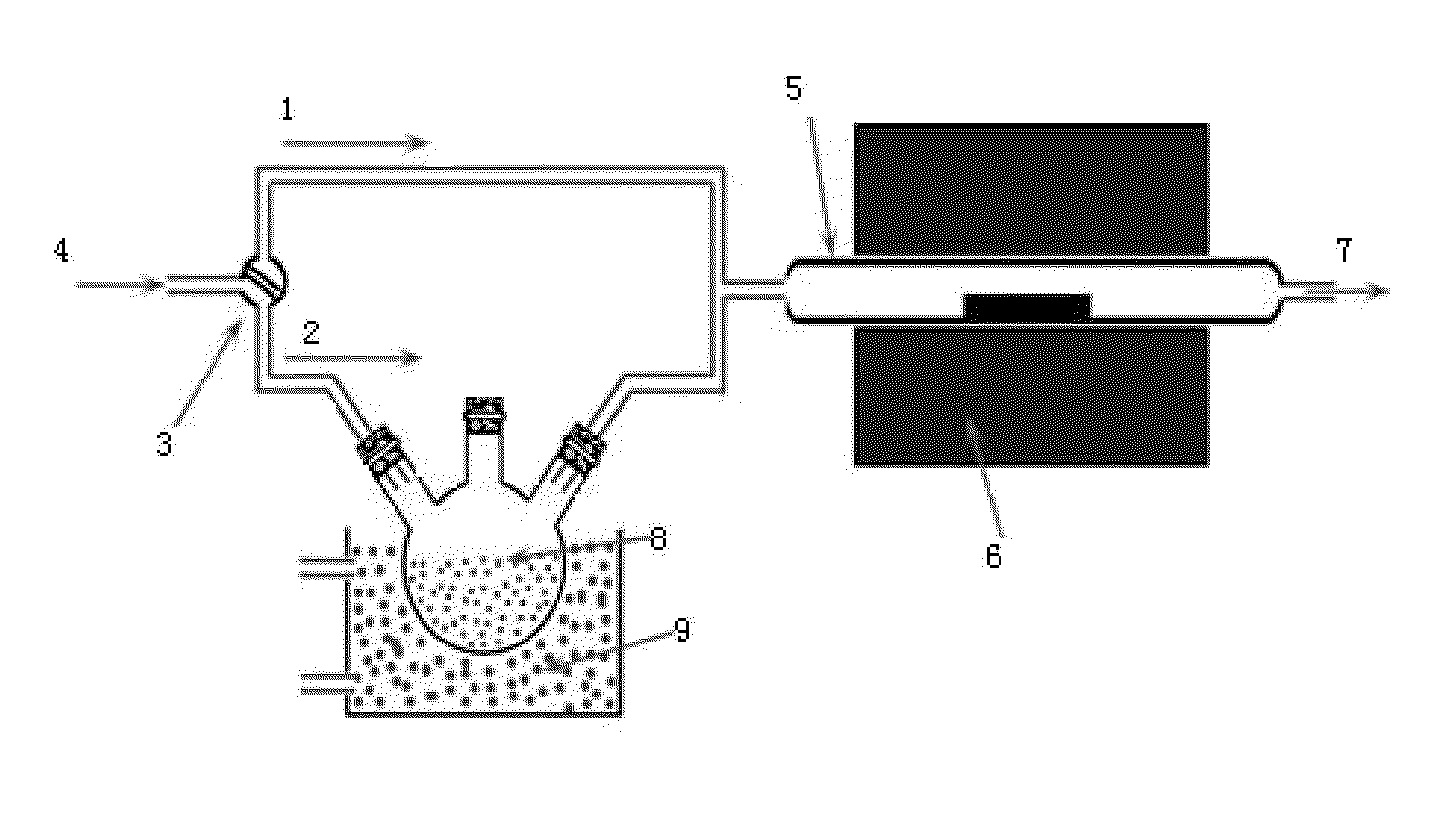

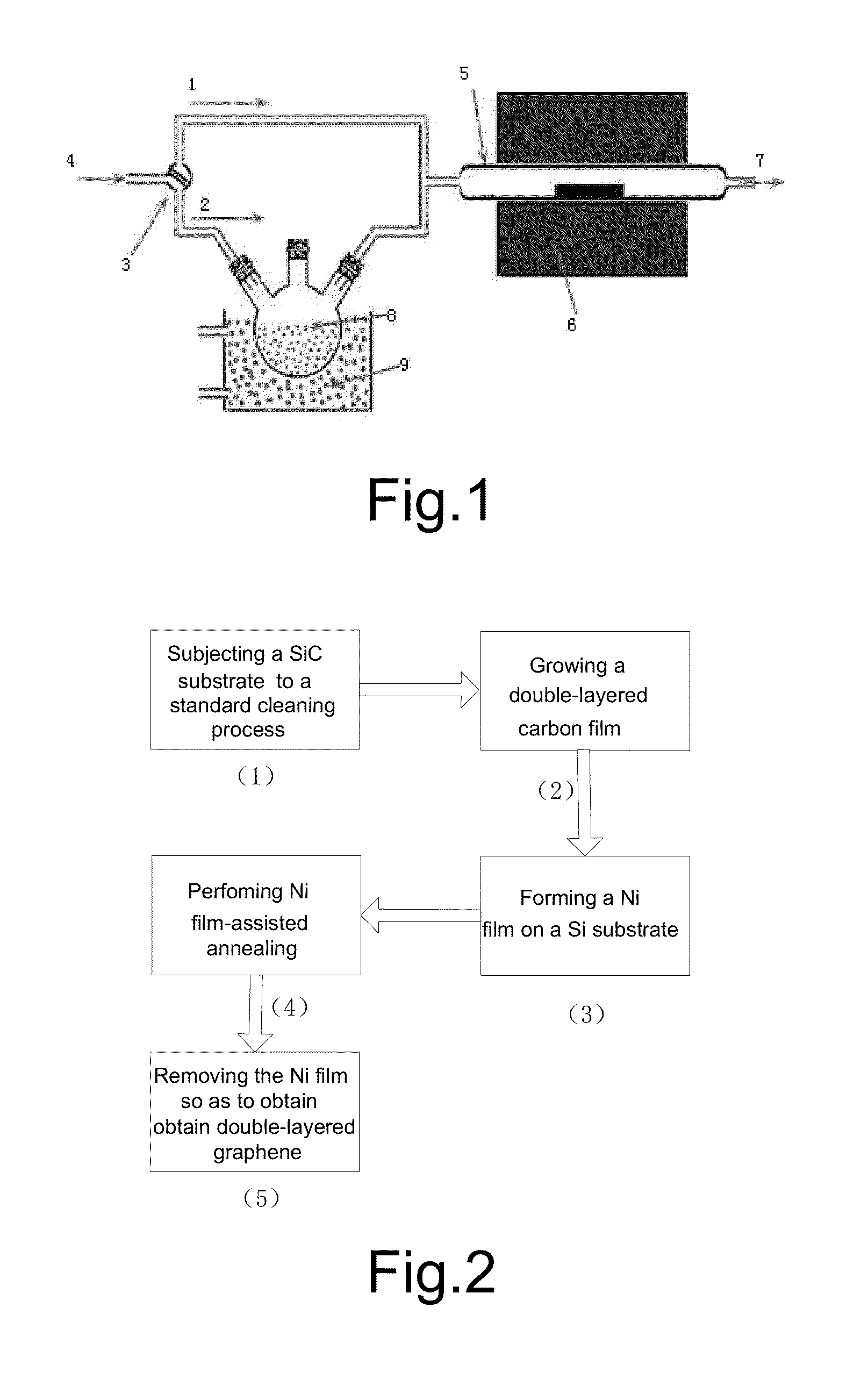

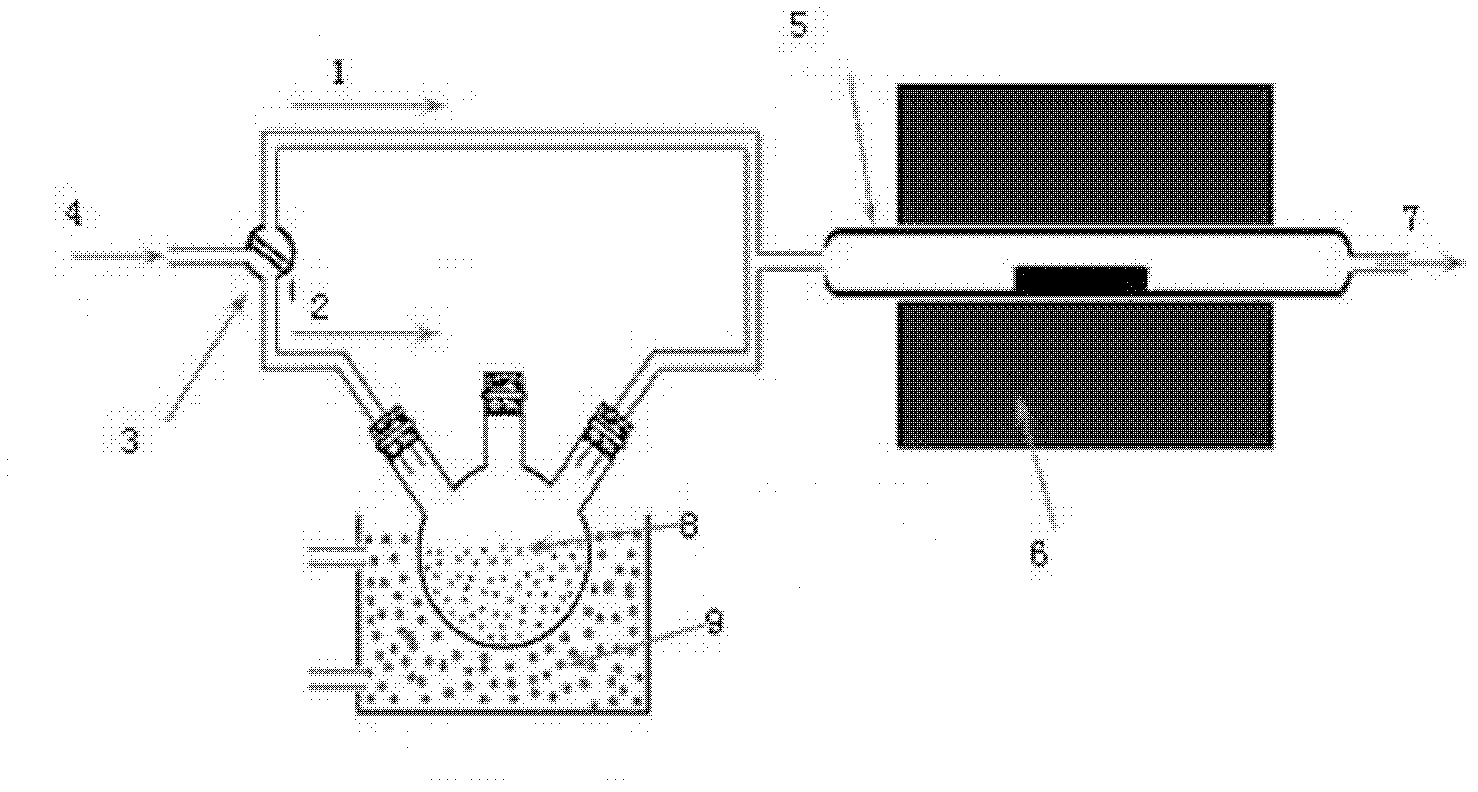

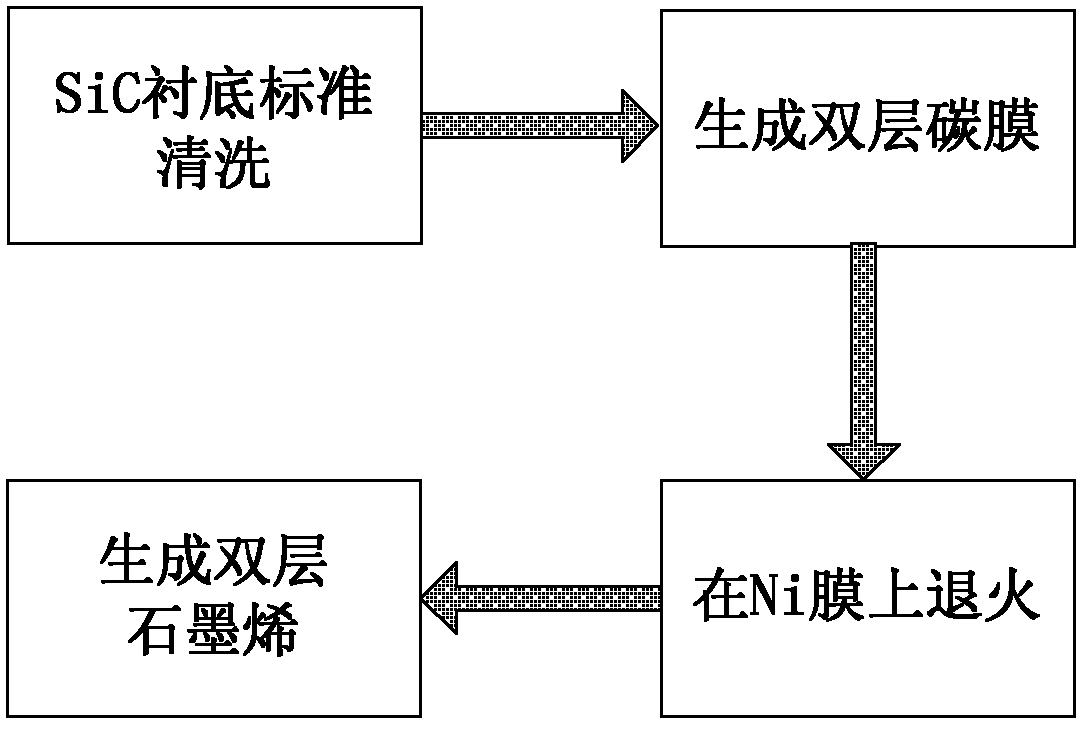

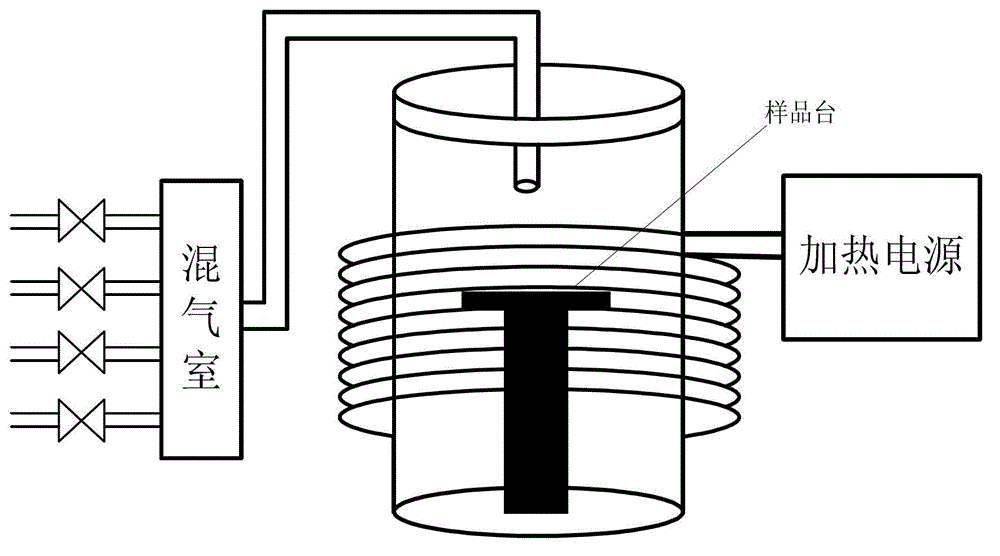

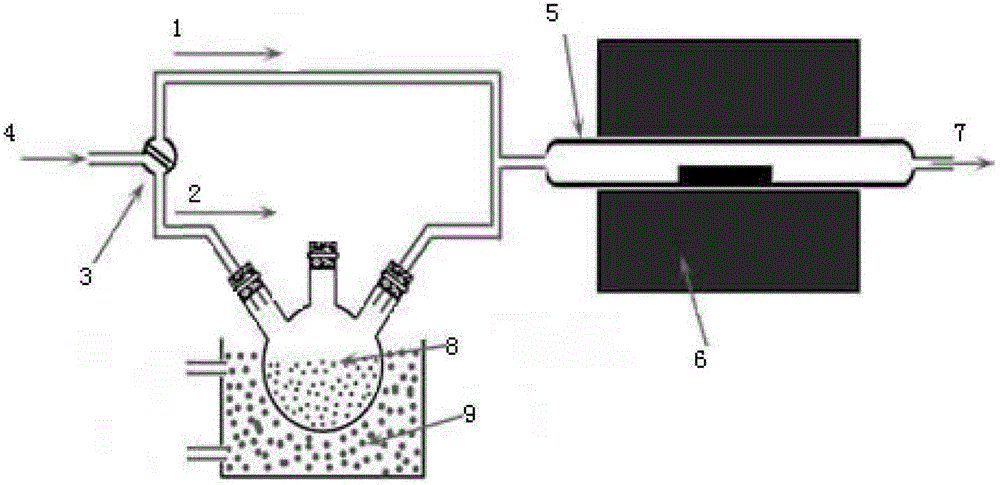

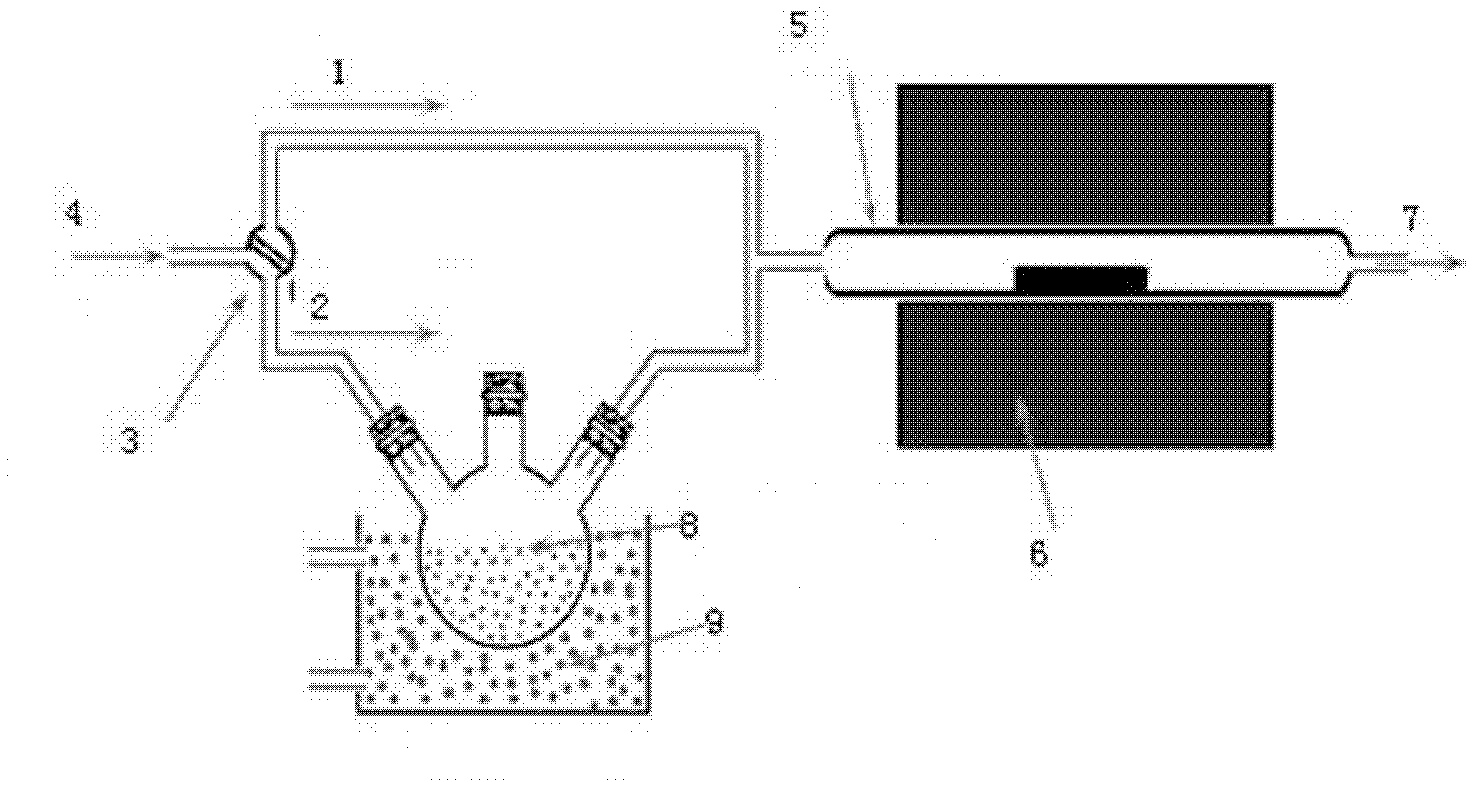

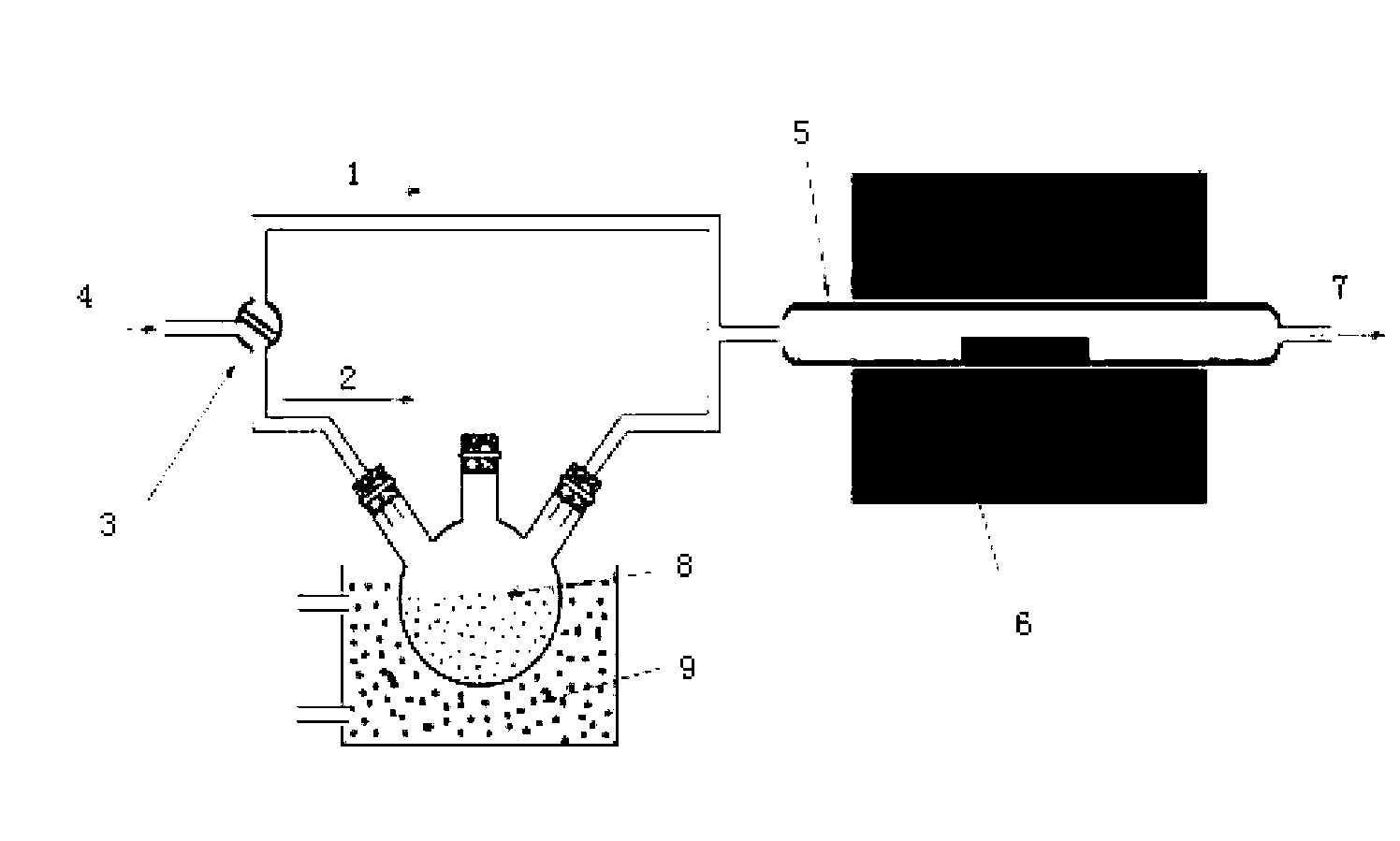

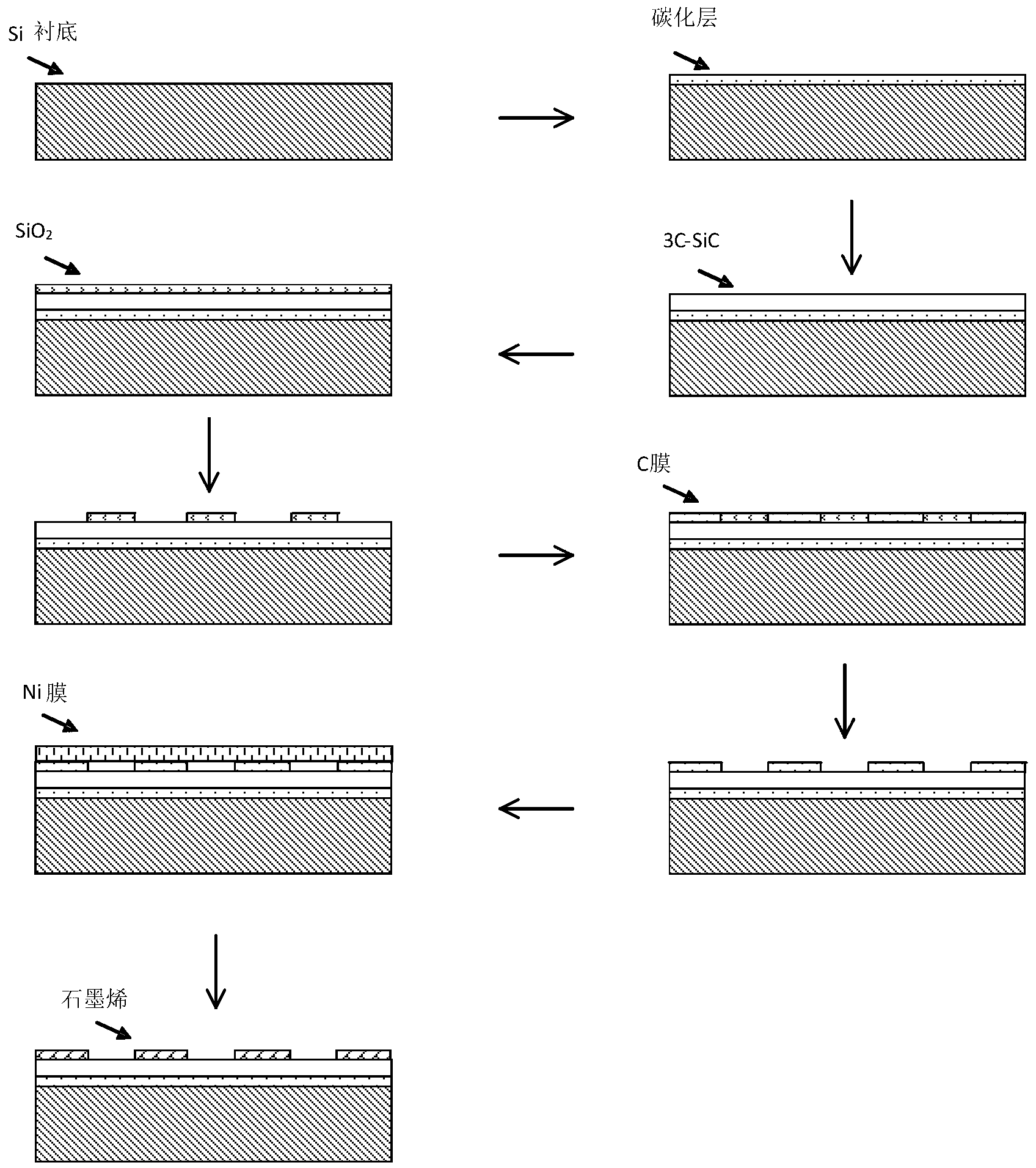

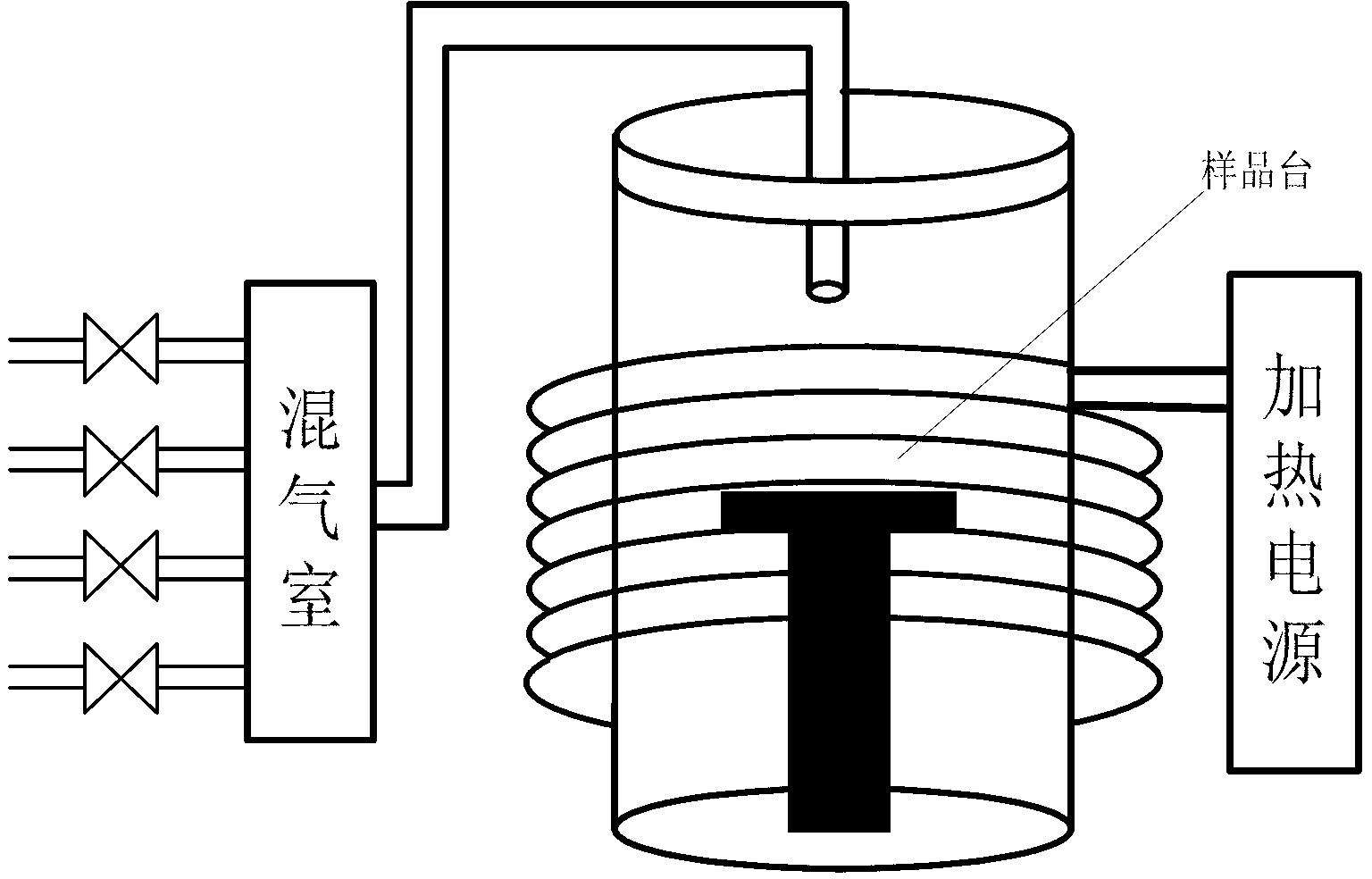

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

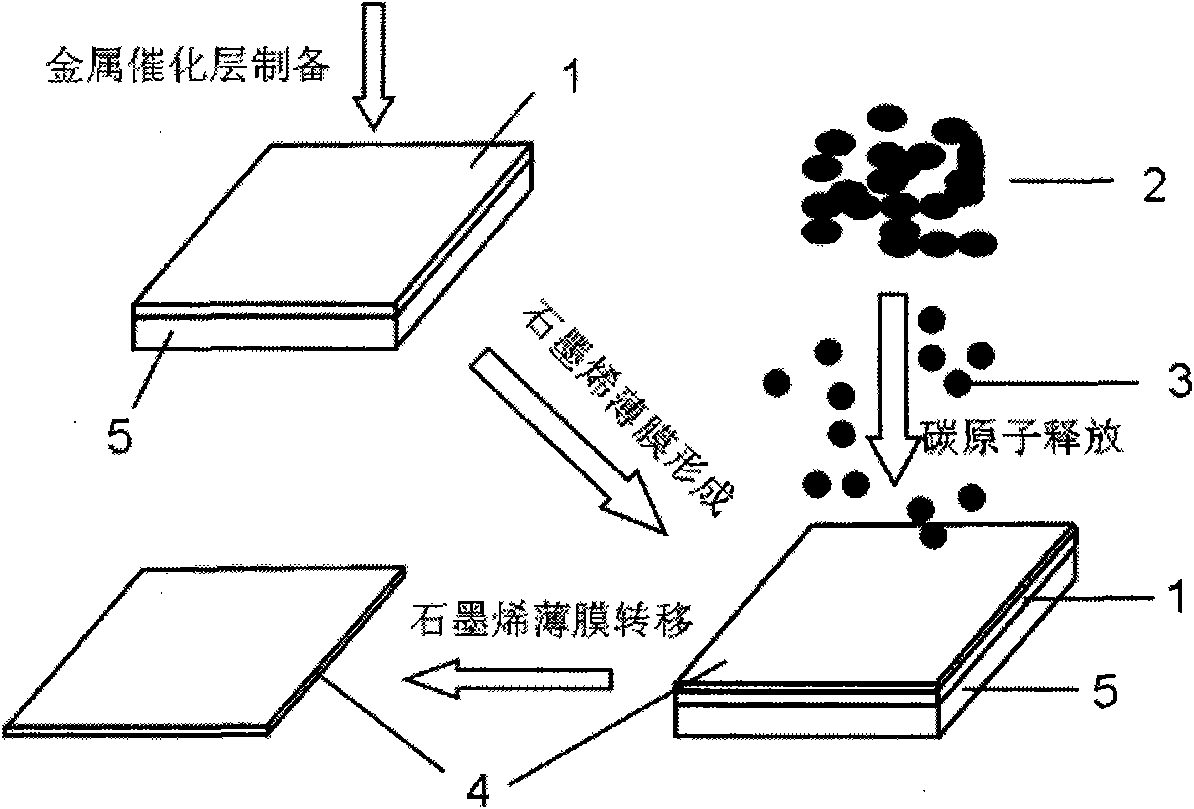

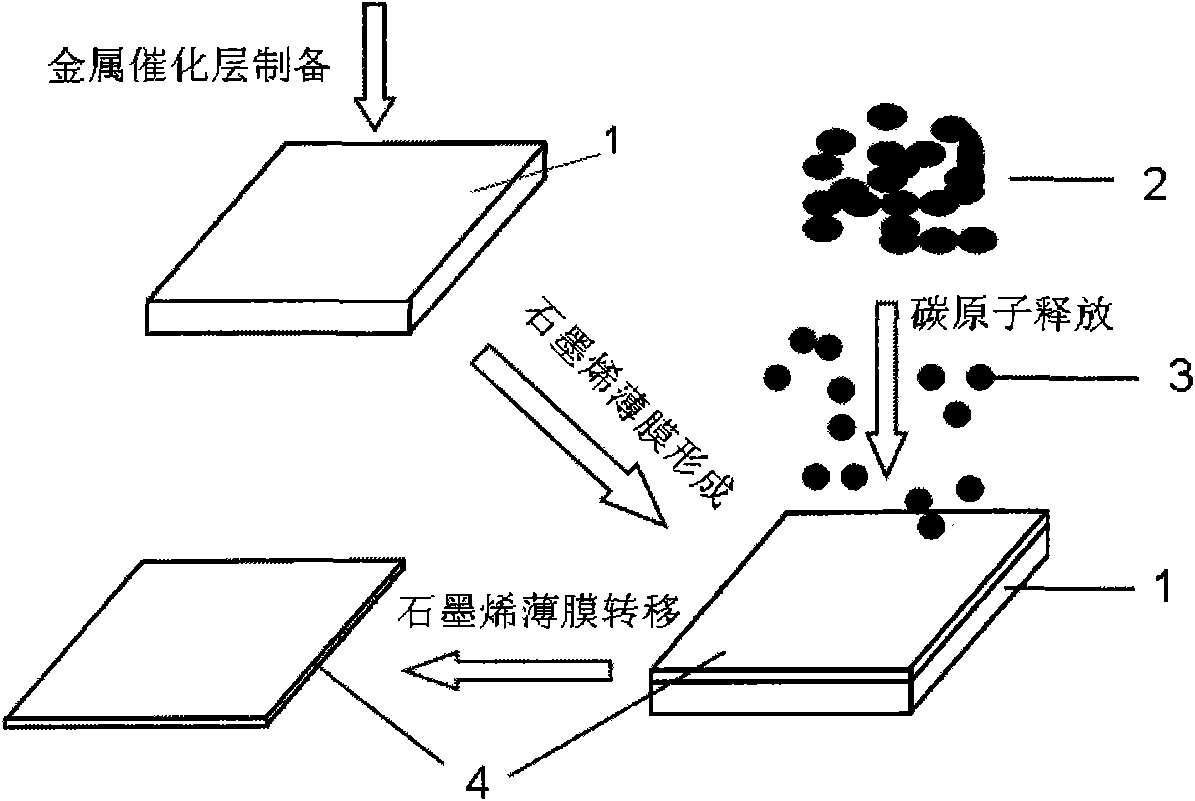

Method for preparing graphene membrane

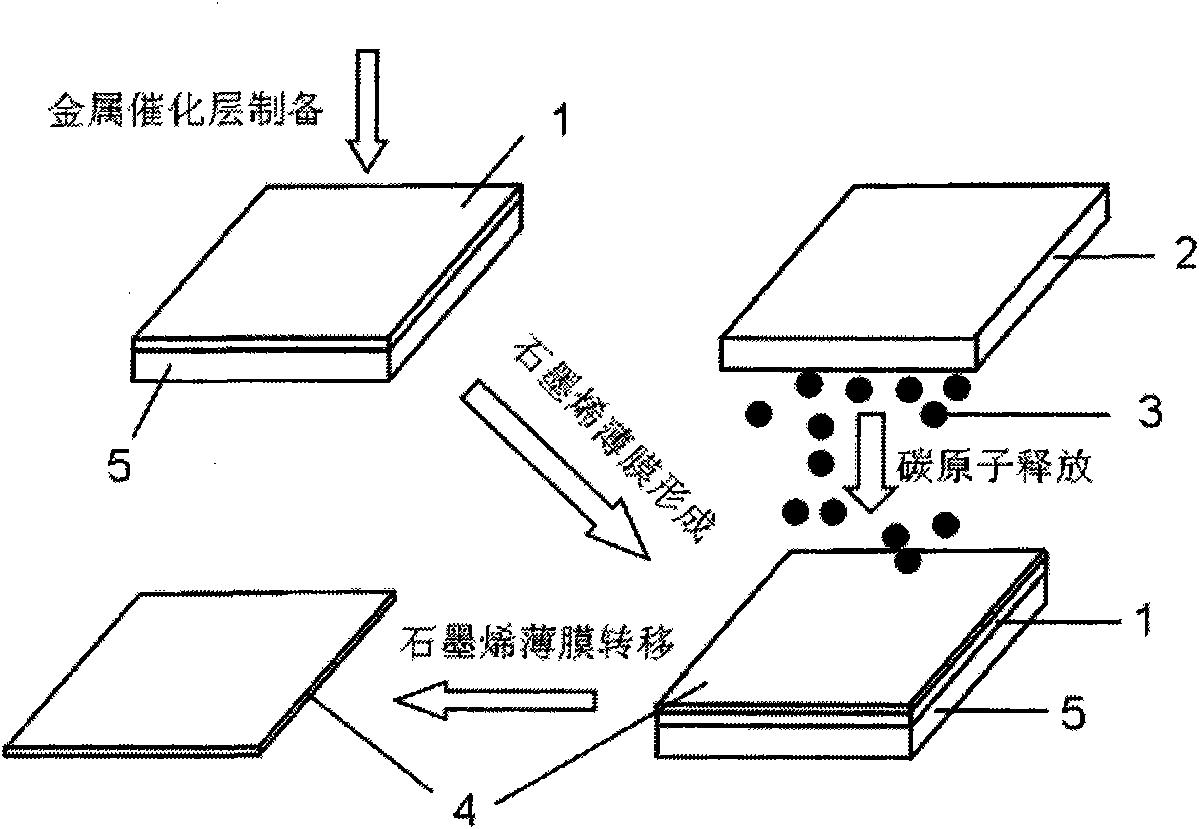

The invention discloses a method for preparing a graphene membrane. Carbon atoms are released from a solid carbon source by a method such as heat treatment, heat evaporation, sputtering, electron beam deposition, laser deposition or plasma deposition to form the graphene membrane on a catalytic layer or a substrate, wherein the solid carbon source is graphite, amorphous carbon, diamond, fullerene or carbon nano tubes. In the method for preparing the graphene membrane, the solid carbon source is used, the method is simple; and the prepared graphene membrane is easy to control in terms of thickness, structure and size, has excellent photoelectric characteristics and is suitable for preparing high-performance photoelectronic devices on a large scale.

