Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Smooth and uniform appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic-inorganic hybridization ultraviolet cured paint for protecting metallic surface

InactiveCN101307194AReduce pollutionSimple operation processLiquid surface applicatorsCoatingsSilanesStrong acids

The invention relates to organic-inorganic hybrid ultraviolet cured paint for metal surface protection. The paint comprises the following components in percentage by weight: 10 to 25 percent of epoxy modified silicon dioxide gel-resin, 15 to 30 percent of bisphenol-A epoxy acrylic ester, 5 to 15 percent of urethane acrylate, 35 to 45 percent of reactive diluent, 2 to 5 percent of toughener, 4 to 6 percent of photoinitiator, 0.5 to 0 percent of addition agent, wherein the epoxy modified silicon dioxide gel-resin is prepared by hydrolyzing a mixture of ethyl orthosilicate and gamma-glycidoxy propyl trimethoxy silane by a sol-gel method first and then adding diethylenetriamine. The paint film formed after the curing of paint has good strength, hardness, flexibility and strong acid and base resistance. The invention solves the problems that the organic-inorganic hybrid paint has high requirement on curing and common ultraviolet cured paint has poor adhesive force and flexibility when cured on metal base materials.

Owner:JIANGSU UNIV OF SCI & TECH

Cyanide-free bright electrogilding additive and application thereof

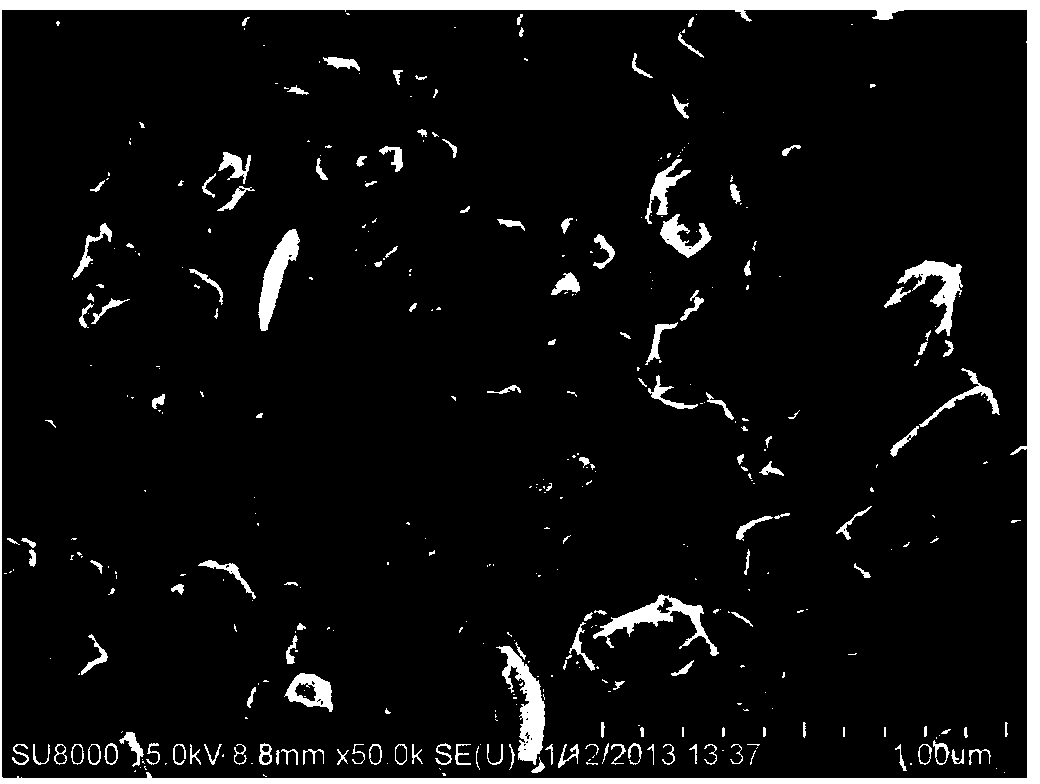

The invention discloses a cyanide-free bright electrogilding additive and an application thereof, which belongs to the technical field of electrogilding. The electrogilding additive is prepared from additives and ultra-pure water, wherein the additives are organic additives or mixtures of inorganic additives and organic additives; the concentration of each component in the additive is 0.5-30g / L. The cyanide-free bright electrogilding additive disclosed by the invention has the functions of improving the brightness of a plated layer, refining crystal grains, stabilizing plating liquid and reducing surface tension. Therefore, the additive can be applied to electrogilding plating liquid, and the addition amount is 0.1-100mL / L. By adopting the additive disclosed by the invention, the properties of the plating liquid and the plating layer of a multi-coordination agent cyanide-free electrogilding system can be effectively improved, the plating liquid has no unstable situations of decomposition, precipitation and the like under long-time working condition, and an electrogilding layer which is golden and full bright macroscopically, uniform and compact in micro crystal, flat and crackless can be obtained under the electroplating condition.

Owner:HARBIN INST OF TECH

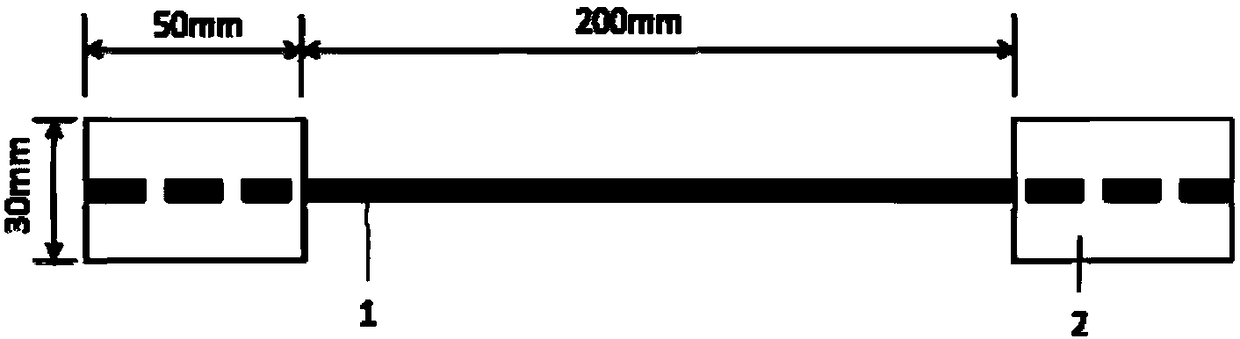

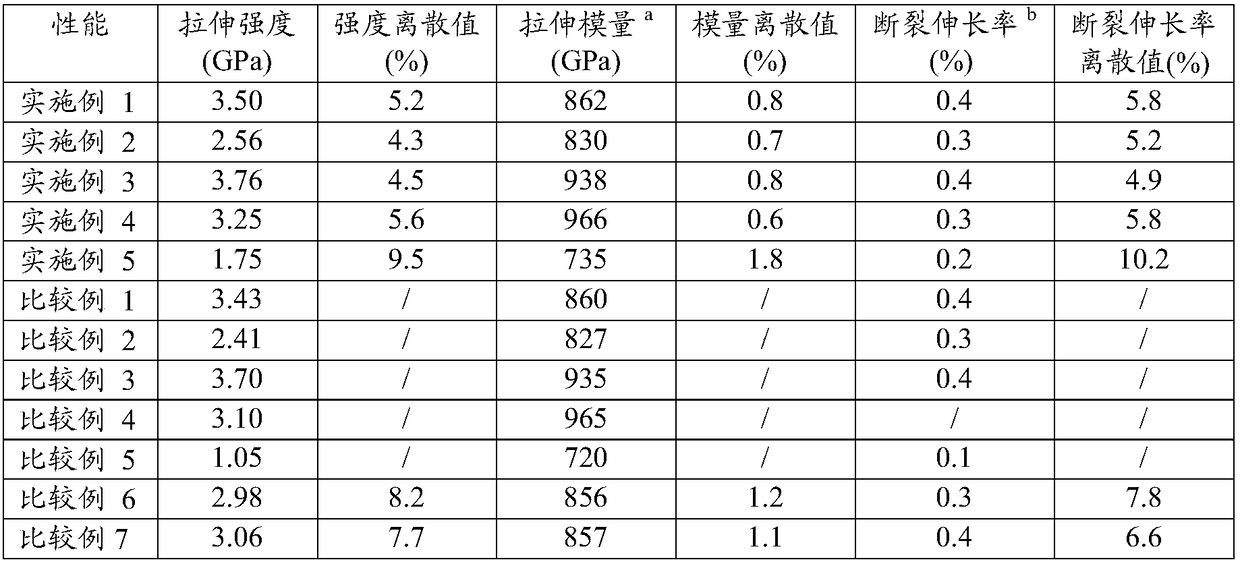

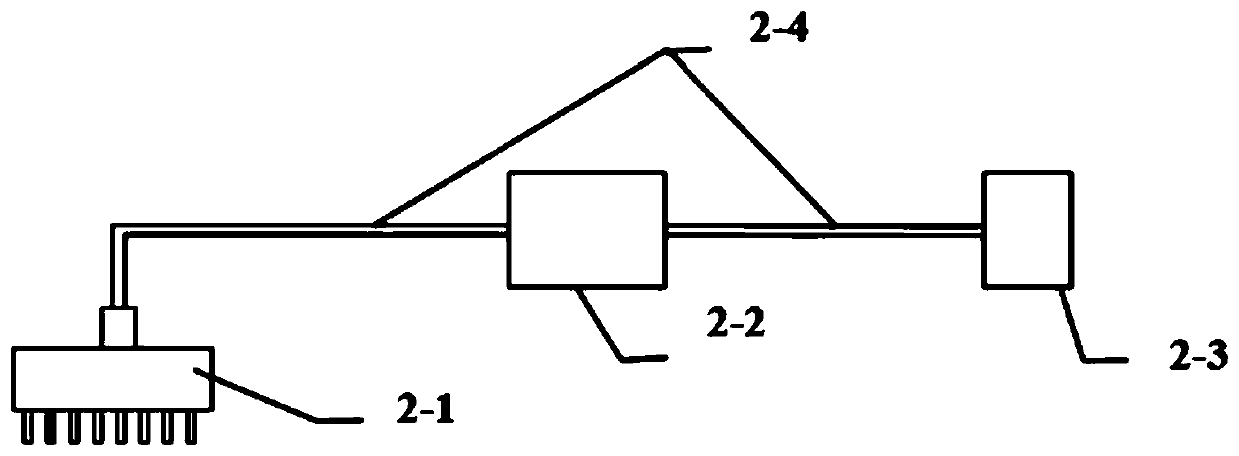

Test sample for tensile properties of large tow carbon fiber multifilament and sample preparation method thereof

ActiveCN108469366AImprove mechanical propertiesPrevent tear damagePreparing sample for investigationFiberTest sample

The invention relates to a test sample for tensile properties of a large tow carbon fiber multifilament and a sample preparation method thereof, and belongs to the field of material property testing.The method comprises the steps that tension is applied to wind the carbon fiber multifilament of not less than 24 k around a frame; gum dipping, gum leaching and heat curing are conducted on the framewound with the multifilament, and the gum-dipped multifilament is cut into multifilament segments after cooling; a set of metal or composite reinforcing sheets are respectively bonded to the two endsof the multifilament segments, wherein each set includes two reinforcing sheets disposed oppositely, a structure glue film is bonded to the inner surface of at least one of the two reinforcing sheets, the middle region and the peripheral edge region of the inner surface are vacated in bonding, and the two ends of the multifilament segments are located in the middle region; the reinforcing sheetsare pressed, heated and cured to obtain the test sample. By adopting the method, the mechanical properties of the reinforcing sheets are improved, the bonding strength between the multifilament and the reinforcing sheets is improved, and the problems of tear damage of the reinforcing sheets and debinding and slippage of fiber when the obtained test sample is used in a tensile test are avoided.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

