Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Conductivity factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The conductivity factor (CF) of dissolved salts in a given solution is a measurement of conductivity. Using the electrical conductivity between two electrodes in a water solution, the level of dissolved solids in that solution can be measured. Measurements can then be used to dose the solution with the necessary nutrients in the case of hydroponics. Conductivity measurements are also used in ecology and environmental sciences to assess the level of nutrients in lakes and rivers. For a discussion of conductivity in this context, see Total dissolved solids.

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

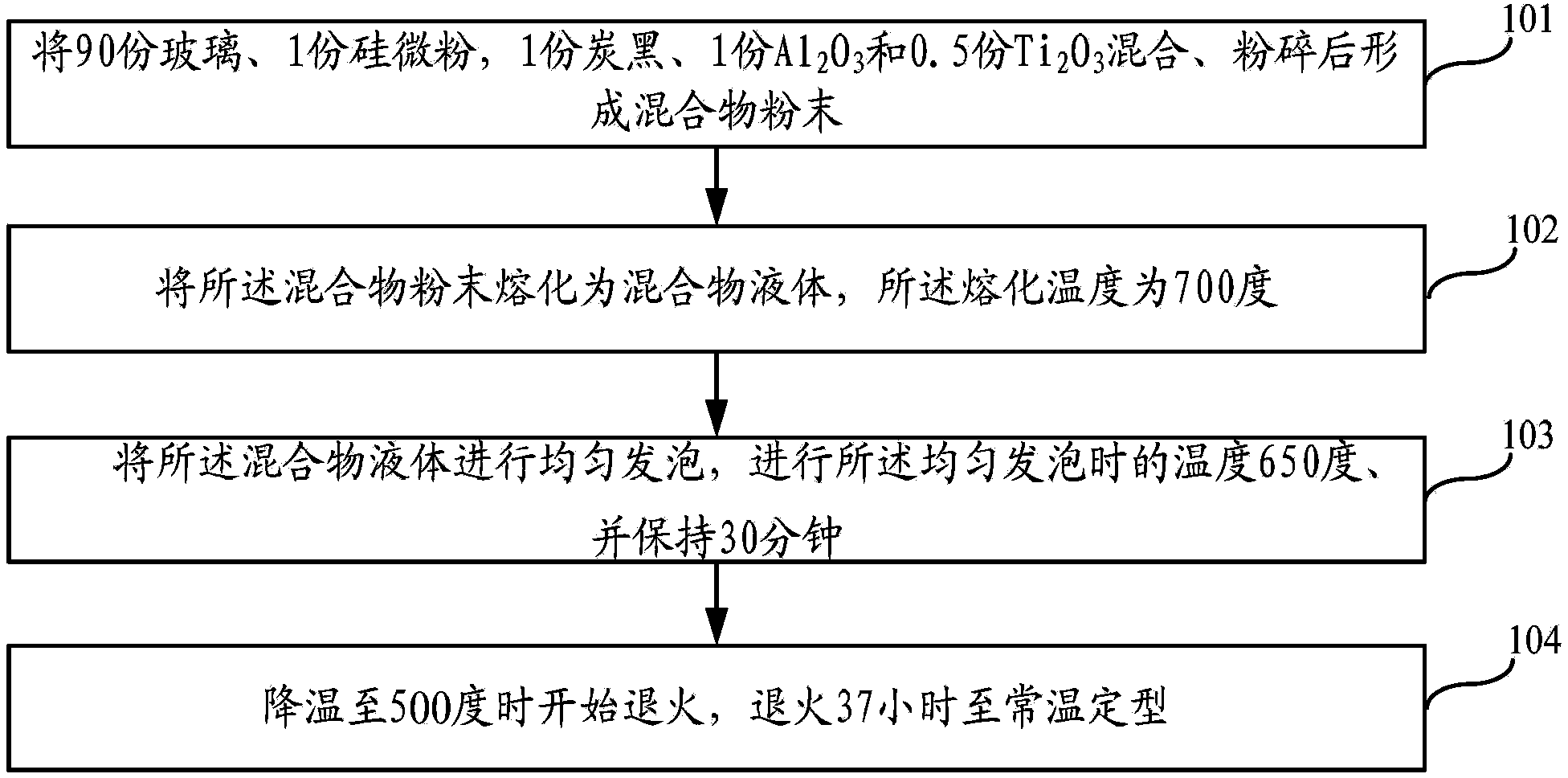

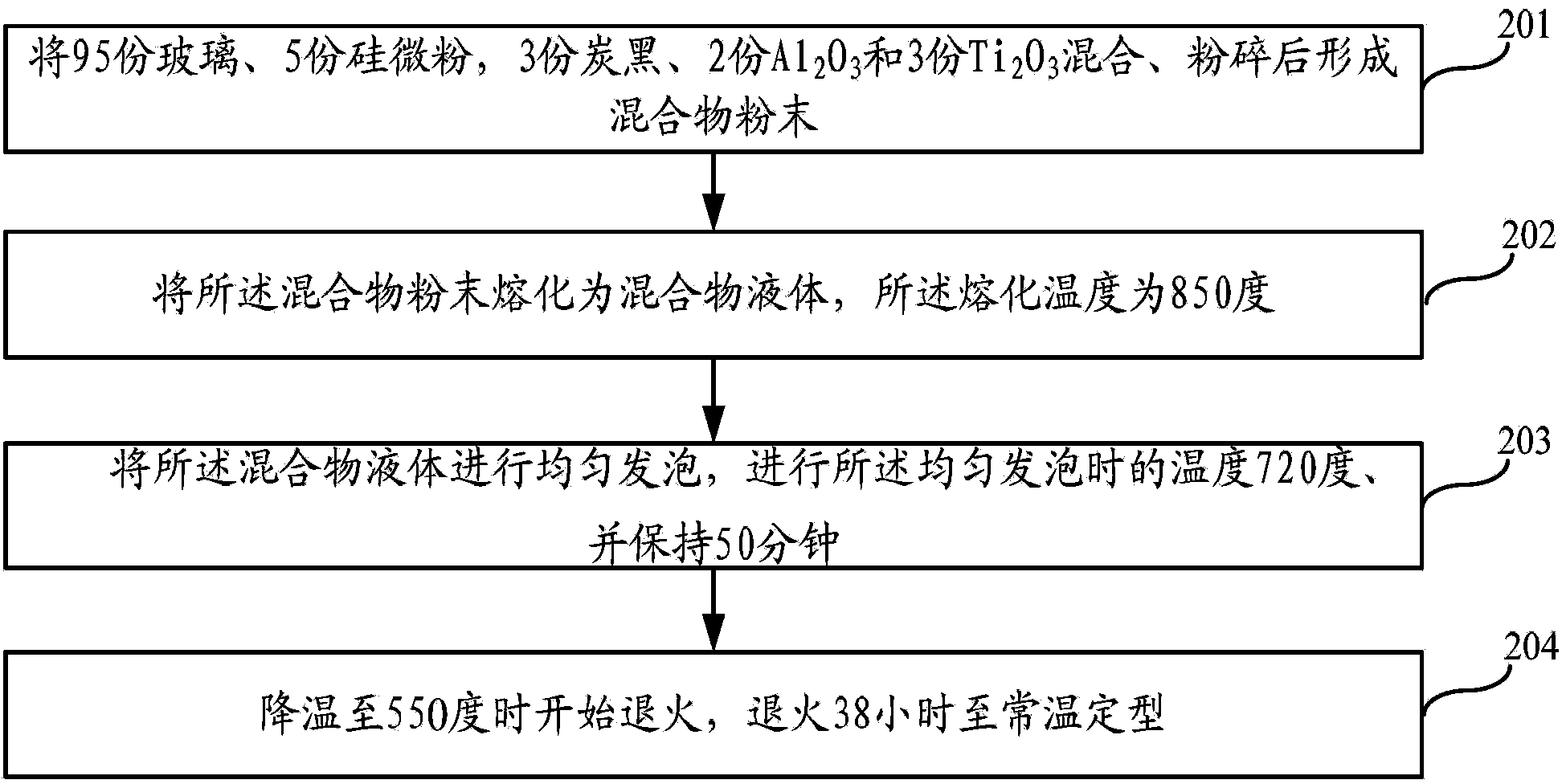

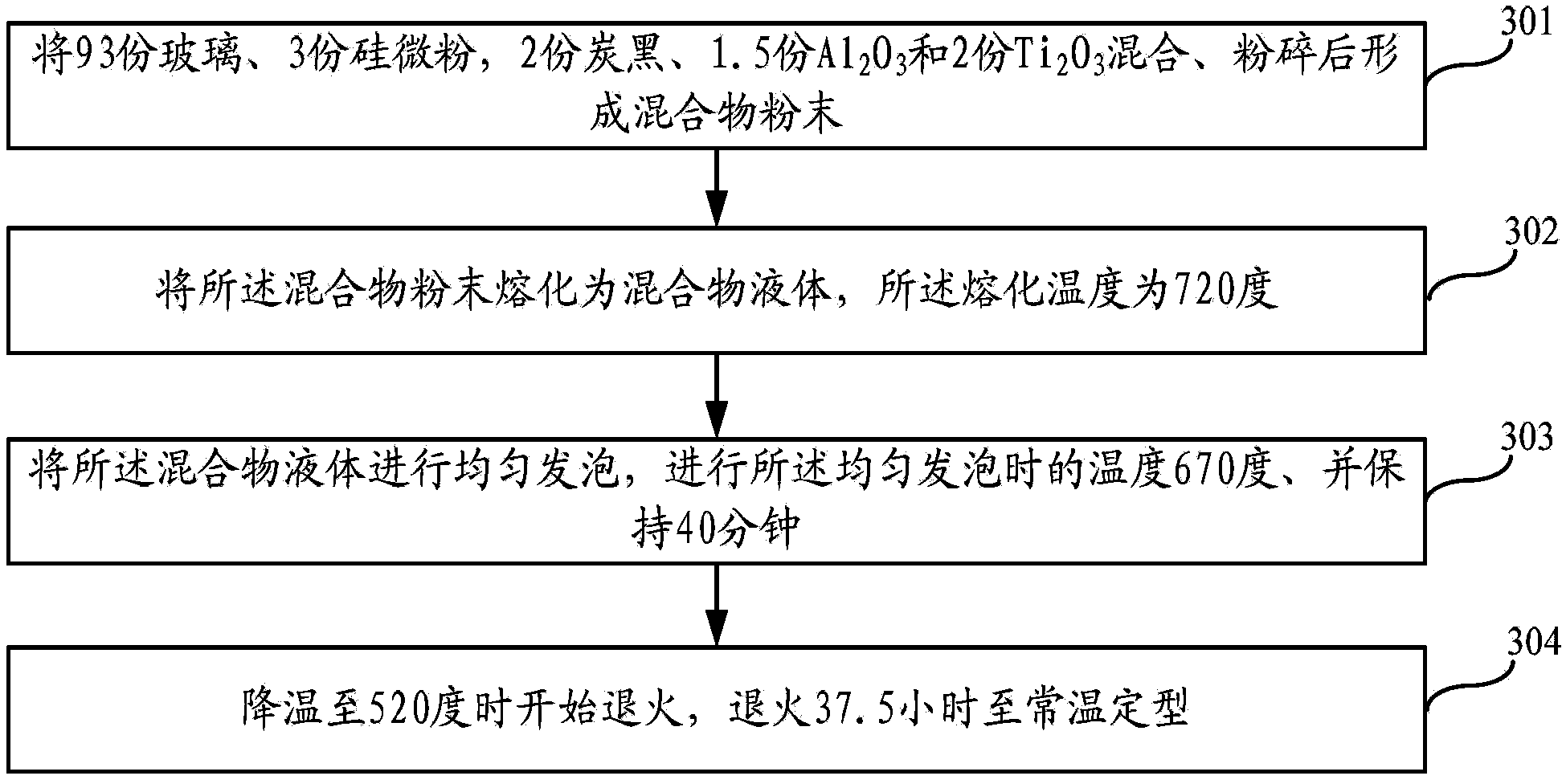

Foam glass and production method thereof

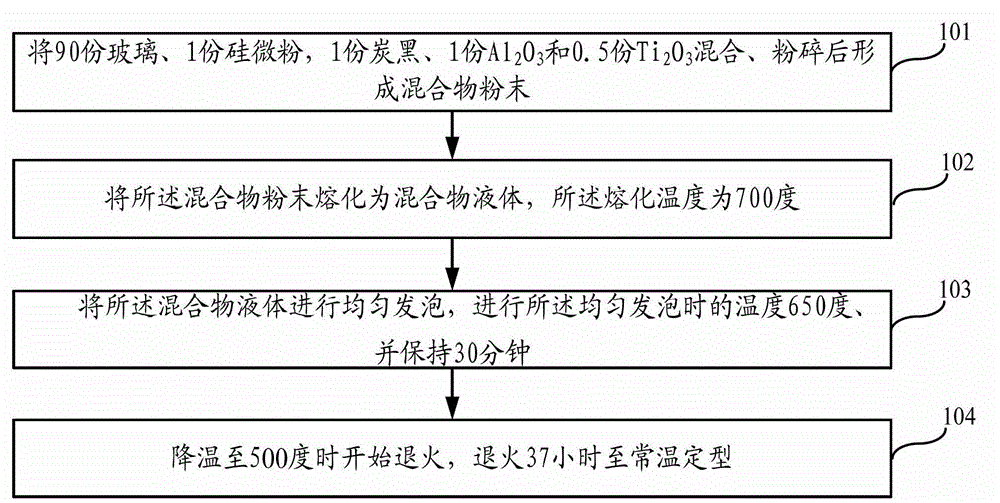

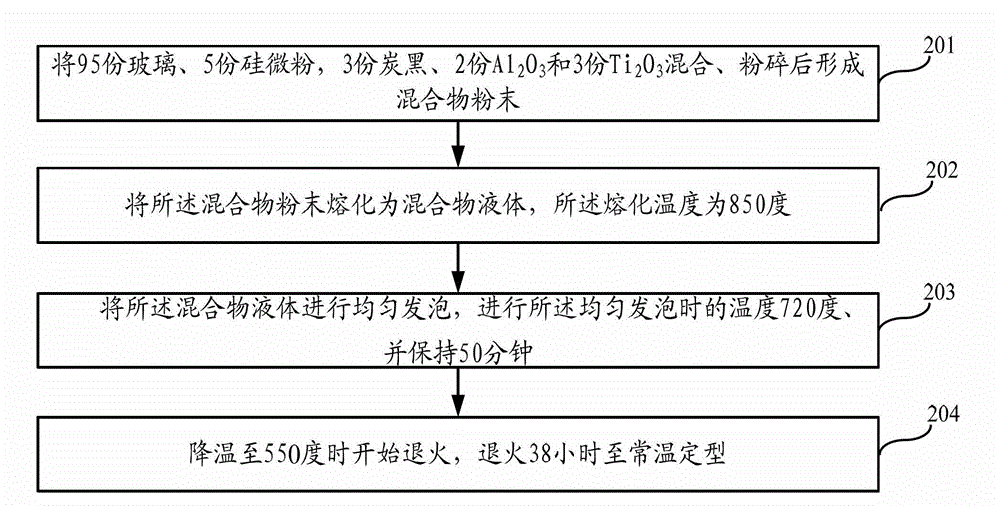

The invention relates to the field of industrial production, in particular to foam glass which has the advantages that the strength of the foam glass is improved and meanwhile the heat conductivity factor of the foam glass is reduced. The foam glass comprises the following components in parts by weight: 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator. The production method of the foam glass comprises the following steps of: mixing and crushing 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator to form mixture powder; melting the mixture powder into mixture liquid at the melting temperature of 700-850 DEG C; then uniformly foaming the mixture liquid at the temperature of 650-720 DEG C and keeping the uniform foaming for 30-50 minutes; starting to anneal when cooling to 500-550 DEG C after the uniform foaming is finished; and annealing for 37-38 hours to normal temperature for shaping.