Owner:ZHEJIANG UNIV

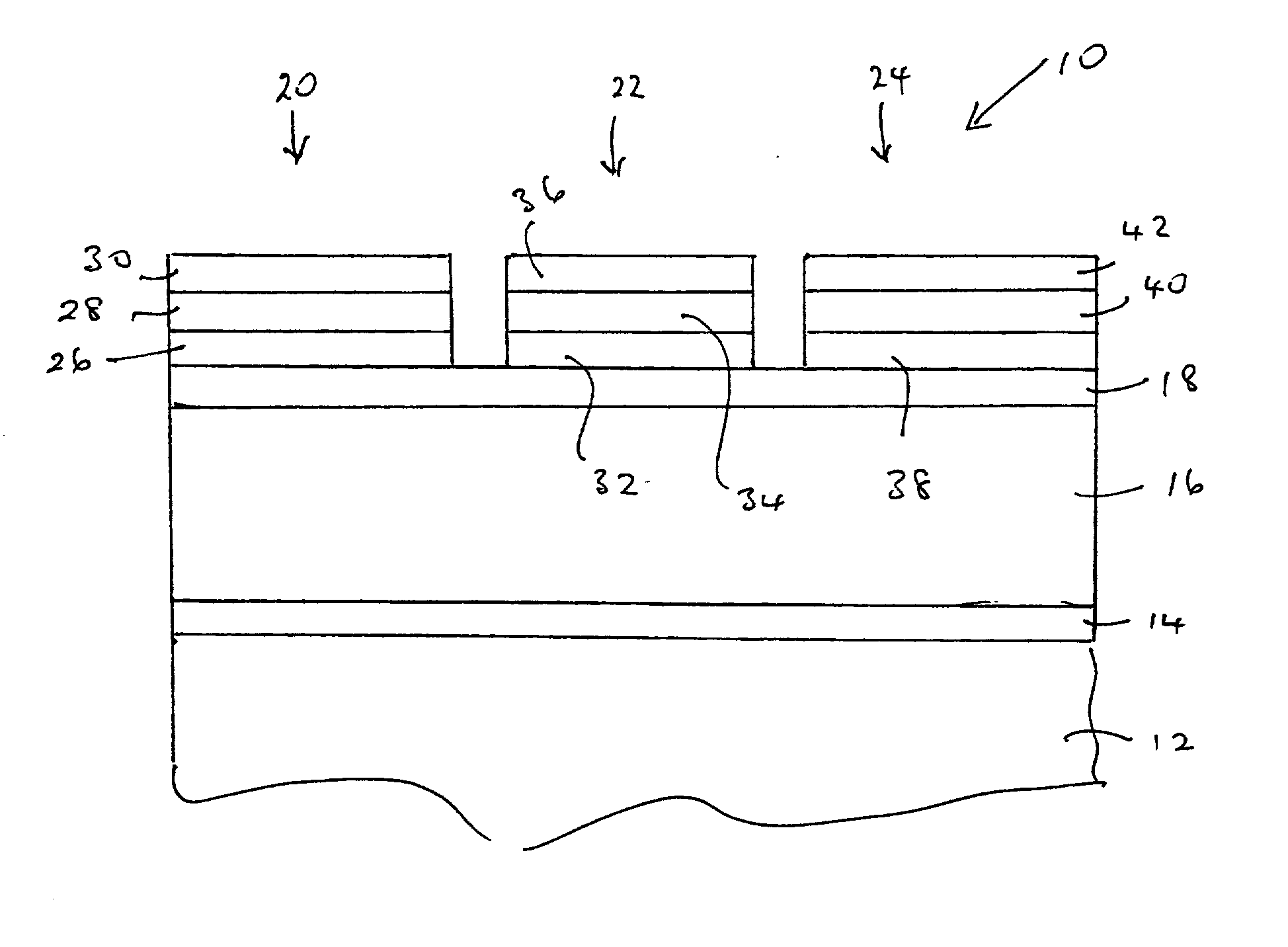

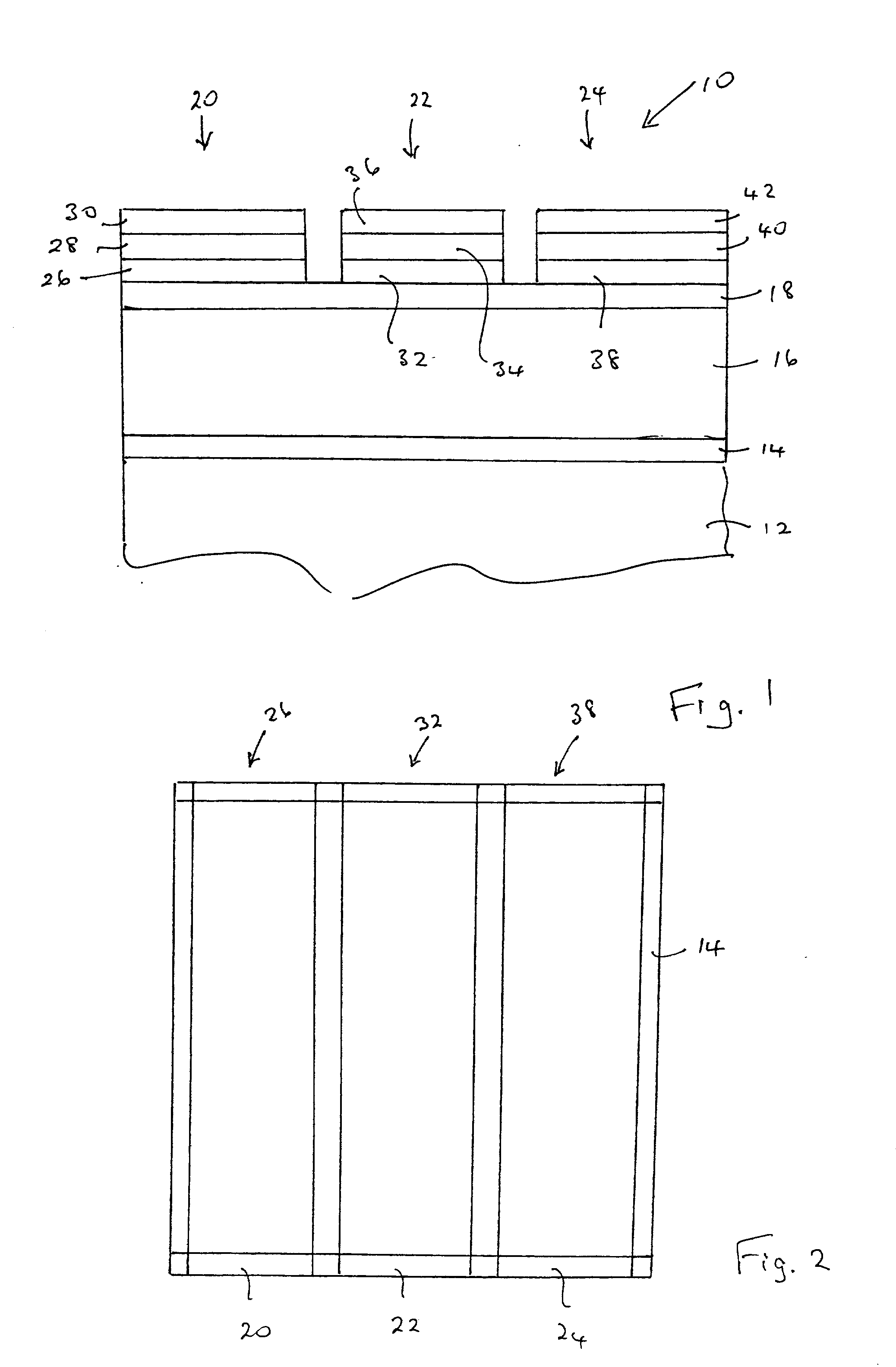

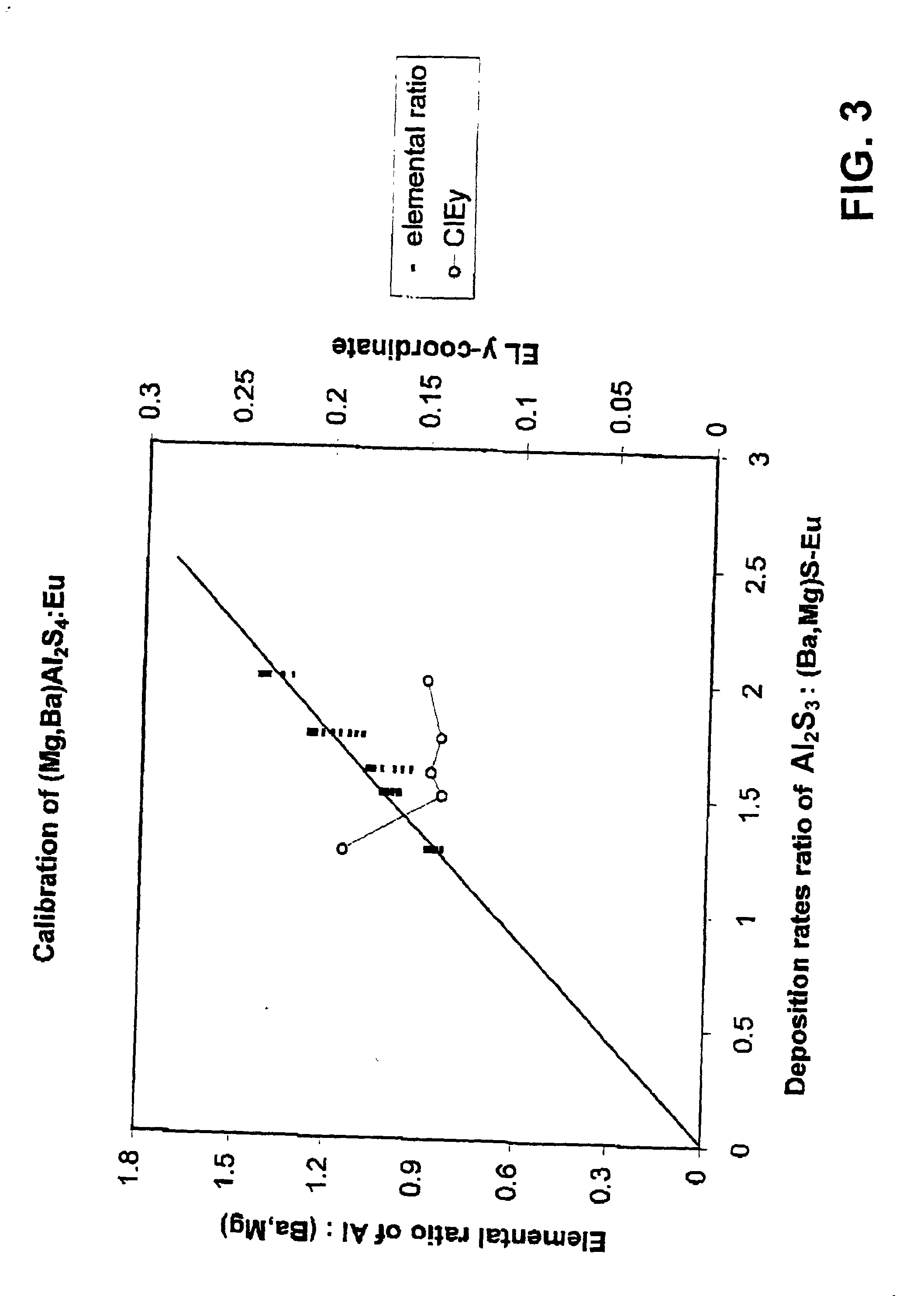

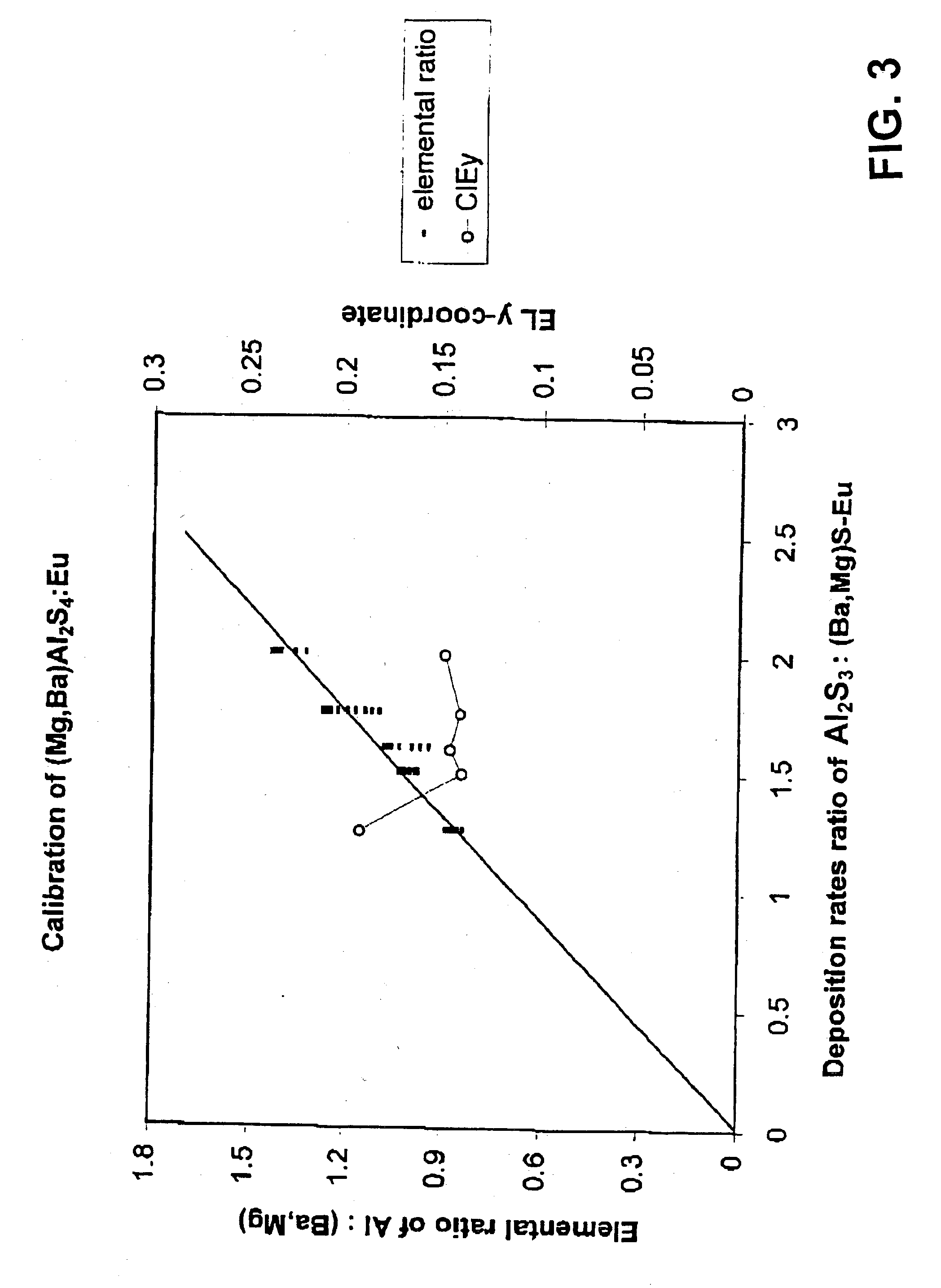

Magnesium barium thioaluminate and related phosphor materials

A phosphor and a method of deposition. The phosphor comprises a composition of the formula M'aBa1-aM''2M'''4':RE, where M' is at least one element selected from magnesium and calcium, M'' is at least one element selected from aluminum, gallium and indium, M''' is at least one element selected from sulphur, selenium and tellurium, RE is at least one rare earth element, especially europium or cerium, and 0<a<1. Deposition is preferably by dual source electron beam deposition. The phosphor may be annealed. The phosphor provides a high luminosity blue emission that does not require an optical filter to achieve acceptable colour coordinates for the blue sub-pixel element for a full colour thin film or thick film electroluminescent display. The blue sub-pixel pixel performance meets the luminosity and colour temperature specifications for current generation cathode ray tube displays.