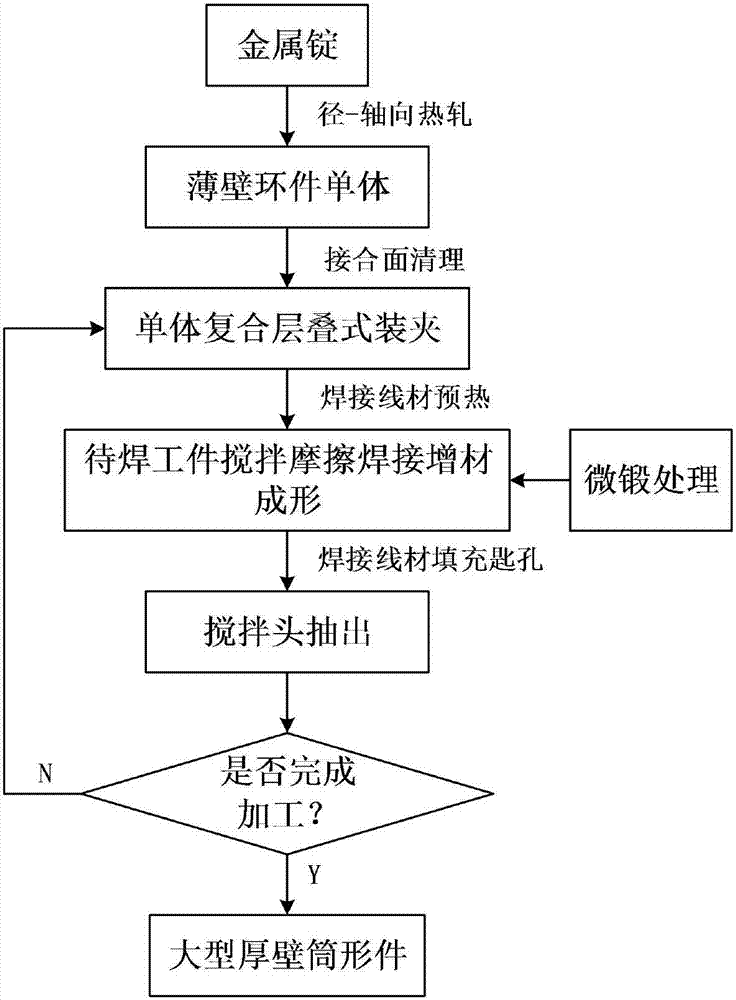

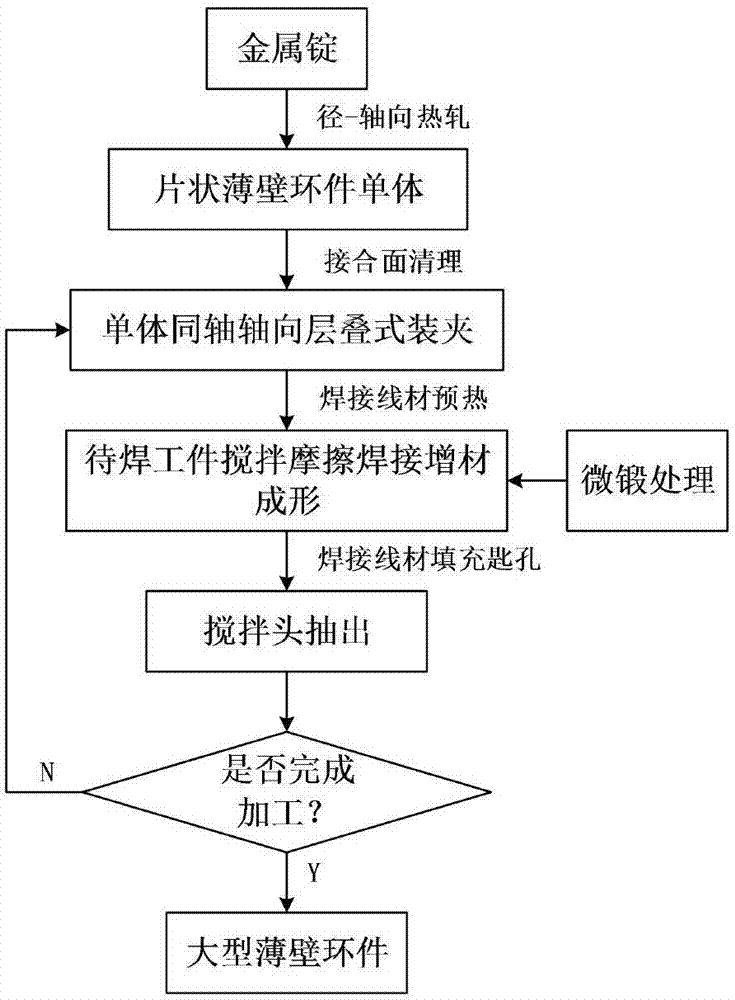

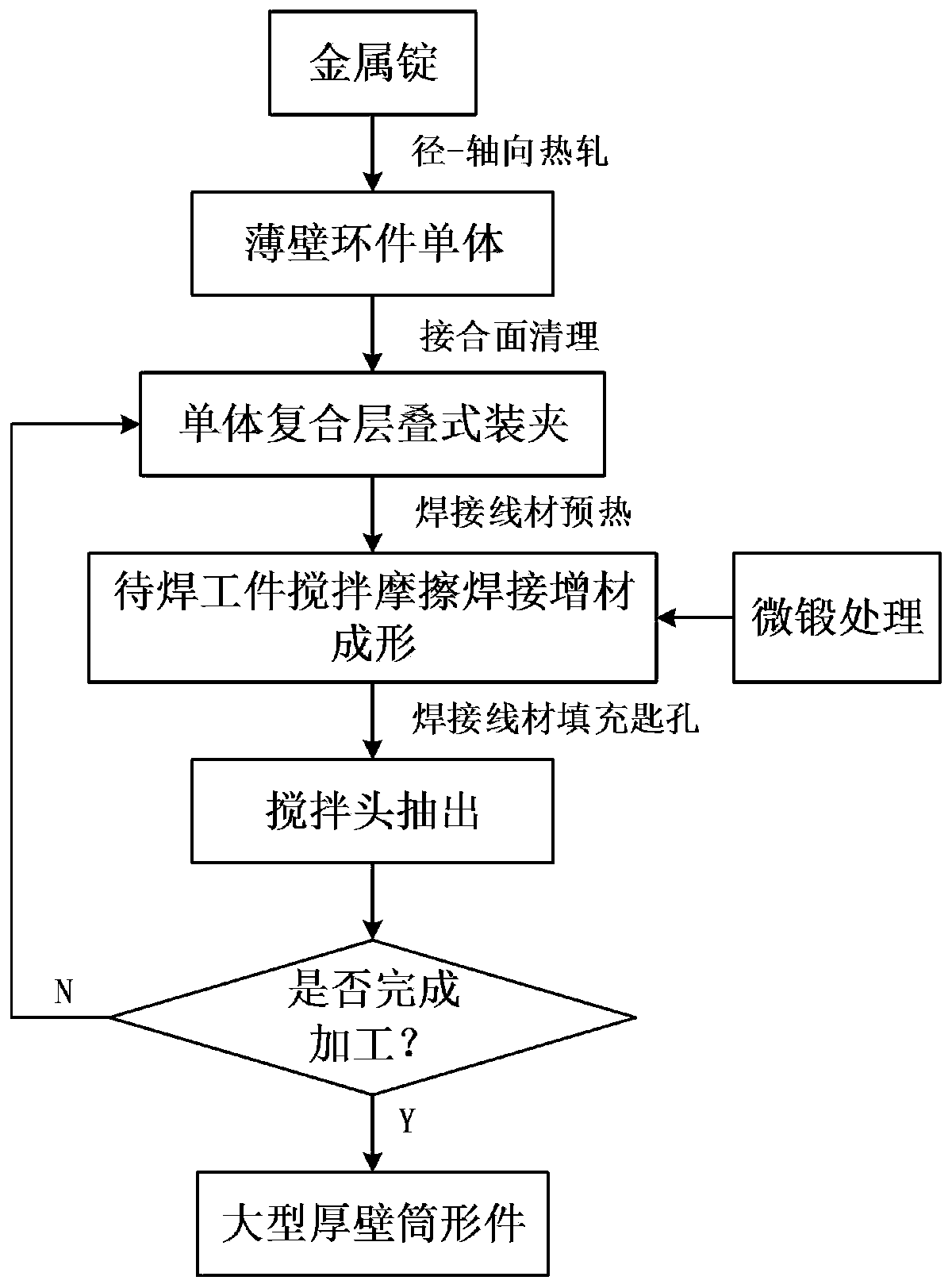

Composite stack-up type stirring friction welding additional material forming technology of large-scale thick-wall cylindrical piece

InactiveCN107020447AImprove mechanical propertiesIncrease profitNon-electric welding apparatusFriction weldingRoll forming

The invention discloses a composite stack-up type stirring friction welding additional material forming technology of a large-scale thick-wall cylindrical piece. The forming technology comprises the following steps: first, carrying out roll forming on a thin-wall annular piece monomer; then, carrying out radial stack-up type stirring friction welding additional material forming on the thin-wall annular piece monomer to finish the forming process of a first thin-wall annular piece monomer radial stack-up type stirring friction welding additional material of a first layer; then, carrying out axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomer, and carrying out axial superposition welding on a third thin-wall annular piece monomer of a second layer and the first thin-wall annular piece monomer; then, carrying out radial and axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomers, and carrying out radial and axial welding on a fourth thin-wall annular piece monomer, the second and third thin-wall annular piece monomers of the second layer; and finally, carrying out radial, axial and radial and axial composite stack-up type stirring friction welding additional material forming on the thick-wall cylindrical piece. With adoption of the forming technology, the material utilization ratio is remarkably increased, the energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV +1

