Thermosetting rosinyl resin composition and preparation method thereof

The technology of a rosin-based resin and composition is applied in the field of thermosetting rosin-based resin composition and its preparation, which can solve the problems of long reaction time, inconvenient industrial production, cumbersome methods, etc., and achieves simple and easy preparation steps and is beneficial to industrial production , The effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

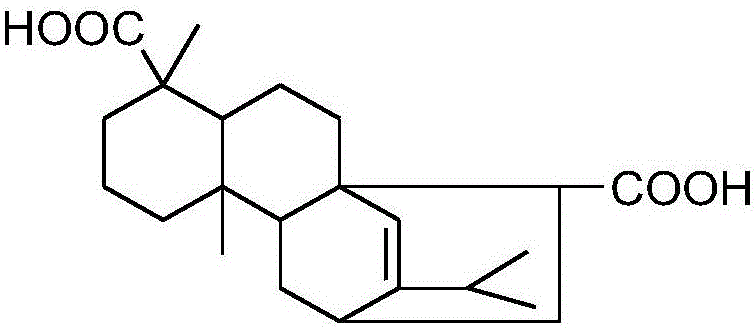

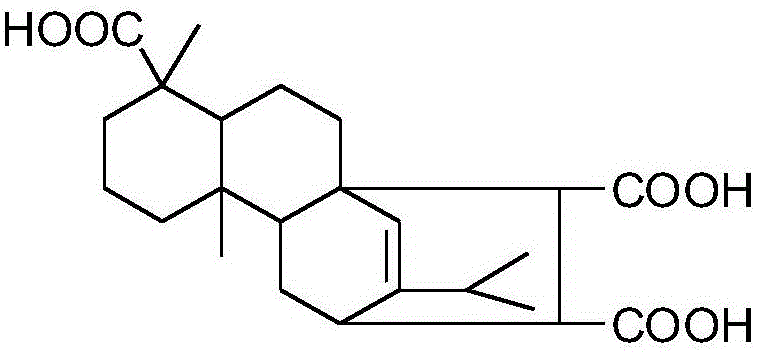

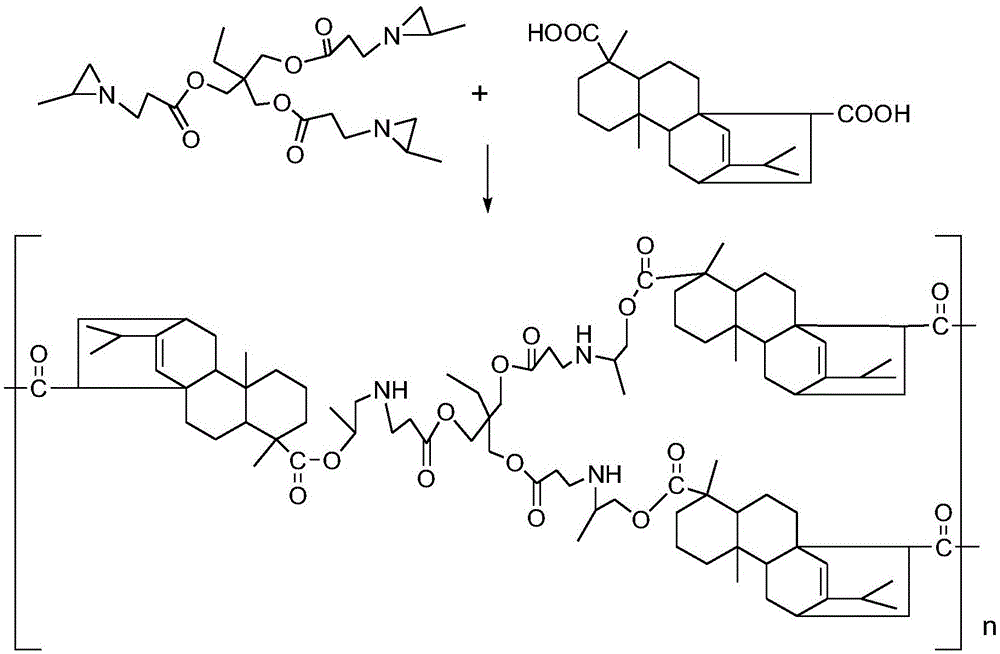

Method used

Image

Examples

Embodiment 1

[0026] Mix 5 kg of modified rosin I with 2 kg of polyethylene glycol 400, heat to 130°C, stir until a uniform viscous liquid is formed, then cool down to 115°C, and slowly add 2.5 kg of trifunctional aziridine crosslinking agent , Stir while adding, so that the three are uniformly mixed, after the addition is completed, stop stirring, stand at this temperature for 15 minutes, stop heating, and cool to obtain a transparent rosin-based resin composition.

Embodiment 2

[0028] Mix 5 kg of modified rosin I with 2 kg of polyethylene glycol 400, heat to 130°C, stir until a uniform viscous liquid is formed, then cool down to 115°C, and slowly add 3.5 kg of trifunctional aziridine crosslinking agent , Stir while adding, so that the three are uniformly mixed, after the addition is completed, stop stirring, stand at this temperature for 15 minutes, stop heating, and cool to obtain a transparent rosin-based resin composition.

Embodiment 3

[0030] Mix 5 kg of modified rosin I with 2 kg of polyethylene glycol 2000, heat to 130°C, stir until a uniform viscous liquid is formed, then cool down to 115°C, and slowly add 3.5 kg of trifunctional aziridine crosslinking agent , Stir while adding, so that the three are uniformly mixed, after the addition is completed, stop stirring, stand at this temperature for 15 minutes, stop heating, and cool to obtain a light yellow non-transparent rosin-based resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com