Owner:IFIRE TECH INC

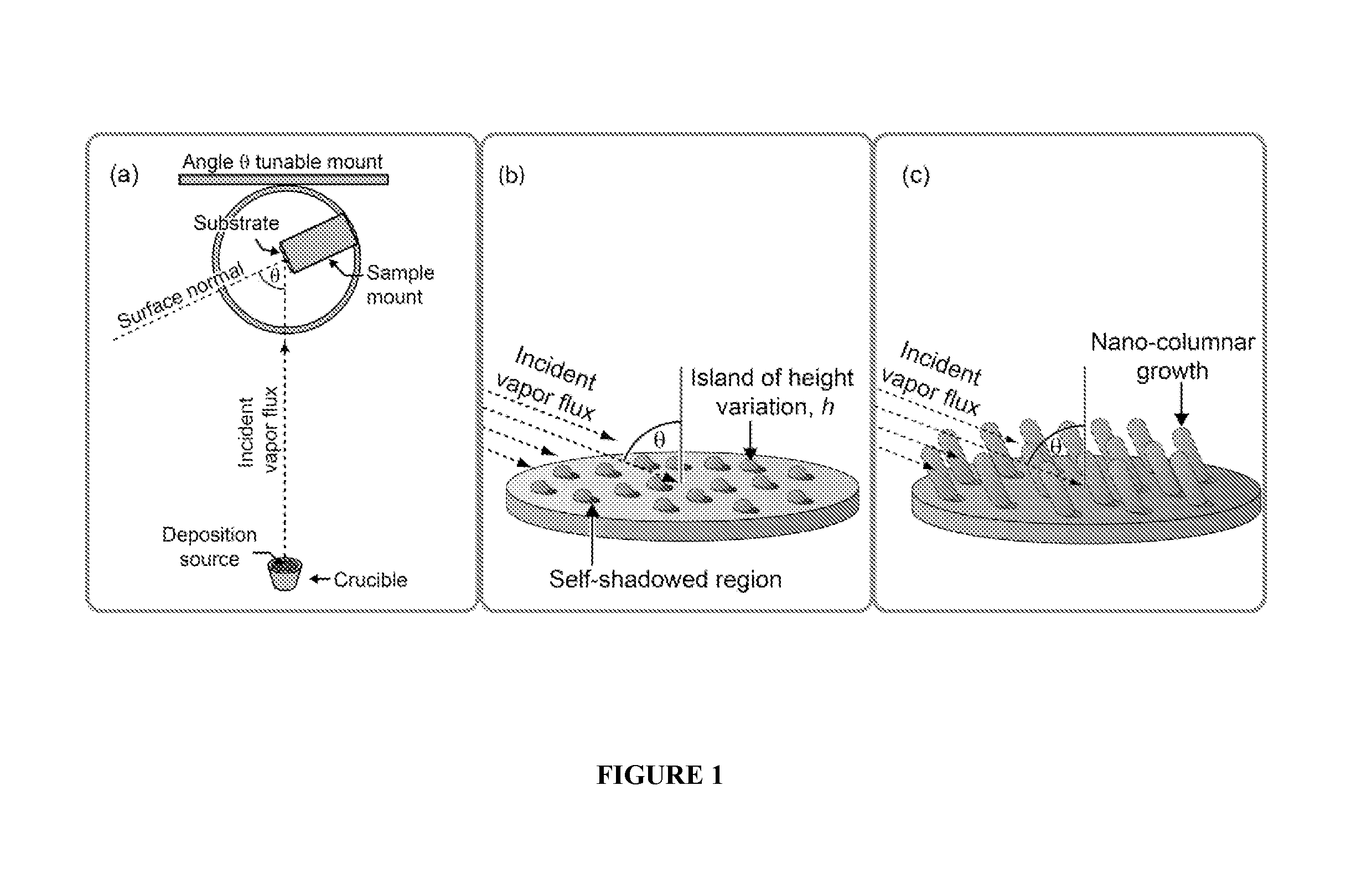

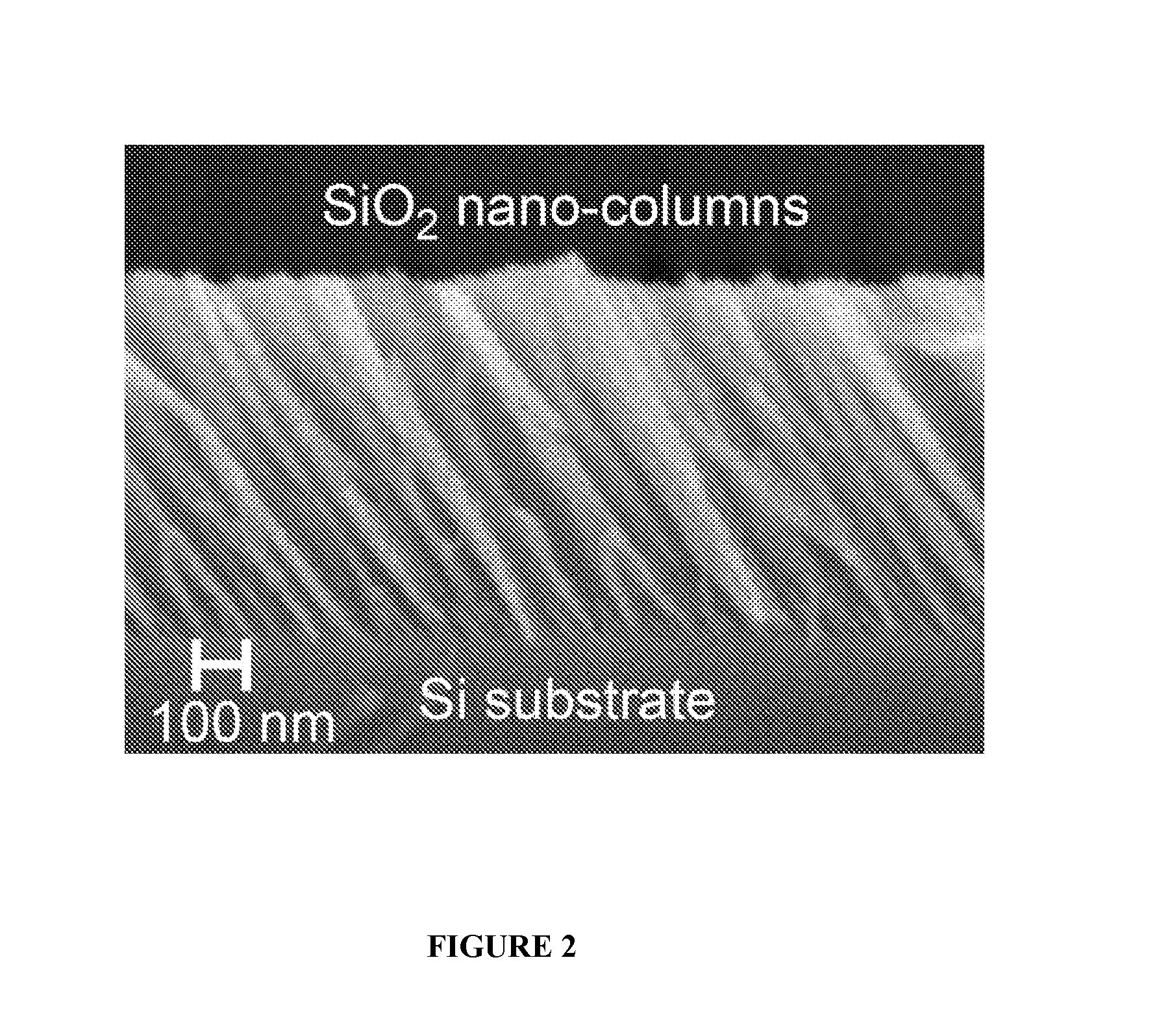

Tunable nanoporous films on polymer substrates, and method for their manufacture

ActiveUS20130209780A1Maintenance characteristicMaterial nanotechnologyElectric discharge heatingPolymer scienceElectron beam deposition

The invention is directed to a composite polymer / nanoporous film system and methods of fabrication of tunable nanoporous coatings on flexible polymer substrates. The porosity of the nanoporous film can be tuned during fabrication to a desired value by adjusting the deposition conditions. Experiments show that SiO2 coatings with tunable porosity fabricated by oblique-angle electron beam deposition can be deposited on polymer substrates. These conformable coatings have many applications, including in the field of optics where the ability to fabricate tunable refractive index coatings on a variety of materials and shapes is of great importance.

Owner:RENESSELAER POLYTECHNIC INST

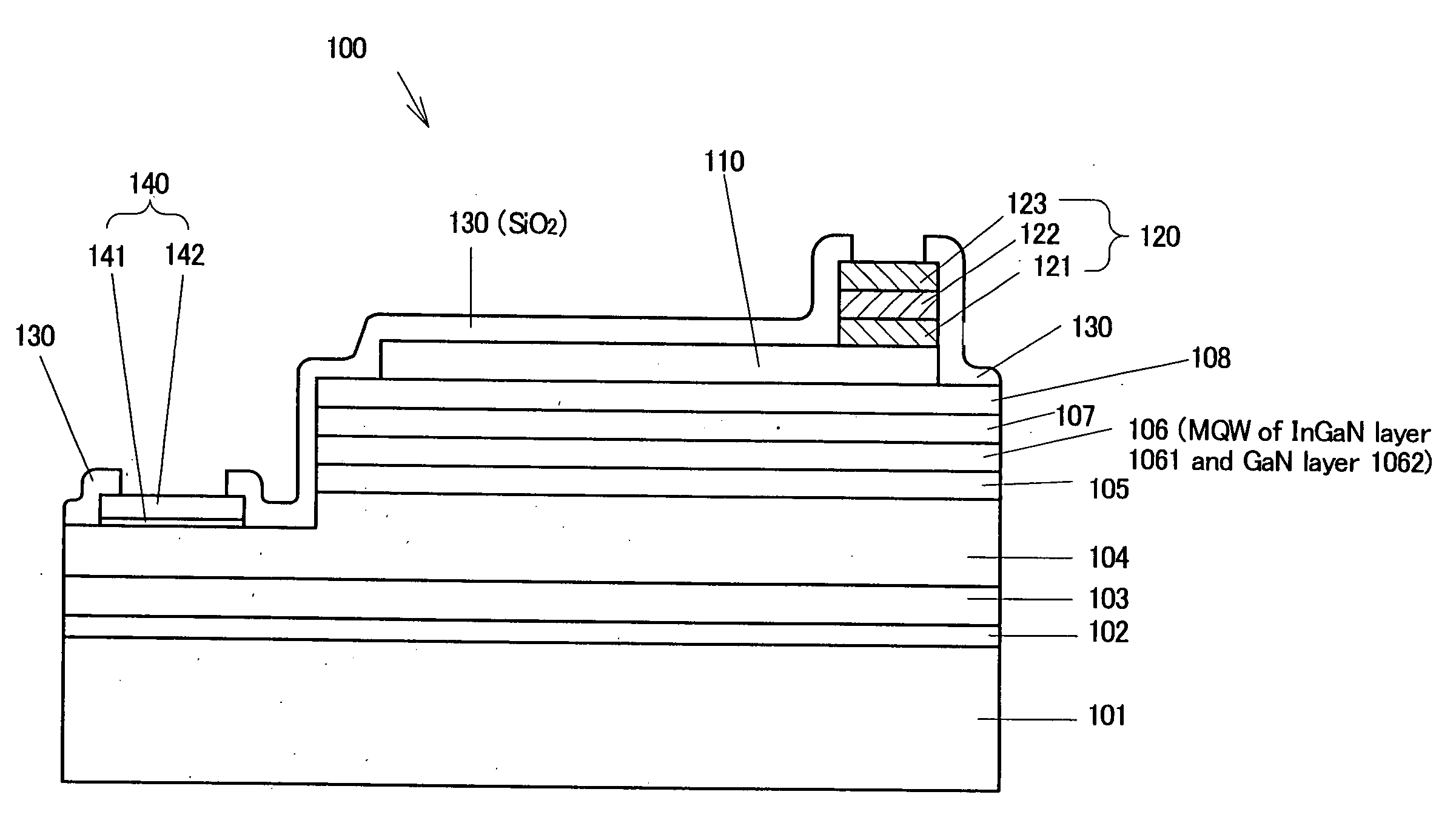

Method for forming an electrode

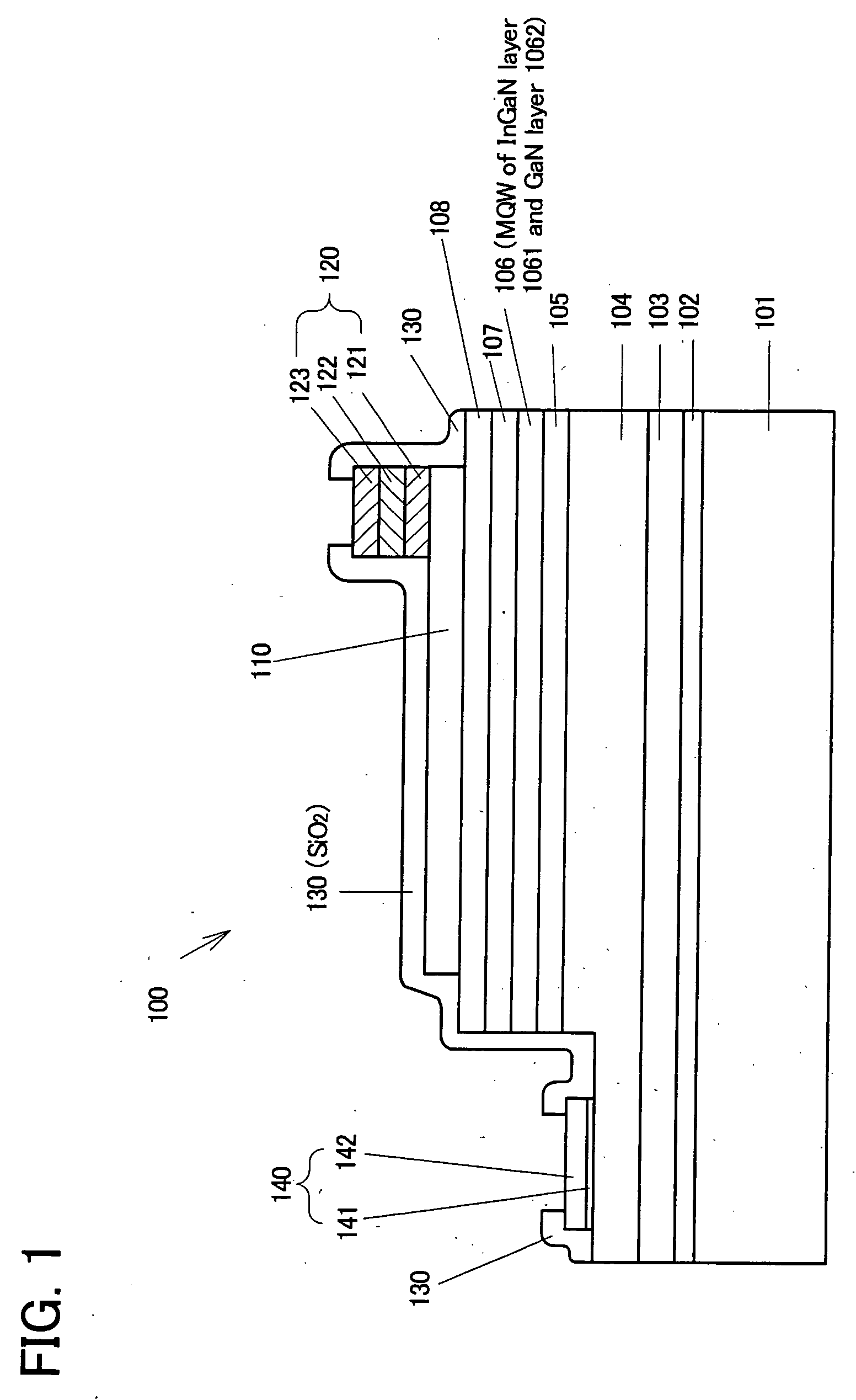

ActiveUS20060073692A1High light transmittanceLow resistivitySolid-state devicesSemiconductor/solid-state device manufacturingElectron beam depositionIndium tin oxide

In a semiconductor light-emitting device 100, a buffer layer 102, a undoped GaN layer 103, a high carrier concentration n+-layer 104, an n-type layer 105, an emission layer 106, a p-type layer 107, and a p-type contact layer 108 are deposited in sequence on a sapphire substrate. The semiconductor light-emitting device 100 comprises a light-transparent electrode 110 made of indium tin oxide (ITO) which is deposited in the low pressure vacuum chamber flowing at least oxygen gas through electron beam deposition or ion plating treatment and thermal process are carried out.

Owner:TOYODA GOSEI CO LTD

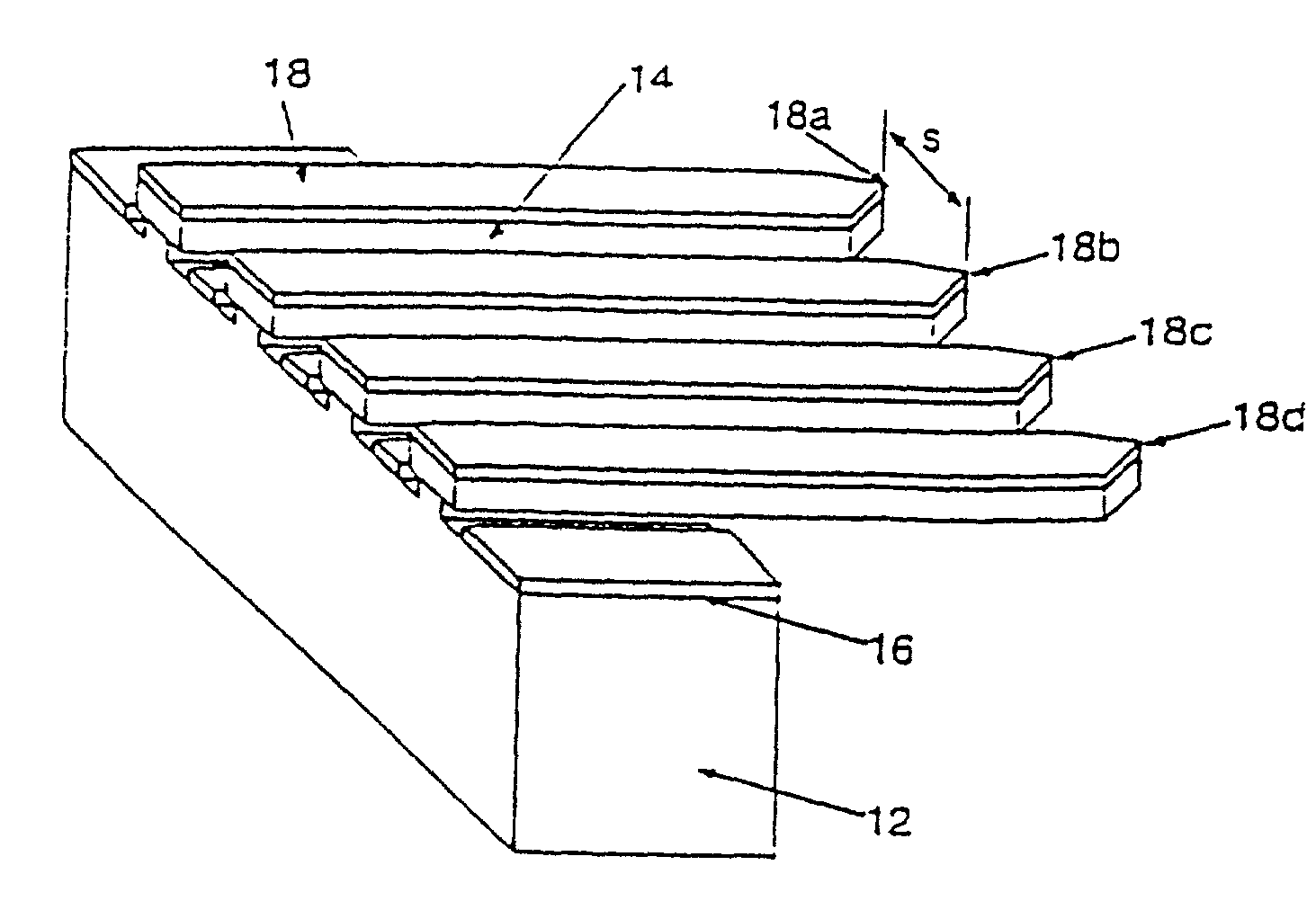

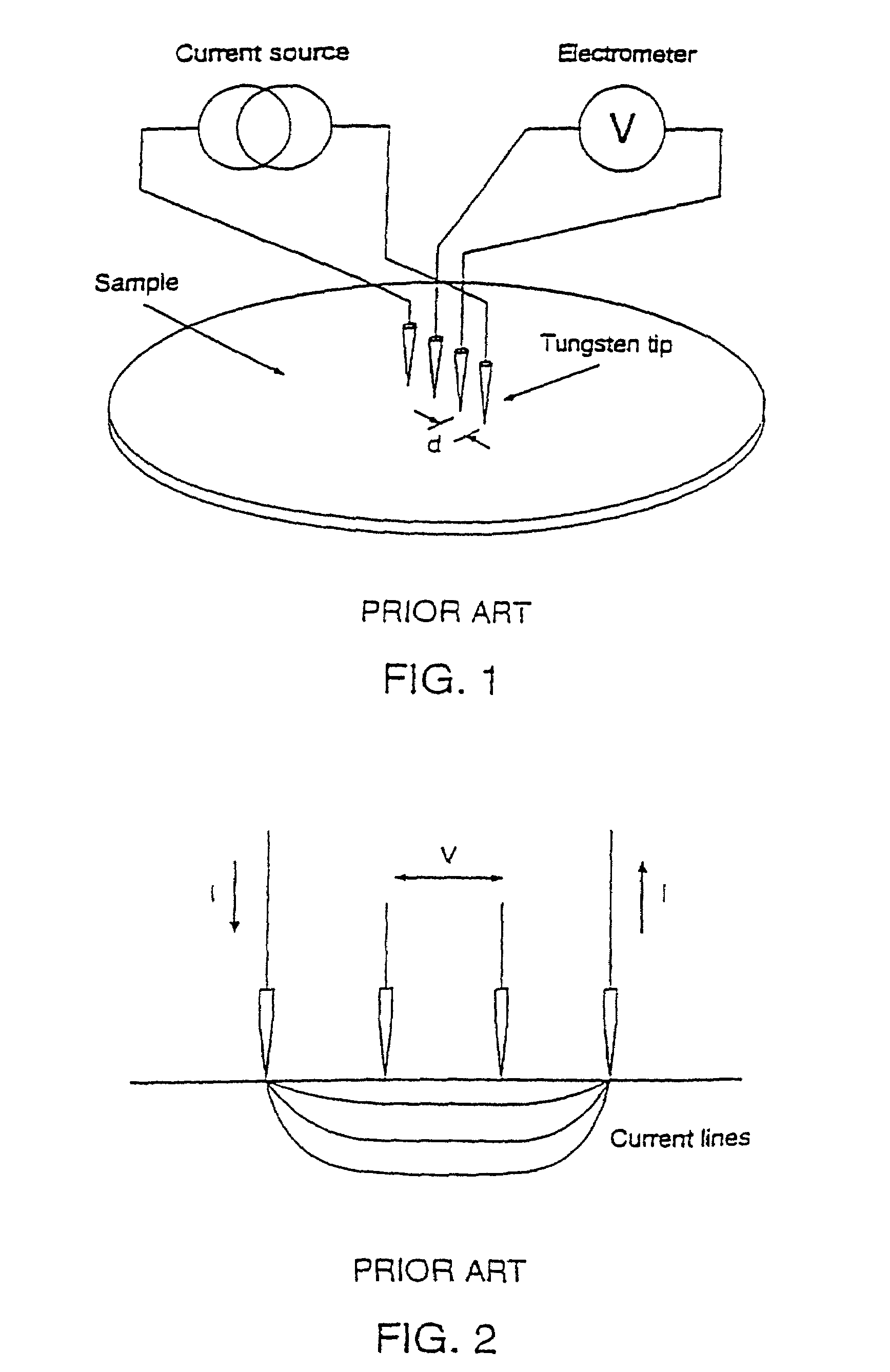

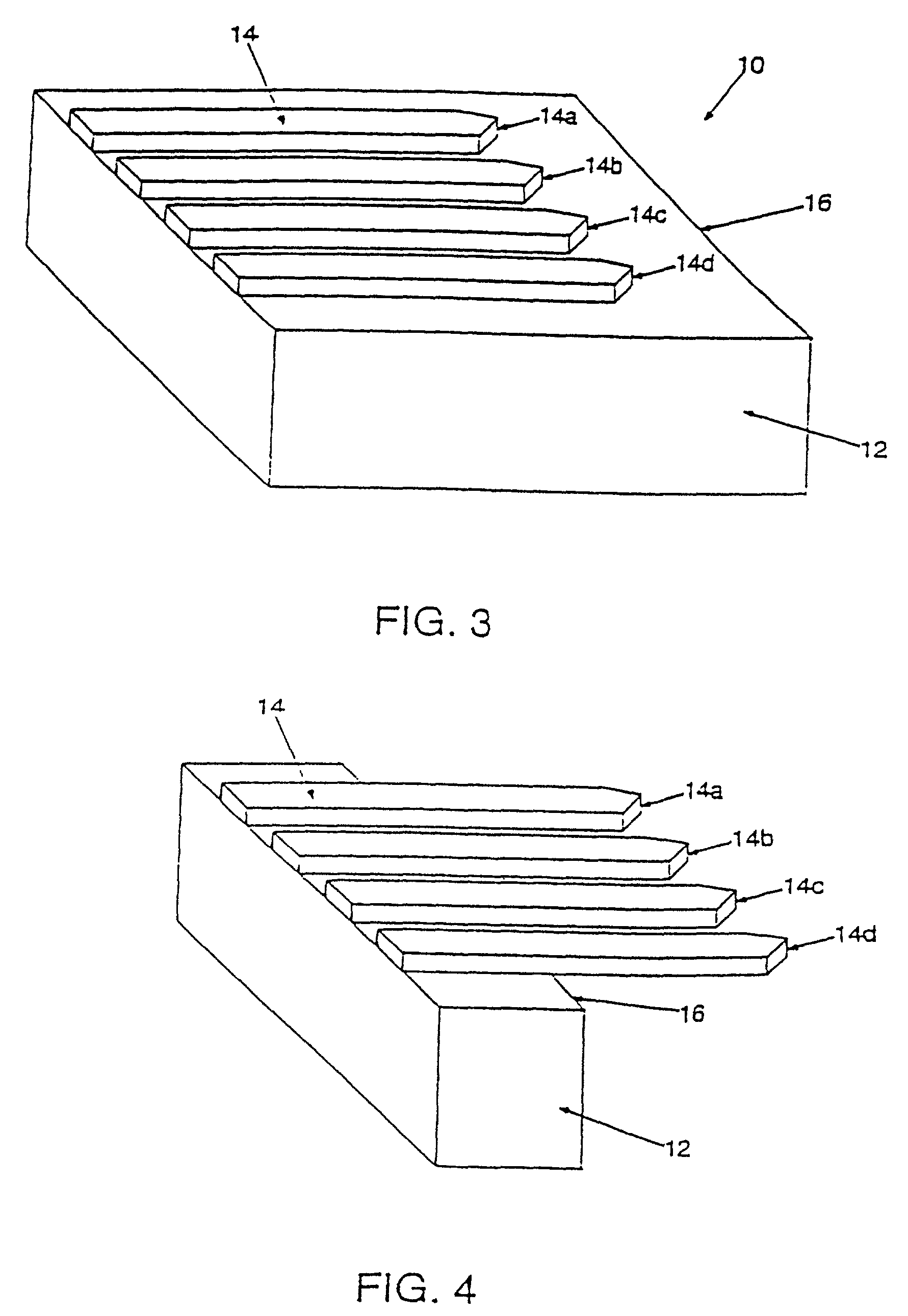

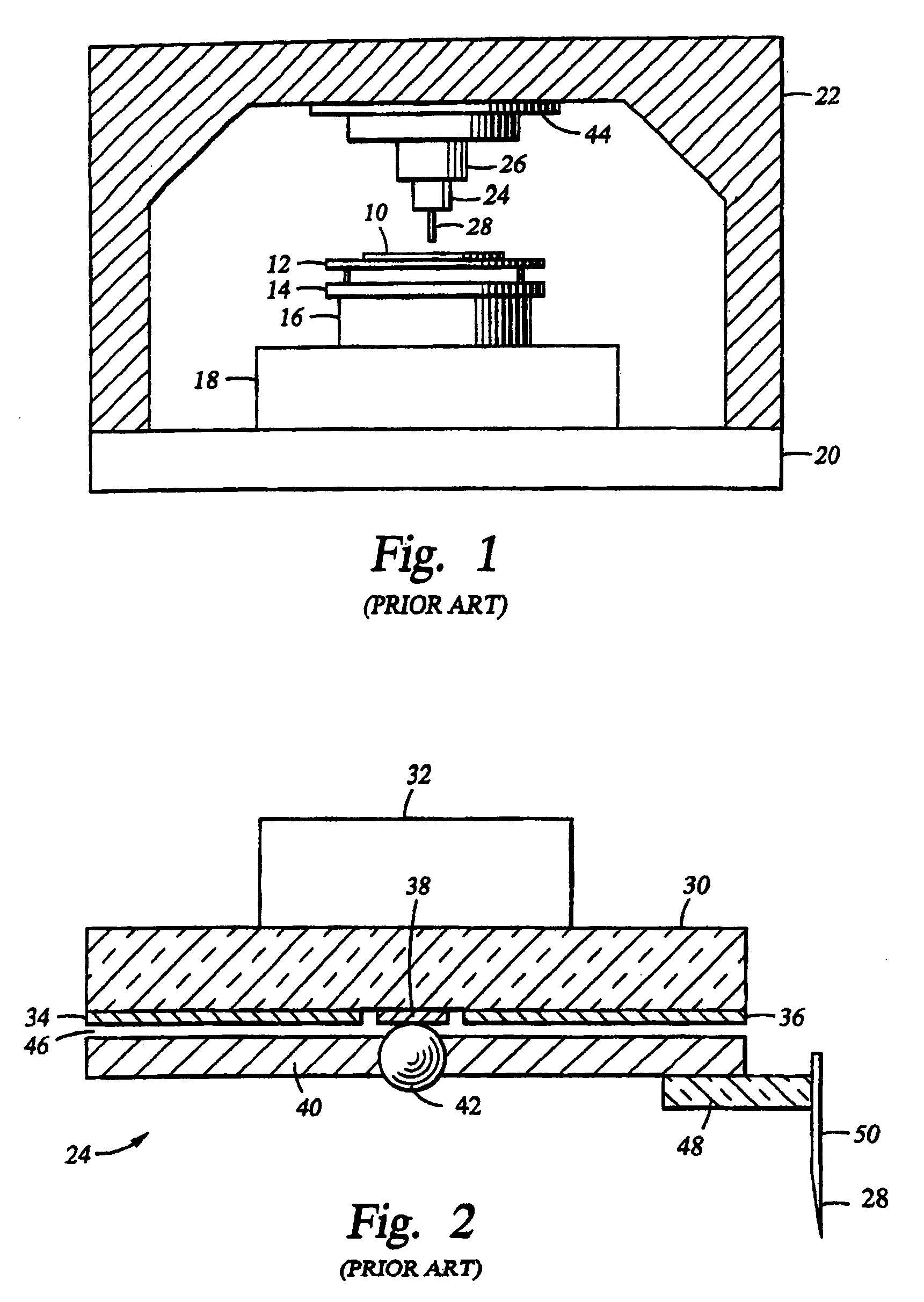

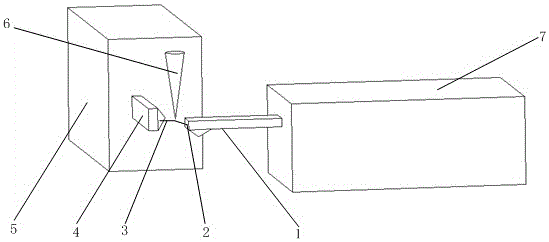

Nano-drive for high resolution positioning and for positioning of a multi-point probe