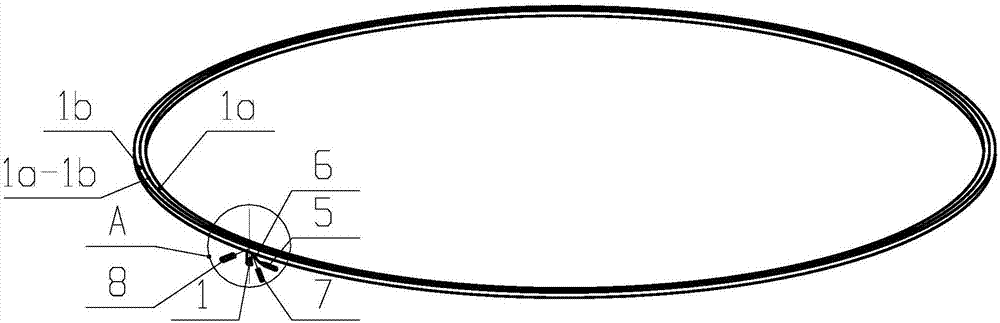

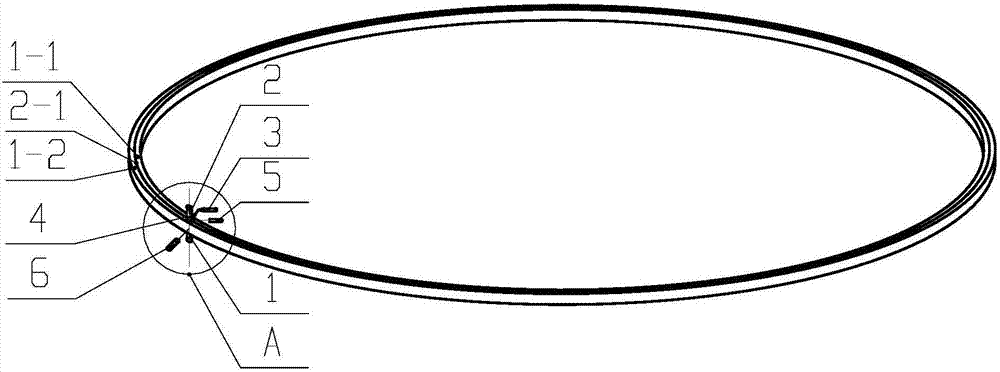

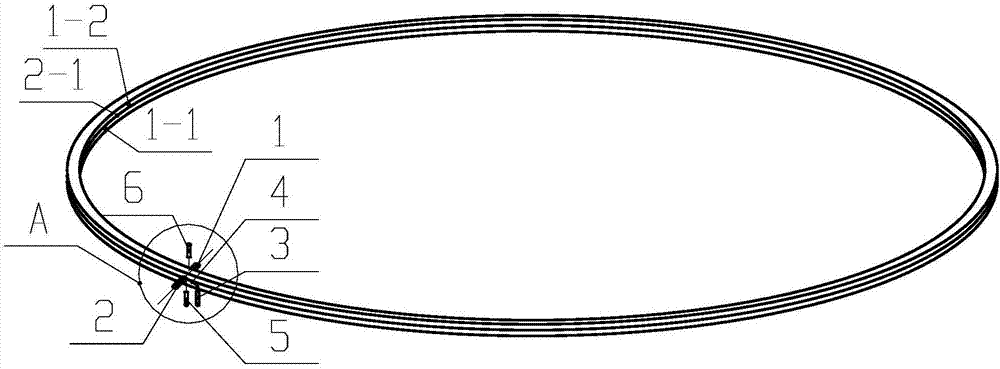

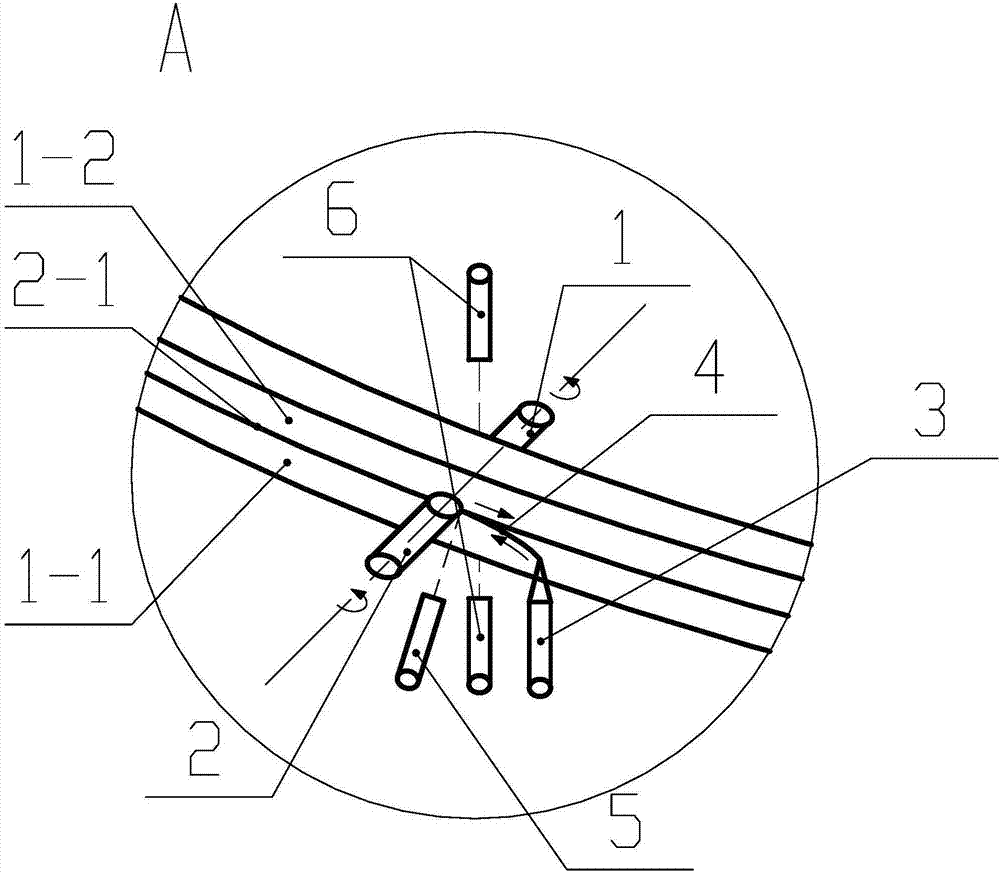

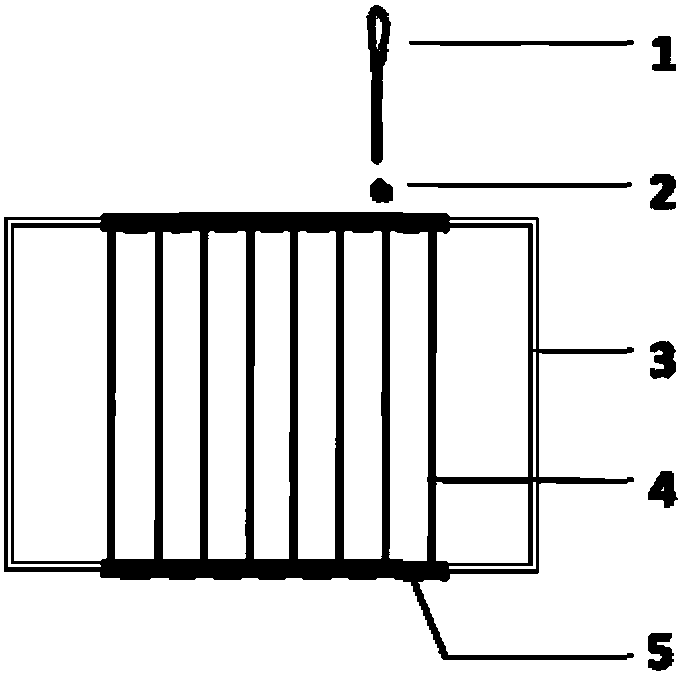

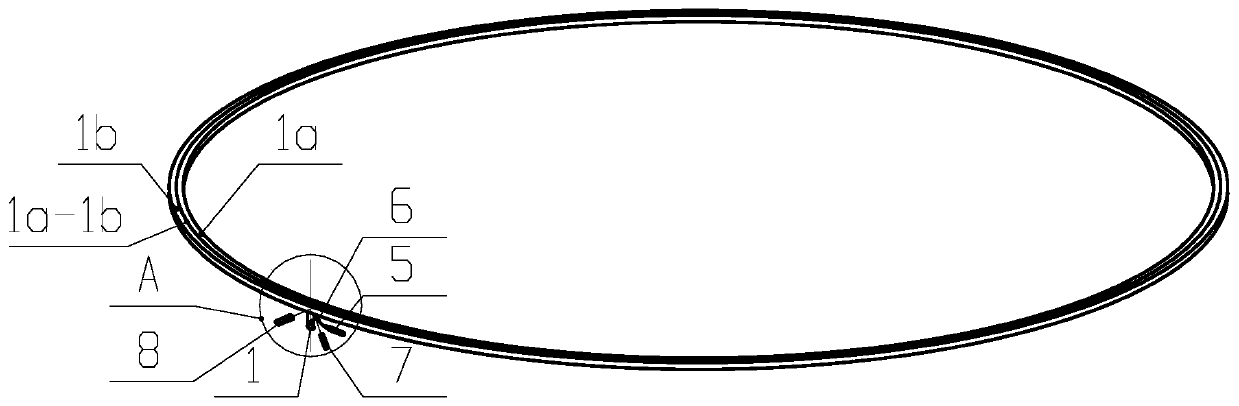

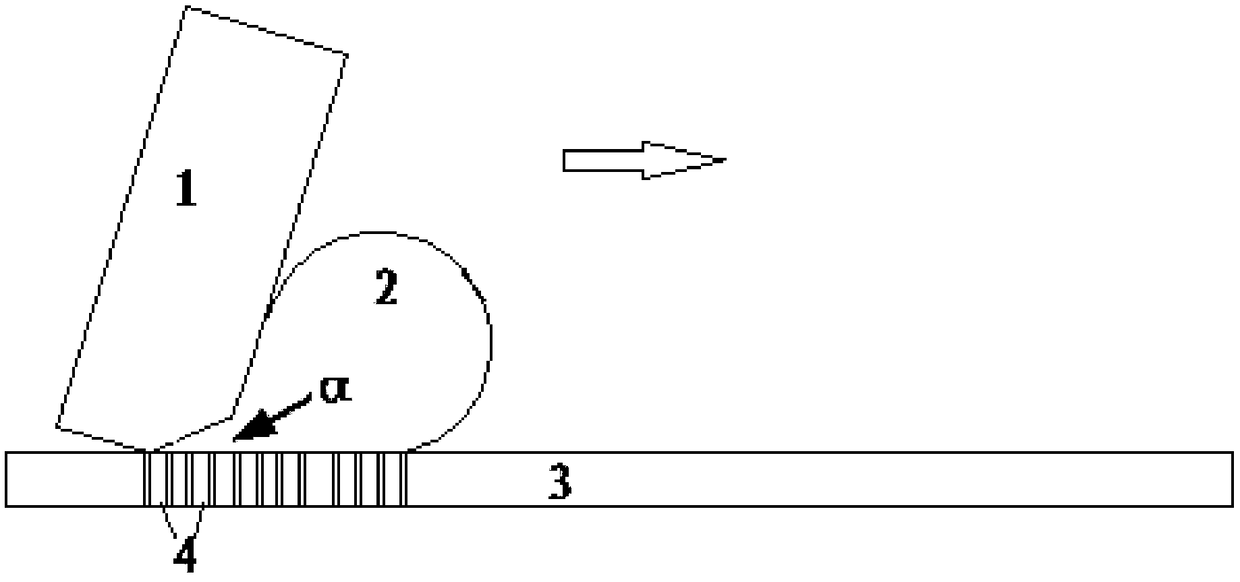

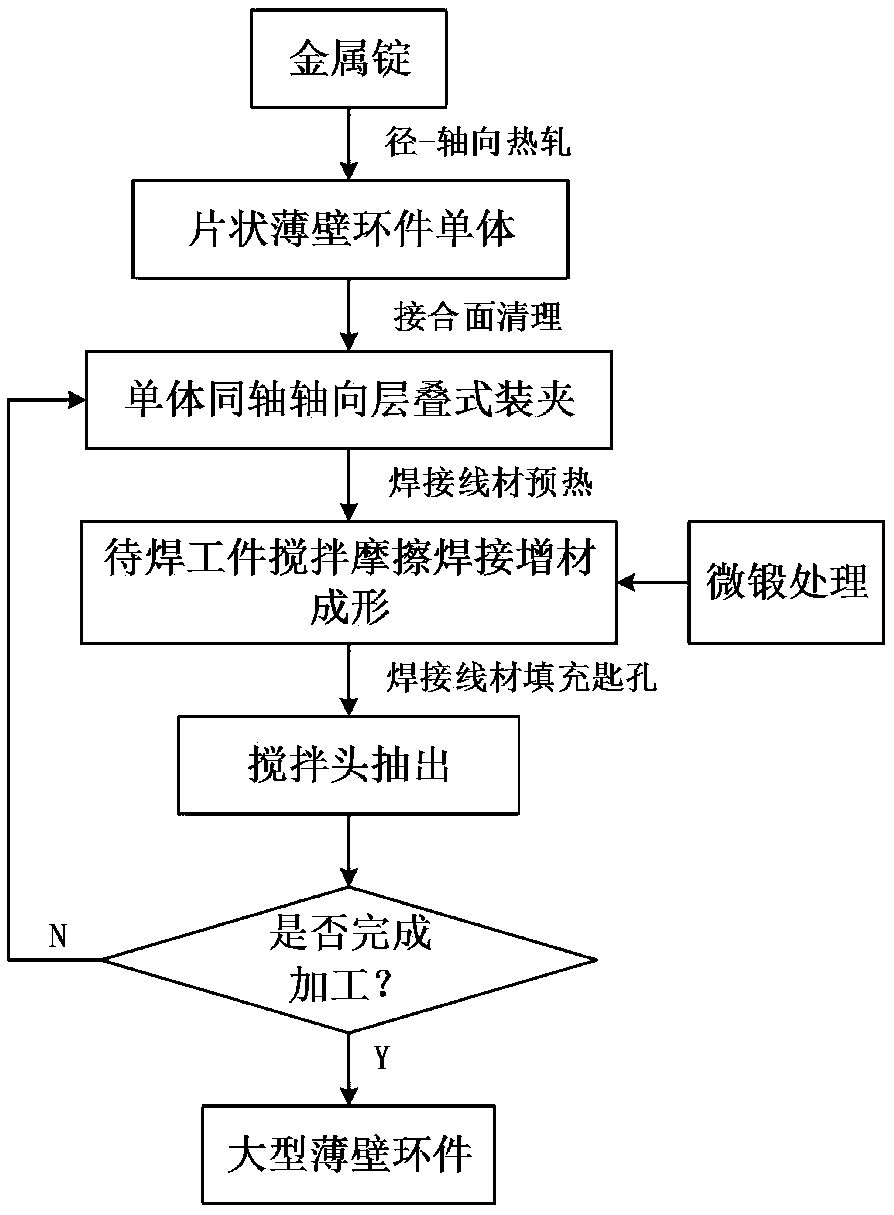

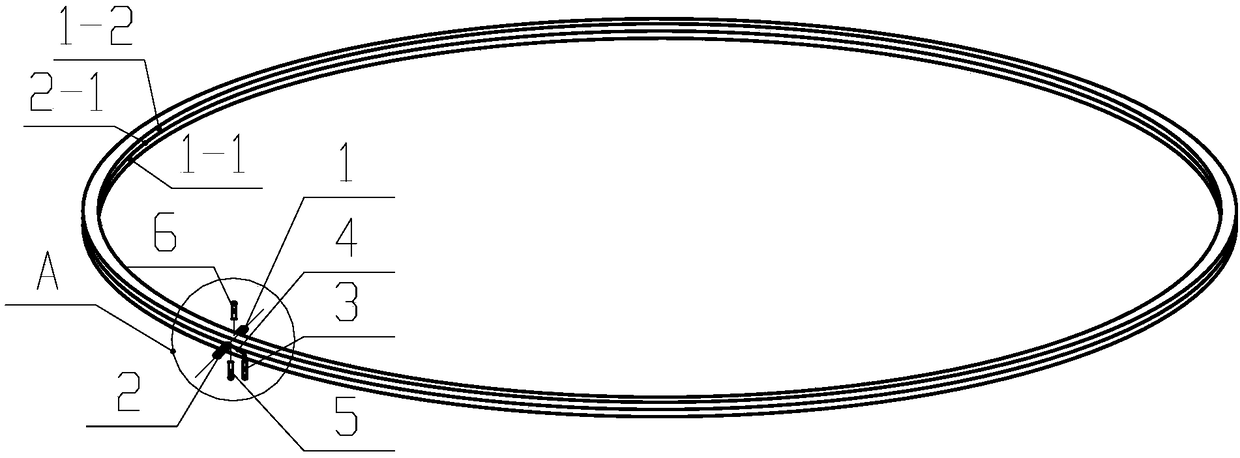

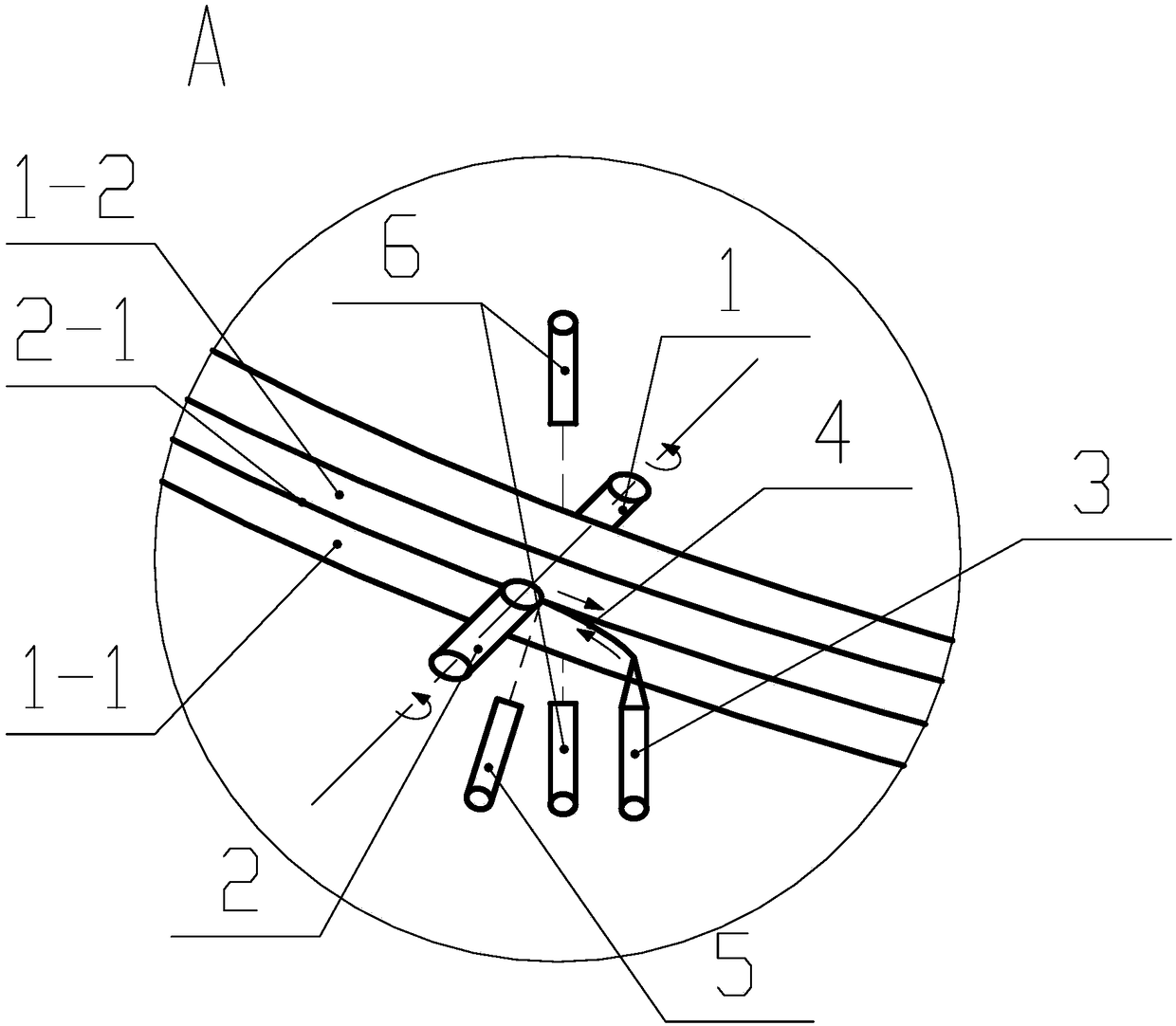

Radial stacking type friction-stir welding material adding forming process for large thick-wall ring part

InactiveCN106925883ASmooth and uniform appearanceIncrease profitNon-electric welding apparatusMetal formingEngineering

Disclosed is a radial stacking type friction-stir welding material adding forming process for a large thick-wall ring part. A sheet-shaped thin-wall ring part single body is prepared through radial-axial hot rolling technology, and radial stacking type double-shaft friction-stir welding material adding forming of the thin-wall ring part single body is conducted through double-shaft friction-stir welding material adding forming technology. A welding wire used by welding needs to be preheated by a laser heater, and plasticizing of the welding wire during welding is convenient. Meanwhile, during welding, micro forging treatment needs to be conducted on plasticized metal through an ultrasonic vibration exciter, and the effect that the texture form of the metal forming a weld joint approximately completely forms a welding core is ensured. One week after welding is conducted along the weld joint, a keyhole is filled with the welding wire constantly, meanwhile, a stirring head is drawn out of a workpiece slowly, and thus welding of the first ring of thin-wall ring part single body is completed. Finally, radial stacking type friction-stir welding material adding forming of the thick-wall ring part is conducted. Through the radial stacking type friction-stir welding material adding forming process, the utilization rate of materials can be increased significantly, energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV

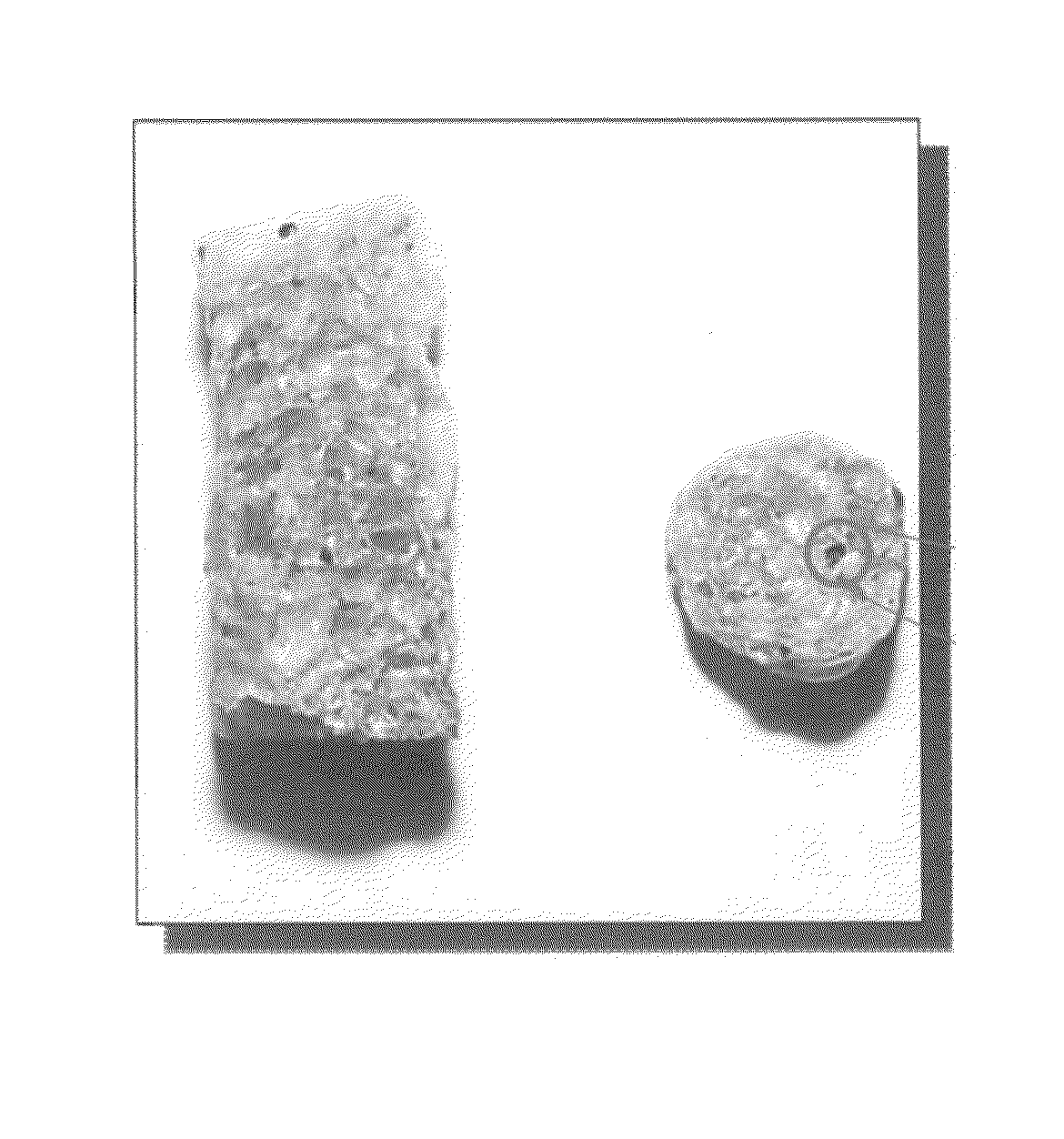

Cereal-Based Product with Improved Eating Quality Fortified with Dietary Fiber and/or Calcium

Inhibition of expansion of a cereal product, such as a ready-to-eat cereal, by a particulate insoluble component such as fiber and / or calcium is avoided by pelletizing the particulate insoluble component. A binder component, such as gelatinized starch, is used to bind particles of the particulate insoluble component into a coherent mass which is formed into non-expanded pellets for fortification of the cereal product. The expanded cereal products, such as extruded puffed RTE cereals which contain the pellets, exhibit a crisp, uniform texture and cell structure, improved, prolonged bowl life, a non-gritty mouthfeel, and a smooth, uniform surface appearance even though they are fortified with high amounts of the solid or particulate insoluble nutritional components.