Owner:BEIJING SHOUBANG NEW MATERIAL

Novel autoclaved fly ash self-insulation wall material and production process

InactiveCN101913830ALight weightImprove seismic performanceSolid waste managementCeramicwareForming gasSilicon dioxide

The invention discloses a novel autoclaved fly ash self-insulation wall material and a production process. The wall material is produced by adding water into raw materials, mixing, pouring, forming gas, standing, hardening, cutting and autoclaved curing. The wall material is characterized by comprising the following raw materials in percentage by weight: 7 to 10 percent of cement, 15 to 25 percent of lime, 2 to 4 percent of gypsum, 45 to 55 percent of fly ash, 8 to 25 percent of lightweight silicon dioxide micro powder, 0.1 to 0.25 percent of gas forming agent, 0.1 to 0.4 percent of foam stabilizer and 0.8 to 1.5 percent of admixture; the pouring temperature is between 30 and 45 DEG C, and the water temperature is controlled to be between 34 and 50 DEG C; and during steam curing, steam is injected to perform curing for 10 to 15 hours, the temperature in a kettle is kept between 160 and 180 DEG C, and the pressure in the kettle reaches 0.8 to 1.4MPa. The heat conductivity factor of the wall material can reach below 0.9W / (mk), and the compressive strength of the wall material is remarkably improved compared with a B04-grade building block. The wall material can well utilize the fly ash, utilize wastes, save energy, be in accordance with national energy-saving policy and meet national standard for 65 percent energy efficiency, and is an ideal novel energy-saving wall material.

Owner:河南省建筑科学研究院有限公司

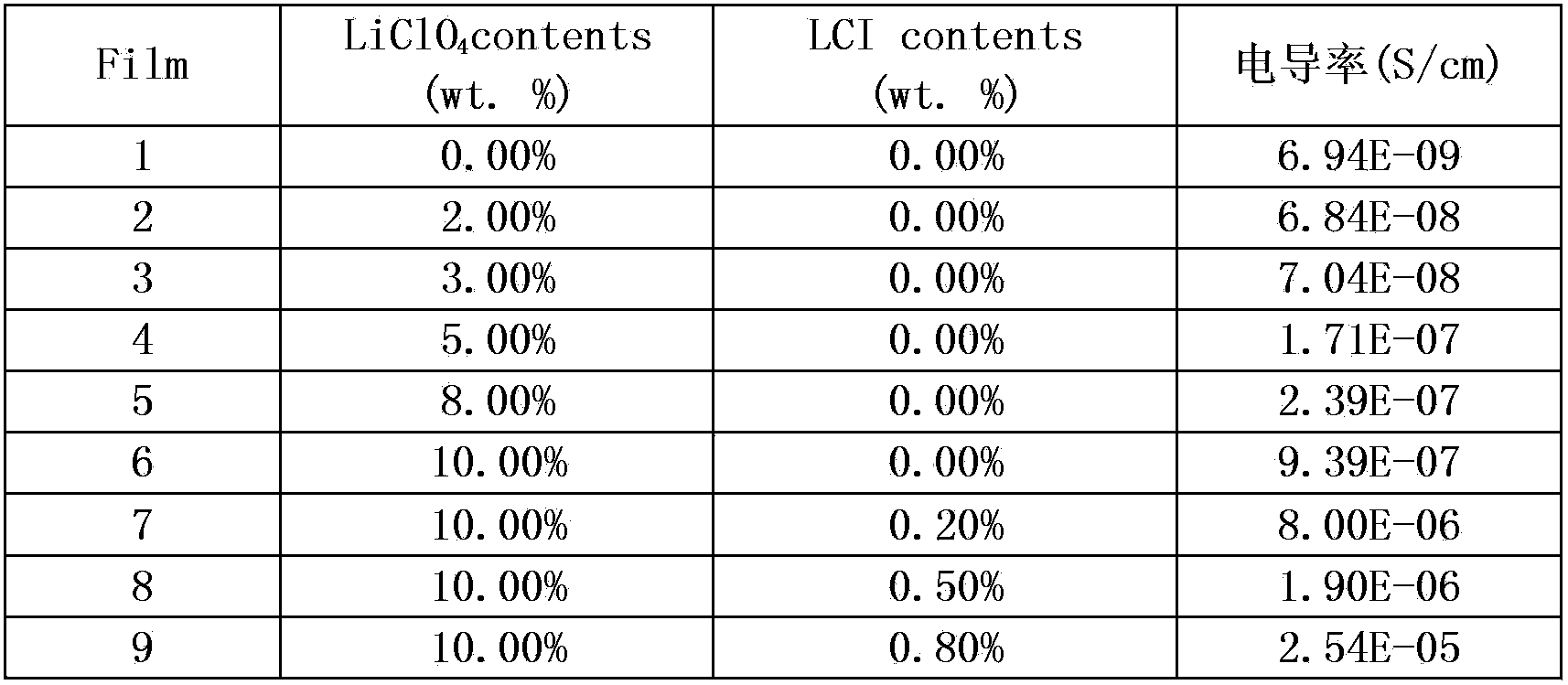

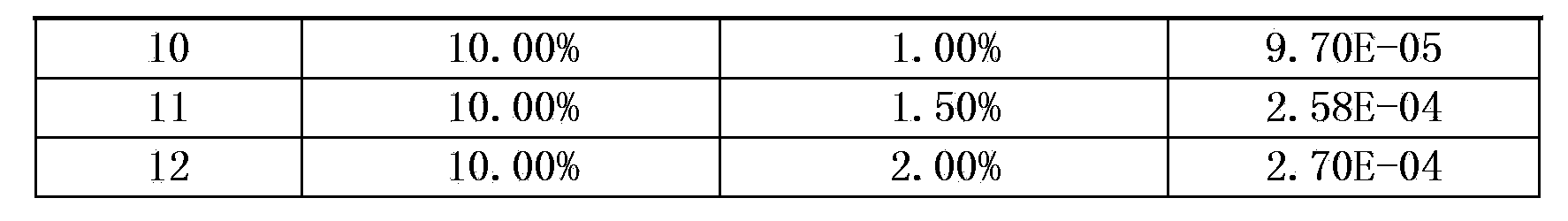

Liquid crystalline ionomer PEO/PMMA solid electrolyte and preparation method thereof

InactiveCN103855423AImprove mechanical propertiesEasy transferSolid electrolytesSecondary cellsLiquid crystallineSolvent

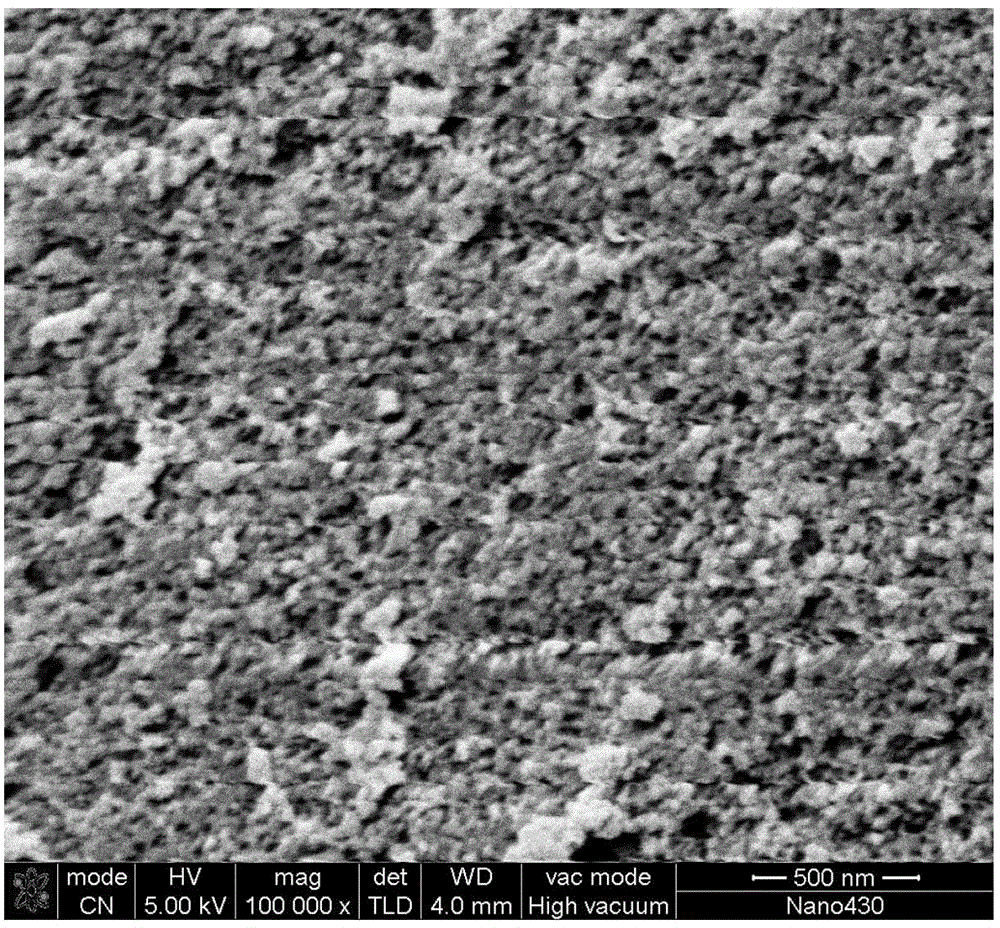

The invention relates to a liquid crystalline ionomer PEO / PMMA solid electrolyte and a preparation method thereof, which is characterized in that the liquid crystalline ionomer PEO / PMMA solid electrolyte is composed of PEO, PMMA, lithium salt, the liquid crystalline ionomer and an aprotic solvent; the preparation method comprises the following steps: taking PEO and PMMA as matrix, dissolving PEO and PMMA in a first anhydrous solvent to form a first solution; dissolving lithium salt and the liquid crystalline ionomer in a second anhydrous solvent to form a second solution; blending and uniformly stirring the first solution and the second solution to prepare a mixed solution; knifing the mixed solution to prepare an electrolyte membrane with certain thickness, and evaporating the solvent to form a solid polymer electrolyte. The liquid crystalline ionomer PEO / PMMA solid electrolyte solves the problem that the glass-transition temperature of current PEO is low and is not stable under room temperature, PMMA is stable and can not reach the requirement due to low conductivity at room temperature, the liquid crystalline ionomer is simultaneously added, the ionic transmission is increased, the ion conductivity is increased, and the matrix mechanical property is increased.

Owner:SHENYANG POLYTECHNIC UNIV

High strength nanophase ceramic composite insulation material and preparation method thereof

InactiveCN101723692AHigh strengthLow thermal conductivityManufacturing convertersCeramic compositeCompressive deformation

The invention discloses a high strength nanophase ceramic composite insulation material which comprises the following raw materials in parts by weight: 120-180 parts of floating beads, 10-50 parts of siliceous dust, 35-60 parts of potassium titanate whisker, 500-600 parts of silicone gel, inorganic bond or mixture of silicone gel and inorganic bond, 5-24 parts of titanium dioxide, 8-12 parts of kaoline, 10-16 parts of kieselguhr and 50-108 parts of alumina silicate fibre mesh cloth. The nanophase ceramic composite insulation material has high compressive strength, small heat conductivity factors, high temperature resistance of 800 DEG C to 1000 DEG C, very high compressive deformation rate, light material volume weight as well as good economic benefic and social benefit.

Owner:SHANGHAI GUOKE CHEM NEW MATERIAL

Hydrocarbon saturation evaluation method based on non-conductive pore model

InactiveCN103543474AEnrich and develop oil and gas saturatedEnrichment and Development Evaluation TheoryElectric/magnetic detectionAcoustic wave reradiationPorosityLithology

The invention provides a hydrocarbon saturation evaluation method based on a non-conductive pore model, and belongs to the field of oil-gas exploration and development. The method includes determining non-conductive porosity in a stratum and the ratio in the total porosity according to rock physical experiments, and utilizing an evaluating equation based on the non-conductive pore hydrocarbon saturation to determine the hydrocarbon saturation of a reservoir stratum. The method is effective to complex reservoir stratum, which is not adaptable to the traditional Archie theory, hydrocarbon saturation quantifying evaluation; lithological background conductivity factors are taken into account, and the method is particularly adaptable to the reservoir stratum which has large changes in lithology and strong heterogeneity; the method is adaptable to hydrocarbon saturation evaluation of complex reservoir stratums of various volcanic rocks, fractured carbonate rocks, metamorphosed rocks and the like, and reliable technique support is provided for efficient exploration and development of complex oil and gas reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