InactiveUS7304486B2Electronic circuit testingResistance/reactance/impedenceElectron beam depositionEngineering

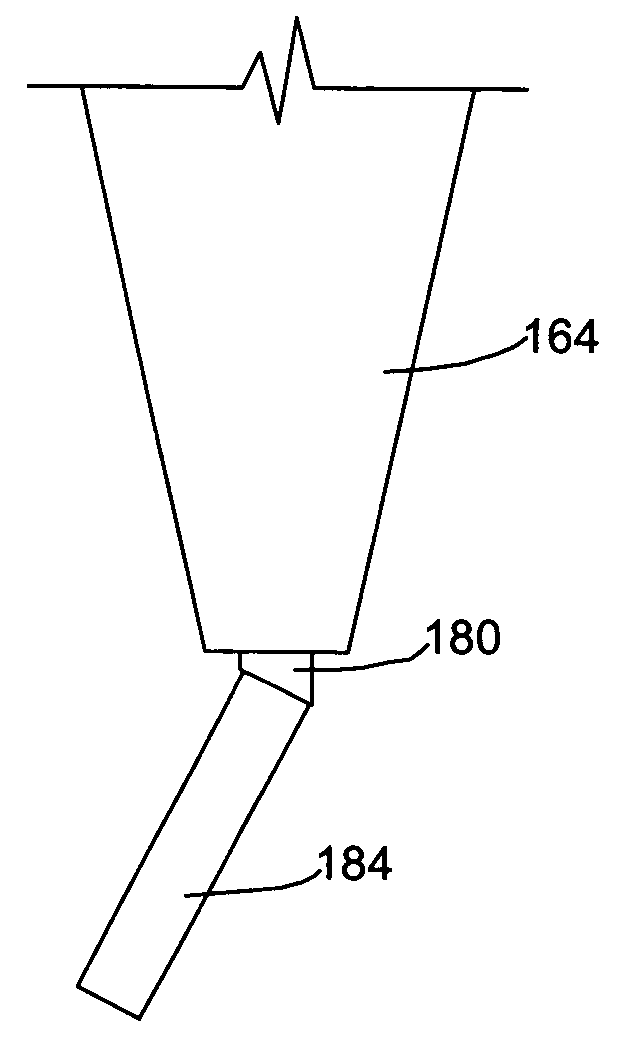

The multi-point probe comprises a supporting body defining a first surface, a first multitude of conductive probe arms each of the probe arms defining a proximal end and a distal end being positioned in co-planar relationship with the first surface of the supporting body. The probe arms are connected to the supporting body at the proximal ends thereof and have the distal ends freely extending from the supporting body, giving individually flexible motion to the first multitude of probe arms. The probe arms originate from a process of producing the probe arms on a wafer body in facial contact with the wafer body and removal of a part of the wafer body providing the supporting body and providing the probe arms freely extending therefrom. The multi-point probe further comprises a third multitude of tip elements extending from the distal end of the first multitude of probe arms. The tip elements originate from a process of metallization of electron beam depositions on the probe arms at the distal ends thereof.

Owner:CAPRES

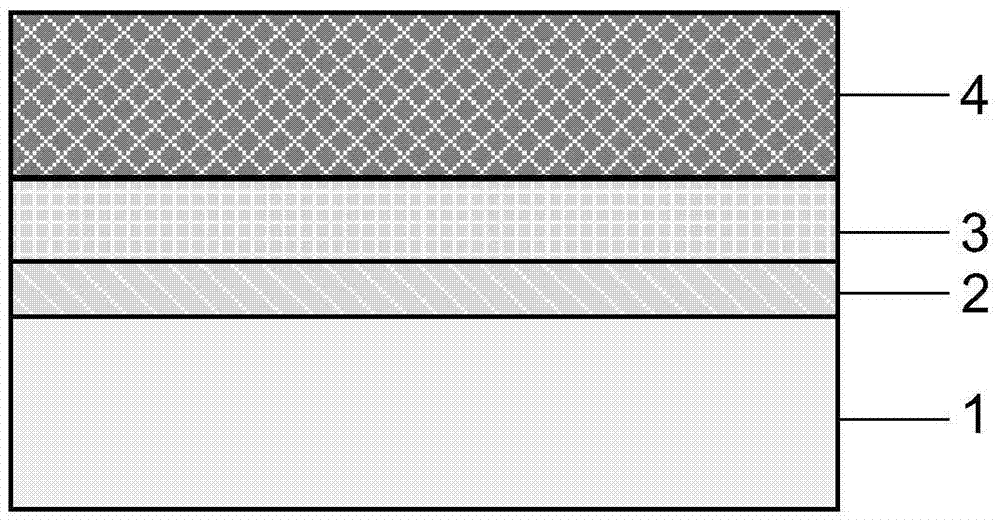

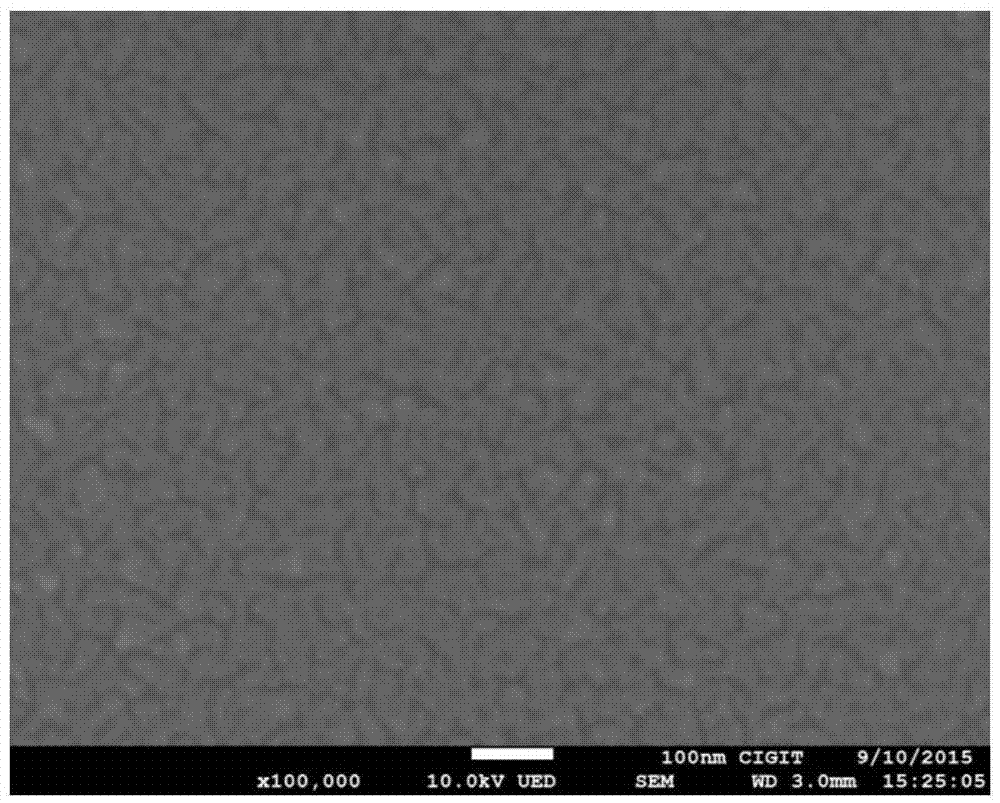

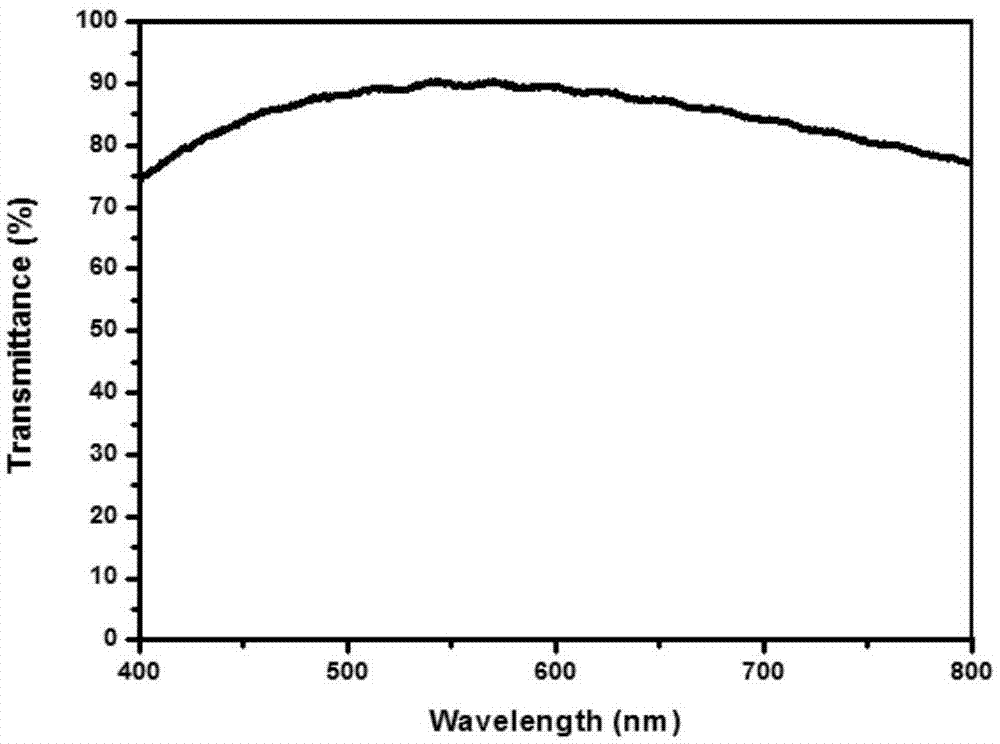

Transparent electrode based on ultrathin metal and preparation method thereof

ActiveCN105449106AImprove stabilityFinal product manufactureSolid-state devicesElectron beam depositionOptoelectronics

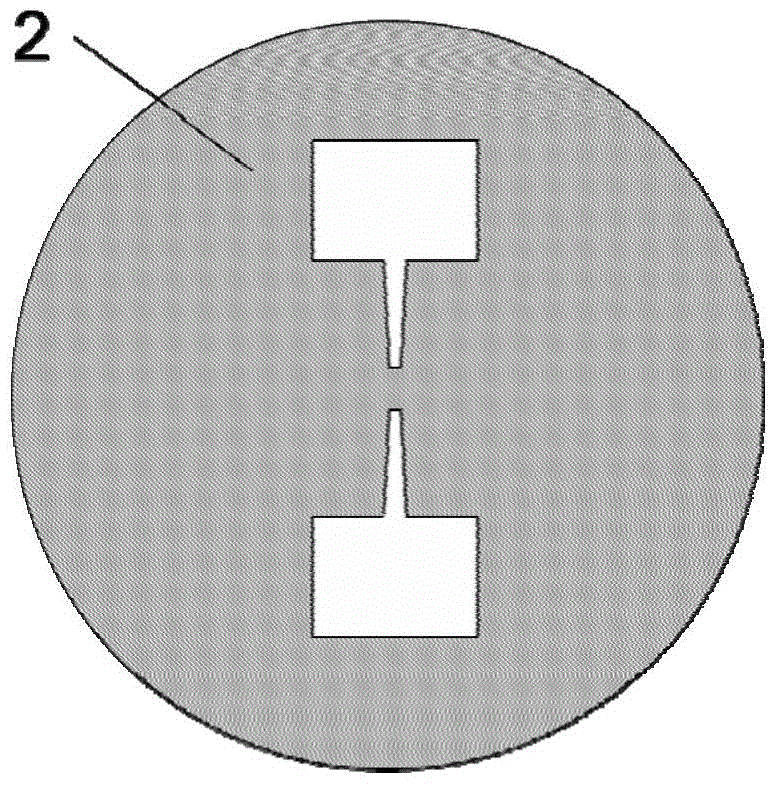

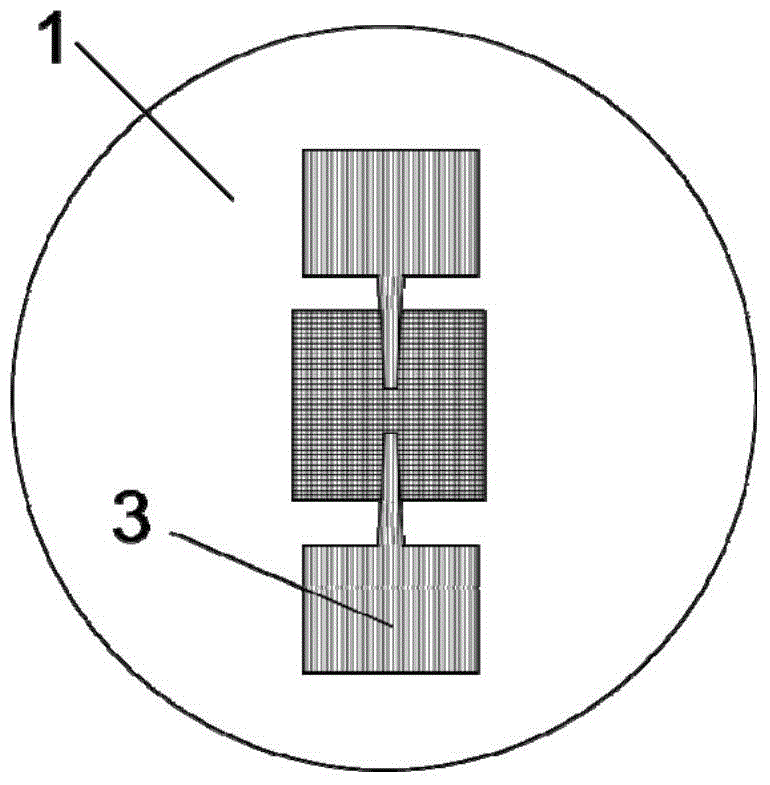

The invention relates to a transparent electrode based on an ultrathin metal and a preparation method thereof. The transparent electrode is of a four-layer structure, and comprises a transparent base (1), a nucleating seed crystal layer (2), an ultrathin metal layer (3) and an antireflection layer (4) from bottom to top in sequence. The preparation method of the transparent electrode comprises the following steps: cleaning and drying the transparent base; depositing on the transparent base to form the uncleating seed crystal layer; depositing on the uncleating seed crystal layer to form the ultrathin metal in a vacuum evaporation or electron beam deposition or magnetron sputtering deposition manner; and depositing on the ultrathin metal to form the antireflection layer in a solution spin-coating manner or solution blade-coating or vacuum evaporation or magnetron sputtering deposition manner. The transparent electrode disclosed by the invention has the characteristics of low production cost, simple technology, easy flexible integration, high stability, good surface morphology and the like.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

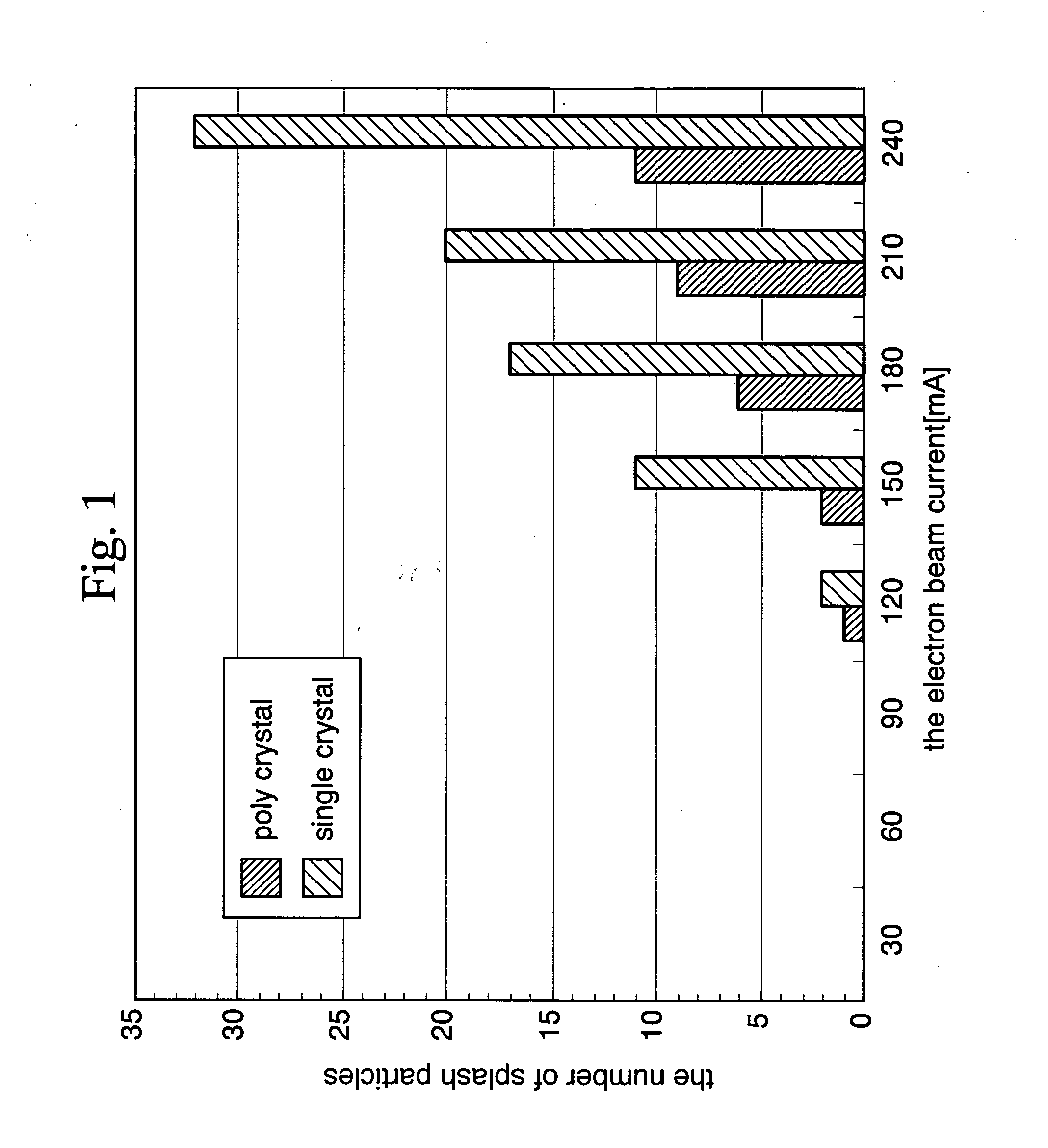

Mgo vapor deposition material and method for preparation thereof

InactiveUS20050045065A1Improve film propertiesReduce defectsPolycrystalline material growthVacuum evaporation coatingSulfurElectron beam deposition

Polycrystals with a MgO purity of at least 99.0%, a relative density of at least 90.0%, a sulfur S content of 0.01 to 50 ppm, a chlorine Cl content of 0.01 to 50 ppm, a nitrogen N content of 0.01 to 200 ppm, and a phosphorus P content of 0.01 to 30 ppm. Even when vapor deposition is conducted using electron beam deposition, almost no splash occurs, and the film characteristics of the product MgO film can also be improved.

Owner:MITSUBISHI MATERIALS CORP

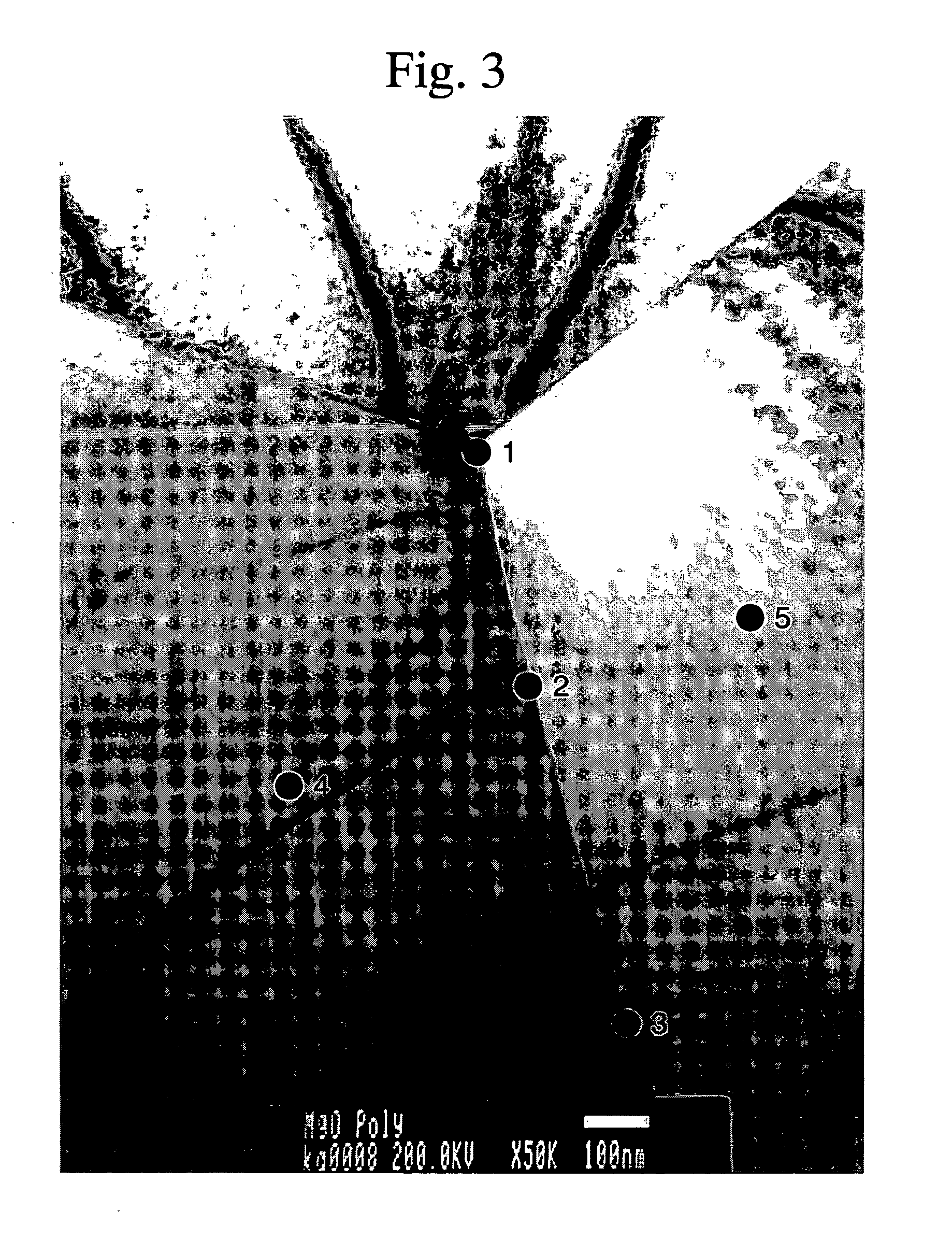

Method for electron beam-initiated coating for application of transmission electron microscopy

InactiveUS7180061B2Material analysis using wave/particle radiationPreparing sample for investigationElectron beam depositionMicroanalysis

A method for preparing a specimen for application of microanalysis thereto includes forming an initial conductive layer over a defined area of interest on a semiconductor substrate, the initial conductive layer formed through an electron beam deposition process. A volume of substrate material surrounding the area of interest is removed, thereby forming the specimen, including said area of interest and said initial conductive layer over the area of interest. The specimen is then removed from the bulk substrate material.