Owner:GENERAL MILLS INC

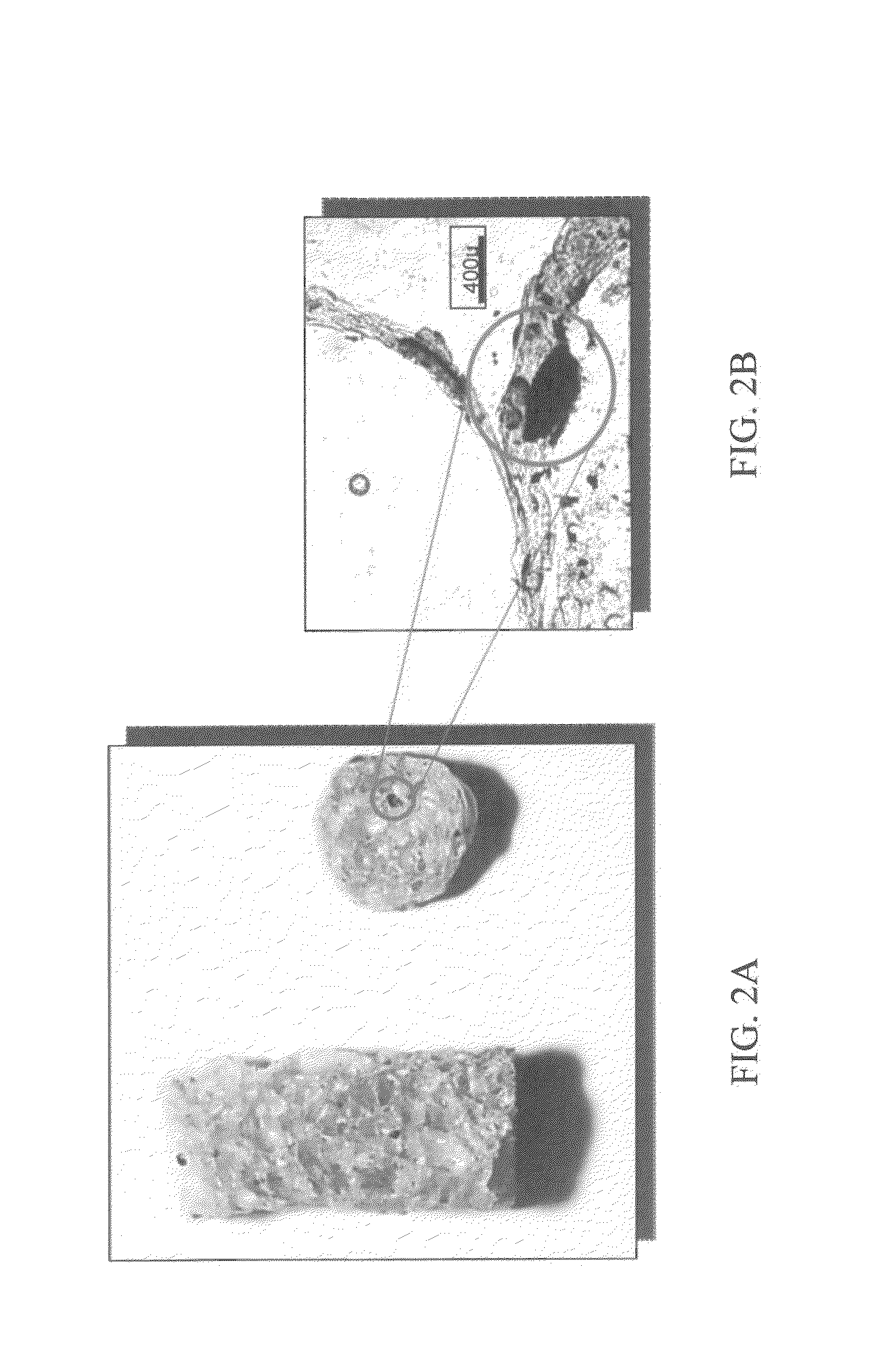

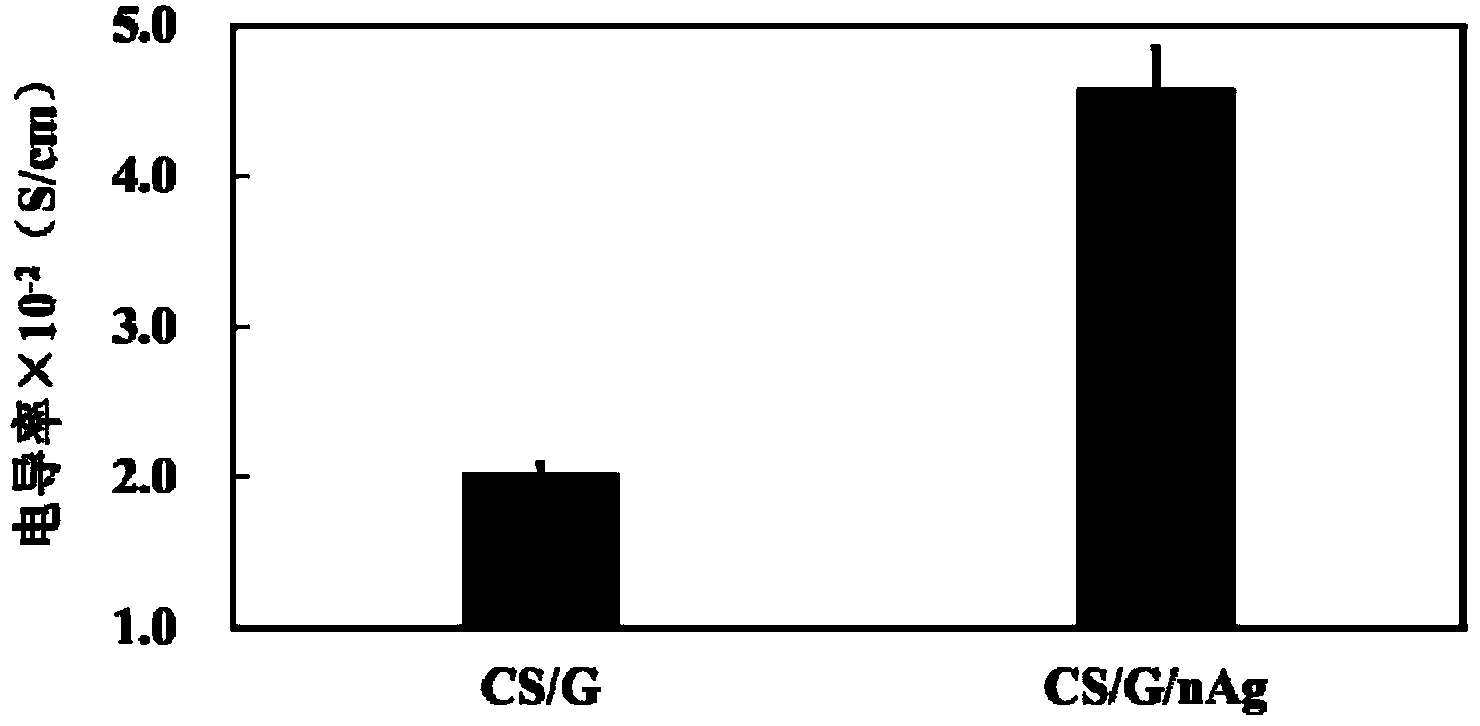

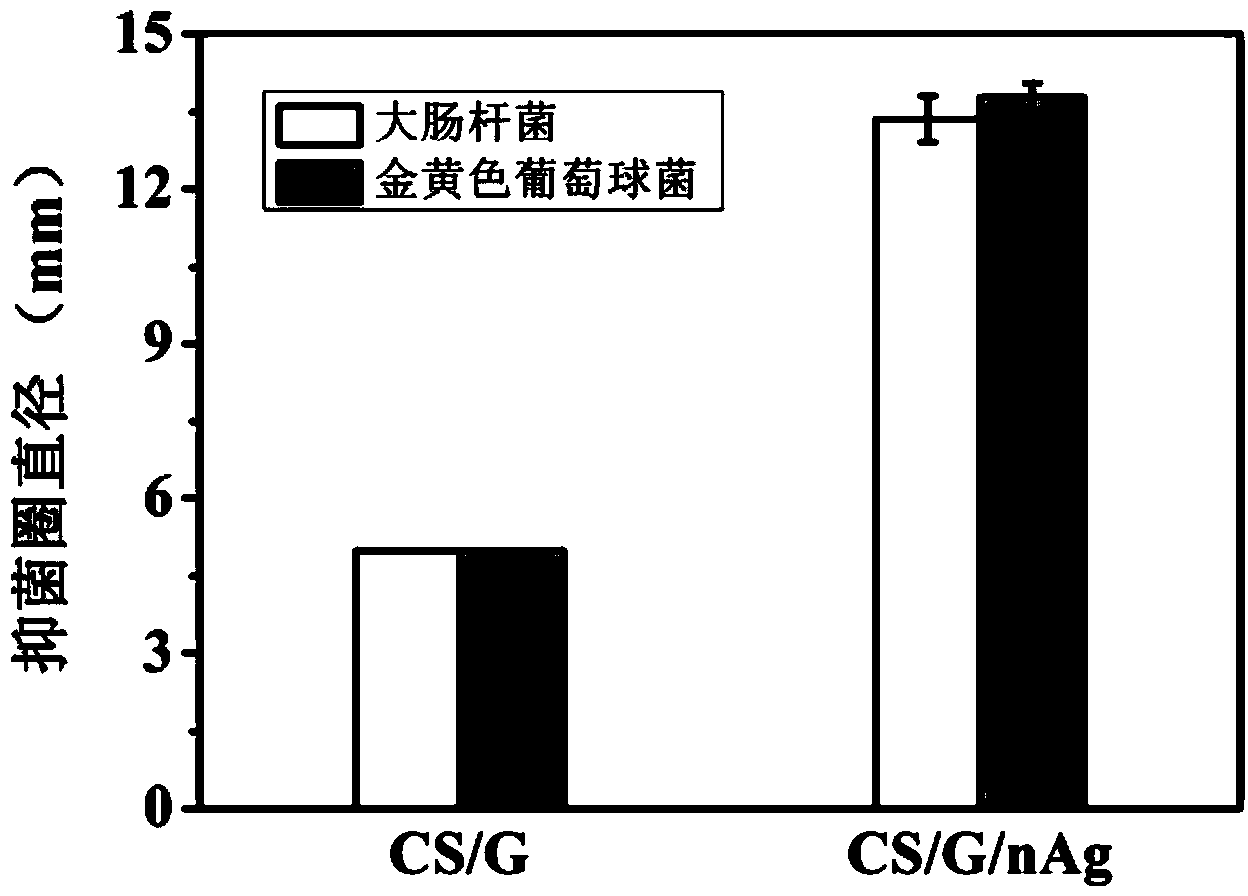

Chitosan/gelatin/nano-silver conductive antibacterial material and preparation method thereof

InactiveCN104233436AImprove mechanical propertiesCo-depositionElectrolytic coatingsNanotechnologyBiocompatibility TestingAntibacterial activity

The invention relates to a chitosan / gelatin / nano-silver conductive antibacterial material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing a chitosan solution; (2) preparing an electro-deposition liquid; and (3) preparing the chitosan / gelatin / nano-silver conductive antibacterial material, namely immersing a titanium alloy plate serving as a negative pole and a platinum plate serving as a positive pole in the electro-deposition liquid prepared in the step (2), taking out and washing the titanium alloy plate with a deposition layer after electro-deposition is completed, then immersing in a 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution of which the concentration is 0.05-0.20mol / L, and carrying out post-treatment at the end of the reaction to obtain the chitosan / gelatin / nano-silver conductive antibacterial material. The preparation method is simple and convenient to operate and easy to control, and has the characteristics of simple equipment, mild reaction condition and the like; the prepared material has excellent biocompatibility and biodegradability and has conductive performance and excellent antibacterial activity.

Owner:WUHAN UNIV OF TECH

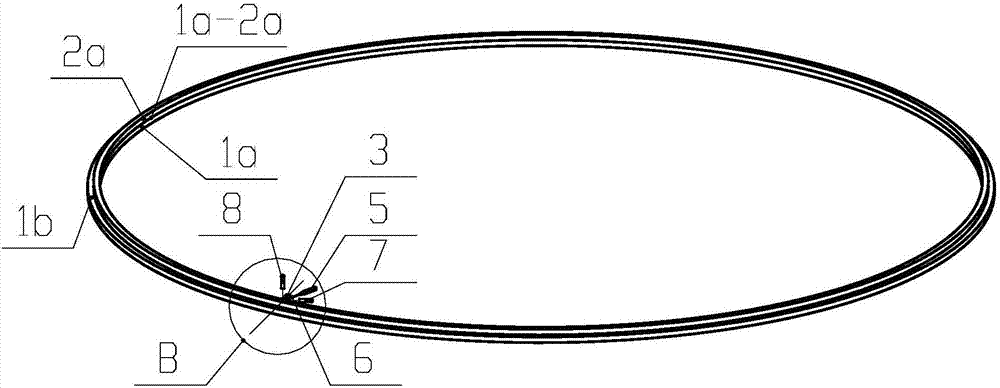

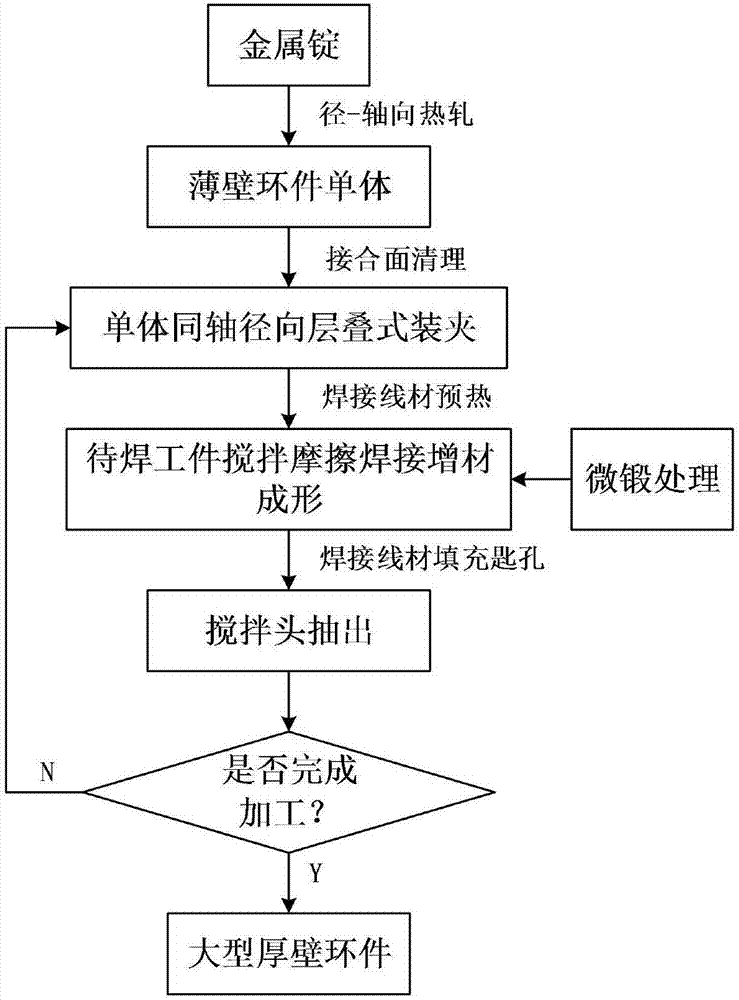

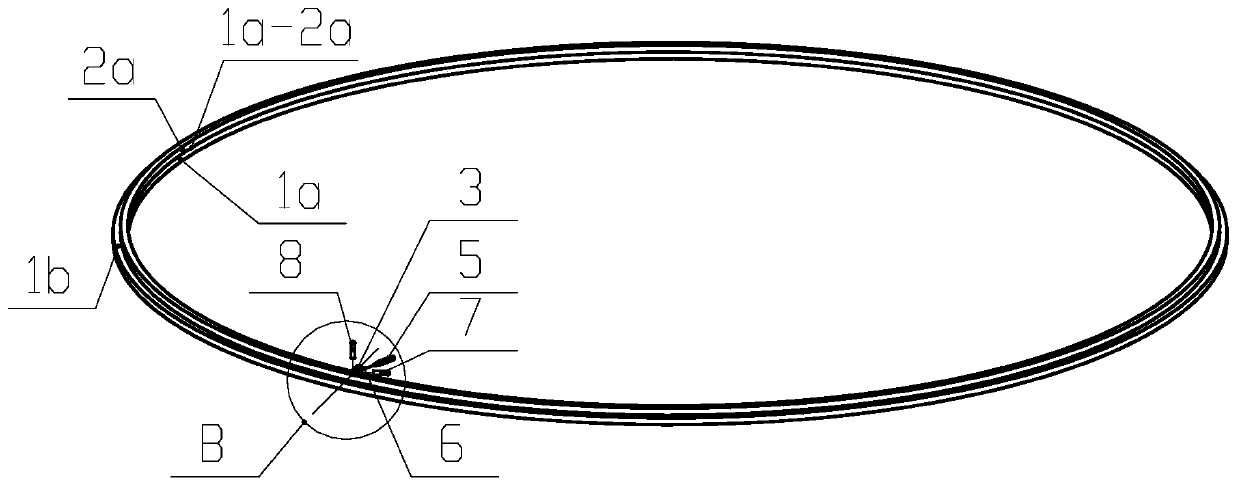

Axial stacking type friction-stir welding material adding forming process for large thin-wall ring part

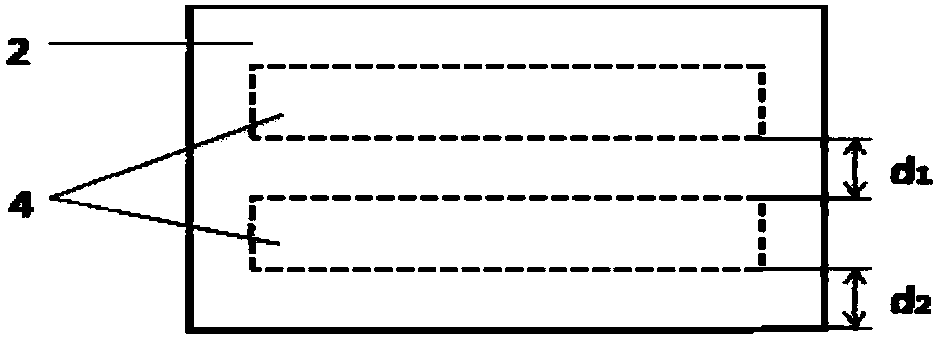

InactiveCN106925884AImprove mechanical propertiesSmooth and uniform appearanceNon-electric welding apparatusMetal formingEngineering

Disclosed is an axial stacking type friction-stir welding material adding forming process for a large thin-wall ring part. A sheet-shaped thin-wall ring part single body is prepared first through radial-axial hot rolling technology, then axial stacking type welding forming of the sheet-shaped thin-wall ring part single body is conducted through friction-stir welding material adding forming technology. A welding wire used by welding needs to be preheated by a laser heater, and plasticizing of the welding wire during welding is convenient. Meanwhile, during welding, micro forging treatment needs to be conducted on plasticized metal through an ultrasonic vibration exciter, and the effect that the texture form of the metal forming a weld joint approximately completely forms a welding core is ensured. One week after welding is conducted along the weld joint, a keyhole is filled with the welding wire constantly, meanwhile, a stirring head is drawn out of a workpiece slowly, and thus welding of the first layer of sheet-shaped thin-wall ring part single body is completed. Finally, axial stacking type friction-stir welding material adding forming of the thin-wall ring part is conducted layer by layer. Through the axial stacking type friction-stir welding material adding forming process, the utilization rate of materials is increased significantly, energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV

Sample preparation method for testing tensile property of asphalt-based carbon fiber multifilament

The invention relates to a sample preparation method for testing the tensile property of an asphalt-based carbon fiber multifilament, and belongs to the technical field of material property testing. The method comprises the following steps: applying tension to wind a carbon fiber multifilament on a frame, and fixing the bent part of the multifilament on the frame with a fixing material; placing the frame with wound multifilament vertically along the extension direction of the multifilament, dripping a glue solution from the upper end of the frame to ensure that the dripped glue solution flowsfrom the upper end of the multifilament to the lower end along the multifilament until the multifilament is completely soaked to obtain a glue dipped multifilament frame; and curing the glue dipped multifilament frame, cutting the multifilament, and pasting a paper reinforcing sheet to obtain a tensile sample. According to the method provided by the invention, fiber damages in the operation process are avoided, the sample preparation efficiency is improved, the problem of fiber monofilament brittle fracture caused by the surface tension of the glue solution and the gravities of the glue solution and the multifilament is also avoided, the maximum developed strength of the multifilament is ensured, the accuracy of the tensile strength test value is greatly improved, and the tensile strengthdispersion coefficient is reduced.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

