Light emitting element and electron beam deposition apparatus for manufacturing same

An electron beam deposition and light-emitting element technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of thick substrates or metal supports, inability to form ultra-thin pixels, and performance degradation of small light-emitting elements, etc. To achieve the effect of improved ladder coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

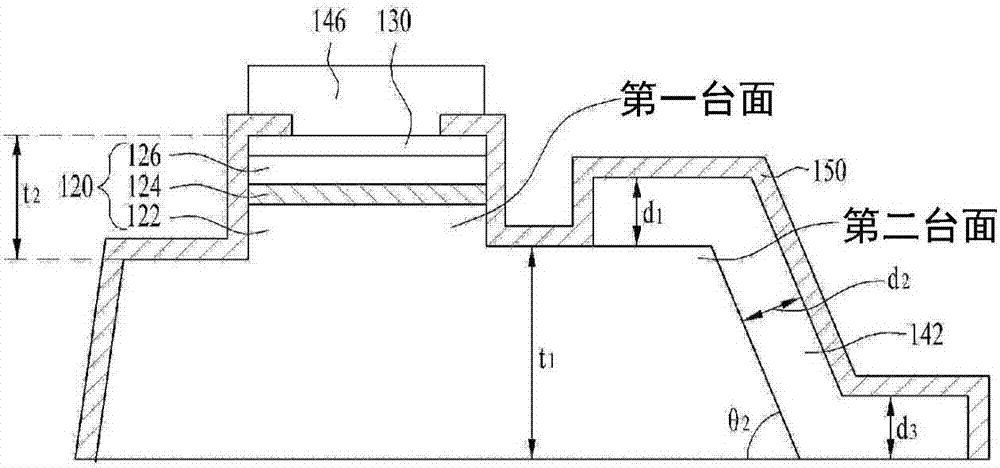

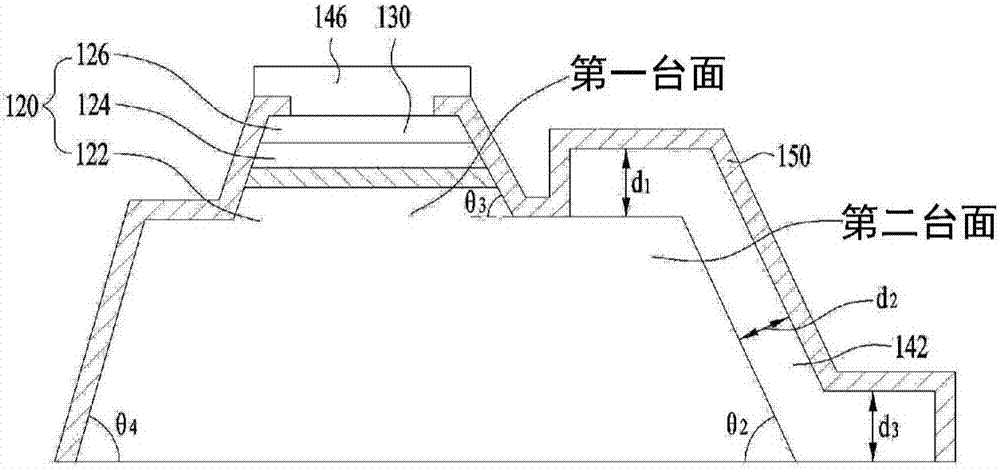

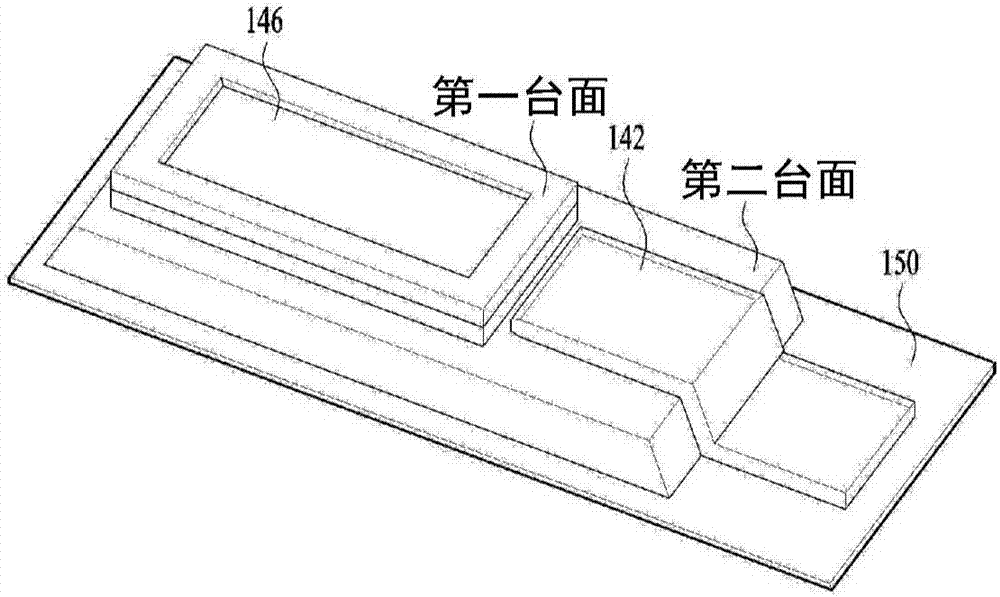

[0031] Hereinafter, the embodiments will be described in detail with reference to the accompanying drawings, so as to specifically achieve the above-mentioned objects.

[0032] In the description of the embodiments disclosed herein, it should be understood that when an element is referred to as being formed "on" or "under" another element, it can mean directly being "on" or "under" the other element. Or it is indirectly formed "above" or "below" other elements, with one or more elements interposed therebetween. It should also be understood that “on” or “under” an element may be described with respect to the drawings.

[0033] In addition, for example, related terms such as "first", "second", "above / upper / above" and "below / lower / below" used in the following description can be used to distinguish any substance or element from Another substance or element without requiring or containing any physical or logical relationship or sequence between these substances or elements.

[0034] In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com