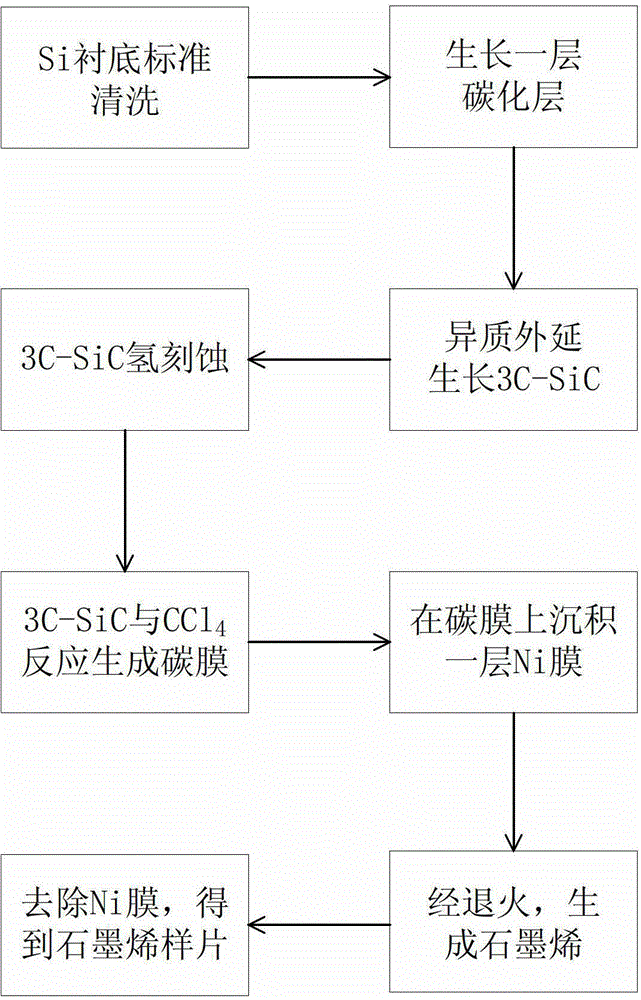

Preparation method of large-area graphene on Si substrate based on Ni film annealing

A graphene and large-area technology, applied in the field of microelectronics, can solve problems such as low processing temperature, inappropriate production, and graphene film defects, and achieve the effects of low porosity, smooth surface, and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1, preparing a graphene material based on Ni film annealing on a 4-inch Si substrate.

[0041] Step 1: Clean the 4-inch Si substrate with a mixed solution of ammonia water and hydrogen peroxide, and a mixed solution of hydrochloric acid and hydrogen peroxide in sequence.

[0042] (1.1) According to NH 4 OH:H 2 o 2 :H 2Prepare a solution at a ratio of O=1:2:5, place a 4-inch Si substrate in the solution, soak for 10 minutes, rinse with deionized water repeatedly, and then dry to remove organic residues on the surface of the sample;

[0043] (1.2) According to HCl: H 2 o 2 :H 2 A solution was prepared at a ratio of O=1:2:8, and a 4-inch Si substrate after removing surface organic residues was placed in the solution, soaked for 10 minutes, rinsed repeatedly with deionized water, and then dried to remove ionic pollutants .

[0044] Step Two: Vacuum.

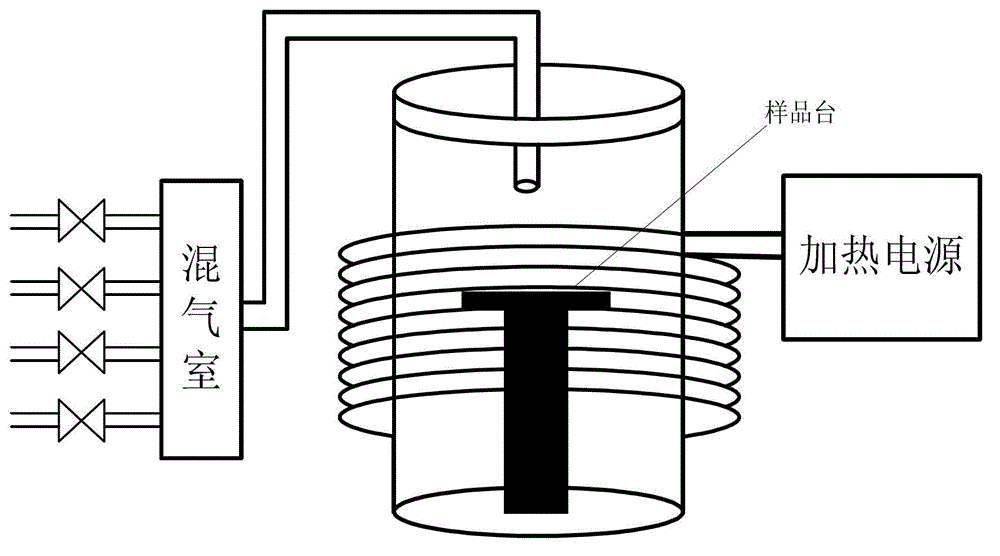

[0045] Put the Si substrate into the reaction chamber of the CVD system, and evacuate the reaction chamber ...

Embodiment 2

[0061] Example 2, preparing a graphene material based on Ni film annealing on an 8-inch Si substrate.

[0062] Step 1: Clean the 8-inch Si substrate with a mixed solution of ammonia water and hydrogen peroxide, and a mixed solution of hydrochloric acid and hydrogen peroxide in sequence.

[0063] The cleaning steps are the same as the first step in Example 1.

[0064] Step 2: Vacuum.

[0065] Put the Si substrate substrate into the reaction chamber of the CVD system, and evacuate the reaction chamber to 10 -7 mbar level.

[0066] Step 3: Grow the carbonized layer.

[0067] in H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1100 ° C, and then the flow rate of 30ml / min is introduced into the reaction chamber. 3 h 8 , grow a layer of carbonized layer on the Si substrate, the growth time is 6min.

[0068] Step 4: growing a 3C-SiC epitaxial film on the carbonized layer.

[0069] Rapidly raise the temperatur...

Embodiment 3

[0081] Example 3, preparing a graphene material based on Ni film annealing on a 12-inch Si substrate.

[0082] Step 1: Clean the 12-inch Si substrate with a mixed solution of ammonia water and hydrogen peroxide, and a mixed solution of hydrochloric acid and hydrogen peroxide in sequence.

[0083] The cleaning steps are the same as the first step in Example 1.

[0084] Step 2: Put the Si substrate substrate into the reaction chamber of the CVD system, and evacuate the reaction chamber to 10 -7 mbar level.

[0085] Step 3: In H 2 In the case of protection, the temperature of the reaction chamber is raised to the carbonization temperature of 1200 ° C, and then the flow rate of 30ml / min is introduced into the reaction chamber. 3 h 8 , for 4 min to grow a carbonized layer on the Si substrate.

[0086] Step 4: Rapidly raise the temperature of the reaction chamber to the growth temperature of 1350°C, and feed SiH at a flow rate of 35ml / min respectively 4 and C with a flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com