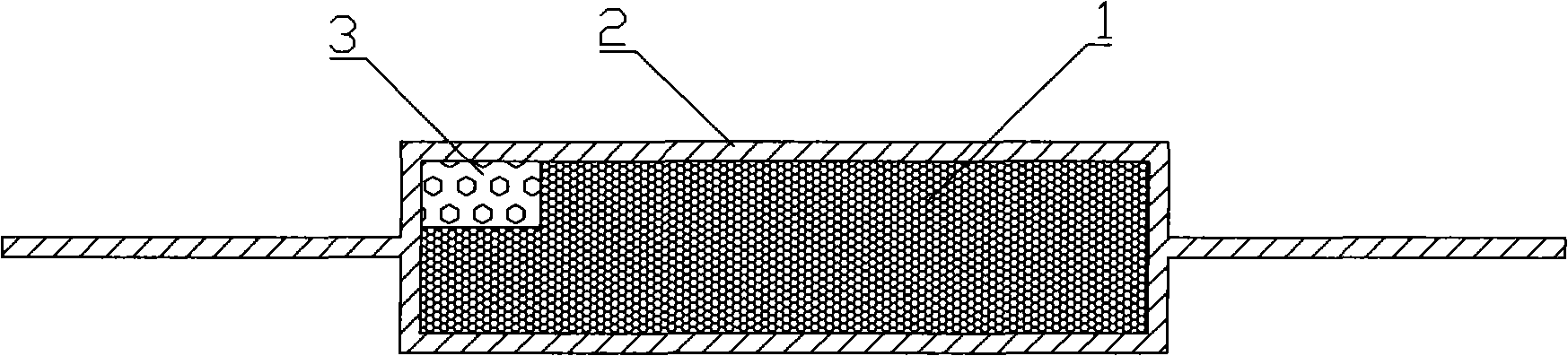

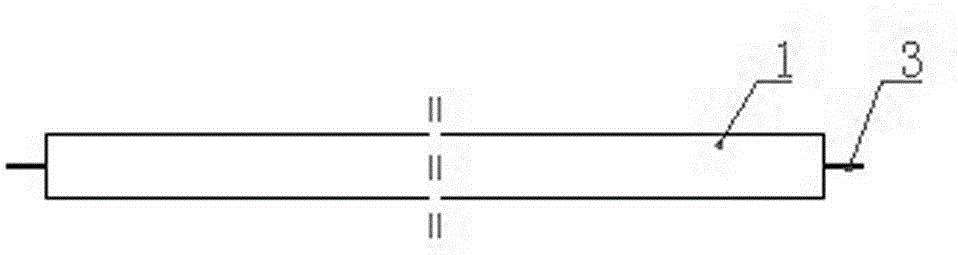

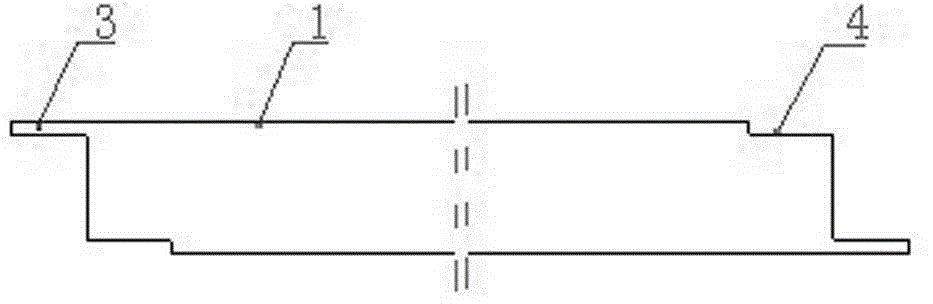

Vacuum insulating board with built-in absorber

InactiveCN101793341ALow thermal conductivityGood insulation performanceThermal insulationPipe protection by thermal insulationGlass fiberConductivity factor

The invention discloses a vacuum insulating board with a built-in absorber, which comprises glass fiber core materials, an aluminum foil and the absorber. The aluminum foil is hermetically coated outside the glass fiber core materials; the inside of the aluminum foil is vacuumized; the absorber is arranged in the aluminum foil and used for water absorption; and the absorber comprises an absorbent container and an absorbent arranged in the absorbent container. Because the absorbent can effectively absorb the residual water of the glass fiber core materials and the penetrated water in the aluminum foil, the invention can effectively improve the vacuum degree in the aluminum foil, thereby reducing the heat conductivity factor of the insulating board and improving the heat insulation effect of the insulating board.

Owner:CHONGQING ZAISHENG TECH CORP

Inorganic fiber composite thermal insulation material and preparation method thereof

The invention discloses an inorganic fiber composite thermal insulation material and a preparation method thereof, which belong to the technical field of thermal insulation material preparation. The thermal insulation material is formed by dispersing and mixing polyphenyl granules, silica, white carbon black, glass wool and aluminum silicate wool through a strong airflow. The thermal insulation material disclosed by the invention has the advantages of light volume weight and small heat conductivity factor, can adapt to complex building nodes and is suitable for thermal insulation of outer walls of buildings.

Owner:HEJIAN TIANHAO INSULATION MATERIAL

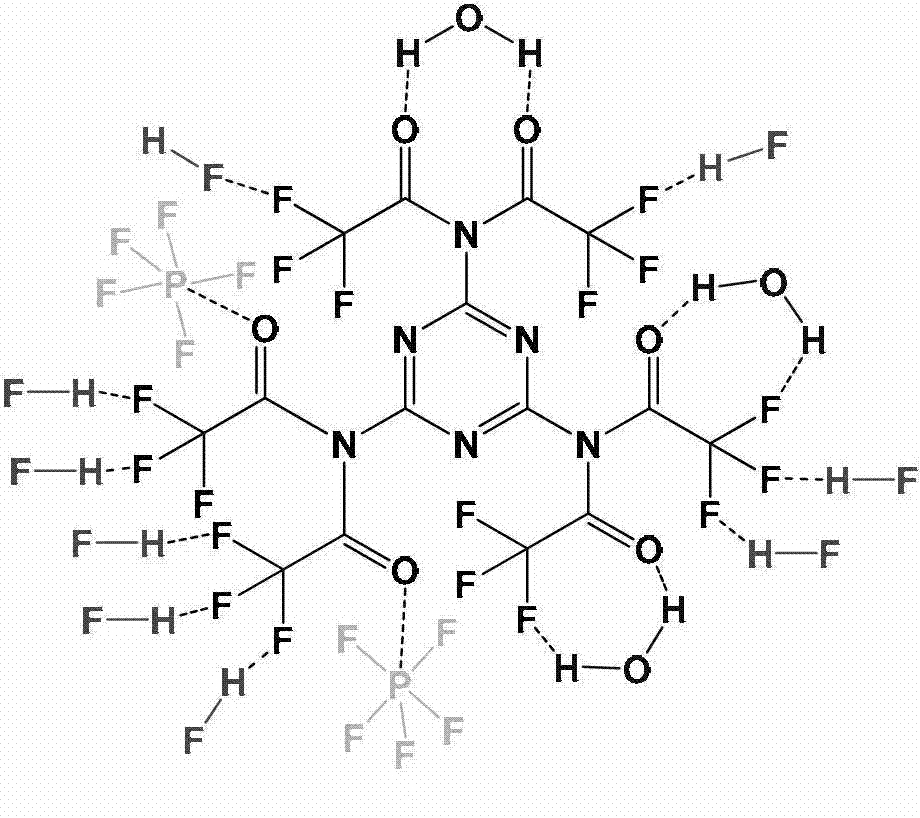

Lithium ion battery and electrolyte solution thereof

InactiveCN103094615AImprove electrochemical performanceImprove cycle performanceSecondary cellsElectrochemistryLithium-ion battery

The invention discloses a lithium ion battery and an electrolyte solution thereof. The electrolyte solution contains lithium salt, a non-aqueous organic solvent and additives, wherein the additives comprise perfluoroalkylacyl melamine derivatives. Compared with the prior art, the perfluoroalkylacyl melamine derivatives as the additives are added into the electrolyte solution of the lithium ion battery, and the additives and a trace amount of HF and H2O in the electrolyte solution form stable hydrogen bonds, so that the compatibility of an anode and a cathode of the battery is not influenced, the hydrolytic and pyrolytic reaction of LiPF6 can be also inhibited, the storage stability and cycle performance of the electrolyte are improved, an SEI (solid electrolyte interface) film is protected, and the capacity fade of the battery in the storage and cycle processes is reduced; and in addition, the additives are low in toxicity, cheap and very low in influence on the viscosity and the electric conductivity of the electrolyte solution, and not only can improve the electrochemical and cycle performances of the lithium ion battery but also does not increase the cost.

Owner:NINGDE AMPEREX TECH

Foam glass and production method thereof

The invention relates to the field of industrial production, in particular to foam glass which has the advantages that the strength of the foam glass is improved and meanwhile the heat conductivity factor of the foam glass is reduced. The foam glass comprises the following components in parts by weight: 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator. The production method of the foam glass comprises the following steps of: mixing and crushing 90-95 parts of glass, 1-5 parts of silicon micro-powder, 1-3 parts of foaming agent, 1-2 parts of modification additive and 0.5-3 parts of foaming accelerator to form mixture powder; melting the mixture powder into mixture liquid at the melting temperature of 700-850 DEG C; then uniformly foaming the mixture liquid at the temperature of 650-720 DEG C and keeping the uniform foaming for 30-50 minutes; starting to anneal when cooling to 500-550 DEG C after the uniform foaming is finished; and annealing for 37-38 hours to normal temperature for shaping.

Owner:BEIJING SHOUBANG NEW MATERIAL

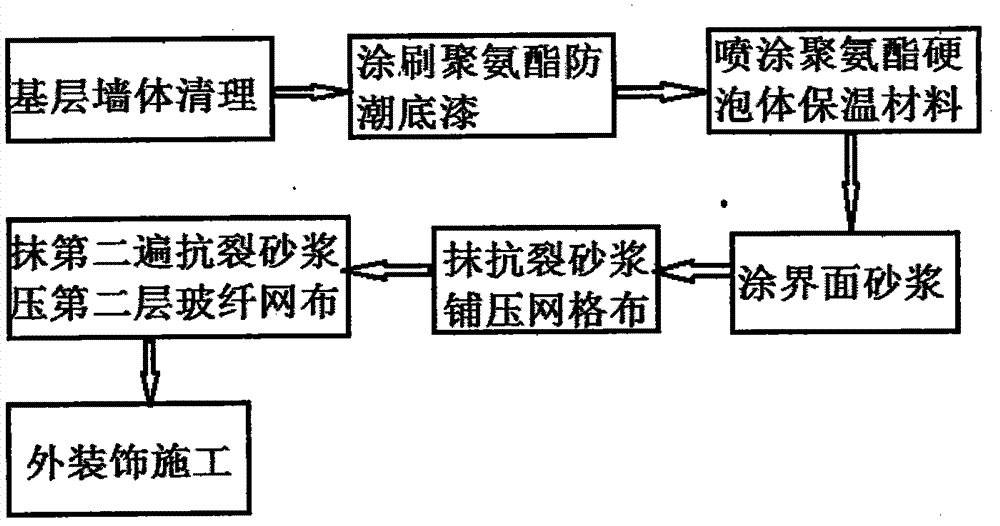

Polyurethane rigid foam used for thermal insulation technique of wall

InactiveCN102817474ALow thermal conductivityImprove insulation effectHeat proofingBuilding material handlingFiberglass meshAdhesion force

The invention relates to a polyurethane rigid foam used for a thermal insulation process of a wall, wherein the process flow comprises cleaning a foundation wall, coating an anti-mist polyurethane primer, spraying the thermal insulation polyurethane rigid foam, coating interface treating agent, plastering anti-crack mortar, laying fiberglass mesh, plastering the anti-crack mortar for the second time, pressing the second fiberglass mesh and conducting exterior decoration. Compared with prior art, the polyurethane rigid foam adopted in the invention has a stronger adhesion force. As the overall construction is conducted, there is no assemble joint or construction joint in a thermal insulation layer; the phenomenon of 'hot-cold bridge' is avoided; the service life of the thermal insulation layer of the wall is prolonged; and in addition, as the adopted polyurethane rigid foam is low in heat conductivity factor, the thermal insulation performance of the wall adopting the process is better.

Owner:安徽省科捷能源科技有限公司

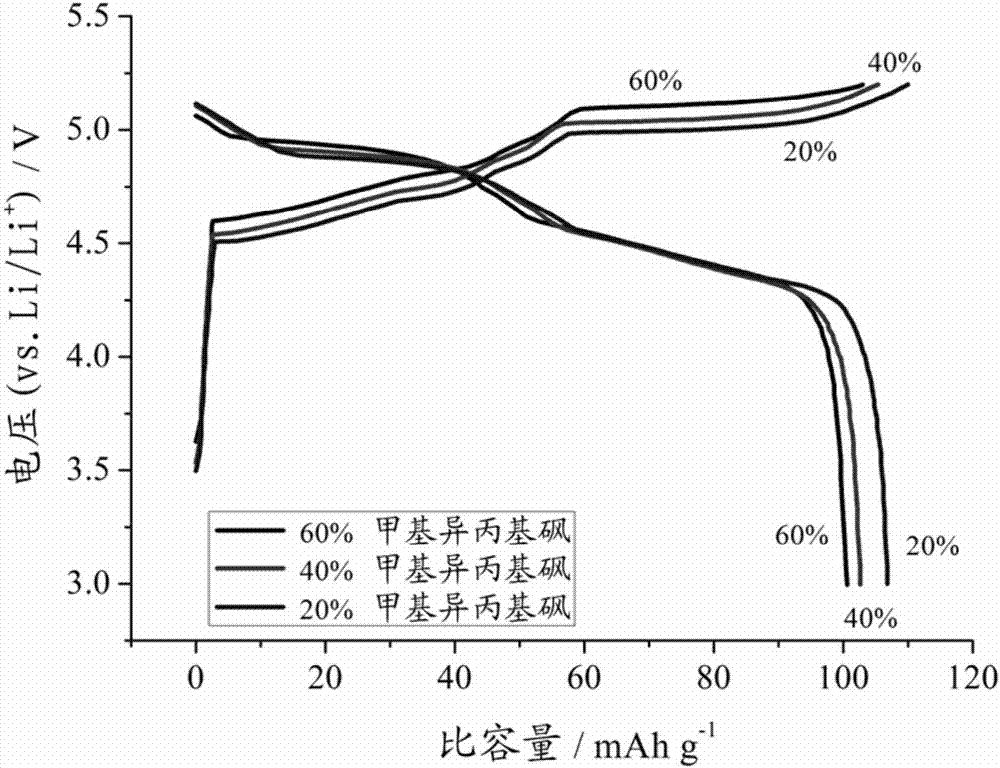

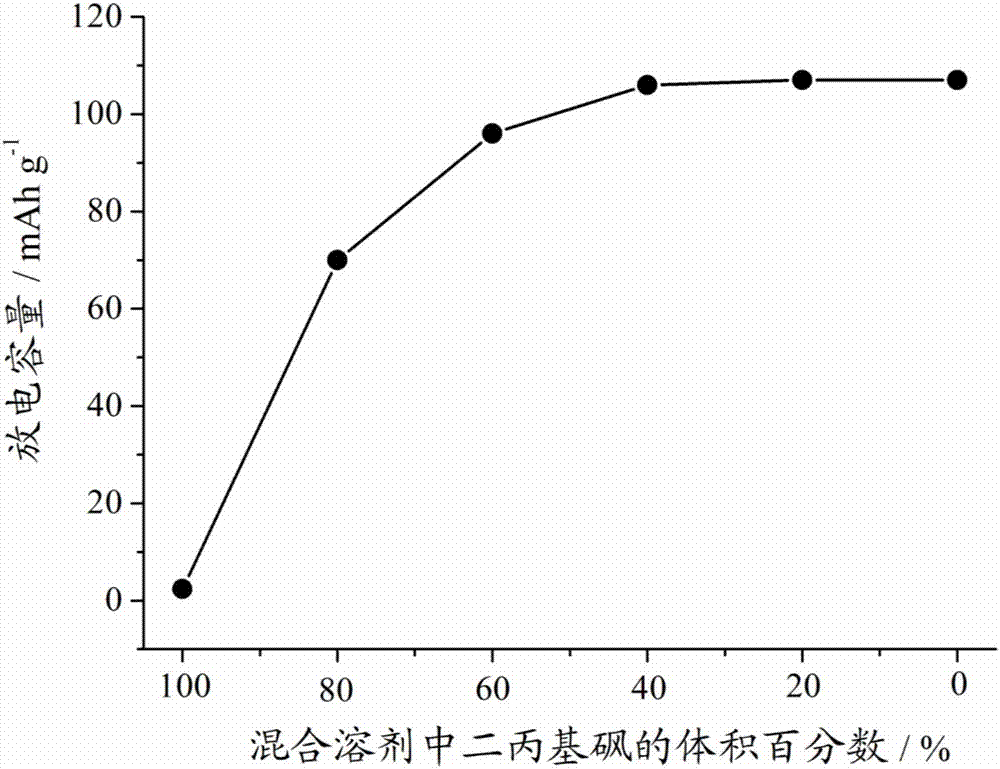

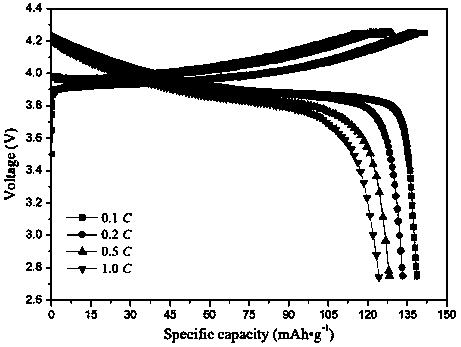

Electrolyte solution and double-ion battery

InactiveCN107086327AImprove antioxidant capacityLow viscositySecondary cellsElectrolytesOrganic solventHigh rate

