Transparent electrode based on ultrathin metal and preparation method thereof

An ultra-thin metal and transparent electrode technology, applied in the field of electrodes, can solve the problems of poor stability and insufficient photoelectric performance of ultra-thin metal transparent electrodes, and achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

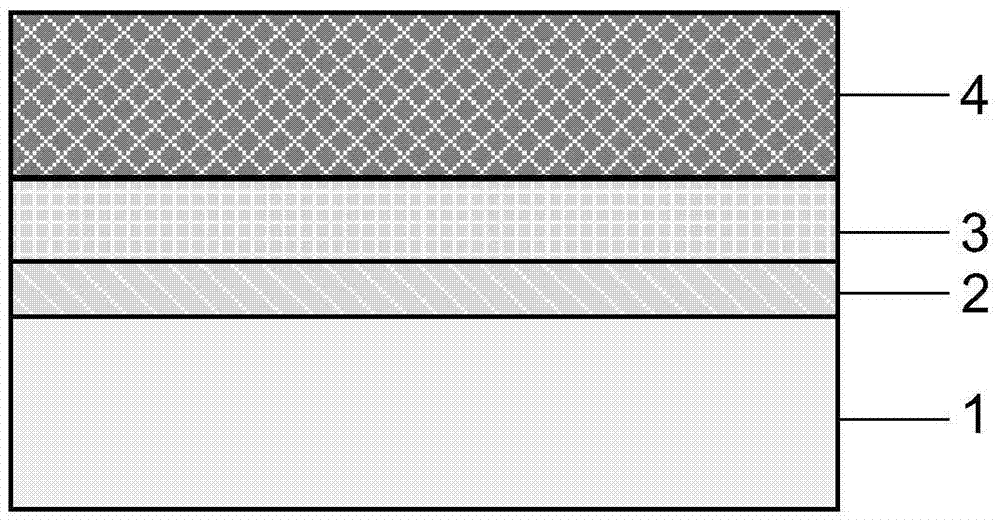

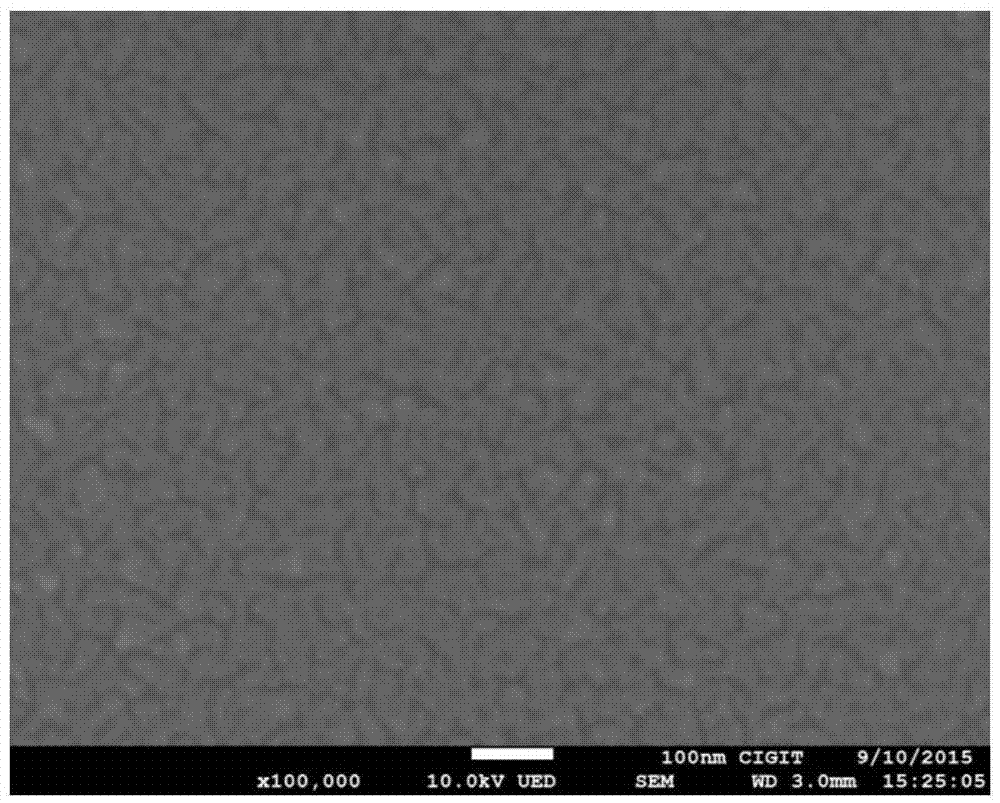

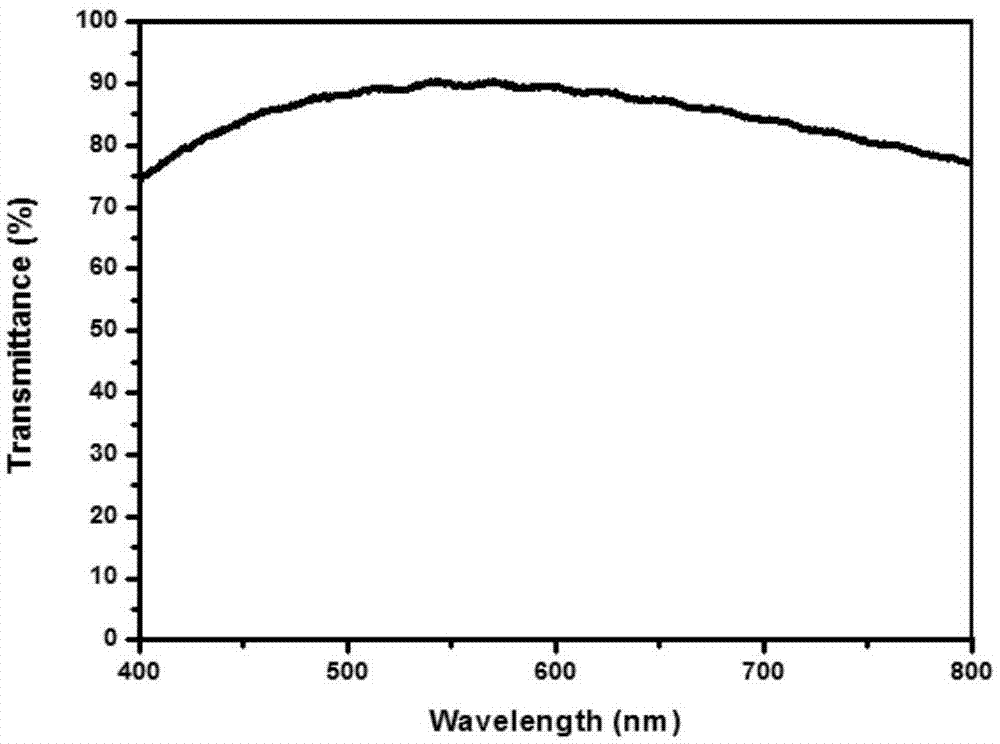

[0028] A transparent electrode, using a magnetron sputtering coater as an ultra-thin film growth method, depositing ZnO on a flexible transparent substrate 1 by magnetron sputtering as a nucleation seed layer 2, and then co-sputtering Ag and Al to grow an ultra-thin metal Layer 3, CuSCN anti-reflection and anti-reflection layer 4 is deposited by spin coating, and finally forms an ultra-thin metal transparent electrode of the ZnO-Ag / Al-CuSCN system. The specific preparation method is:

[0029] (1) Ultrasound a PET sheet with a side length of 2 inches and a thickness of 0.2 mm in ethanol solution for 10 minutes, dry it with nitrogen, put it into the magnetron sputtering loading chamber immediately, and start vacuuming;

[0030] (2) Wait until the vacuum degree of the back of the reaction chamber is better than 1×10-6 Torr, put the sample into the cavity of the reaction chamber and rotate the sample holder at a speed of 10 rpm. Using Ar with a purity higher than 99.99% as the dep...

Embodiment 2

[0038] A transparent electrode, using a magnetron sputtering coater as an ultra-thin film growth method, depositing TiO on a transparent substrate 1 by magnetron sputtering 2 For the nucleation seed layer 2, a small amount of O 2 Sputter Ag to deposit oxygen-doped ultra-thin silver, deposit CuI anti-reflection and anti-reflection layer 4 by spin coating, and finally form TiO 2 -AgO x -CuI system ultra-thin metal transparent electrode, the specific preparation method is:

[0039] (1) Ultrasound the quartz glass with a side length of 2 inches and a thickness of 1 mm in ethanol solution for 10 minutes, dry it with nitrogen, put it into the magnetron sputtering loading chamber immediately, and start vacuuming;

[0040] (2) Wait until the vacuum degree of the back of the reaction chamber is better than 1×10-6 Torr, put the sample into the cavity of the reaction chamber and rotate the sample holder at a speed of 10 rpm. Using Ar with a purity better than 99.99% as the deposition ...

Embodiment 3

[0048] A transparent electrode, using a magnetron sputtering coater as an ultra-thin film growth method, depositing ZnO on a flexible transparent substrate 1 as a nucleation seed layer 2, and depositing ultra-thin silver by sputtering NiO x Anti-reflection and anti-reflection layer 4, finally forming ZnO-Ag-NiO x The ultra-thin metal transparent electrode of the system, the specific preparation method is as follows:

[0049] (1) Ultrasound the quartz glass with a side length of 2 inches and a thickness of 1 mm in ethanol solution for 10 minutes, dry it with nitrogen, put it into the magnetron sputtering loading chamber immediately, and start vacuuming;

[0050] (2) Wait until the vacuum degree of the back of the reaction chamber is better than 1×10-6 Torr, put the sample into the cavity of the reaction chamber and rotate the sample holder at a speed of 10 rpm. Using Ar with a purity higher than 99.99% as the deposition atmosphere, the ZnO is grown by radio frequency sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com