Owner:IBM CORP

Preparation method of graphene on SiC substrate based on Ni film-aided annealing

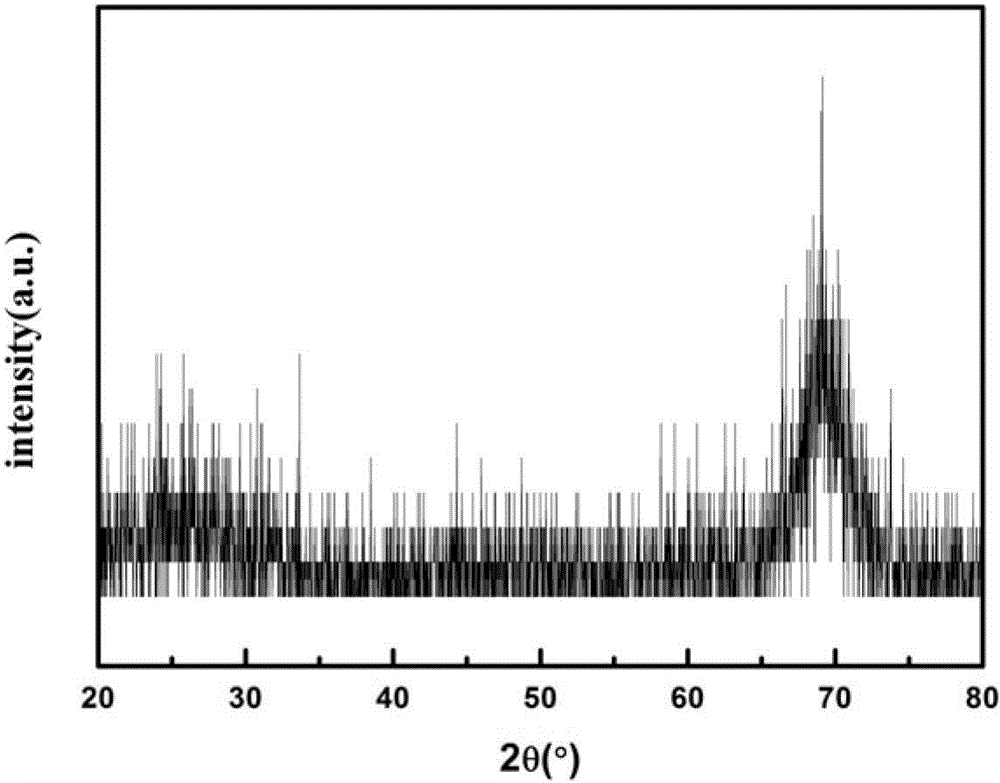

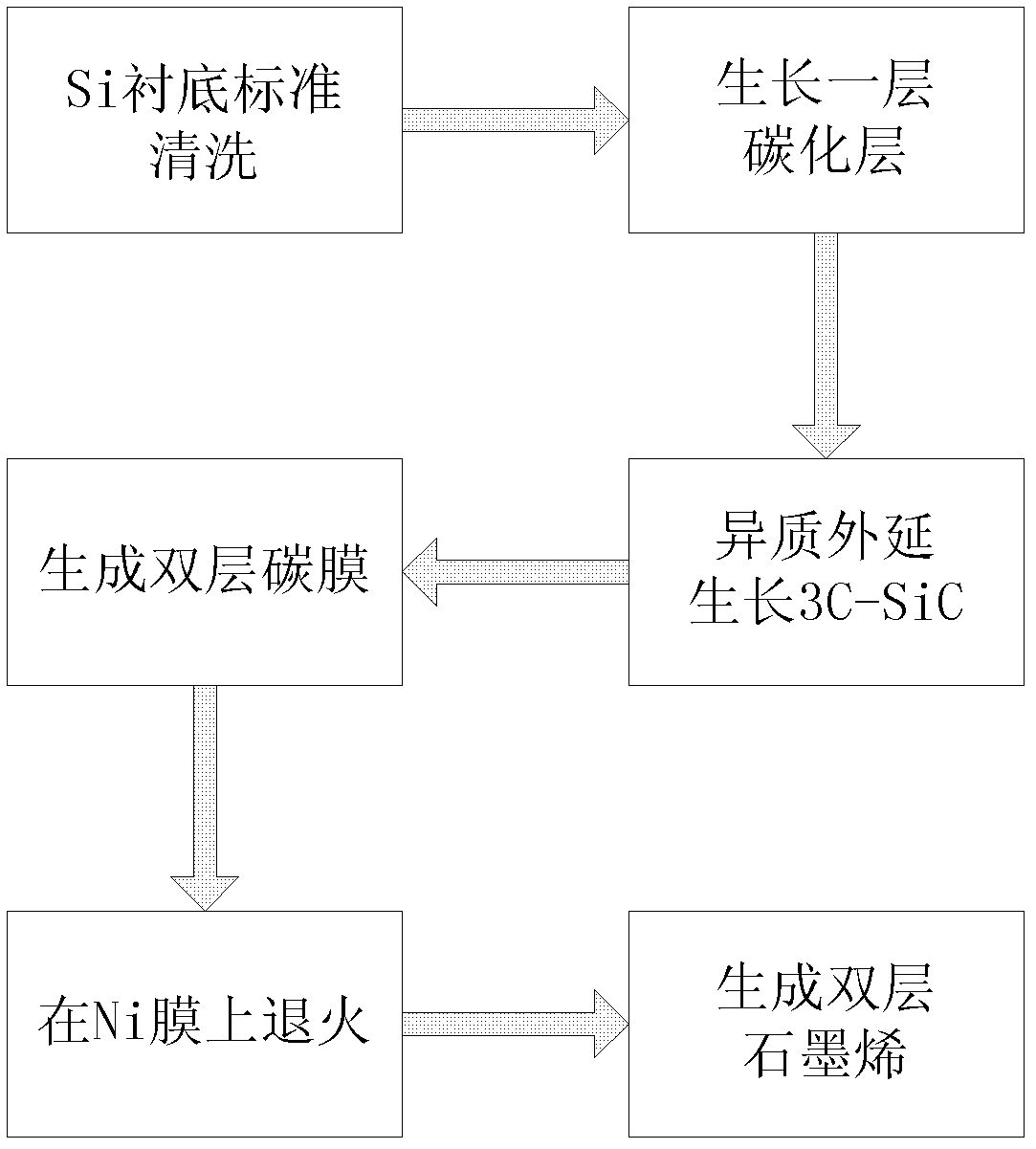

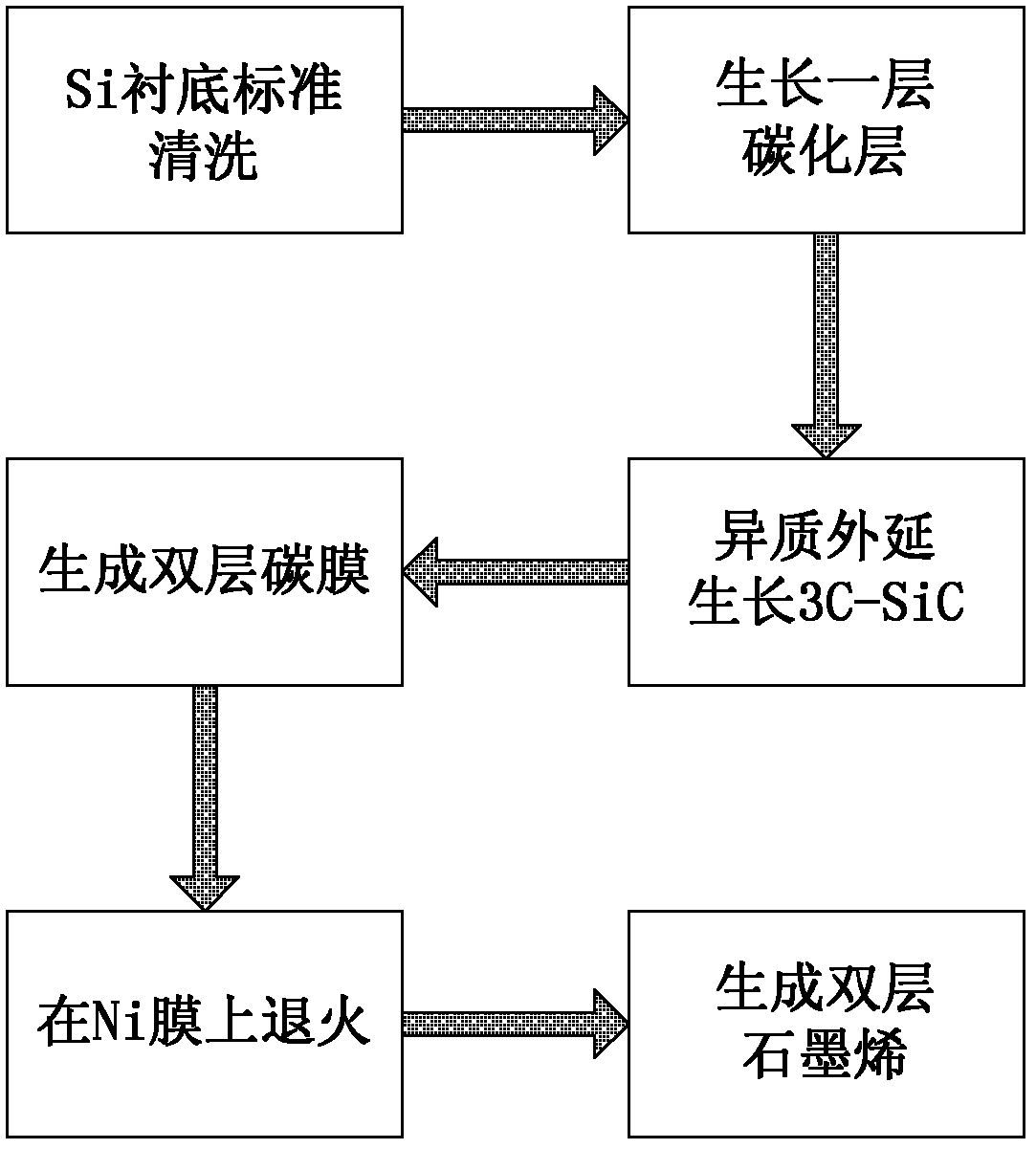

InactiveCN102505114AThe method is simpleSimple processMaterial nanotechnologyVacuum evaporation coatingPorosityCarbon film

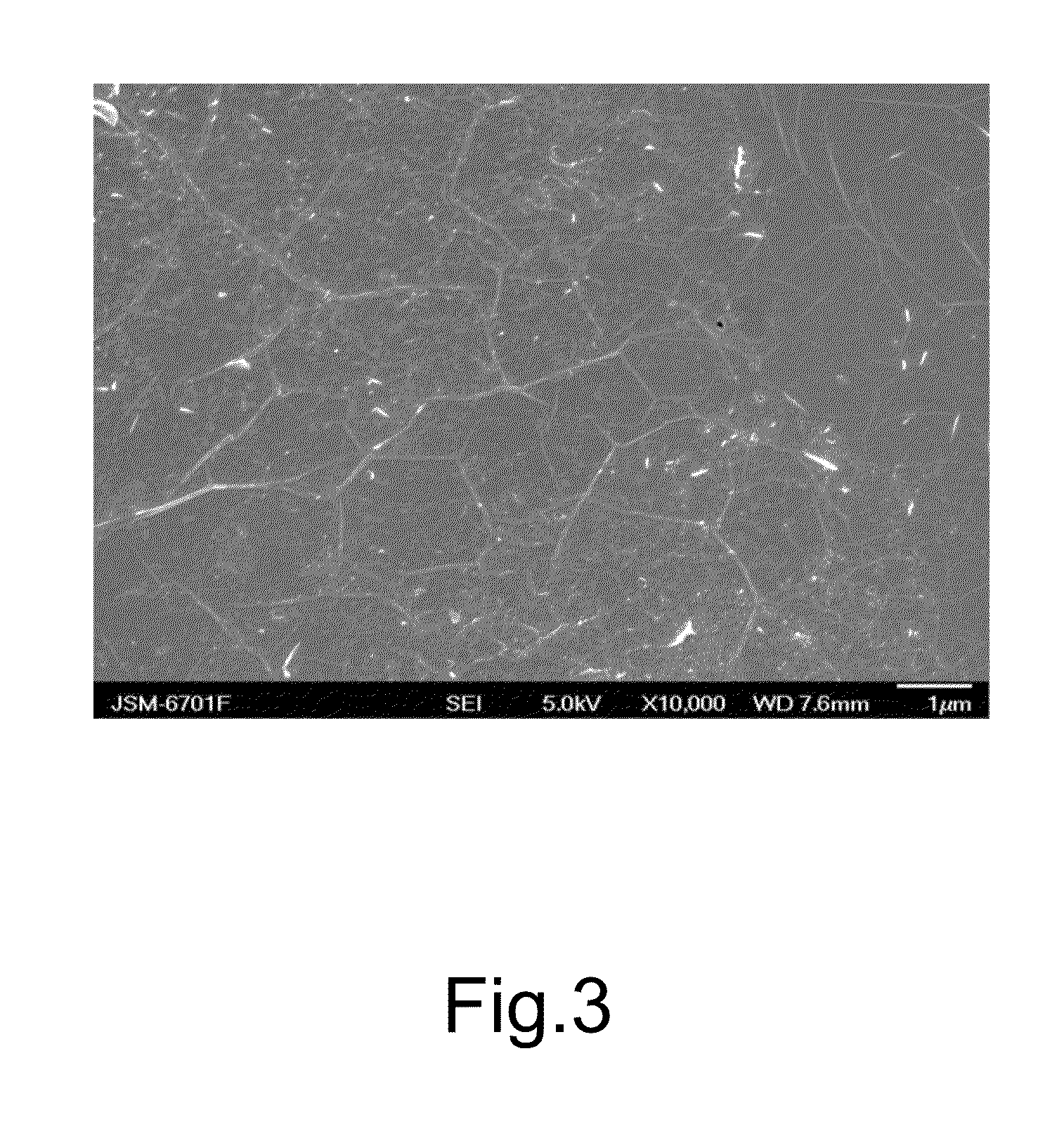

The invention discloses a preparation method of graphene on a SiC substrate based on Ni film-aided annealing, and is mainly used for solving the problems of non-smooth surface, low continuity and non-uniform layers of graphene prepared by the prior art. The method comprises the following steps of: performing standard cleaning of a SiC sample piece; placing the cleaned SiC sample piece in a quartz tube, carrying CCl4 vapor by Ar into the quartz tube, and reacting SiC with gaseous CCl4 at 750-1150 DEG C to generate a double-layer carbon film; performing electron beam deposition on the Si substrate to obtain a Ni film with thickness of 350-600 nm; placing the carbon surface of the generated double-layer carbon film sample piece on the Ni film, placing in Ar, and annealing at a temperature of 900-1100 DEG C for 10-20 minutes to generate double-layer graphene; and finally removing the Ni film from double-layer graphene sample piece. The method disclosed by the invention has the advantages of simple process and high safety; and double-layer graphene has smooth surface, good continuity and low porosity, and can be used for sealing gas and liquid.

Owner:XIDIAN UNIV

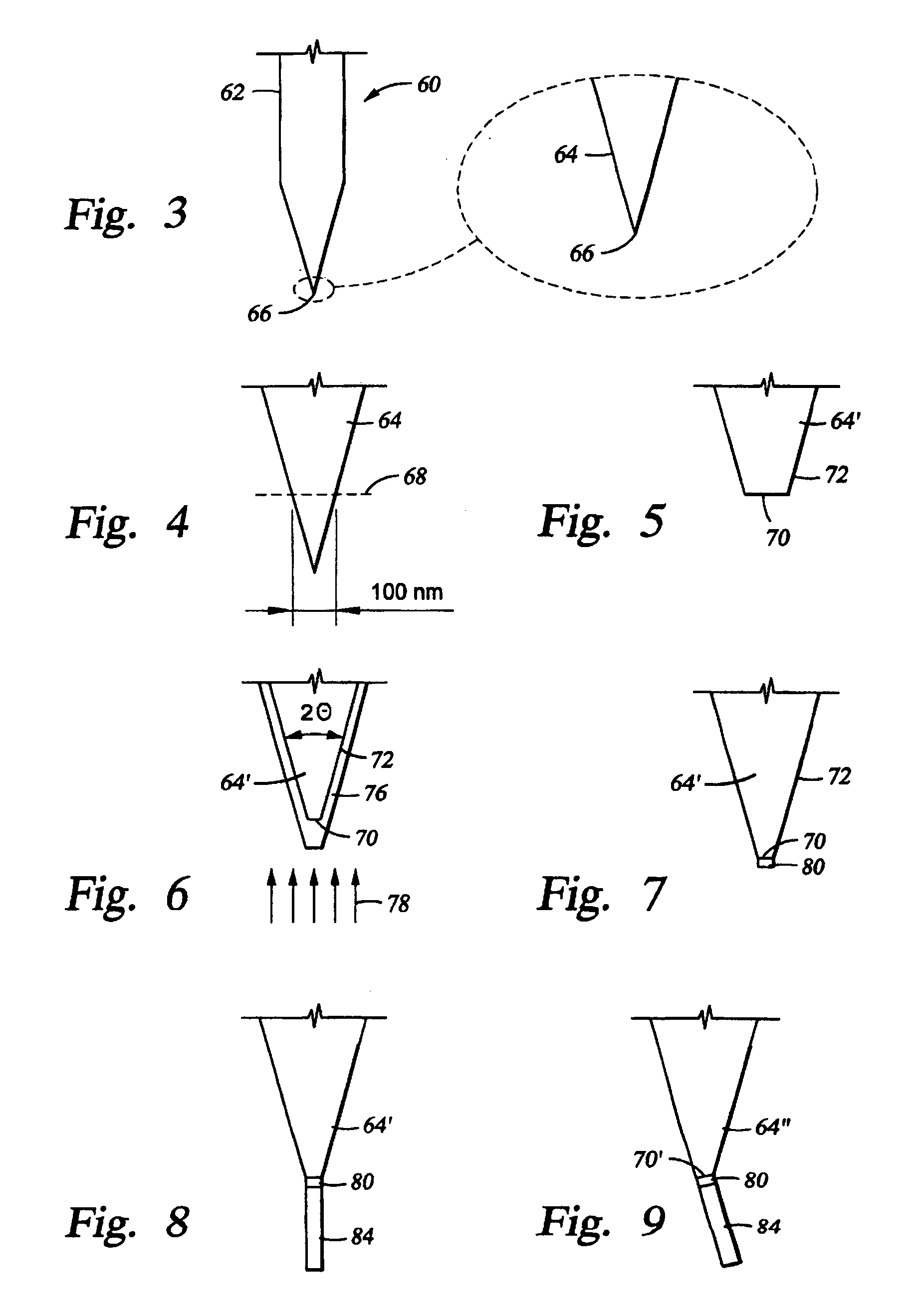

Directed growth of nanotubes on a catalyst

InactiveUS7032437B2Material nanotechnologyNanostructure manufactureElectron beam depositionSilicon dioxide

A method of fabricating a nanotube probe tip and the resultant probe tip, particularly for use in an atomic force microscope. A moderately sharply peaked support structure has its tip cut or flattened to have a substantially flat end of size of about 20 to 200 nm across. The support structure may be formed by etching a conical end into a silica optical fiber. Nickel or other catalyzing metal such as iron is directionally sputtered onto the flat end and the sloped sidewalls of the support structure. The nickel is anisotropically etched to remove all the nickel from the sidewalls but leaving at least 15 nm on the flat end to form a small nickel dot. A nanotube is then grown with the nickel catalyzing its growth such that only a single nanotube forms on the nickel dot and its diameter conforms to the size of the nickel dot. In another preferred embodiment of the invention, a catalyst material can be directly deposited on to the probe end using charged particle beam deposition, such as electron beam deposition.

Owner:FEI CO

Magnesium barium thioaluminate and related phosphor materials

InactiveUS20040027048A1Discharge tube luminescnet screensElectroluminescent light sourcesIndiumCerium

A phosphor and a method of deposition. The phosphor comprises a composition of the formula M'aBa1-aM''2M'''4; RE, where M' is at least one element selected from magnesium and calcium, M'' is at least one element selected from aluminum, gallium and indium, M''' is at least one element selected from sulphur, selenium and tellurium, RE is at least one rare earth element, especially europium or cerium, and 0<a<1. Deposition is preferably by dual source electron beam deposition. The phosphor may be annealed. The phosphor provides a high luminosity blue emission that does not require an optical filter to achieve acceptable colour coordinates for the blue sub-pixel element for a full colour thin film or thick film electroluminescent display. The blue sub-pixel pixel performance meets the luminosity and colour temperature specifications for current generation cathode ray tube displays.

Owner:IFIRE IP CORP

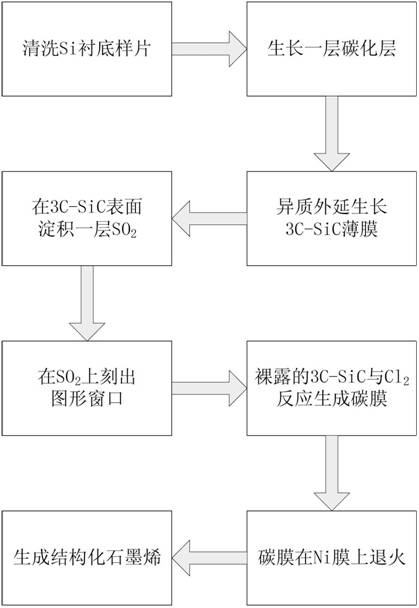

Method for preparing structured graphene based on reaction of Cl2 and Ni film annealing

InactiveCN102674333AEasy to refactorImprove continuitySemiconductor/solid-state device manufacturingGraphenePorosityCarbon film

The invention discloses a method for preparing structured graphene based on reaction of Cl2 and Ni film annealing, mainly aiming at solving the problems that the graphene prepared by the prior art is poor in continuity and uneven in the number of layers. The realization process of the method comprises the steps of: (1) leading a carbide layer to grow on a Si substrate for transition; (2) leading a 3C-SiC film to grow at the temperature of 1200-1300 DEG C; (3) depositing a layer of SiO2 on the surface of the 3C-SiC film, and carving a graphic window; (4) after the graphic window is formed, leading the exposed 3C-SiC to have reaction with Cl2 at the temperature of 700-1100 DEG C, and generating a carbon film; (5) then, putting the generated carbon film sample piece into a buffer hydrofluoric acid solution, and removing the SiO2 outside the window; (6) after that, depositing a layer of Ni film on another Si sample piece by electron beams; and (7) arranging the carbon film sample piece without SiO2 on the Ni film, and arranging in Ar gas; and carrying out annealing at 900-1100 DEG C for 15-30minutes, and generating the structured graphene at the position of the window of the carbon film. The structured graphene prepared by the invention is smooth in the surface, good in continuity and low in porosity, thus being used for making a microelectronic device.

Owner:XIDIAN UNIV

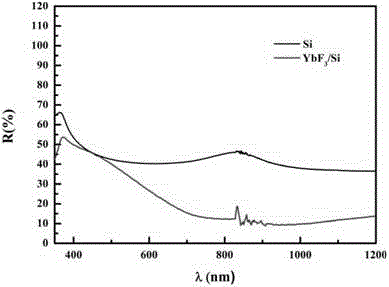

Up-and-down-conversion luminescent high-transmittance amorphous fluoride film and preparation method thereof

ActiveCN102719252AImprove photoelectric conversion efficiencyImprovement of narrow spectral response rangeVacuum evaporation coatingSputtering coatingCarbon coatingCurrent range

The invention discloses an up-and-down-conversion luminescent high-transmittance amorphous fluoride film and a preparation method thereof, and belongs to the field of solid luminescent materials. The film comprises YbF3 and ErF3, and the molar fraction of the ErF3 is 0.5%-15%. The preparation method includes: adding YbF3 powder into ErF3 powder for ball-milling mixing, drying prior to tabletting, and calcining for 6h-8h at the temperature of 600-750 DEG C by a carbon coating method so that a ceramic target is calcined; and using an electron beam deposition method which includes that a silicon wafer and quartz are used as a substrate, and under the vacuum condition, the substrate temperature ranges from 400 DEG C to 500 DEG C, the target spacing ranges from 25cm to 32cm, the deposition beam current ranges from 3mA to 6mA, and the deposition time ranges from 15min to 90min. The amorphous film achieves combination of up-conversion and down-conversion mechanisms and is capable of effectively converting an ultraviolet wave band (300nm-400nm) and an infrared wave band (around 980nm) to a visible light wave band (around 656nm), and the transmittance of the film is averagely higher than 95% so that the film is hopefully applied to solar cells to improve photoelectric efficiency of the same.