The invention provides an electrolyte solution. The electrolyte solution comprises an electrolyte and an organic solvent. The organic solvent includes a mixture of a chained sulfone and a chained carbonate. The mixture of the chained sulfone and chained carbonate is used as the organic solvent of the electrolyte solution so that the chained sulfone has excellent oxidation resistance, oxidation resistance of the electrolyte solution is improved and coulombic efficiency and cycle performances of a double-ion battery are effectively improved. The chained carbonate has low viscosity, and can improve conductivity and cell high-rate performance of the electrolyte solution so that through cooperation, the prepared double-ion battery has a good cell capacity and the cycle performances.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

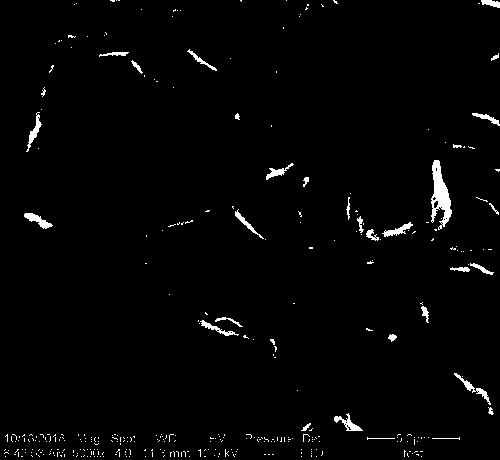

Short SiC fiber/SiO2 aerogel composite material and preparation method thereof

InactiveCN104692757ALarge specific surface areaLow thermal conductivityConductivity factorTemperature resistance

The invention provides a short SiC (Silicon Carbide) fiber / SiO2 (Silicon Dioxide) aerogel heat-insulation composite material and a preparation method thereof. The composite material is characterized by being prepared from a SiC fiber and SiO2 collosol. The preparation method comprises the following steps; adding the SiC fiber to the SiO2 collosol, mixing uniformly, standing to form a gel, and aging to form alcogel; soaking the alcogel in absolute ethyl alcohol; modifying the surface of the alcogel by hexamethyldisiloxane or hexamethyl disiloxane; replacing a solvent in the alcogel with glycol and methanol respectively; and performing atmospheric pressure drying on a gel at different temperatures, thereby obtaining the short SiC fiber / SiO2 aerogel composite material. The composite material prepared by the method has the characteristics of large specific surface area, low heat conductivity factor, high-temperature resistance and the like, and the preparation method is simple and low in cost, and is suitable for industrial production.

Owner:金成

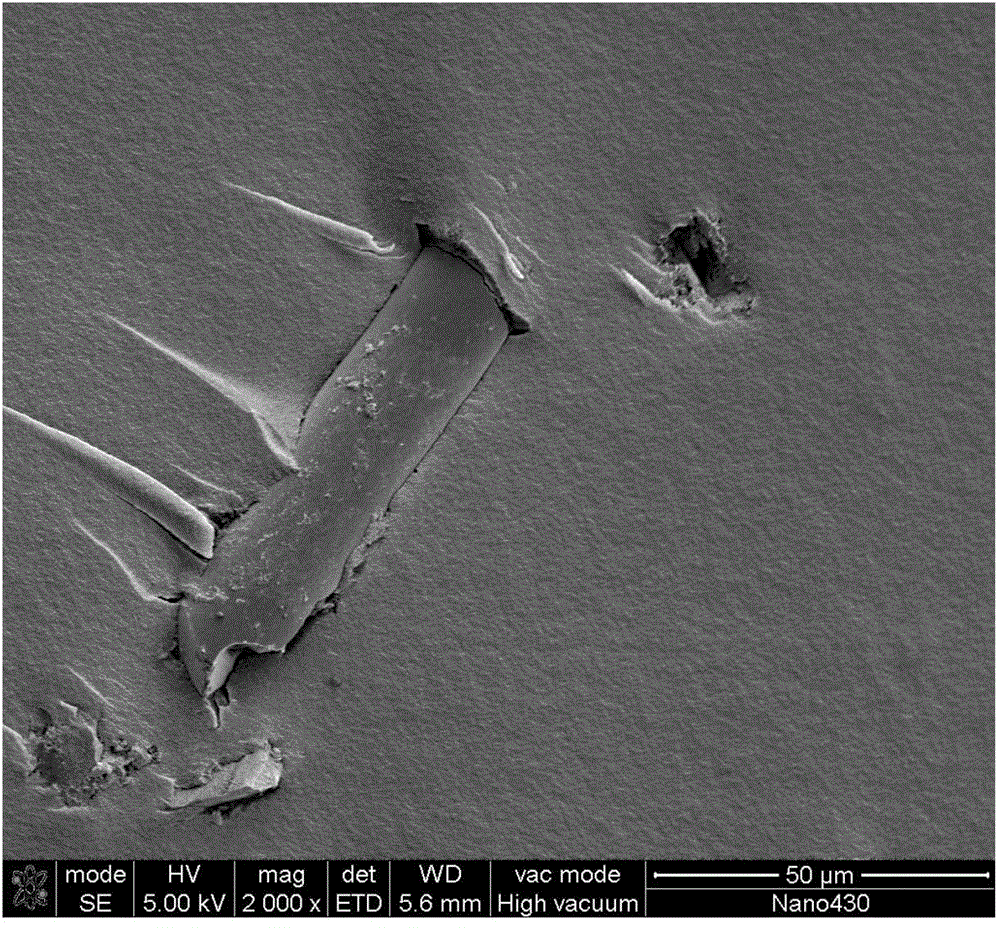

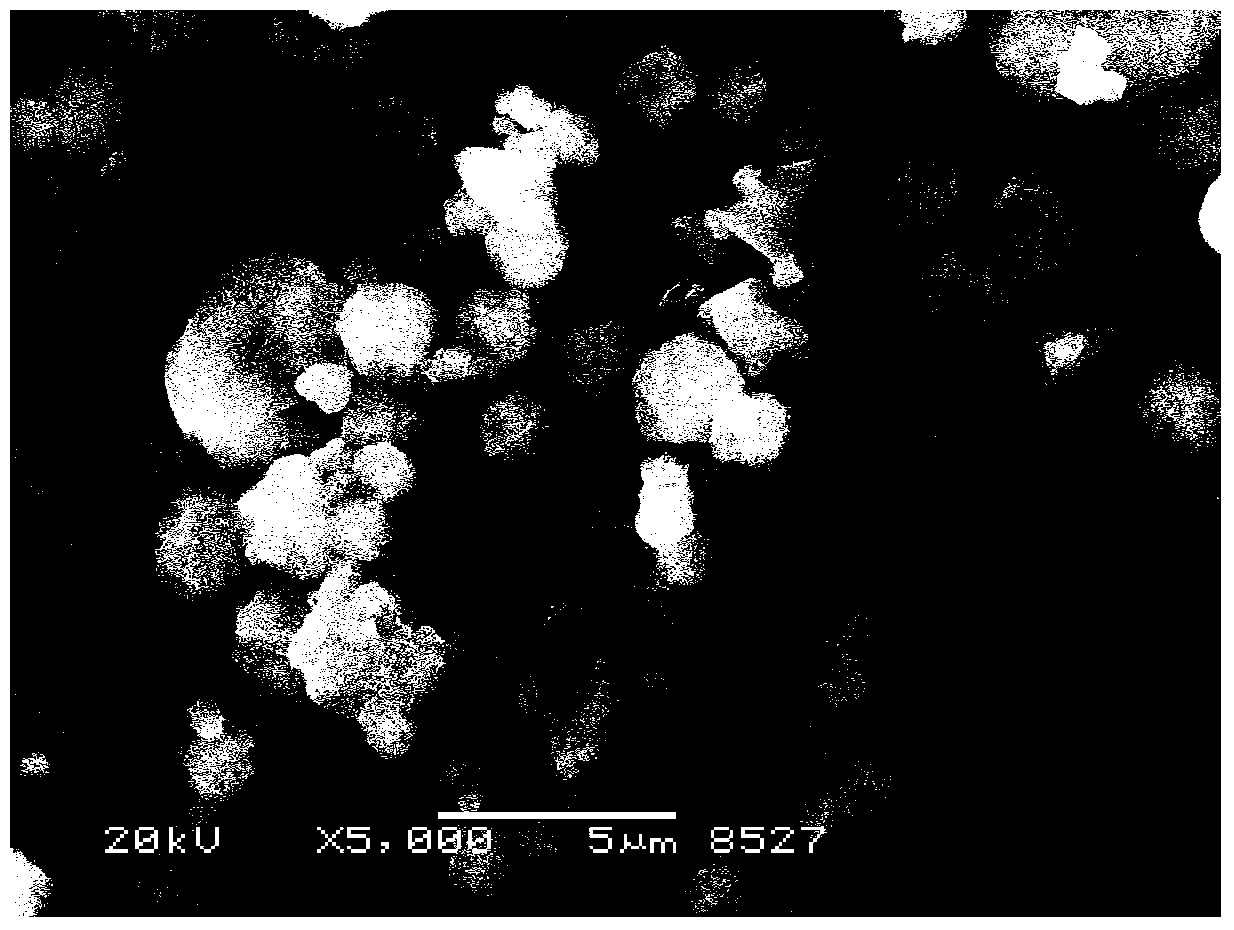

Preparation method of sphere-like fast ion conducting material of modified calcium lithium titanate

InactiveCN103633366AUniform particlesImprove electrochemical performanceSecondary cellsElectrolytesAir atmosphereHigh rate

The invention discloses a preparation method of a sphere-like fast ion conducting material of modified calcium lithium titanate. The preparation method is characterized by comprising the following steps: (1) mixing lithium source, calcium sources, titanium sources and a salt solution of a modified material Y according to the stoichiometric proportion of Li0.1-zYxCa0.9-xTizO3 and adding the mixture to ethanol water to obtain a mixed solution; (2) adding a complexing agent to the mixed solution, stirring and hydrolyzing to obtain an intermediate mixed solution; (3) conducting spray drying on the intermediate mixed solution, heating the obtained product under air atmosphere until the temperature of the obtained product is 600-900 DEG C, keeping the temperature for 2-12 hours to obtain the sphere-like fast ion conducting material of modified calcium lithium titanate. According to the invention, the hydrolyzing, complexing and spray drying methods are adopted, so that the reagents are mixed in the solution at a molecular or atomic level, so as to prepare the sphere-like particulate material with uniform particles and good electrochemical performance. The sphere-like fast ion conducting material has the advantages of higher ionic conductivity at the room temperature, high rate capability and good cycle performance.

Owner:YANGTZE UNIVERSITY

Forming paper with low-heat-conducting performance for low-temperature cigarette nozzle bar

InactiveCN108618194AGood horizontal insulation effectImprove cooling effectCigar manufactureFiberHeat conducting

The invention provides forming paper with the low-heat-conducting performance for a low-temperature cigarette nozzle bar. The forming paper is formed that plant fiber paper and organic plastic film paper are alternately bonded, wherein the plant fiber paper is arranged on an outermost layer, adjacent layers are bonded through glycerol triacetate, and the organic plastic film paper is polyethyleneglycol terephthalate plastic paper or polyvinyl chloride plastic paper or polylactic acid plastic paper. According to the forming paper, materials used in the forming paper comprise plant fiber paperwith the low heat conductivity factor, organic plastic and silicon dioxide particles, the whole heat conductivity factor is low, and the transverse heat insulation effect on smoke in the nozzle bar isgood; the forming paper is applied to a paper tube bar and can be made into a paper tube bar with the thickness similar to the thickness of a wall, the hollow diameter is large, a smoke channel is large, the contact area between follow-up cooling materials and smoke can be increased, and the temperature of smoke can be reduced.

Owner:HUBEI CHINA TOBACCO IND

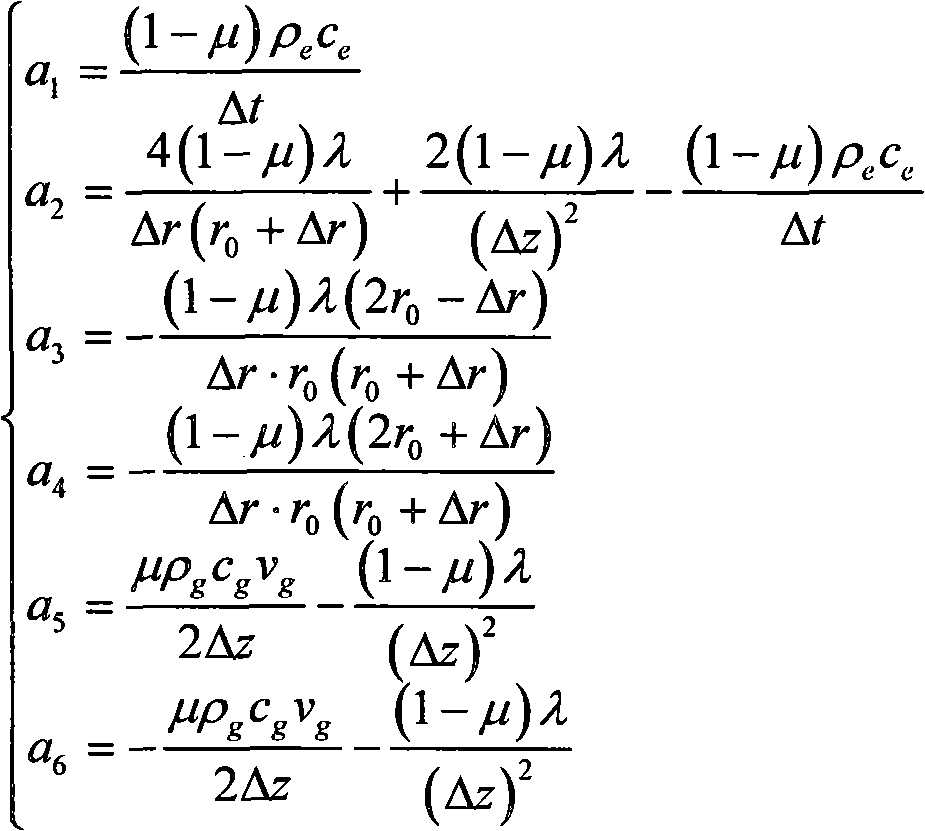

Determination method of oxidation heat liberation intensity of loose coal

InactiveCN101984349AShort test cycleGood repeatabilityMaterial heat developmentExothermic processEngineering

Provided is a determination method of oxidation heat liberation intensity of loose coal. Oxidation heat qic and conductivity factor lambada of loose coal are measured accurately based on the internal rule of heat and mass transfer of loose coal. The heat wire is placed at the center of the loose coal as the heat source and temperature measurement points and gas collection points are arranged inside the loose coal. The screened loose coal samples are loaded into a cylindrical heat insulation reaction container after the density and voidage thereof being measured. First, the loose coal samples are put in nitrogen atmosphere and heated until the temperature thereof reaches the predetermined value. Then the samples are left to cool naturally. The temperatures of temperature measurement points are collected continuously. Conductivity factor lambada of loose coal samples at different temperatures are calculated by the value of the factors of temperature, time, density, specific heat capacity and voidage. Then air is fed into the coal samples continuously. The temperatures of temperature measurement points and oxygen concentrations of the samples are monitored continuously during the cooling process. Finally, oxidation heat liberation intensity qic of loose coal samples at different temperatures are calculated by the value of the factors of temperature, conductivity factor, time, density, specific heat capacity, voidage and air flow meter. The experimental time is reduced and the obtained results are more accurate by utilizing the above method. As a result, the method is applicable to the measurement of exothermic process of coals.