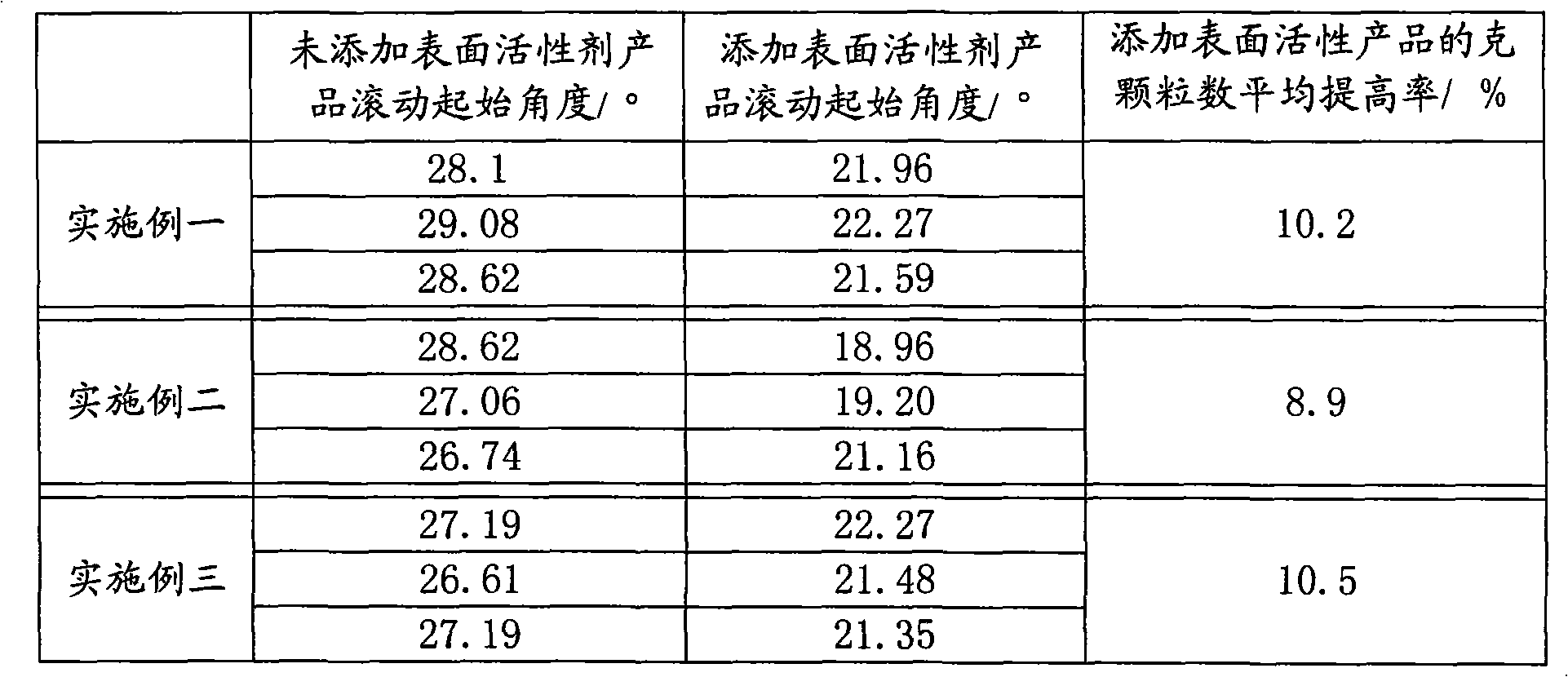

Method for improving appearance quality of granules made from diammonium phosphate slurry

ActiveCN101279860AReduce gas-liquid interfacial tensionLow viscosityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSpray GranulationDiammonium phosphate

Disclosed is a method for improving the appearance quality of a formed diammonium phosphate slurry particle, which relates to a fertilizer containing ammonium salts, the method uses surface active agents to change the gas-liquid interfacial tension and viscosity of slurry so as to improve the particle sphericity and homogeneity when in diammonium phosphate slurry granulation, thereby reaching the purpose of improving the product appearance quality of diammonium phosphate particles; the method has the detailed technical proposal that: proper surface active agents or combinations thereof are firstly selected, and the surface active agents or combinations thereof are then prepared into a saturation solution; and then the solution is pumped to the pipe-connecting part of a suction inlet of a slurry pump by a gear pump, and the slurry-spraying granulation can be implemented after the solution enters the slurry for mixing. Using the method of the invention and adding the surface active agents to the slurry can largely reduce the gas-liquid interfacial tension and viscosity of the diammonium phosphate slurry by only consuming a little amount thereof, then the solution can be adapted to the size required by the granulation technique, and medium-sized particles do not stick to one another or seldom stick to one another in the granulation process, thereby ensuring the roundness, smoothness, uniformity and cleanness of the diammonium phosphate particle appearance and improving the product appearance and product grade.

Owner:WENGFU (GRP) CO LTD

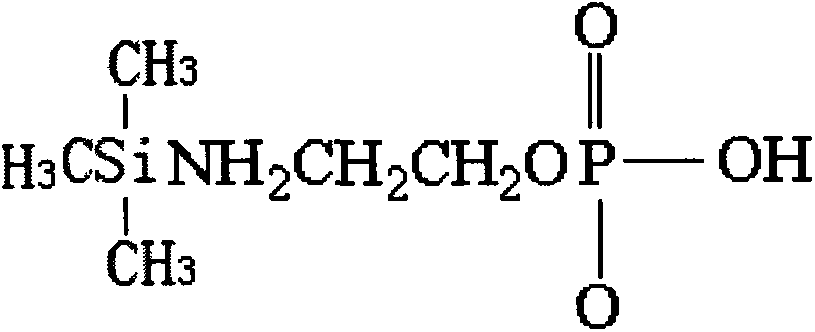

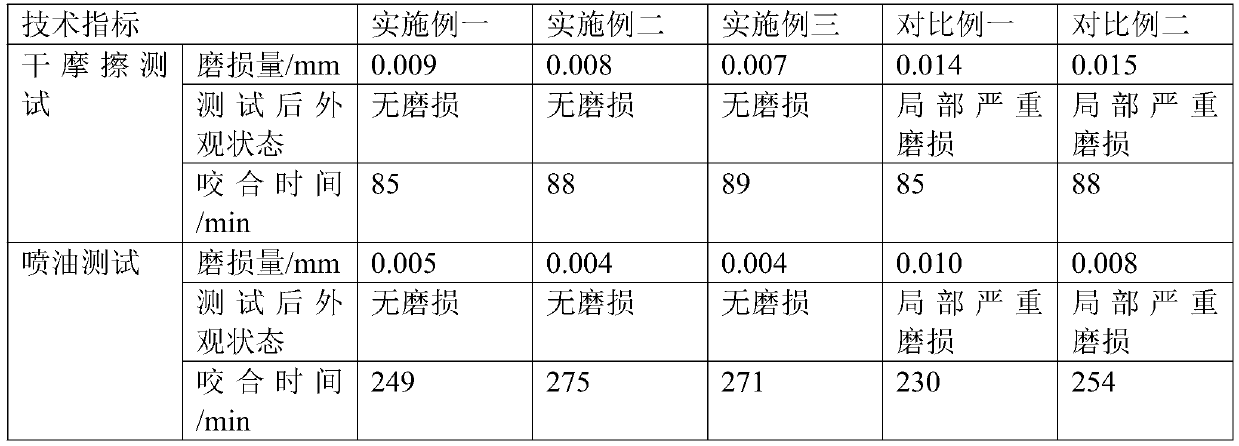

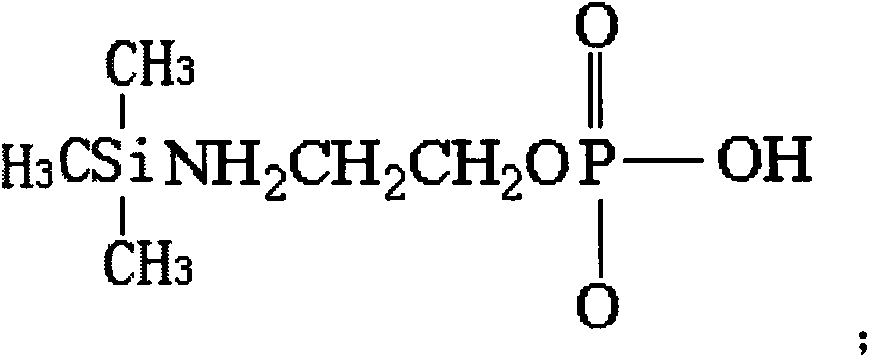

Preparation method of wear-resistant and flame-retardant swash plate

InactiveCN103865362AReasonable compositionUniform compositionFireproof paintsPositive displacement pump componentsHeat resistanceWear resistant

The invention discloses a preparation method of a wear-resistant and flame-retardant swash plate. The prepared swash plate comprises a base plate and a wear-resistant coating, wherein the wear-resistant coating comprises base resin, silicon-containing phosphate, PTFE (polytetrafluoroethylene) particles, graphite fluoride and composite filler. The wear-resistant paint disclosed by the invention is reasonable in composition and has excellent heat resistance and adhesion. The swash plate based on the wear-resistant paint has excellent wear resistance and flame retardance, has dry state or oil state friction property far better than that of swash plates prepared from the existing resin, and can meet the requirements of auto air conditioning compressors.

Owner:崔劲

Preparation method of cyanate ester based wear-resistant self-lubricating swash plate

InactiveCN110283527AImprove mechanical properties and heat resistanceLow dielectric lossPositive displacement pump componentsPretreated surfacesEpoxy resin compositeCyanate ester

The invention discloses a preparation method of a cyanate ester based wear-resistant self-lubricating swash plate. The preparation method comprises following steps: preparation of a promoter; preparation of an oxidized graphene / cyanate ester-epoxy resin composite material; preparation of a wear-resistant self-lubricating coating layer; spraying; and curing; wherein the oxidized graphene / cyanate ester-epoxy resin composite material is dissolved in acetone so as to obtain a composite material acetone solution with a mass concentration of 40%; 30 mass parts of a solid lubricating agent is added into 100 mass parts of the composite material acetone solution for uniform mixing so as to obtain a wear-resistant coating layer solution. The wear-resistant coating is reasonable in composition, and excellent in heat resistance and bonding performance, so that the swash plate prepared based on the wear-resistant coating possesses excellent wear resistance, wet state friction performance and oil state friction state are both much better than that of conventional resin swash plates, and the requirements of automobile air-conditioning compressor can be satisfied.

Owner:浙江儒商科技有限公司

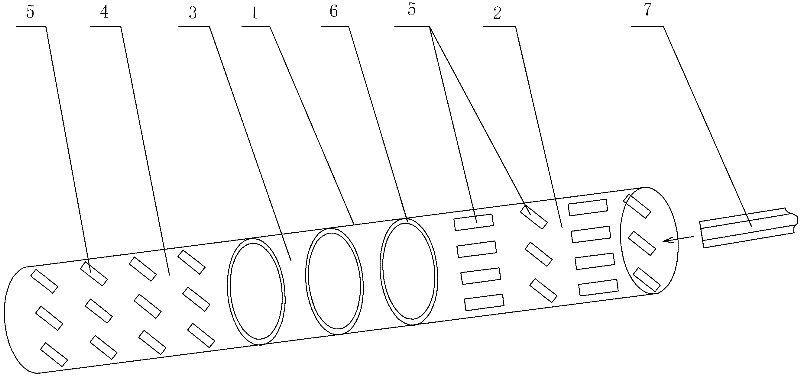

High-nitrogen organic-inorganic compound fertilizer and steam-free compound fertilizer pelleting equipment

ActiveCN102503644AReduce joinReduce heat consumptionFertiliser formsFertilizer mixturesEngineeringEnergy consumption

The invention discloses a high-nitrogen organic-inorganic compound fertilizer and a steam-free compound fertilizer pelleting equipment which comprises a drum and a heat generator; at least three pelleting areas are arranged in the drum, including a first pelleting area at front segment of the drum, a second pelleting area at the middle segment of the drum and a third pelleting area at the rear segment of the drum; a plurality of rows of material lifting devices are arranged in the first pellleting area; each row of material lifting devices consists of a plurality of material lifting plates including rows of inclined material lifting plates and rows of horizontal material lifting plates which are arranged in an intercrossed manner; a plurality of baffle rings are arranged on the inner wall of the second pelleting area; a plurality of rows of material lifting devices are arranged in the the third pelleting area and each row of material lifting devices consists of a plurality of inclined material lifting plates which are put in order; the heat generator is a high temperature blowing mechanism; and the inclination direction of the inclined material lifting plates is the same as the blowing direction. After adopting the new steam-free pelleting technology, the invention realizes the effect that the drum can pellet without steam, thereby a steam boiler is omitted, thus the investment, the energy consumption and the production cost are reduced, and the unsafe factors are avoided.

Owner:DONGGUAN BAODE BIOLOGICAL ENG

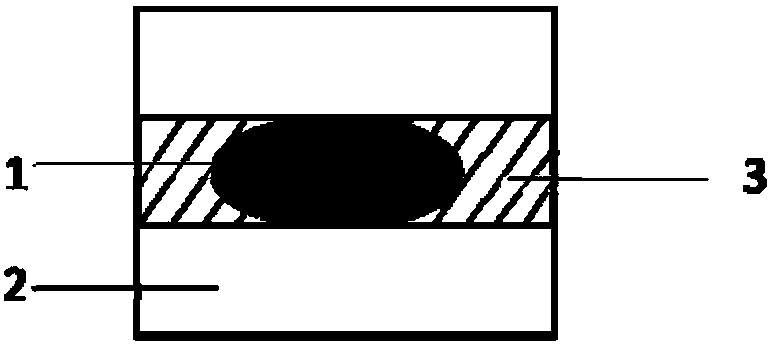

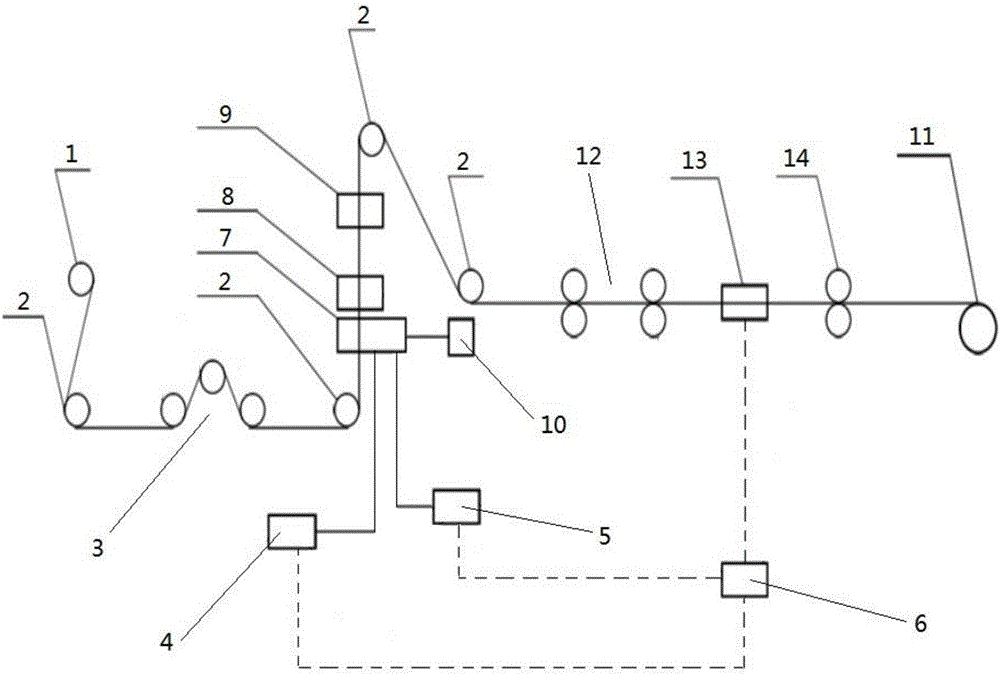

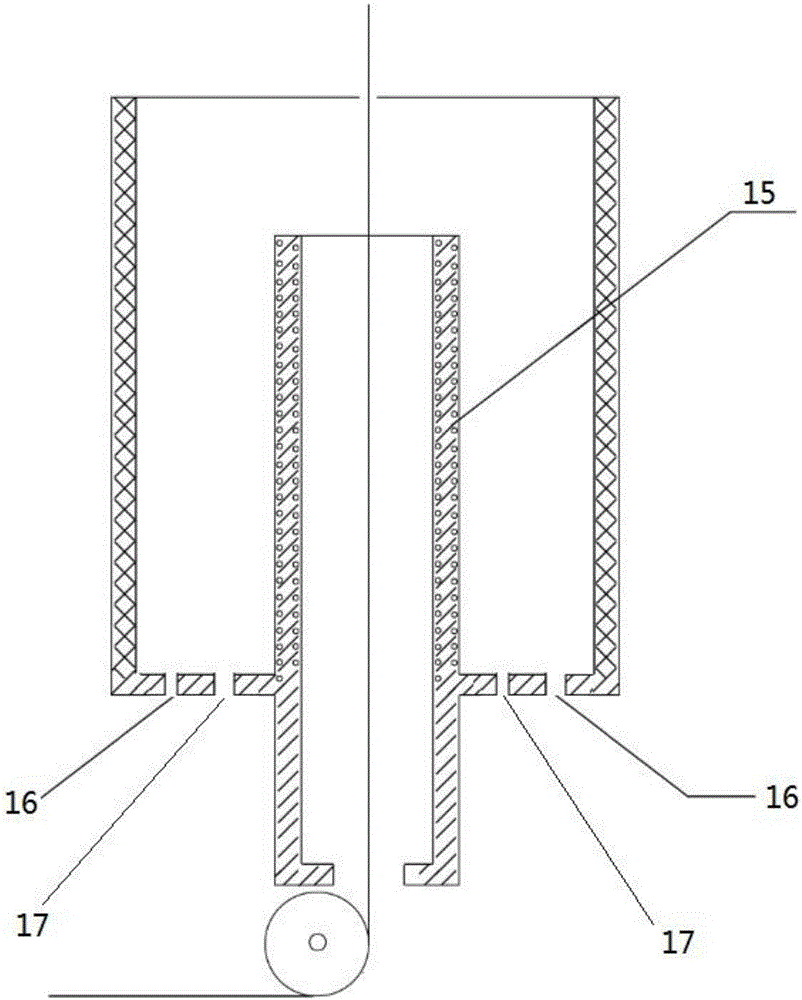

Liquid spray electrotherapy room treated by coating carbon fibers and coating system thereof

InactiveCN106638006AIncrease conversion rateUniform resin contentTextiles and paperFiberCarbon fibers

The invention relates to a liquid spray electrotherapy room treated by coating carbon fibers and a coating system thereof. The coating system is composed of a de-coiling device, a guiding device, a flattening device, a liquid spray electrotherapy room, an electrostatic coating room, a melting furnace, an adjusting device, an electrostatic device, a resin content test system, a traction device, a coiling device, a powder device, a control system and a compressed air source. A presoaked fabric passes by the liquid spray electrotherapy room with liquid spray electricity and then passes by the coating room with the electrostatic resin powder, so that the two sides of the presoaked fabric are coated with the resin powder; the fabric is flattened by the melting furnace under high temperature, and then the resin is adhered to the presoaked fabric; in order to uniformly and flatly soak, an X-ray instrument and a computer are adopted for detecting and controlling in the whole soaking process, so as to guarantee the controllable increasing of the soaked resin content of the fabric and meet the requirement of the manufacturing for 1000mm wide high-quality pre-coated fabric. The device is suitable for solvent-free thermosetting resin and thermoplastic resin.

