Environment-friendly, high-intensity and desulfurated plaster wall brick and manufacture method thereof

A desulfurized gypsum and production method technology, applied in the field of building materials, can solve the problems of inability to realize mass utilization of solid waste desulfurized gypsum, low utilization rate of desulfurized gypsum, inconvenient transportation and use, etc., and achieve saving production cycle, light density and compactness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further describe the present invention, the environment-friendly high-strength desulfurized gypsum wall brick of the present invention and its production method will be described in more detail below in conjunction with the accompanying drawings and examples.

[0045] The weight percent of its composition of environmental protection high-strength desulfurization gypsum wall body brick of the present invention is according to Table 1 formula:

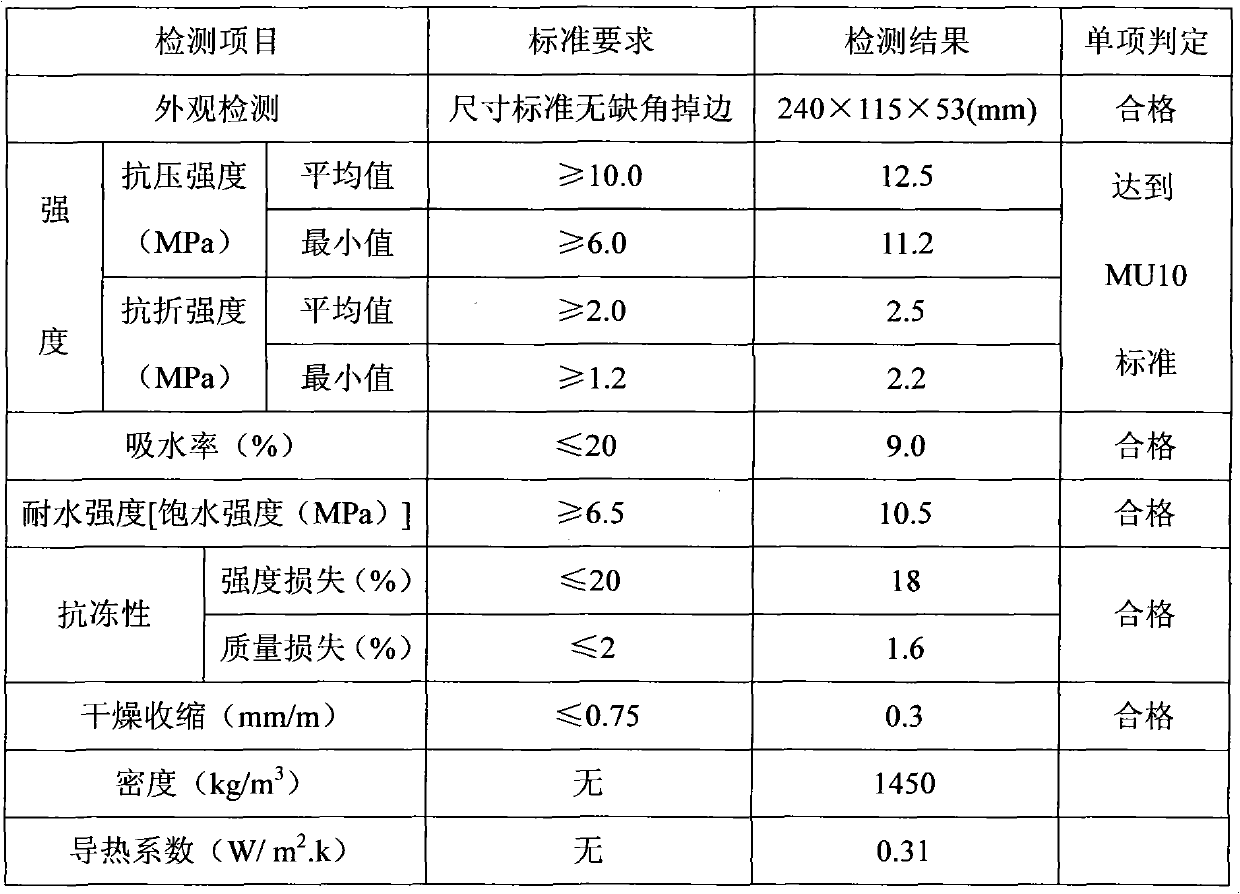

[0046] Table 1 Formula of environmentally friendly high-strength desulfurized gypsum wall bricks (weight%)

[0047]

[0048] Note: Desulfurization gypsum is used directly without treatment, and its water content is about 23%.

[0049] Coagulant is organic silicon among the embodiment 1-5.

[0050] The crystal-transforming agent in Example 1-3 is: sodium citrate; the crystal-transforming agent in Example 4-5 is: aluminum sulfate.

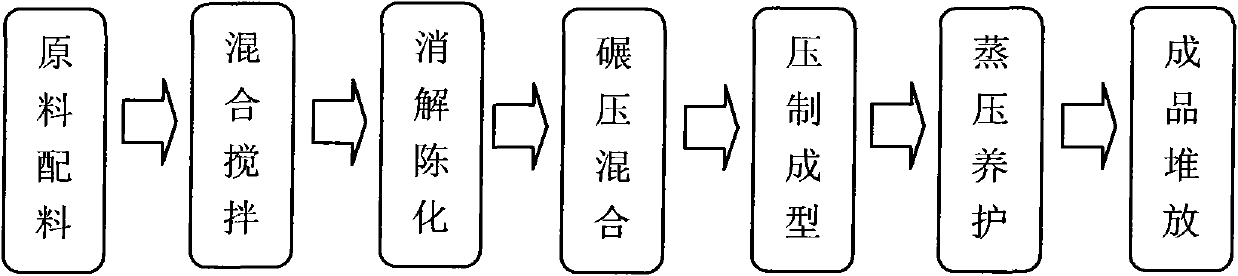

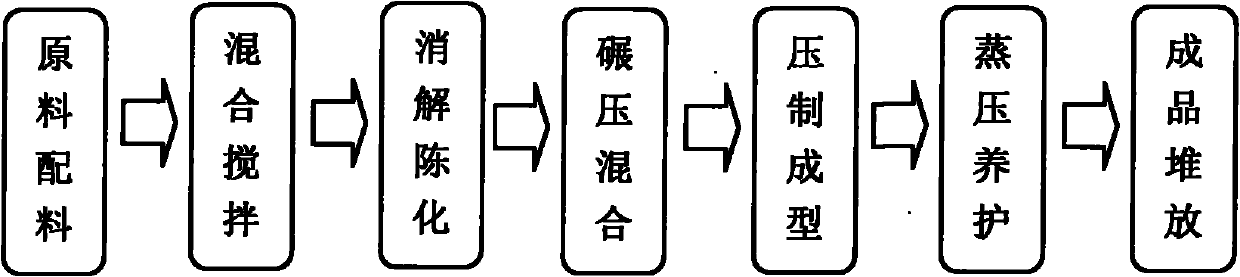

[0051] According to the raw materials configured by the above formula, the process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com