Radial stacking type friction-stir welding material adding forming process for large thick-wall ring part

An additive forming and friction stir technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of difficulty in manufacturing large-scale rolling and forging equipment, multi-material loss, and the formation of flash at weld seams, etc. Material utilization and production efficiency, reduced energy consumption, uniform and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

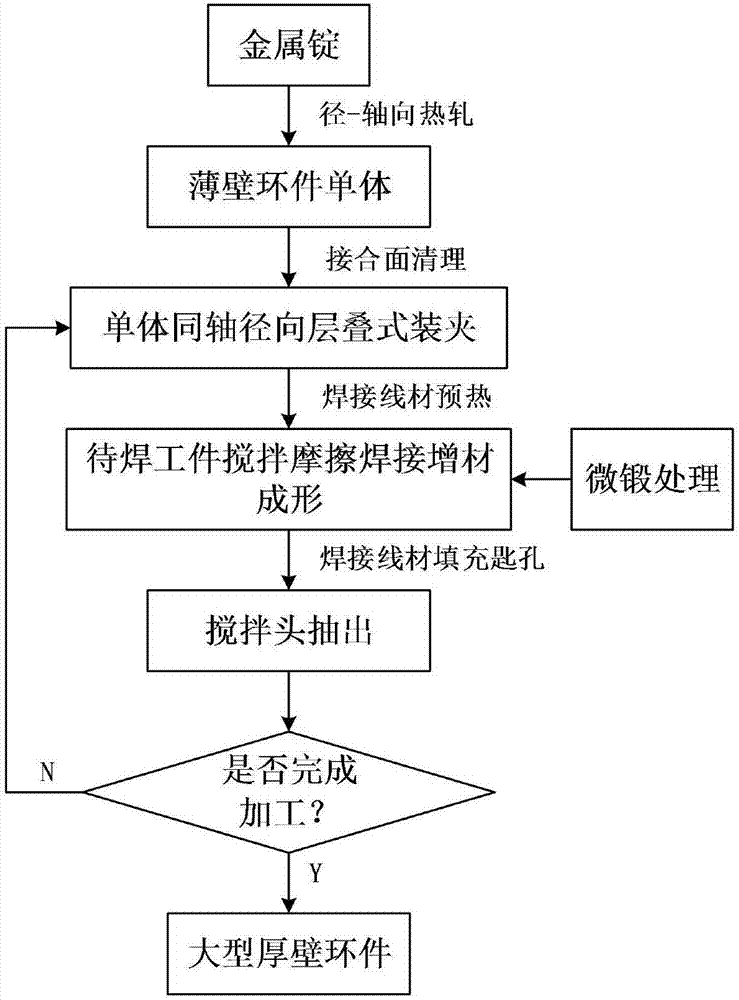

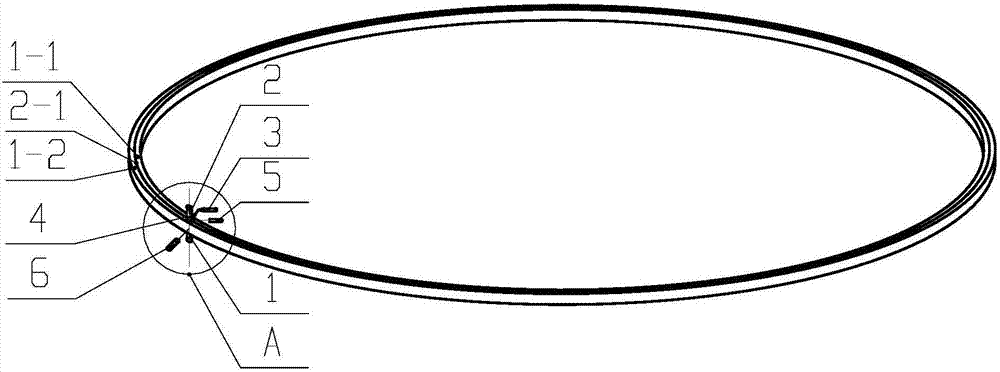

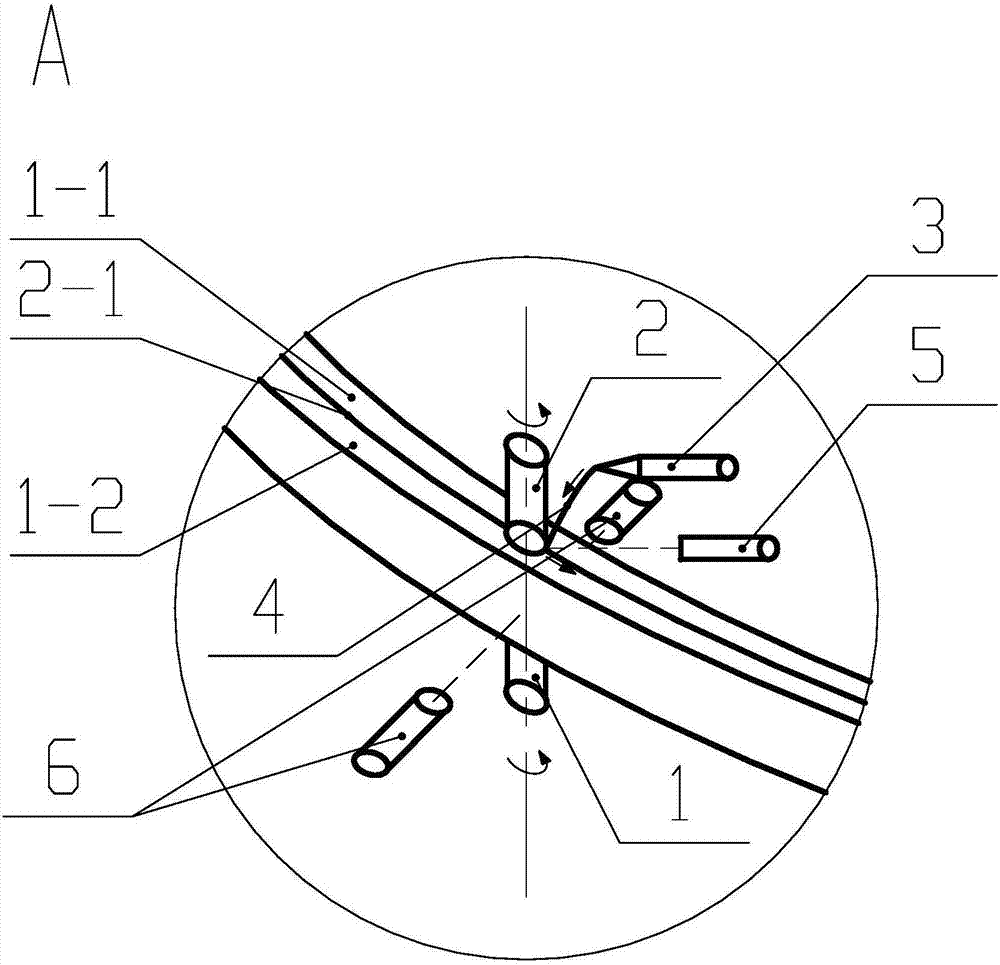

[0022] refer to figure 1 , figure 2 and image 3 , a radial stacked friction stir welding additive forming process for large thick-walled rings, including the following steps:

[0023] 1) Thin-walled ring single-piece rolling forming: According to the production requirements of the product and the requirements of the thin-walled ring single-piece processing drawings, the radial-axial hot rolling technology is used to make thin-walled ring billets, and the prepared metal ingots are passed through blanking, billet making, Ring rolling, heat treatment and machining processes are used to prepare thin-walled ring monomers required for friction stir welding additive forming;

[0024] 2) Thin-walled ring single piece radially stacked biaxial friction stir welding additive forming: first, the first thin-walled ring single piece 1-1 and the second thin-walled ring piece s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com