Owner:李元珍 +2

Composite laminated friction stir welding additive forming process for large thick-walled cylindrical parts

InactiveCN107020447BImprove mechanical propertiesIncrease profitNon-electric welding apparatusFriction weldingThick wall

The invention discloses a composite stack-up type stirring friction welding additional material forming technology of a large-scale thick-wall cylindrical piece. The forming technology comprises the following steps: first, carrying out roll forming on a thin-wall annular piece monomer; then, carrying out radial stack-up type stirring friction welding additional material forming on the thin-wall annular piece monomer to finish the forming process of a first thin-wall annular piece monomer radial stack-up type stirring friction welding additional material of a first layer; then, carrying out axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomer, and carrying out axial superposition welding on a third thin-wall annular piece monomer of a second layer and the first thin-wall annular piece monomer; then, carrying out radial and axial stack-up type stirring friction welding additional material forming technology on the thin-wall annular piece monomers, and carrying out radial and axial welding on a fourth thin-wall annular piece monomer, the second and third thin-wall annular piece monomers of the second layer; and finally, carrying out radial, axial and radial and axial composite stack-up type stirring friction welding additional material forming on the thick-wall cylindrical piece. With adoption of the forming technology, the material utilization ratio is remarkably increased, the energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV +1

Hole plugging method of printed circuit board

ActiveCN108419367AUniform coverageUniform appearancePrinted circuit aspectsPrinted element electric connection formationEngineeringPrinted circuit board

Disclosed is a hole plugging method of a printed circuit board. By virtue of preparation of hole plugging resin and a combination of an air extracting apparatus and a scraper, a plug hole is filled with resin ink on a screen plate, and final curing is performed. By virtue of the method, resin ink can uniformly cover a circuit and a base material, and the resin ink in the plug hole is high in saturation degree.

Owner:梅州金时裕科技有限公司

Axial layered friction stir welding additive forming process for large thin-walled rings

InactiveCN106925884BImprove mechanical propertiesSmooth and uniform appearanceNon-electric welding apparatusMetal formingFriction stir welding

Disclosed is an axial stacking type friction-stir welding material adding forming process for a large thin-wall ring part. A sheet-shaped thin-wall ring part single body is prepared first through radial-axial hot rolling technology, then axial stacking type welding forming of the sheet-shaped thin-wall ring part single body is conducted through friction-stir welding material adding forming technology. A welding wire used by welding needs to be preheated by a laser heater, and plasticizing of the welding wire during welding is convenient. Meanwhile, during welding, micro forging treatment needs to be conducted on plasticized metal through an ultrasonic vibration exciter, and the effect that the texture form of the metal forming a weld joint approximately completely forms a welding core is ensured. One week after welding is conducted along the weld joint, a keyhole is filled with the welding wire constantly, meanwhile, a stirring head is drawn out of a workpiece slowly, and thus welding of the first layer of sheet-shaped thin-wall ring part single body is completed. Finally, axial stacking type friction-stir welding material adding forming of the thin-wall ring part is conducted layer by layer. Through the axial stacking type friction-stir welding material adding forming process, the utilization rate of materials is increased significantly, energy consumption is reduced, and the overall performance of the product is improved.

Owner:XI AN JIAOTONG UNIV

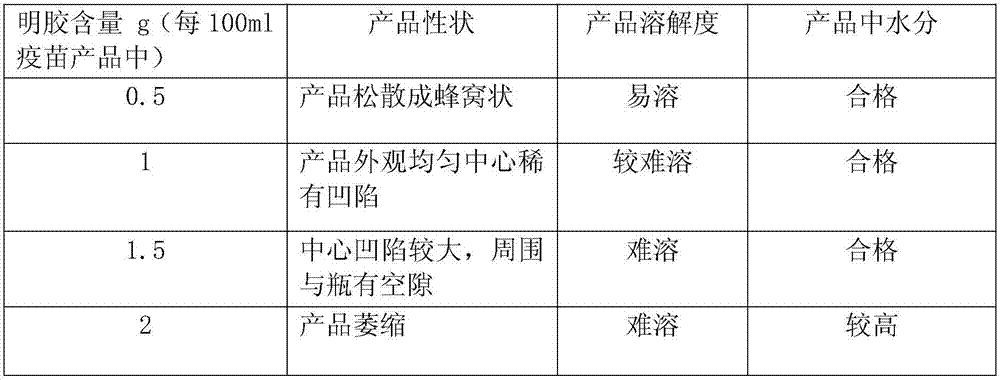

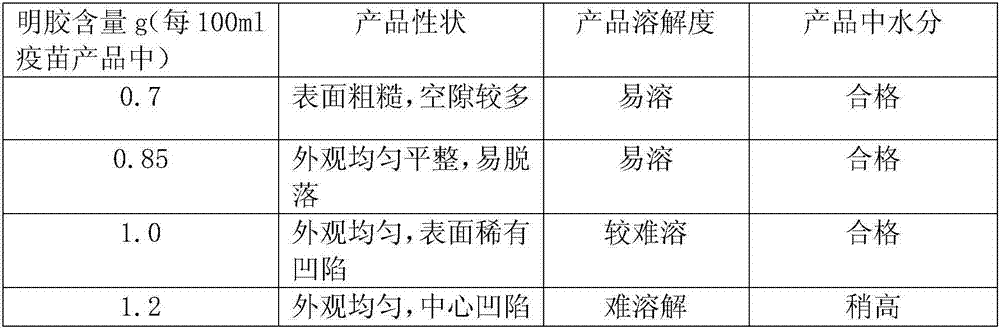

Gelatin protective agent for chicken infectious laryngotracheitis recombined avian pox virus live vaccine

InactiveCN107281495ASimple componentsSmooth and uniform appearanceAntiviralsAntibody medical ingredientsSucrose measurementSucrase

The invention discloses a gelatin protective agent for chicken infectious laryngotracheitis recombined avian pox virus live vaccine. The gelatin protective agent is prepared from the following components: gelatin, saccharose and sterile injection water, wherein each 100ml of the gelatin protective agent is prepared from 4.25g of the gelatin, 25g of the saccharose, and the balance of the sterile injection water. The chicken infectious laryngotracheitis recombined avian pox virus live vaccine using the gelatin protective agent is easy to dissolve and fall off, and the appearance is uniform and flat.

Owner:YANGLING LVFANG BIOLOGICAL ENG CO LTD

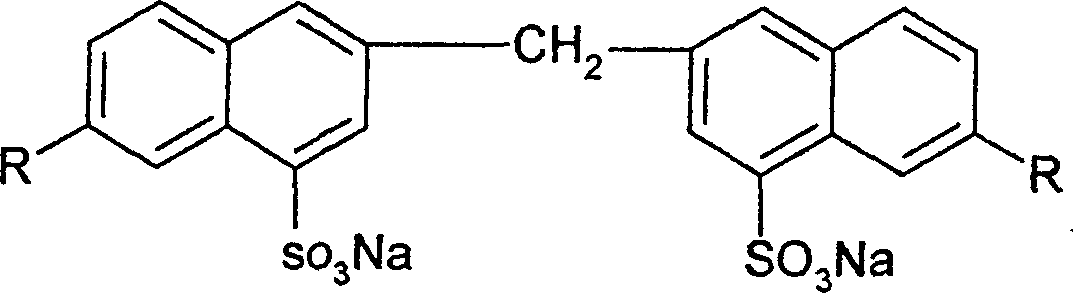

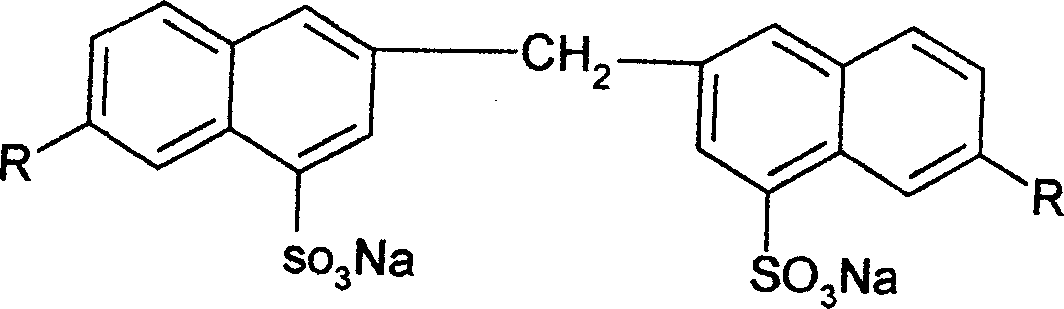

Disperser composition and application thereof

InactiveCN1919437AImprove performanceHigh activityTransportation and packagingMixingWater dispersibleNaphthalenesulfonate

The invention discloses a disperser composition and application, which is composed of 10-90% naphthalenesulfonate and 90-10% polycarboxylate to prepare water dispersing particle pesticide.

Owner:JIANGSU PESTICIDE RES INST

Sealing agent for corrosion resistance of zinc-plated spring and preparation method thereof

InactiveCN106047127AImprove stabilityPromote wettingAnti-corrosive paintsPolyurea/polyurethane coatingsOrganic solventFilm-forming agent

The invention relates to the technical field of zinc-plated surface treatment and particularly relates to a sealing agent for corrosion resistance of zinc-plated springs and a preparation method thereof. The sealing agent comprises, by weight, 10-18 parts of a film-forming agent, 5-12 parts of a corrosion inhibitor, 3-6 parts of a functional additive, 2-5 parts of an organic solvent and 100 parts of deionized water. The sealing agent has good wetting and permeable performances and has strong binding force between a film layer and a base body. The sealing agent can form a film layer being flat and uniform in appearance and being free of pores and bubbles, and is good in corrosion resistant performance.

Owner:ANHUI HONGQIAO METAL MFG

Processing method of six-flavor pumpkin seeds

InactiveCN109674007ARich fragranceRich flavorSeed preservation by dryingNatural extract food ingredientsFlavorPumpkin seed

The invention discloses a processing method of six-flavor pumpkin seeds, and belongs to the technical field of the food processing. The method comprises the following steps: selecting a material; andpreparing soup liquid A, i.e., after mixing momordica grosvenori, rhizoma dioscoreae, poria cocos, semen euryales, peppermint, ginseng and water, boiling, and filtering to obtain the soup liquid A; preparing soup liquid B, i.e., mixing table salt, white granulated sugar, brown granulated sugar, brown sugar syrup and the soup liquid A, boiling for 30-50 minutes to obtain the soup liquid B; flavoring, mixing the soup liquid B, a sweetening agent, edible essence, tert-butylhydroquinone and pumpkin seeds, firstly boiling, and soaking for 30-60 minutes; and successively performing draining treatment, peeling treatment and polishing treatment. A prepared finished product is capable of keeping good appearance and abundant taste, improving the effects of the pumpkin seeds for keeping health, clearing heat to decrease internal heat, prolonging a guarantee period of the product, and meeting the higher requirements of a consumer on quality of the pumpkin seeds.

Owner:CHACHA FOOD CO LTD

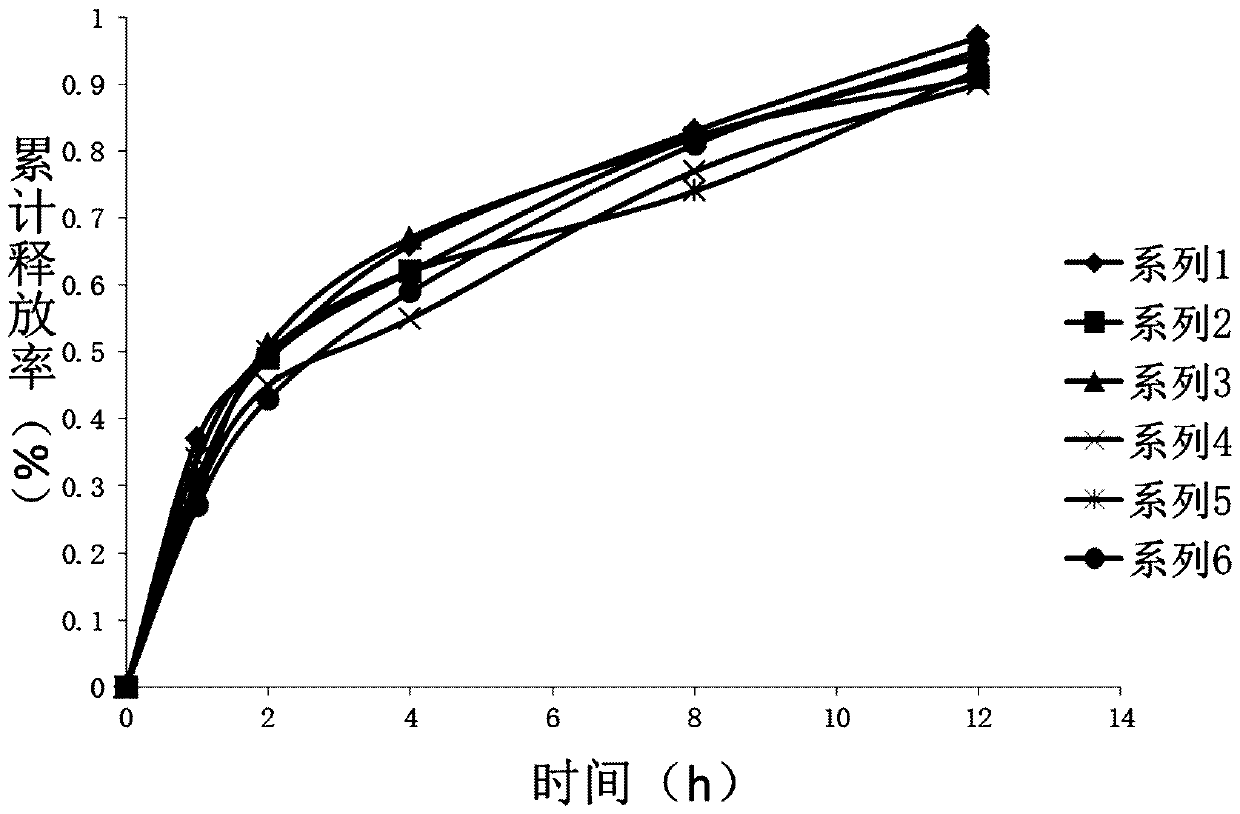

Anari series mongolian drug intragastric floating sustained release preparation and preparation method thereof

InactiveCN107854671AImprove bioavailabilityImprove complianceOrganic active ingredientsDigestive systemAdjuvantLarge dose

The invention relates to an Anari series mongolian drug intragastric floating sustained release preparation and a preparation method thereof, and belongs to the technical field of manufacturing of drugs. At present, most Anari compounds are powder, and are easy in moisture absorption, adhesion and caking, larger in administration dosage, pungent in flavor and poor in compliance. The Anari series mongolian drug intragastric floating sustained release preparation comprises a main drug and a pharmaceutic adjuvant, wherein the main drug comprises Anari or extract thereof; a sustained release adjuvant is used for constructing a skeleton structure of the drug and controlling the dissolving-out speed of the drug; an often release adjuvant is used for enabling the drug to float and the preparationto be formed; the often release adjuvant comprises a floating auxiliary and / or a filling agent and / or a binding agent and / or a lubricating agent. By adopting a positioning sustained release dosing system, the Anari series mongolian drug intragastric floating sustained release preparation is steady and lasting in drug release and can float sustainably, so that intragastric positioning dosing is achieved, the bioavailability of oral administration of the Anari, the defects of the powder of large dose and frequent dosing can be overcome, bad flavor of the drug can be covered, and the complianceof patients is improved. Therefore, a more ideal treatment effect is achieved.

Owner:张慧文

Process for mechanical plasma spray welding of sealing surface of hard alloy valve

InactiveCN110270748AIncrease profitImprove surface qualityPlasma welding apparatusStellite alloyCobalt

The invention relates to the valve manufacturing industry, in particular to a process for mechanical plasma spray welding of a sealing surface of a hard alloy valve, and mainly aims to a Y-type globe valve. According to the process, the problem of the limit to overlaying of the sealing surface and guide ribs by using other welding methods due to narrow space in a valve body is solved. The process is applied, a special device is adopted,a powder (Stellite 21) cobalt-based material is used, the welding process parameter is reasonably determined, a control program is programmed, the program is input into a device system touch screen, a spray welding device is mechanically operated, and plasma spray welding is applied to spray hard alloy powder on the positions of the sealing surface and the guide ribs of the valve body uniformly; and the use ratio of the welding materials reaches 95% or more. Spray welded enables appearance shaping to be smooth and uniform, the production efficiency is high, and the critical process work is automatically completed.

