Enhanced chemical-corrosion-resistant polyformaldehyde material and preparation method thereof

A polyoxymethylene material, chemical corrosion resistance technology, applied in the field of reinforcement material modification, can solve problems such as short service life, and achieve the effect of improving strength and corrosion resistance, improving mechanical properties and heat resistance, and good fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

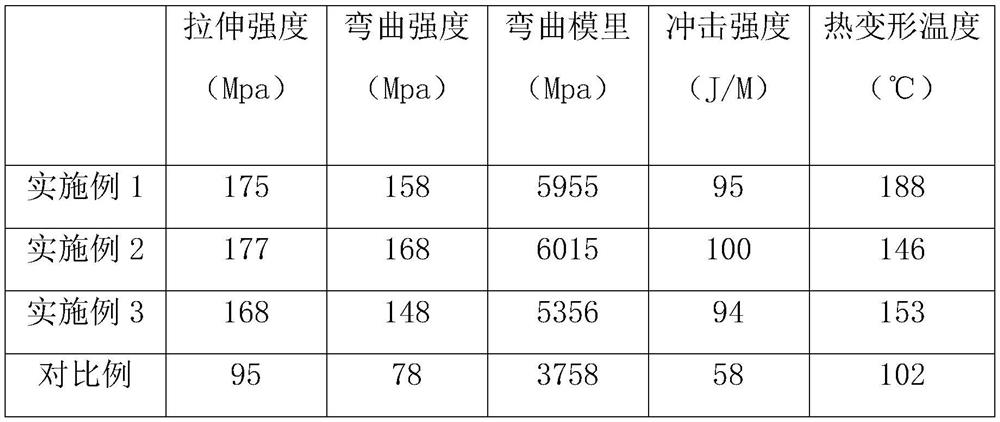

Examples

Embodiment 1

[0015] The reinforced and chemically resistant polyoxymethylene material of this embodiment is composed of the following components by weight fraction: polyoxymethylene 60%; glass fiber 5%; compatibilizer 1%; antioxidant 0.1%; micro-crosslinking agent 0.1% %; lubricant 0.1%.

[0016] A preparation method of reinforced, chemically resistant polyoxymethylene material, comprising the steps of:

[0017] S1. Add polyoxymethylene, compatibilizer, antioxidant, micro-crosslinking agent, and lubricant to the high-speed mixer for high-speed premixing according to the above-mentioned components by weight;

[0018] S2, take the mixture obtained in the S1 step and add it from the feeding port of the screw extruder, and add glass fiber in the middle section of the twin-screw extruder at the same time, the processing temperature is 170°C, the screw speed is 250r / min, and the pressure of the extruder is 10MPa, and then melt-extruded and granulated to obtain a finished polyoxymethylene materi...

Embodiment 2

[0020] The reinforced, chemically resistant polyoxymethylene material of this embodiment is composed of the following components by weight fraction: polyoxymethylene 75%; glass fiber 25%; compatibilizer 2%; antioxidant 0.3%; micro-crosslinking agent 0.3% %; lubricant 0.3%.

[0021] A preparation method of reinforced, chemically resistant polyoxymethylene material, comprising the steps of:

[0022] S1. Add polyoxymethylene, compatibilizer, antioxidant, micro-crosslinking agent, and lubricant to the high-speed mixer for high-speed premixing according to the above-mentioned components by weight;

[0023] S2, take the mixture obtained in the step S1 and add it from the feeding port of the screw extruder, and add glass fiber in the middle section of the twin-screw extruder at the same time, the processing temperature is 180°C, the screw speed is 300r / min, and the pressure of the extruder is 13MPa, and then melt-extruded and granulated to obtain the finished product 2 of the polyox...

Embodiment 3

[0025] The reinforced, chemically resistant polyoxymethylene material of this embodiment is made up of the following components by weight fraction: polyoxymethylene 95%; glass fiber 40%; compatibilizer 3%; antioxidant 0.5%; micro-crosslinking agent 0.5% %; lubricant 0.5%.

[0026] A preparation method of reinforced, chemically resistant polyoxymethylene material, comprising the steps of:

[0027] S1. Add polyoxymethylene, compatibilizer, antioxidant, micro-crosslinking agent, and lubricant to the high-speed mixer for high-speed premixing according to the above-mentioned components by weight;

[0028] S2, take the mixture obtained in the step S1 and add it from the feeding port of the screw extruder, and add glass fiber in the middle section of the twin-screw extruder at the same time, the processing temperature is 200°C, the screw speed is 350r / min, and the pressure of the extruder is 15MPa, and then melt-extruded and granulated to obtain the finished product 3 of the polyoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com