Owner:BEIJING UNIV OF TECH

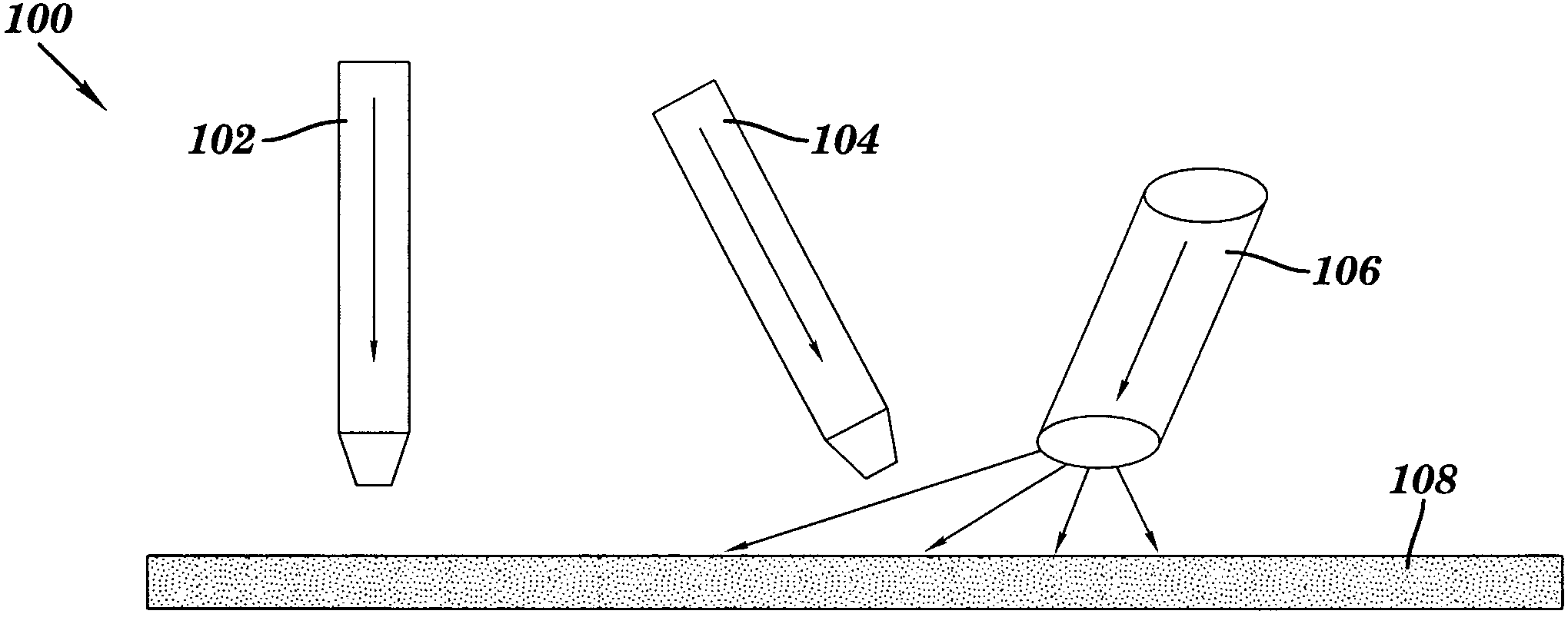

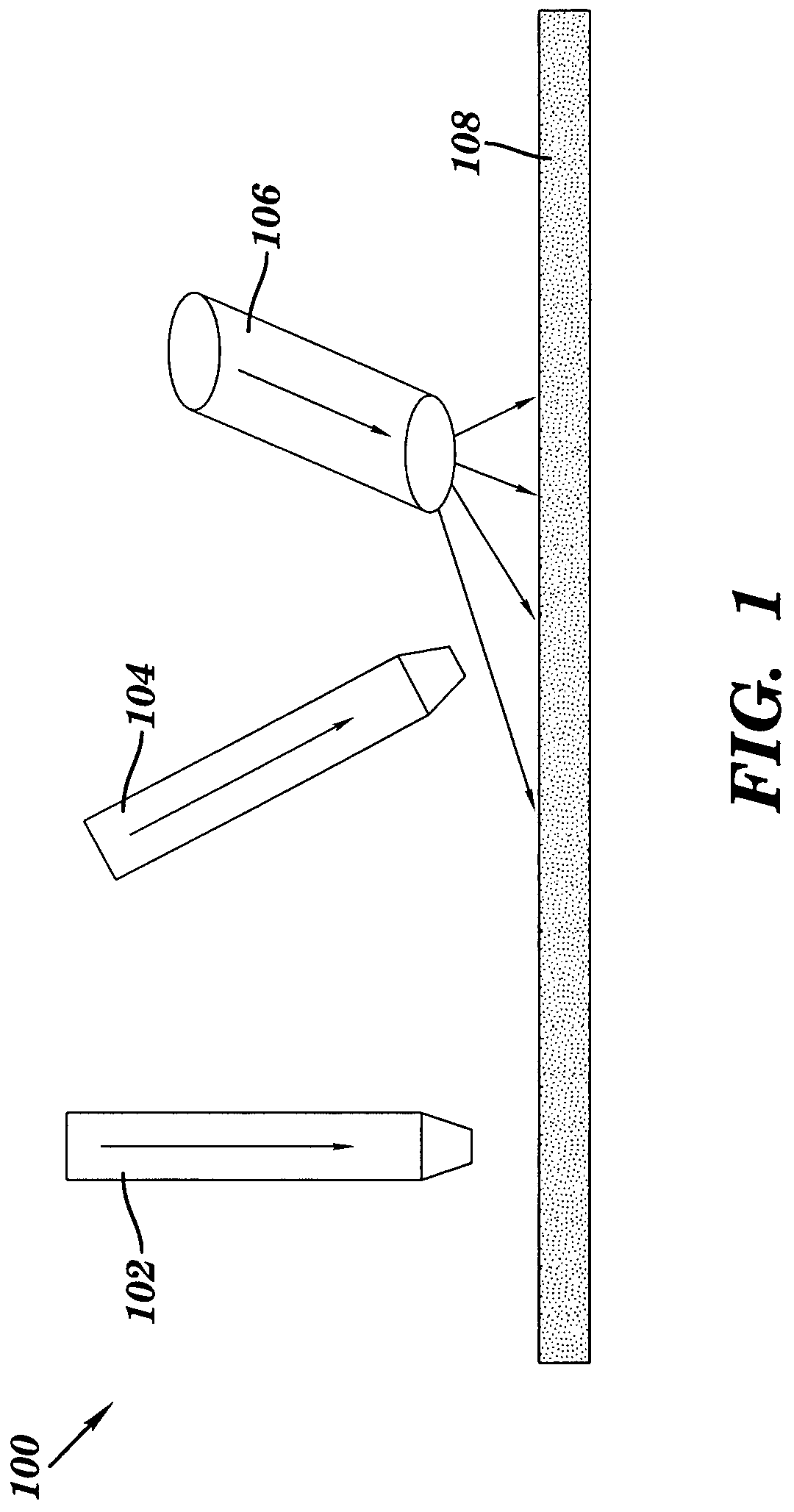

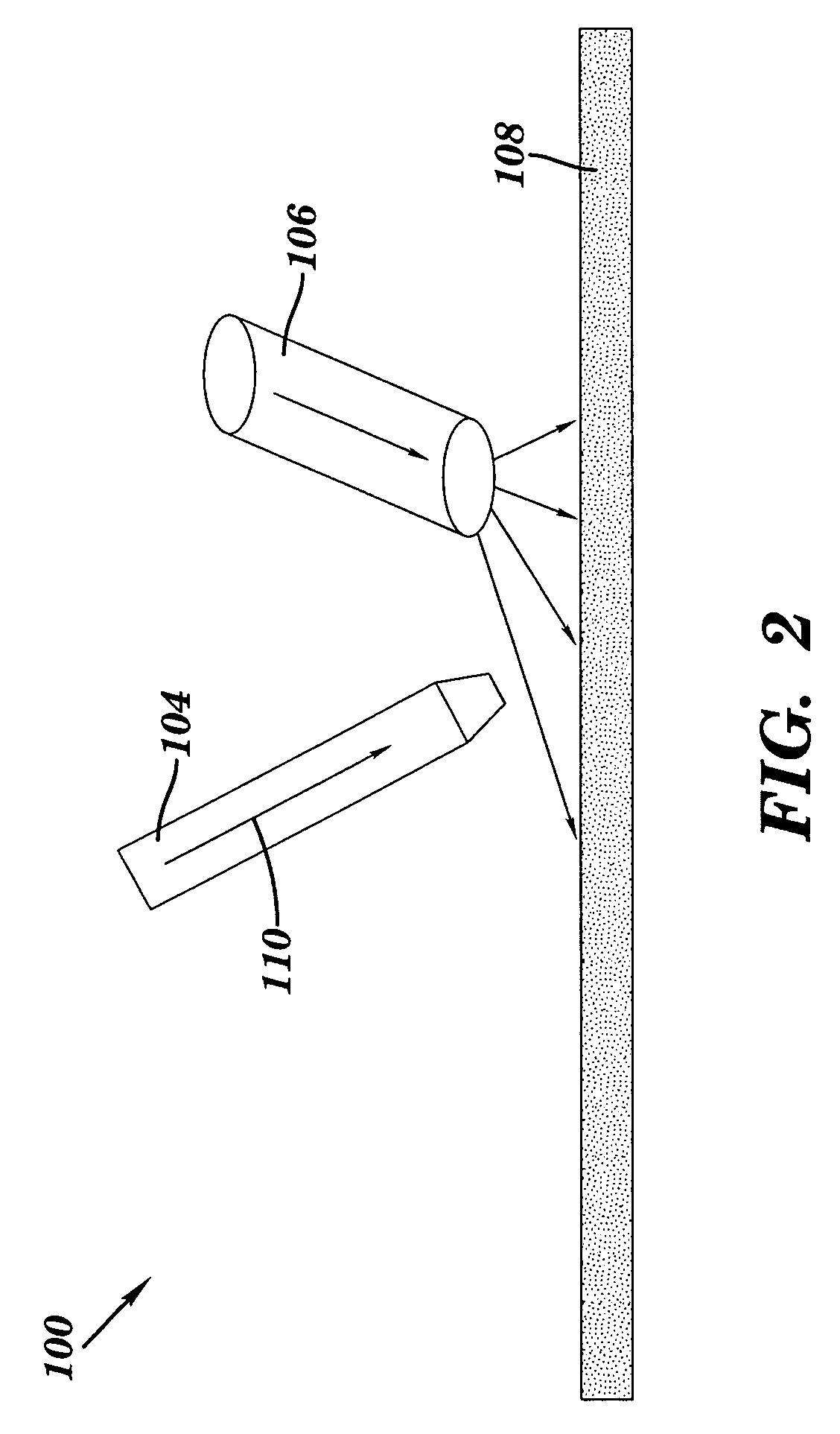

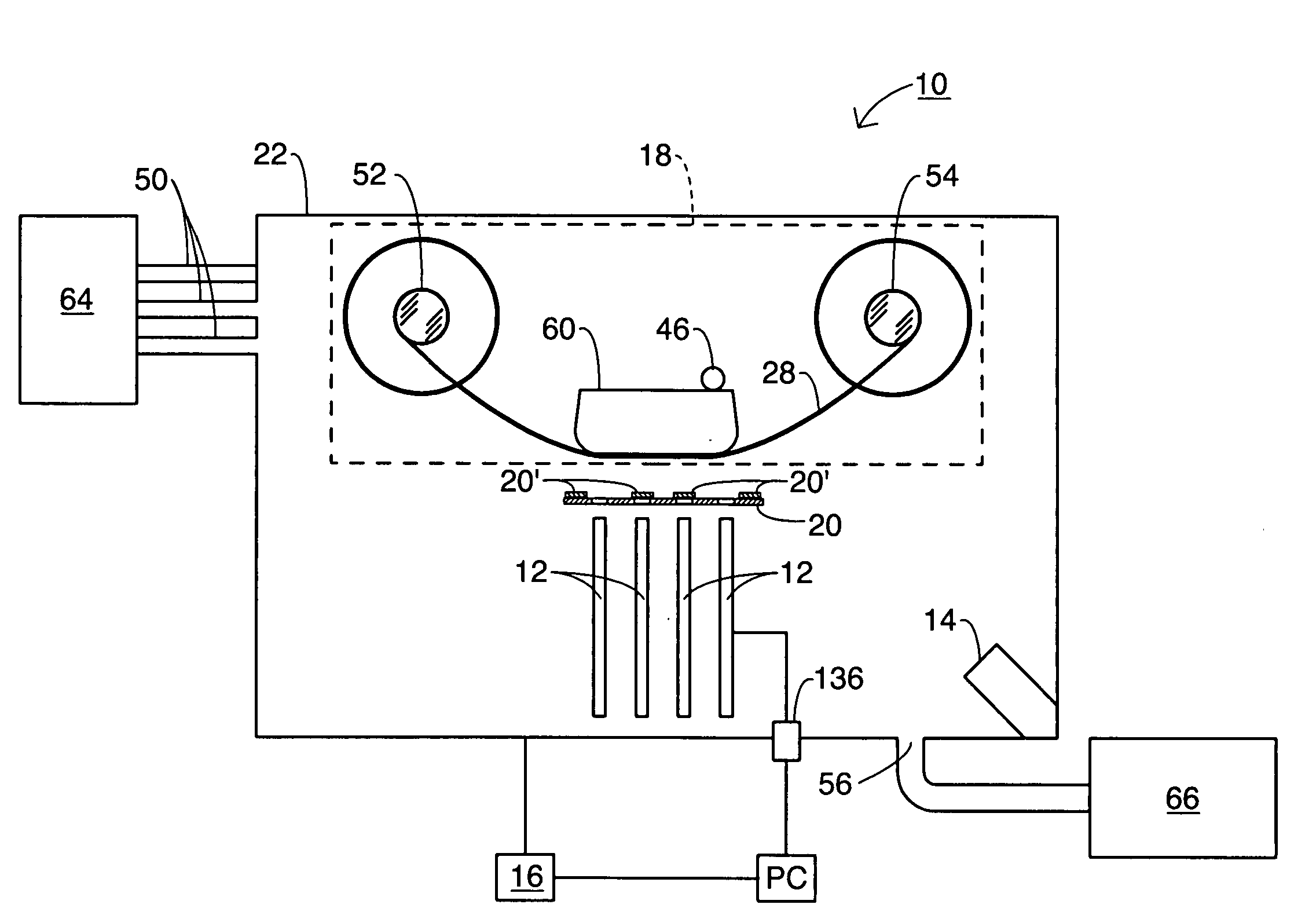

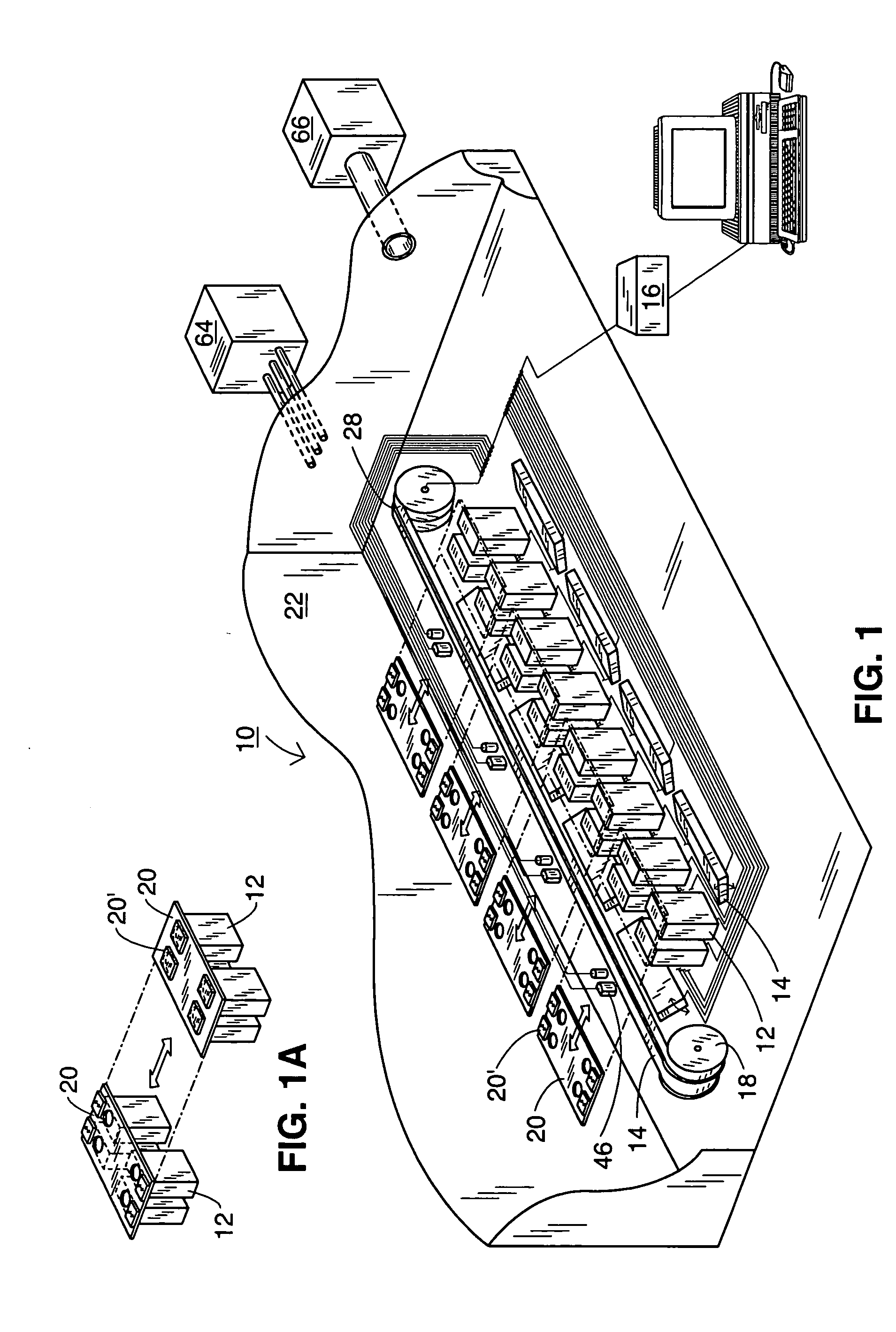

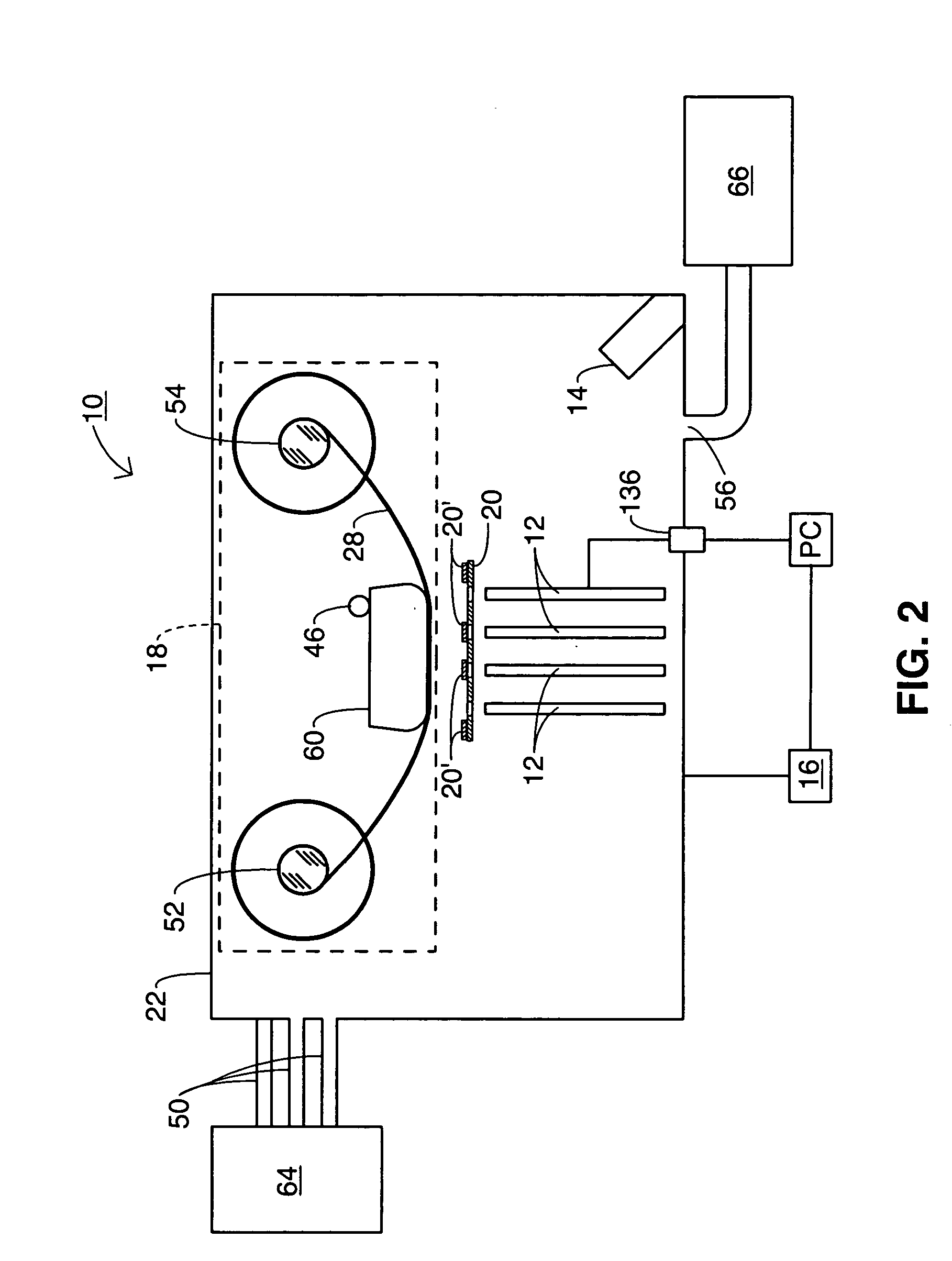

Tape-manufacturing system having extended operational capabilites

InactiveUS20050092253A1Maintain integrityGuaranteed to workVacuum evaporation coatingSputtering coatingElectrical conductorMagnetic tape

A tape-manufacturing system for coating at least one tape substrate such as, for example, for the manufacture of a high-temperature superconductor (HTS) conductor is disclosed. The tape-manufacturing system includes at least two electron beam (e-beam) deposition sources, at least one assist source and, optionally, a controller. Each e-beam deposition source may be in-process repairable. Each e-beam deposition source is capable of communicating an evaporant material with at least a portion of at least one tape substrate to deposit a coating thereon. The at least one assist source is capable of communicating a beam of a species to the coating. The controller communicates with the at least two e-beam deposition sources and the at least one assist source.

Owner:SUPERPOWER INC

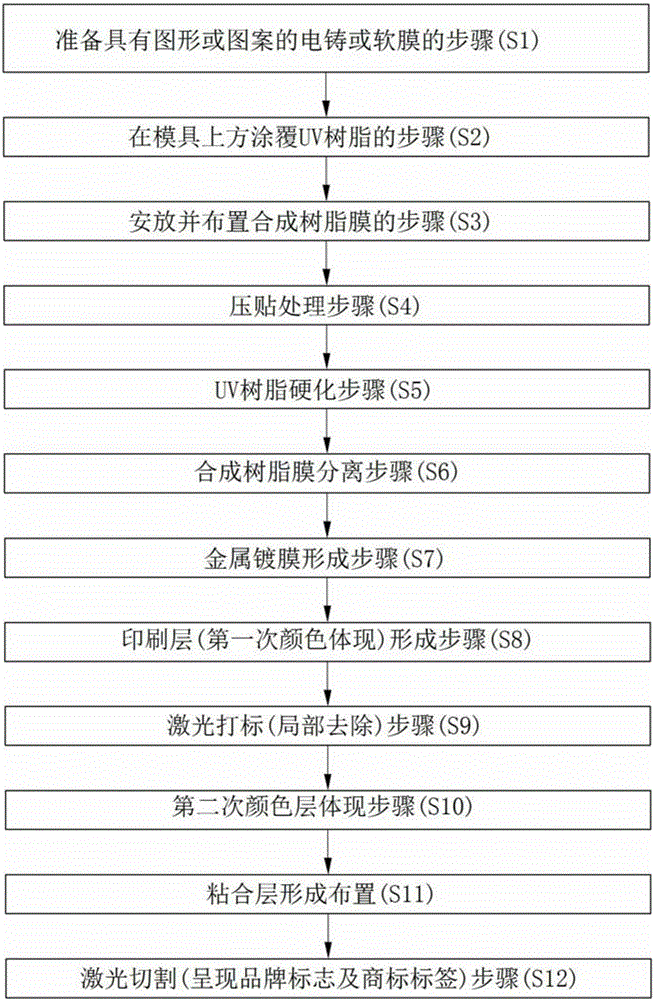

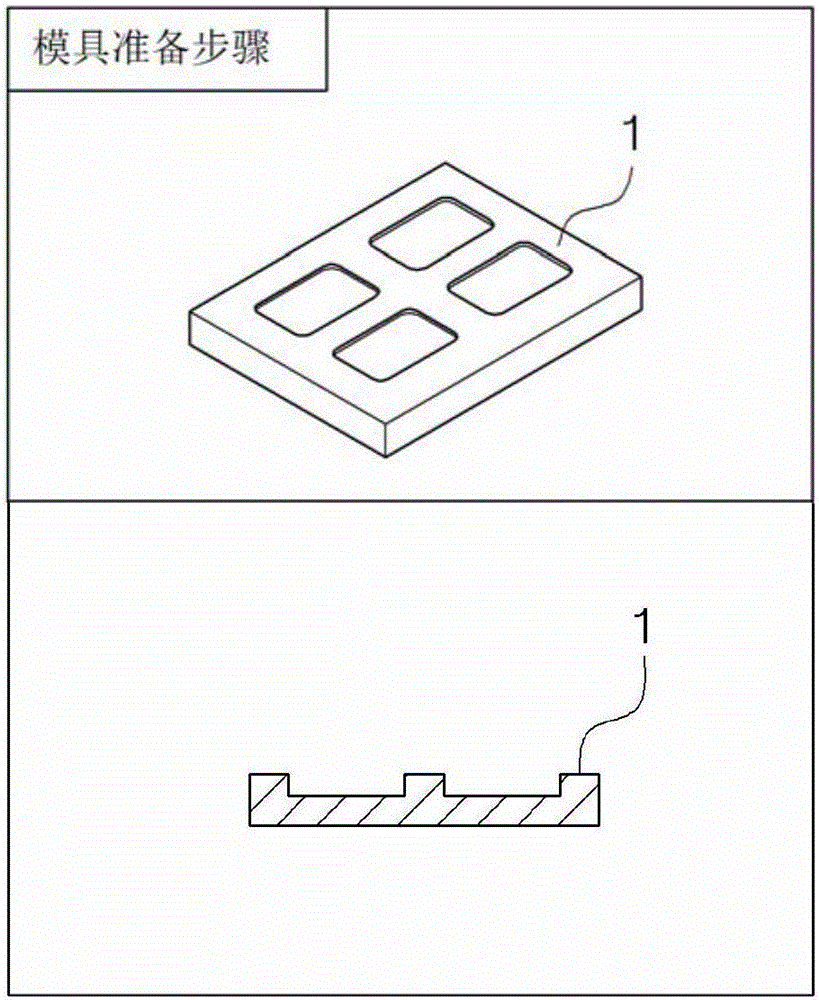

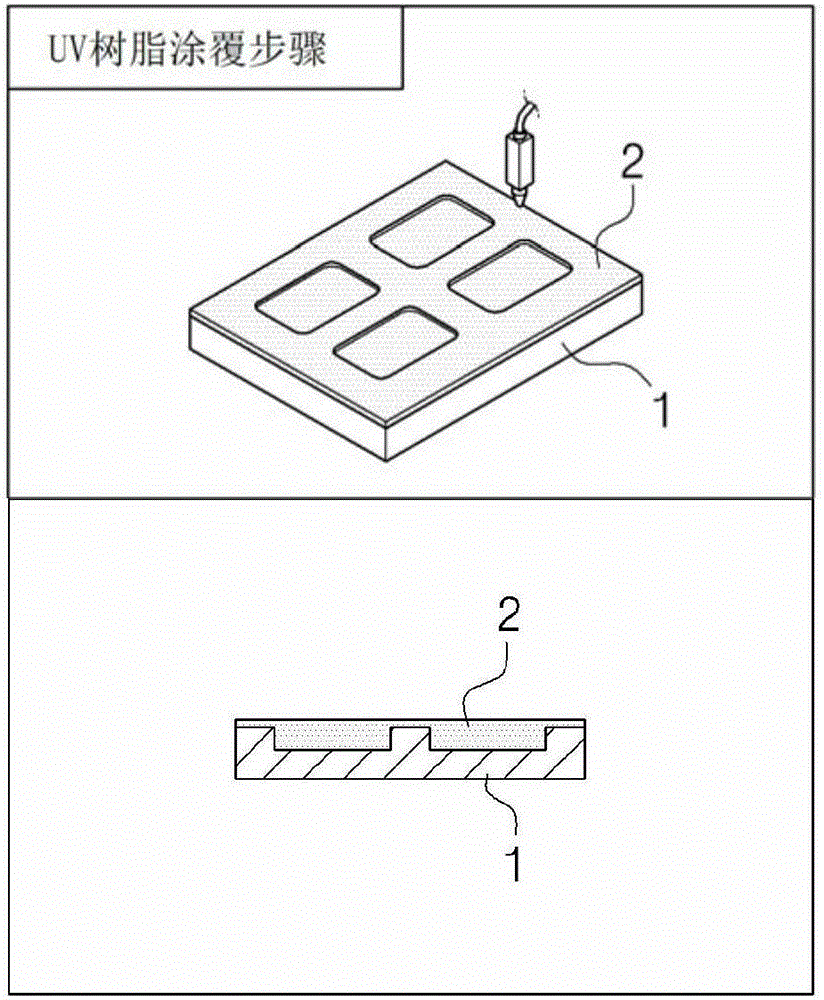

Method for manufacturing brand logo and trademark label using synthetic resin film

InactiveCN105247596AAdd eleganceImprove aestheticsStampsPaper/cardboard articlesTrademarkUltraviolet lights

The present invention relates to a method for manufacturing a brand logo and a trademark label using a synthetic resin film, comprising: a first step for preparing an electroformed mold or a soft mold having an image or pattern; a second step for applying a UV resin; a third step for positioning a transparent synthetic resin film through which light is able to pass; a fourth step for performing compression using a pressing roller; a fifth step for curing the UV resin by irradiating ultraviolet light; a sixth step for obtaining a film having the image and pattern by separating the synthetic resin film through delamination; a seventh step for forming a metal deposited film on the rear surface of the synthetic resin film; an eighth step for forming a printed layer for protecting the metal deposited film, exhibiting a light-transmission blocking function, and implementing a primary color; a ninth step for exposing only a portion where a secondary color is to be implemented by partially removing the printed layer and the metal deposited film, which are formed on the rear surface of the synthetic resin film, through laser marking; a tenth step for forming a secondary color implementation layer by carrying out electron beam deposition or by performing printing through a silk printing technique; an eleventh step for attaching double-sided tape or applying an adhesive primer; and a twelfth step for exposing a brand logo and a trademark label by performing laser cutting.

Owner:株式会社爱睦全球

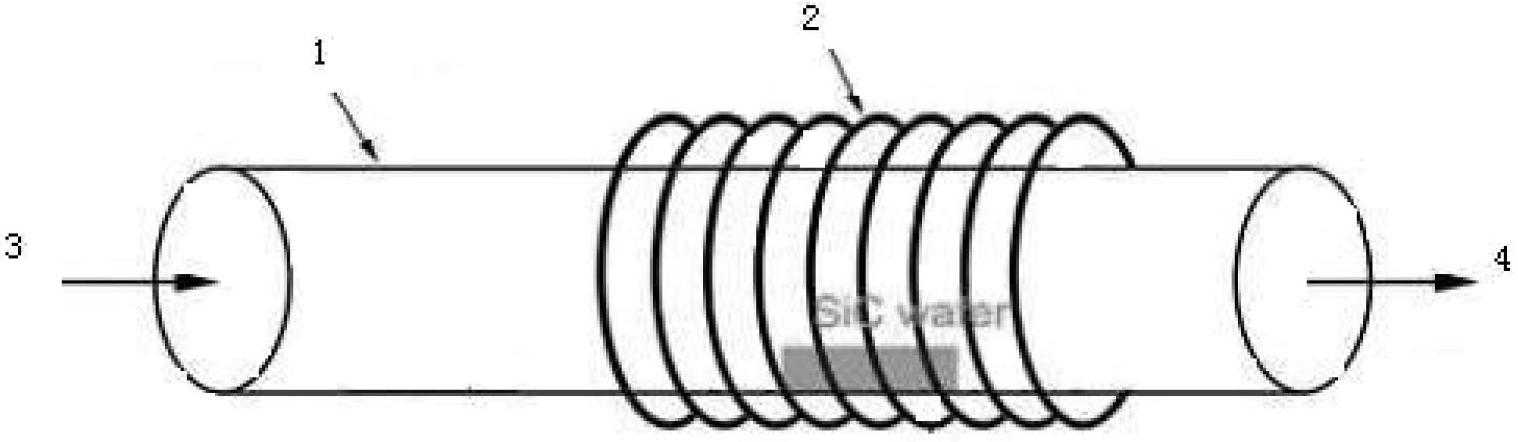

Preparation method of large-area graphene on Si substrate based on Ni film annealing

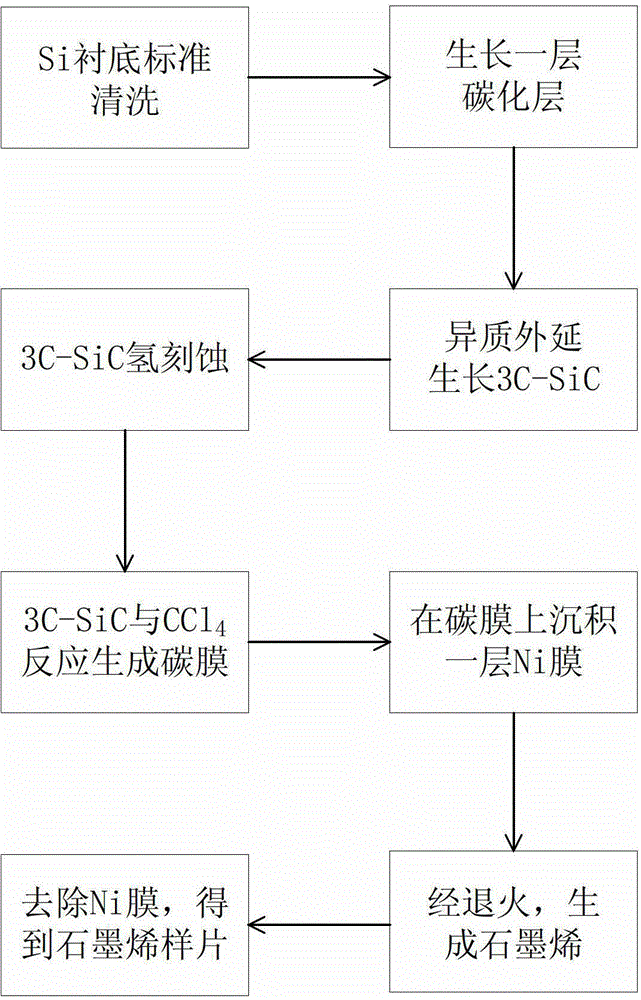

The invention discloses a preparation method of large-area graphene on an Si substrate based on Ni film annealing and mainly solves the problems of small area, poor continuity and non-uniform layers of graphene prepared in the prior art. The preparation method comprises the following implementation steps: growing a carburization layer on the 4-12-inch Si substrate to be used as a transition and growing a 3C-SiC heteroepitaxial film at the temperature of 1200 DEG C to 1350 DEG C by utilizing growth gas sources C3H8 and SiH4; carrying out hydrogen etching on the grown 3C-SiC film and removing a compound generated by etching; reacting 3C-SiC with gaseous CCl4 at a temperature of 800-1,000 DEG C to generate a carbon film; electron beam-depositing an Ni film on the carbon film, putting a sample sheet plated with the Ni film into Ar gas and annealing for 10-20 minutes at a temperature of 1,000-1,250 DEG C to generate a graphene sample sheet; and finally removing the Ni film from the graphene sample sheet. The graphene prepared by the method has the advantage that the area can reach 12 inches, the continuity is good, the surface is smooth, and the porosity is low. The graphene can be used for manufacturing microelectronic devices and biological sensors or sealing gas and liquid.