Owner:江苏万恒铸业有限公司

Wear-resistant and flame-retardant swash plate

ActiveCN103865363AReasonable compositionUniform compositionFireproof paintsPositive displacement pump componentsWear resistantHeat resistance

The invention discloses a wear-resistant and flame-retardant swash plate. The swash plate comprises a base plate and a wear-resistant coating, wherein the wear-resistant coating comprises base resin, silicon-containing phosphate, PTFE (polytetrafluoroethylene) particles, graphite fluoride and composite filler. The wear-resistant paint disclosed by the invention is reasonable in composition and has excellent heat resistance and adhesion. The swash plate based on the wear-resistant paint has excellent wear resistance and flame retardance, has dry state or oil state friction property far better than that of swash plates prepared from the existing resin, and can meet the requirements of auto air conditioning compressors.

Owner:福建省永阳国有资本投资集团有限公司

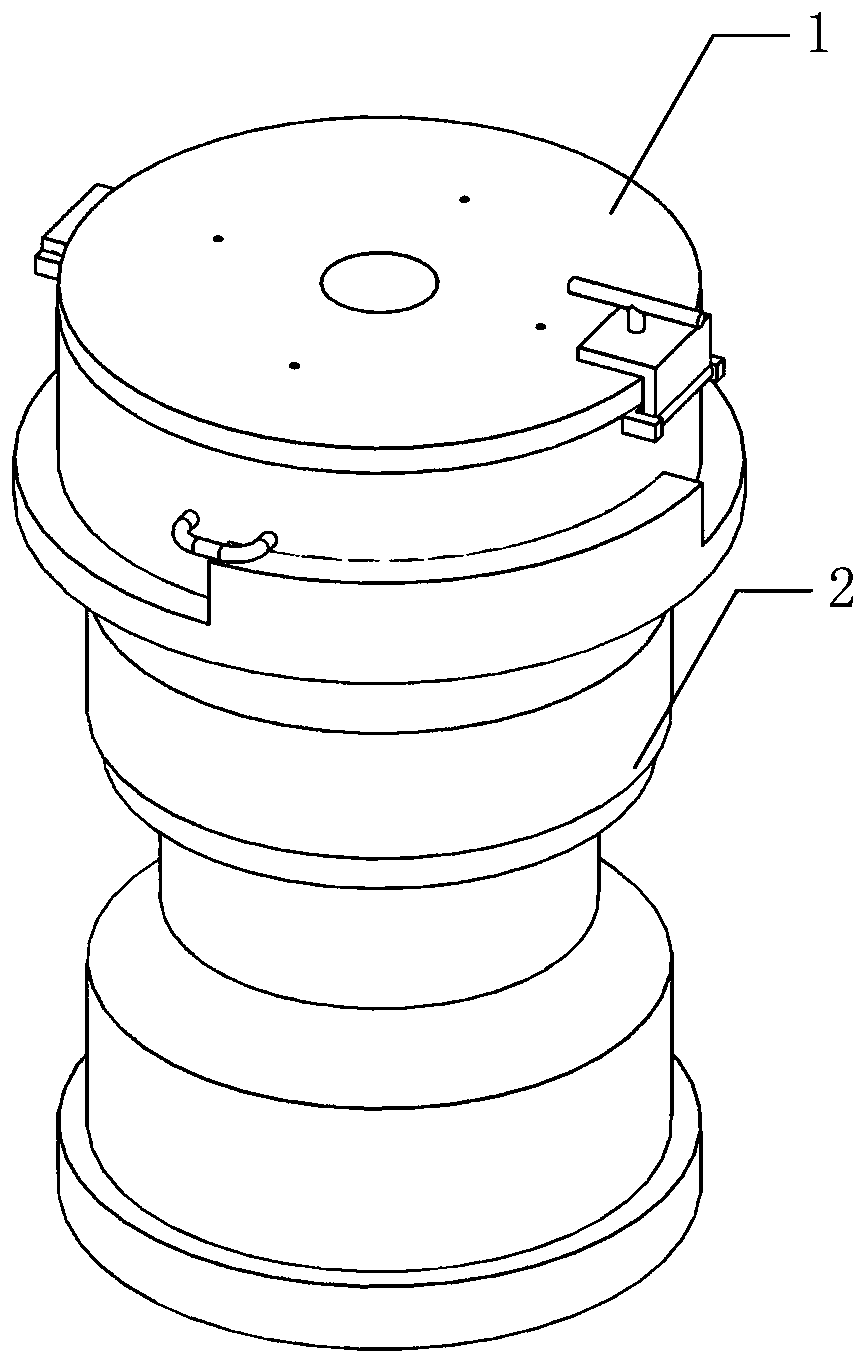

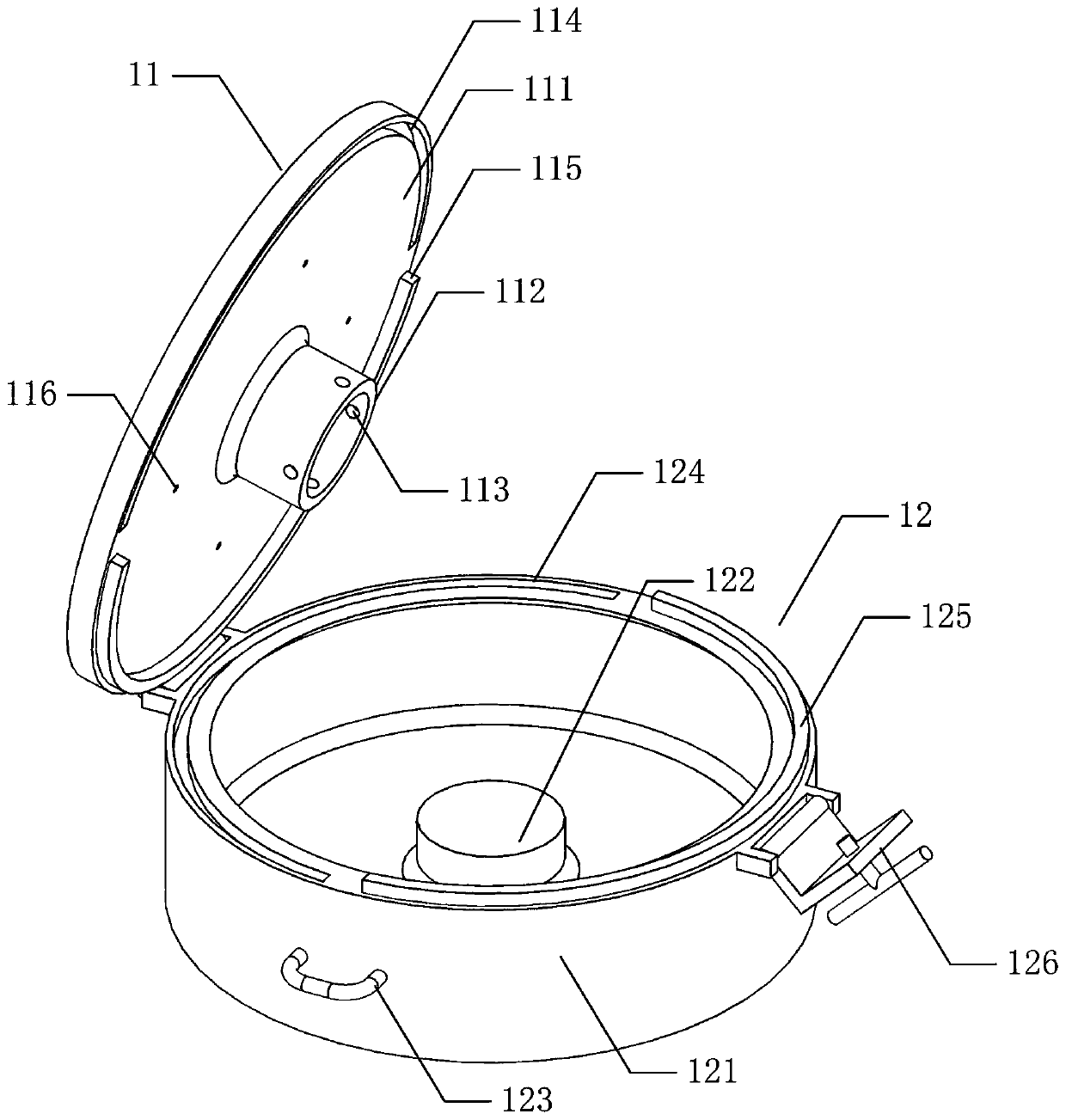

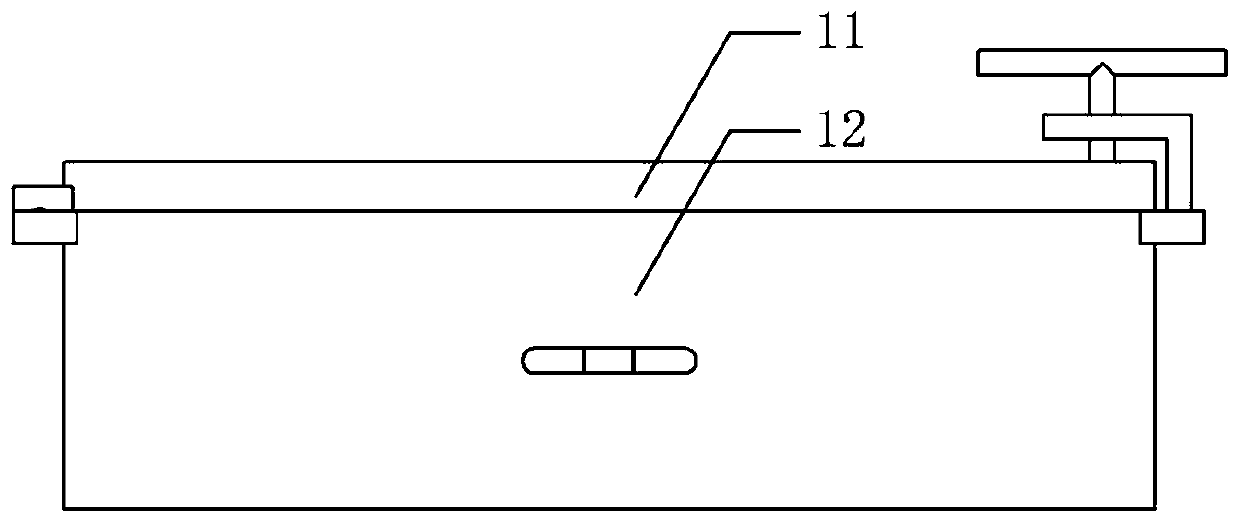

Forming device of polyurethane solid tire and solid tire preparation method

The invention discloses a forming device of a polyurethane solid tire and a solid tire preparation method. The forming device comprises a mold (1) and a heavy load bearing rotary table (2) for drivingthe mold (1) to rotate; the mold (1) comprises an upper mold (11) and a lower mold (12) which are opened and closed in a hinged mode on the side edge, the upper mold (11) and the lower mold (12) arefastened through a locking mechanism (126) after being assembled, and a solid tire forming mold cavity (13) is formed in the mold (1); a casting cavity (112) is formed in the center of the upper mold(11); the inner side wall of the lower mold (12) is a tire forming arc-shaped surface, and a circular truncated cone (122) is buckled with the pouring cavity (112) after the mold is closed; and a positioning groove connected with the heavy load bearing rotary table (2) is arranged at the bottom of a body B (121). According to the forming device, the process formula and the process parameters are optimized, the polyurethane solid tire is produced by using the forming device of the polyurethane solid tire, the solid tire with stable quality performance can be quickly and efficiently obtained, the production efficiency is improved, and the production cost is reduced.

Owner:YONGYI RUBBER CO LTD

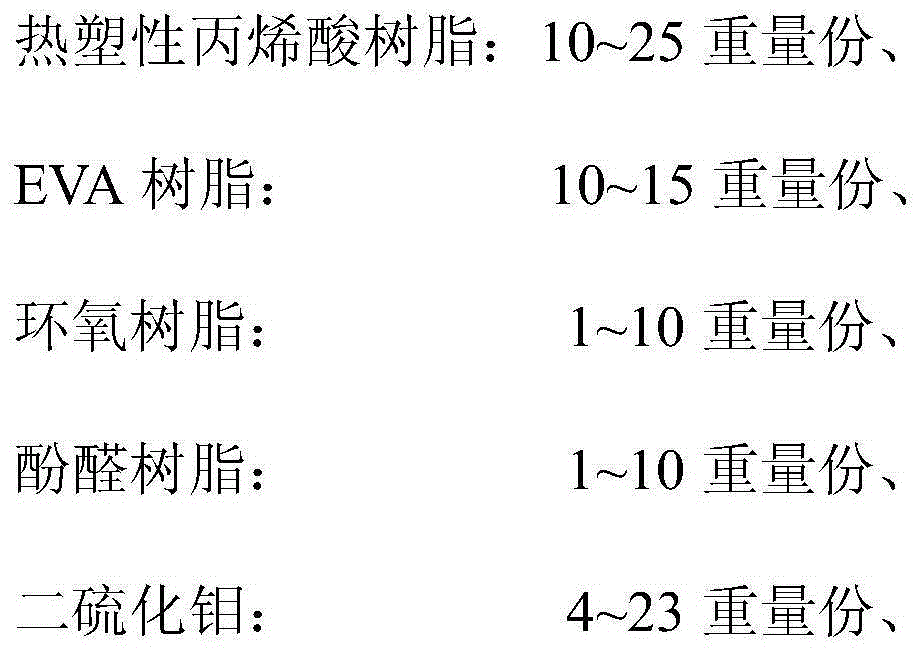

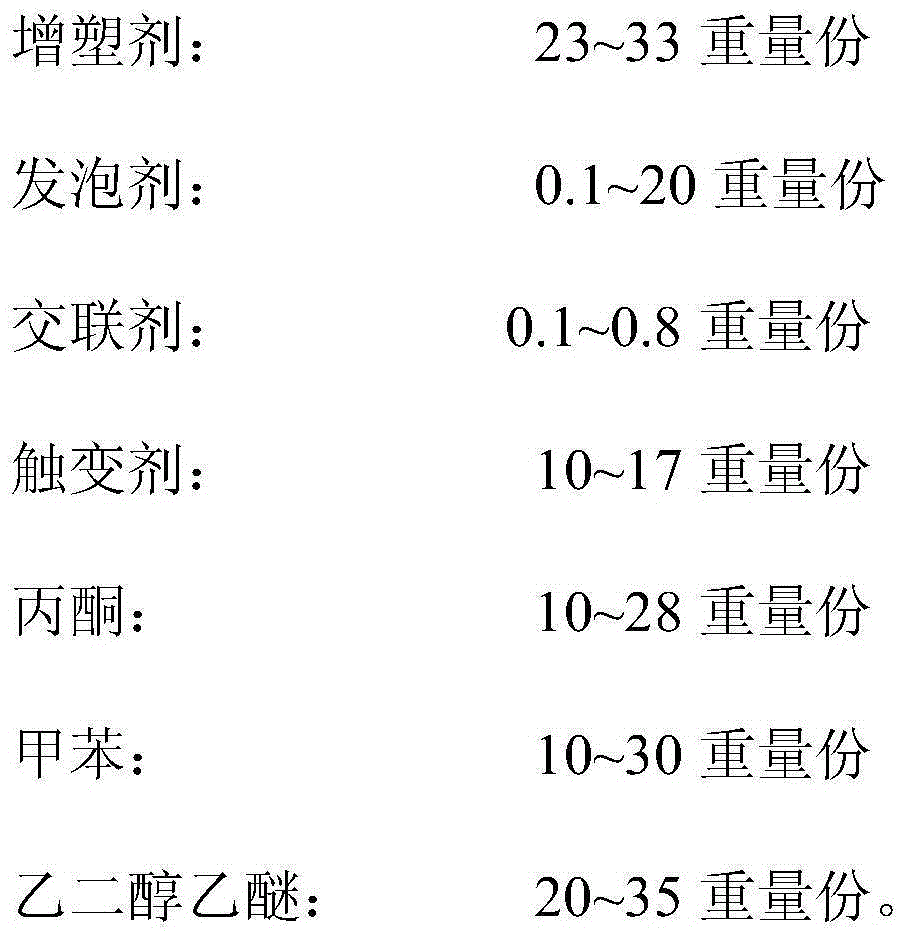

Shock-absorbing and lubricating coating for buildings and preparation method and applying method of shock-absorbing and lubricating coating

InactiveCN105086691ASmooth and uniform appearanceNo impuritiesEpoxy resin coatingsEpoxyAcrylic resin

The invention provides a shock-absorbing and lubricating coating and a preparation method and an applying method of the shock-absorbing and lubricating coating. The shock-absorbing and lubricating coating comprises the following materials in parts by weight: 10-25 parts of thermoplastic acrylic resin, 10-15 parts of EVA resin, 1-10 parts of epoxy resin, 1-10 parts of phenolic resin, 4-23 parts of molybdenum disulfide, 0.01-0.3 parts of an organosilan coupling agent and 35-55 parts of a mixed solvent, wherein the mixed solvent comprises the following materials in parts by weight: 23-33 parts of a plasticizer, 0.1-20 parts of a foamer, 0.1-0.8 part of a cross-linking agent, 10-17 parts of a thixotropic agent, 10-28 parts of acetone, 10-30 parts of methyl benzene and 20-35 parts of ethylene glycol ethyl ether. The shock-absorbing and lubricating coating is favorable in adhesion, wear resistance, moisture and heat resistance and flexibility, high in impact strength and relatively low in friction coefficient; besides, sustained pressure of 100 MPa or above can be borne, the stretching and shearing strengths are excellent, and certain stability is realized; curing is completely free of adhesion, surface curing and internal curing are not different, effective sliding of a shock-absorbing support part for buildings is realized under the action of transverse seismic waves, and the shock-absorbing and shock-resisting effects are achieved.

