Preparation method of cyanate ester based wear-resistant self-lubricating swash plate

A cyanate ester, self-lubricating technology, used in mechanical equipment, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as increasing the difficulty of preparation, harmful to the social environment, and increasing social energy consumption, and achieves easy spray thickness. , the composition is reasonable, the effect of improving mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

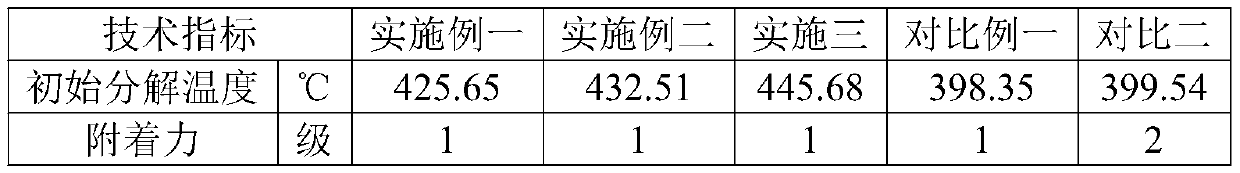

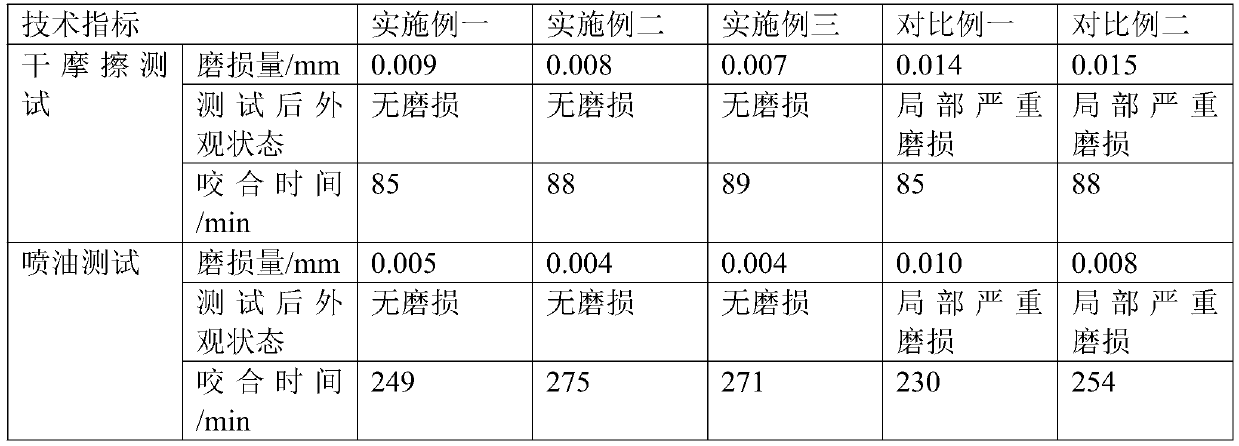

Embodiment 1

[0028] The preparation method of a kind of wear-resistant self-lubricating swash plate based on cyanate ester involved in this embodiment includes the following steps: preparation of accelerator, preparation of graphene oxide / cyanate ester-epoxy resin composite material, wear-resistant Preparation, spraying and curing of self-lubricating coatings.

[0029]Step (1) preparation of accelerator: add methyl tin mercaptide aqueous solution and fatty acid mercaptoethanol ester, slowly and evenly drop ammoniacal liquor or sodium hydroxide aqueous solution to pH value 7.5 under stirring, reaction temperature is 45 ℃, and reaction time is After 3 hours, stand still and separate layers, separate the upper layer ammonium chloride aqueous solution or sodium chloride aqueous solution, and the lower oil phase is washed with water to obtain the fatty acid mercaptoethanol ester methyl tin liquid product. The mercaptan methyl tin used is one of the three major organotin varieties. It is a trans...

Embodiment 2

[0042] The preparation method of a kind of wear-resistant self-lubricating swash plate based on cyanate ester involved in this embodiment includes the following steps: preparation of accelerator, preparation of graphene oxide / cyanate ester-epoxy resin composite material, wear-resistant Preparation, spraying and curing of self-lubricating coatings.

[0043] Step (1) preparation of accelerator: add methyl tin mercaptide aqueous solution and fatty acid mercaptoethanol ester, slowly and evenly drop ammoniacal liquor or sodium hydroxide aqueous solution to pH value 7.7 under stirring, reaction temperature is 48 ℃, and reaction time is After 2.5 hours, static layering, the upper layer of ammonium chloride aqueous solution or sodium chloride aqueous solution was separated, and the lower oil phase was washed with water to obtain the fatty acid mercaptoethanol ester methyl tin liquid product. The mercaptan methyl tin used is one of the three major organotin varieties. It is a transpare...

Embodiment 3

[0056] The preparation method of a kind of wear-resistant self-lubricating swash plate based on cyanate ester involved in this embodiment includes the following steps: preparation of accelerator, preparation of graphene oxide / cyanate ester-epoxy resin composite material, wear-resistant Preparation, spraying and curing of self-lubricating coatings.

[0057] Step (1) Preparation of accelerator: add methyl tin mercaptide aqueous solution and fatty acid mercaptoethanol ester, slowly and uniformly drop ammoniacal liquor or sodium hydroxide aqueous solution to pH value 8 under stirring, reaction temperature is 50 ℃, reaction time is After 3 hours, stand still and separate layers, separate the upper layer ammonium chloride aqueous solution or sodium chloride aqueous solution, and the lower oil phase is washed with water to obtain the fatty acid mercaptoethanol ester methyl tin liquid product. The mercaptan methyl tin used is one of the three major organotin varieties. It is a transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com