Owner:CHINA UNIV OF MINING & TECH

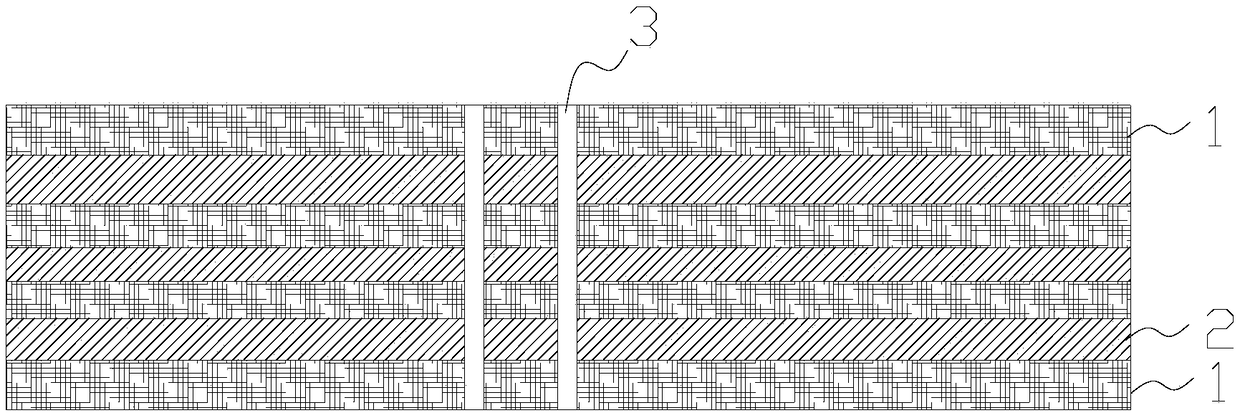

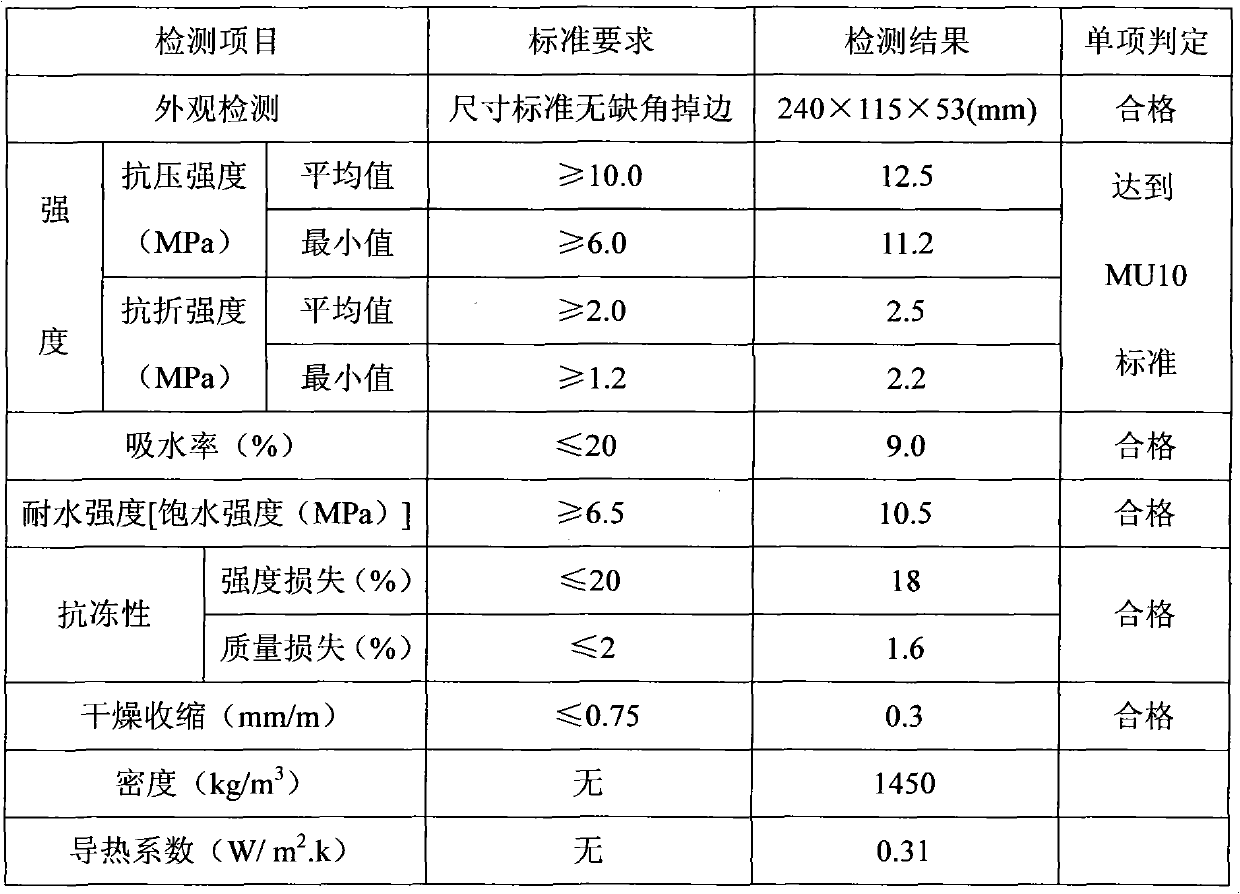

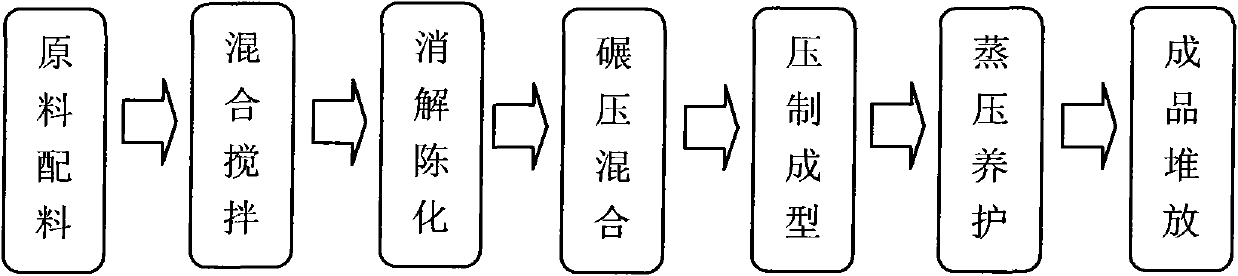

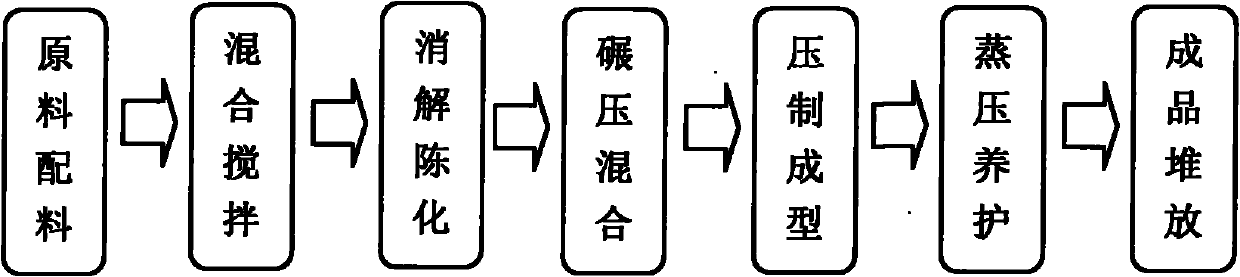

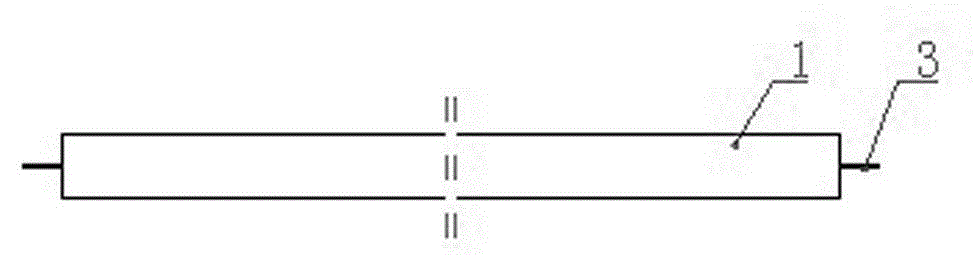

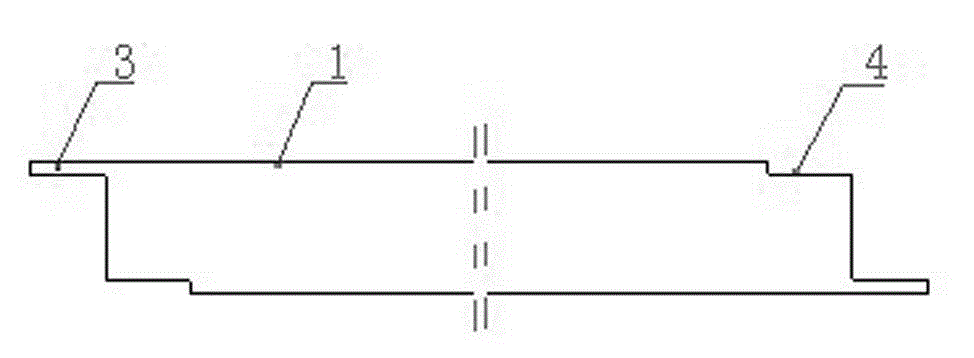

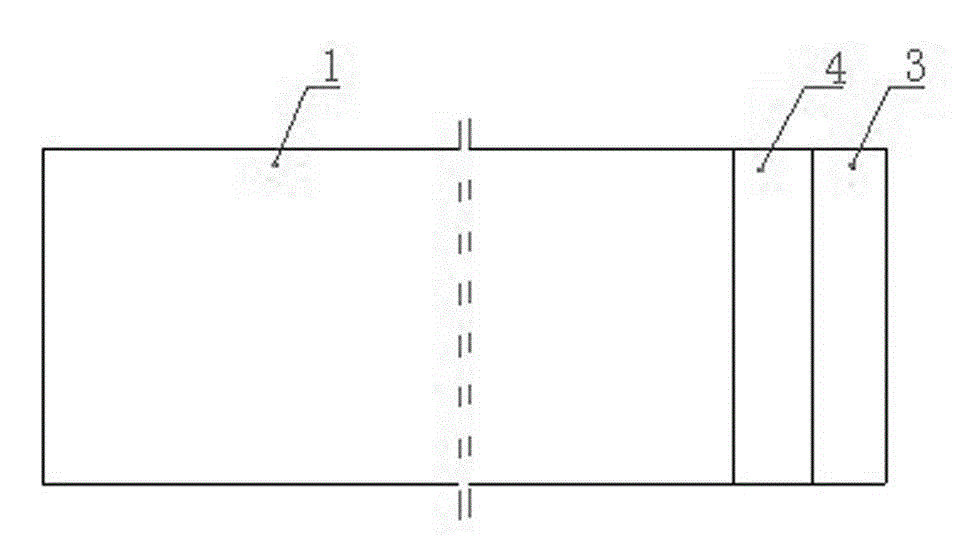

Environment-friendly, high-intensity and desulfurated plaster wall brick and manufacture method thereof

InactiveCN101921098AImprove utilizationImprove water resistanceSolid waste managementBrickConductivity factor

The invention discloses an environment-friendly, high-intensity and desulfurated plaster wall brick and a manufacture method thereof. The environment-friendly, high-intensity and desulfurated plaster wall brick comprises the raw materials of desulfurated plaster, powdered coal ash, calcined lime, coagulating agent and crystal-converting agent. The manufacture method of the plaster wall brick comprises the following steps of: preparing the raw materials, stirring in a mixing way, clearing up and aging, rolling and mixing, compressing and forming, and autoclaving and maintaining. The content (quality) range of each component is as follows: 65%-75% of desulfurated plaster, 19%-30% of powdered coal ash, 4%-5% of calcined lime, 0.8%-1.2% of coagulating agent and 0.2%-0.4% of crystal-converting agent. The step of compressing and forming is performed by a mould pressing type press machine, wherein the compressing pressure is larger than 20MPa; and the autoclaving and maintaining constant temperature is 130-150 DEG C, and the time of the constant temperature is 5-7h. The environment-friendly, high-intensity and desulfurated plaster wall brick has the advantages of high intensity, low density, low conductivity factor, good water resistance and good performance, and has large solid waste using quality.