Owner:WUXI JIABANG ELECTRIC POWER PIPE FACTORY

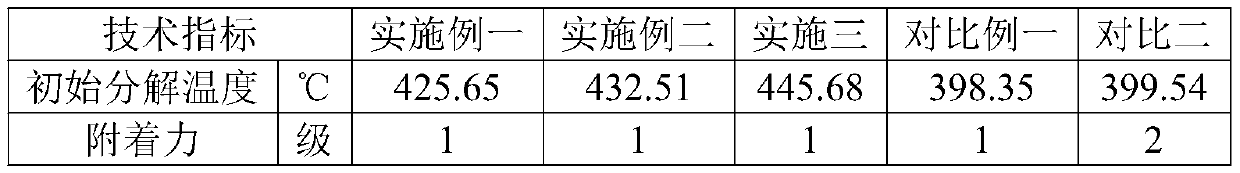

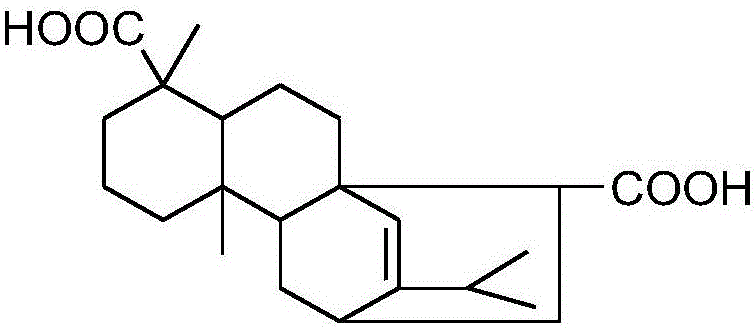

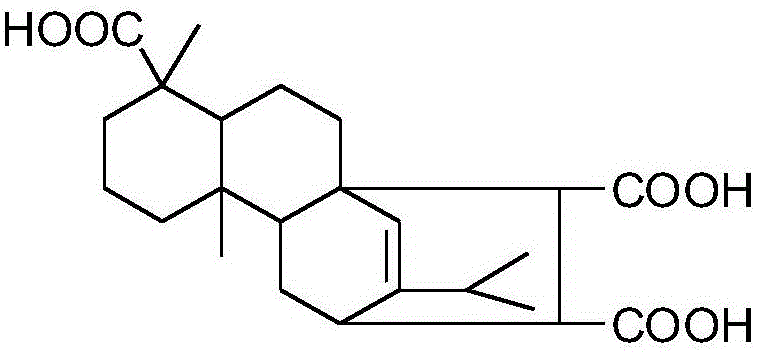

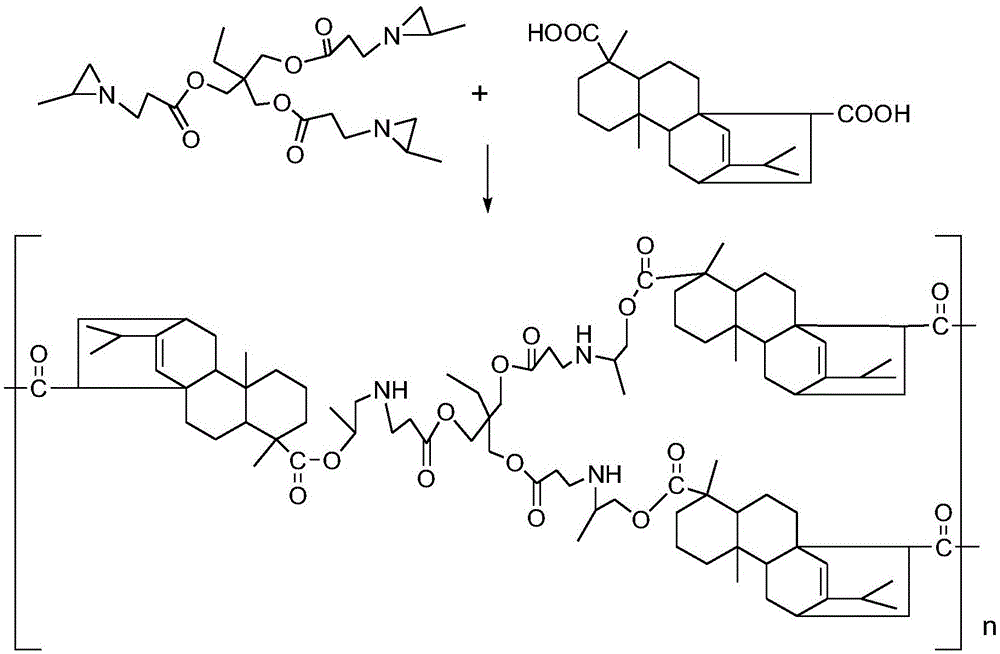

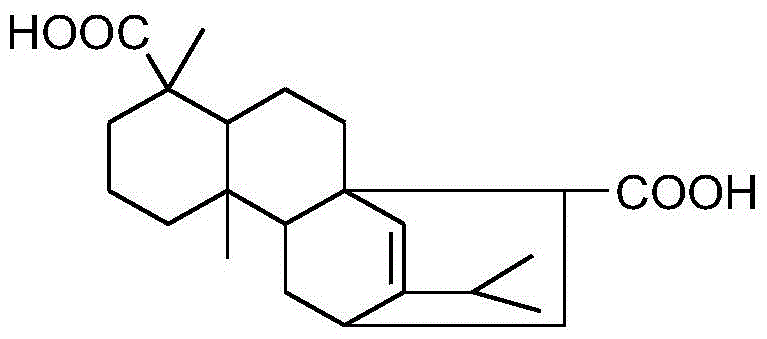

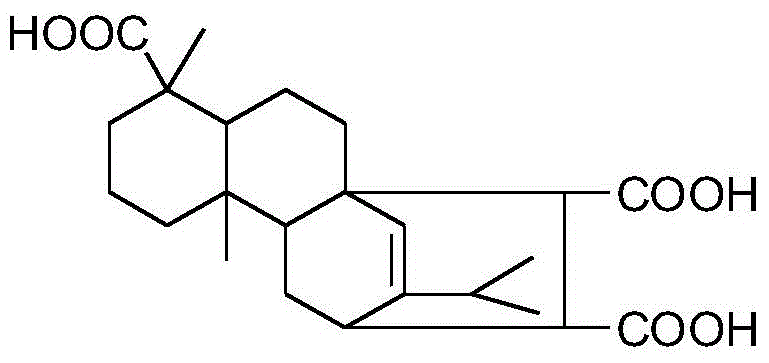

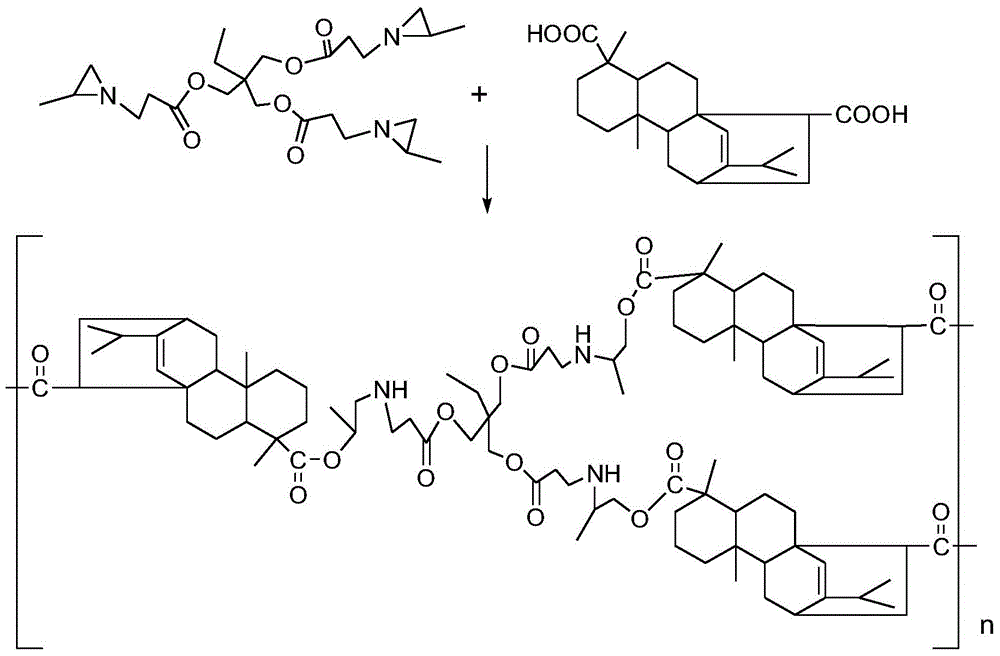

Thermosetting rosinyl resin composition and preparation method thereof

InactiveCN105153407AHigh reactivityFast cross-linkingNatural resin chemical modificationAlcoholAziridine

The invention relates to the field of resin compositions, particularly a thermosetting rosinyl resin composition and a preparation method thereof. The thermosetting rosinyl resin composition comprises modified rosin, dibasic alcohol and a crosslinking agent. In a mass ratio of 1:(0.2-0.8):(0.3-1.5). Aziridine is used as the crosslinking agent; and the crosslinking agent has the advantages of very high reaction activity with the carboxyl group in the rosin and high crosslinking speed. The preparation method has the advantages of simple and feasible steps, low reaction temperature, short time and mild conditions, relates to fewer varieties of raw materials in the whole crosslinking process, does not need any special equipment or catalyst, and is beneficial to industrial production. The prepared rosinyl resin composition has uniform and smooth appearance; and the varieties and consumptions of the modified rosin and dibasic alcohol can be changed to adjust the elasticity, strength, color and transparency of the resin composition material, thereby greatly widening the application range of the rosinyl resin composition material.

Owner:SHANDONG UNIV OF SCI & TECH

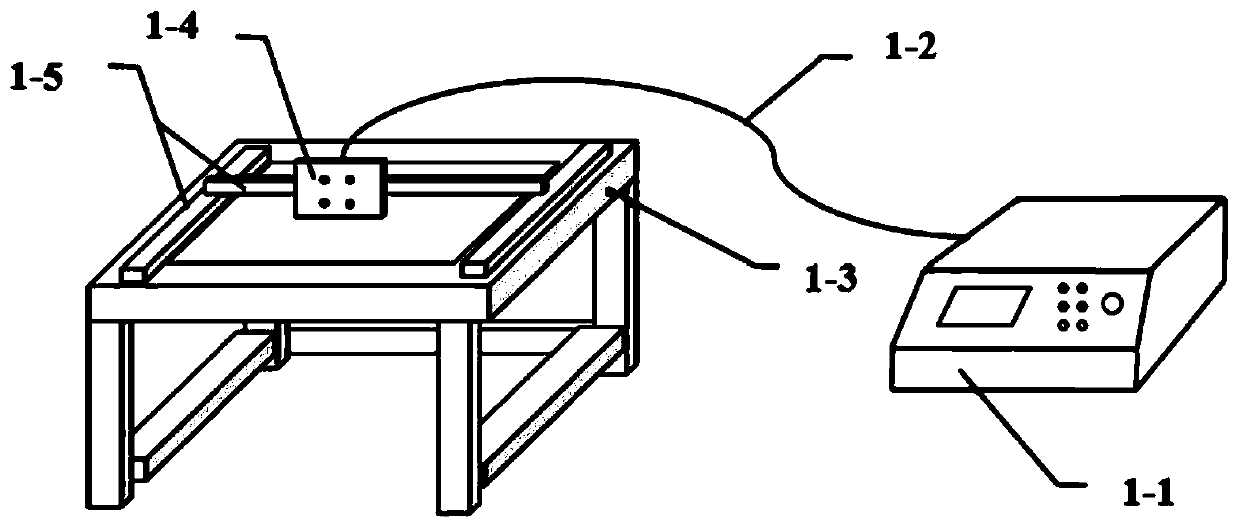

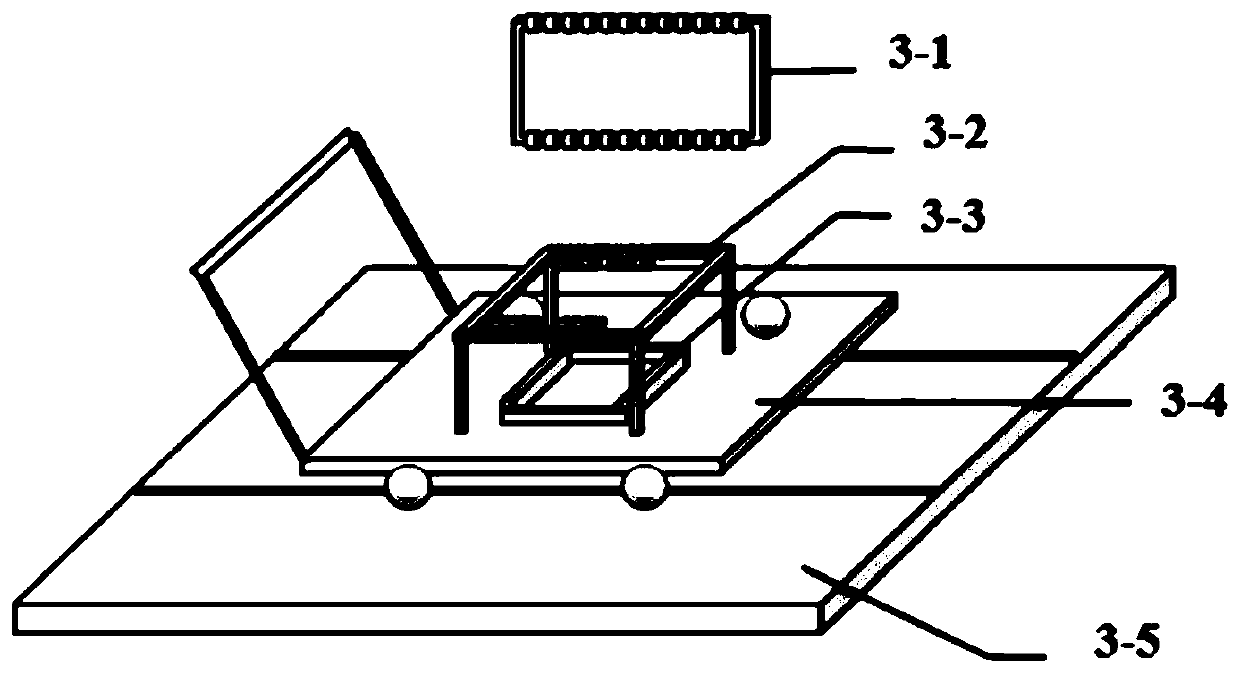

Tensile property sample preparation device of ultra-high modulus carbon fiber multifilament and sample preparation method

The invention relates to a tensile property sample preparation device of an ultra-high modulus carbon fiber multifilament and a sample preparation method, and belongs to the technical field of material property testing. The tensile property sample preparation device of the ultra-high modulus carbon fiber multifilament includes a precision control system, an automatic glue dispensing system and anauxiliary positioning system. The sample preparation method comprises the following steps of: placing a pre-wound ultra-high modulus carbon fiber multifilament frame on a sample preparation glue dispensing device, and automatically adding a glue solution through the precision control system; then placing the glue-dipped carbon fiber multifilament in an oven for curing; and pasting a reinforcing sheet for tensile testing. The invention solves the problem of high damage and brittle fracture of fibers encountered during a manual glue-dipping process of ultra-high modulus carbon fibers, and prepares multifilament tensile sample strips with smooth appearance. The tensile property sample preparation device of the ultra-high modulus carbon fiber multifilament and the sample preparation method disclosed by the invention have important popularization and application prospects in the engineering development and production of the ultra-high modulus carbon fibers and composite materials thereof, and high thermal conductivity mesophase pitch-based carbon fibers and composite materials thereof.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

A kind of thermosetting rosin-based resin composition and preparation method thereof

InactiveCN105153407BHigh reactivityFast cross-linkingNatural resin chemical modificationAlcoholReaction temperature

Owner:SHANDONG UNIV OF SCI & TECH

Aluminum-matrix aquo-system metal micropowder coating and process therefor

InactiveCN108003706ASmooth and uniform appearanceImprove the decorative effectFireproof paintsAnti-corrosive paintsHeat resistanceMetal

The invention discloses an aluminum-matrix aquo-system metal micropowder coating and a process therefor and relates to the technical field of machinery. The aluminum-matrix aquo-system metal micropowder coating is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of hydrochloric acid, 15-20 parts of tartaric acid, 5-10 parts of HS-99, 5-10 parts of dodecyl sulfuric acid and 10-20 parts of additives. The process for the aluminum-matrix aquo-system metal micropowder coating comprises the steps of pretreatment, coating solution preparing, coating, flushing, preheating, baking, cooling and the like. The aluminum-matrix aquo-system metal micropowder coating prepared by the process has the advantages of uniform and smooth appearance, relatively highornamental performance and relatively good corrosion resistance and heat resistance; and the coating process is simple and convenient, so that the labor cost is reduced.

Owner:永康市狐桃工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com