Owner:XIDIAN UNIV

Transparency conductive film and preparation method thereof

InactiveCN101159178AHigh visible light transmittanceImprove conductivityConductive layers on insulating-supportsElectroluminescent light sourcesEvaporationSolar cell

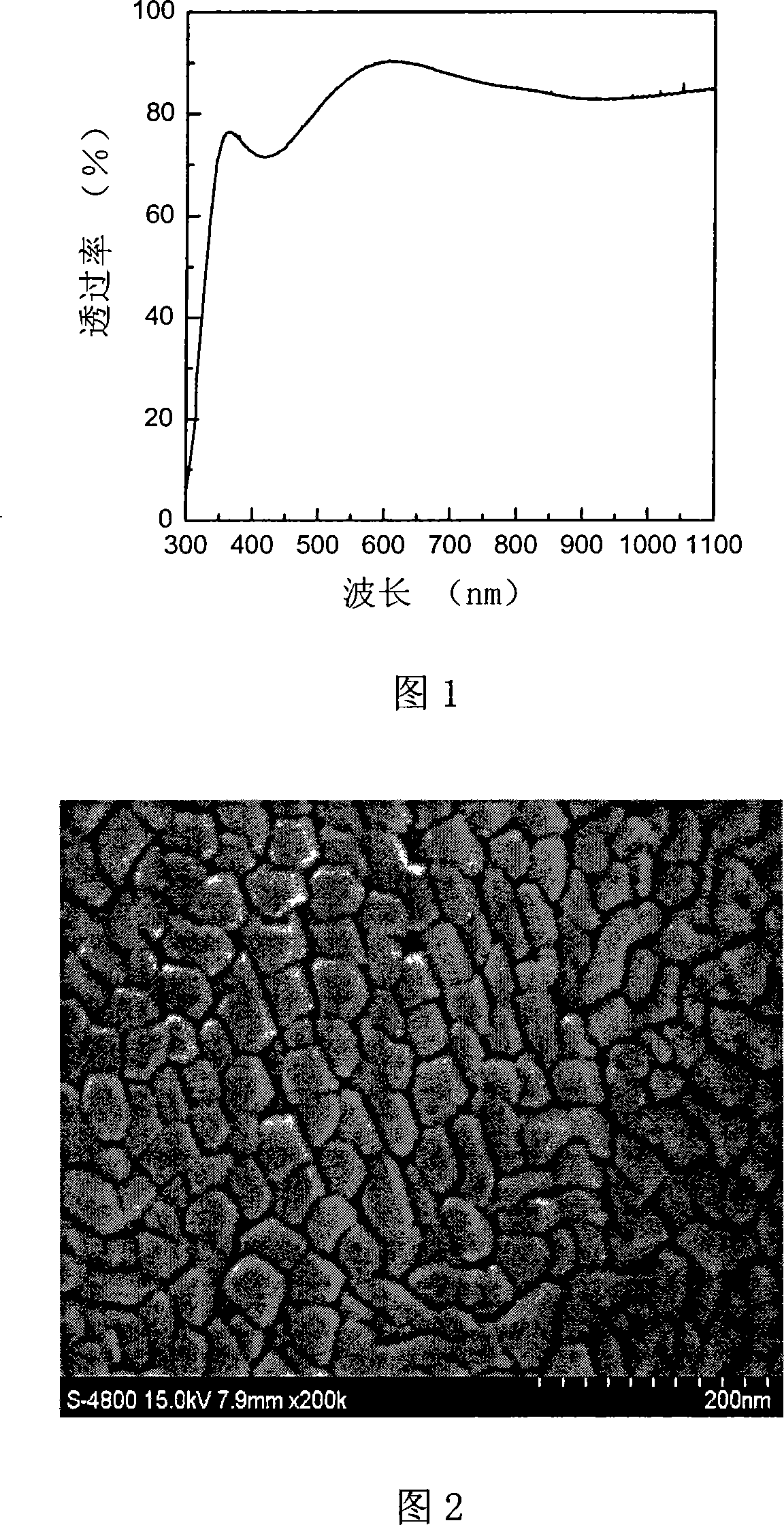

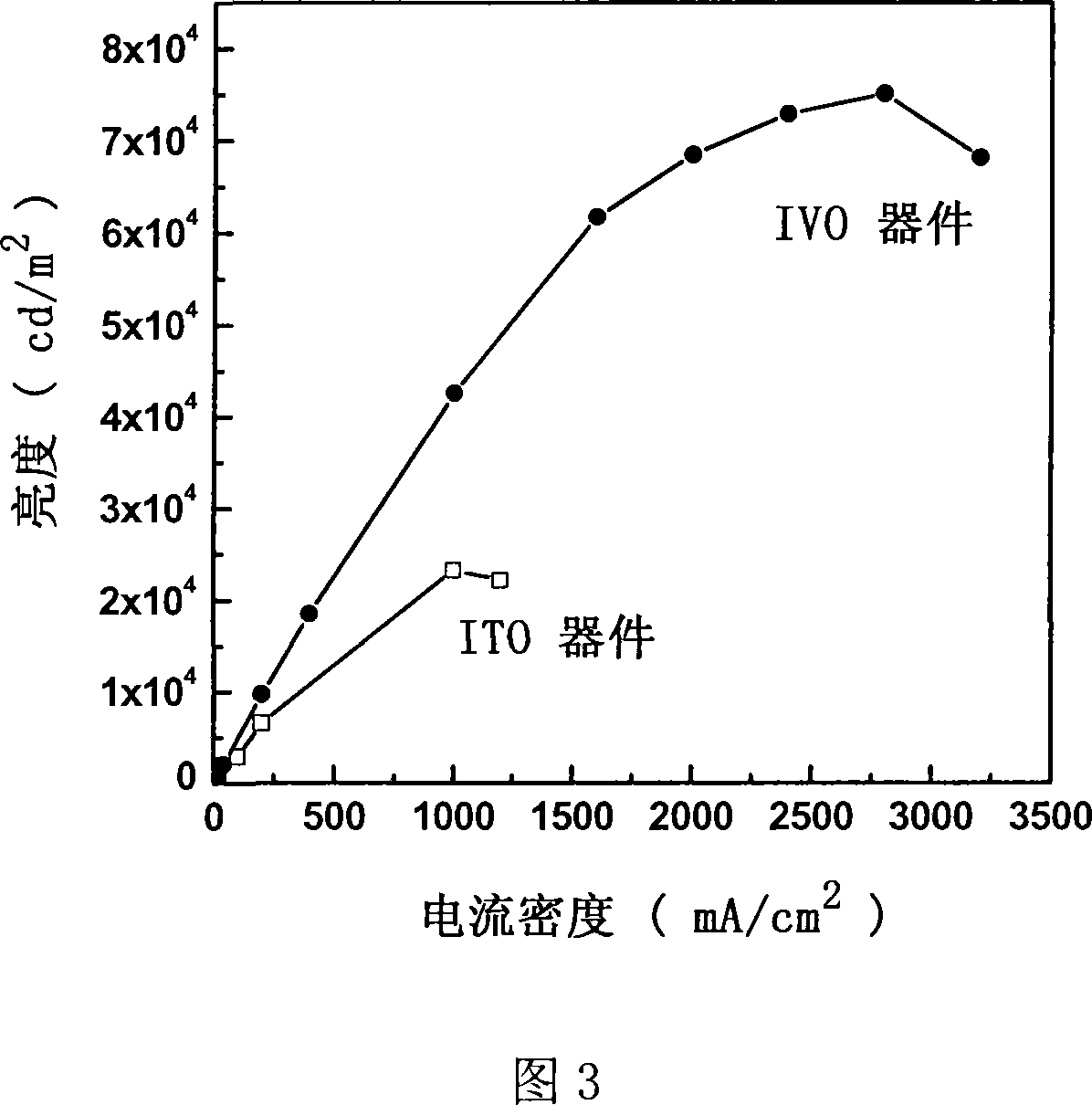

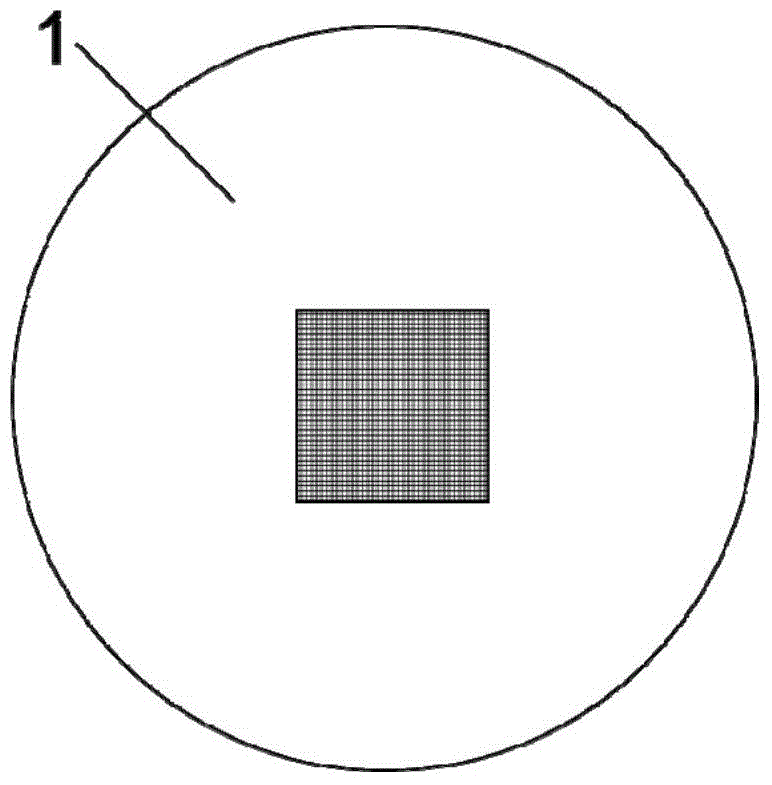

The invention relates to a transparent conductive thin film widely applied in the technical fields such as a LCD screen, an electroluminescent display, a solar cell, a TFT, an organic and inorganic semiconductor laser, and thermal-insulating energy-saving glass, as well as a preparation method thereof. The thin film (IVO) is an indium vanadium oxide (In2O3:V) formed by doping V element in a main material In2O3, and the content of V in the IVO material accounts for 0.1 percent-30 percent of the content of In. The thin film can be prepared by a plurality of film plating techniques such as high vacuum thermal evaporation, electron beam deposition and sputtering. The thin film is firm, and has good conductivity, visible light transparency and chemical stability.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Transmission electron microscope film window for in-situ high-resolution observation of electric field induced phase transition process of phase transition material

InactiveCN103954636AGuaranteed phase change processStudy Electrical ResponseElectric discharge tubesPreparing sample for investigationAdhesiveLaser cutting

A transmission electron microscope film window for in-situ high-resolution observation of an electric field induced phase transition process of a phase transition material. The observation method comprises the following steps: processing electrode shapes on a metal sheet used as a mask plate by laser cutting or metal etching methods; covering a SiNx film window with the mask plate, plating metal electrodes by a film-plating machine; performing electron beam deposition at two ends of each obtained electrode by FIB to prepare Pt electrodes with small spacing; cutting and processing the SiNx film between the electrodes and the film between the Pt electrodes by focused ion beam to obtain a sample platform with a bridge structure; plating a film sample on the SiNx film window with the prepared electrodes by magnetron sputtering; connecting an electrified sample pole of a transmission electron microscope with the electrodes through a conductive adhesive, and performing in-situ electric experiments. The transmission electron microscope film window of the invention solves the problem that in-situ observation of the phase transition process of a phase transition material cannot be realized in a device, prevents sample damage caused by routine FIB preparation, and reduces the difficulty of sample preparation.

Owner:BEIJING UNIV OF TECH

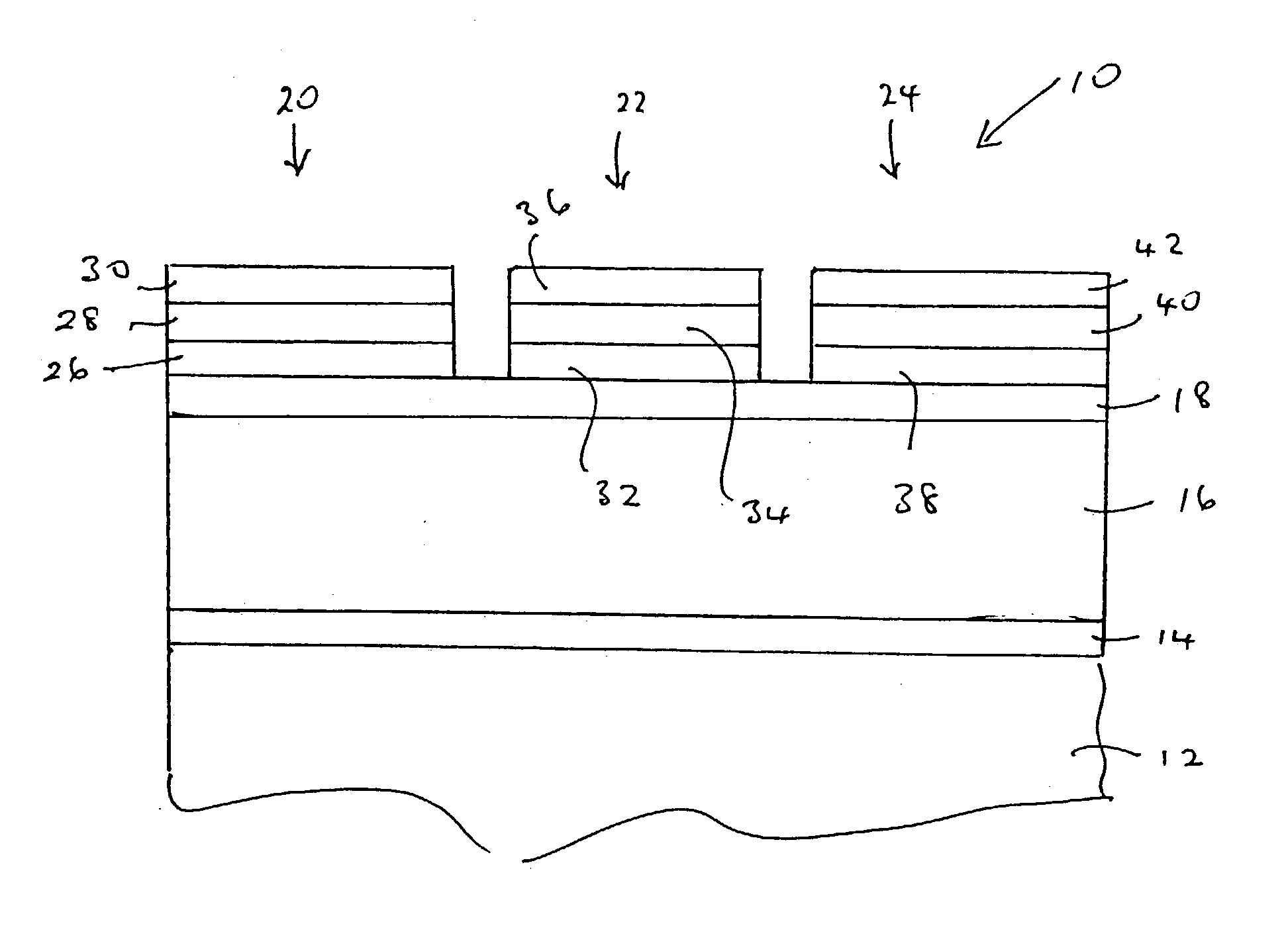

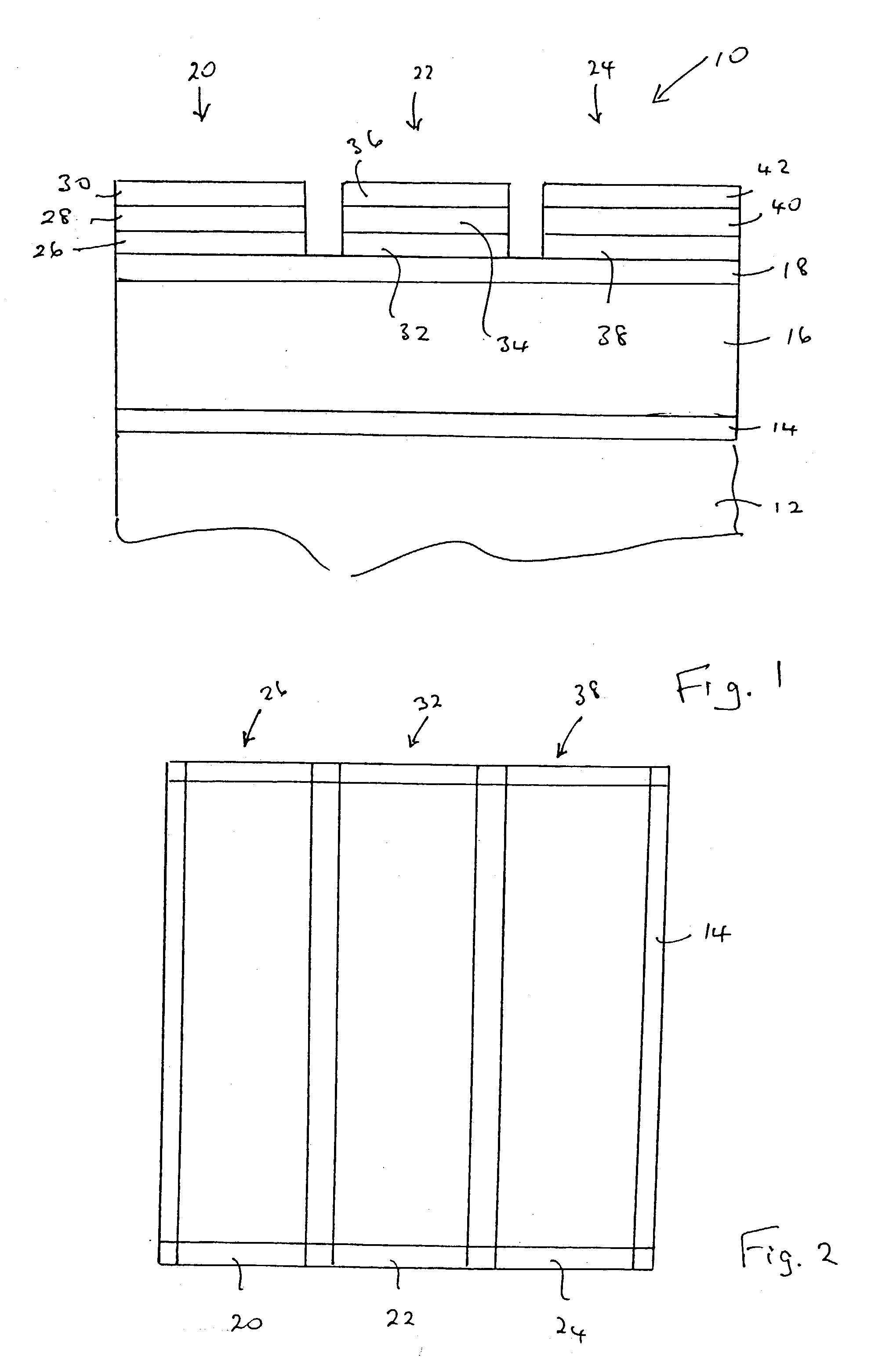

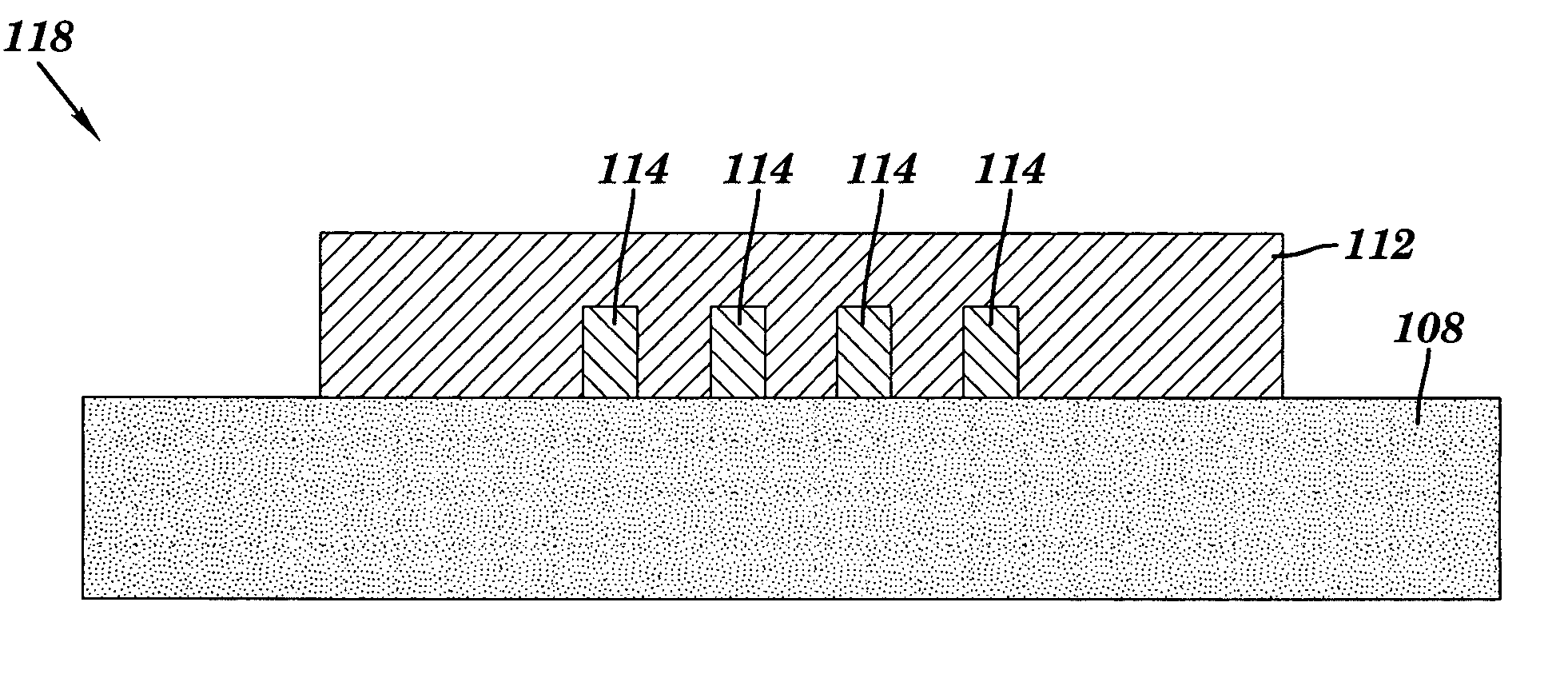

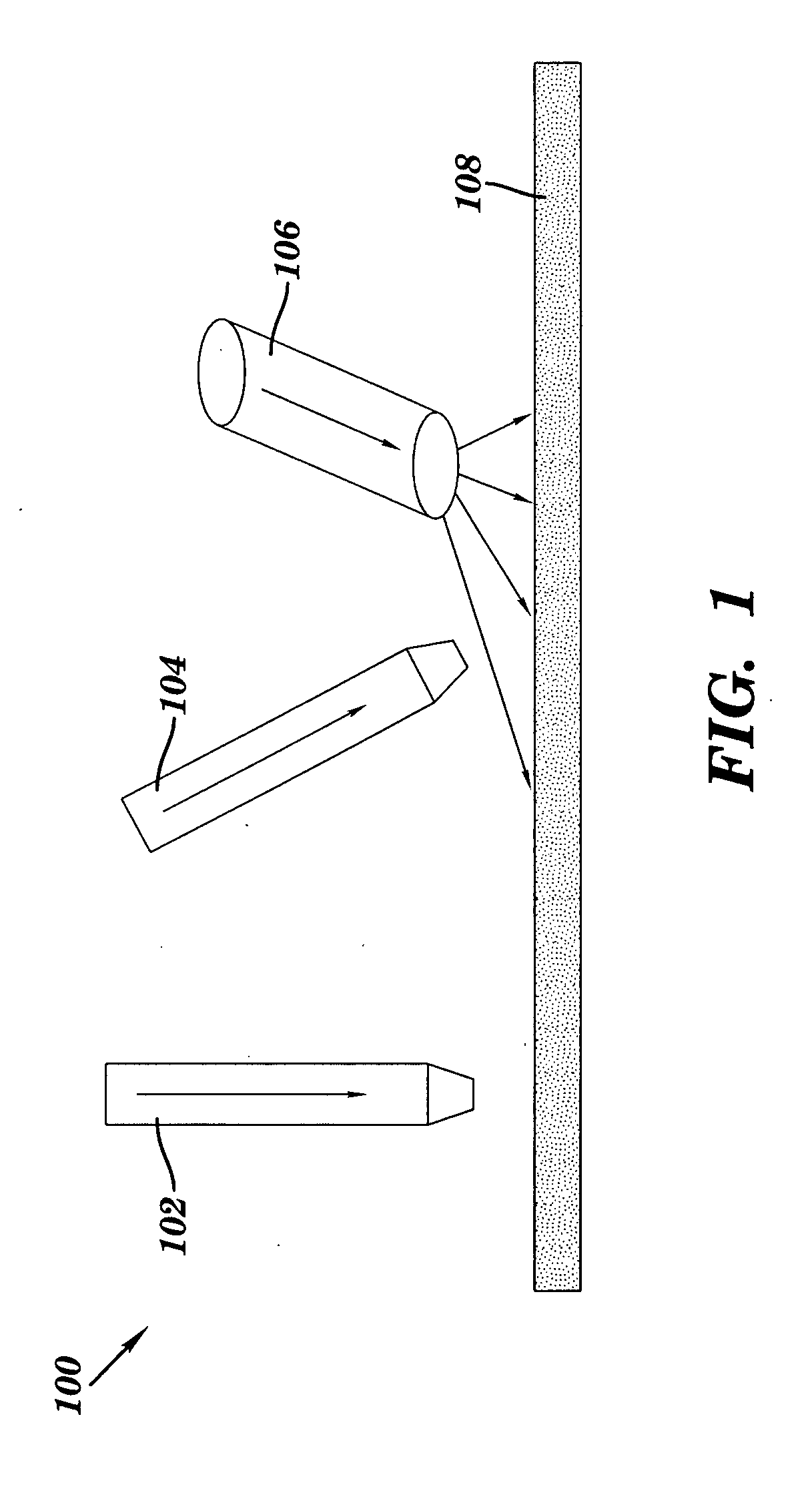

Light emitting element and electron beam deposition apparatus for manufacturing same

ActiveCN107210340AGood step coverageSolid-state devicesSemiconductor/solid-state device manufacturingElectron beam depositionActive layer

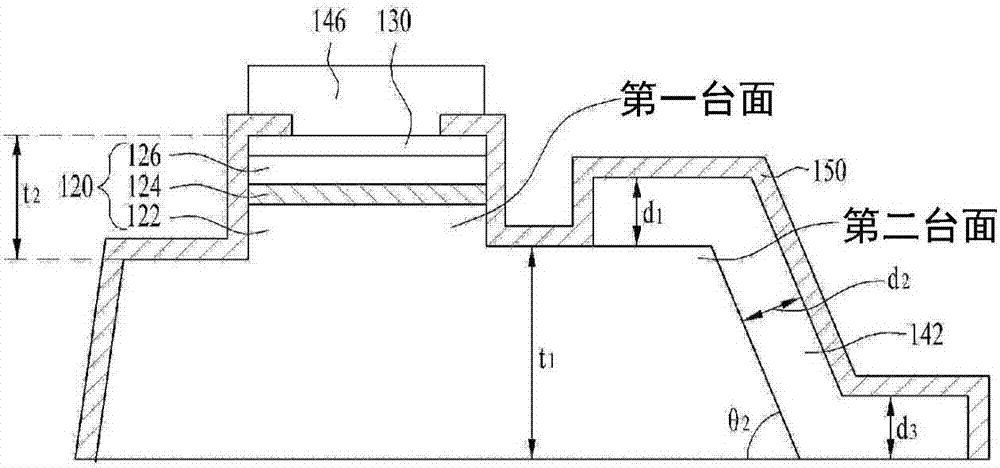

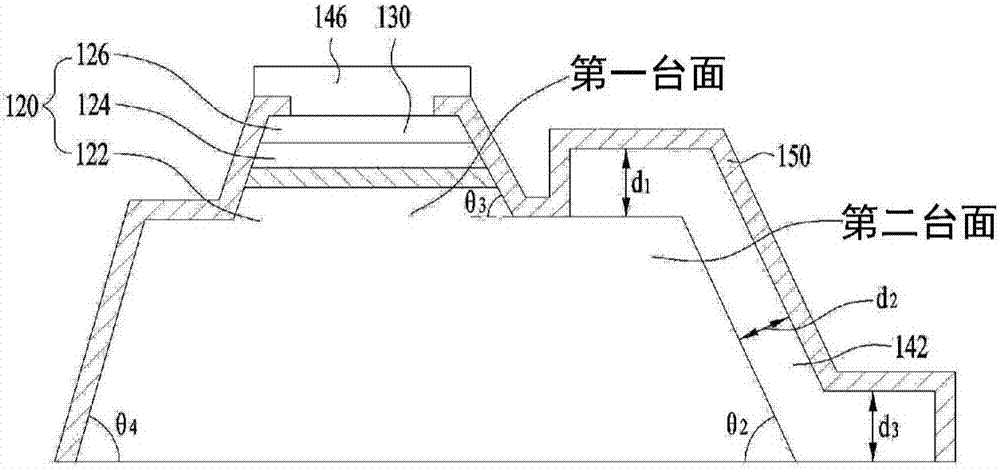

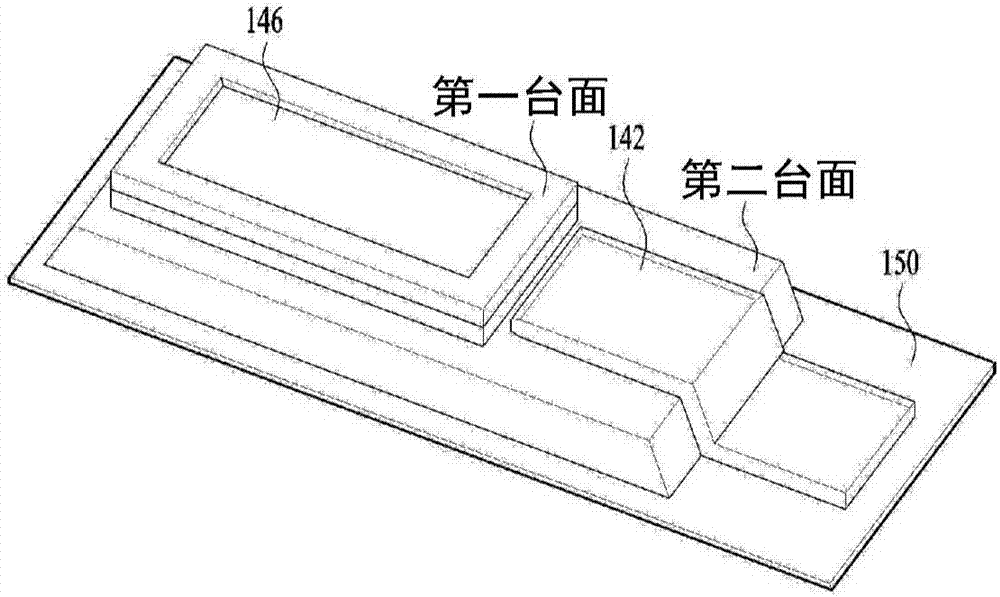

A light emitting element of an embodiment may comprise: a light emitting structure including a first conductive type semiconductor layer, an active layer, and a second conductive type semiconductor layer; and first and second electrodes placed on the first and second conductive type semiconductor layers respectively, wherein the light emitting structure includes a first mesa region, the first conductive type semiconductor layer includes a second mesa region, and the first electrode includes: a first region which is a partial region of the upper surface of the second mesa region; a second region which is the side surface of the second mesa region; and a third region arranged to extend from the edge of the side surface of the second mesa region, wherein the first, second, and third regions are formed such that the thicknesses of the first region (d1), the second region (d2), and the third region (d3) have a ratio of d1:d2:d3 = 1:0.9-1.1:1.