Owner:ANHUI KEDA IND CO LTD +1

Slurry material with cold accumulation and heat resistance function and high water content

InactiveCN102718457AGood effectOutstanding cooling performanceCeramicwareHydration reactionSuspending Agents

The invention relates to a slurry material with a cold accumulation and heat resistance function and high water content and belongs to cold accumulation and heat resistance materials. The slurry material with the cold accumulation and heat resistance function and high water content utilizes natural cold energy to accumulate cold and reduce temperature to effectively protect ever-frozen ground and ensure engineering stability. The material is mainly formed by a basic material and an auxiliary material, wherein the basic material consists of sulphoaluminate cement clinker and suspending agents, and the auxiliary material consists of gypsum, calcium oxide, coagulation accelerators, water-retaining agents and suspending agents. Inorganic materials in the slurry material perform hydration reaction to form net-structured ettringite which can solidify a large amount of free water in a short time to form a hardening body with certain strength. A heat conductivity factor changes according to phase transition between ice and water; the hardening body has a small heat conductivity factor in a thermotropic state in summer; and under the condition of subzero temperature in winter, the free water in the material is frozen to be ice so that the heat conductivity factor of the hardening body becomes large. The slurry material with the cold accumulation and heat resistance function and high water content has the advantages of being obvious in temperature reduction effect, simple in preparation, low in preparation cost, convenient to construct, wide in application range, friendly to environment and the like.

Owner:CHINA UNIV OF MINING & TECH

Flame-retardant polymer solid electrolyte material and electrolyte membrane and application thereof

ActiveCN109585916AGood heat resistance and flame retardant performanceEnsure safetySecondary cellsSolid state electrolyteOrganic solvent

The invention provides a flame-retardant polymer solid electrolyte material and an electrolyte membrane and application thereof. The solid electrolyte material is prepared from, by weight, 60-80% of flame-retardant waterborne polyurethane, 15-35% of lithium salt, and 1-5% of nano alumina. The preparation method of the electrolyte membrane comprises the following steps: stirring flame-retardant waterborne polyurethane and nano aluminum oxide to obtain a mixed solution, adding a lithium salt into the mixed solution, uniformly stirring to obtain a membrane casting solution, casting the membrane casting solution into a mold, and drying to form the membrane, thereby obtaining the electrolyte membrane. The electrolyte material disclosed by the invention adopts flame-retardant waterborne polyurethane as a matrix, so that the solid electrolyte is endowed with high ionic conductivity under a low-temperature condition, has heat-resistant, flame-retardant and stable properties, meanwhile, avoidsusing an organic solvent, and is low in environmental pollution.

Owner:JILIN NORMAL UNIV

Method for producing vacuum heat insulation board from expanded perlite

ActiveCN102720921ALow thermal conductivityLow priceThermal insulationPipe protection by thermal insulationFiberHigh resistance

The invention relates to a method for producing a vacuum heat insulation board from expanded perlite. A manufacture process comprises the following steps of: material proportioning: the expanded perlite, auxiliary materials, fibers, vacuum active stabilizers and gas absorption agents are fed into a mixing machine to be fully mixed; drying: the uniformly stirred mixed materials are dried; core material forming: the dried materials and the gas absorption agents are fed into a mold, and the mold is put into a pressing machine for pressing formation; and wrapping: a core board formed through pressing is taken out from the mold, a layer of non-woven fabrics is wrapped on the periphery of the core board, and a vacuum heat insulation core board for building is obtained; and the core board is placed into a high-resistance gas membrane bag for vacuum pumping, the vacuum degree is 0.02 to 20Pa, and then, the opening sealing is carried out. The method has the advantages that the sound absorption performance of the expanded perlite is good, the self heat conductivity factor is low, a heat insulation layer with high performance is formed among perlite particles through the mixing of the auxiliary materials, the fibers and the perlite, and the heat insulation performance and the intensity are further improved. Inorganic materials are adopted and are nonflammable.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

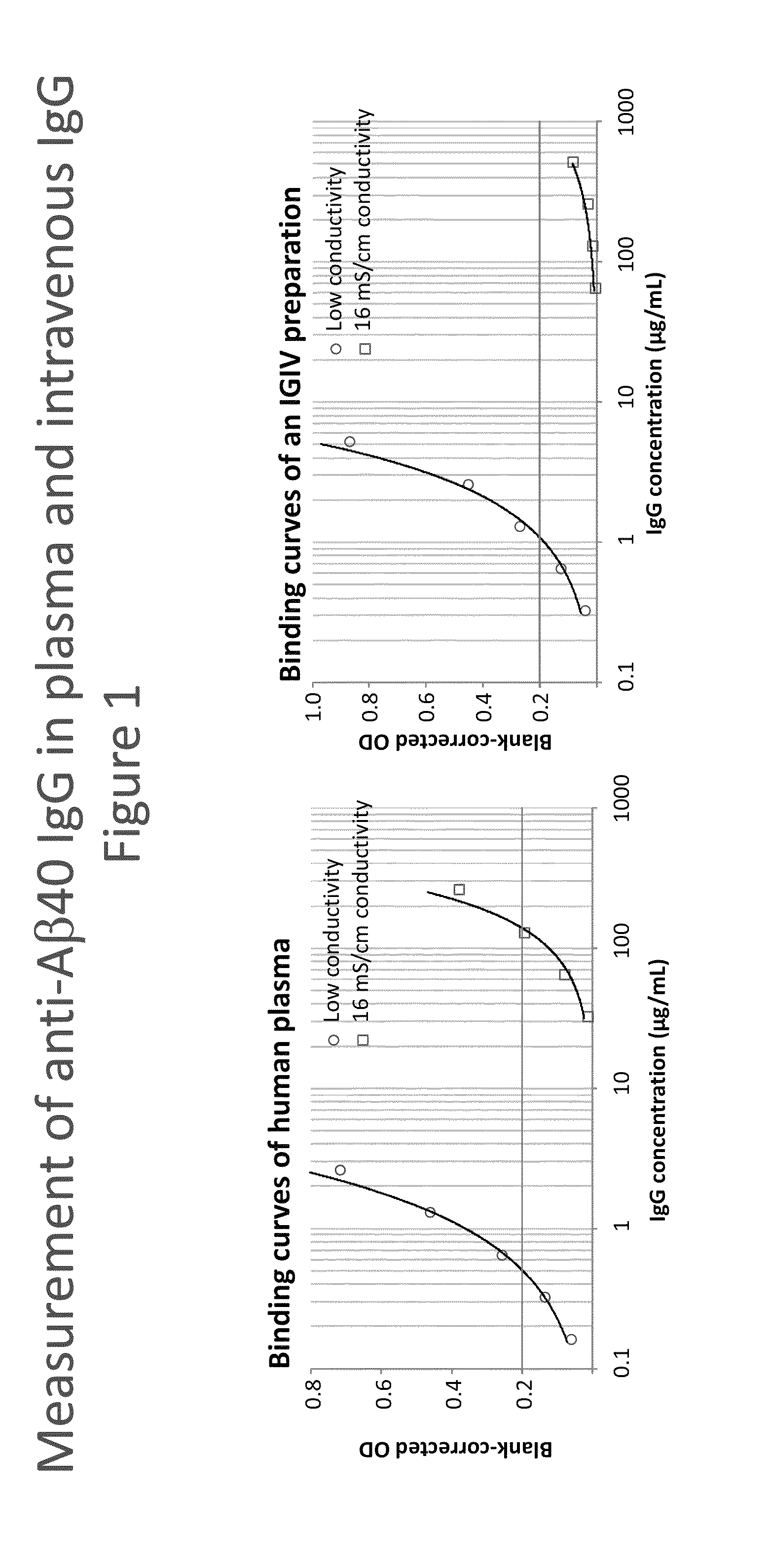

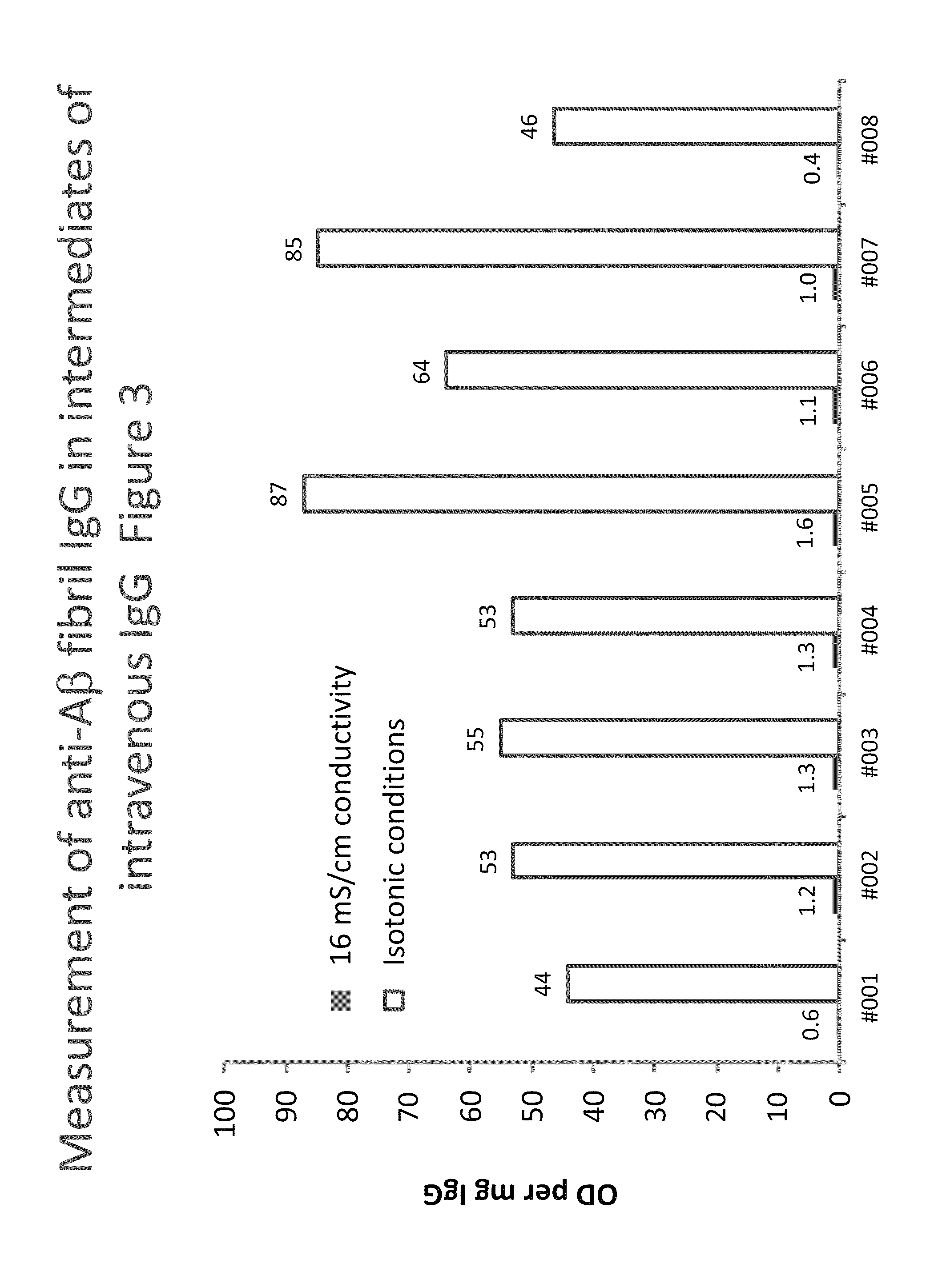

Measurement of autoantibodies at low conductivity with increased sensitivity

ActiveUS9075069B2High sensitivityReduce conductivityMicrobiological testing/measurementBiological material analysisConductivity factorBiochemistry

Methods for detecting or capturing low-avidity autoantibodies in a biological sample are provided. Target antigen used to assay for the low-avidity autoantibodies of interest is immobilized on a solid phase. The biological sample is contacted under low conductivity condition with the target antigen for which the autoantibodies has specific binding affinity. Binding of the target antigen to the autoantibodies of interest in the biological sample is then detected to ascertain the presence or concentration of the autoantibodies of interest.

Owner:TAKEDA PHARMA CO LTD

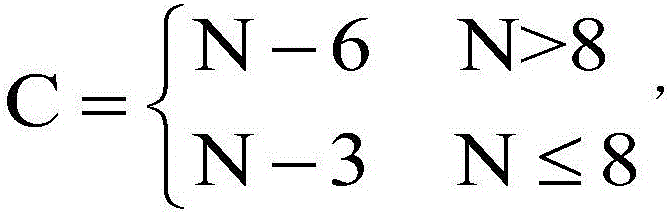

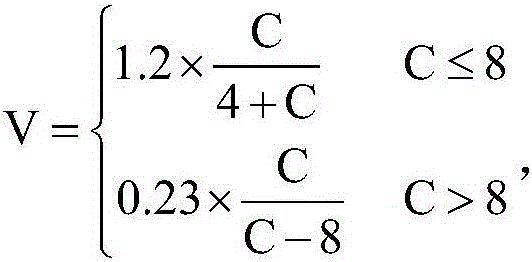

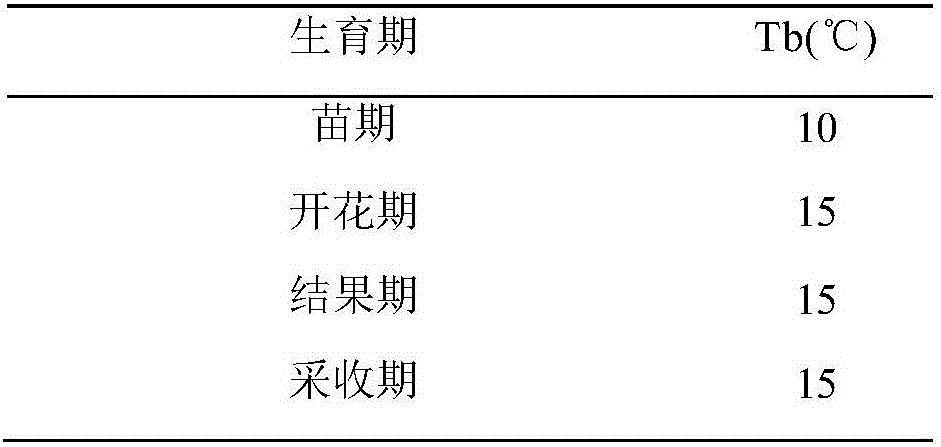

Nutrient solution management technology based on greenhouse tomato leaf length

InactiveCN106576547ALess one-time investmentEasy to put inFertilising methodsConductivity factorGreenhouse

The invention provides a nutrient solution management technology based on the greenhouse tomato leaf length. The nutrient solution management technology comprises the following steps that 1, the leaf length of greenhouse tomato feature leaves is subtracted by the standard leaf length of the feature leaves, it is indicated that water and fertilizer are oversupplied if the result is larger than zero, it is indicated that the water and fertilizer are undersupplied if the result is smaller than zero, and it is indicated that the water and fertilizer are supplied properly if the result is equal to zero; 2, the specific conductance value of a current irrigation nutrient solution is subtracted by the EC value of the nutrient solution under the deficiency condition without water and fertilizer, the difference value is multiplied by the number of days of irrigation of the nutrient solution, the result is the over-application or under-application nutrient solution nutrient quantity, and the specific conductance value of the current irrigation nutrient solution is deduced through the average growth rate a of the feature leaves; and 3, the final specific conductance value of the nutrient solution is determined according to the over-application or under-application nutrient solution nutrient quantity for adjustment, and the adjusted nutrient solution is used for irrigating crops. According to the nutrient solution management technology based on the greenhouse tomato leaf length, only the length of the feature leaves of greenhouse tomatoes needs to be measured, the one-time input is low, and measurement is quite simple and practicable.

Owner:JIANGSU UNIV

Preparation method of biopolymer electrolyte with water as solvent

ActiveCN110010966AAvoid security issuesImprove conductivitySolid electrolytesSecondary cellsWater bathsCellulose acetate

The invention relates to the field of lithium ion battery gel polymer electrolytes, in particular to a preparation method of a biopolymer electrolyte with water as a solvent. The preparation method sequentially comprises the following steps of: 1) mixing and stirring cellulose acetate, hydroxyethyl cellulose and deionized water according to a certain proportion for 12 hours to obtain a mixed solution; 2) performing water-bath heating of urea, choline chloride and glycerol according to a certain mess ratio and dissolving the mixture to a colorless and transparent state to obtain a deep eutecticsolvent; 3) adding the deep eutectic solvent into the mixed solution for blending for 6h, adding a lithium salt for continuous stirring for 6h, pouring the mixed solution in a culture dish for standing and bubble removal at a room temperature, and drying the mixed solution in a vacuum drying oven at a temperature of 100 DEG C to prepare a thin film. The film prepared by the method is good in surface shape, simple in synthetic process and convenient to operate, and has high conductivity.

Owner:HARBIN UNIV OF SCI & TECH

Method for producing vacuum heat insulation board from expanded perlite

ActiveCN102720921BLow thermal conductivityLow priceThermal insulationPipe protection by thermal insulationFiberHigh resistance

The invention relates to a method for producing a vacuum heat insulation board from expanded perlite. A manufacture process comprises the following steps of: material proportioning: the expanded perlite, auxiliary materials, fibers, vacuum active stabilizers and gas absorption agents are fed into a mixing machine to be fully mixed; drying: the uniformly stirred mixed materials are dried; core material forming: the dried materials and the gas absorption agents are fed into a mold, and the mold is put into a pressing machine for pressing formation; and wrapping: a core board formed through pressing is taken out from the mold, a layer of non-woven fabrics is wrapped on the periphery of the core board, and a vacuum heat insulation core board for building is obtained; and the core board is placed into a high-resistance gas membrane bag for vacuum pumping, the vacuum degree is 0.02 to 20Pa, and then, the opening sealing is carried out. The method has the advantages that the sound absorption performance of the expanded perlite is good, the self heat conductivity factor is low, a heat insulation layer with high performance is formed among perlite particles through the mixing of the auxiliary materials, the fibers and the perlite, and the heat insulation performance and the intensity are further improved. Inorganic materials are adopted and are nonflammable.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Method for preparing high-performance light-weight insulating brick by using quartz mine

The invention relates to a method for preparing high-performance light-weight insulating bricks by using quartz mine. The method is that low-price natural high-quality quartz mine is used as basic raw material, the crushed natural quartzite and the soda ash react with each other and are prepared into water glass, framework material is filled and finally high-performance light-weight insulating bricks are obtained by using the sol-gel technology. The heat conductivity factor of the insulating bricks under room temperature is 0.05-0.06W / m.K and the density is 500-600Kg / m3. The effect is very excellent when the insulating bricks are used for long time in industrial furnaces with temperature no more than 1000 DEG C. Moreover, the insulating bricks can also be used in other places requiring heat isolation and heat insulation.

Owner:沈阳临德陶瓷研发有限公司

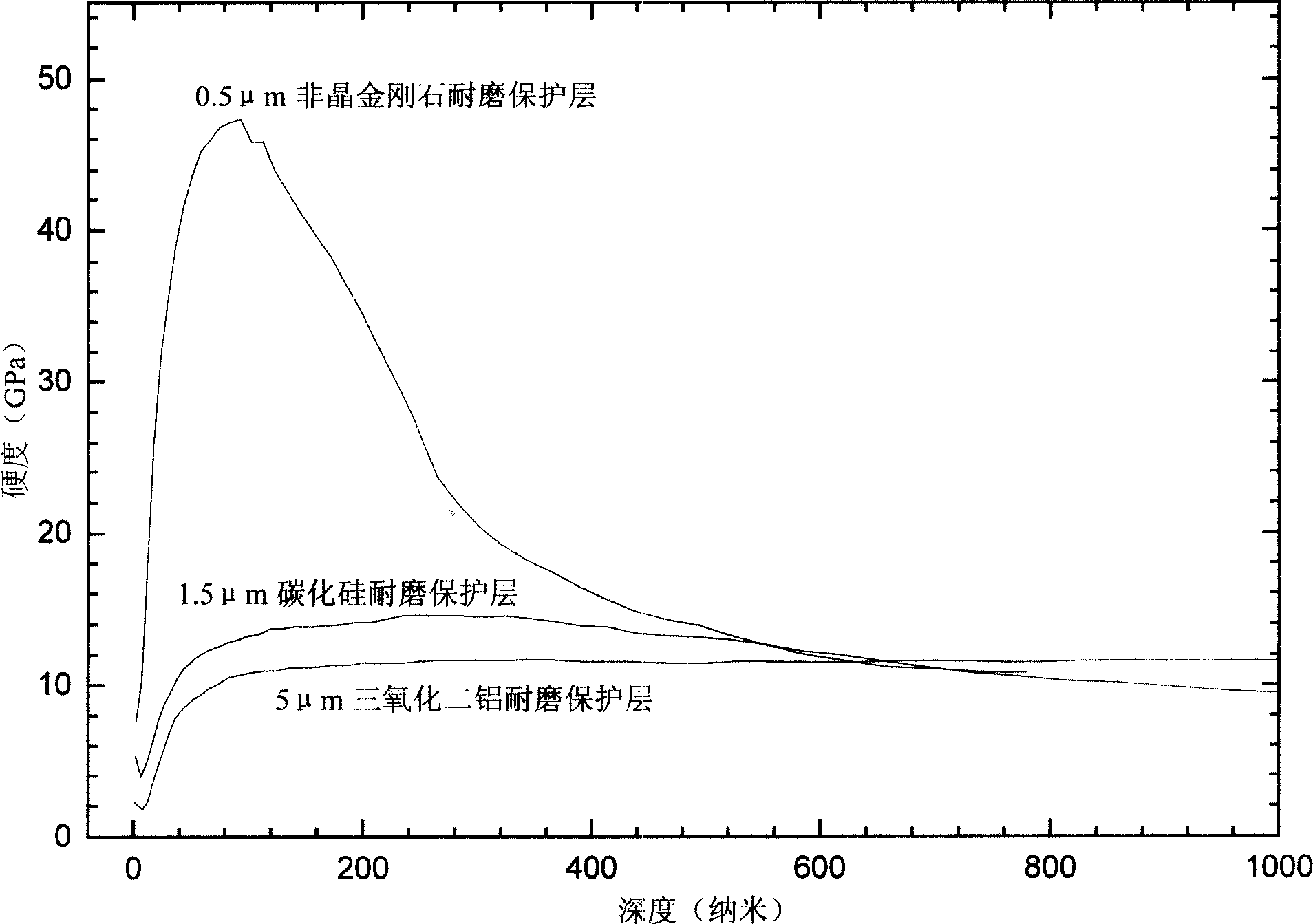

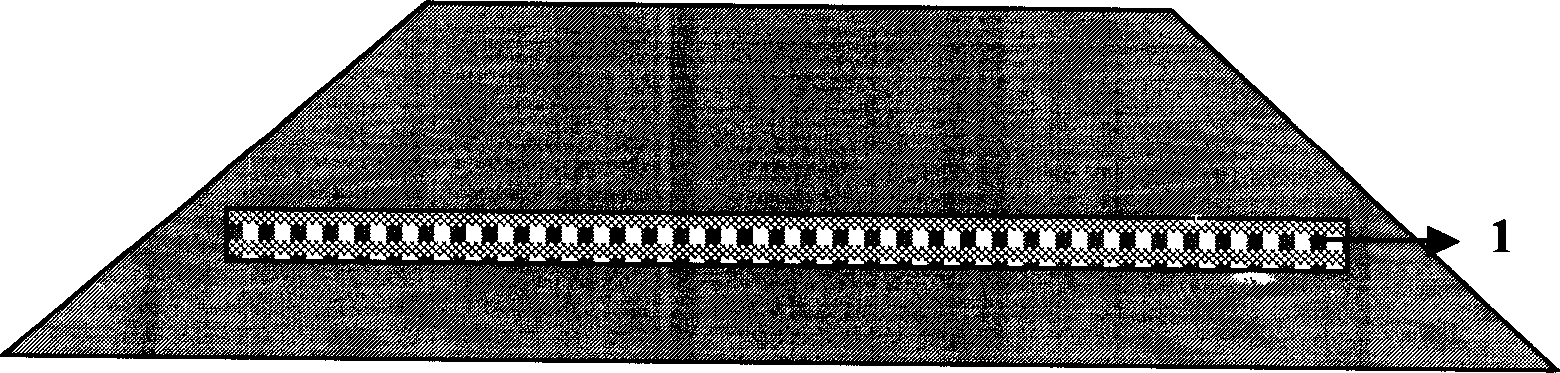

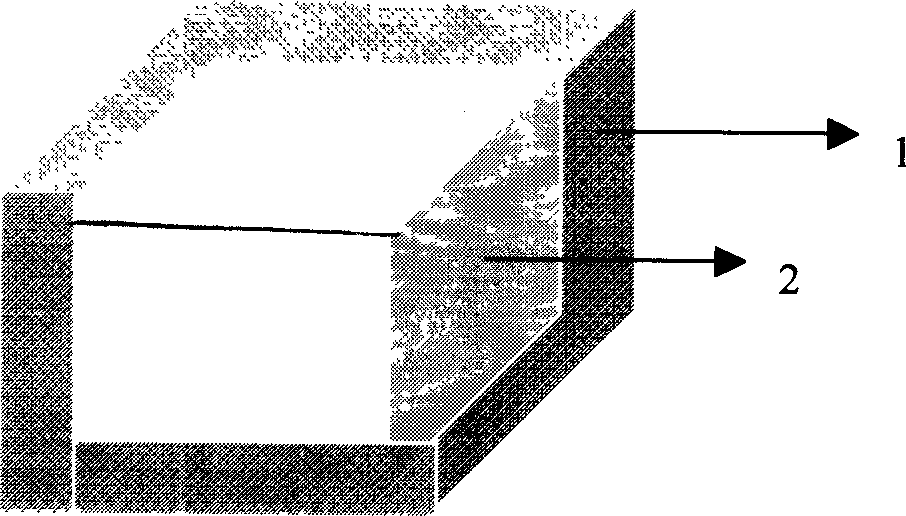

Amorphous diamond wear proof protective layer of heat-sensitive printing head and its preparing method

The present invention relates to the amorphous diamond wearing coat of the heat-sensitive printing head and the preparation method. The present invention use the filtering negative electrode air-void electric arc to deposit amorphous diamond film on the heat-variable printing head, and the thickness of the film is between 0.3 and 2 micron m. The present invention contains some approaches as following. Firstly, clean. Secondly, chalk line. Thirdly, etch. Fourthly, deposit. The last is final treatment. The amorphous diamond wearing coat of the present invention has the excellences such as the slippery surface, low friction factor and the conductivity factor is finer. The preparation method adopts energy downing gradient method, which makes the stress of the wearing coat low and the associability strong, so it extends the operational life span of the heat- sensitive printing head.

Owner:HARBIN INST OF TECH

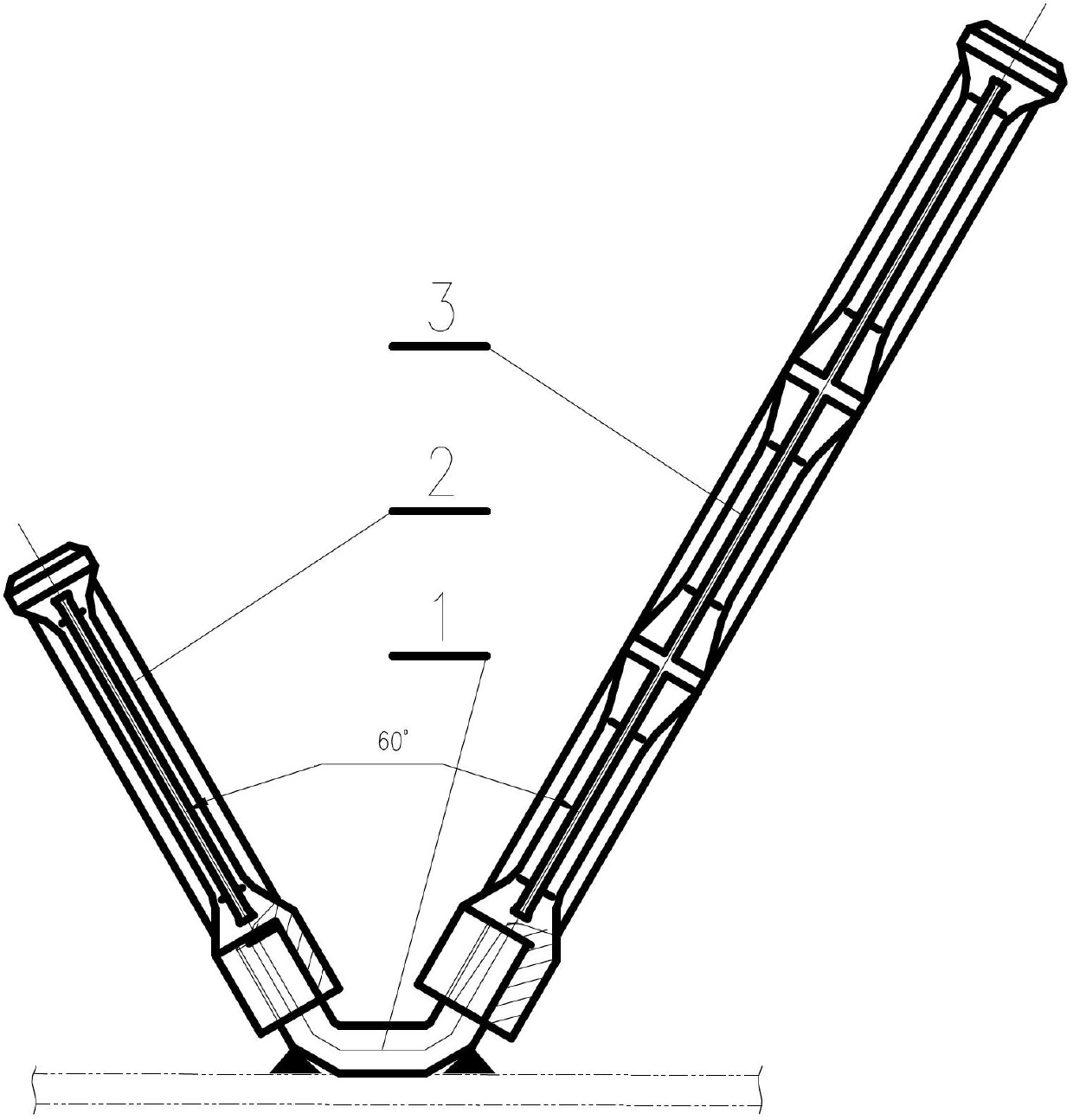

Natural cold-energy variator of heat conductivity coefficient

InactiveCN1746436AReduce adverse effectsMeet the cooling requirementsFoundation engineeringFrostConductivity factor

A natural chilling device with vary conductivity factor. It contains closed shell and pulsating material. The shell contains 80-90% water of its whole volume and pulsating material. The device is set on the object that needs certain temperature, such as railway, highway and so on. Adjustment of environment and temperature of frost table can be realized by the change of conductivity factor with the change of temperature and characteristics of hidden heat change when phase changes.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Light thermal-insulation ceramic tiles and preparation method thereof

The invention discloses light thermal-insulation ceramic tiles, which are prepared by using the following raw materials in percentage by weight: 60.0 to 90.0 percent of ceramic tile raw material, 2.0 to 10.0 percent of additive, 10 to 20 percent of pore-forming material and 0.01 to 2 percent of foaming agent. The ceramic tiles are light, nonabsorbent, heat-proof, fire retardant, nontoxic, harmless, chemical corrosion resistance and mouldproof. The ceramic tiles have a small conductivity factor, stable performance and high mechanical strength. The ceramic tiles are low in cost, simple in process, convenient and quick in construction and good in decoration effect.