Owner:LG INNOTEK CO LTD

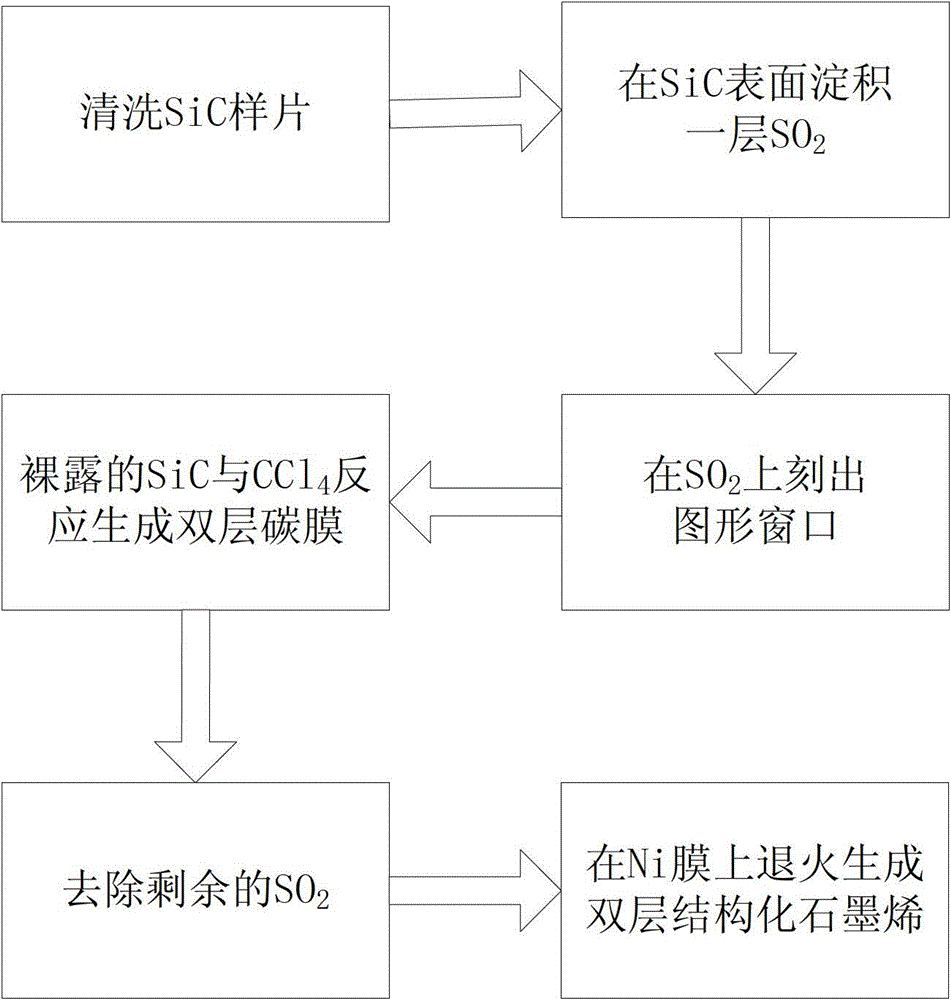

Preparation method of structured grapheme on SiC substrate based on Ni membrane annealing

The invention discloses a preparation method of structured grapheme on a SiC substrate based on Ni membrane annealing, which solves the problems of unsmooth surface, poor continuity and uniform layer numbers of the prepared grapheme in the prior art. The preparation method comprises the following steps: performing standard cleaning on a SiC sample, depositing a layer of SiO2 on the surface of the SiC sample, etching a figure window on SiC2; placing the windowed sample in a quartz tube, reacting with bare SiC through gaseous state CC14 under the temperature of 750-1150 DEG C to generate a double layer carbon film; then placing the generated double layer carbon film sample in a buffer hydrofluoric acid solution to remove residual SiO2; performing electron beam deposition of a Ni membrane with thickness of 350-600nm on the other Si samples, placing the sample without SiO2 on the Ni membrane, placing in Ar gas and annealing for 10-20 minutes, and generating the double layer structured grapheme at a window position. The method provided by the invention has the advantages of simple process, high security, smooth surface of the double layer structured grapheme, good continuity and low porosity, and can be used for making a microelectronic electronic device.

Owner:XIDIAN UNIV

Graphene preparation method based on auxiliary annealing of Ni film

InactiveCN102505140AQuality improvementLow pricePolycrystalline material growthAfter-treatment detailsCarbon filmPorosity

The invention discloses a graphene preparation method based on the auxiliary annealing of a Ni film. The preparation method mainly solves the problems of small area, poor continuity and nonuniform layers of the prepared graphene in the prior art. The preparation method comprises the steps that a carburization layer is firstly grown on a 4-12-inch Si underlay substrate to be used as the transition, then, a 3C-SiC hetero epitaxy film is grown at the temperature of 1200 DEG C to 1350 DEG C, and the growth air sources are C3H8 and SiH4; then, the 3C-SiC takes reaction with gaseous CCl4 at 800 to 1000 DEG C for generating a double-layer carbon film; next, the electron beam deposition of the Ni film with the thickness being 300 to 500nm is carried out on an Si base body; the carbon surface of a generated double-layer carbon film sample sheet is placed on the Ni film, then, the sample sheet and the Ni film are simultaneously placed in Ar gas, and the annealing is carried out for 15 to 25 minutes at the temperature of 900 to 1100 DEG C for generating double-layer grapheme; and finally, the Ni film is taken away from the double-layer graphene sample sheet. The preparation method has the advantage that the double-layer grapheme has large area, smooth surface, good continuity and low porosity rate, and the double-layer grapheme can be used for sealing gas and liquid.

Owner:XIDIAN UNIV

Si-substrate patterned graphene preparation method based on Ni film annealing

InactiveCN102938368AGuaranteed performanceImprove continuityGrapheneSemiconductor/solid-state device manufacturingCarbon filmHydrofluoric acid

The invention discloses an Si-substrate patterned graphene preparation method based on Ni film annealing, which solves the problme that the graphene has to be subjected to shape cutting by electron beam etching before being made into components. The preparation method comprises the following steps: (1) growing a carbonization layer on an Si substrate as transition, and growing a 3C-SiC film at 1200-1350 DEG C; (2) depositing a SiO2 layer on the surface of the 3C-SiC film, and etching a pattern on the SiO2; (3) reacting the bare 3C-SiC with gas-state CCl4 at 800-1000 DEG C to generate a carbon film; (4) putting the generated carbon film sample wafer in a buffer hydrofluoric acid solution to remove residual SiO2; and (5) depositing a 300-500nm-thick Ni film on the carbon film by using an electron beam, putting the sample wafer with the deposited Ni film in Ar gas, and annealing at 900-1100 DEG C for 15-25 minutes to generate the patterned graphene in the pattern position. The patterned graphene prepared by the method disclosed by the invention has the advantages of stable electron mobility and favorable continuity, and can be directly used for making basic components without etching.

Owner:XIDIAN UNIV

Method for preparing graphene on SiC substrate based on Ni film annealing and chlorine reaction

The invention discloses a method for preparing graphene on an SiC substrate based on Ni film annealing and chlorine reaction and mainly solves the problems of poor continuity and unsmooth surface of graphene prepared in the prior art. The preparation method comprises the following implementation steps: firstly, carrying out RCA cleaning on the SiC substrate; carrying out hydrogen etching on the cleaned SiC substrate and removing etching residues; introducing mixed gas of Ar gas and Cl2 into a quartz tube reaction chamber and reacting SiC with Cl2 for 3-8 minutes at the temperature of 700-1,100 DEG C to generate a carbon film; then electron beam-depositing an Ni film on the carbon film; putting a sample sheet deposited with the Ni film into Ar gas and annealing for 10-30 minutes at the temperature of 950-1,150 DEG C to generate the graphene; and finally removing the Ni film from a graphene sample sheet by utilizing mixed solution of hydrochloric acid and copper sulfate. The graphene generated by the method has the advantages of smooth surface, good continuity and low porosity and can be used for manufacturing microelectronic devices and biological sensors or sealing gas and liquid.

Owner:XIDIAN UNIV

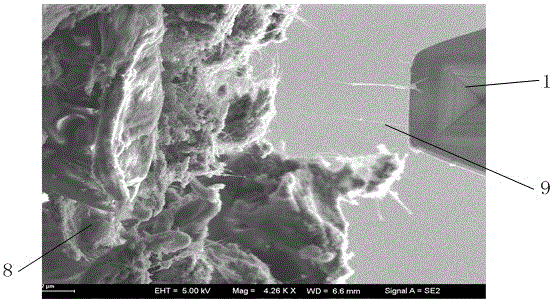

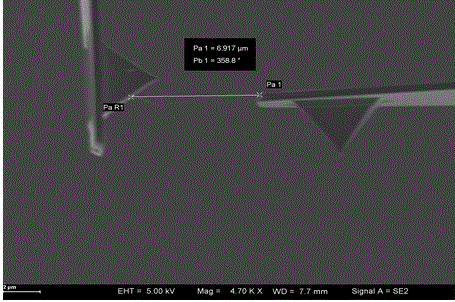

Technology for fusing carbon-carbon bonds of carbon nanotubes by means of electron beam irradiation

InactiveCN106629588AAchieve connectionAccurate connectionSpecific nanostructure formationMultiwalled carbonNano-device

The invention discloses a technology for fusing carbon-carbon bonds of carbon nanotubes by means of electron beam irradiation. The technology comprises the steps that a, multiwalled carbon nanotubes are selected by means of an atomic force microscope probe 1; b, the multiwalled carbon nanotubes are connected to the atomic force microscope probe in a lapped mode to make the multiwalled carbon nanotubes broken; c, two sections of the multiwalled carbon nanotubes are in contact, electron beams are focused by a scanning electron microscope to deposit the multiwalled carbon nanotubes on the joint, so that two sections of suspended carbon-carbon bonds are recovered, and then the carbon nanotubes are fused; d, the fused multiwalled carbon nanotubes are broken; e, the broken ends of the two broken sections of multiwalled carbon nanotubes are made in contact, an electronic gun is turned off after contact, and after the electronic gun is turned on, the multiwalled carbon nanotubes in contact are broken. A nanometer device prepared from the carbon nanotubes can be precisely connected at any angle, accordingly the requirements for manufacturing of nanometer devices are met, a low-temperature controllable connection method for the carbon nanotubes is achieved, and interconnection of the carbon nanotubes can be precisely conducted on some fusion point under the scanning electron microscope with a high resolution (1.5 nm).

Owner:HARBIN UNIV OF SCI & TECH

Method for electron beam-initiated coating for application of transmission electron microscopy

InactiveUS20060065829A1Preparing sample for investigationChemical methods analysisElectron beam depositionMicroanalysis

A method for preparing a specimen for application of microanalysis thereto includes forming an initial conductive layer over a defined area of interest on a semiconductor substrate, the initial conductive layer formed through an electron beam deposition process. A volume of substrate material surrounding the area of interest is removed, thereby forming the specimen, including said area of interest and said initial conductive layer over the area of interest. The specimen is then removed from the bulk substrate material.

Owner:IBM CORP

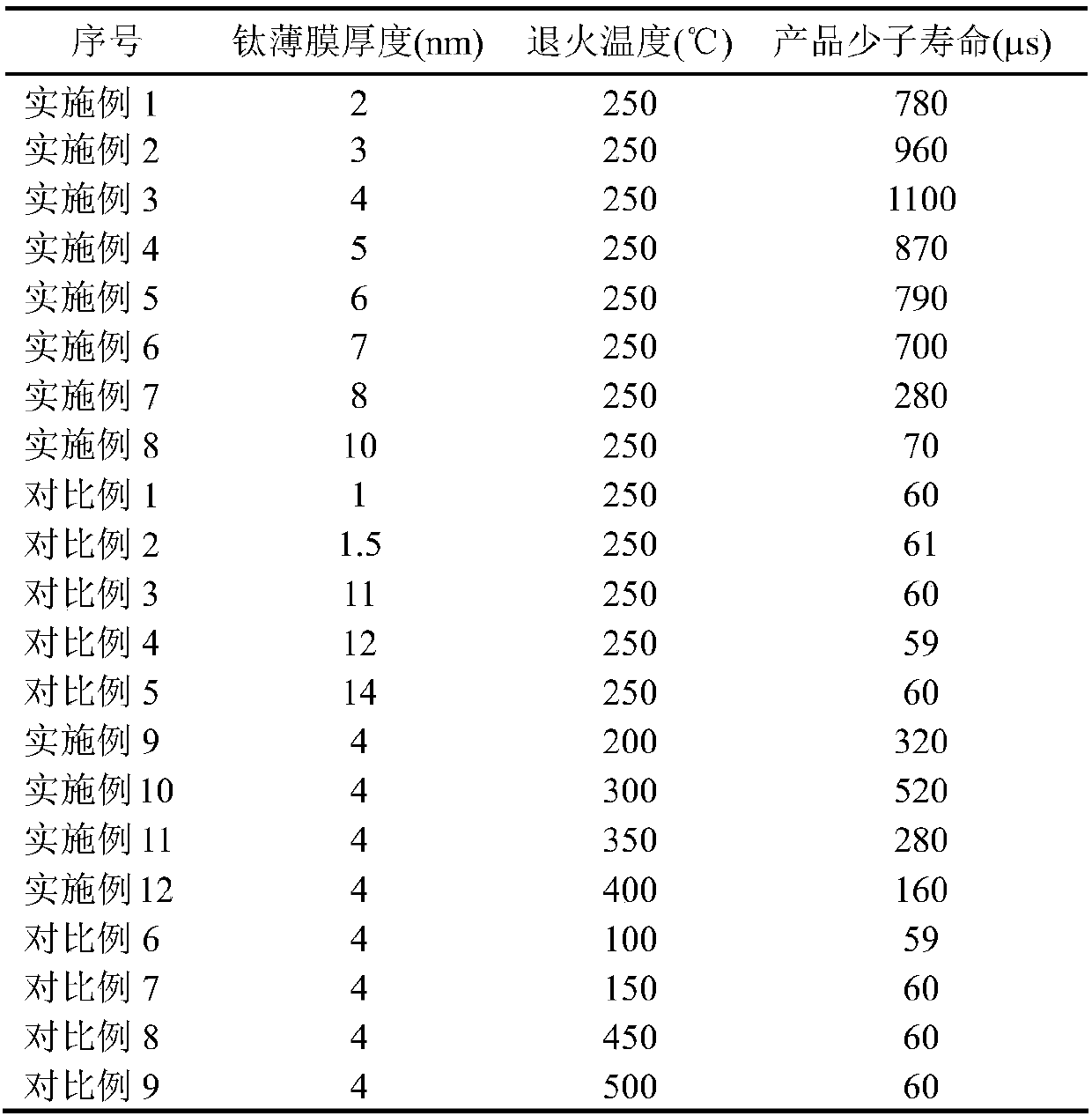

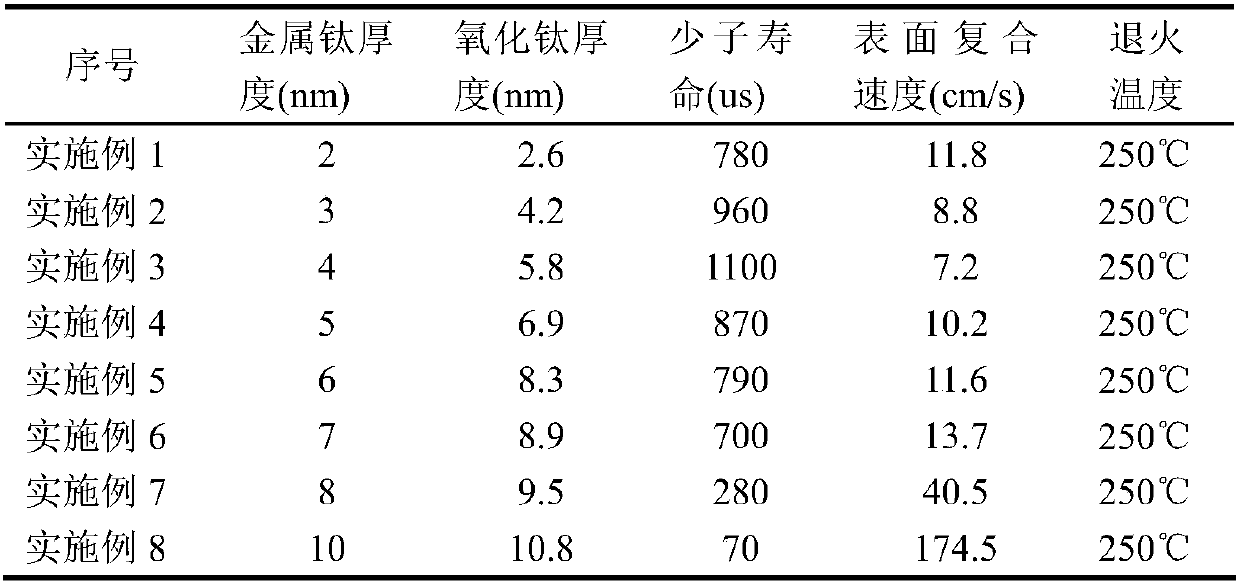

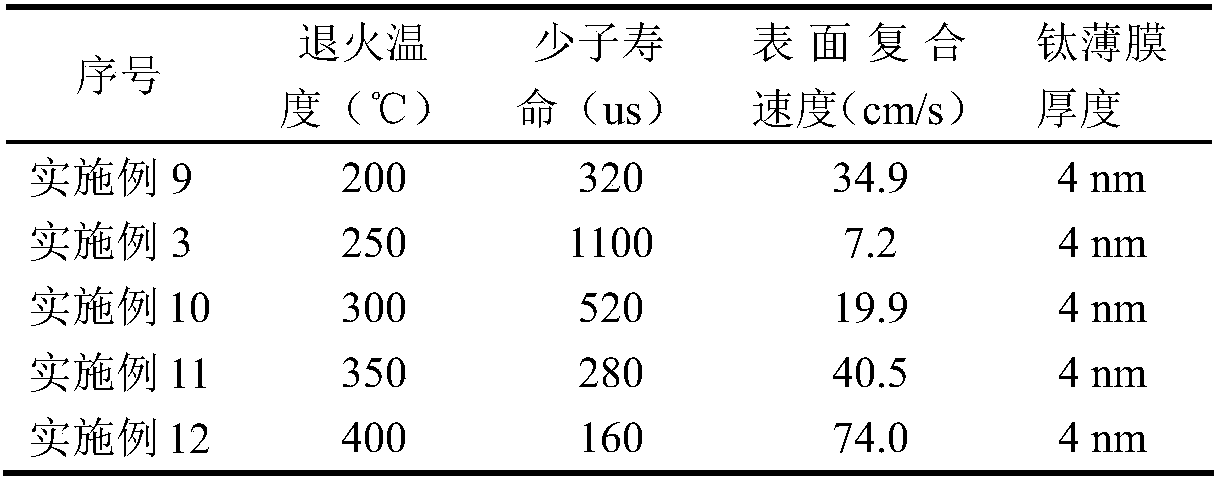

Titanium oxide passivation film preparation method and solar energy cell prepared through utilizing titanium oxide passivation film preparation method

InactiveCN107634122AImprove life expectancyReduce surface recombination rateFinal product manufactureSemiconductor devicesEvaporationOperation mode

The invention discloses a titanium oxide passivation film preparation method. The method comprises steps that an electron beam deposition method is utilized to deposit a metal titanium film with certain thickness at the surface of a silicon chip after pretreatment, then annealing is carried out in the oxygen atmosphere, and cooling in the nitrogen atmosphere is then carried out. The electron beamdeposition method and the metal titanium film are utilized to directly carry out oxidation of the metal titanium film to form a titanium oxide film, compared with the ALD / CVD process, equipment requirements are low, an operation mode and the operation flow are simpler, adjustment on the thickness of the metal titanium film and the oxidation process is facilitated to adapt to different silicon chippassivation demands, the titanium oxide passivation film and other passivation medium layers can excellently form laminated layers, so the better passivation result is realized; the method is suitable for a thermal evaporation method, a magnetron sputtering method to deposit the metal titanium film; deposition of microscale active metal can be easily realized, and thereby doped modification of the final titanium oxide film is realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Method for preparing structured graphene by reaction of SiC and Cl2 based on Ni film annealing

The invention discloses a method for preparing structured graphene by reaction of SiC and Cl2 based on Ni film annealing, mainly aiming at solving the problems that the graphene prepared by the prior art is not smooth in surface, and is poor in continuity and uneven in the number of layers. The realization process of the method comprises the steps of: carrying out standard cleaning on a SiC sample piece; depositing a layer of SiO2 on the surface of the cleaned SiC sample piece, and carving a graphic window; after the graphic window is formed, putting the sample piece into a quartz tube, and generating a carbon film at the temperature of 700-1100 DEG C; then, putting the generated carbon film sample piece into a buffer hydrofluoric acid solution, and removing the SiO2 outside the window; after that, depositing a layer of Ni film on another Si sample piece by electron beams; arranging the carbon film sample piece without SiO2 on the Ni film, and arranging in Ar gas; and carrying out annealing at 900-1100 DEG C for 10-30minutes, and generating the structured graphene. The method has the advantages of being simple in technology, high in safety, smooth in the surface of the generated structured graphene, good in continuity of the generated structured grapheme and low in porosity of the generated structured graphene, thus being used for making a microelectronic device.

Owner:XIDIAN UNIV

Nickel (Ni) film annealing side gate graphene transistor preparation method based on reaction of silicon carbide (SiC) and chlorine gas

InactiveCN103107068AAvoid scattering effectsElectron mobility does not decreaseTransistorSemiconductor/solid-state device manufacturingCarbon filmCharge carrier mobility

The invention discloses a Nickel (Ni) film annealing side gate graphene transistor preparation method based on reaction of silicon carbide (SiC) and chlorine gas, and mainly solves the problem that graphene transistor gate mediums prepared through the prior art result in reduction of migration rates of channel current carriers, and can not effectively control current transferring characteristics. The achieving process of the method is that (1) SiC pattern pieces are cleaned; (2) silicon dioxide (Sio2) masking is deposited on SiC pattern pieces after being cleaned and side gate graphene transistor patterns are photo-etched on the Sio2; (3) the pattern pieces after being photo-etched are placed in a quartz tube and are reacted with chlorine (Cl2) to generate carbon films; (4) the Sio2 masking is removed; (5) a Ni film layer is deposited on an electron beam on carbon film pattern pieces; (6) the carbon film pattern pieces are placed in Argon (Ar) and are generated into side gate graphene in an annealing mode; and (7) a polyether diols (Pd) / Au layer is deposited on the carbon film pattern pieces and is etched into metal contact of the side gate graphene transistor. Side gate graphene transistor manufactured by the Ni film annealing side gate graphene transistor preparation method based on reaction of the SiC and the chlorine gas is high in migration rates of current carriers, capable of accurately controlling channel current of a single transistor and avoiding scattering effect of top gate mediums of a top gate graphene field-effect tube.

Owner:XIDIAN UNIV

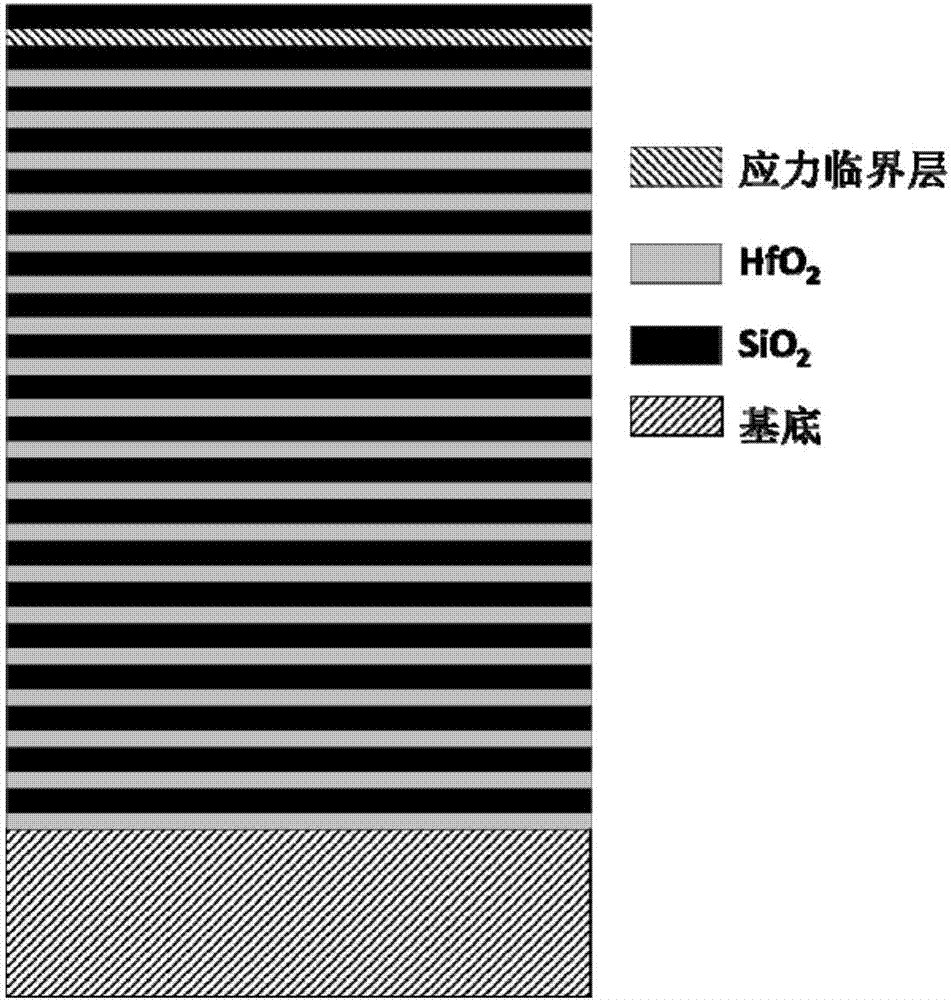

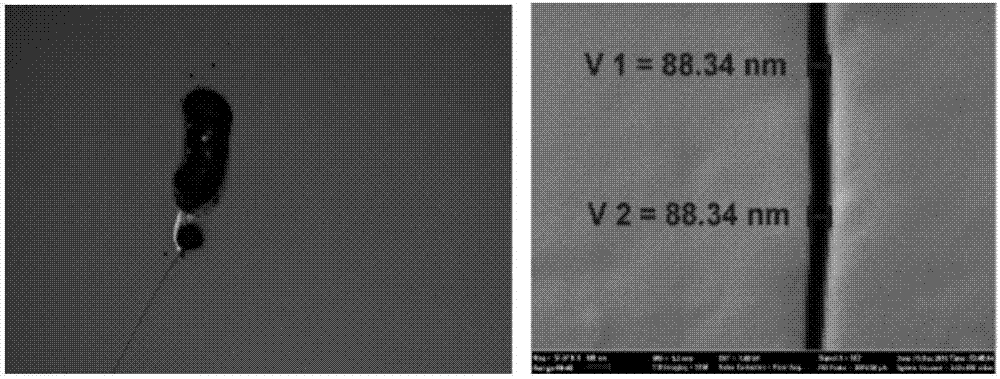

Critical layer stress adjusting method for solving cracking of multi-layer film caused by electron beam deposition

ActiveCN107099772ASolve crackingDoes not increase design difficultyVacuum evaporation coatingSputtering coatingElectron beam depositionIon beam-assisted deposition

Disclosed is a critical layer stress adjusting method for solving cracking of a multi-layer film caused by electron beam deposition. Electron beam deposition technology and ion beam assisted deposition technology are combined to adopt, a stress critical layer is deposited by using the ion beam assisted deposition technology, and the other film layers except to the stress critical layer are deposited by using the electron beam deposition technology. The critical layer stress adjusting method can solve the problem that when a thicker film layer is deposited by the electron beams, the film layer is cracked because tension stress borne by the film layer is too high, and the difficulties of film system designing and practical preparation technologies are not increased.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com