Owner:北京盛康宁科技开发有限公司

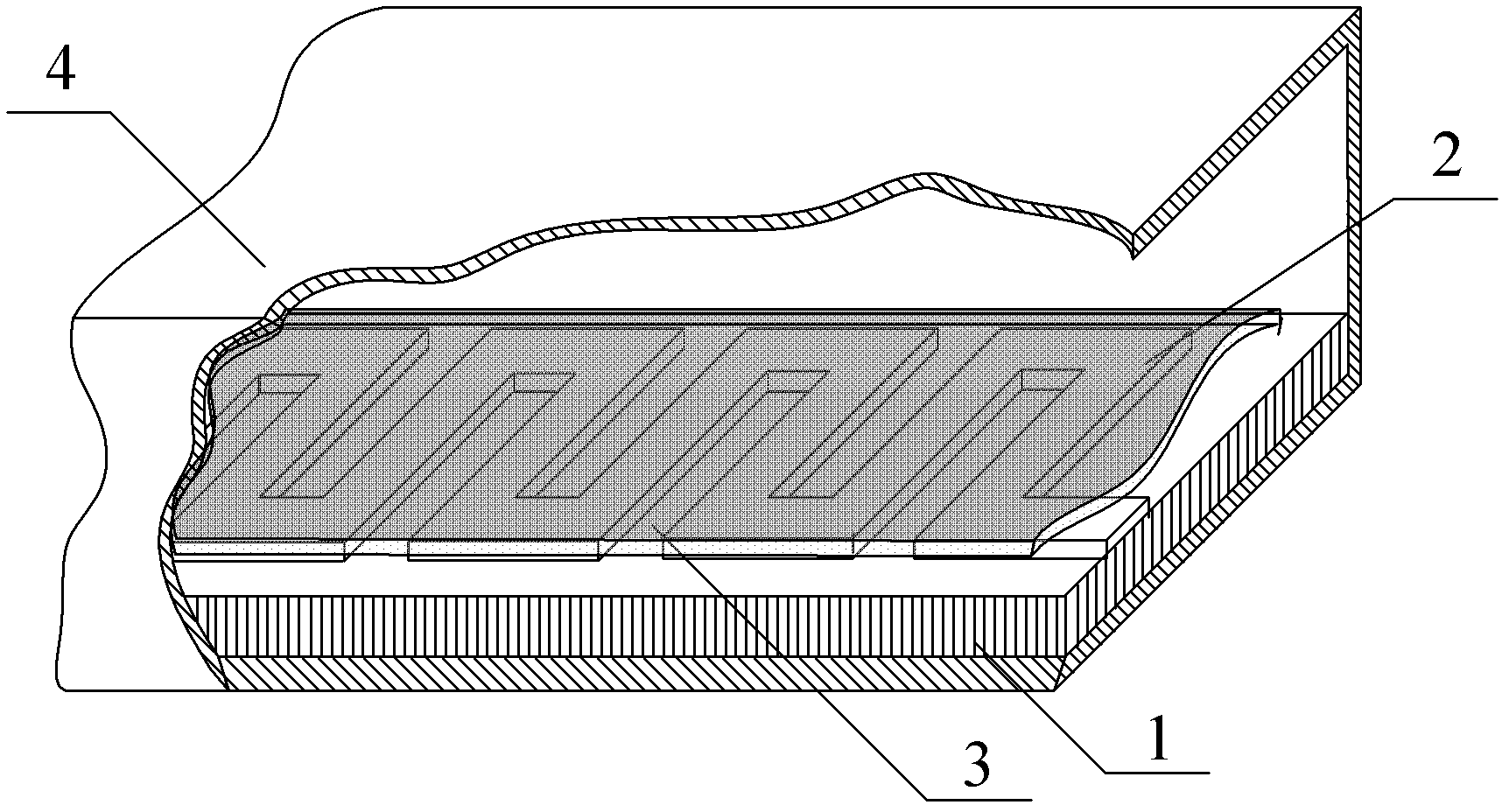

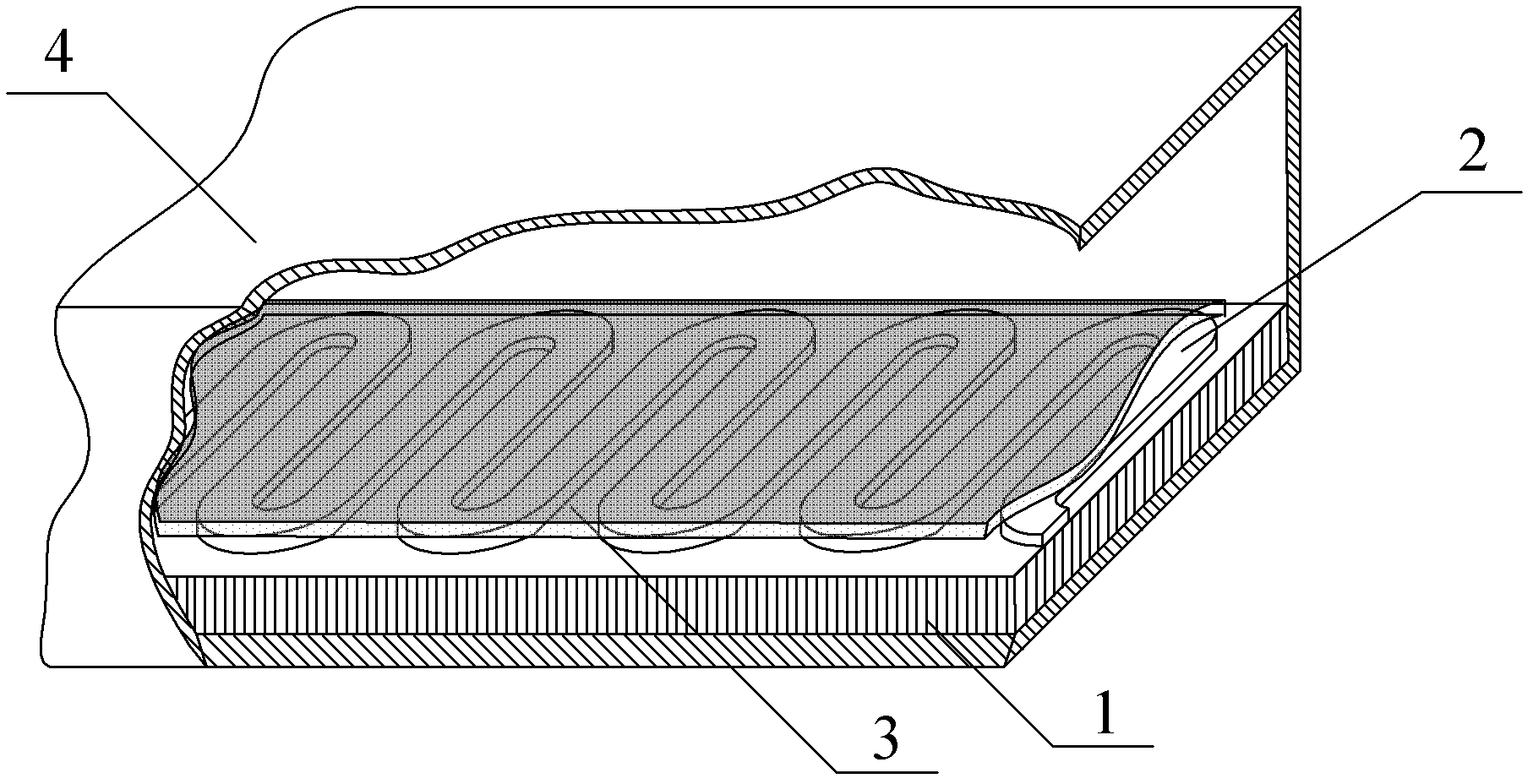

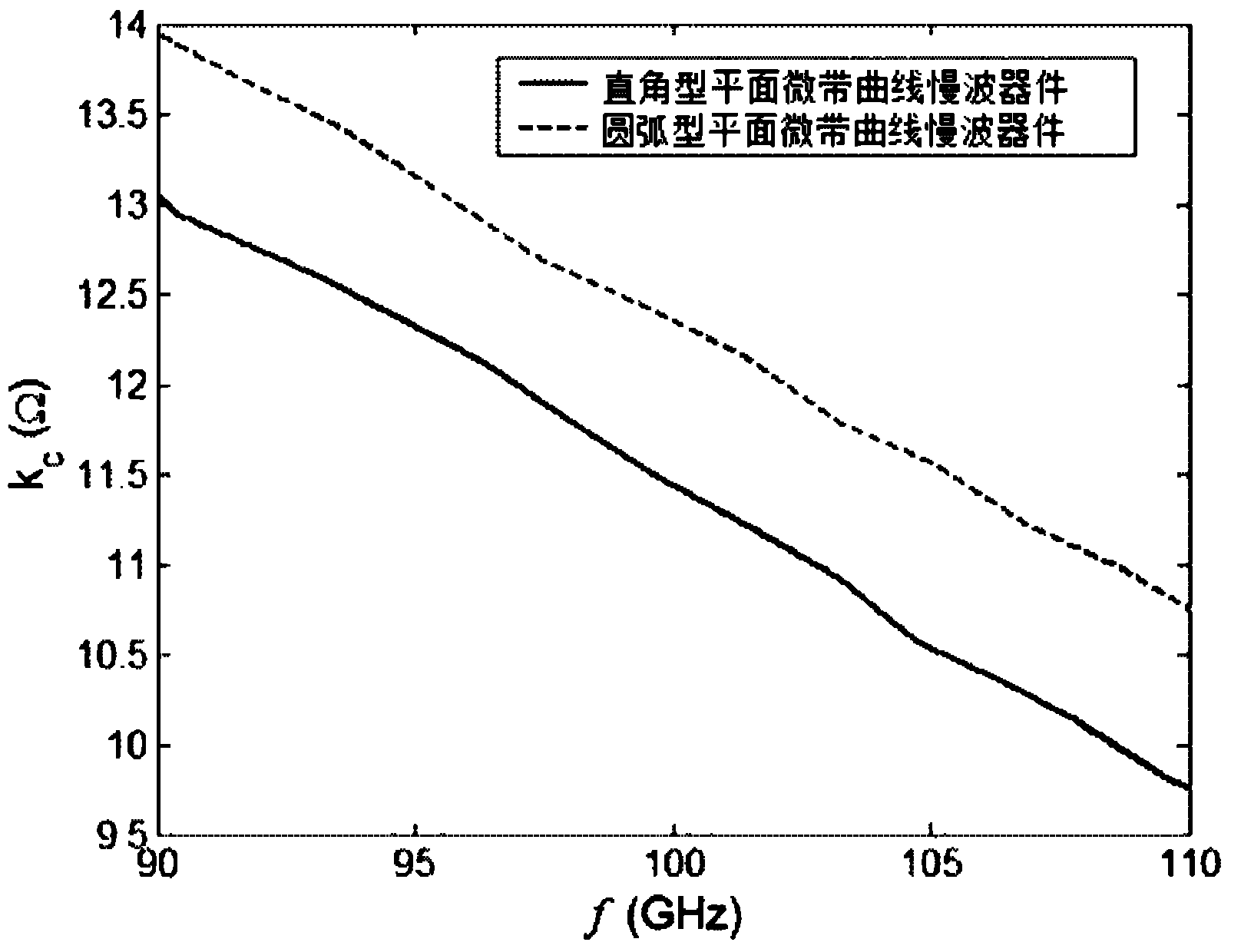

Circular-arc microstrip curve plane slow wave device

InactiveCN102324362AAvoid reflectionsIncrease distanceTransit-tube circuit elementsBoron nitrideElectron

The invention belongs to a circular-arc microstrip curve plane slow wave device which is assorted with a travelling wave tube in a microwave vacuum electronic technology. The circular-arc microstrip curve plane slow wave device comprises a boron nitride substrate, a semicircular microstrip curve and a metal shell, wherein the semicircular microstrip curve is fixed on the substrate and has an input end and an output end. According to the invention, because the microstrip curve the connection part of which is a smooth semicircular-arc is adopted, and boron nitride which has low dielectric constant and higher compression strength, hardness and heat conductivity factor is used as the substrate, not only the coupling impedance and the output power are improved, but also the strength and the heat dissipation of the substrate as well as the finished product ratio and the service life in the production process of the slow wave device are effectively improved. Therefore, the microstrip curve plane slow wave device can work in a frequency band above millimeter waves stably and reliability at the same time of being miniaturized and has the characteristics of good heat dissipation and high coupling impedance and output power, high performance and reliability while cooperatively used with the travelling tube working in a frequency band above millimeter waves, as well as high finished product rate and long service life in the production process of the slow wave device, and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Ceramic anchoring nail for castable liner

ActiveCN102679737AReduce the temperatureReduce heat lossLining supportsConductivity factorToughening

The invention discloses a ceramic anchoring nail for a castable liner. A nail body of the anchoring nail is formed by sintering a composite toughening ceramic material comprising 90%-96.3% of Al2O3 and 3.7%-10% of ZrO2, and a base nail is made of metal. The base nail is welded on a wall plate of equipment and is in threaded connection with a ceramic nail body. The characteristics that the ceramic material cannot be corroded and can resist high temperature, the strength of the ceramic material is hardly changed along with change of temperature, and the heat conductivity factor of the ceramic material is greatly lower than that of metal are sufficiently utilized, so that the temperature of the outer wall of the equipment is obviously reduced on the premise of not reducing the strength of an anchoring part and the adhesive force of the liner, the heat dissipation loss of the equipment is reduced effectively, and the purpose of saving energy is achieved. Besides, the utilization quantity of the metal is greatly saved, and the investment cost of the equipment is lowered.

Owner:北京同创科耐科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com